Patents

Literature

331results about "Composite engine plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

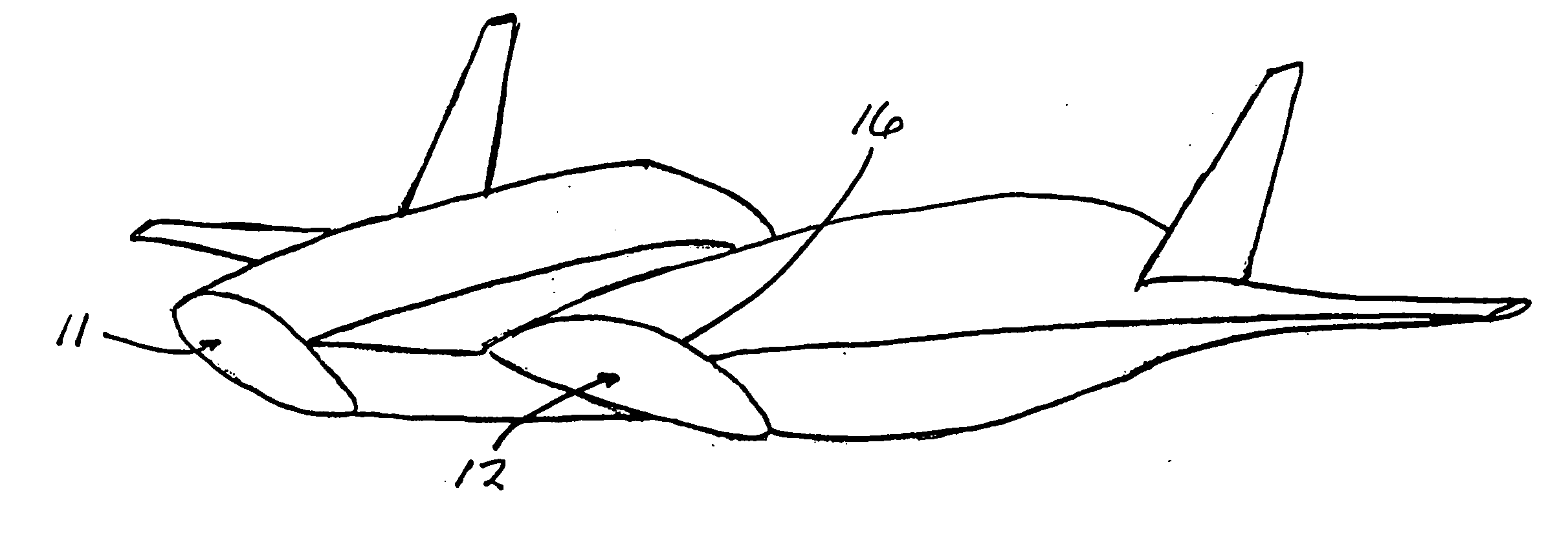

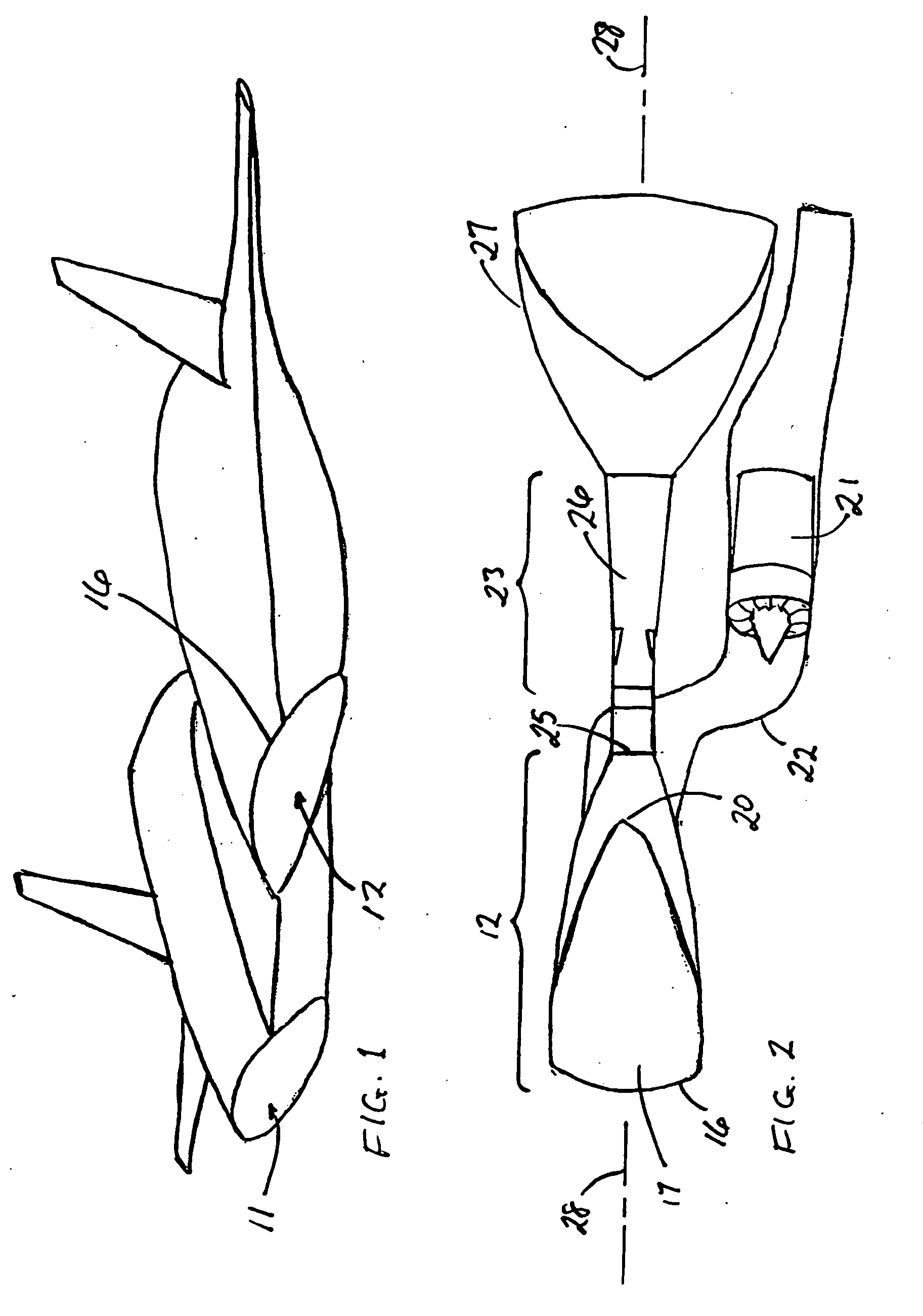

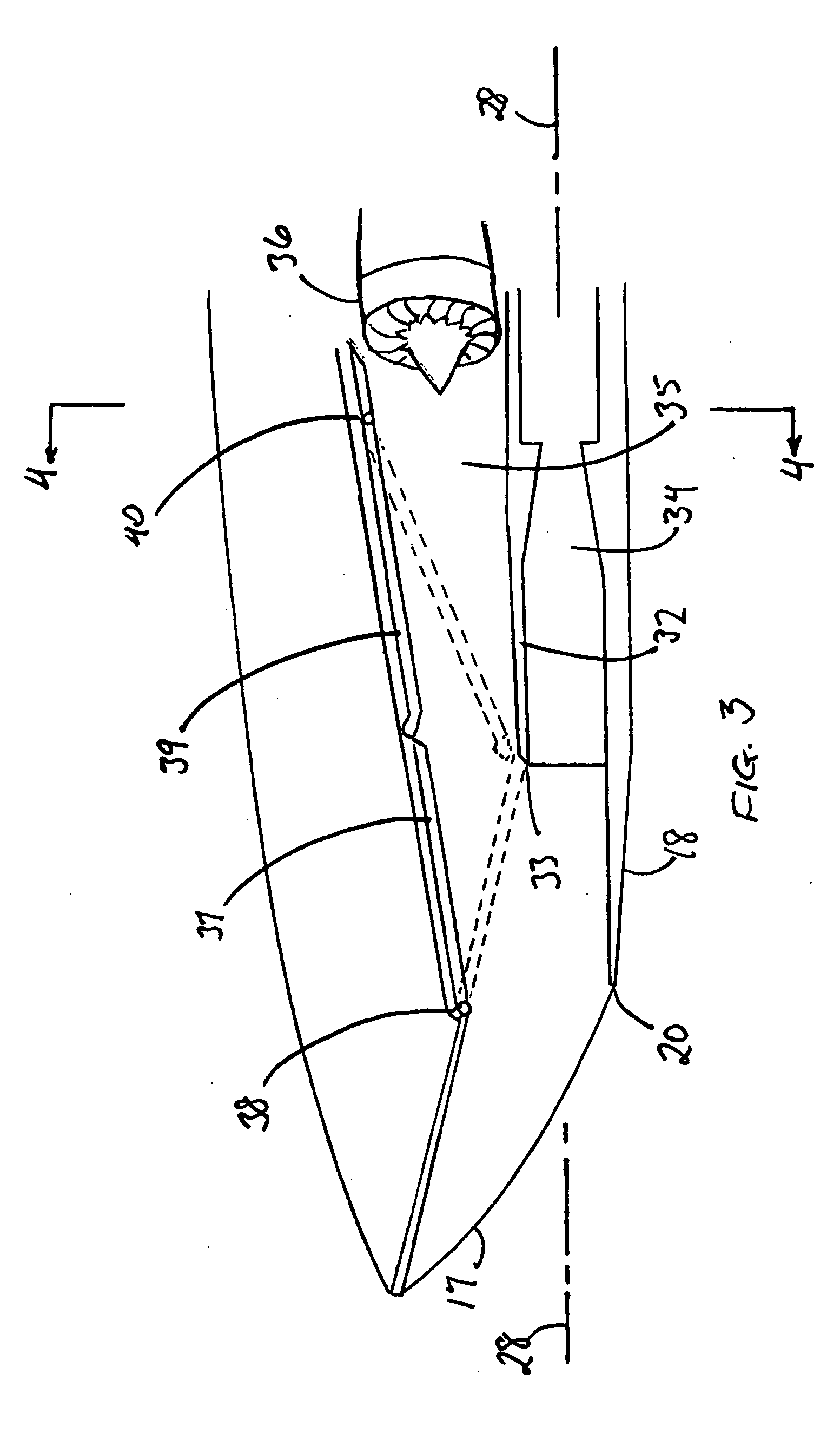

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

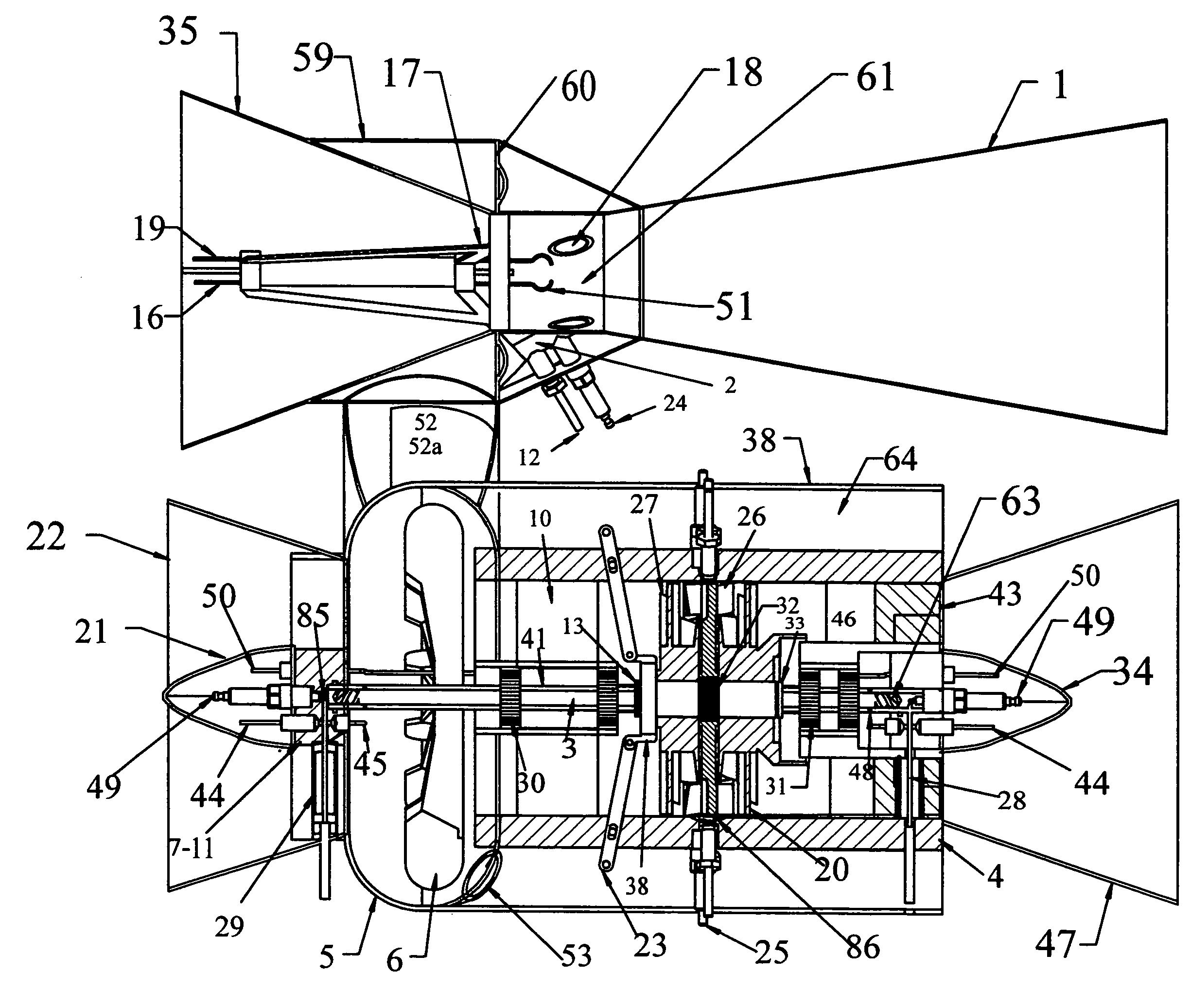

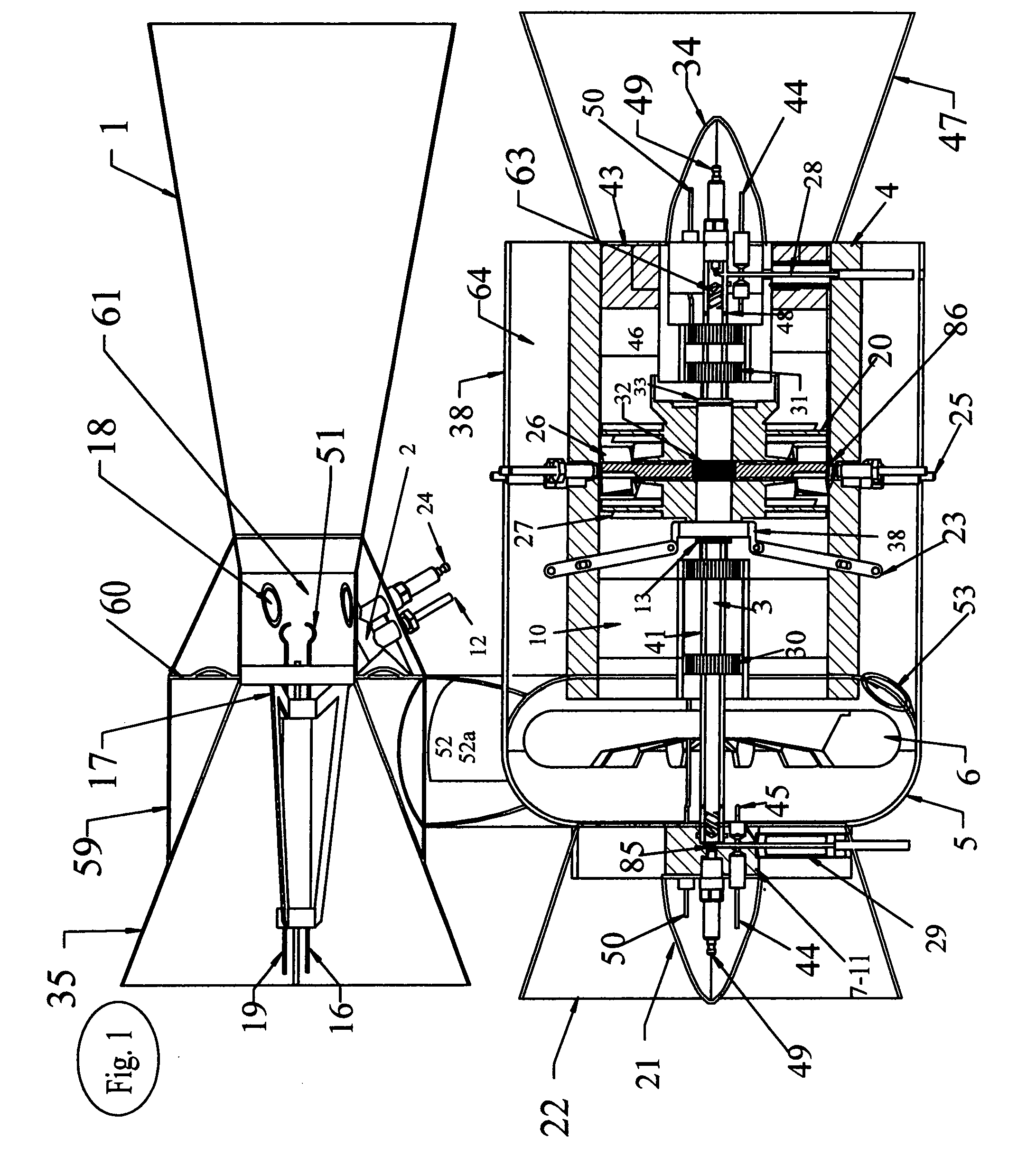

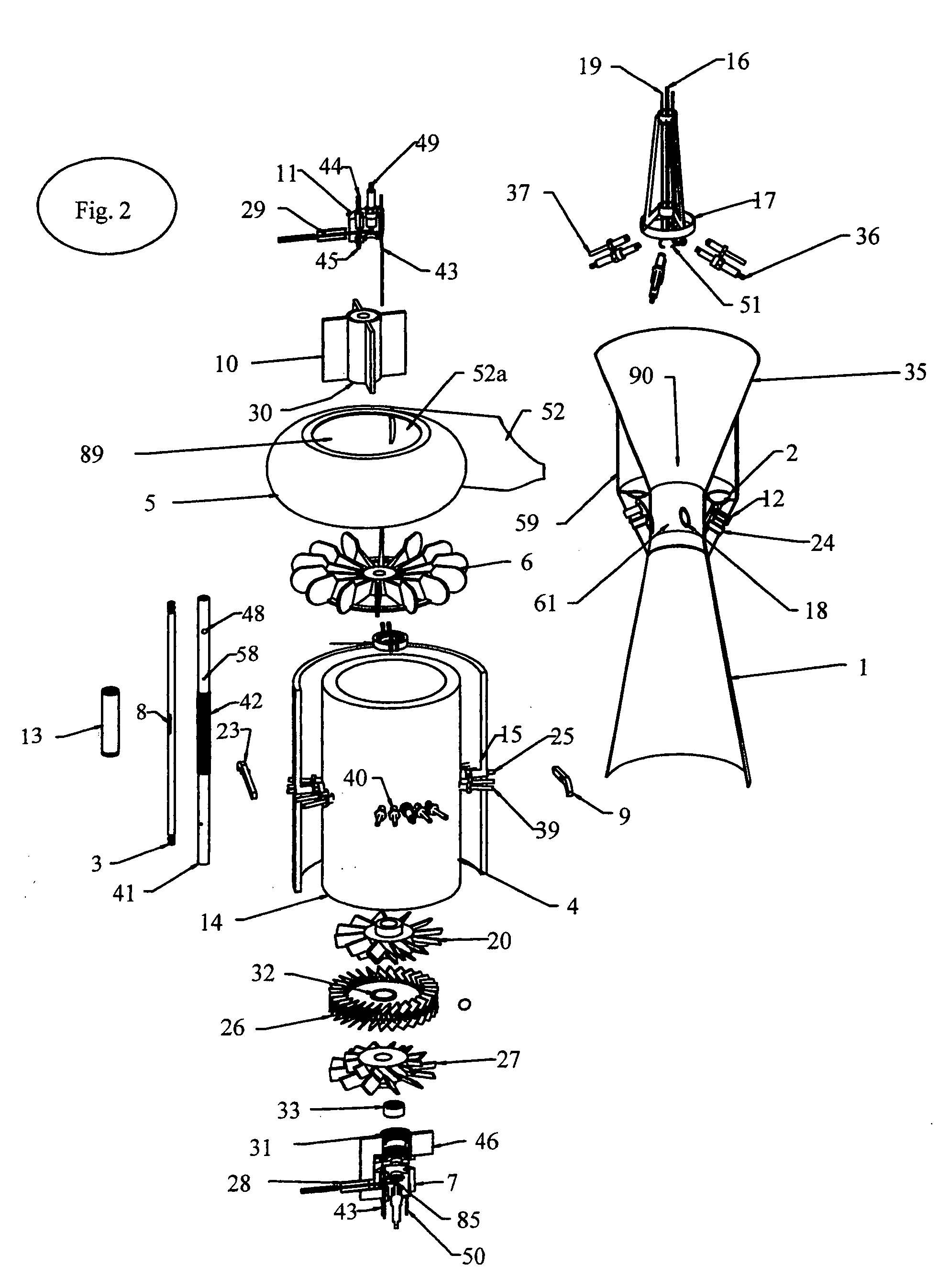

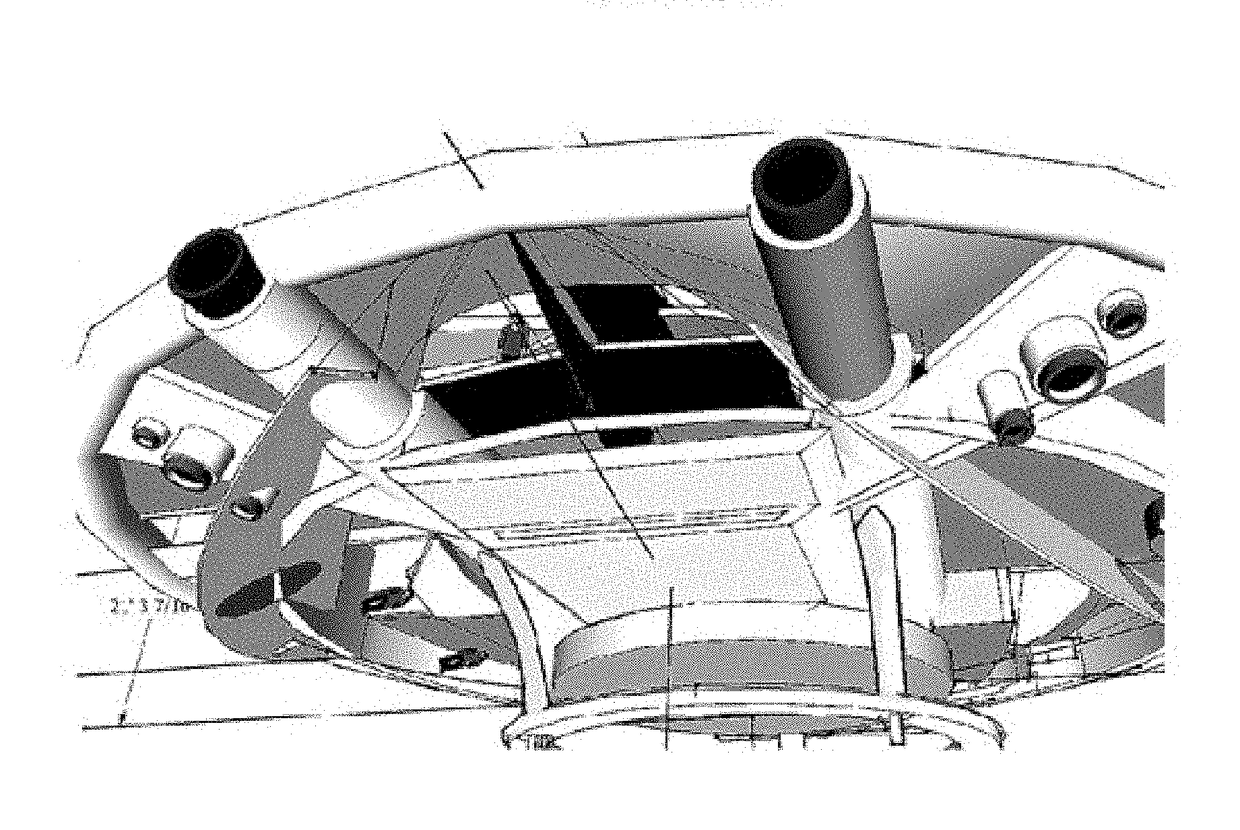

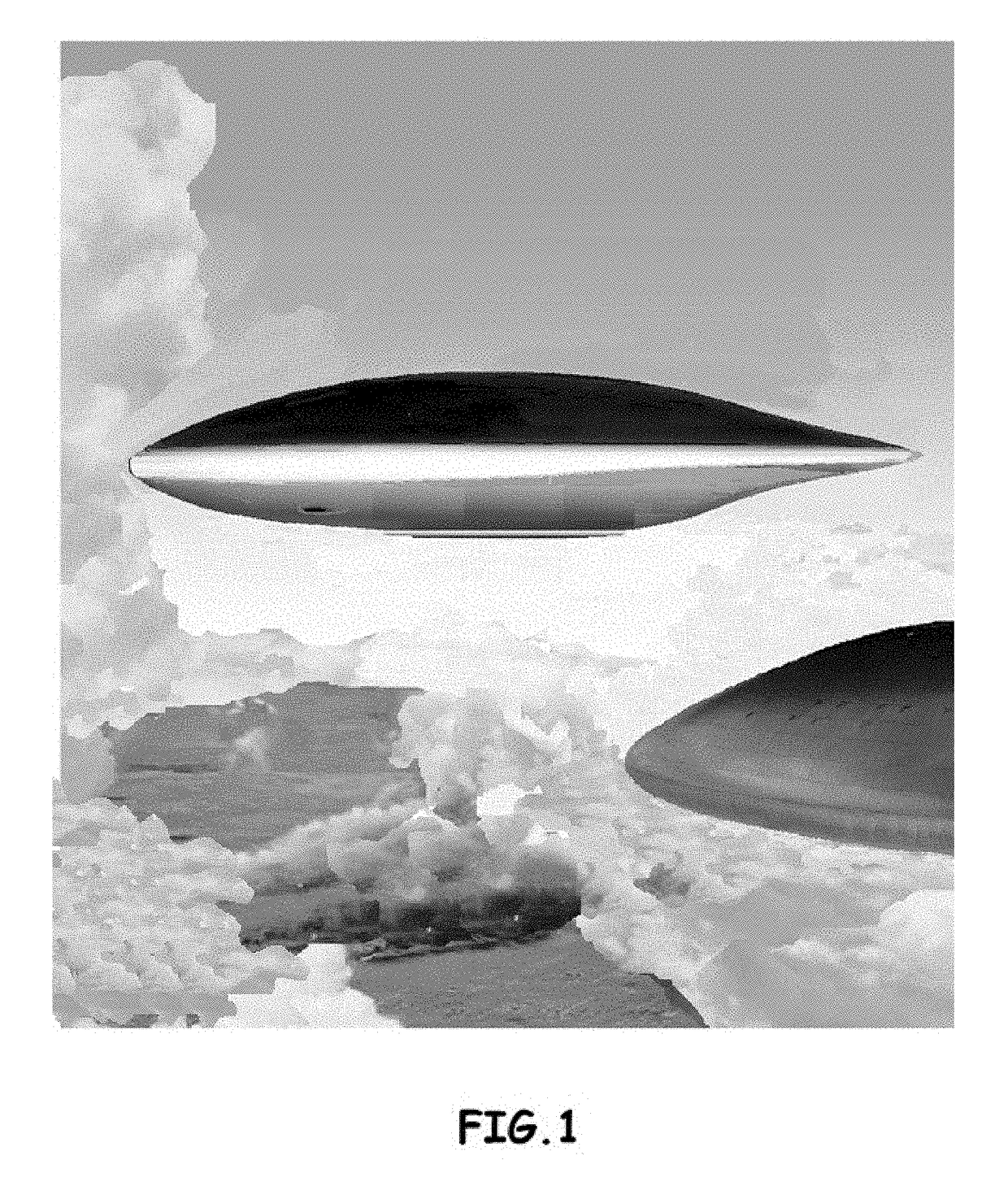

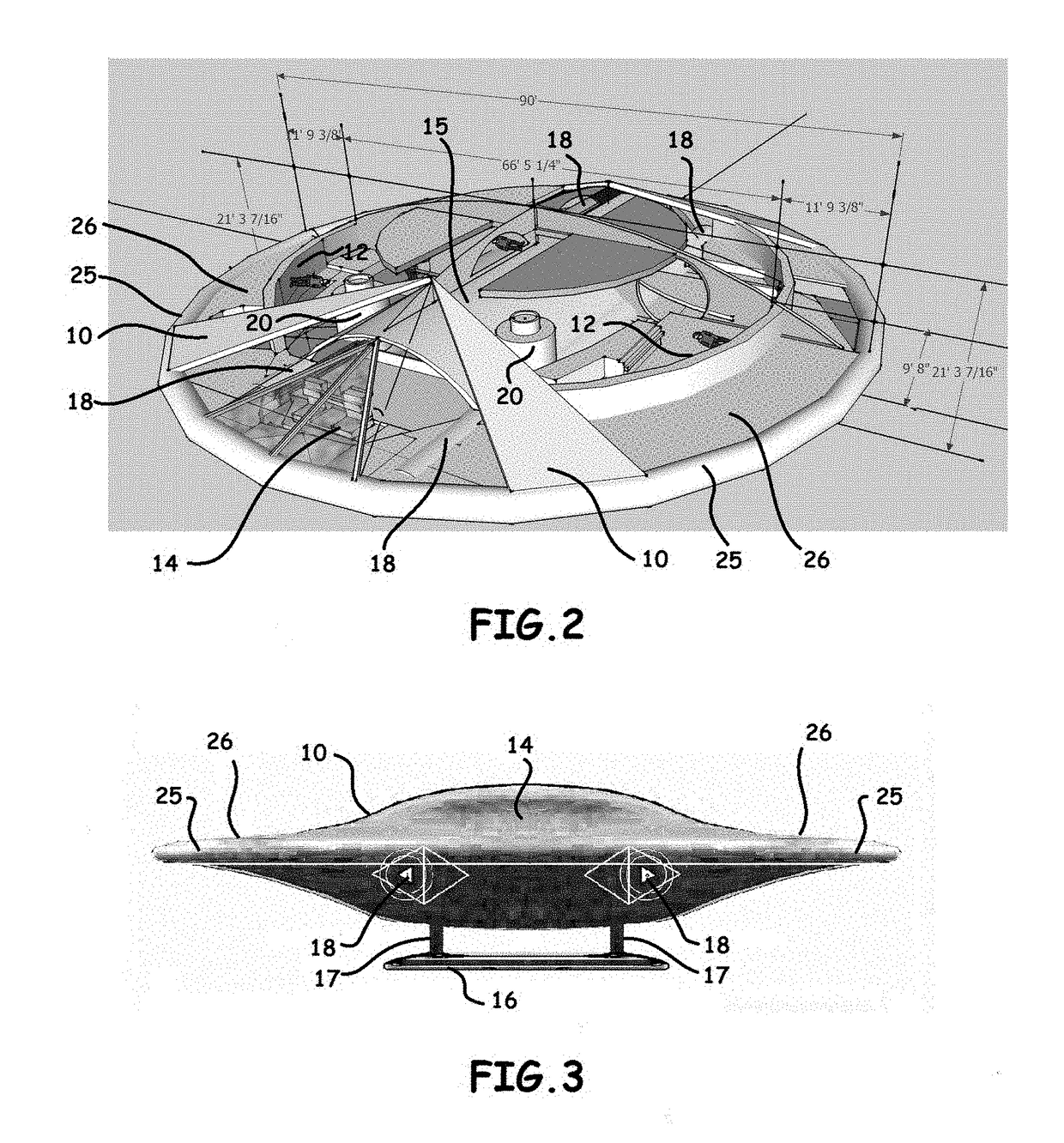

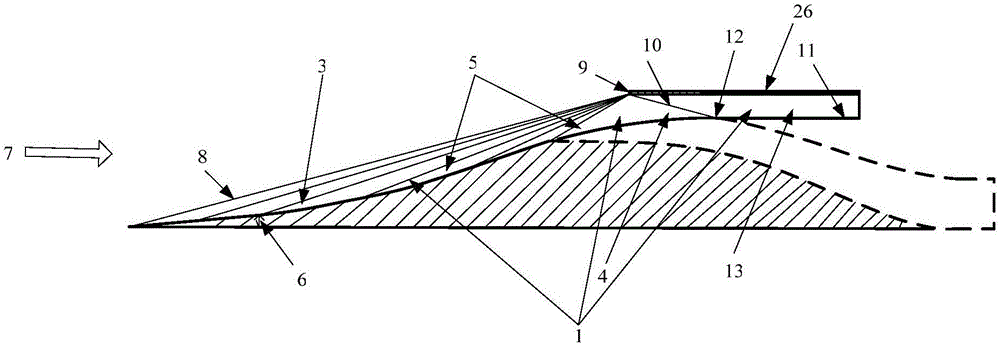

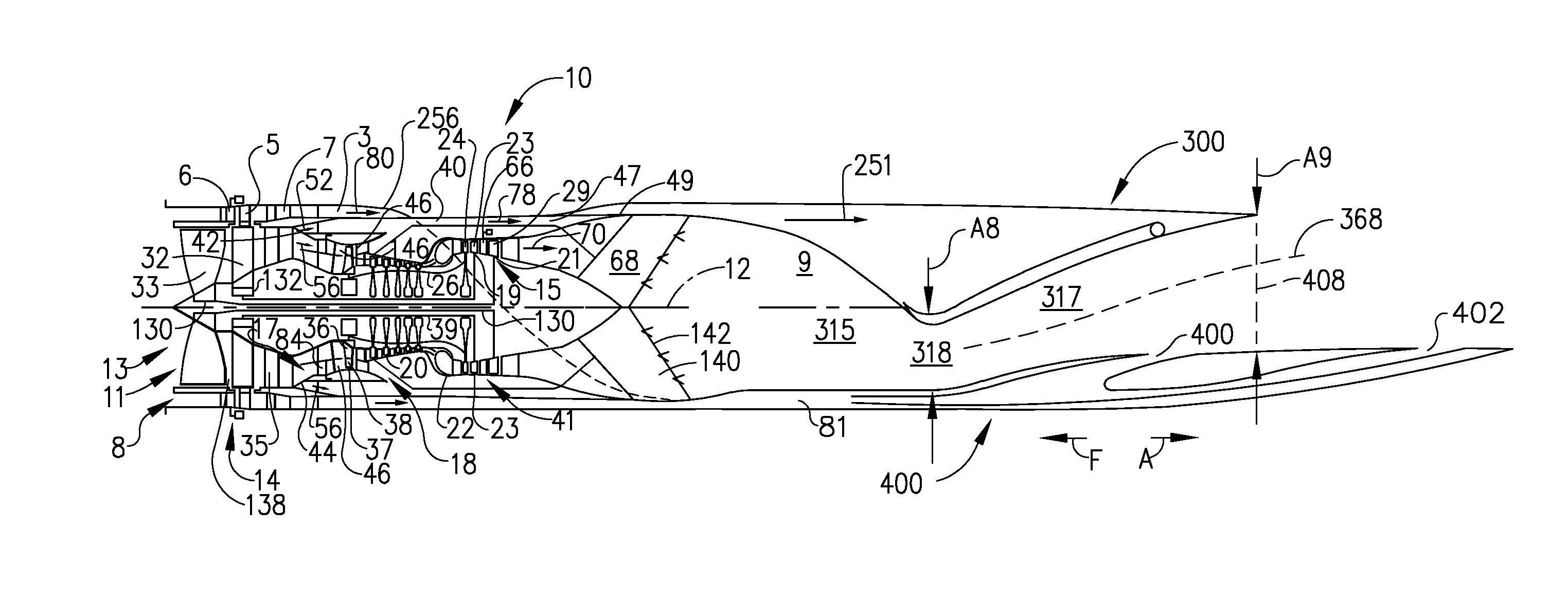

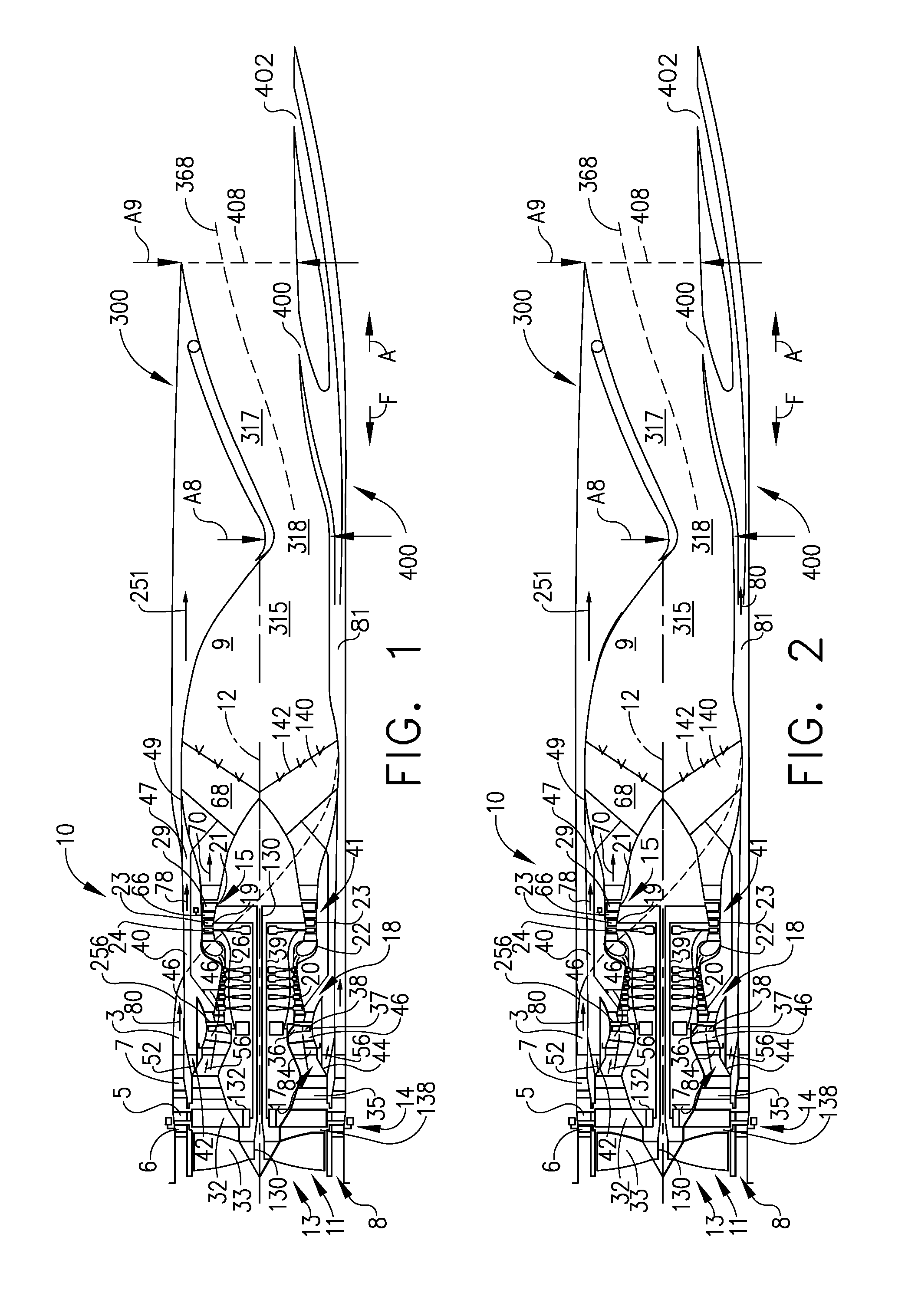

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

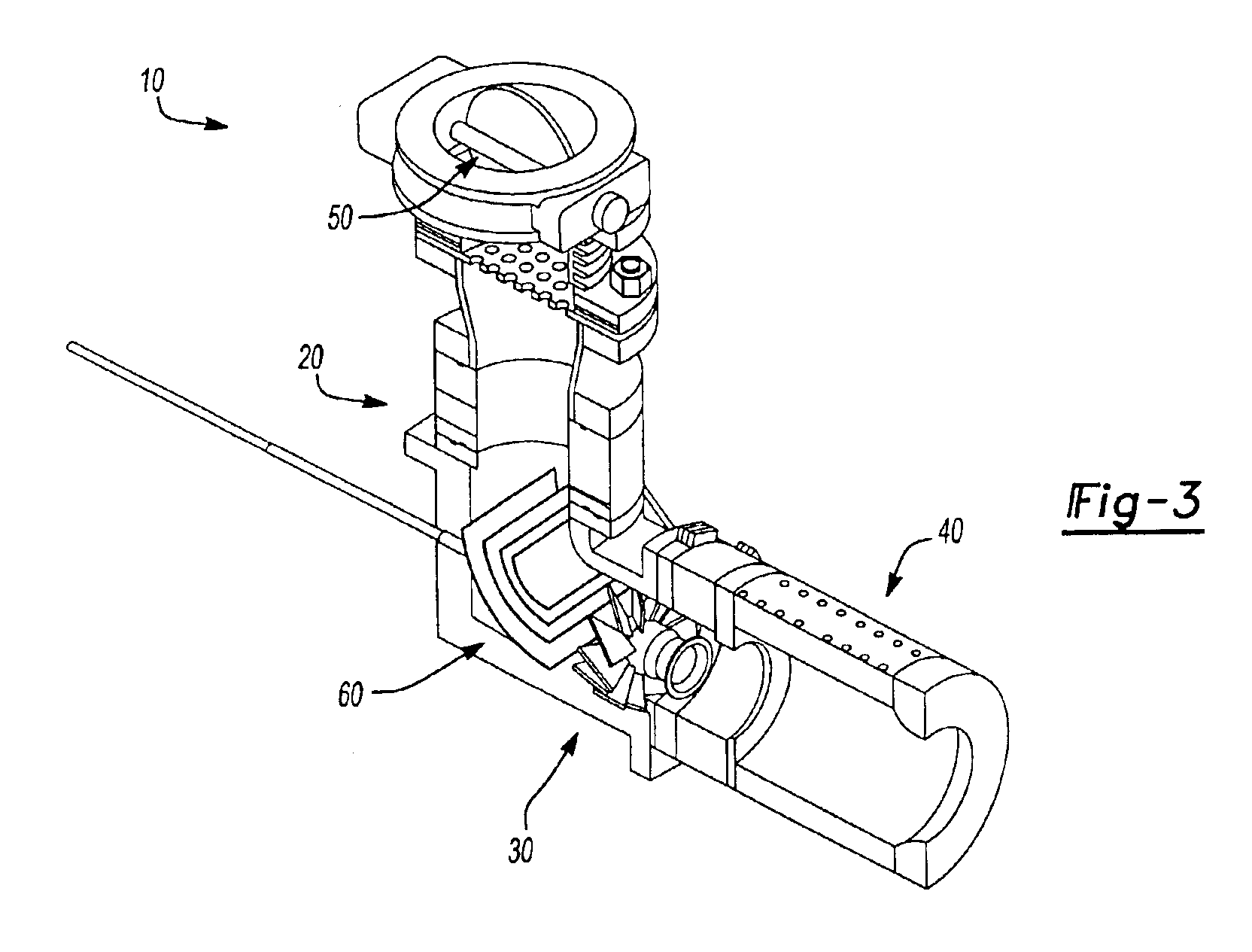

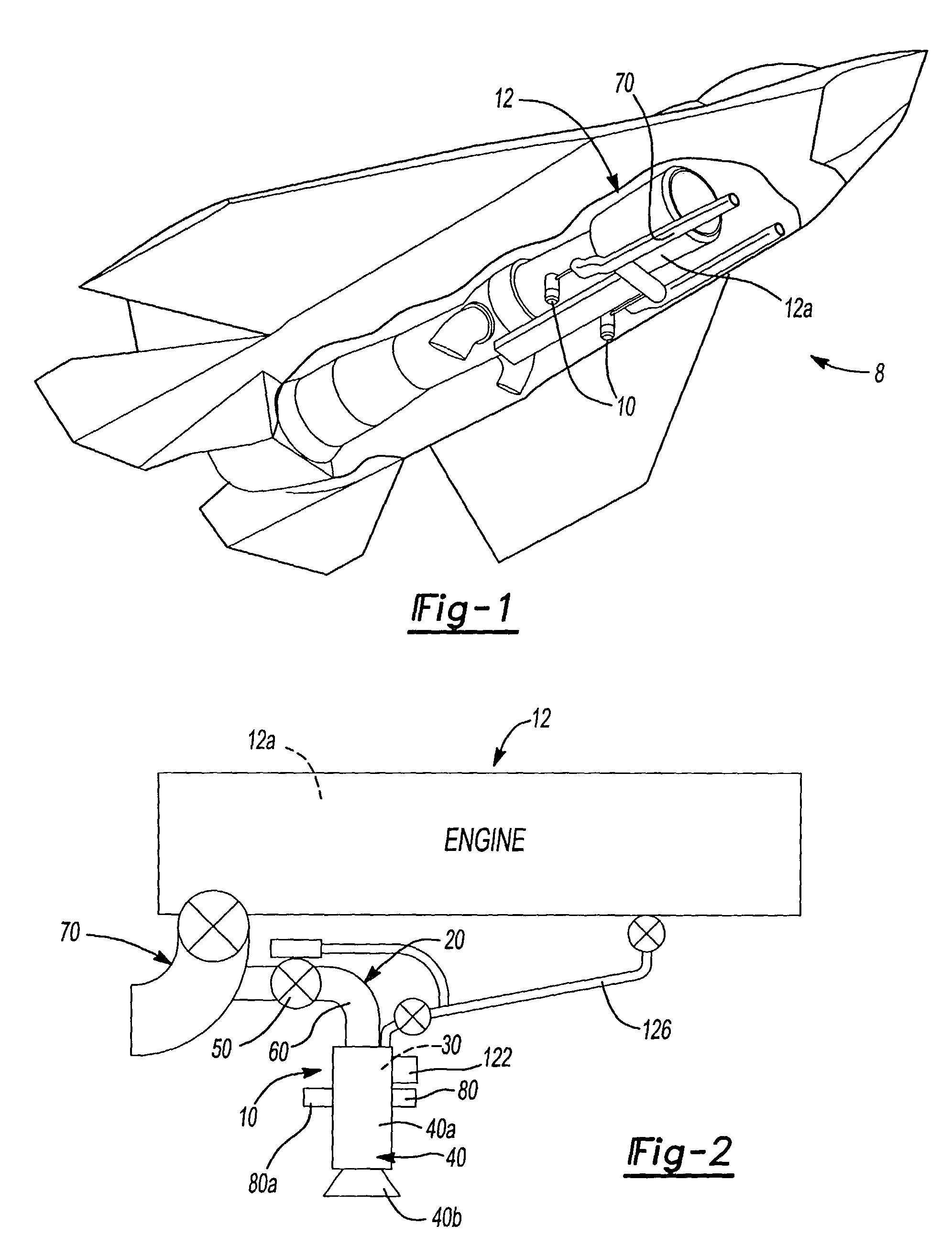

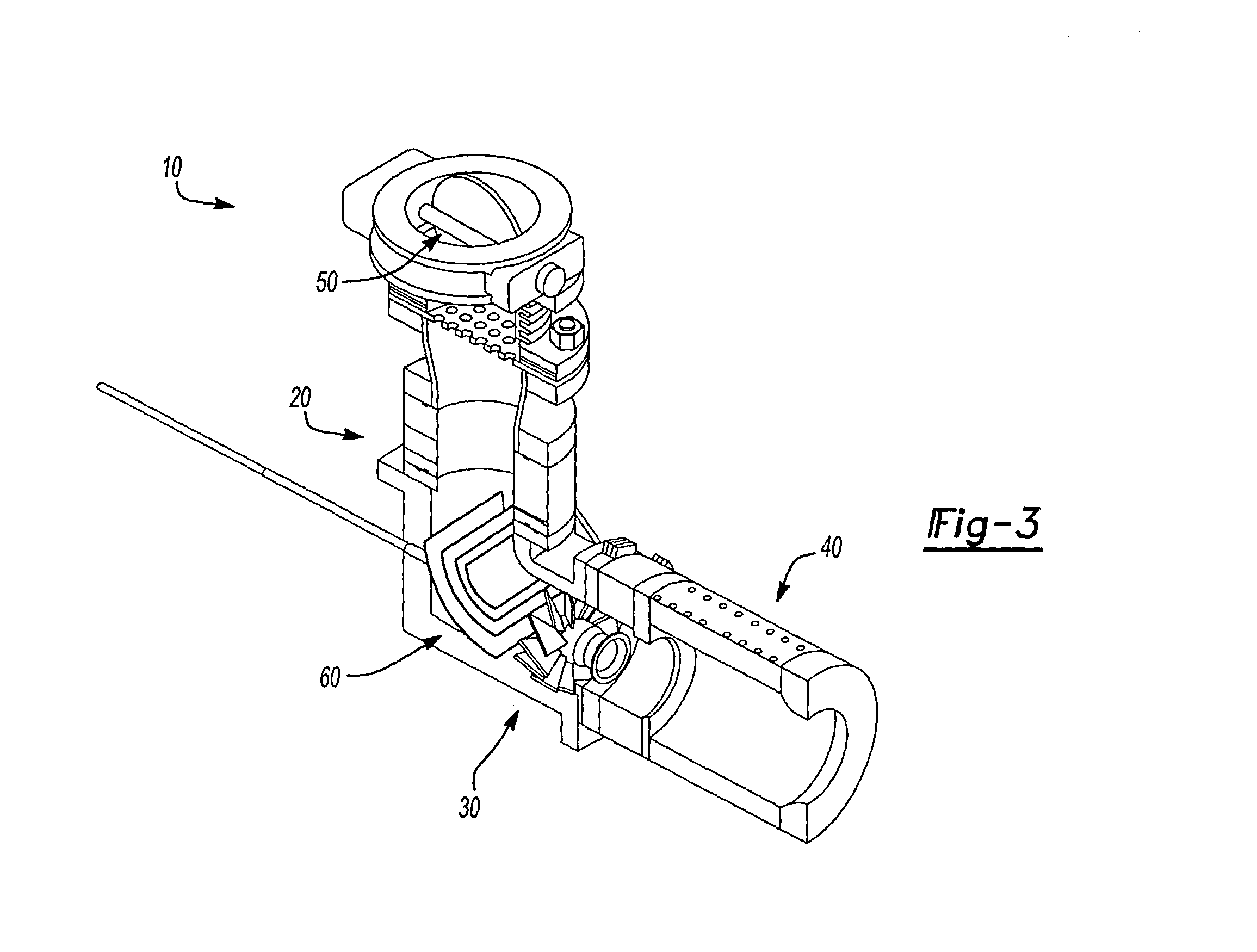

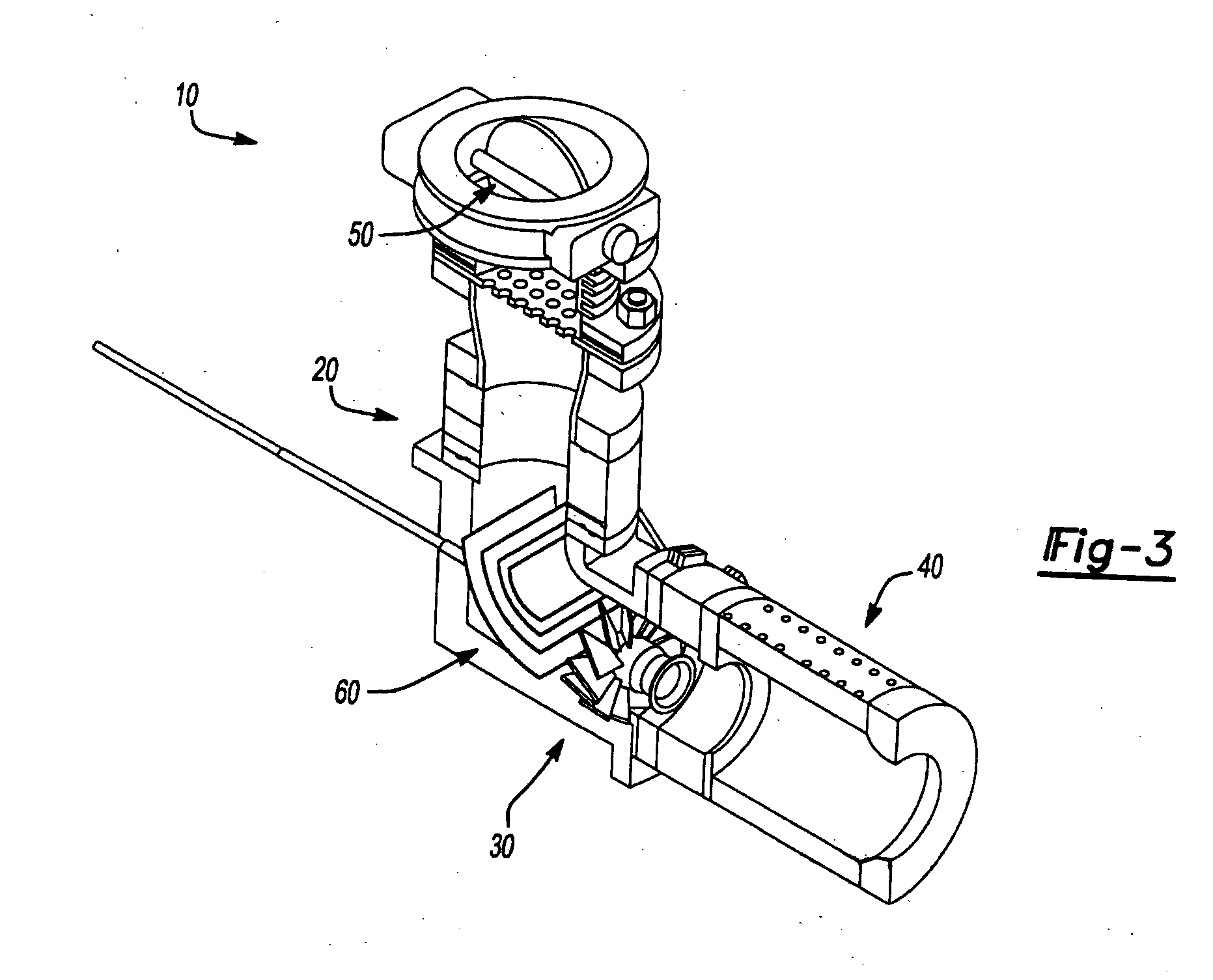

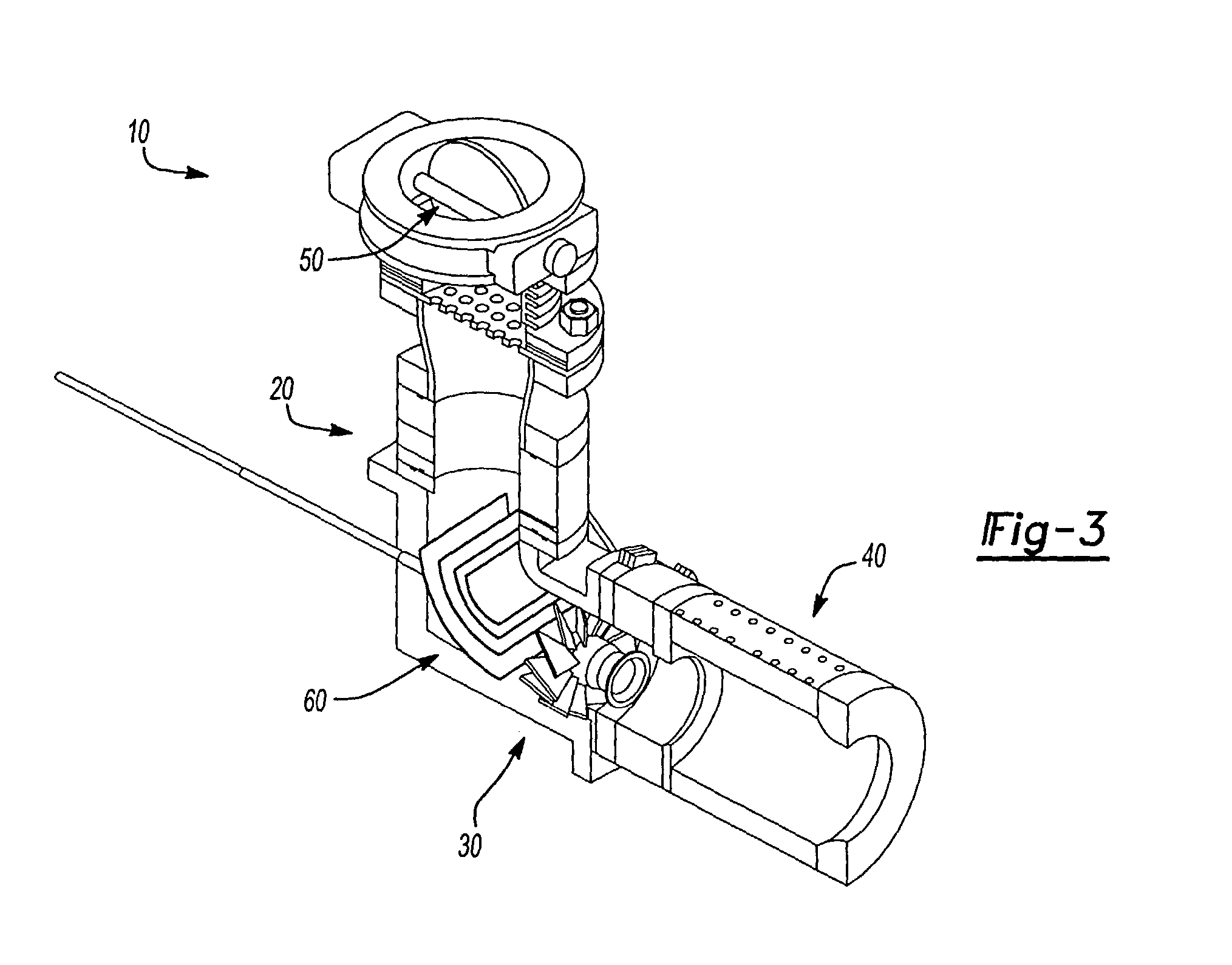

Compact swirl augmented afterburners for gas turbine engines

InactiveUS6895756B2Efficient flame propagationBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityCombustion chamber

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:THE BOEING CO +1

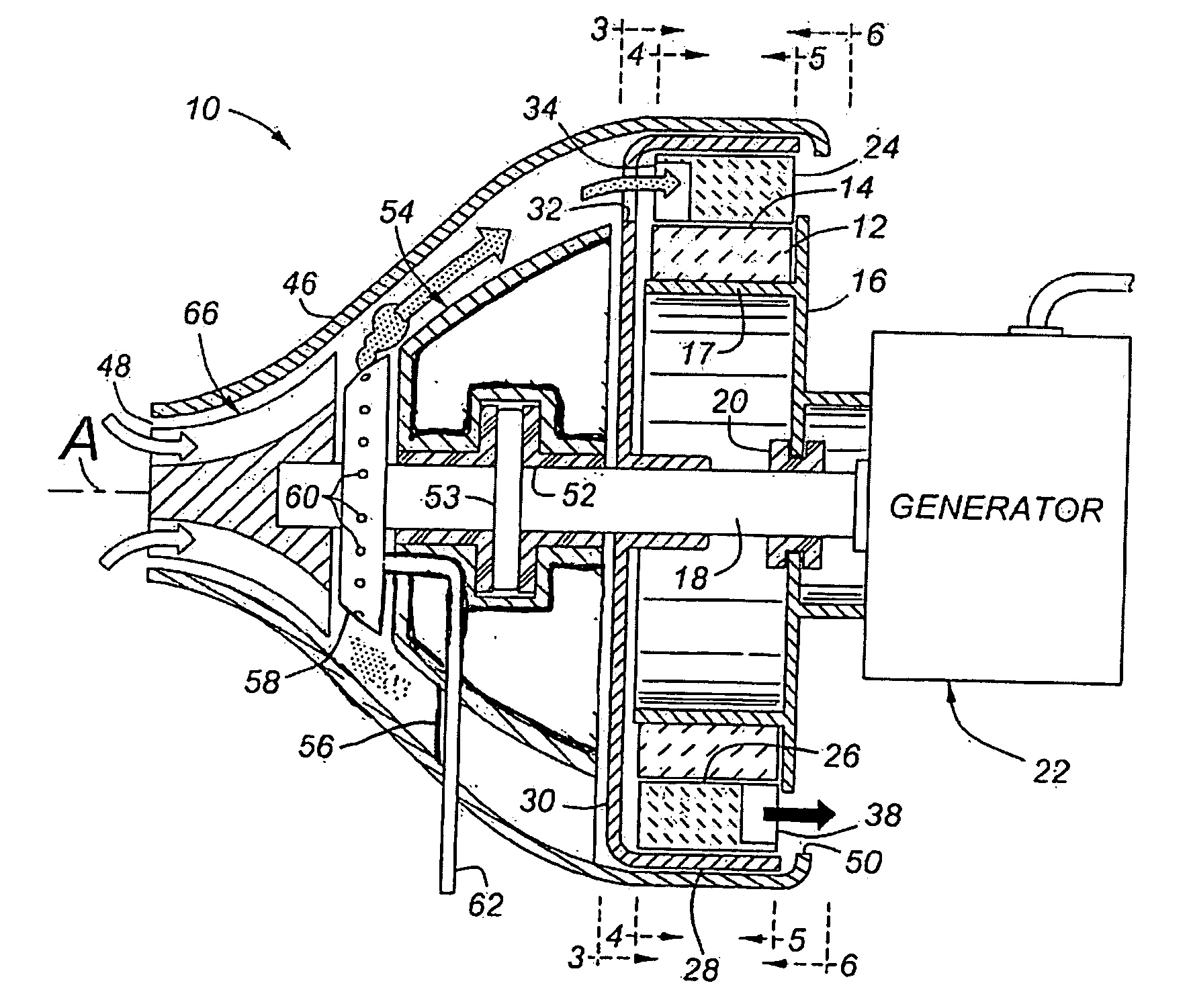

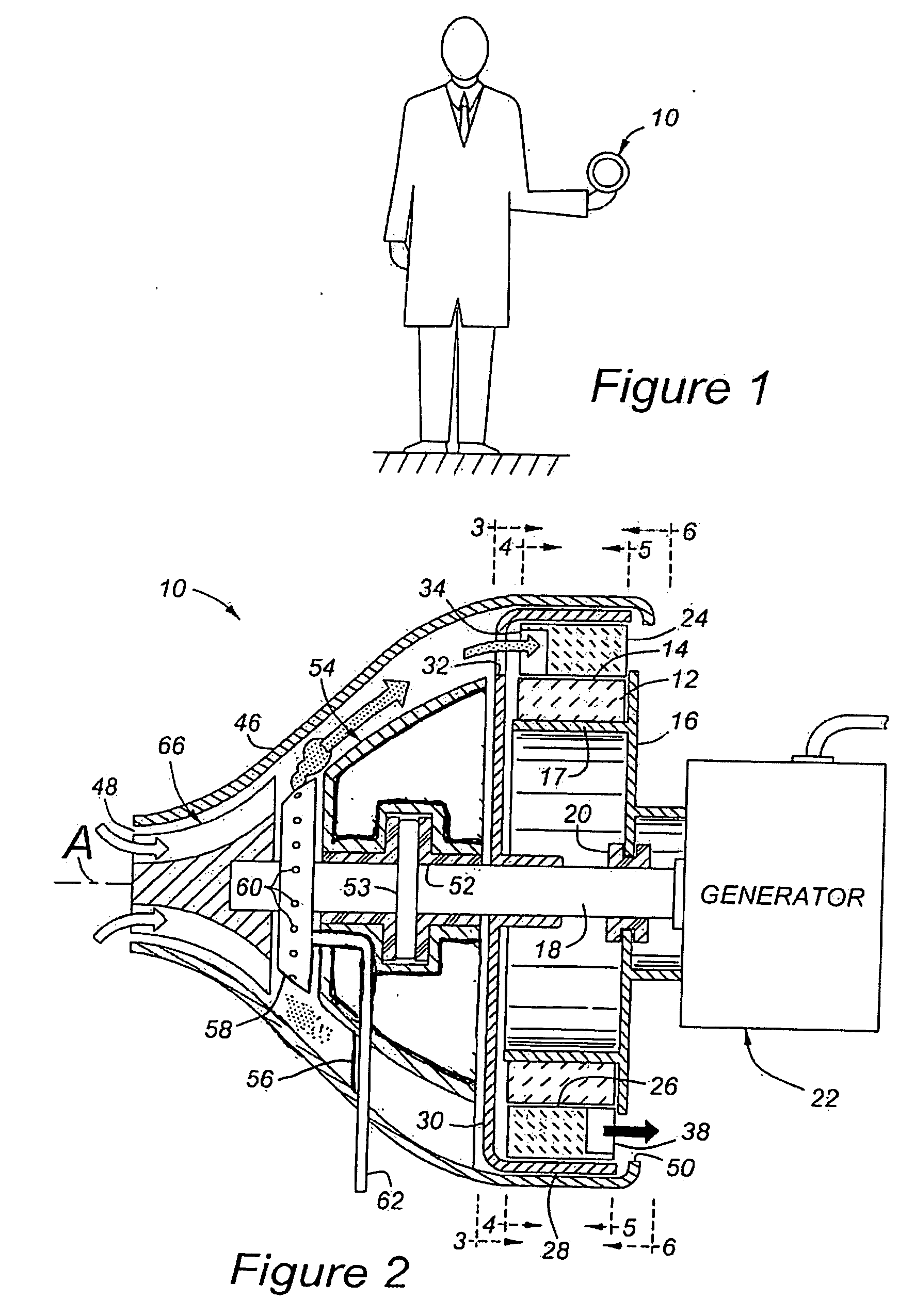

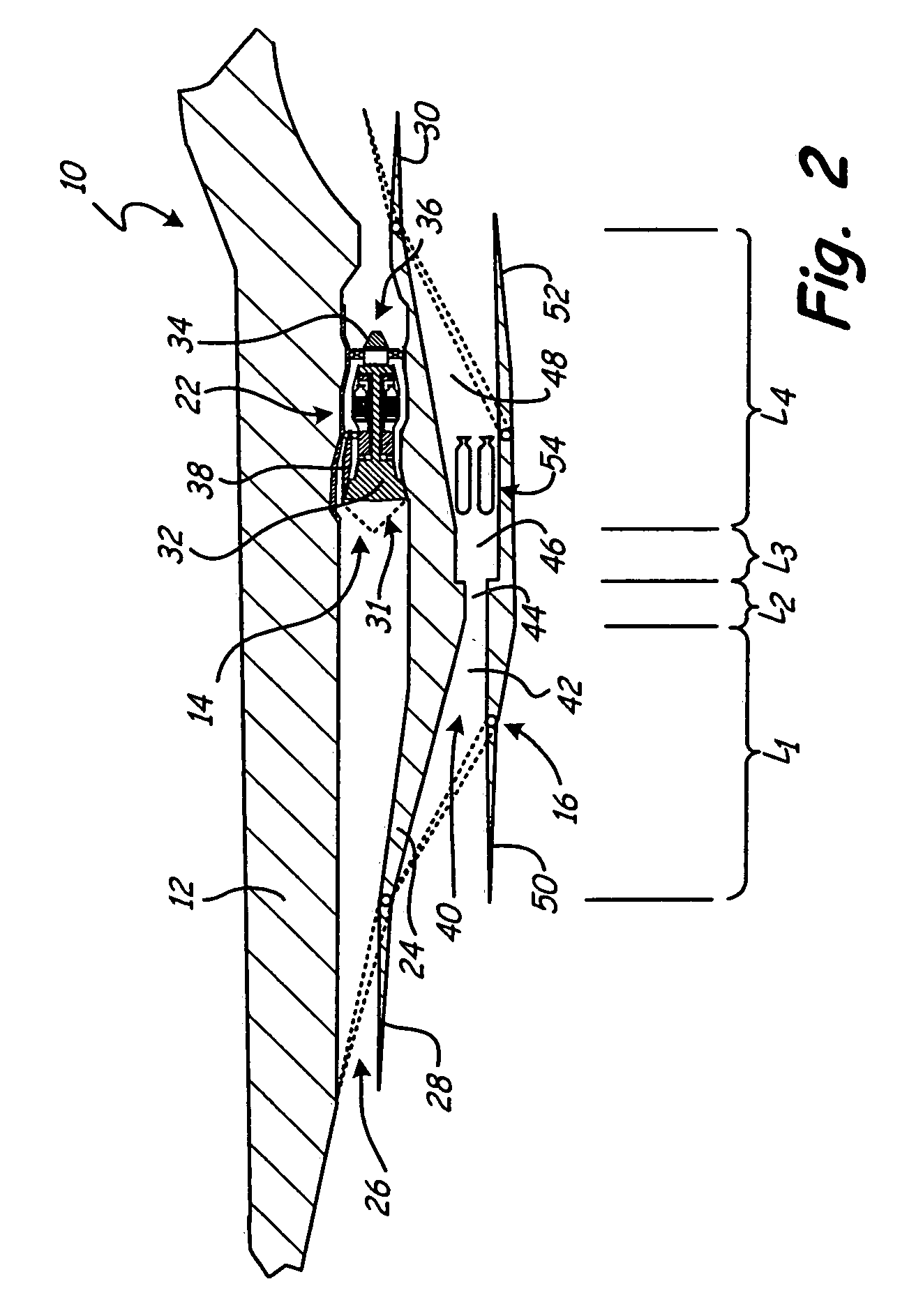

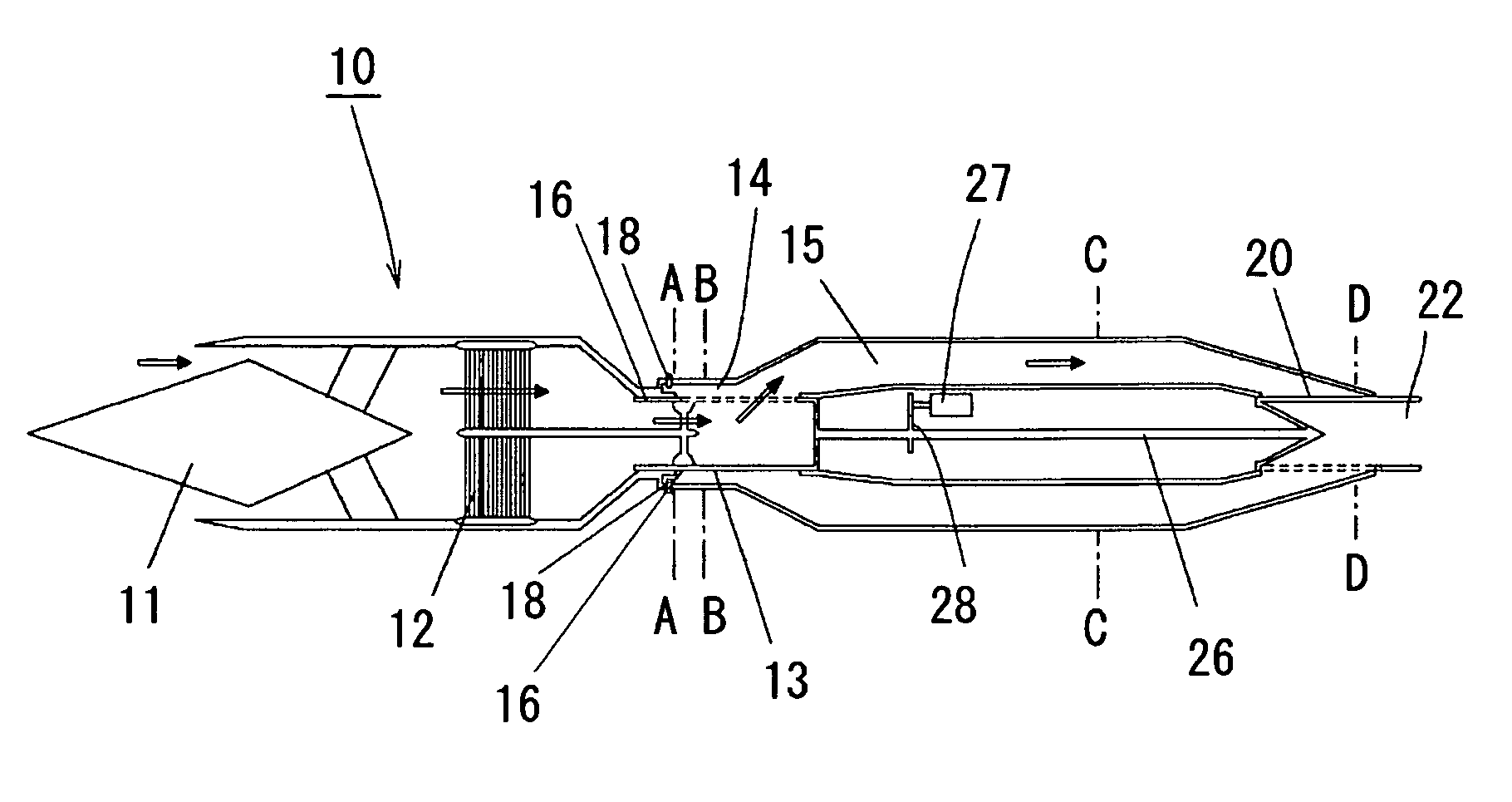

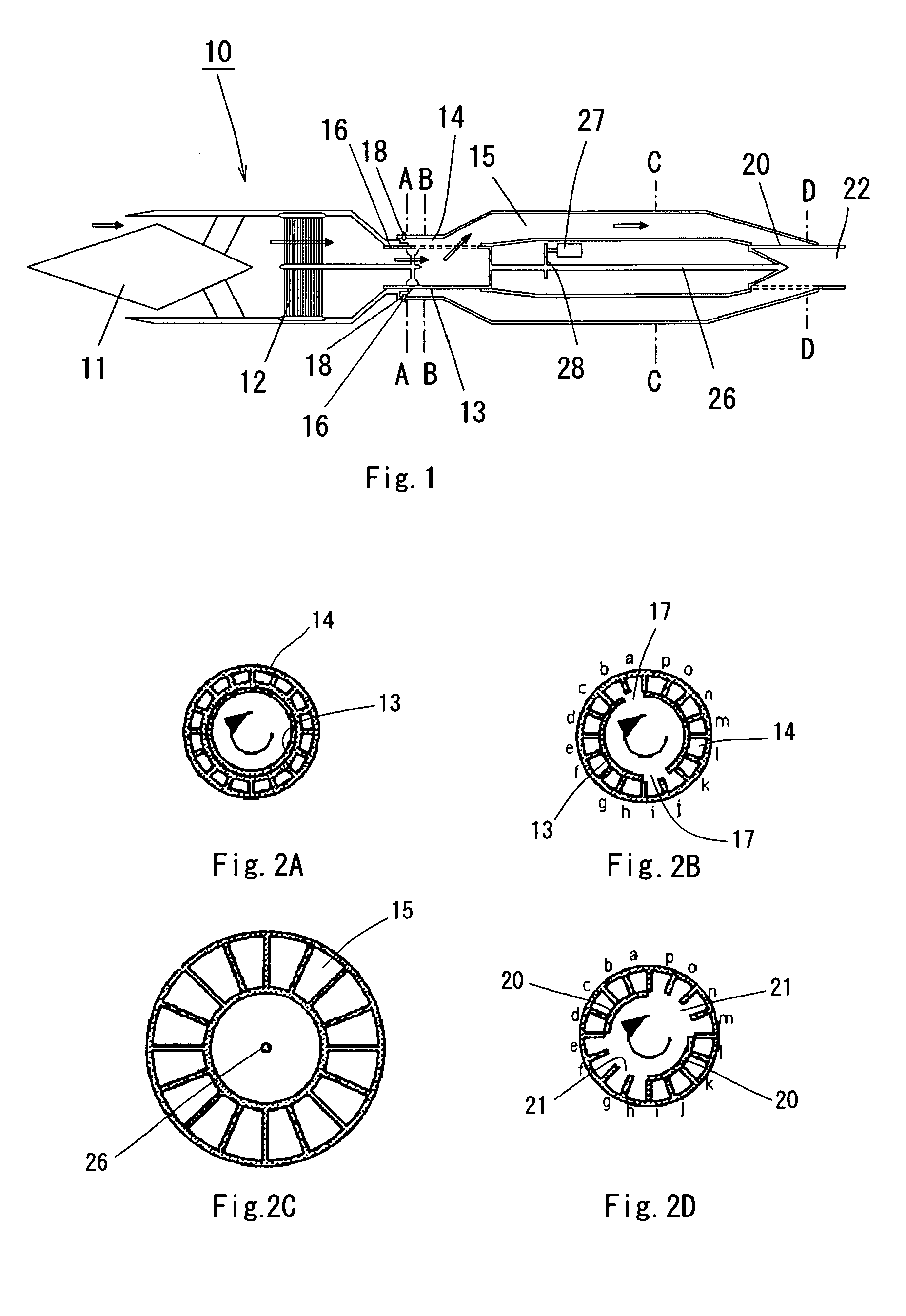

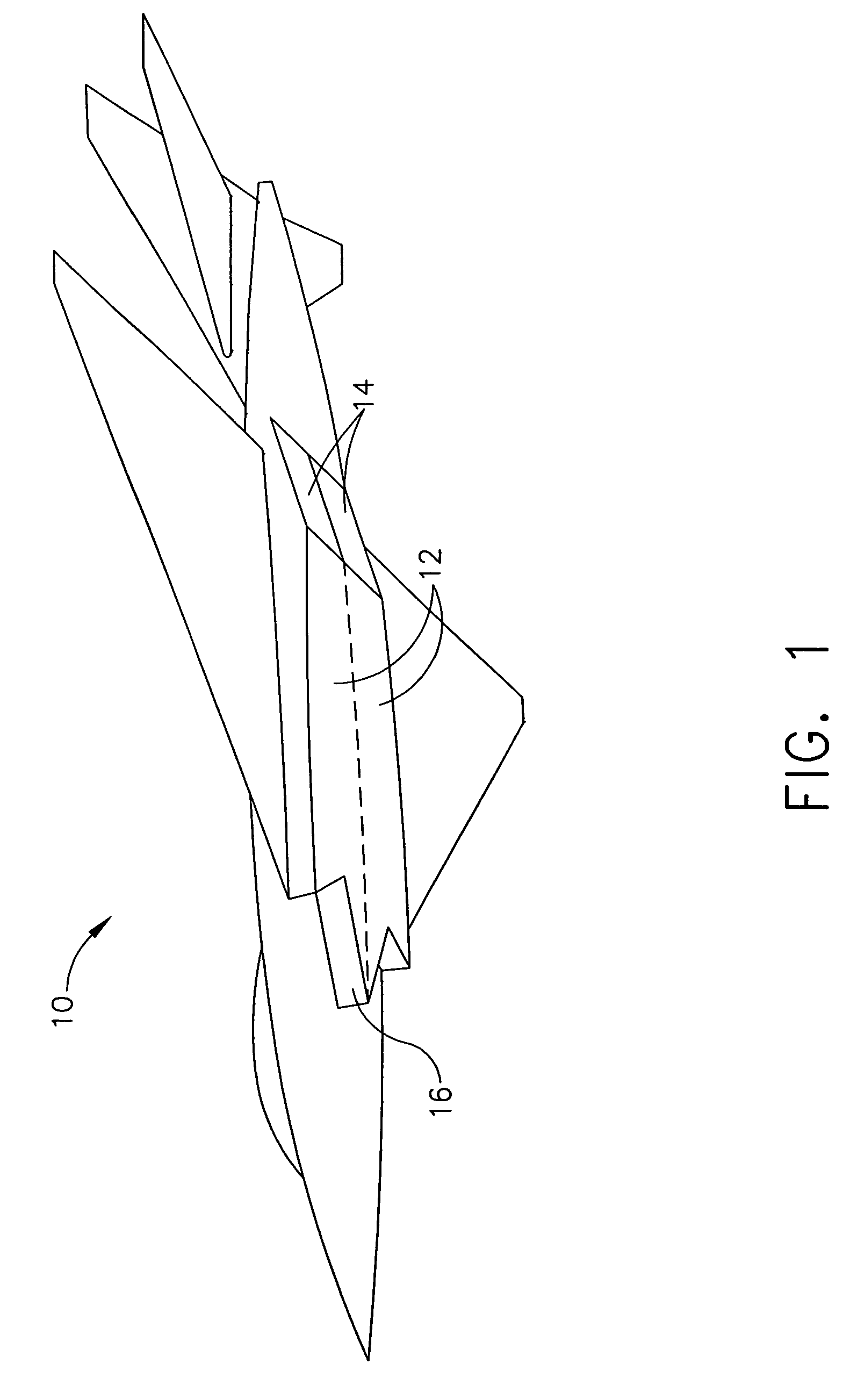

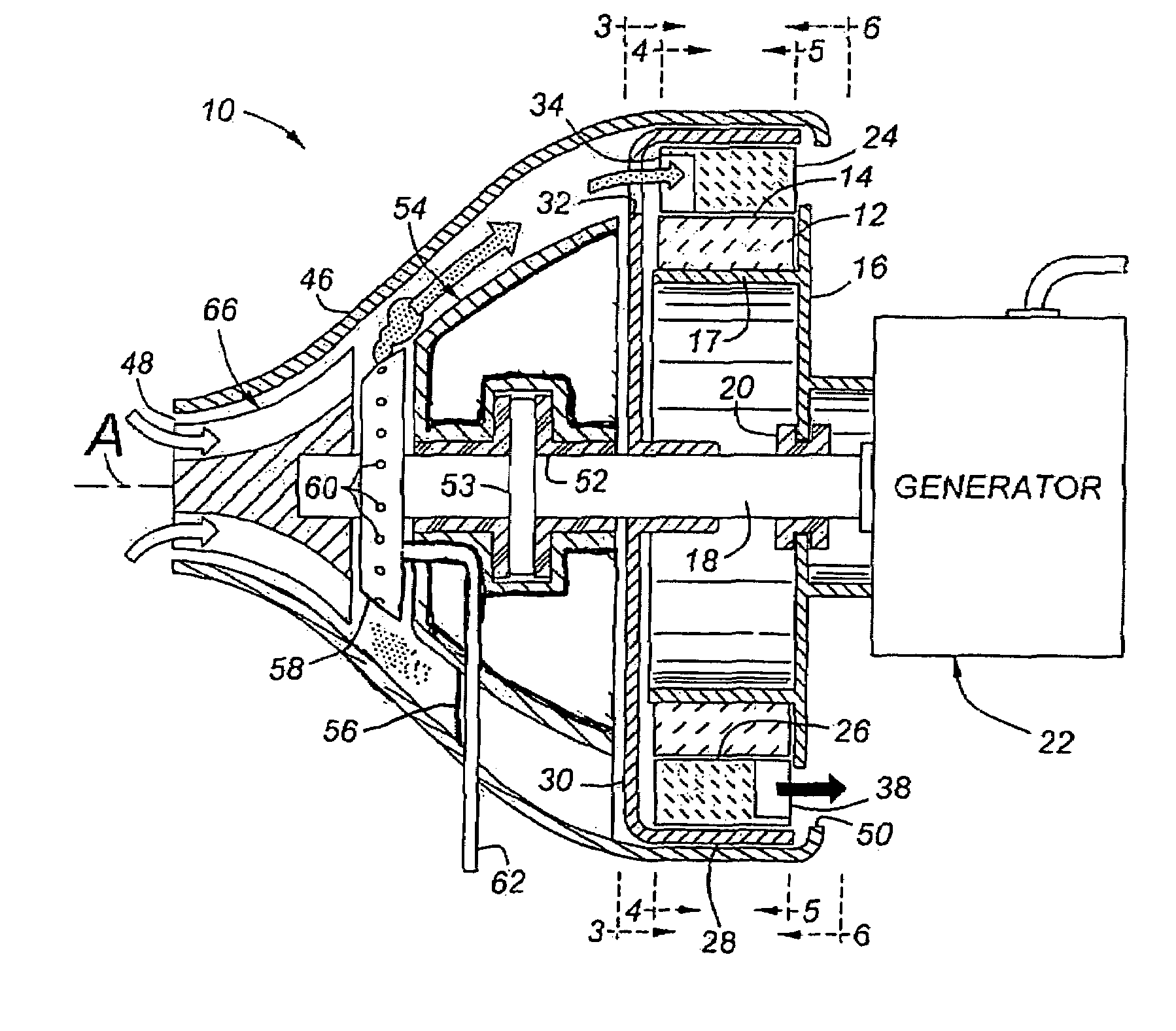

Rotary ramjet turbo-generator

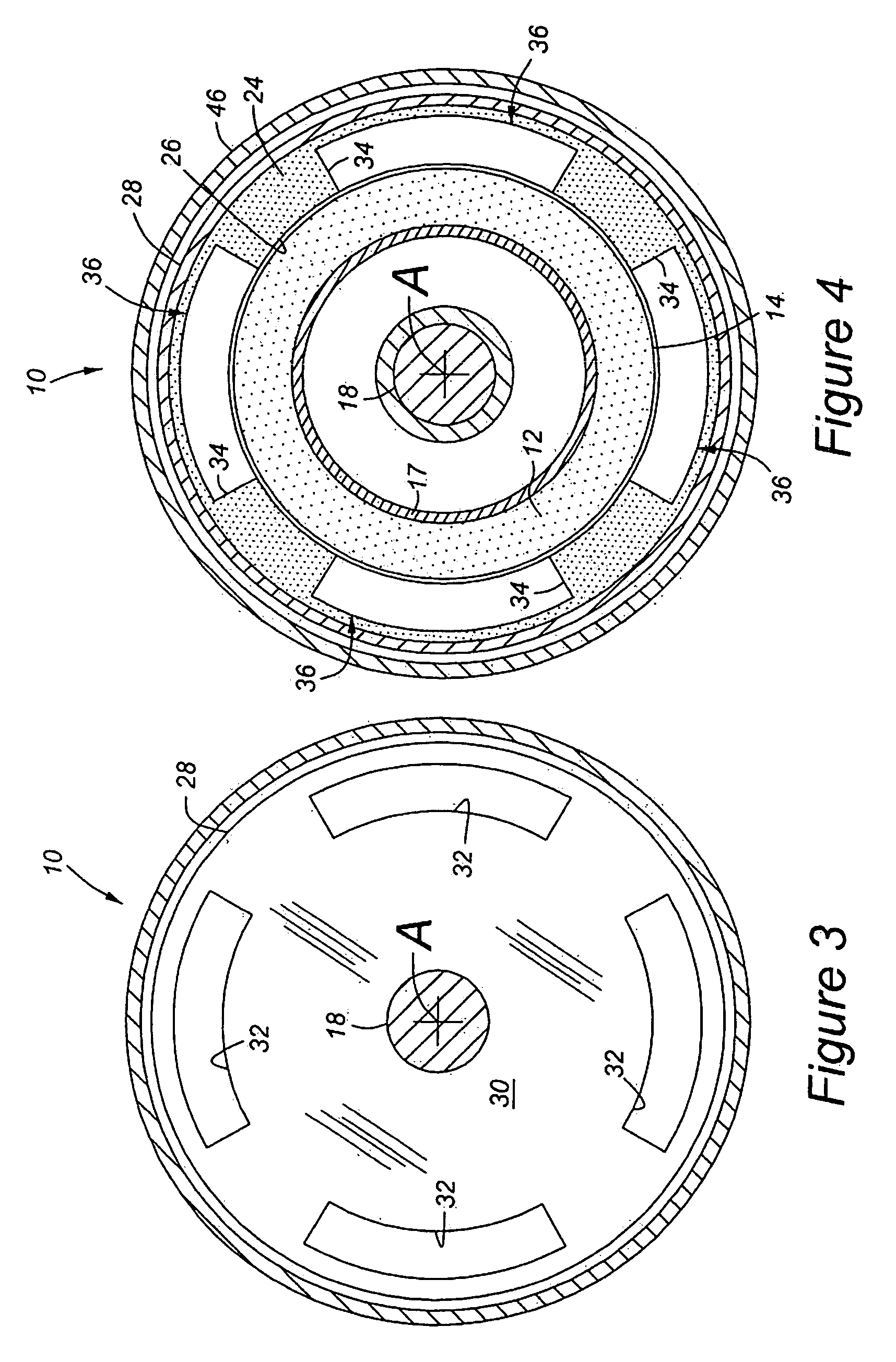

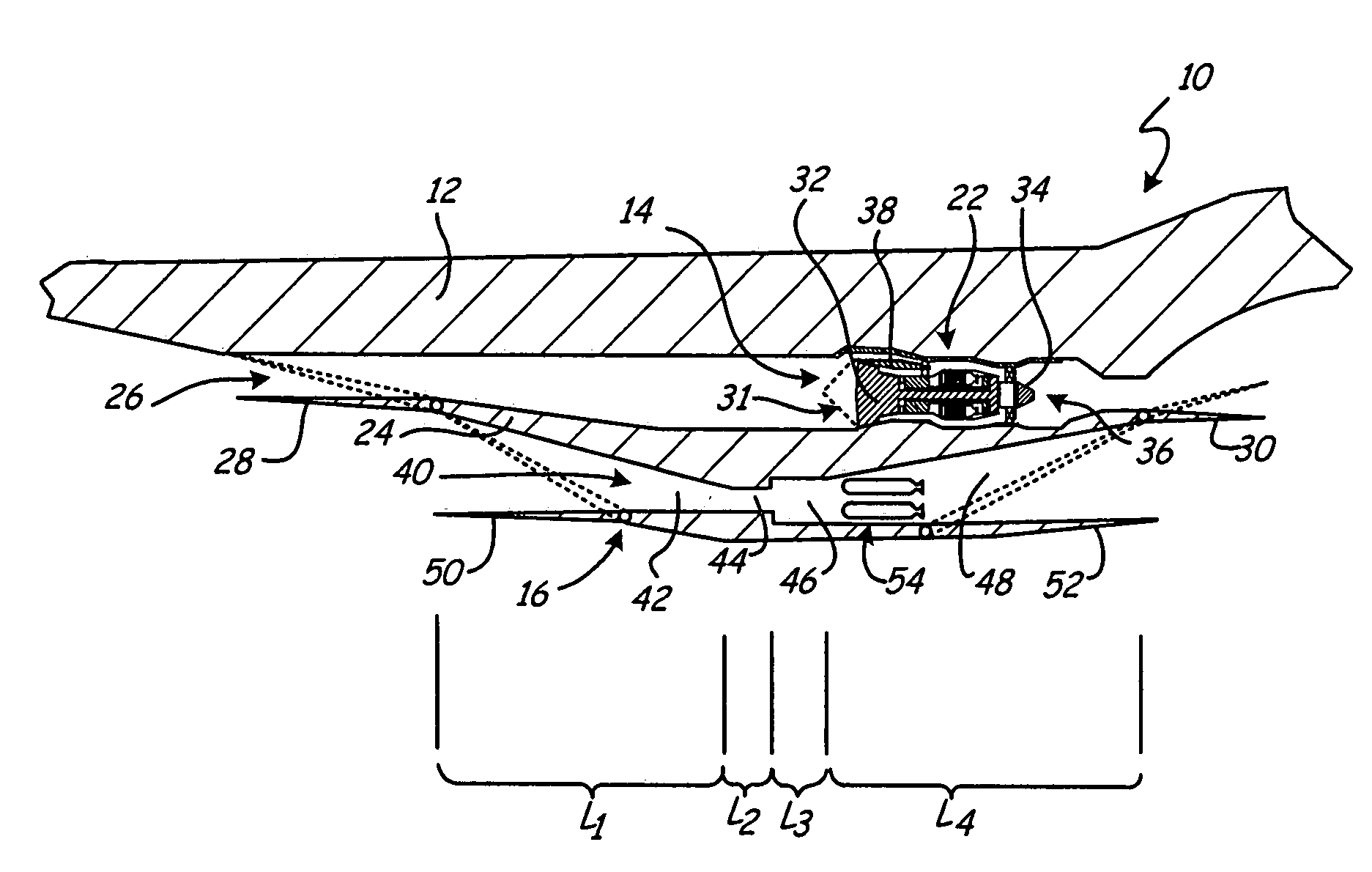

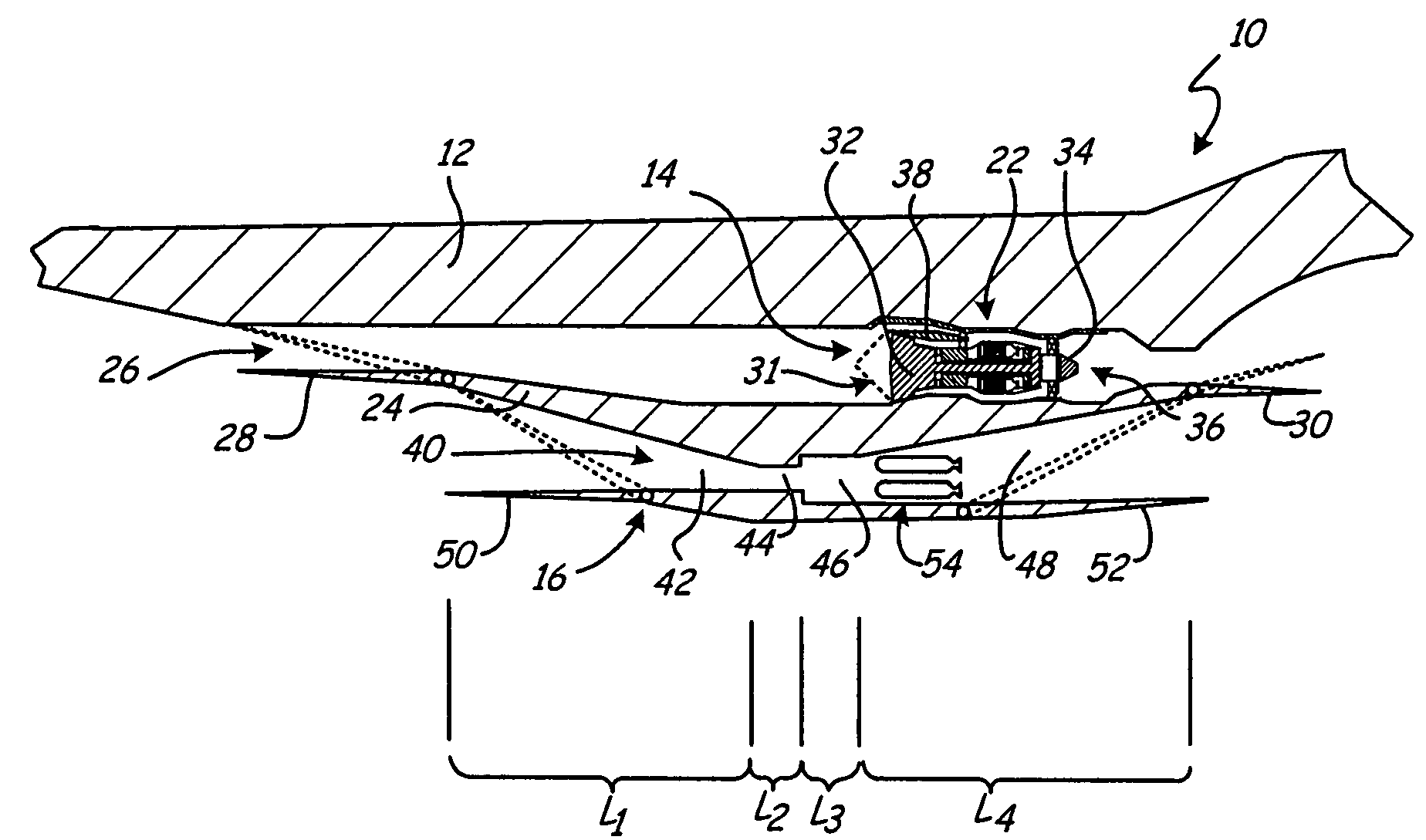

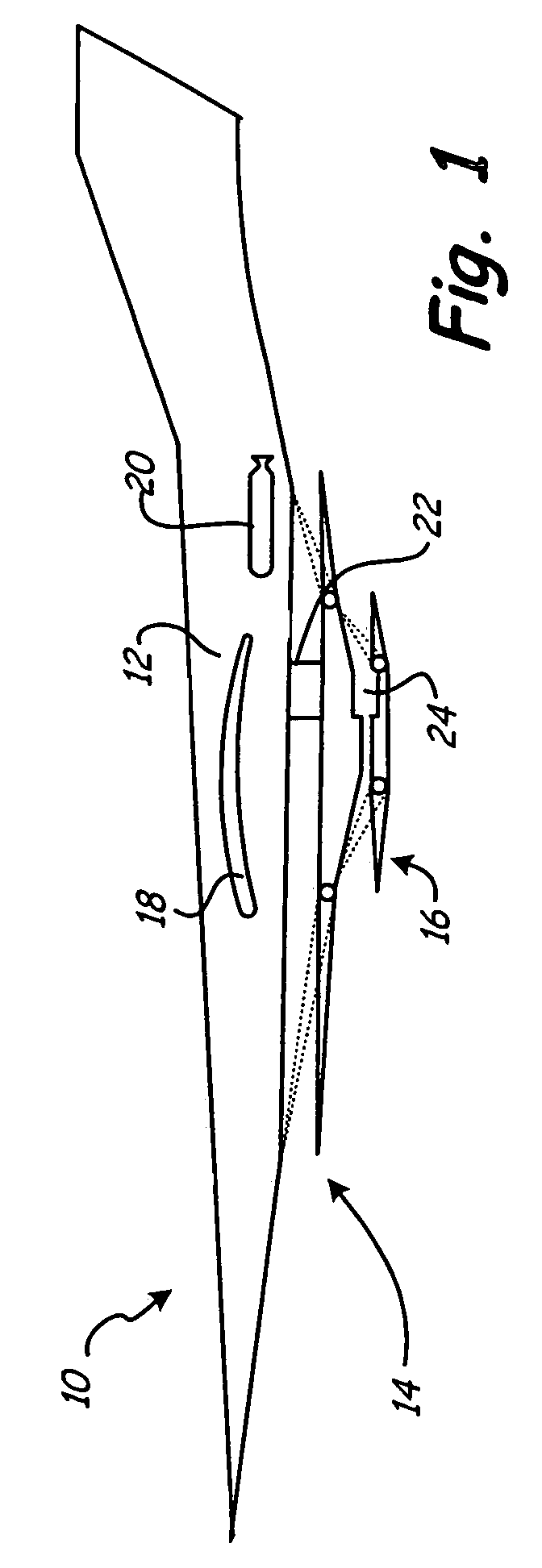

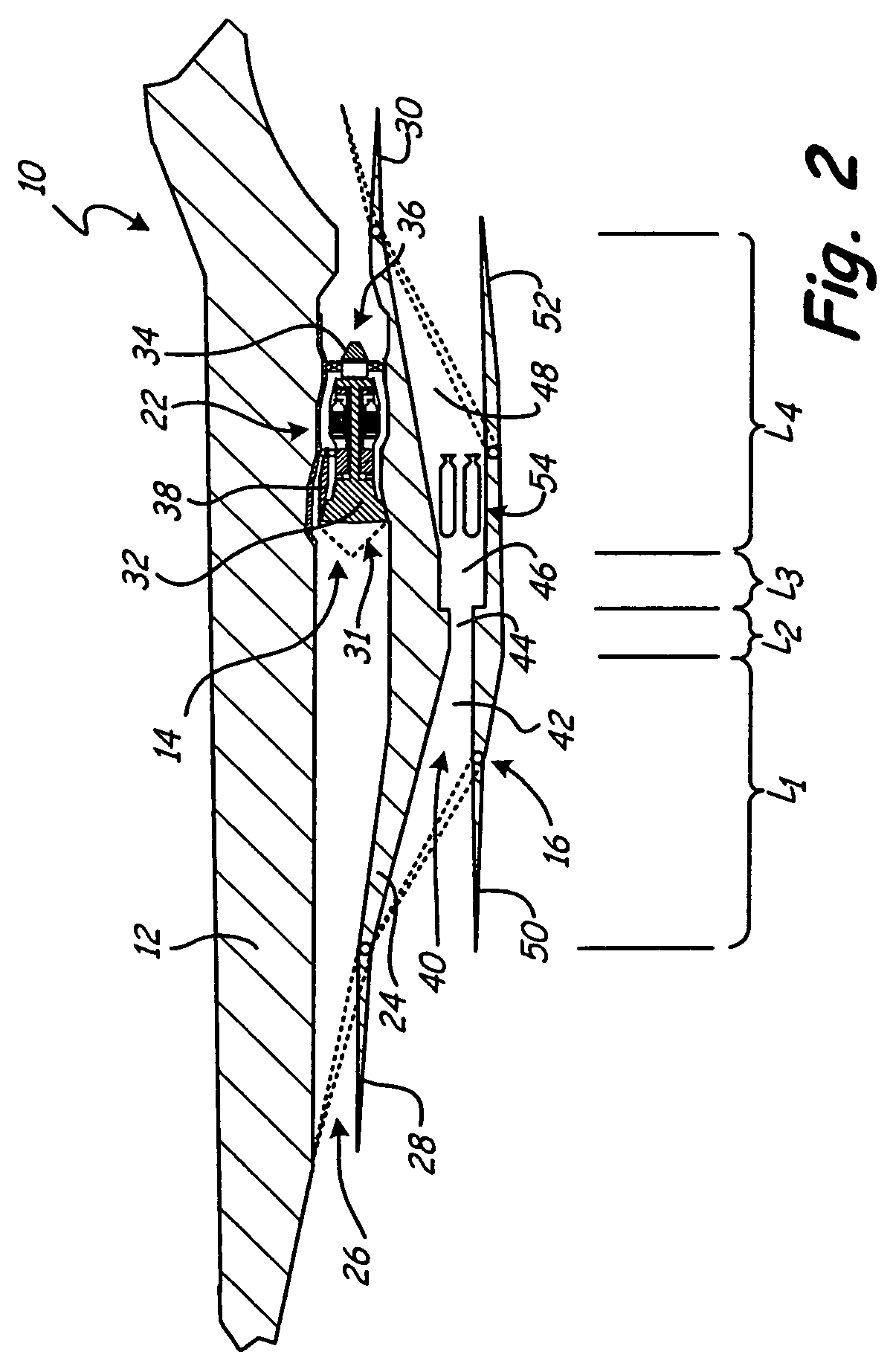

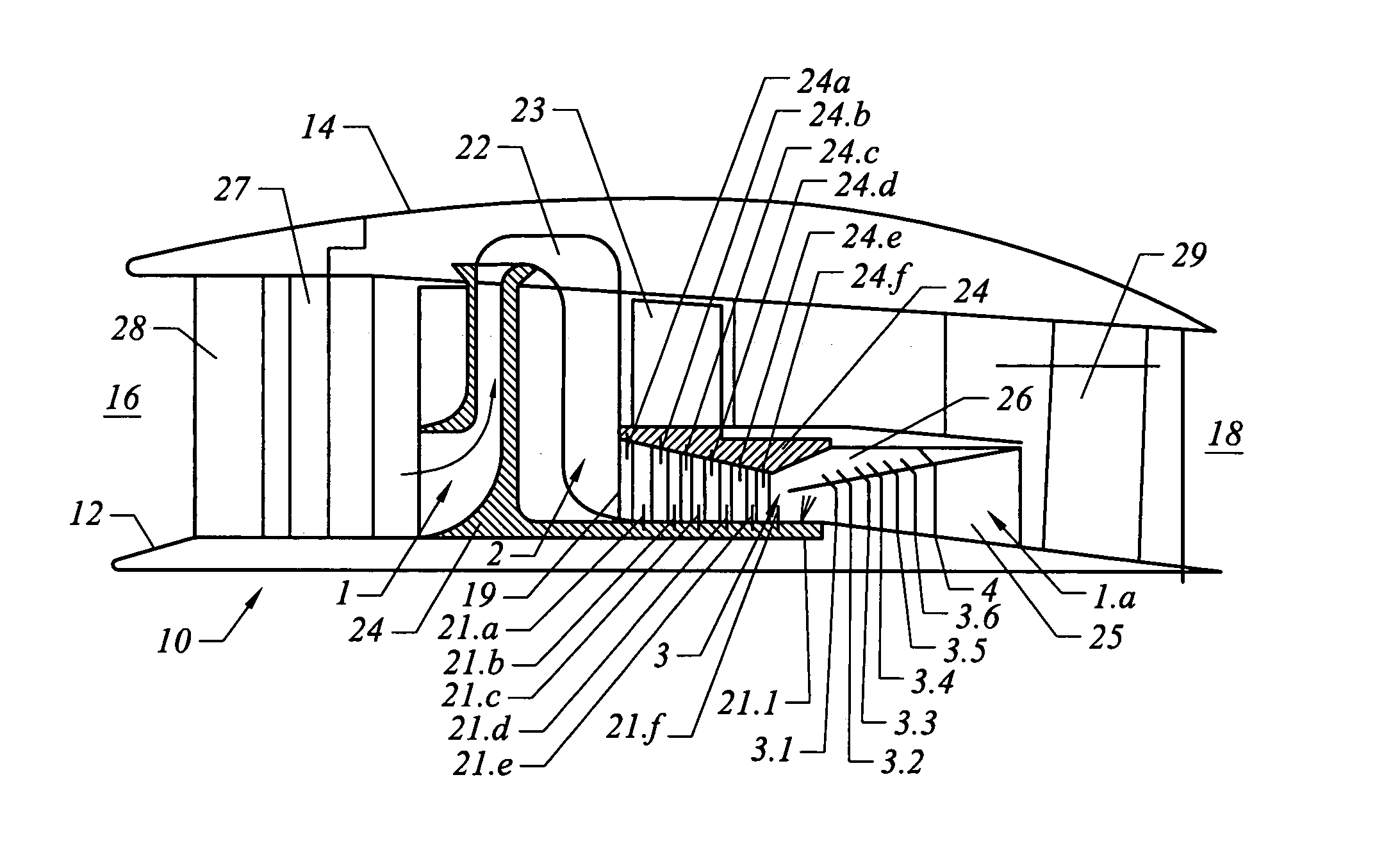

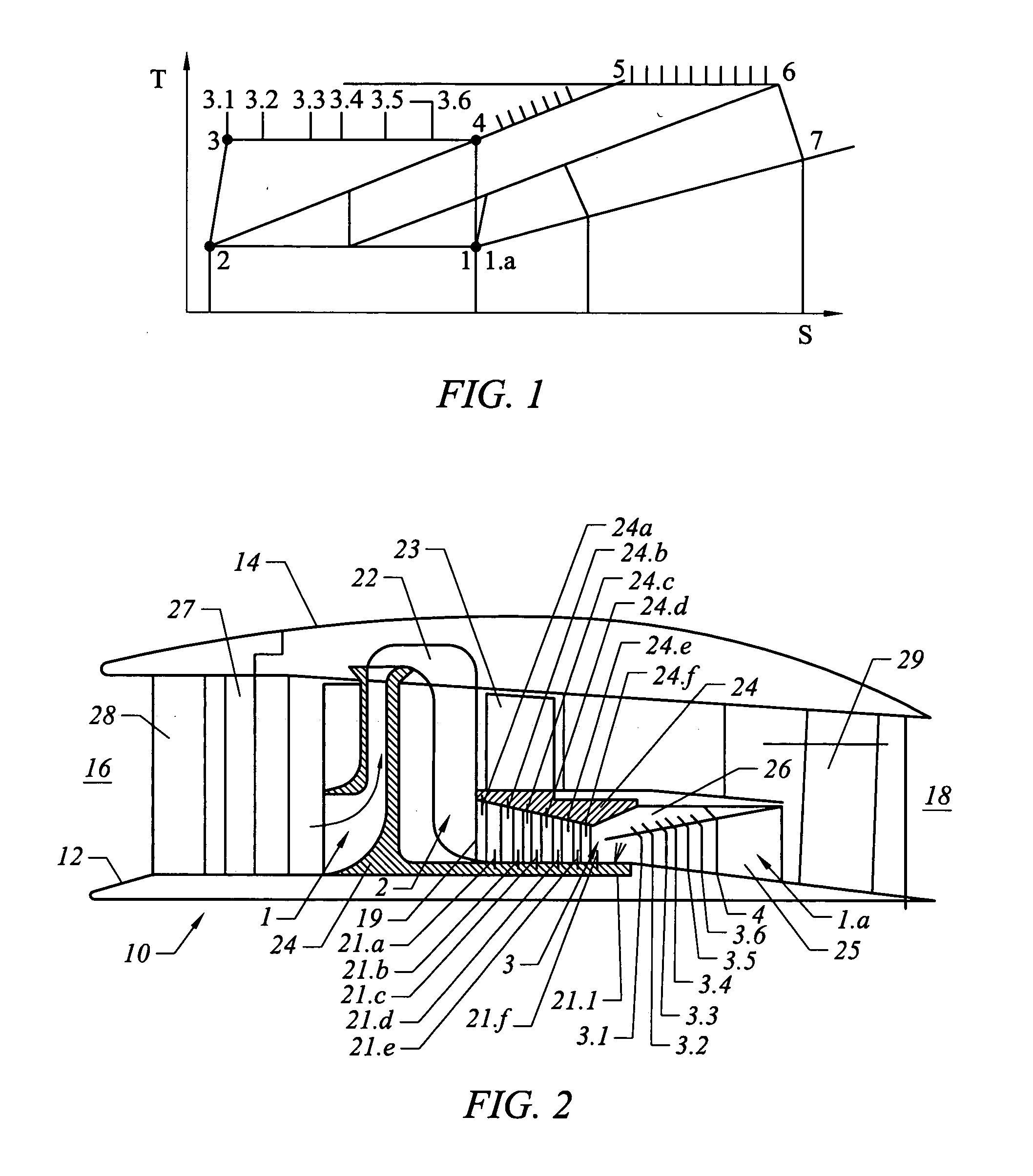

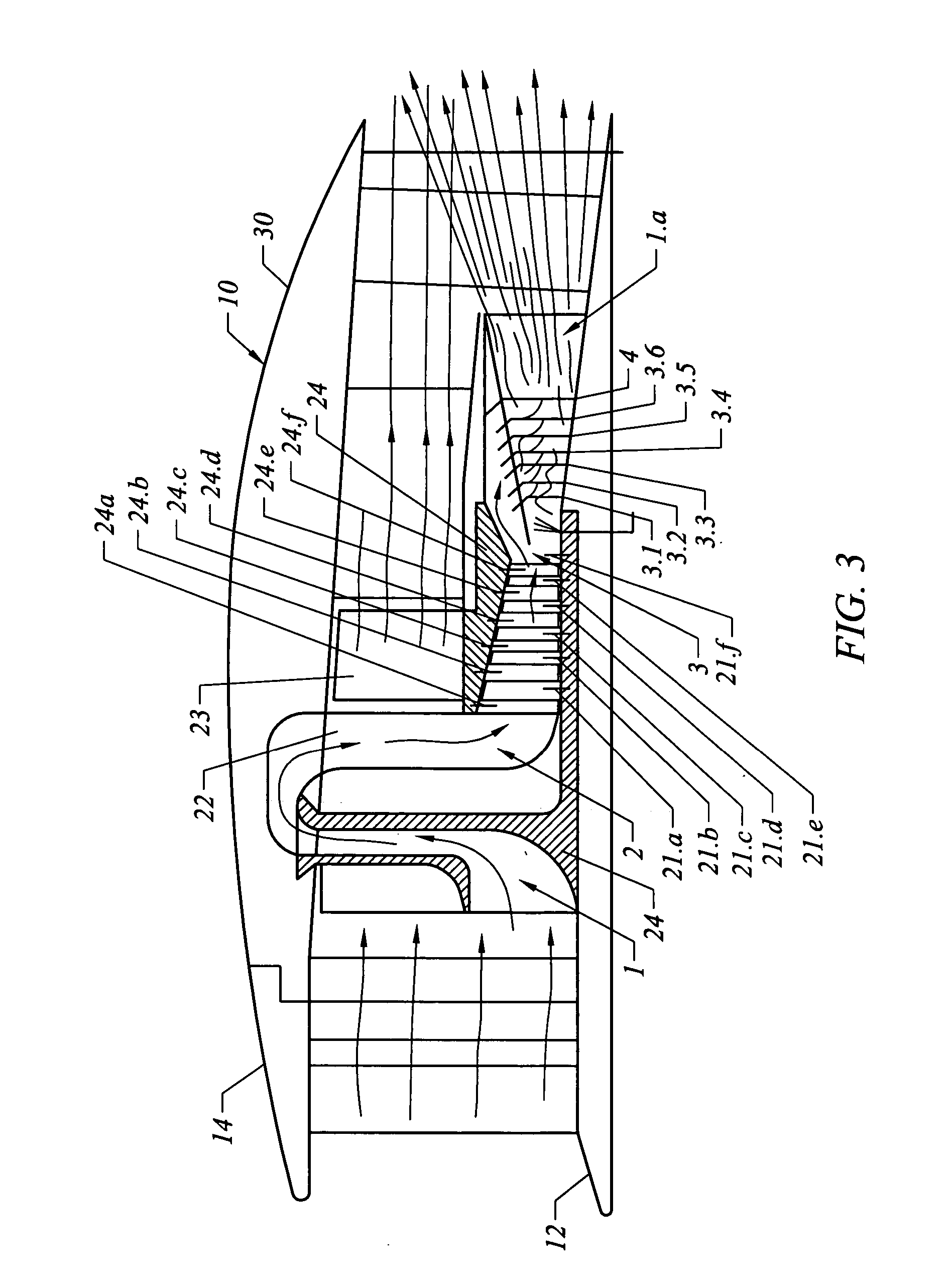

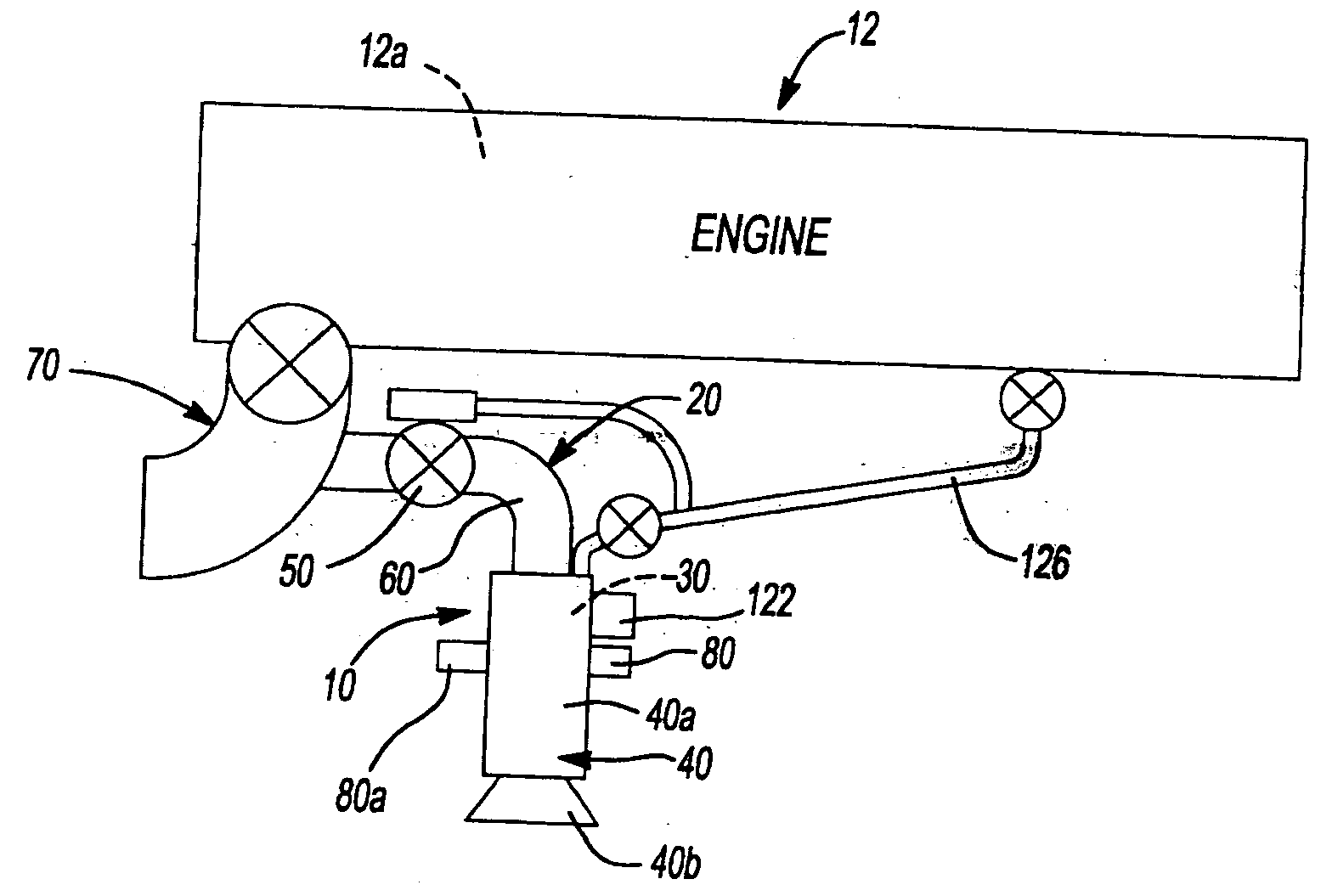

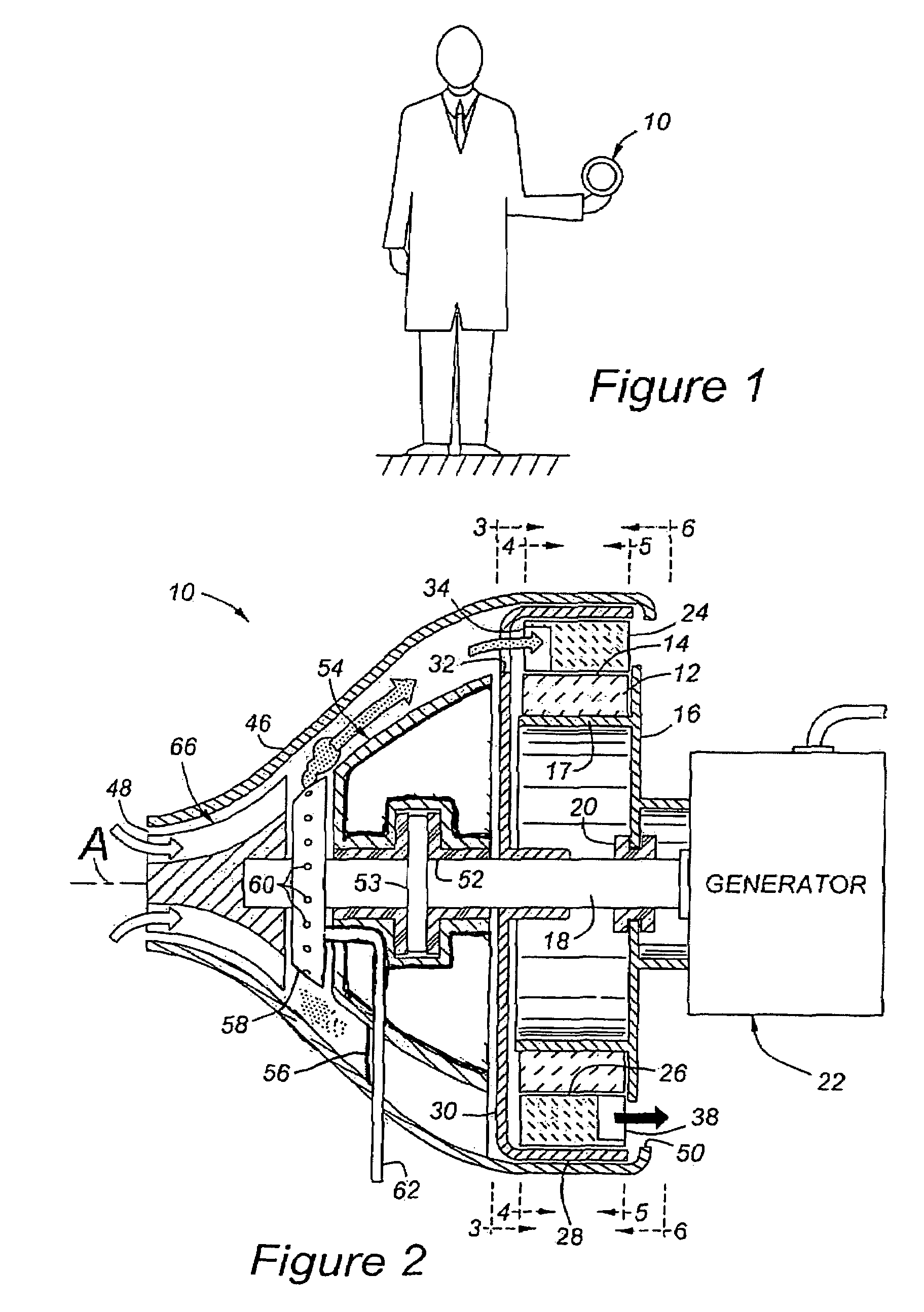

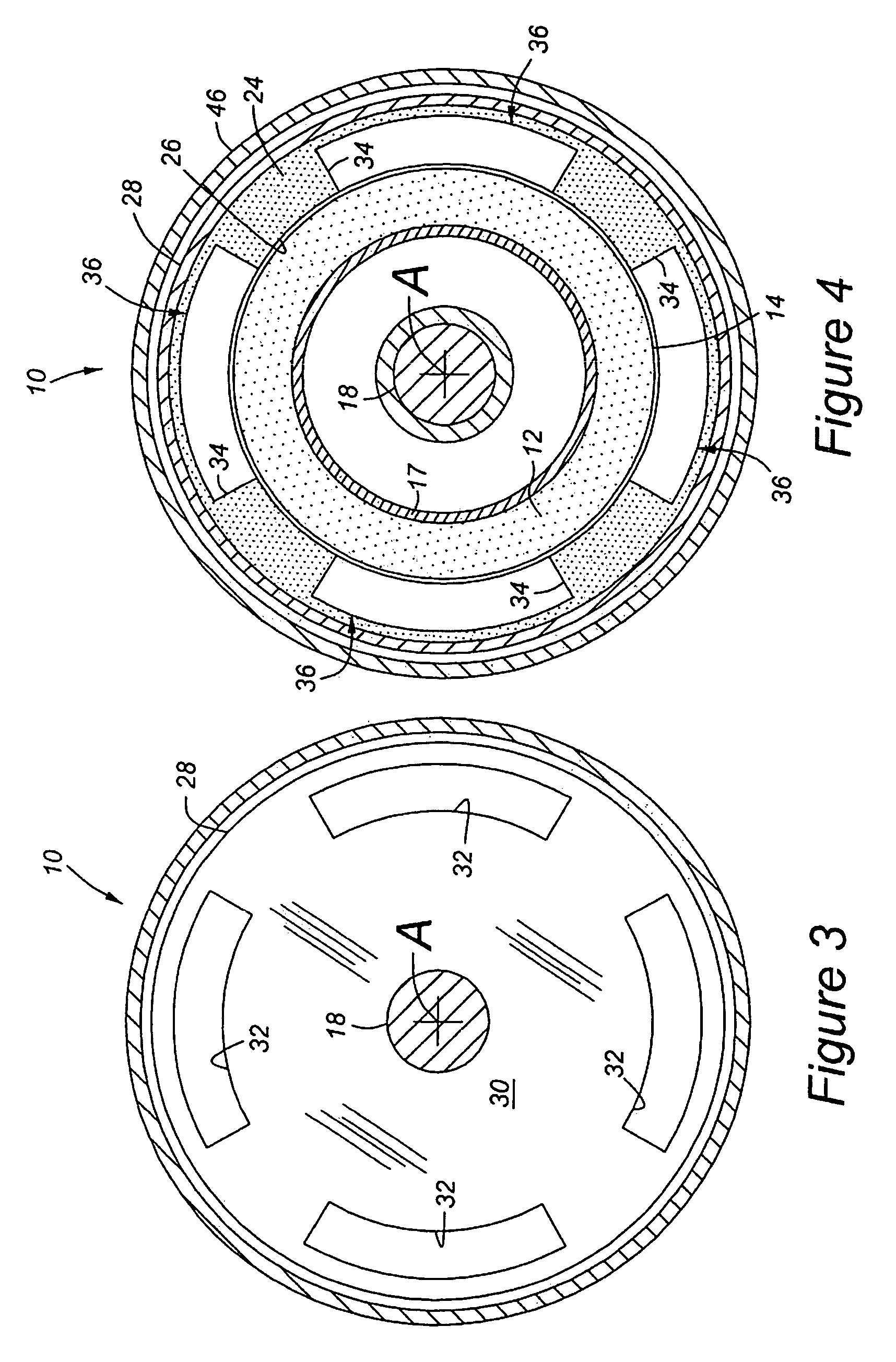

ActiveUS20070056290A1MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

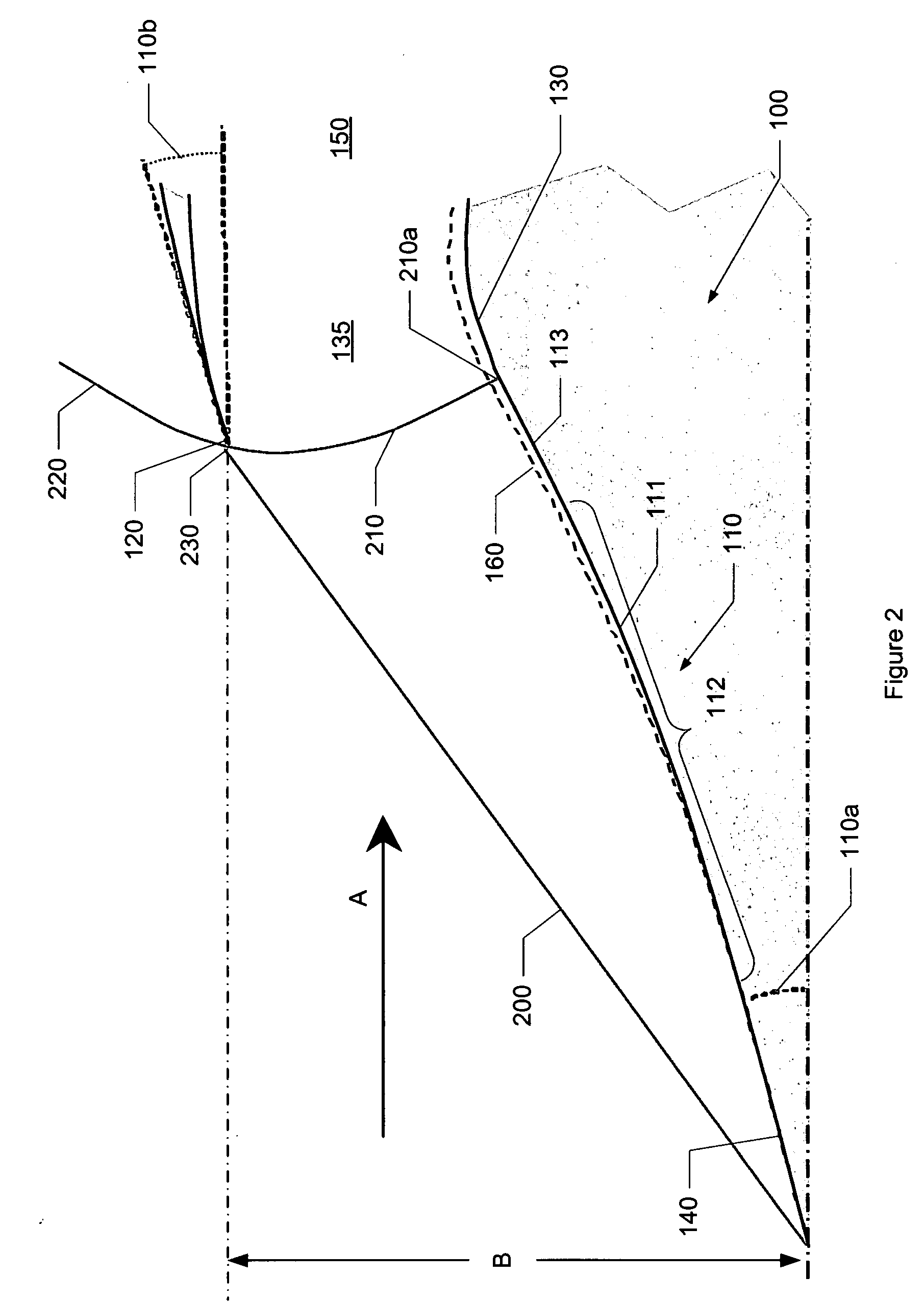

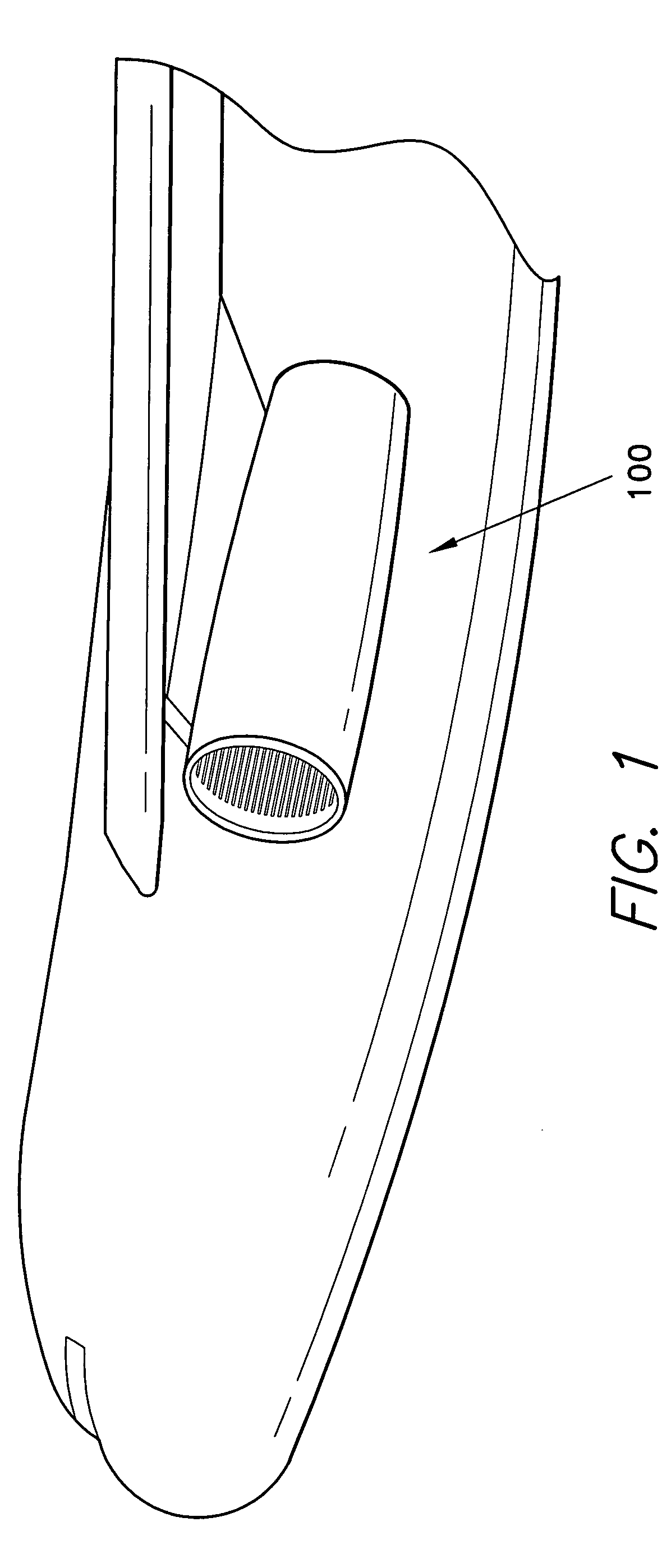

Low shock strength propulsion system

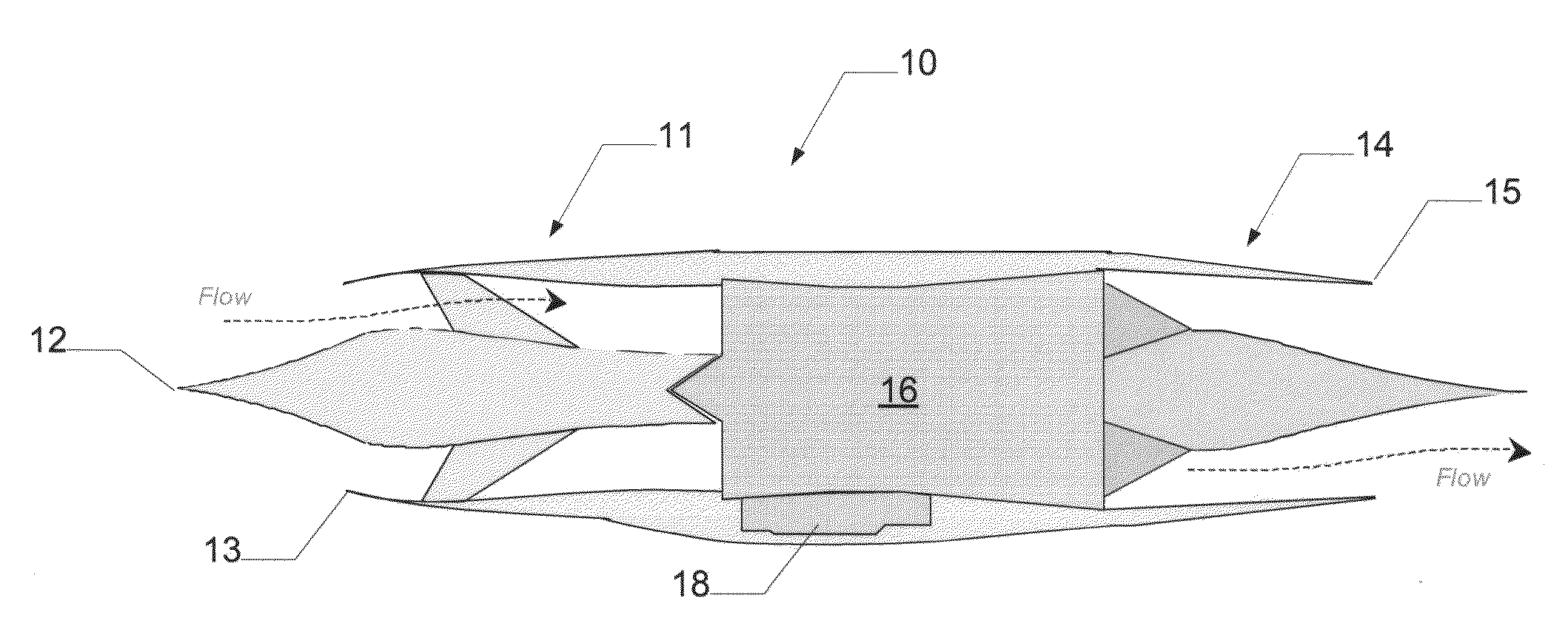

Embodiments of the invention relate to a supersonic nacelle design employing a bypass flow path internal to the nacelle and around the engine. By shaping the nacelle, embodiments of the invention may function to reduce sonic boom strength, cowl drag, and / or airframe interference drag. Embodiments of the invention may also function to improve total pressure recovery and / or total thrust of the primary flow path through the engine.

Owner:GULFSTREAM AEROSPACE CORP

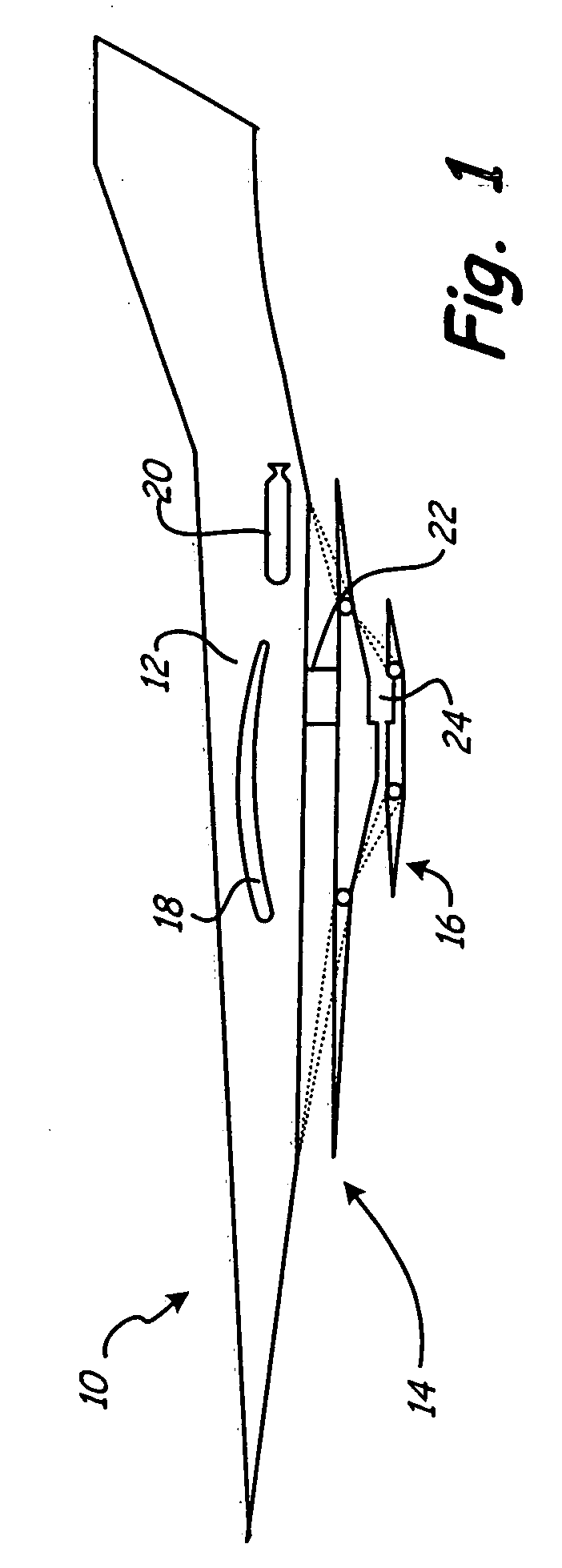

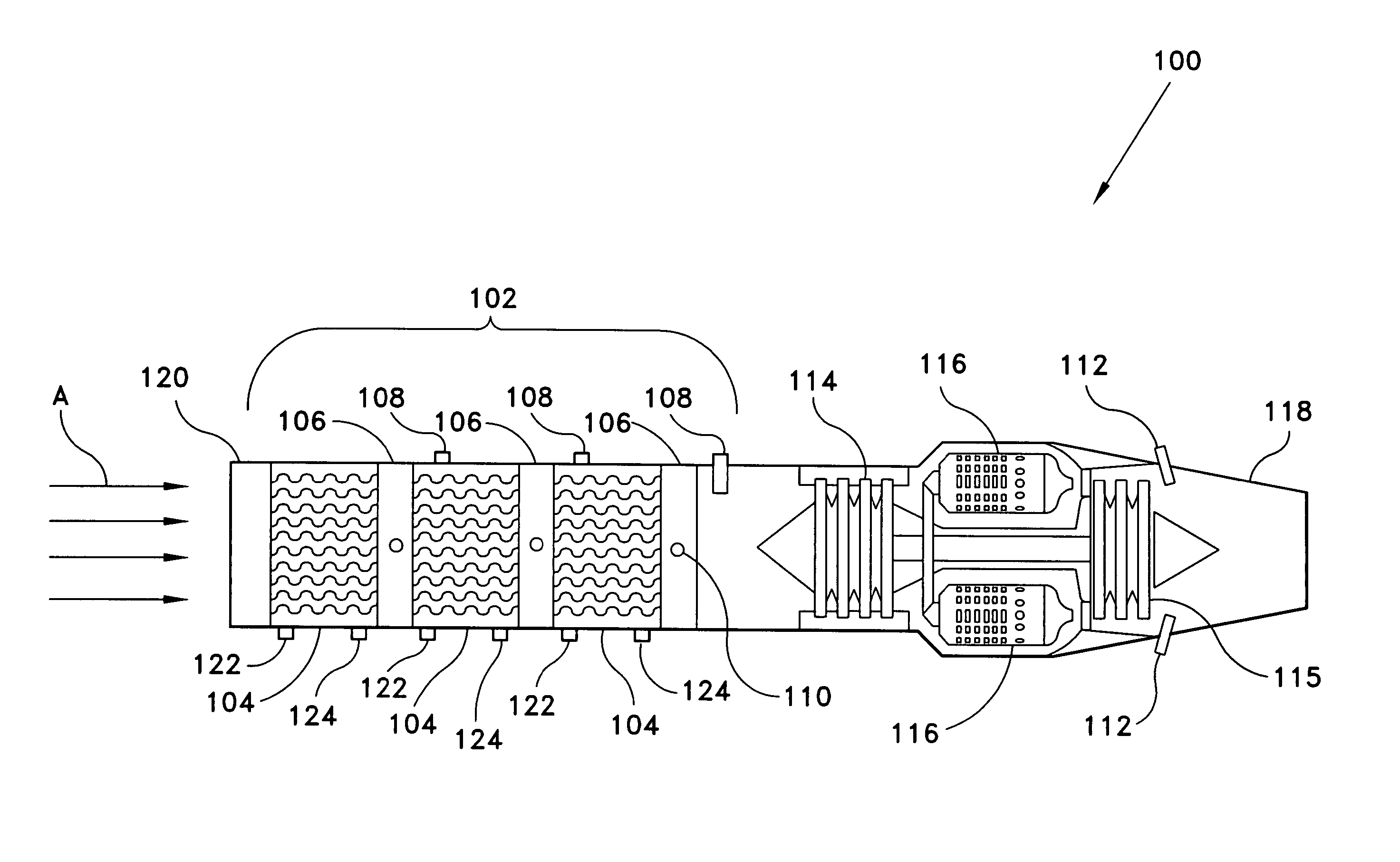

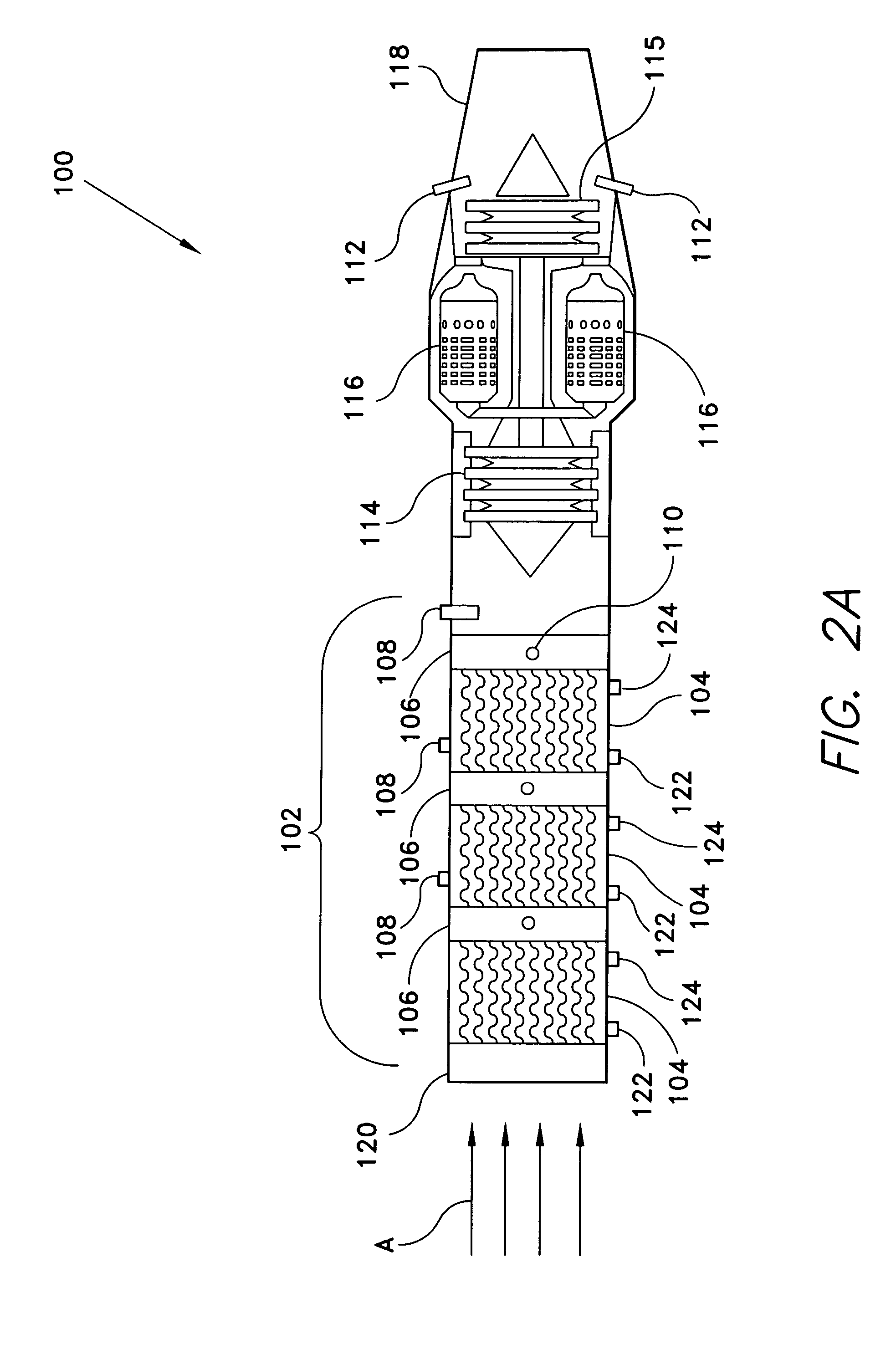

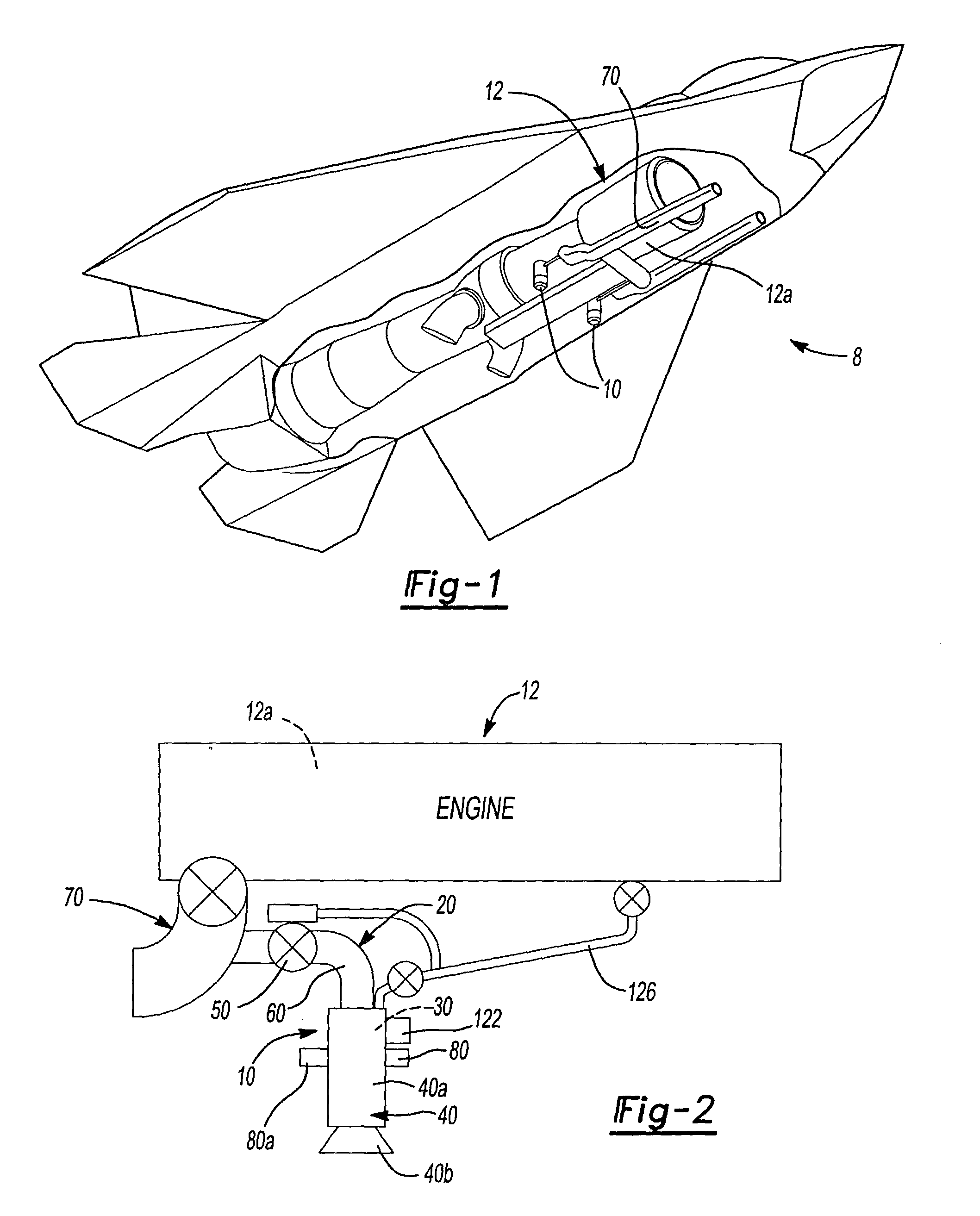

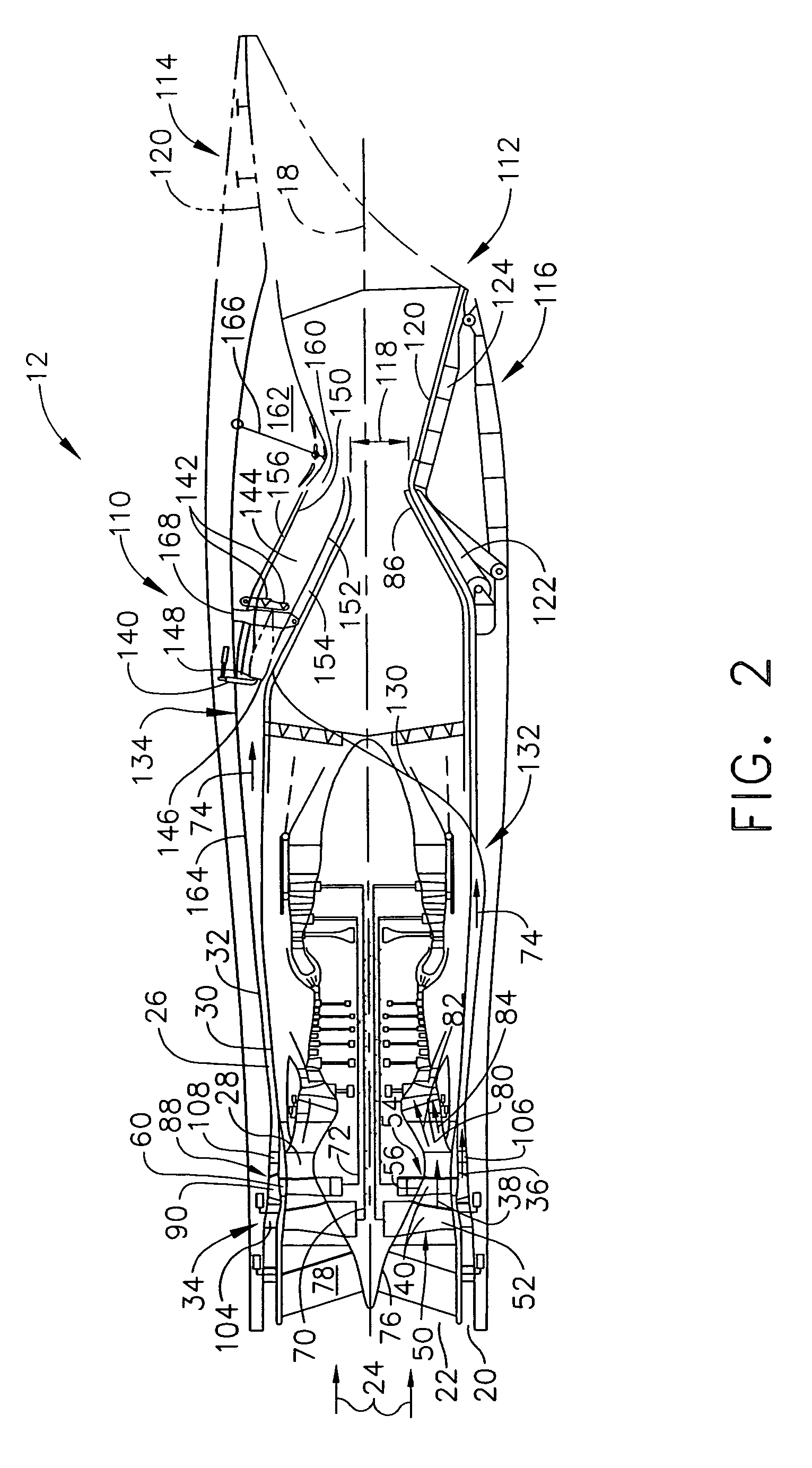

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS6907724B2Shorten the lengthFast atomizationContinuous combustion chamberJet type power plantsRamjetFlame propagation

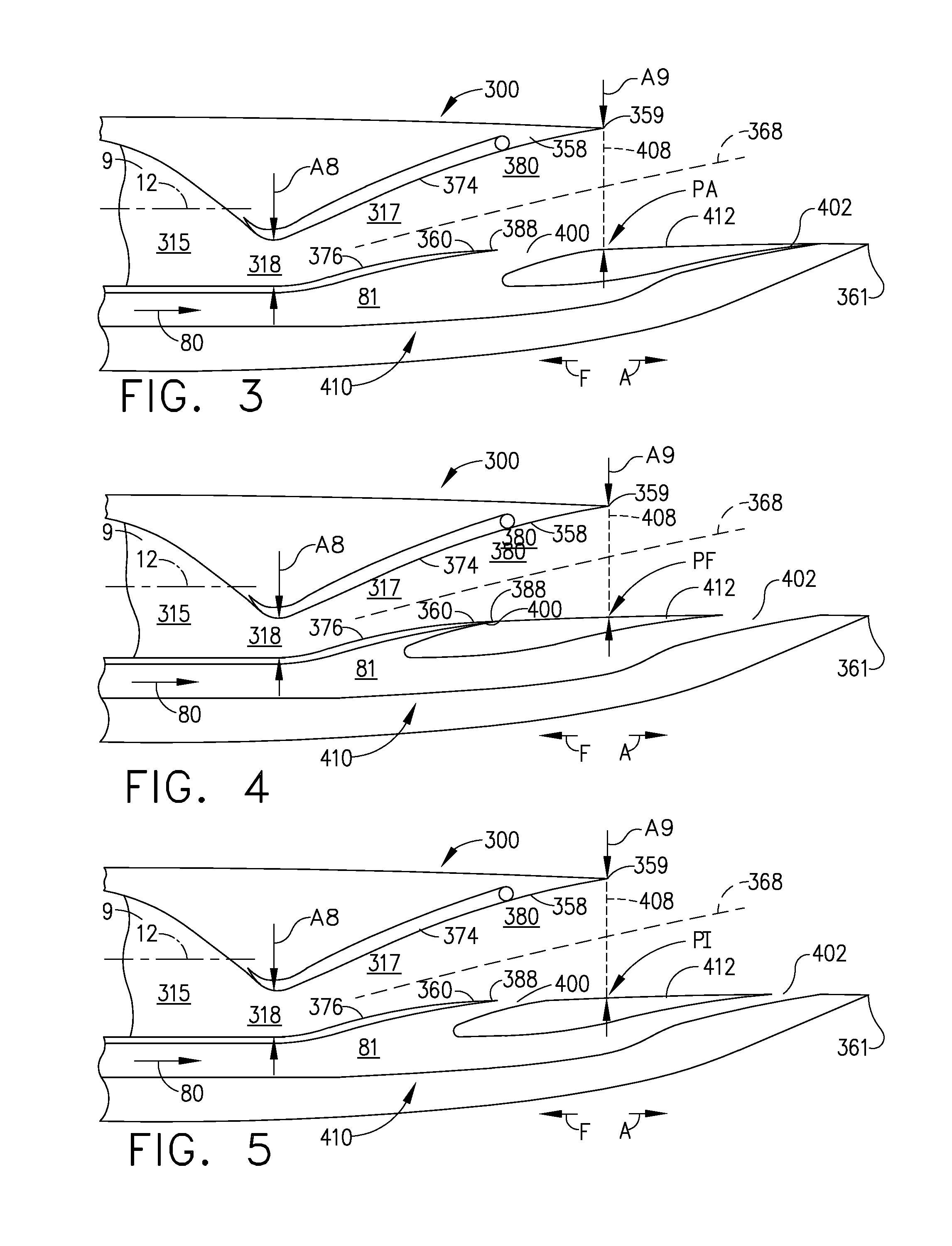

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

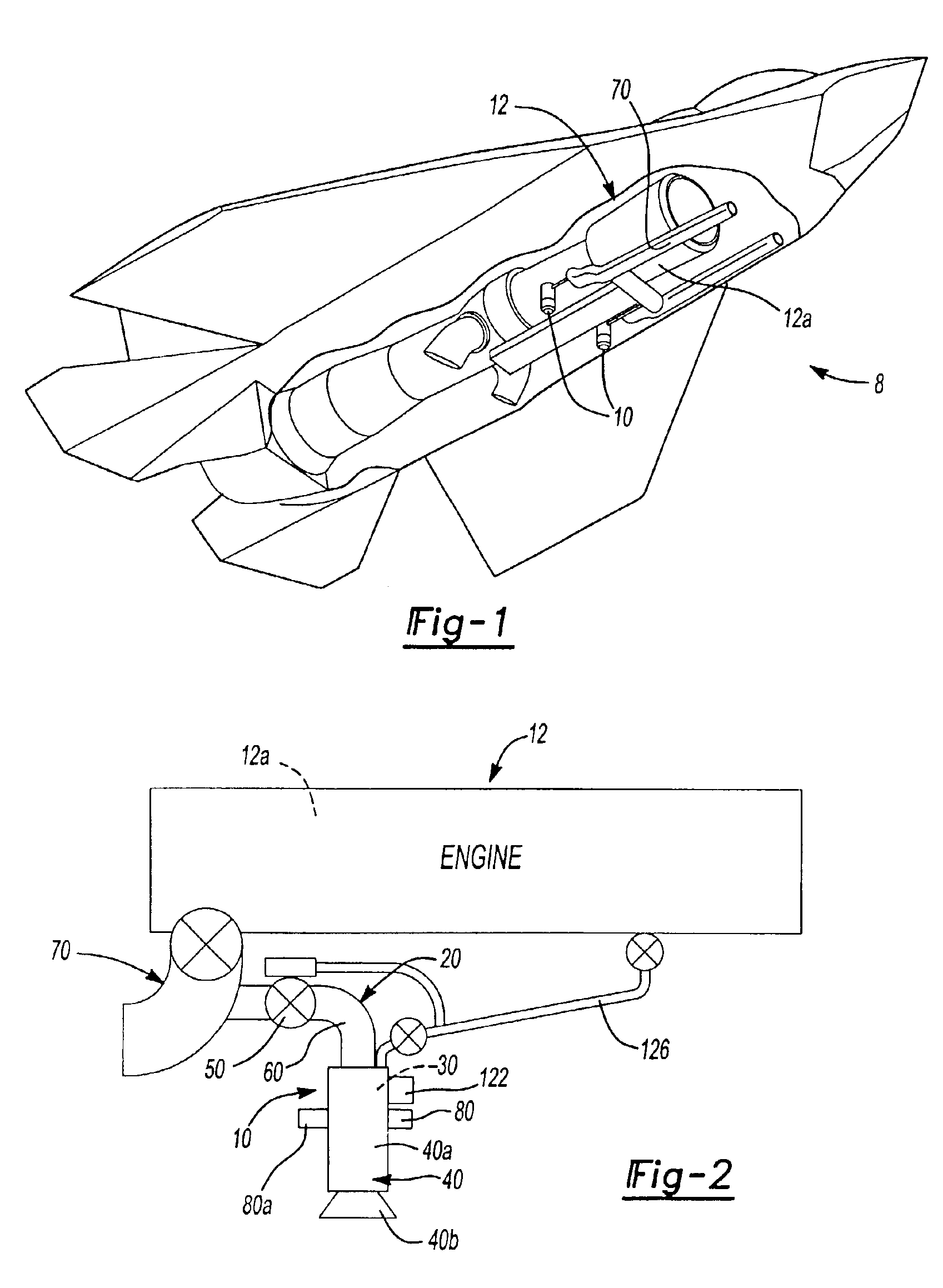

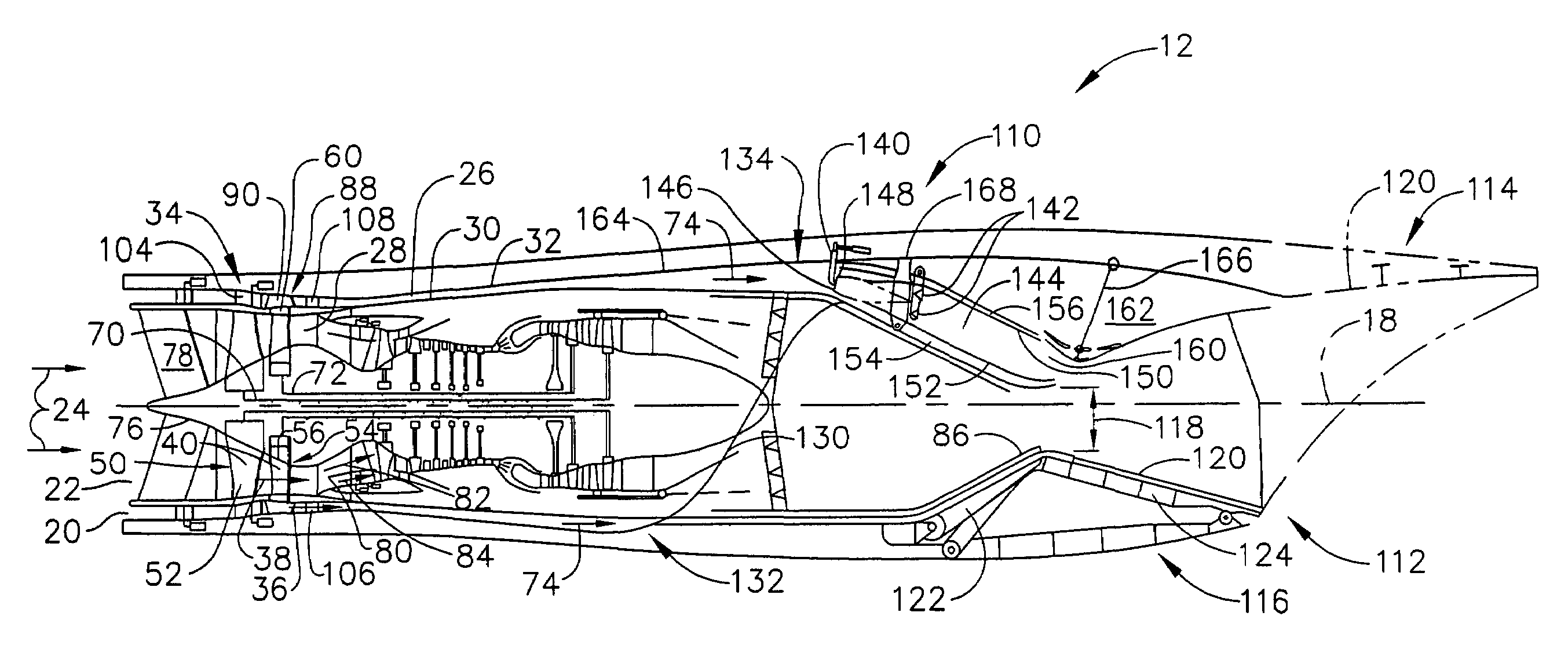

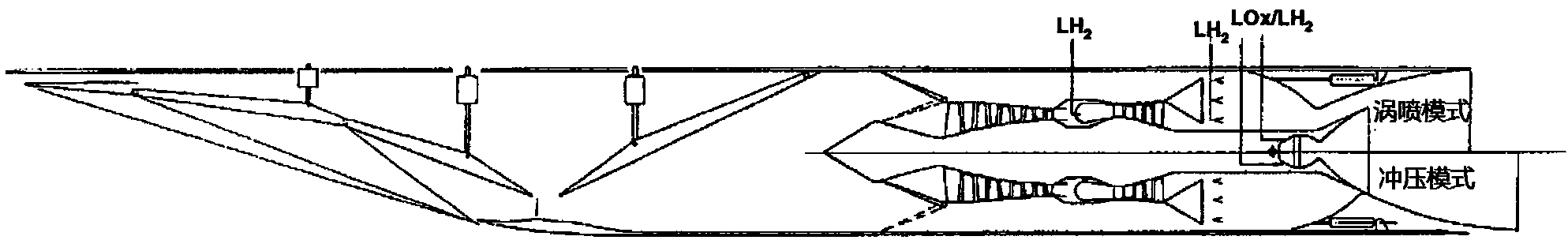

Single-stage hypersonic vehicle featuring advanced swirl combustion

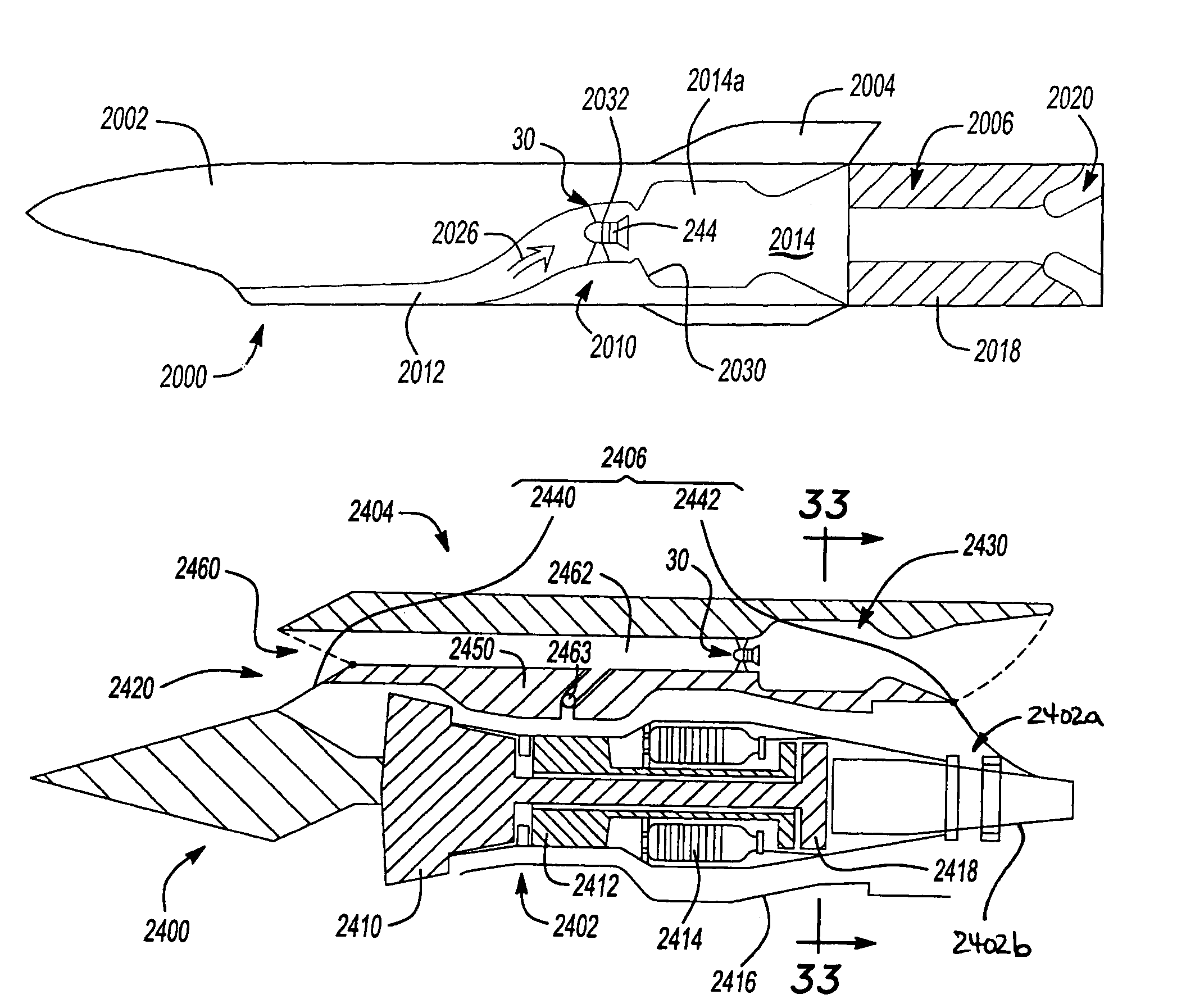

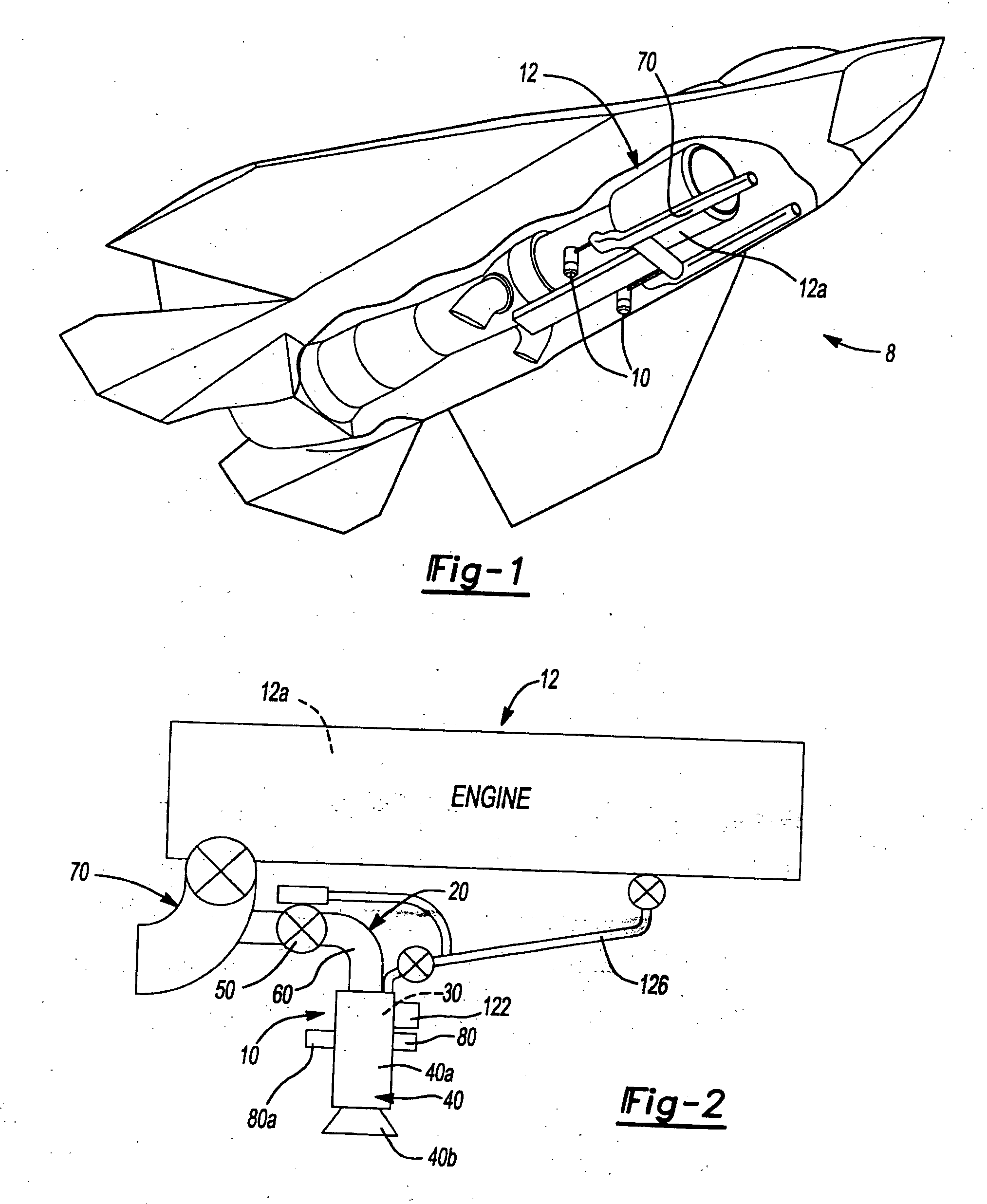

InactiveUS20080283677A1Reduce complexityShorten the lengthAircraft navigation controlPower plant exhaust arrangementsRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

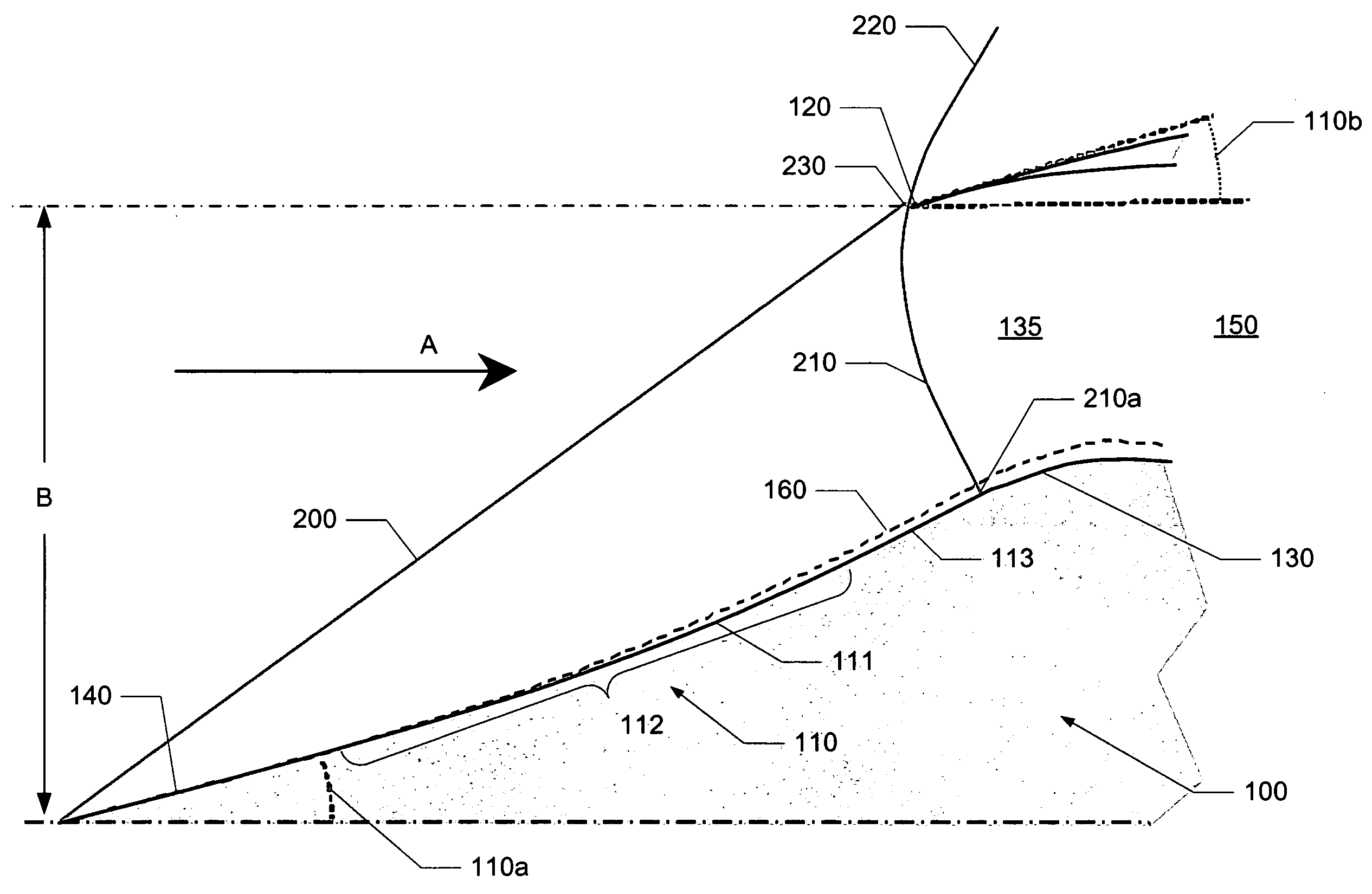

Low shock strength inlet

ActiveUS20090107557A1Power plant exhaust arrangementsAircraft power plant componentsNacelleUltimate tensile strength

Embodiments of the invention relate to a supersonic inlet having a cowl lip configured to capture the conic shock and exhibit a zero or substantially zero cowl angle. The inlet may be configured to employ a relaxed isentropic compression surface and an internal bypass. The nacelle bypass may prevent flow distortions, introduced by the capture of the conic shock, from reaching the turbomachinery, thereby allowing the cowl angle to be reduced to zero or substantially zero. Such a cowl angle may reduce the inlet's contribution to the overall sonic boom signature for a supersonic aircraft while allowing for an increase in engine pressure recovery and a subsequent improvement in generated thrust by the engine.

Owner:GULFSTREAM AEROSPACE CORP

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS7762077B2Reduce complexityShorten the lengthPower plant exhaust arrangementsEfficient propulsion technologiesRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

Turbo rocket with real carnot cycle

InactiveUS20050138914A1Improve efficiencyReduce supplyEngine fuctionsBlade accessoriesCombustion chamberCarnot cycle

Engine embodiments primarily designed for aircraft propulsion and power generation incorporating the Carnot cycle for efficient combustion with typical embodiments including air compressors having one or more stages with isothermal compression and including combustion and expansion chambers having in part isothermal expansion before final adiabatic expansion.

Owner:PAUL MARIUS

Compact swirl augmented afterburners for gas turbine engines

InactiveUS20060230764A1Promotes rapid and efficient atomization and mixingBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityFlame propagation

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel and an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:UNITED TECH CORP

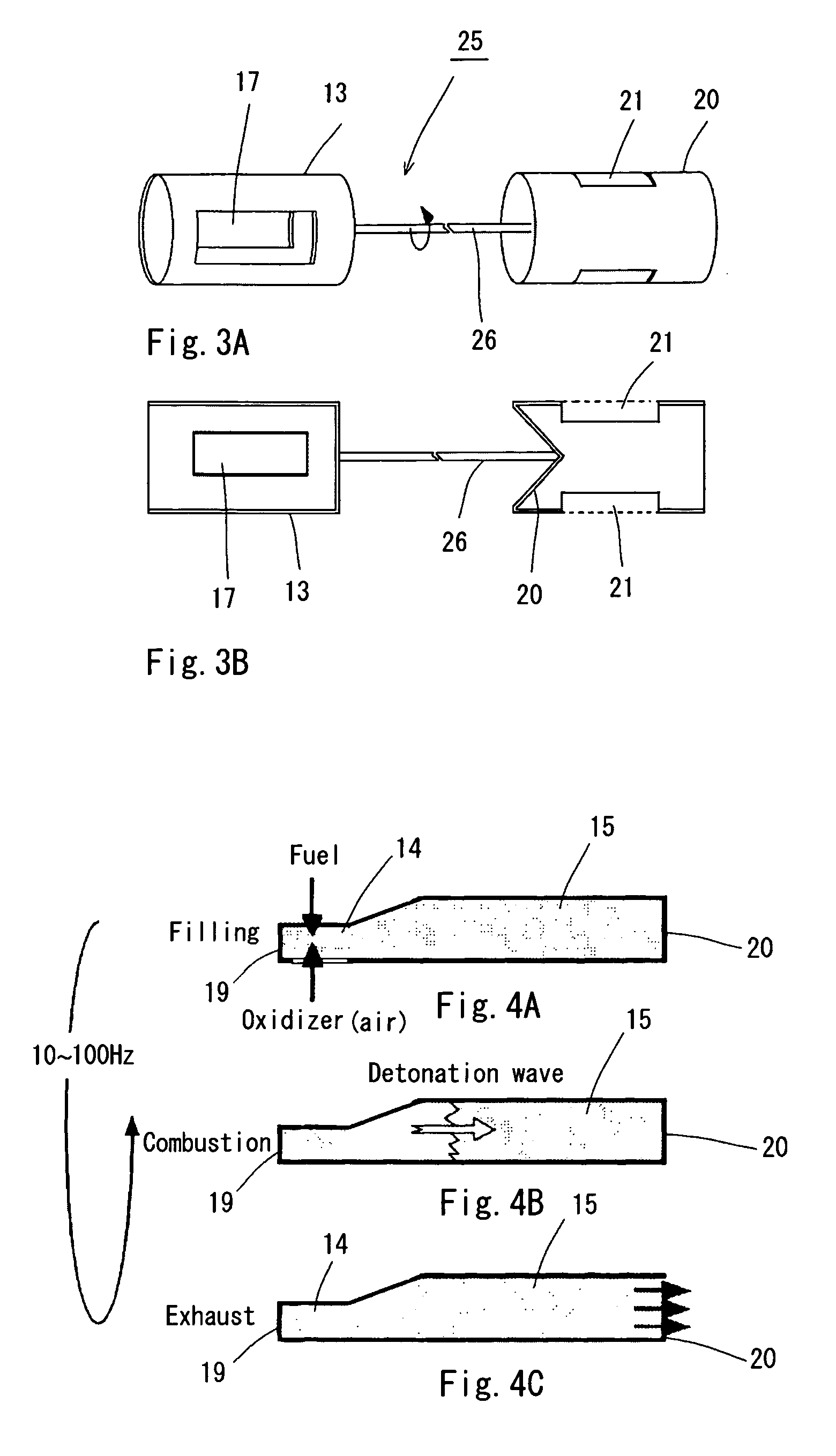

Pulse detonation engine and valve

InactiveUS20050183413A1Accurate timingIncrease air densityPulsating combustionTurbine/propulsion fuel heatingCombustion chamberCombustor

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Jet aircraft electrical energy production system

InactiveUS20050034464A1Improve efficiencyEasy extractionGas turbine plantsAir/fuel supply for combustionJet engineGas turbines

The jet aircraft electrical energy production system produces electrical energy by ionizing airflow through a ram or gas turbine jet engine. The ionized particles in the airflow may also be separated, liquefied, stored for future utilization.

Owner:GONZALEZ E H

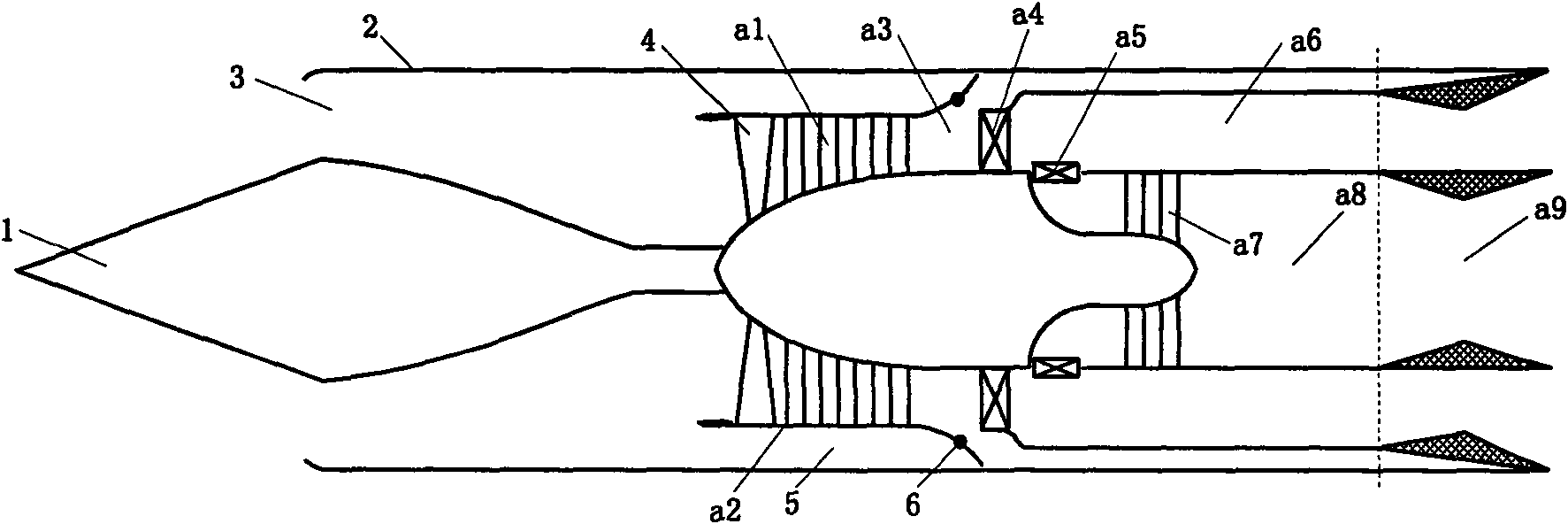

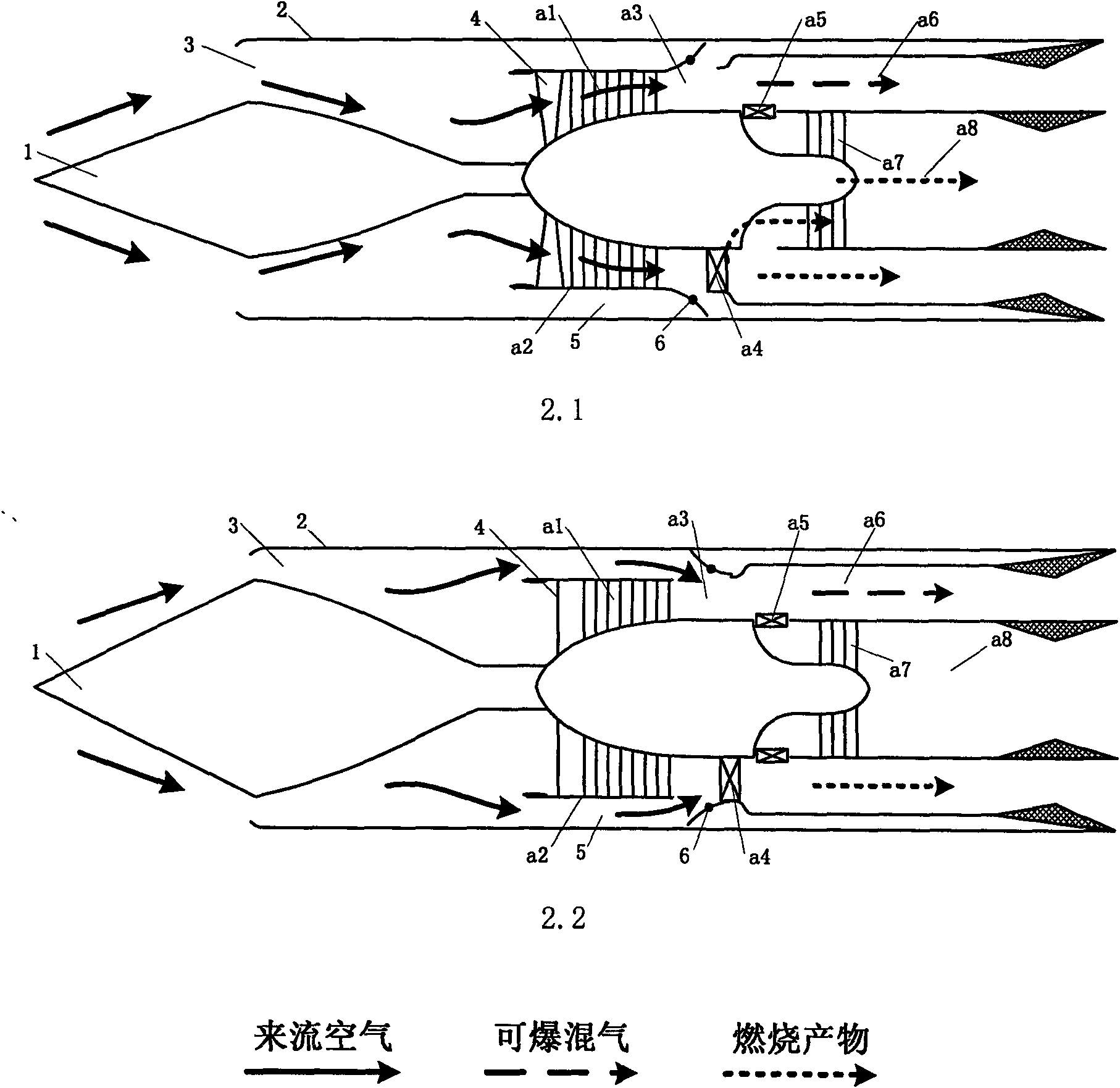

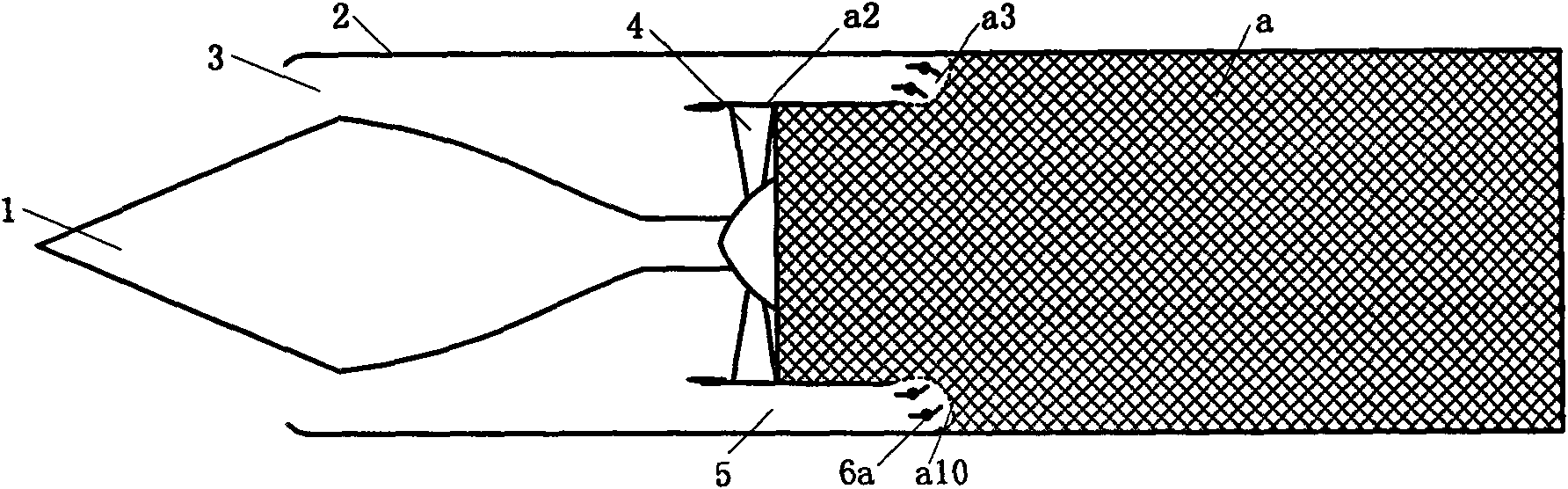

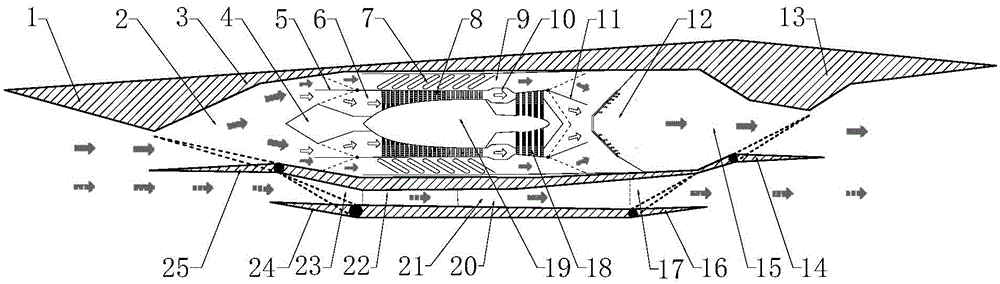

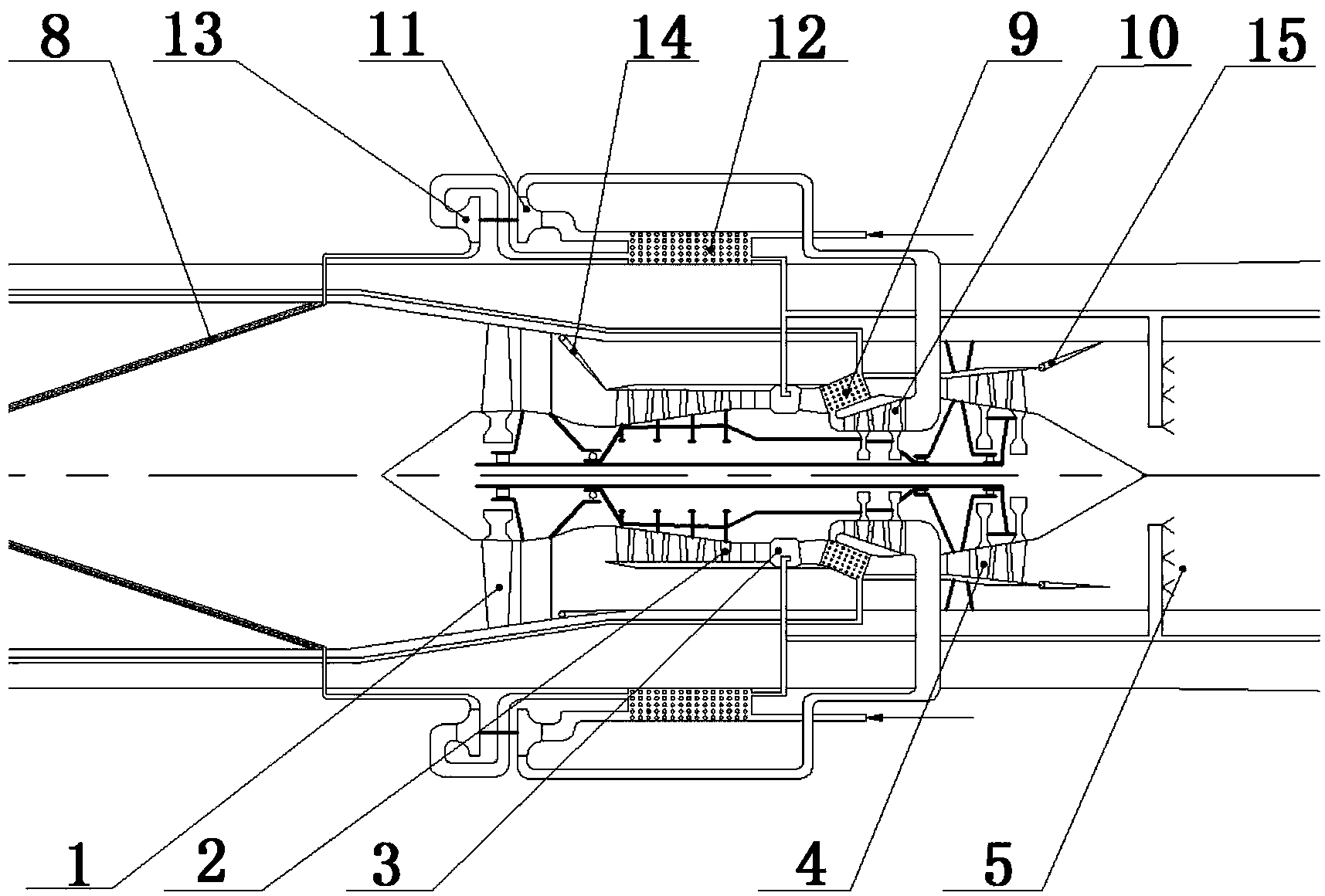

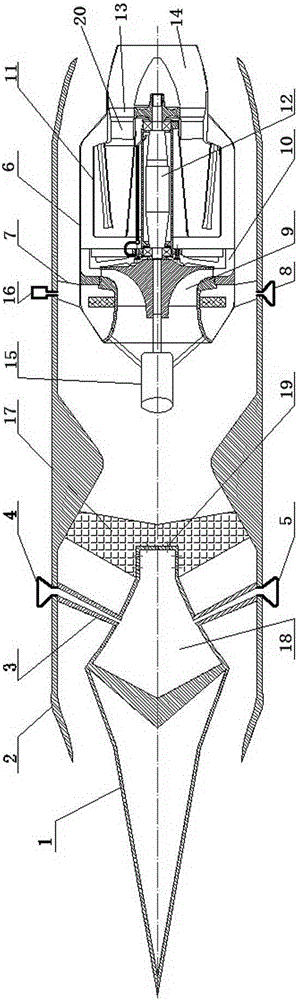

Turboramjet combined engine based on knocking combustion

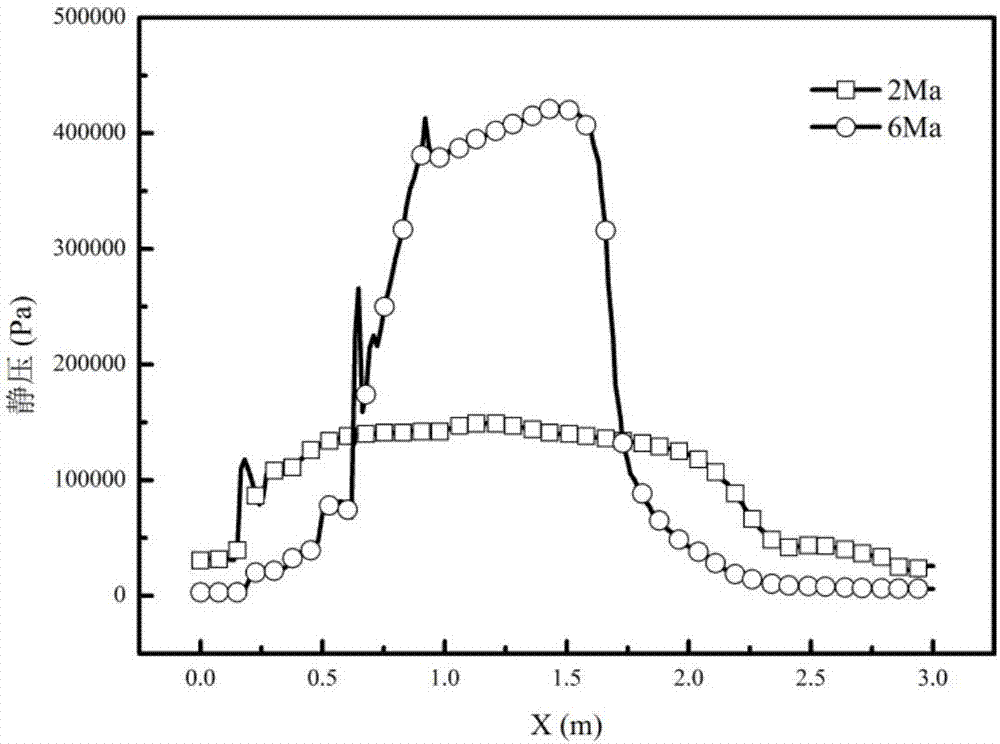

InactiveCN102155331ASolve sizeSolve the weight problemRam jet enginesComposite engine plantsAirflowCombustion

The invention discloses a turboramjet combined engine based on knocking combustion. Along the air flow direction, an adjustable central conical body is positioned at the forefront end of the combined engine, and surrounds into an adjustable air intake channel with a shell; the downstream of the adjustable central conical body is connected with an air intake device of a preposed turbine combined pulsation knocking engine; the upstream of an air pressing machine of the preposed turbine combined pulsation knocking engine is provided with an adjustable inlet guiding blade; an engine shell of the preposed turbine combined pulsation knocking engine surrounds into an annular air duct with the shell; and an adjustable plate is positioned at an expanding pressure buffer chamber between the air duct and the preposed turbine combined pulsation knocking engine. By the turboramjet combined engine based on knocking combustion provided by the invention, the problems of long size, great weight, complex structure, many components, and the like of a complete machine are solved, and simultaneously the propulsive performance of the turboramjet combined engine based on the knocking combustion is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS20050081508A1Rapid fuel atomizationVaporization fastContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

Methods and apparatus for assembling a gas turbine engine

A method for assembling a gas turbine engine includes providing a core engine, and providing a flade system including a flade stream augmentor positioned within a flade duct. The method also includes channeling airflow through the core engine to produce engine thrust, channeling airflow through the flade duct to produce engine thrust, and igniting a portion of the airflow channeled through the flade duct using the flade stream augmentor to increase the amount of thrust produced by the flade system.

Owner:GENERAL ELECTRIC CO

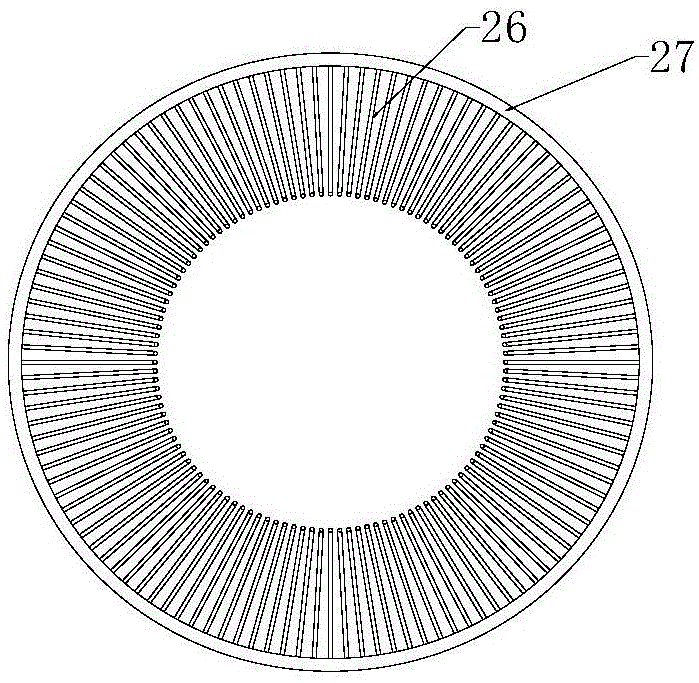

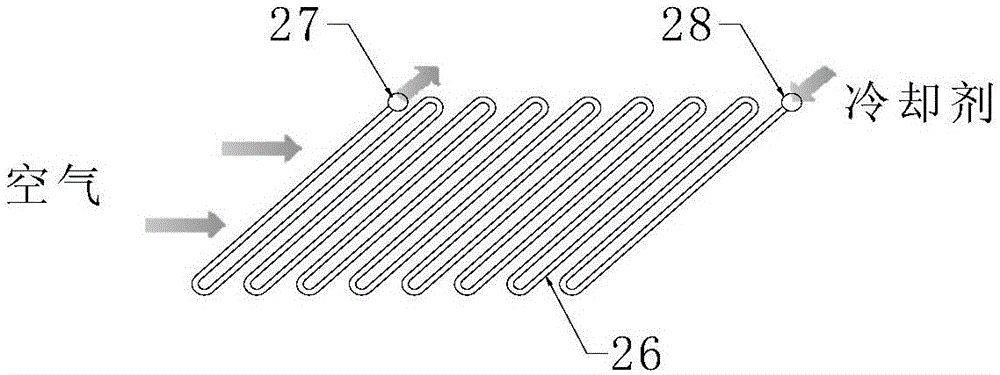

Pre-cooling air-breathing type variable cycle engine

InactiveCN105156227ALower airflow temperatureReduce the temperatureTurbine/propulsion engine coolingGas turbine plantsRamjetCombustion chamber

The invention discloses a pre-cooling air-breathing type variable cycle engine and relates to the reusable pre-cooling air-breathing type variable cycle engine applied to aeronautics and astronautics devices. The engine mainly consists of a pre-cooler, a turbine engine, a super combustion chamber and a super combustion ramjet engine, wherein the pre-cooler and the super combustion chamber form a subsonic combustion ramjet engine; a turbine subsonic combustion ramjet engine is connected with the super combustion ramjet engine in parallel; working states of the turbine subsonic combustion ramjet engine and the super combustion ramjet engine are selected by adjusting a switching adjusting device, so that the working modal of the whole engine is controlled. The pre-cooler can reduce an inlet gas flow temperature of a super combustion chamber, can increase the efficiency of the super combustion chamber, can expand the working range of a subsonic combustion punching modal, and can make up insufficient thrust force when turbine subsonic combustion ramjet engine is transferred to the super consumption ramjet engine, so that the pre-cooling air-breathing type variable cycle engine has the advantage that the transfer class of a combined engine is stably transferred.

Owner:TSINGHUA UNIV

Centripetal aerodynamic platform spacecraft

ActiveUS20170190446A1Reducing required liquid oxygenReducing booster tank capacity weightCosmonautic environmental control arrangementLaunch systemsGravitationSpacecraft

An aerodynamic platform or spacecraft including a habitable 1G centripetal force rotating gravity producing interior corridor within an aerodynamic shell and an aerodynamic drone booster launch system with reentry and reuse capability.

Owner:WILLIAMS SR LAWRENCE ELLIS

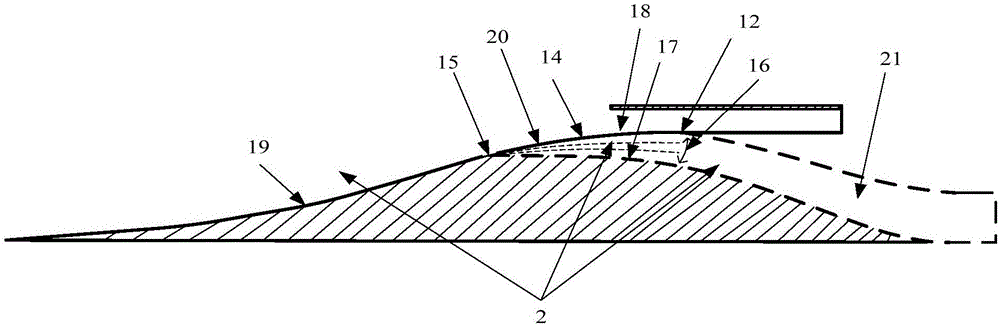

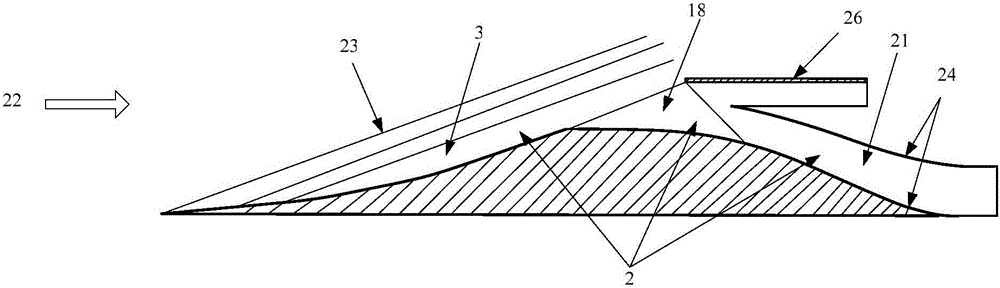

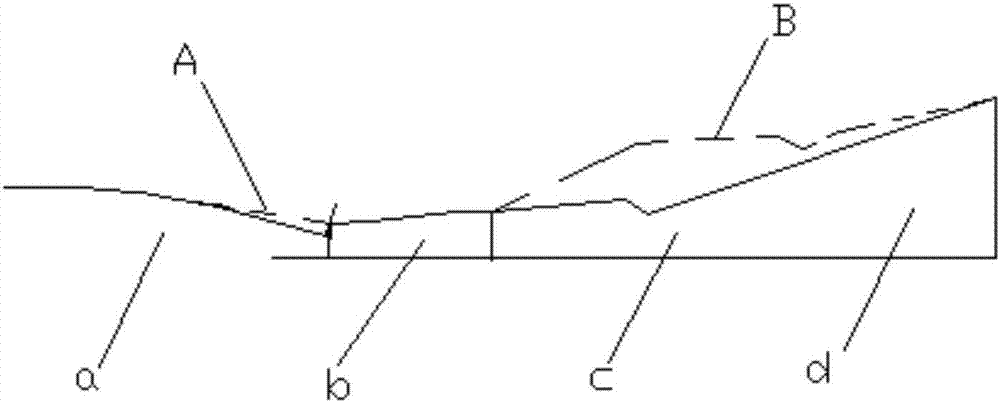

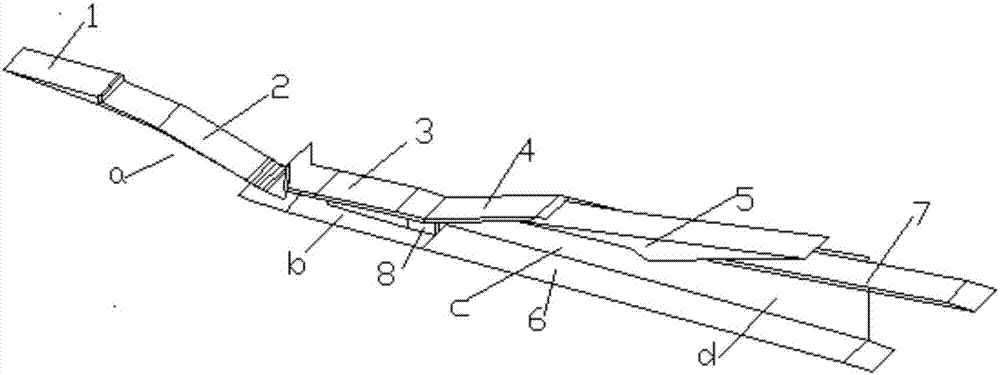

Design method of internal parallel type hypersonic-speed and double-channel air inlet channel

ActiveCN106837549ASolve the disadvantages of not startingPlay the role of drainageGeometric CADGas turbine plantsInternal pressurePunching

The invention provides a design method of an internal parallel type hypersonic-speed and double-channel air inlet channel and relates to a hypersonic-speed air inlet channel of an aircraft. The design method comprises the following steps: designing an external pressure section of the air inlet channel; designing an internal pressure section of a punching channel; designing an isolation section of the punching channel; designing a flow division scheme; designing a low-speed turbine channel with a working Mach number range of a Mach number Ma=0 to 1.8. The designed binary internal parallel type turbine-based combined circulating power air inlet channel structurally comprises the high-speed punching channel, the low-speed turbine channel and a flow division plate of the air inlet channel. The punching channel is composed of the external pressure section of the air inlet channel, the internal pressure section of the punching channel, the flow division plate and the isolation section of the punching channel; a mold surface is generated by adopting an isentropic method. The turbine channel is composed of the external pressure section of the air inlet channel, the internal pressure section of the punching channel, the flow division plate and an expansion section of the turbine channel, and a mold surface is generated through an isentropic compression law and an area uniform transition manner.

Owner:XIAMEN UNIV

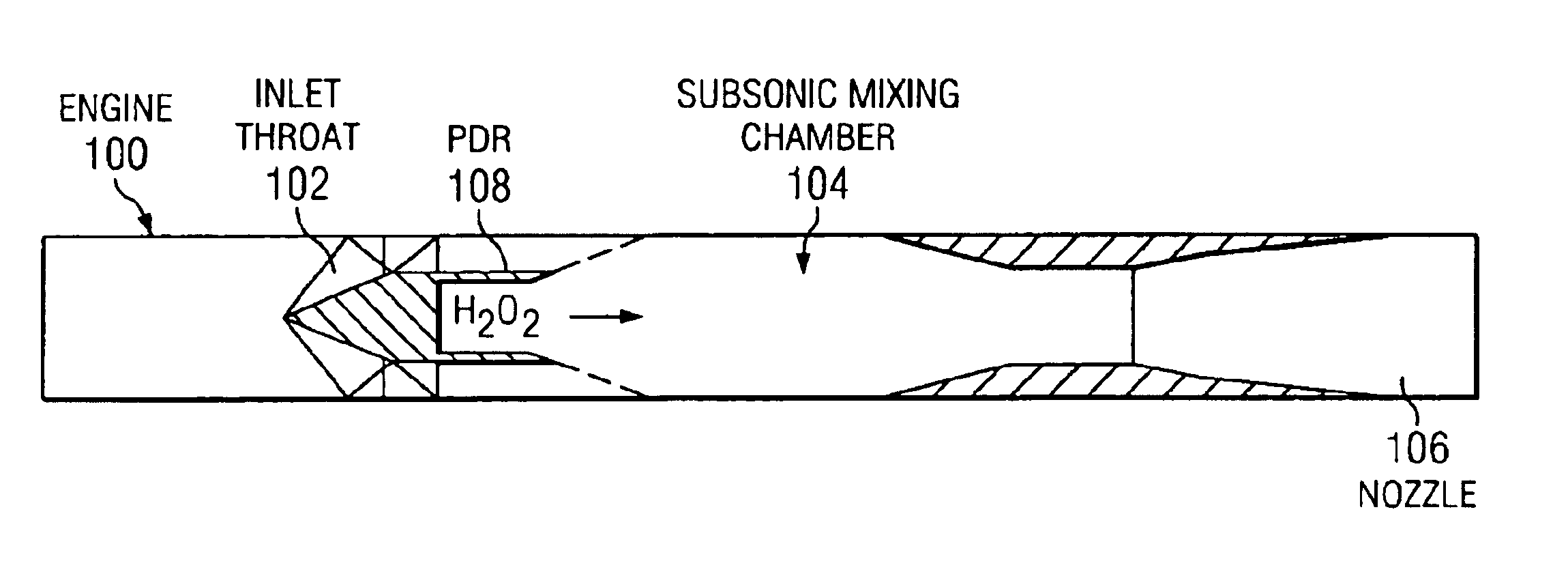

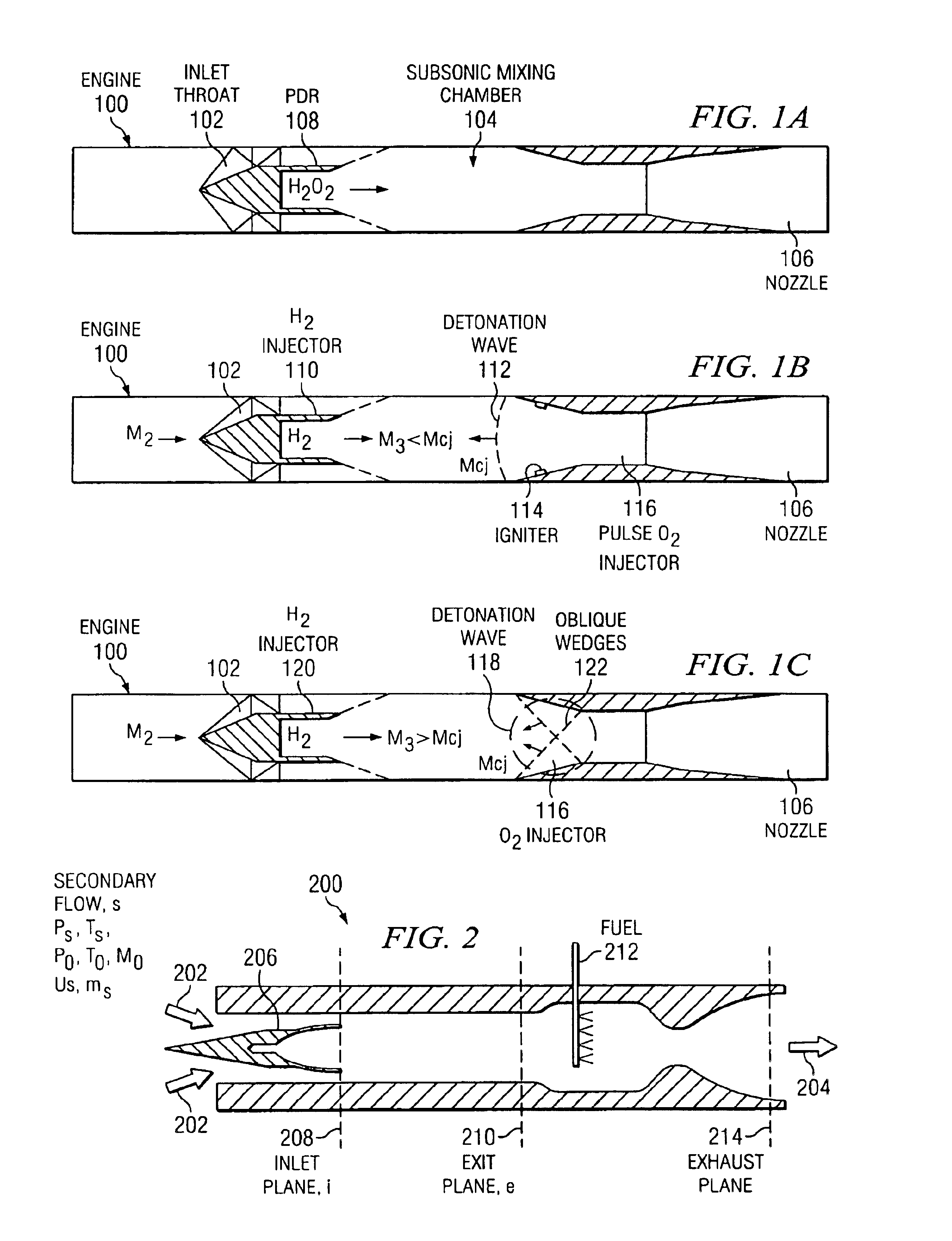

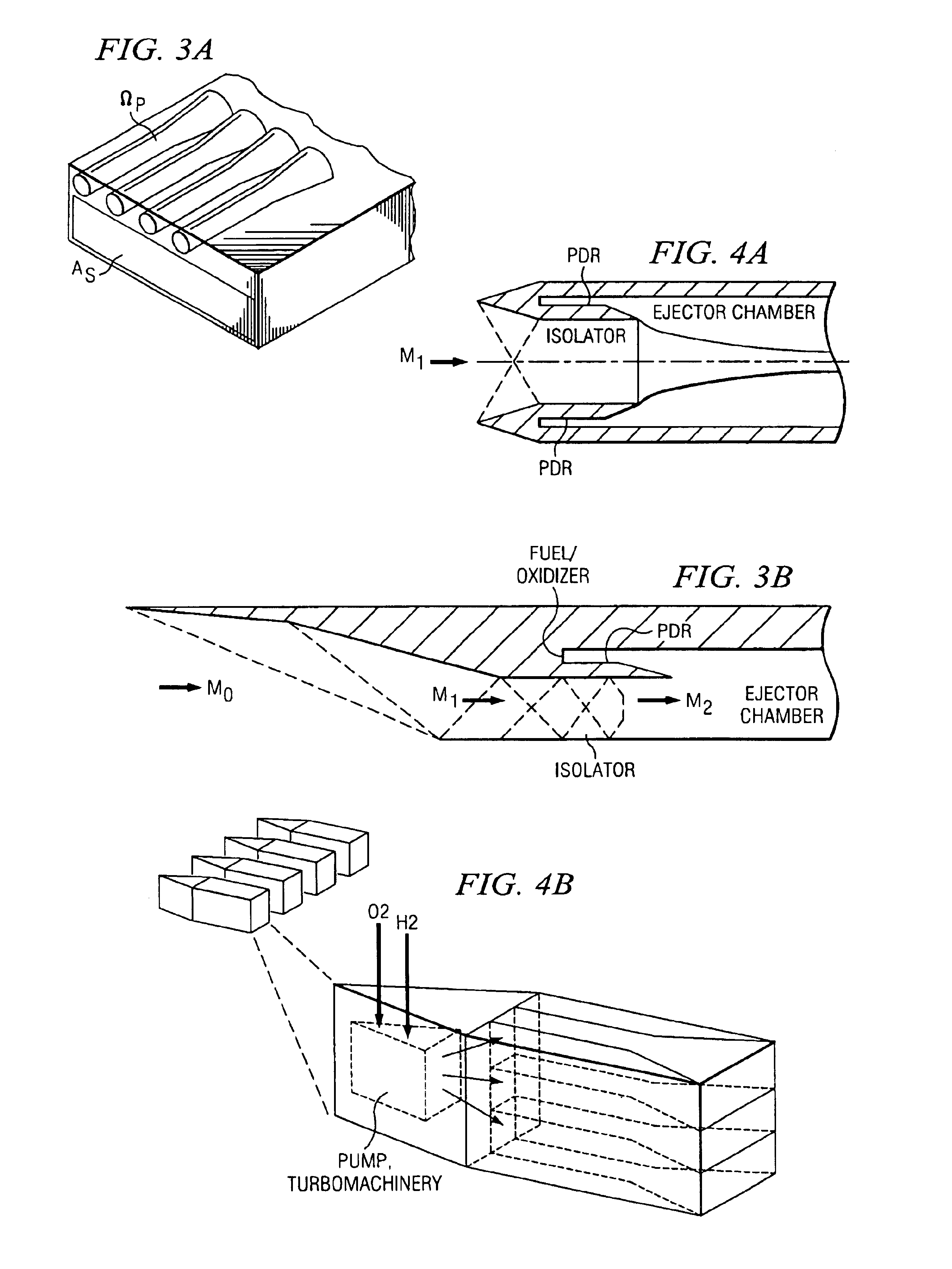

Multi-mode pulsed detonation propulsion system

InactiveUS6857261B2Improve performanceReduce weightCosmonautic vehiclesCosmonautic propulsion system apparatusAviationDetonation

A multi-mode propulsion system for potential application to hypersonic and aerospace planes. The system can employ various propulsion modes at various points in time, with the propulsion system employed at a given point in time being selected according to the velocity of the inlet airflow. In one embodiment, the propulsion system of the present invention has an ejector-augmented pulsed detonation rocket propulsion mode, a pulsed normal detonation wave engine mode, a steady oblique detonation wave engine mode, and a pure pulsed detonation rocket mode.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

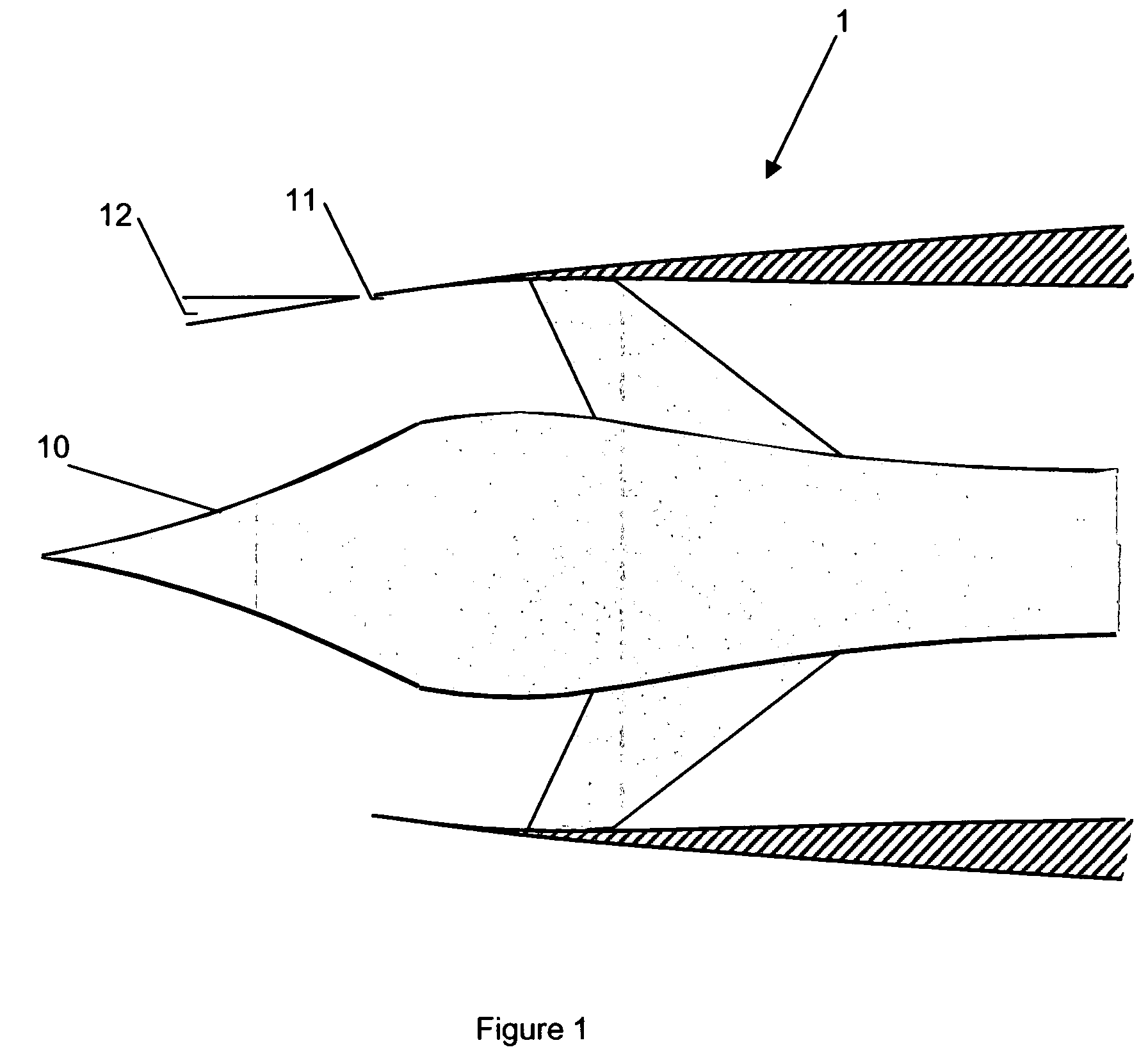

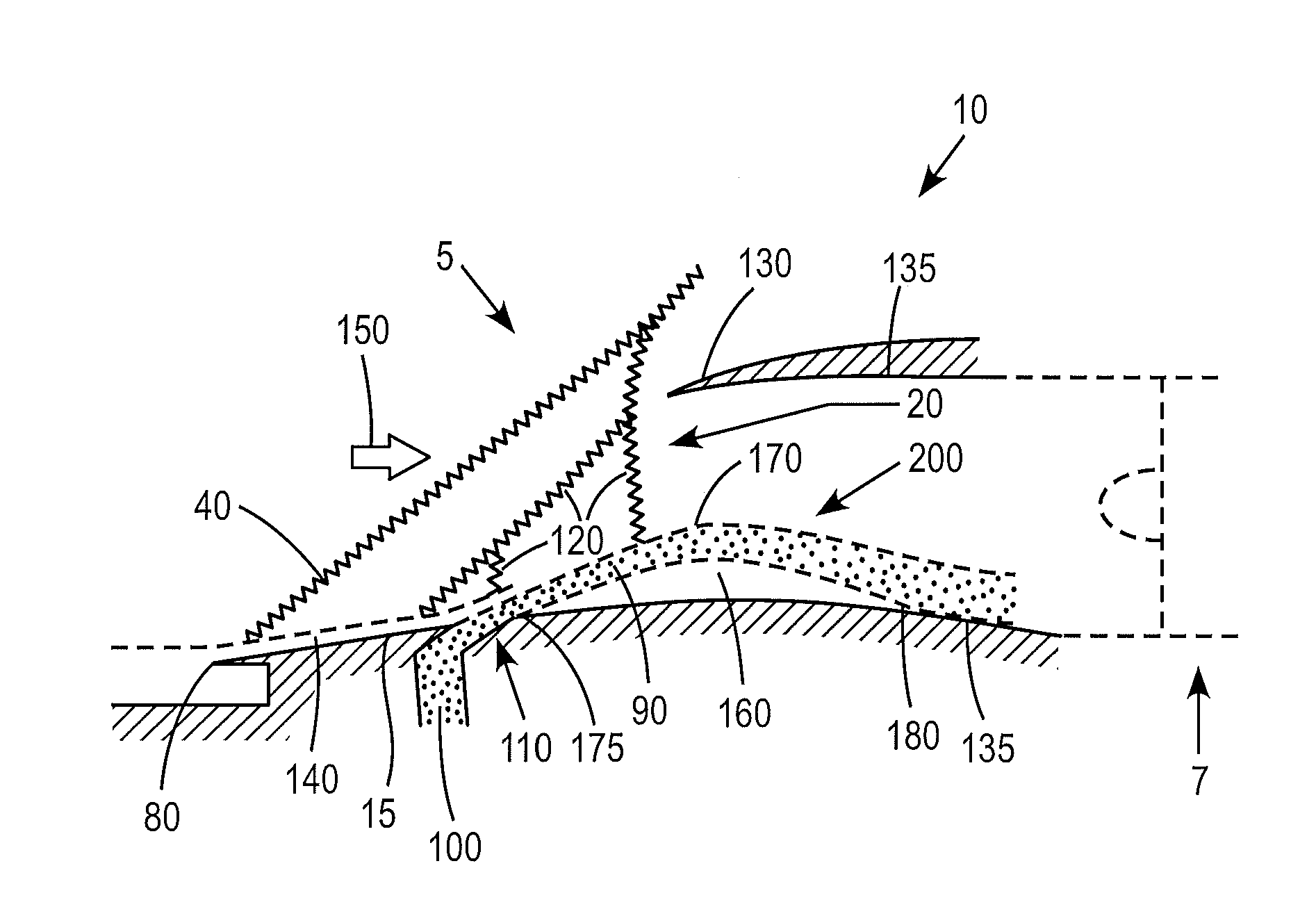

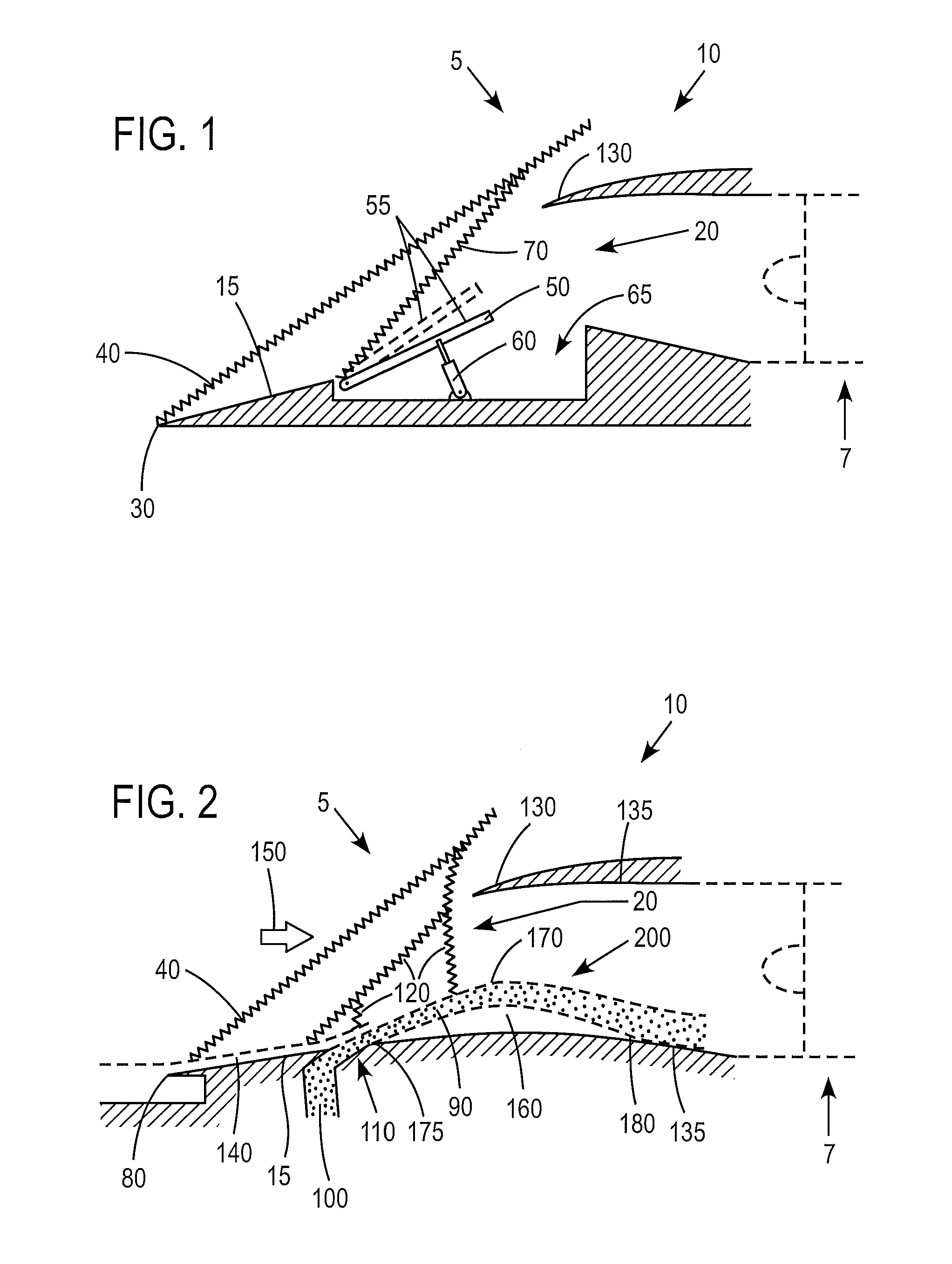

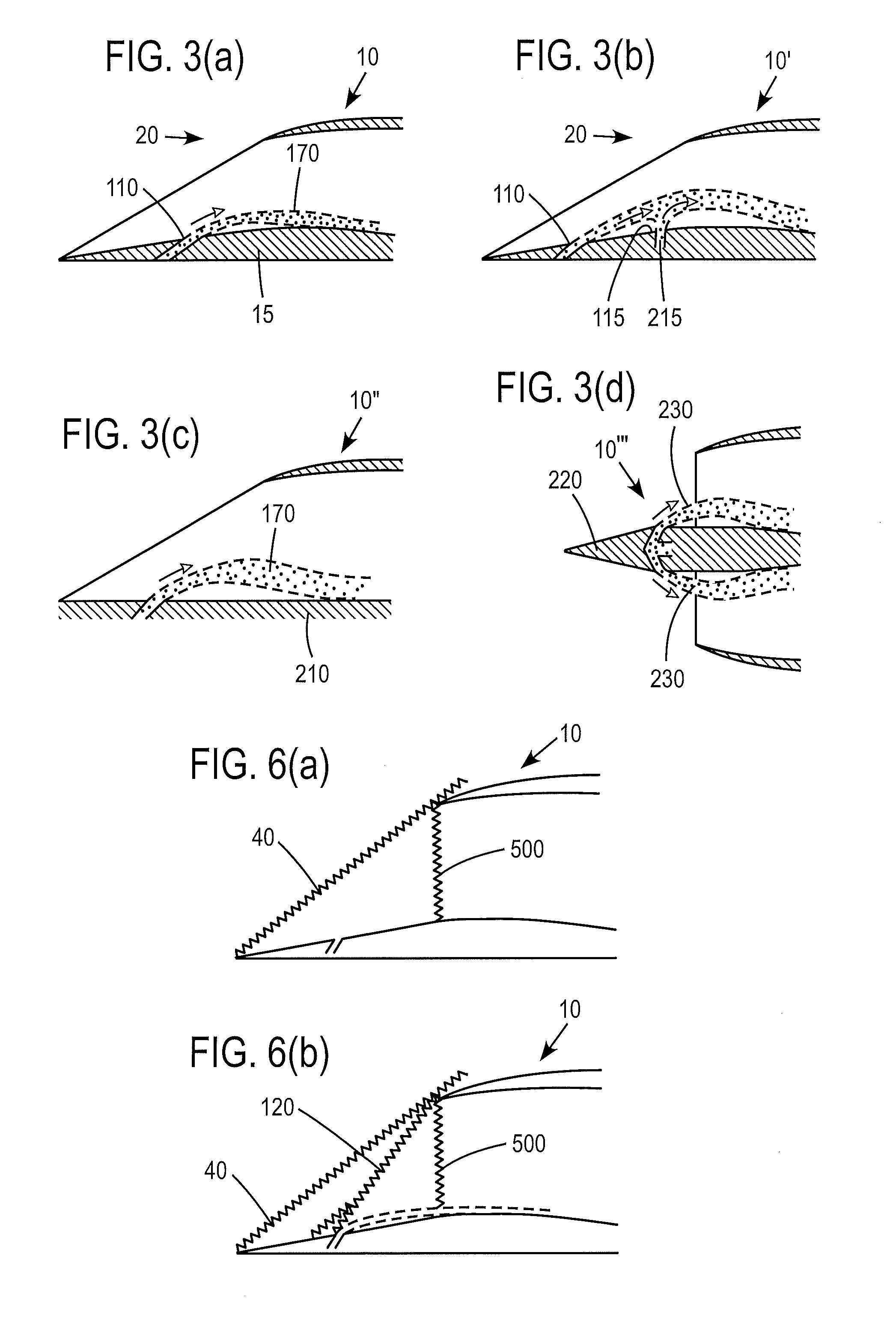

Integrated air inlet system for multi-propulsion aircraft engines

ActiveUS20060107648A1Sacrificing critical thrustIncrease in sizeGas turbine plantsRocket engine plantsLeading edgeShock wave

An air inlet duct for an air-breathing combined-cycle aircraft engines is internally divided into separate channels for low-speed and high-speed components of the engine, and contains one or more movable panels that are fully contained within the duct and pivotal between an open position in which incoming air is directed to both channels and a closed position in which all incoming air is directed to the channel leading to the high-speed engine. This integrated duct utilizes all incoming air at all stages of flight with no change in either the geometry of the air capture portion of the engine or the engine itself, and no exposure of movable leading edges. The result is a minimum of shock waves and a high degree of efficiency in operation of the engine.

Owner:AEROJET ROCKETDYNE INC

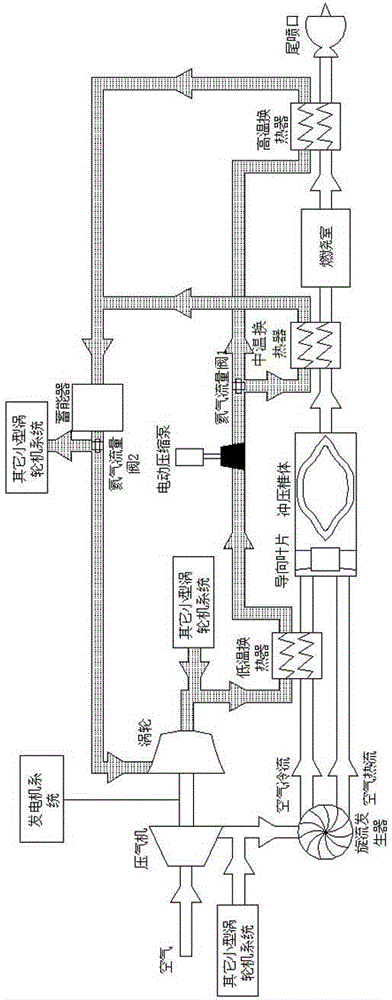

New concept high-speed aerocraft propulsion system layout method

ActiveCN104110326AEfficient cruiseLarge heat capacityRam jet enginesComposite engine plantsSpacecraft propulsionBrayton cycle

The invention provides a new concept high-speed aerocraft propulsion system layout method. Two cycles are built in a propulsion system, namely a Brayton cycle with the air as the working medium and a closed cycle with supercritical state fluid as the working medium. The two cycles are coupled through a supercritical microscopic scale heat exchange technology, a supercritical state fluid turbine and compressor power balance. By adjusting related valves, the propulsion system can be in a turbofan engine model when taking off or flying at a low speed and in a turbine rocket engine model when flying at a high Mach number, so that it is guaranteed that the aerocraft can effectively cruise for a long time in both a subsonic state and a supersonic state. Through the supercritical microscopic scale heat exchange technology, the gas flow temperature at an inlet of a compressor can be effectively reduced when the propulsion system is flying at a high speed, and when the supercritical microscopic scale heat exchange technology is applied in combination with a closed cycle technology, optical distribution of energy of the propulsion system can be achieved. By means of the method, the defects of the propulsion system of an existing high-speed aerocraft are overcome, and working performance of the high-speed aerocraft propulsion system is remarkably improved when Ma ranges from 0 to 5.

Owner:BEIHANG UNIV

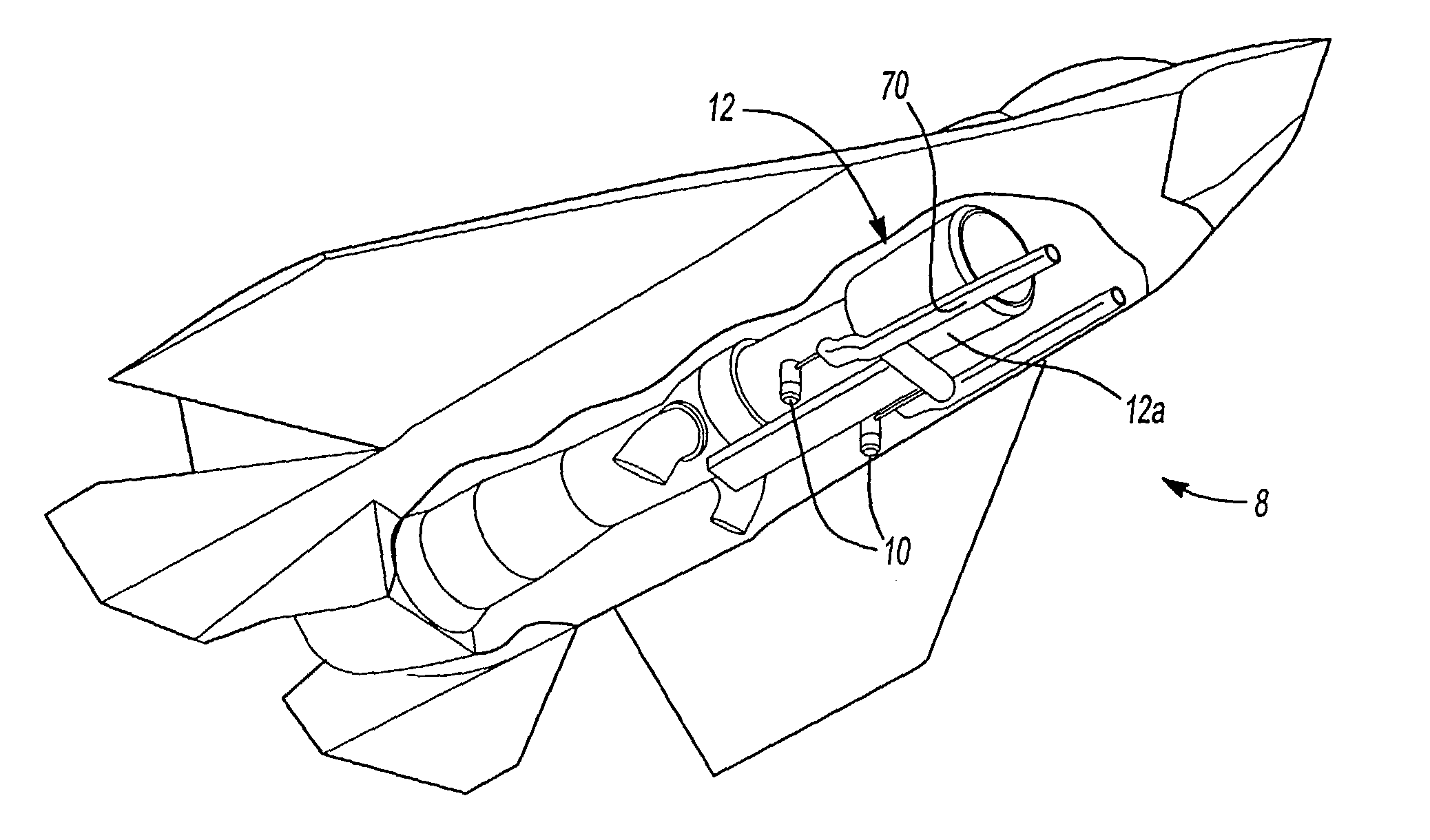

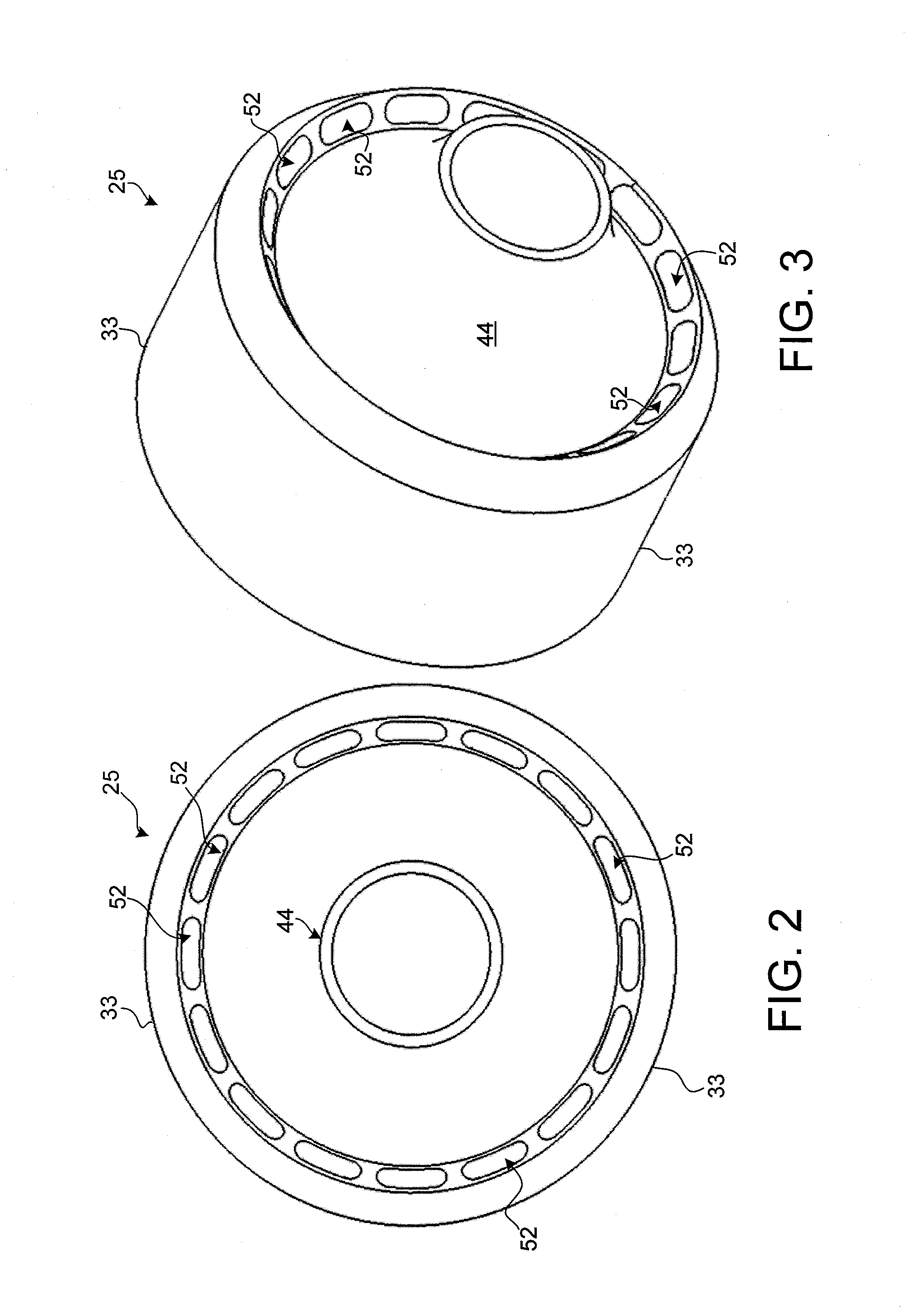

Rotary ramjet turbo-generator

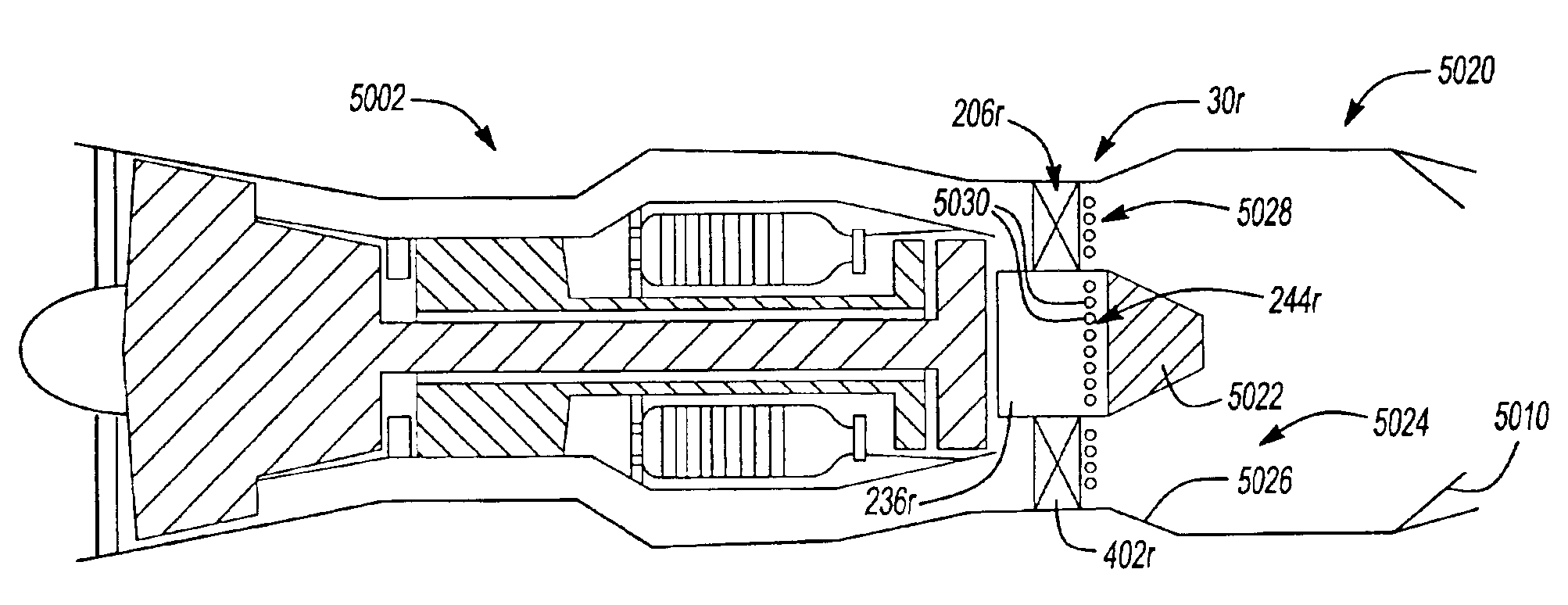

ActiveUS7685824B2MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

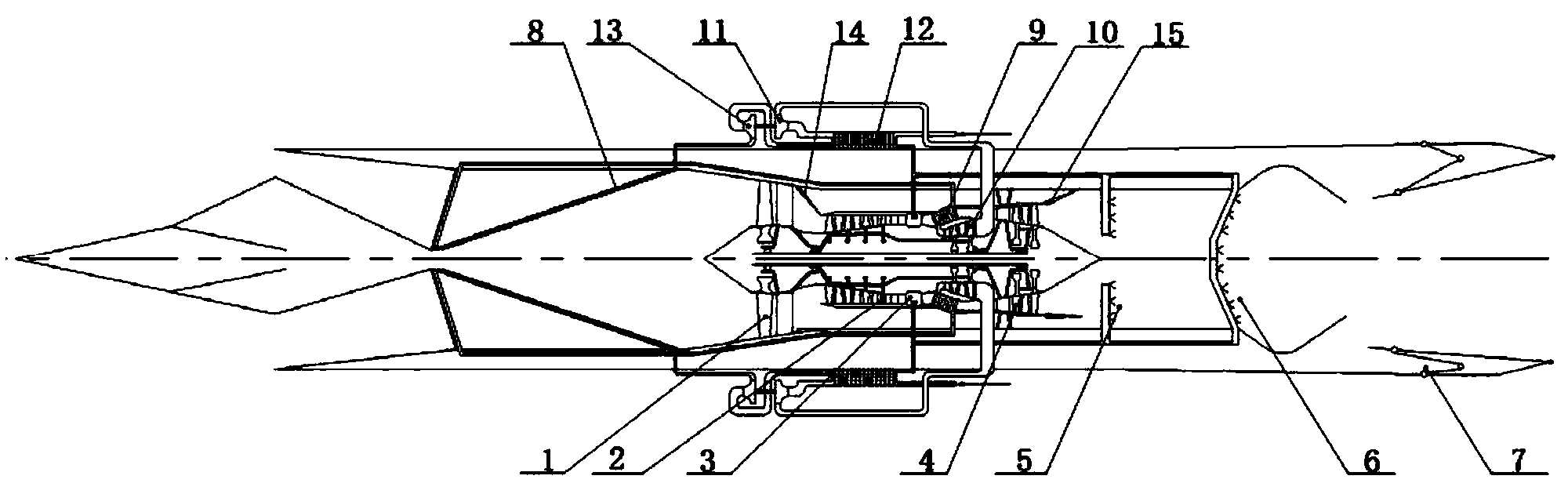

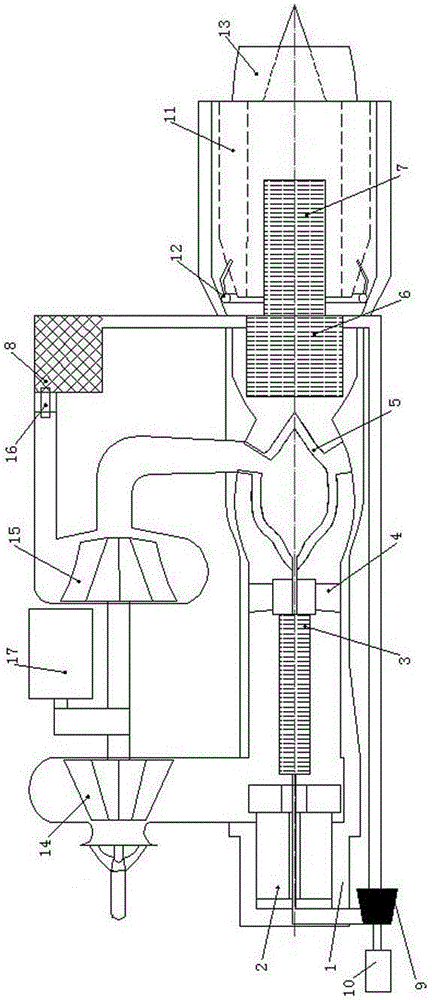

Stamping-turbine air injection composite aero-engine

ActiveCN105221295ASingle stage pressure ratio highReduce consumptionRam jet enginesComposite engine plantsRamjetAviation

The invention discloses a stamping-turbine air injection composite aero-engine and aims to solve the problems that the existing gas turbine engine is complicated in structure and limited in running speed range, and a ramjet engine cannot voluntarily start, cannot run at a low speed, is difficult in cooling, and has higher requirements for the high temperature resistance of a complete machine. The stamping-turbine air injection composite aero-engine comprises a stamping air inflow cone, an outer duct engine case, an inlet guide blade, a liquid oxygen regulating valve, a liquid nitrogen regulating valve, an inner duct engine case, a rectifying blade, a fuel oil regulating valve, a centrifugal compressor, a diffuser, a combustor, a concentric shaft, a worm wheel, an inner duct rectifying nozzle, a starting dynamo and the like. The stamping-turbine air injection composite aero-engine effectively utilizes the stamping effect and advantages of a turbojet engine, participates in precooling treatment, effectively solves the problems that the ramjet engine takes air in the starting and high-speed states, and the engine power is limited, is simple in structure, low in cost, high in efficiency, wide in running speed range and low in running speed of the complete machine, and has a better application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

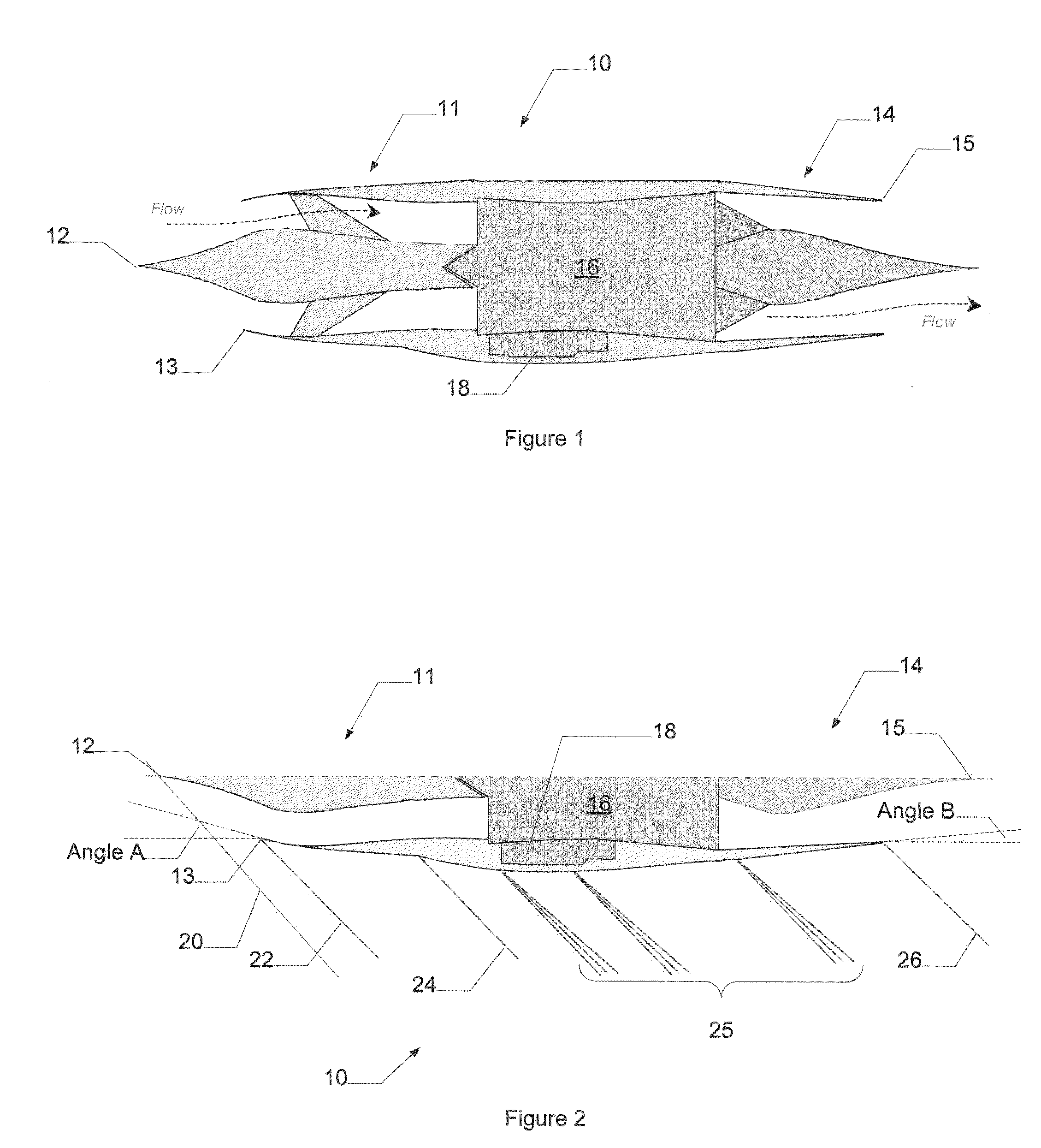

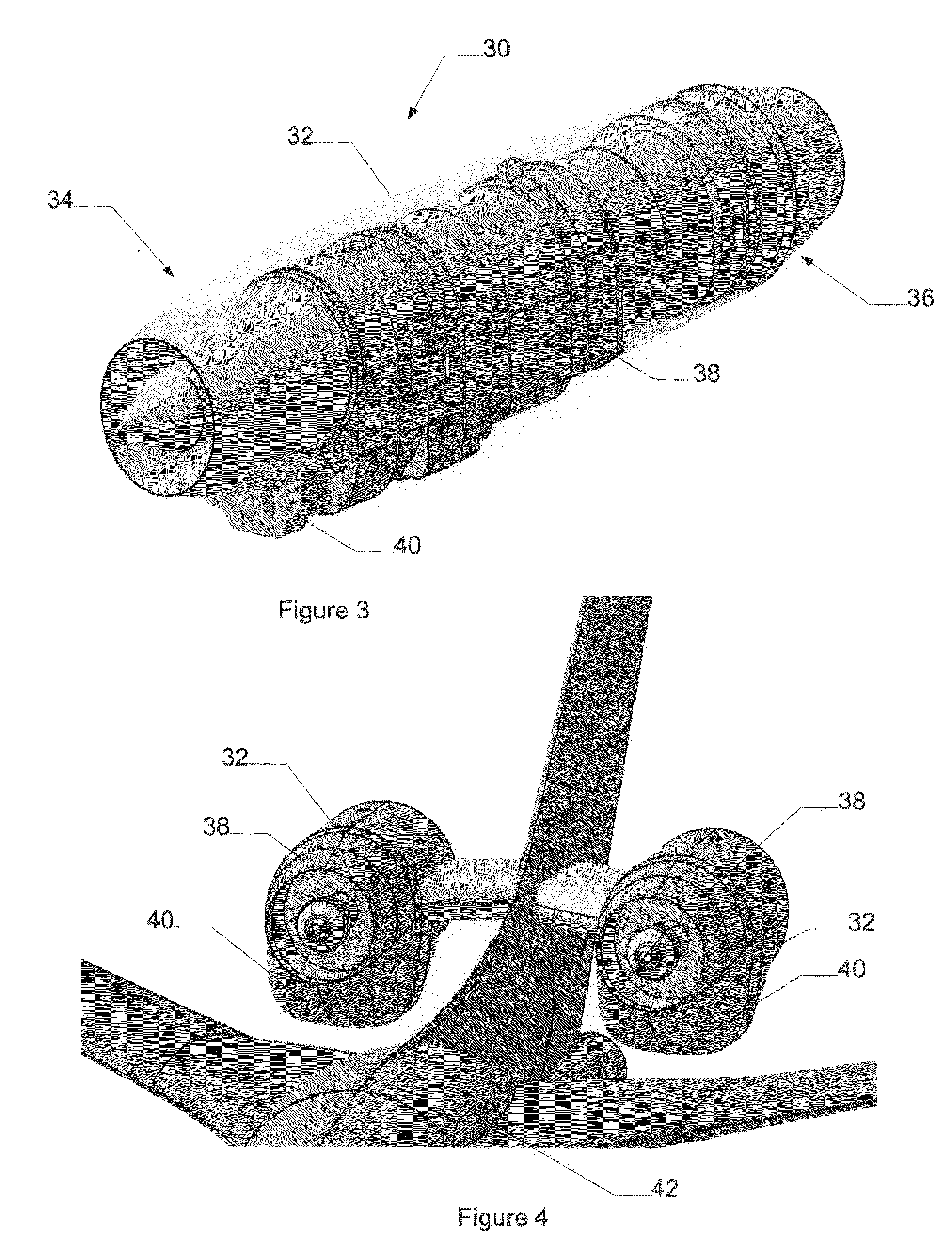

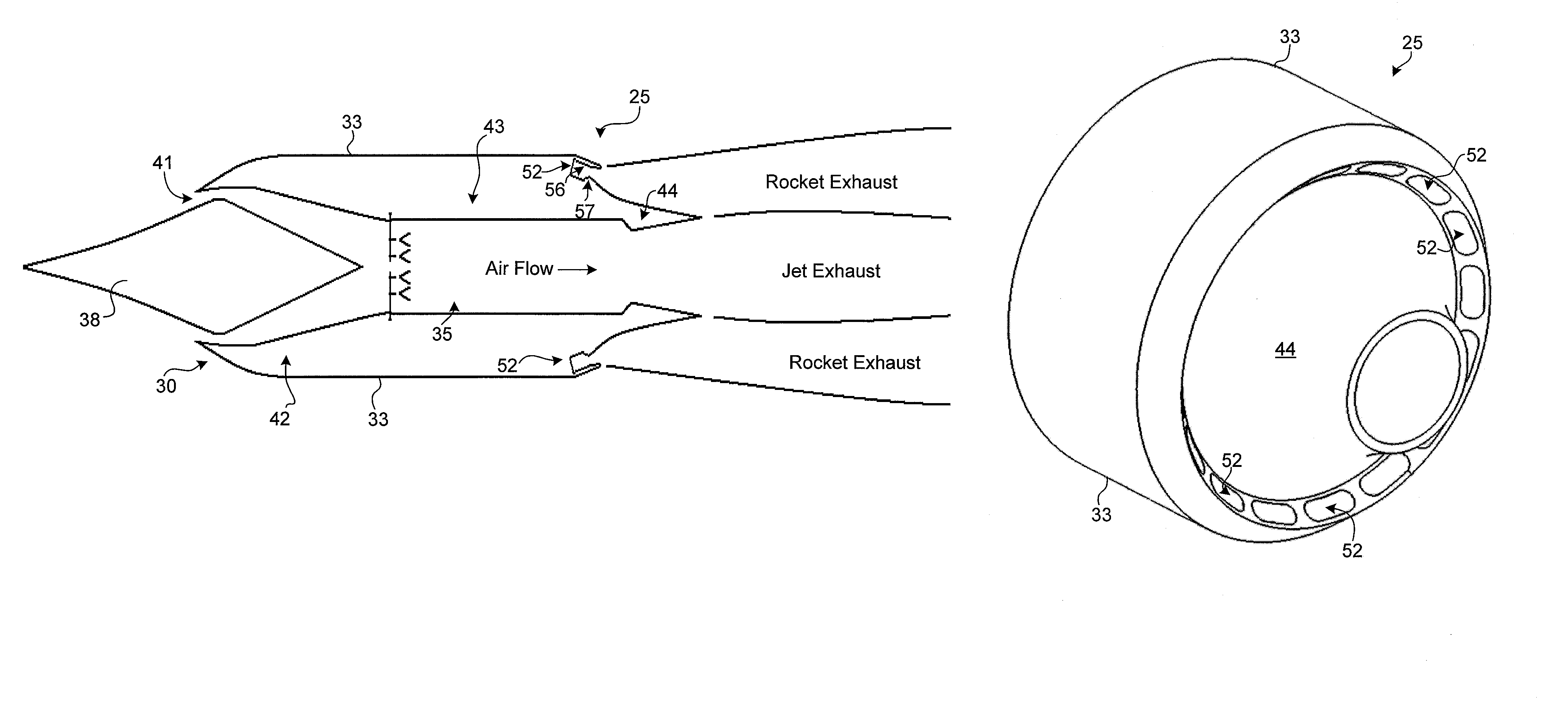

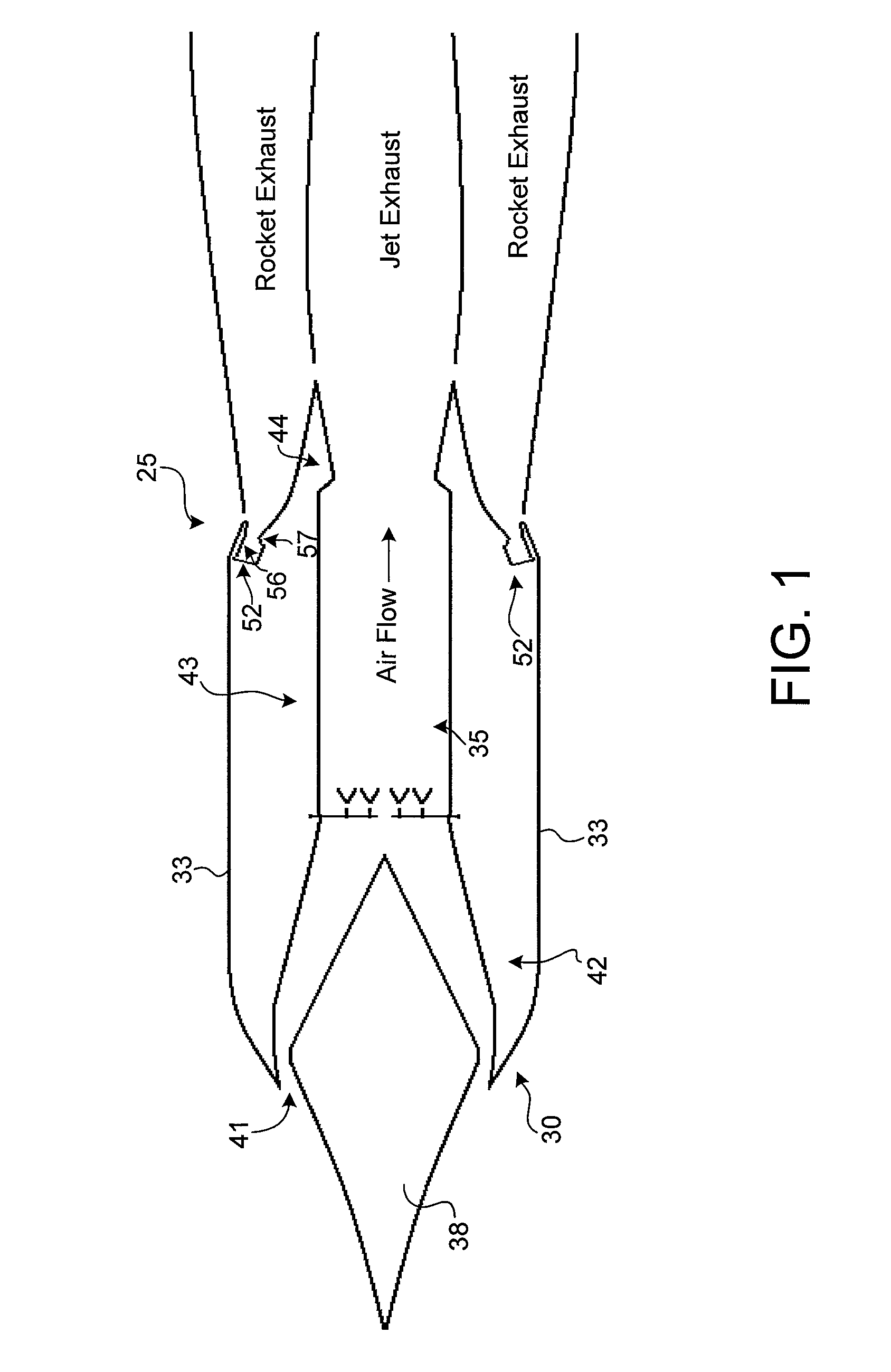

Rocket based combined cycle propulsion unit having external rocket thrusters

The present disclosure generally pertains to rocket based combined cycle (RBCC) propulsion units. In one exemplary embodiment, at least one rocket thruster is integrated with a jet engine but is external to the flow path of the jet engine, forming an altitude compensating plug nozzle. Since the rocket thruster is external to such flow path, the rocket flow from the rocket thruster interacts with the jet flow from the jet engine aft of the nozzle of the jet engine. Such interaction occurs without a significant performance penalty in the operation of the jet engine. In fact, it is possible that the interaction of the rocket flow with the jet flow may actually improve the efficiency of the jet engine under some conditions. Moreover, having the rocket thrusters positioned external to the flow path of the jet engine helps to avoid many of the problems plaguing conventional RBCC propulsion units.

Owner:UNIVERSITY OF ALABAMA

Variable-structure rocket based combined power cycle engine

ActiveCN106907272AReduce heat loadOptimize layoutContinuous combustion chamberGas turbine plantsCombustion chamberPower cycle

The invention discloses a variable-structure rocket based combined power cycle engine. The variable-structure rocket based combined power cycle engine comprises a variable-structure combustion chamber which is a cavity defined by upper top plates, side plates and a fixed bottom plate, wherein the upper top plates comprise a combustion chamber fixed top plate and a combustion chamber adjustable plate, which are in sliding connection from front to rear, and are consistent in width; the combustion chamber fixed top plate is upwards arranged in an inclined mode from front to rear; the combustion chamber adjustable top plate slides back and forth along the trend of the combustion chamber fixed top plate; and a combustion chamber fixed top plate end is an inflow inlet end. The variable-structure rocket based combined power cycle engine disclosed by the invention improves combustion performances, meets matching of a gas inlet system and a gas exhaust system, and improves performances of a tail spray tube.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

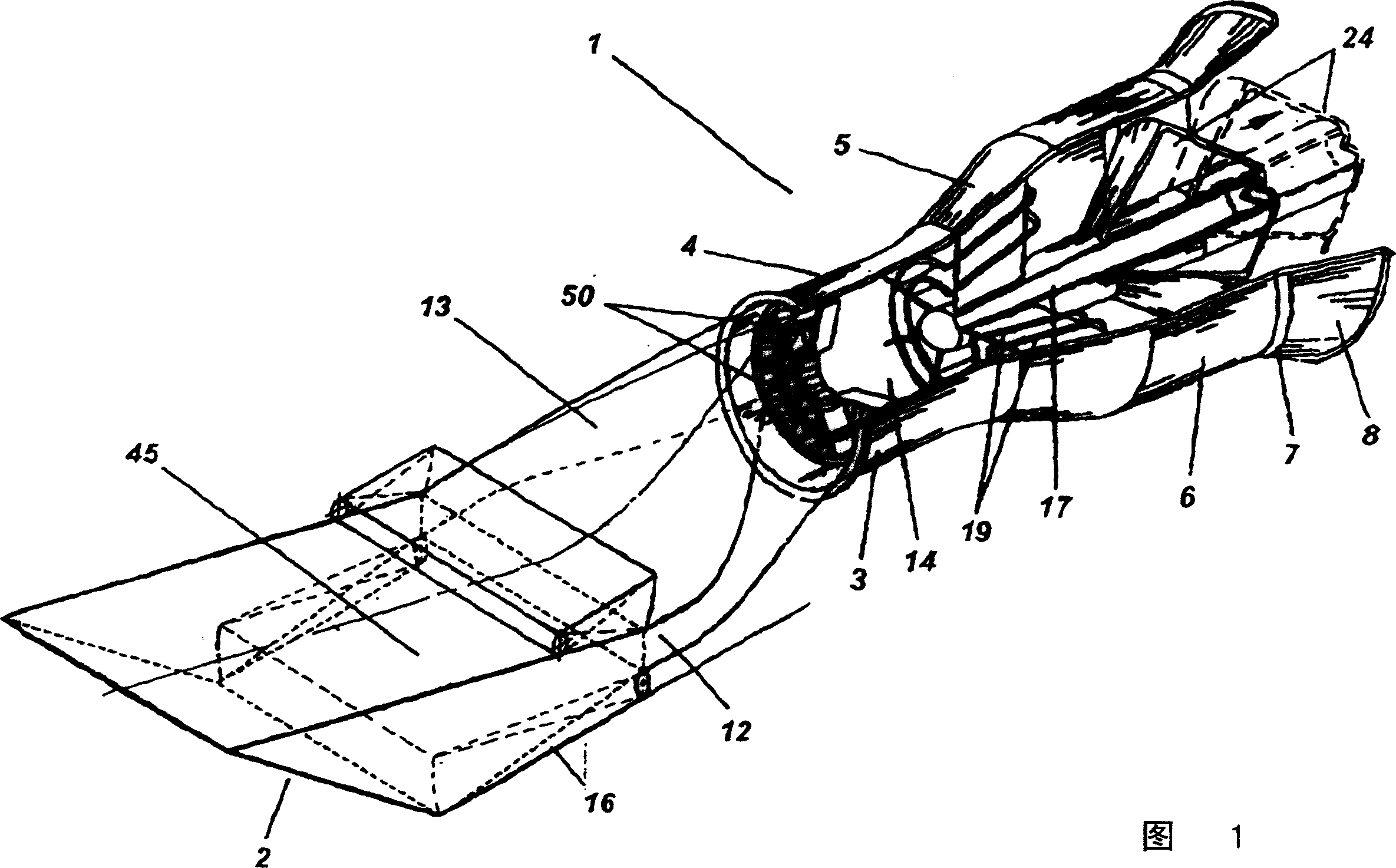

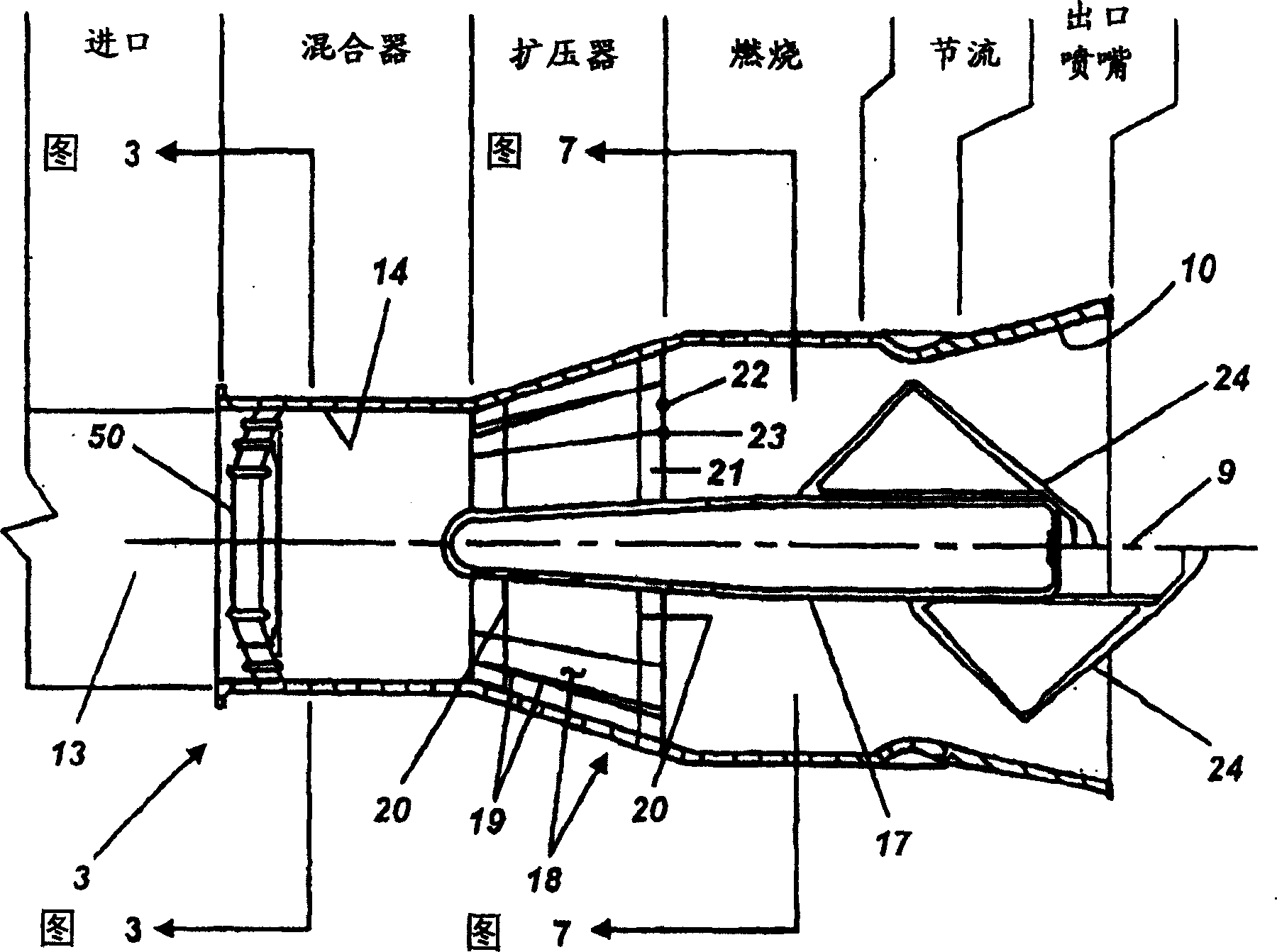

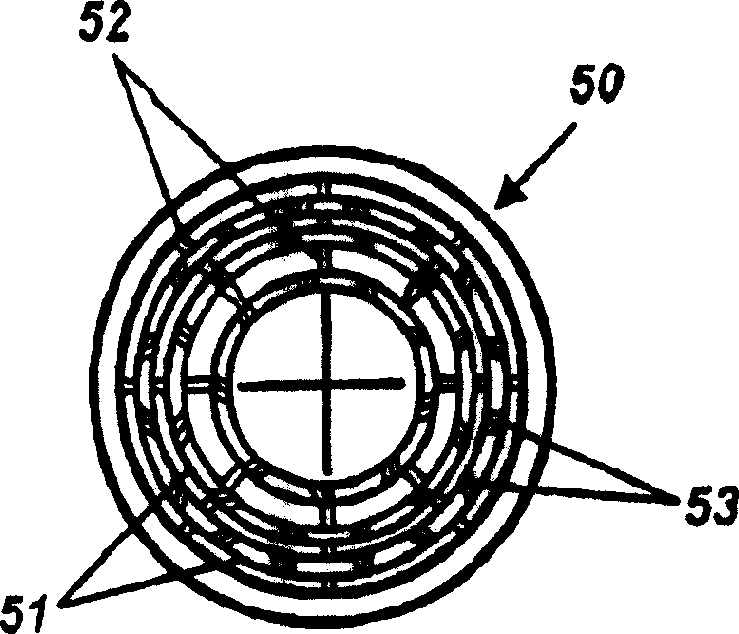

Ejector based engines

An injector-based engine, as exemplified in the injector ramjet (1), is an engine with an inlet (2), mixer (4), diffuser (5), combustor (6) and outlet ) conventionally reinforced ramjet element propulsion duct, allowing operation in the zero to hypersonic range. At the upstream end of the mixer (4), an injector assembly (50) is mounted in the fluid flow channel to form an injector (3). The injector assembly (50) has one or more injector rings with alternately offset injector exhaust nozzles (53) or slots to direct fluid towards the engine inner wall (14) or the engine longitudinal axis (9), respectively. ), thereby improving fluid mixing for shorter mixing zones. The supply of fluid to the injector exhaust nozzle (53) can be accomplished by flow pumps and other elements.

Owner:太空通道有限公司

Relating to air-breathing flight vehicles

An air intake for a supersonic air-breathing flight vehicle introduces or injects fluid in order to create predetermined regions of separated flow and an attendant fluid shear layer. This shear layer forms an aerodynamic boundary for the capture flow with a profile determined and optimised by appropriate injection of fluid. The aerodynamic boundary so generated replaces mechanically moveable solid surfaces used to vary the geometry of prior-art intakes. Use of an introduced or injected fluid can provide an advantage of a variable geometry, but with reduced weight and reduced mechanical complexity. In some embodiments, the injection of fluid has the effect of re-energising any ingested boundary layer, thus obviating the conventional requirement for a bleed system to provide boundary layer control.

Owner:MBDA UK

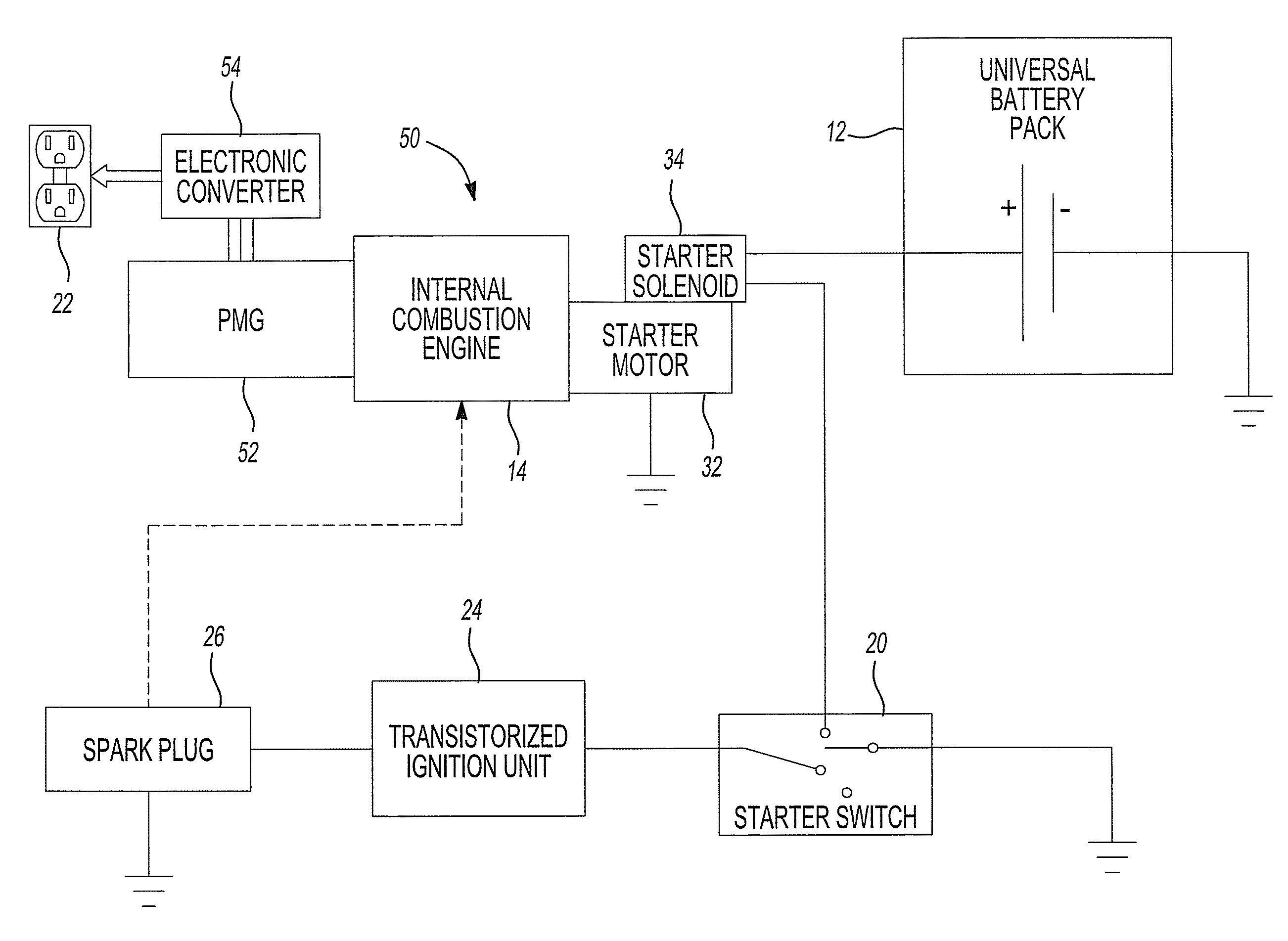

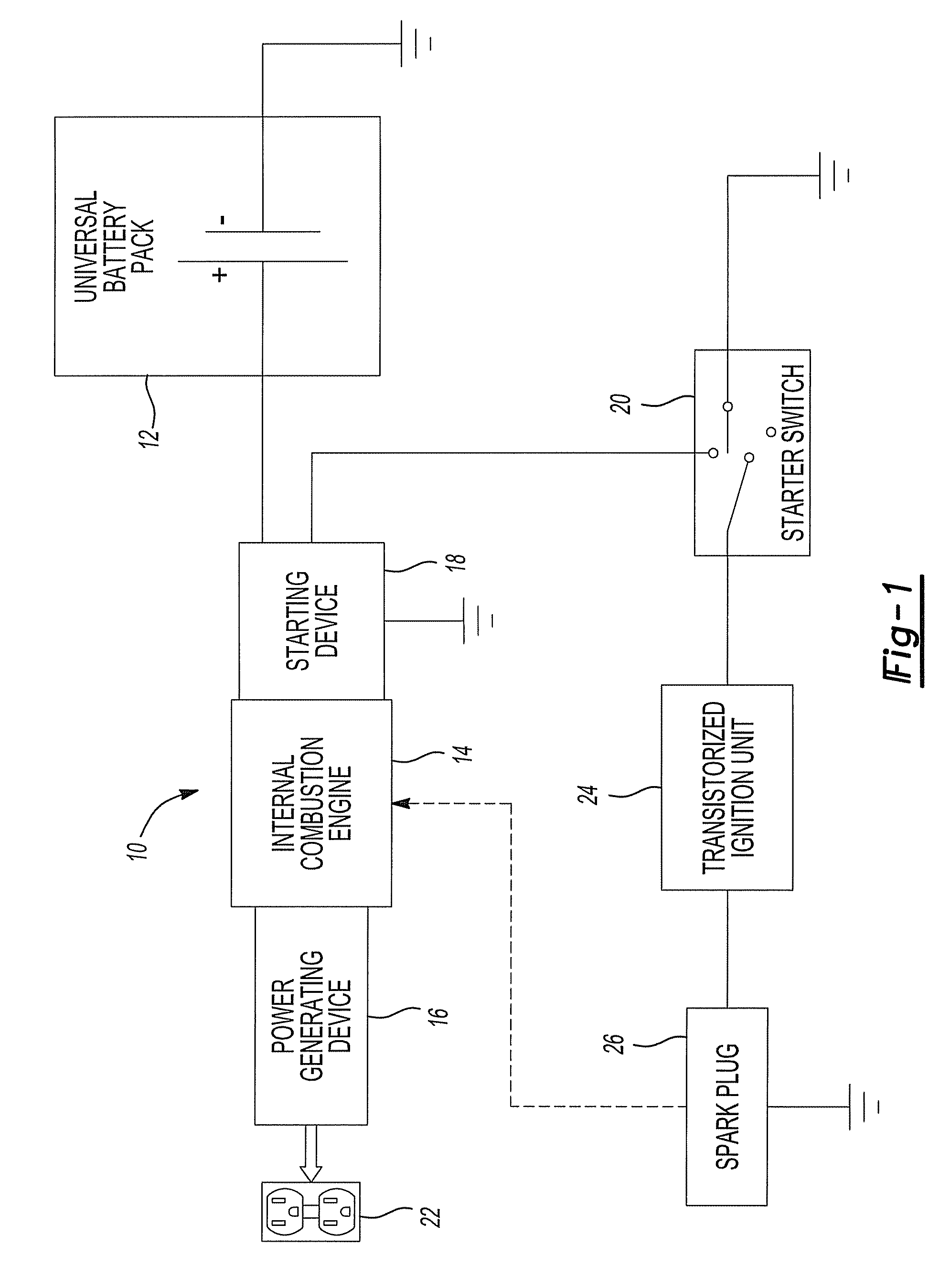

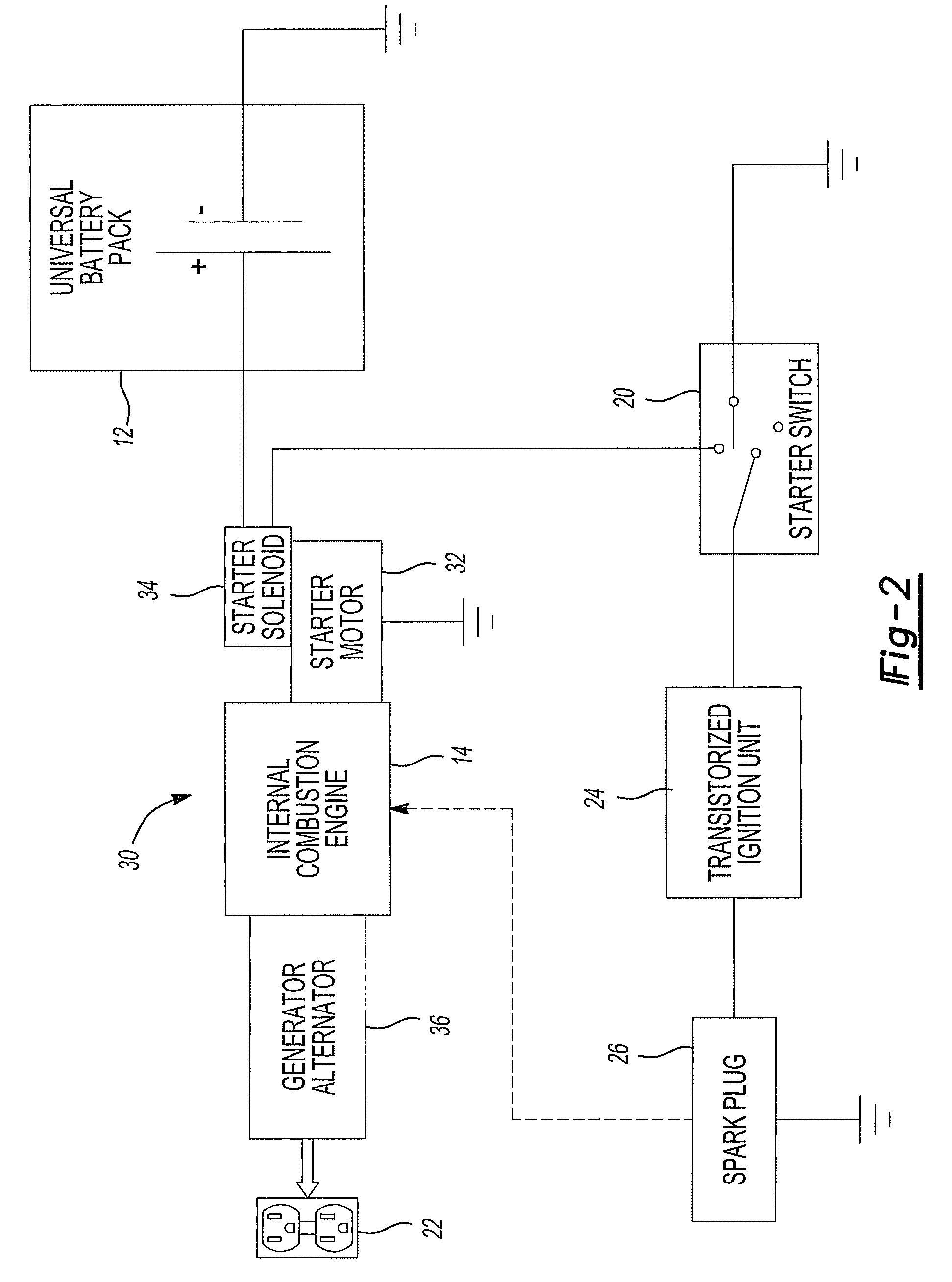

Starter system for portable internal combustion engine electric generators using a portable universal battery pack

A portable power driven system has a manually movable frame. In one example, an internal combustion engine and a generator device that generates AC power are supported on the frame. The internal combustion engine drives the generator device. An electrically powered starting device is coupled to the internal combustion engine. A control panel is coupled to the frame and includes at least one AC outlet and a battery receptacle that is electrically coupled to the starting device. The battery receptacle is materially the same as a foot of a cordless power tool that receives a battery pack. According to one aspect, the battery pack for the cordless power tool may be permanently mounted in the battery receptacle and provides electrical power to the starting device. The battery receptacle may be contained in an enclosure. The enclosure may provide biasing members urging the battery pack into the battery receptacle.

Owner:BLACK & DECKER INC

Distributed compression and cyclone ramjet engine

ActiveCN105257428AReduce the temperatureImprove cycle efficiencyRam jet enginesComposite engine plantsRamjetAviation

The invention discloses a distributed compression and cyclone ramjet engine and aims to solve the problems that an existing ramjet engine cannot start by itself, and can work only by being accelerated to a certain speed by a roll booster, the existing ramjet engine is sensitive to changes in flight states, and when the existing ramjet engine is combined with a turbojet engine or a fanjet to be used as an aero-engine, the beneficial effects that the ramjet engine is simple in structure and the like are lost. The engine comprises turbine systems, a casing, a cyclone generator, a low-temperature heat exchanger, a guide blade, a stamping cone, an intermediate-temperature heat exchanger, a high-temperature heat exchanger and the like. Turbines are heated by heat exchange gas and pushed by cooling circulation, energy of stamping airflow is fully utilized, the circulation efficiency of the engine is effectively improved, cost is reduced, cyclone stamping is utilized, and the problems that the existing ramjet engine cannot be started at a low speed and cannot adapt to various work conditions are solved. The distributed compression and cyclone ramjet engine is ingenious in concept, reasonable in design and capable of achieving static starting of the engine and adapting to various work conditions, and good application prospects are achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Flade discharge in 2-d exhaust nozzle

An aircraft gas turbine engine has a row of FLADE fan blades disposed radially outwardly of and drivingly connected to a fan in the engine's fan section. The FLADE fan blades extend across a FLADE duct circumscribing the fan section. A two dimensional air discharge passage is in fluid flow communication with the FLADE duct and with FLADE air upstream and downstream discharge slots in a divergent flap of a two dimensional exhaust nozzle. A valve fully closes the upstream slot when the downstream slot is fully opened and fully opens the upstream slot when the downstream slot is fully closed. The upstream and downstream slots may be located upstream and downstream respectfully of a nozzle discharge area in the nozzle. A sliding deck slides aft or down to open upstream slot and close downstream slot and slides forward or up to close upstream slot and open downstream slot.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com