100W solid-state relay lead frame

A solid-state relay, lead frame technology, applied in the direction of semiconductor/solid-state device components, electric solid-state devices, circuits, etc., can solve the problems of inability to meet the requirements of high-power use, difficult to form glue dispensing, low insulation voltage, etc., to avoid the above problems. Machine failure, improve product sealing layer, increase the effect of insulation voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

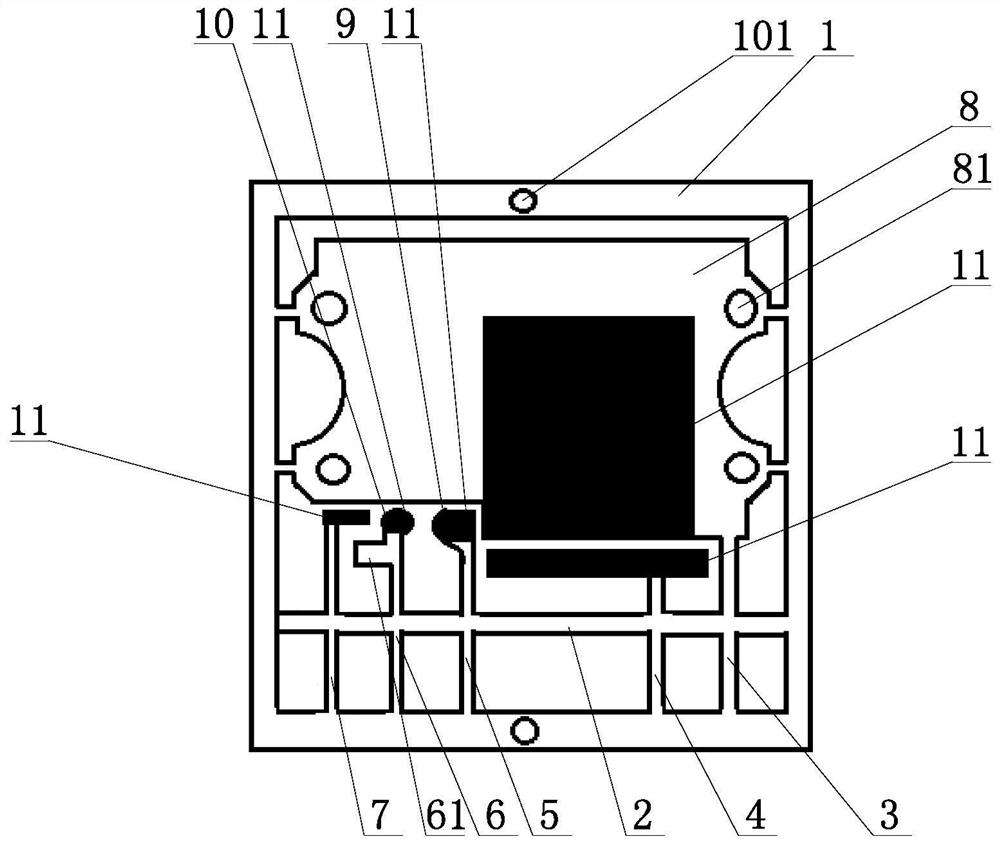

[0022] Such as figure 1 As shown, the 100W solid-state relay lead frame of the present embodiment includes a side rib 1, a positioning hole 101 is provided on the side rib 1, and the first, second, third, The fourth and fifth pins 3, 4, 5, 6, 7, the lower ends of the first, second, third, fourth and fifth pins 3, 4, 5, 6, 7 are connected to the side rib 1, the first The upper end of a pin 3 is connected to the first carrier island 8 with a large area. The first carrier island 8 is made of a thick copper strip, and the first carrier island 8 is provided with a silver-plated area 11 for installing switch chips. , four through holes 81 are opened on the first carrier island 8, and the first carrier island 8 is connected to the side rib 1 through four connecting ribs 82, and the upper ends of the adjacent third pin 5 and fourth pin 6 are respectively Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com