Design method of internal parallel type hypersonic-speed and double-channel air inlet channel

A hypersonic and design method technology, applied in ramjet engines, computing, mechanical equipment, etc., can solve the problems of combination and conversion control difficulties, many variable geometry parts, and few inlets, etc., and achieve a low exit Mach number , simple structure and high flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

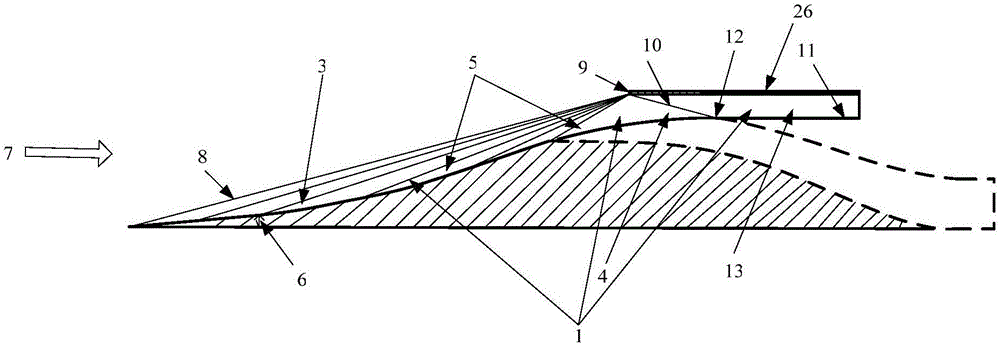

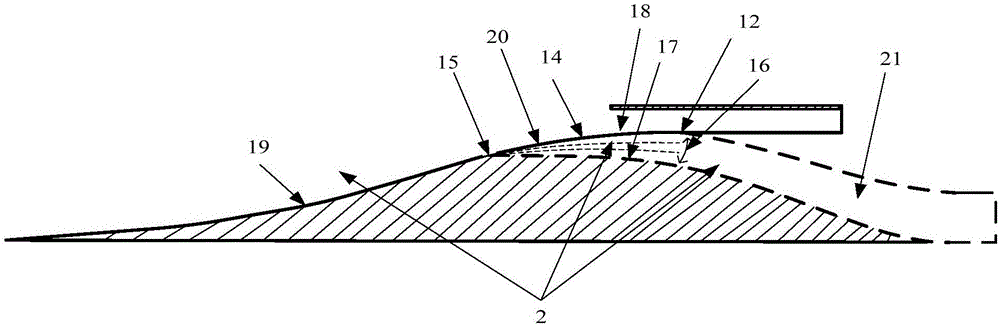

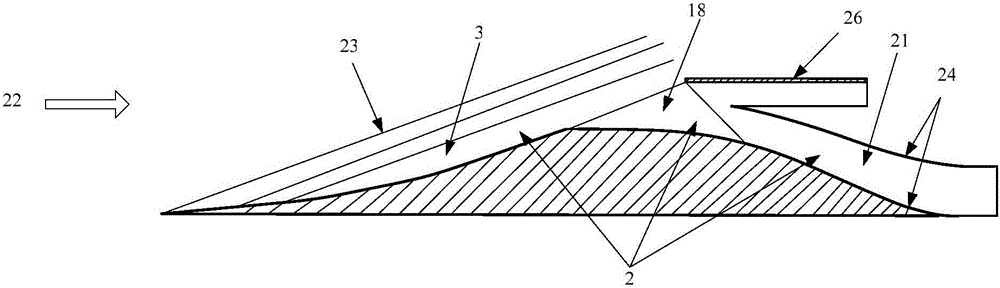

[0045] Referring to the design method of the internal parallel hypersonic dual-channel inlet, in this example, given the Mach number Ma=6 of the incoming flow, the design is as follows: Figure 4 The shown working Mach number ranges from 0 to 6, and the binary turbine-based combined cycle power inlet with transition Mach number Ma=1.8. The intake passage is composed of a high-speed ram channel 1 , a low-speed turbine channel 2 and a splitter plate 14 . Under the design conditions of the inlet, the three-dimensional shock wave at the mouth of the inlet is close to the mouth, and the full flow capture is basically realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com