Induction furnace

A technology of induction furnace and furnace body, applied in the field of induction furnace, can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an induction furnace according to an embodiment of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to the following embodiment, In the range which does not change the summary, it can deform suitably and implement. In the following drawings, some structures may be omitted for convenience of description.

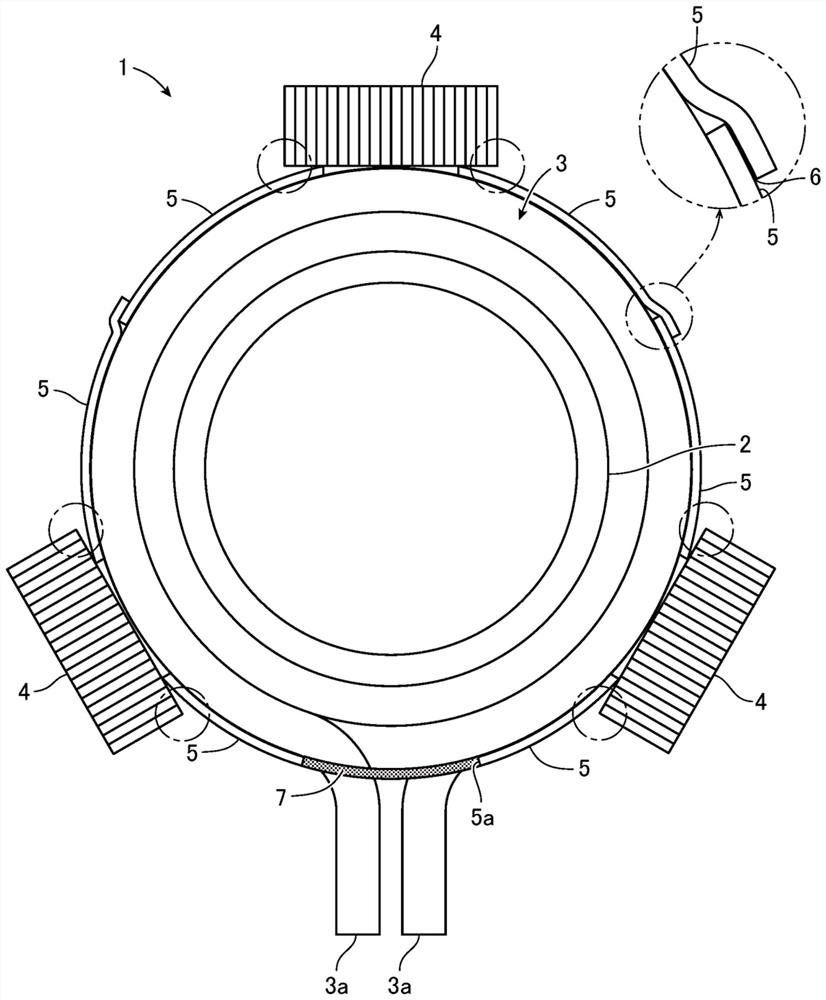

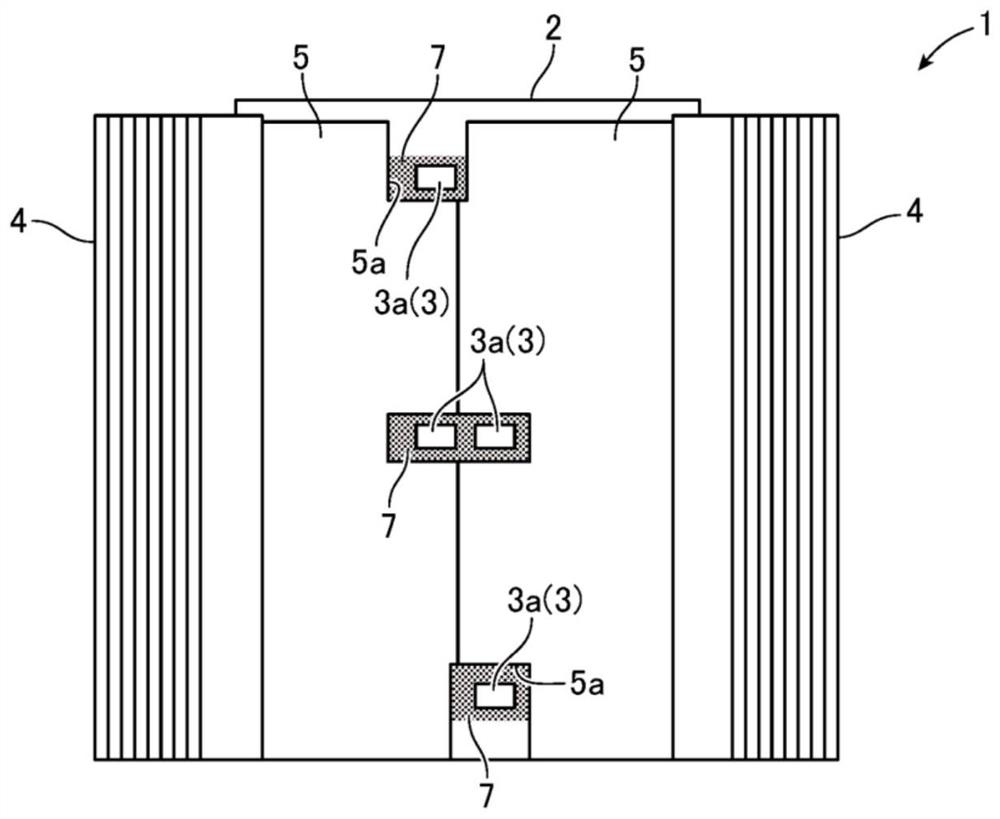

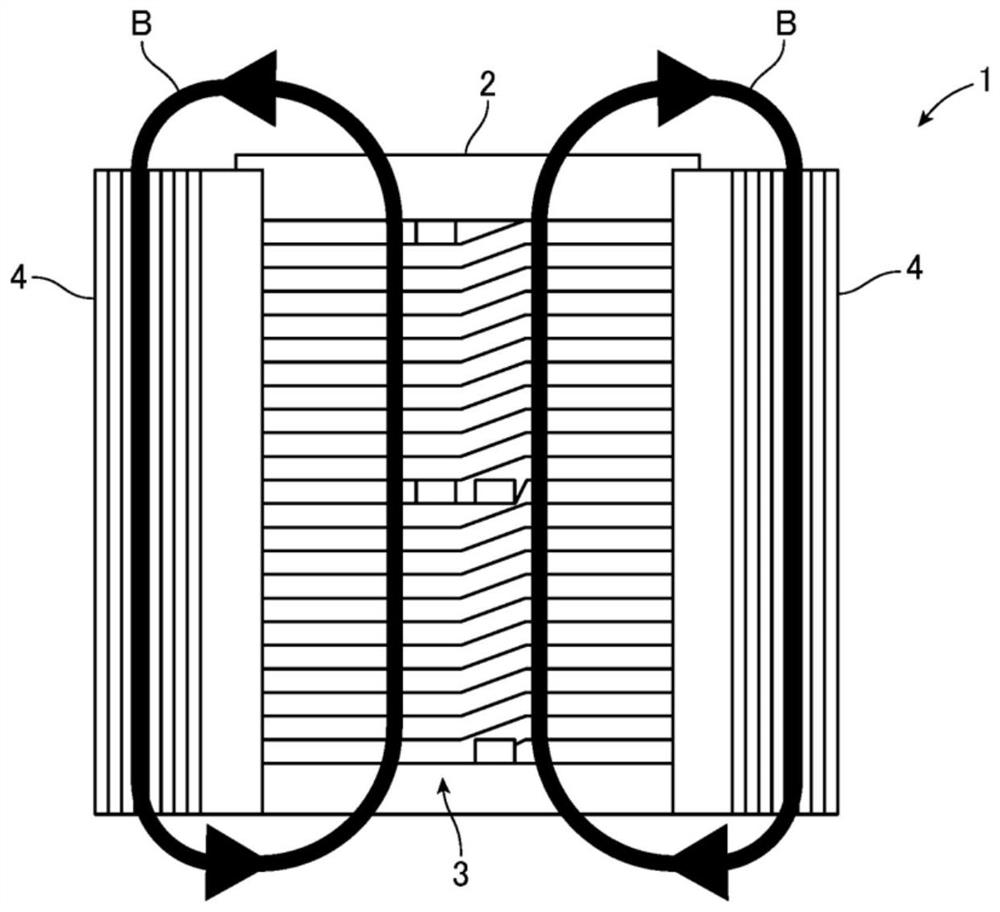

[0022] figure 1 It is a schematic plan view of the induction furnace of embodiment. Such as figure 1 As shown, the induction furnace 1 includes: a bottomed vessel-shaped furnace body 2 with an open top and a cylindrical peripheral wall; and a coil 3 wound around the outer peripheral side of the peripheral wall of the furnace body 2 .

[0023] The furnace body 2 is made of a refractory material or the like, and a material to be melted such as iron scrap is charged into the furnace body 2 to be melted. The coil 3 is disposed concentrically with the furnace body 2, and the end 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com