New concept high-speed aerocraft propulsion system layout method

A high-speed aircraft and propulsion system technology, applied in the field of propulsion system layout, can solve the problems that the aircraft can provide enough power, cannot start by itself, cannot be reused, etc., and achieve ultra-high heat exchange efficiency, weight reduction, and large heat exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

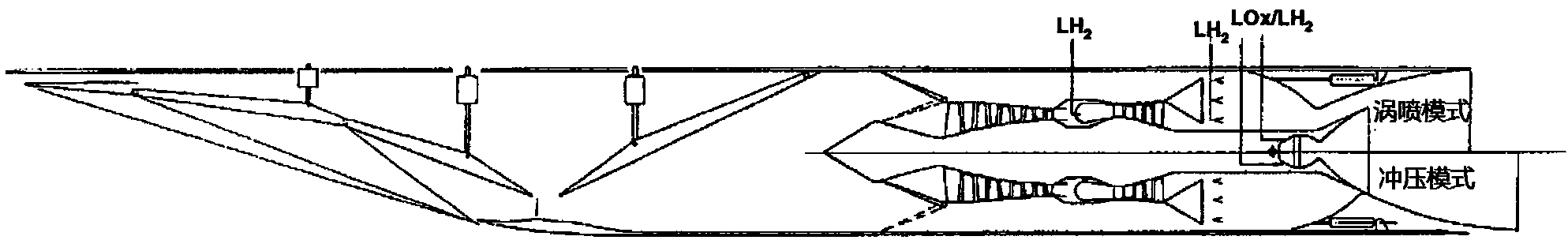

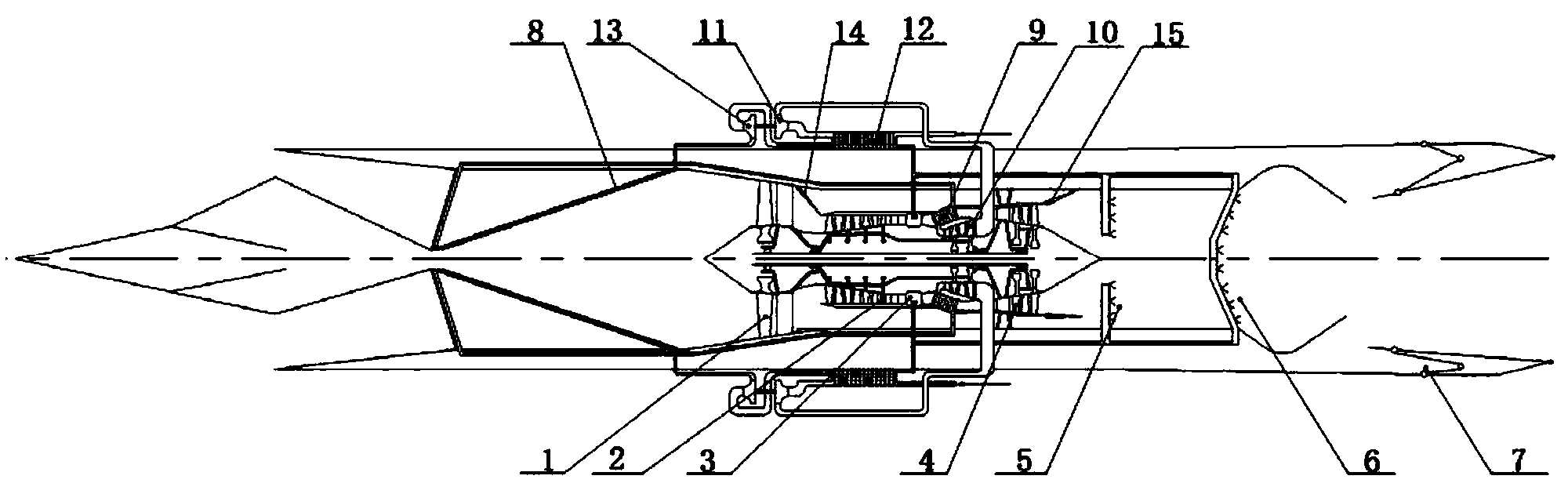

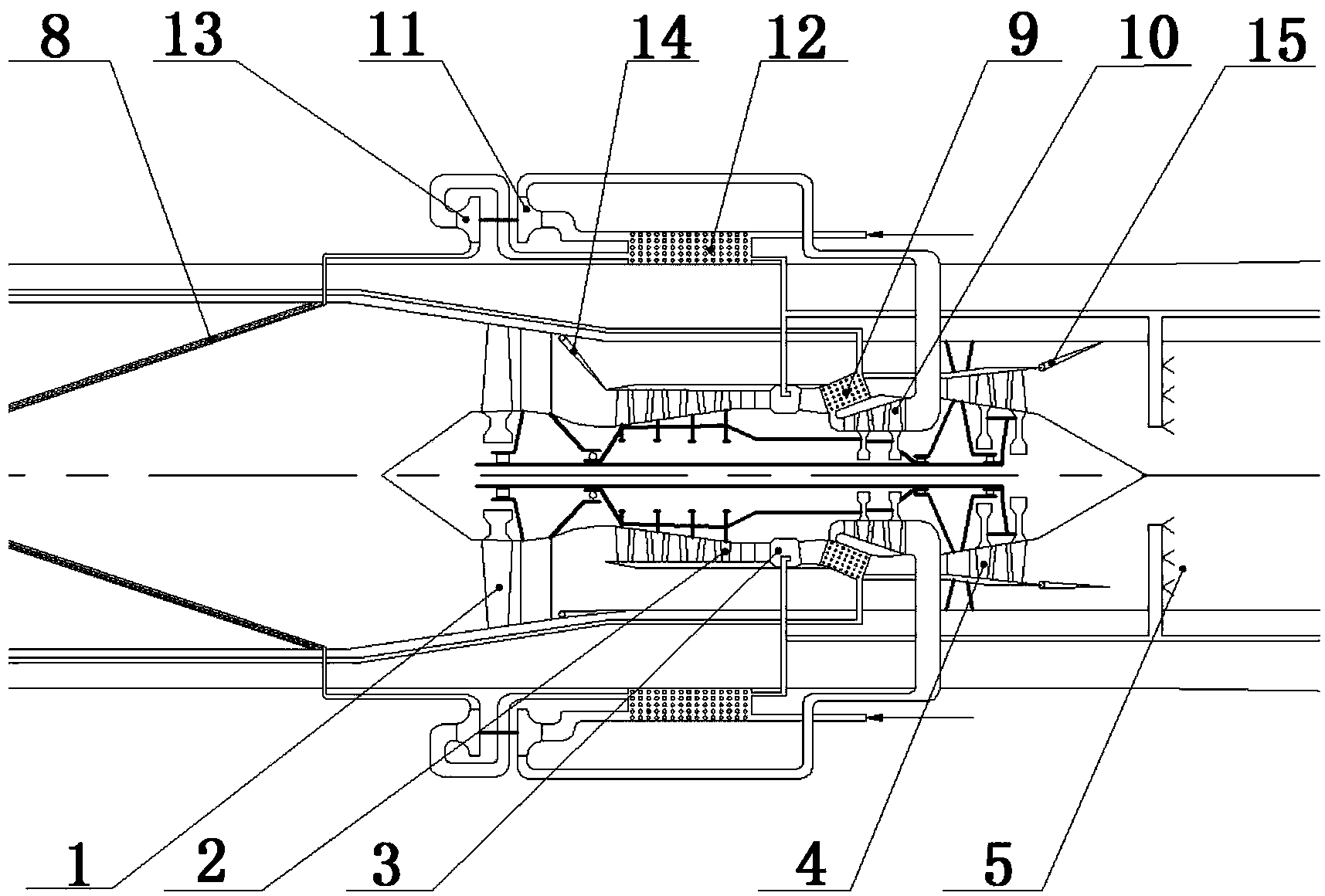

[0031] The present invention is a new-concept high-speed aircraft propulsion system layout based on turbofan-rocket combined engine and supercritical state fluid circulation, including a closed fluid circulation under supercritical state and a mainstream Brayton cycle. It can be used as a high-speed aircraft propulsion system, and its specific implementation is as Figure 4 shown. The Brayton cycle of the system includes: fan 1, core compressor 2, pre-combustion chamber 3, air turbine 4, main combustion chamber 6, air intake 16, tail nozzle 7, and the closed cycle of the system includes: the first heat exchange 8, the second heat exchanger 9, the core turbine 10, the working medium turbine 11, the third heat exchanger 12, the working medium pump 13; in this embodiment, the engine is in Ma=4 state, the afterburner 5, The first valve 14 and the second valve 15 are in a non-working state, so in Figure 4 Not marked in. In the Brayton cycle, the air inlet 16 is located at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com