Double-head fixing type axial flow fan

An axial flow fan, fixed technology, applied in the direction of axial flow pumps, electromechanical devices, mechanical equipment, etc., can solve the problems of reducing service life, reducing user experience, etc., to achieve improved stability, strong space stability, and excellent vibration and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The content of the present invention will be further described in detail below in conjunction with specific embodiments:

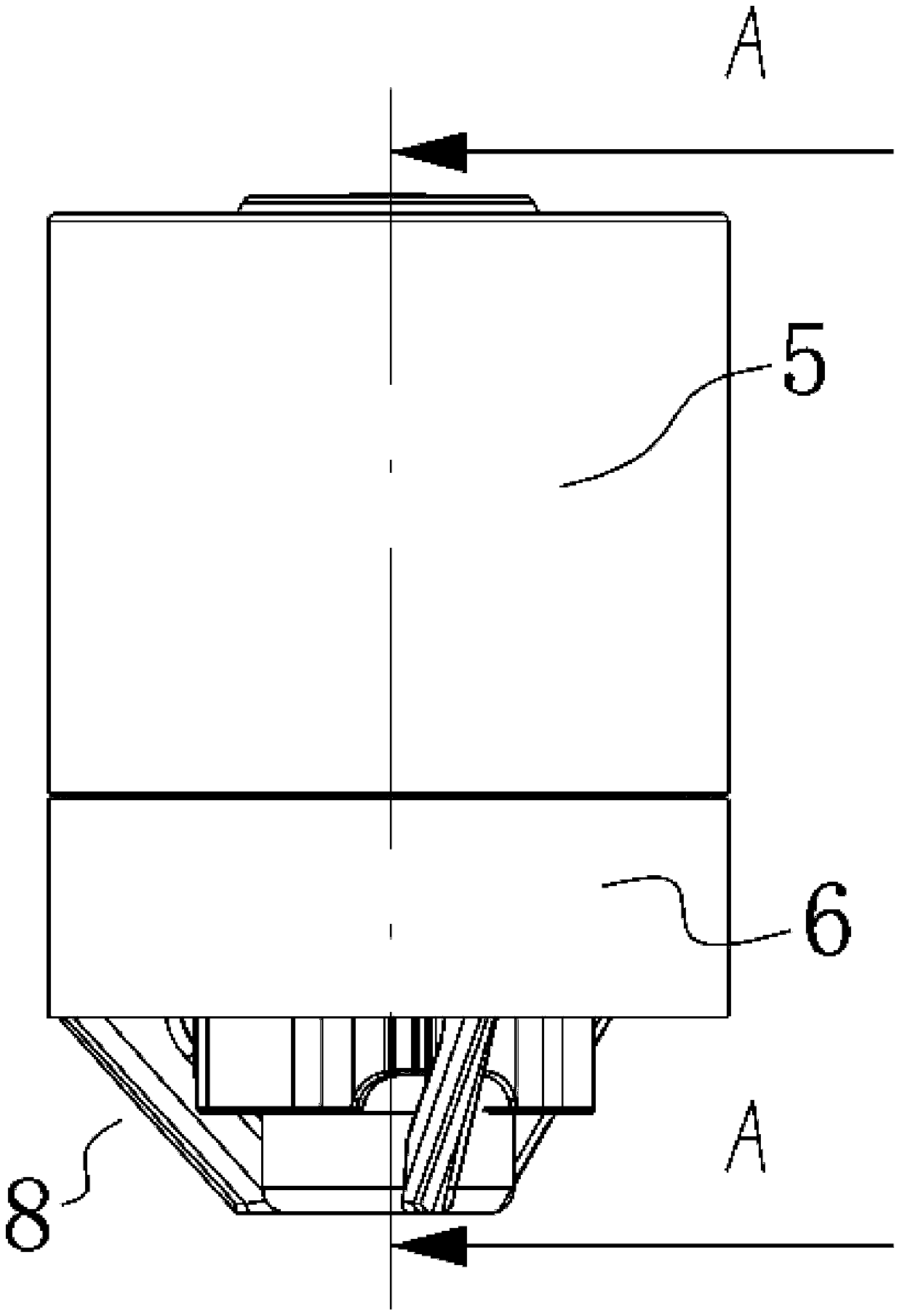

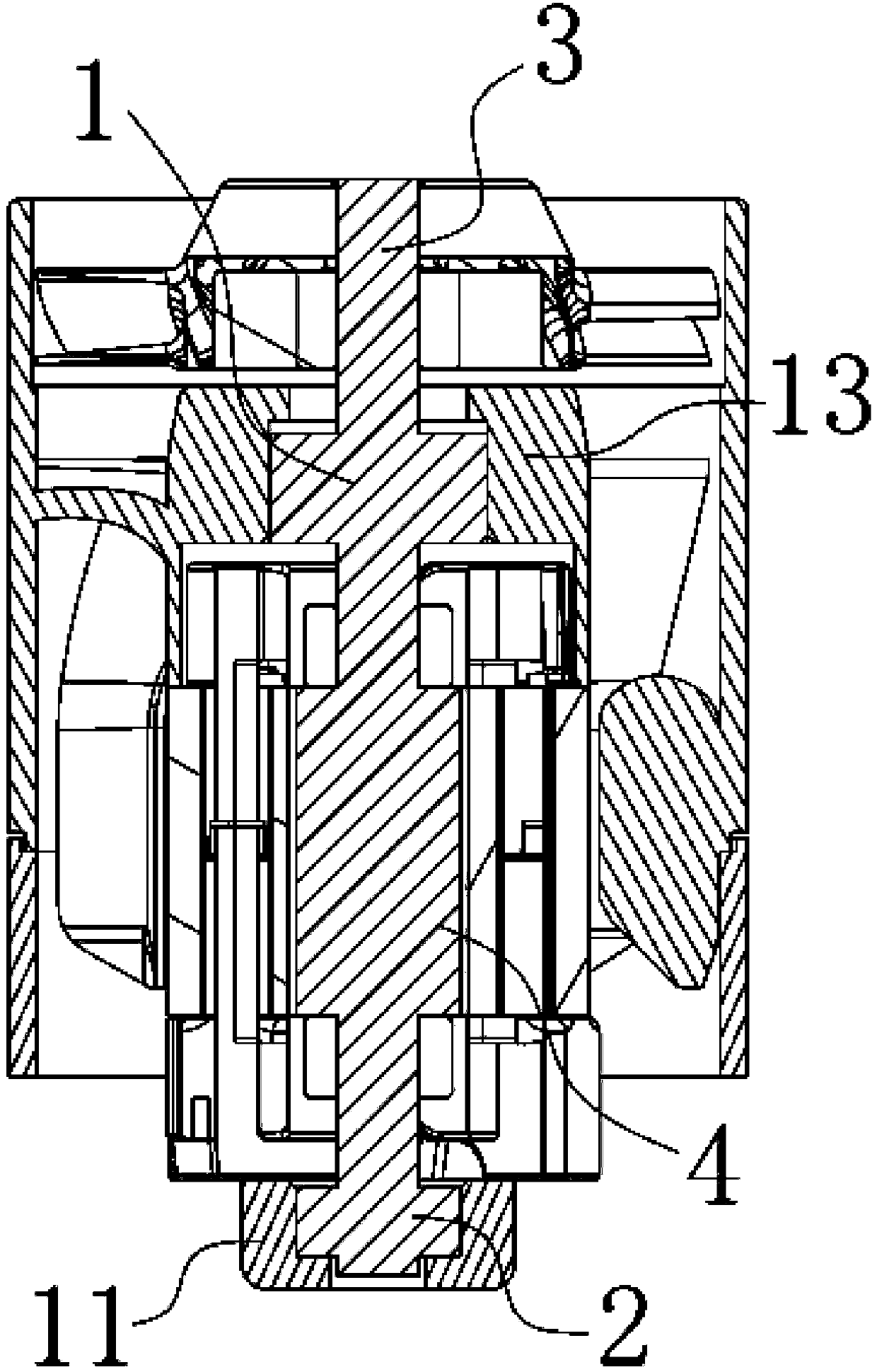

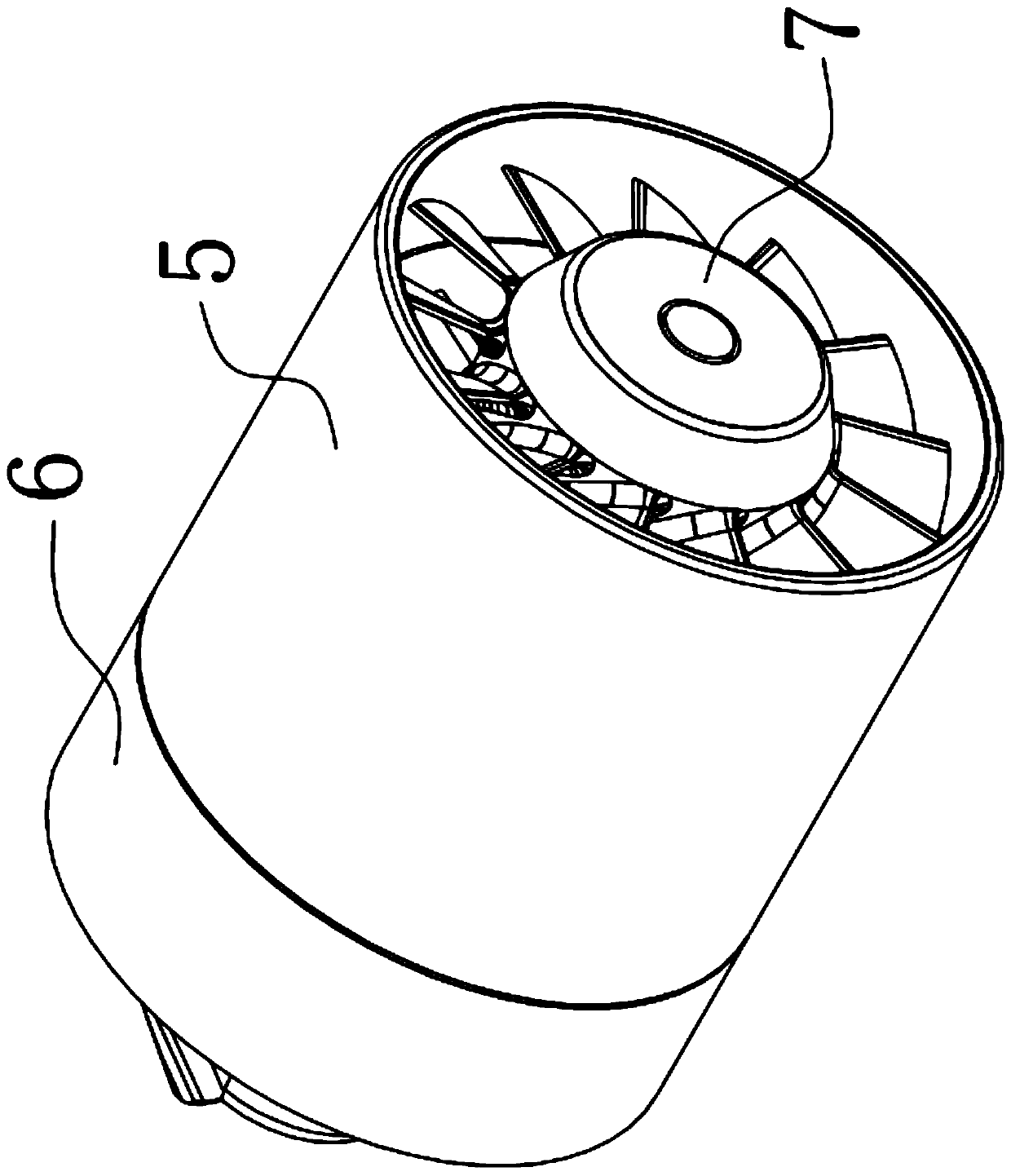

[0041] In order to achieve the purpose of the present invention, a double-head fixed axial flow fan includes: a motor body with a rotating shaft 3 that outputs rotational power; the motor body includes a stator 17 and a rotor 4; a fan blade 7 assembled with one end of the rotating shaft 3; The fixed bearing includes a head end bearing 1 and a tail end bearing 2 respectively arranged at the two shaft ends of the rotor 4. The head end bearing 1, the tail end bearing 2 and the shaft 3 are coaxially fixed; the casing is wrapped on the outside of the motor body, and the head end bearing 1. The end bearing 2 is respectively wrapped by the first wrapping ring 13 and the tail wrapping ring 11. The first wrapping ring 13 and the tail wrapping ring 11 are respectively fixed to the casing by the deflector 14 and the connecting rib 8 between adjacent connecting rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com