Patents

Literature

431results about How to "Easy to disassemble and overhaul" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

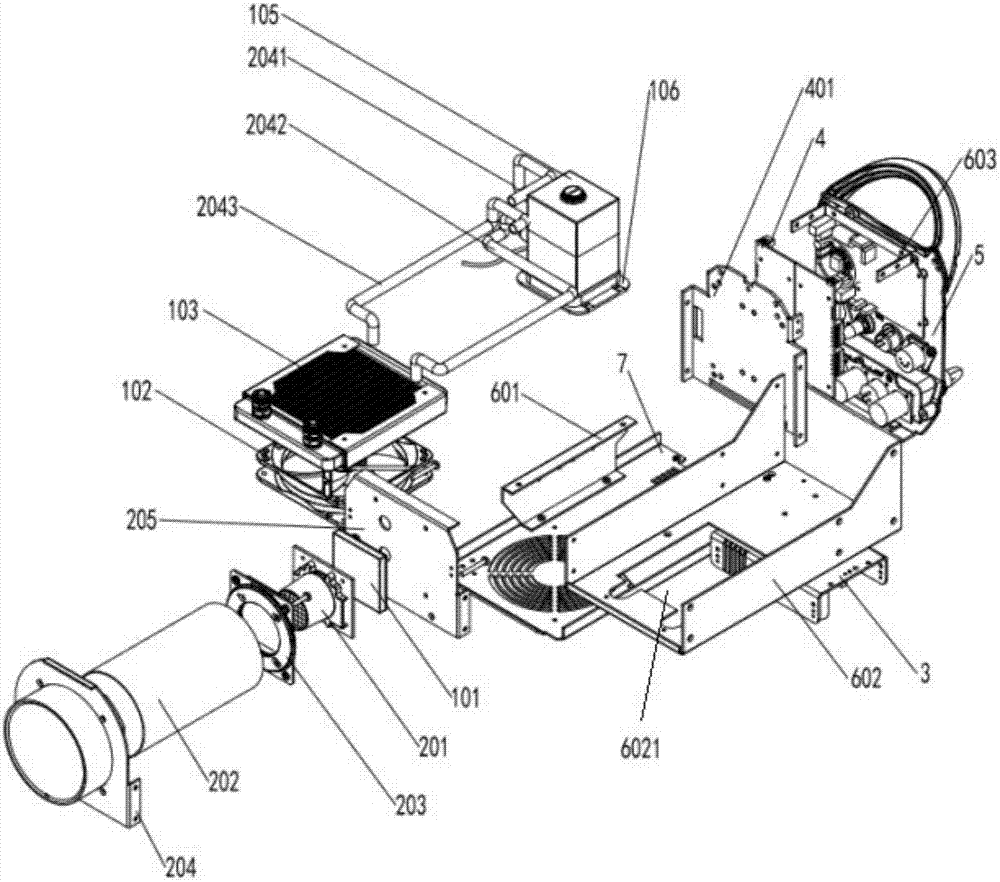

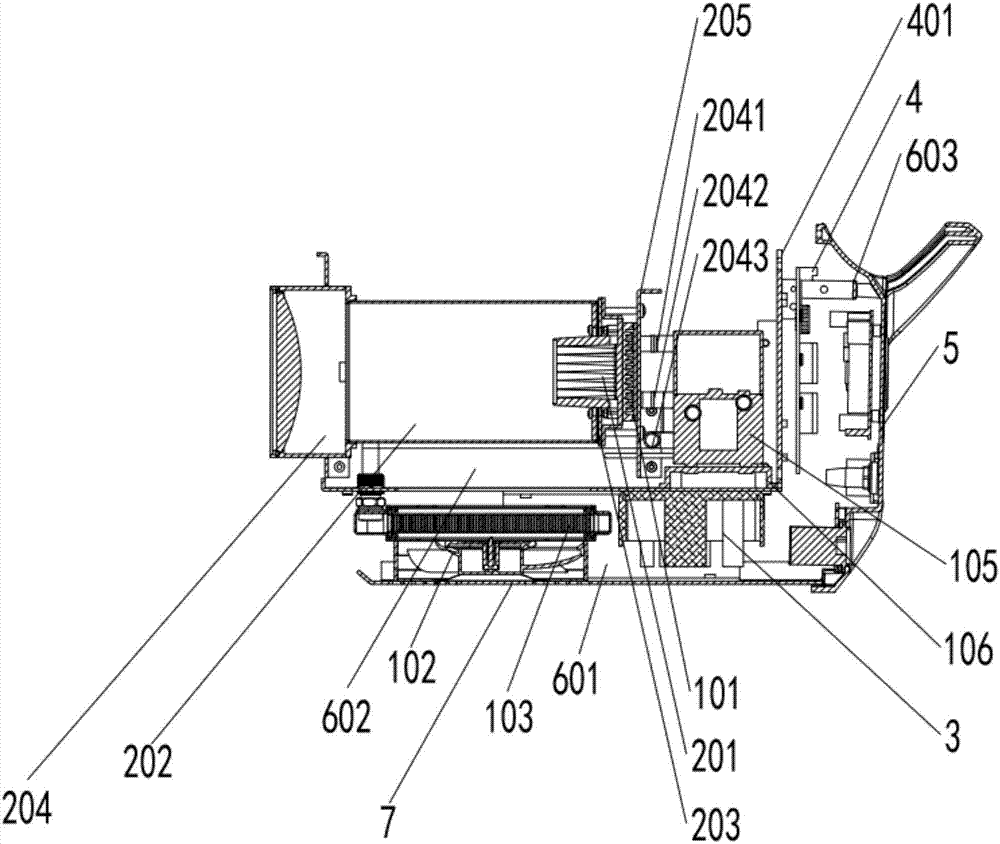

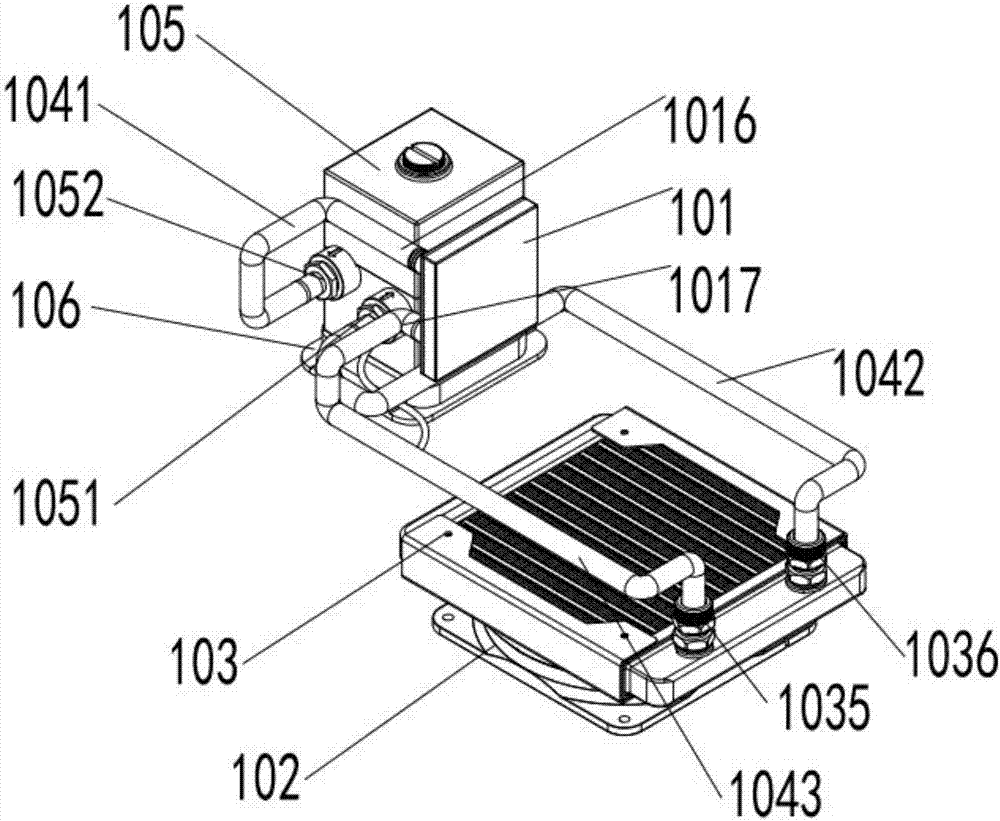

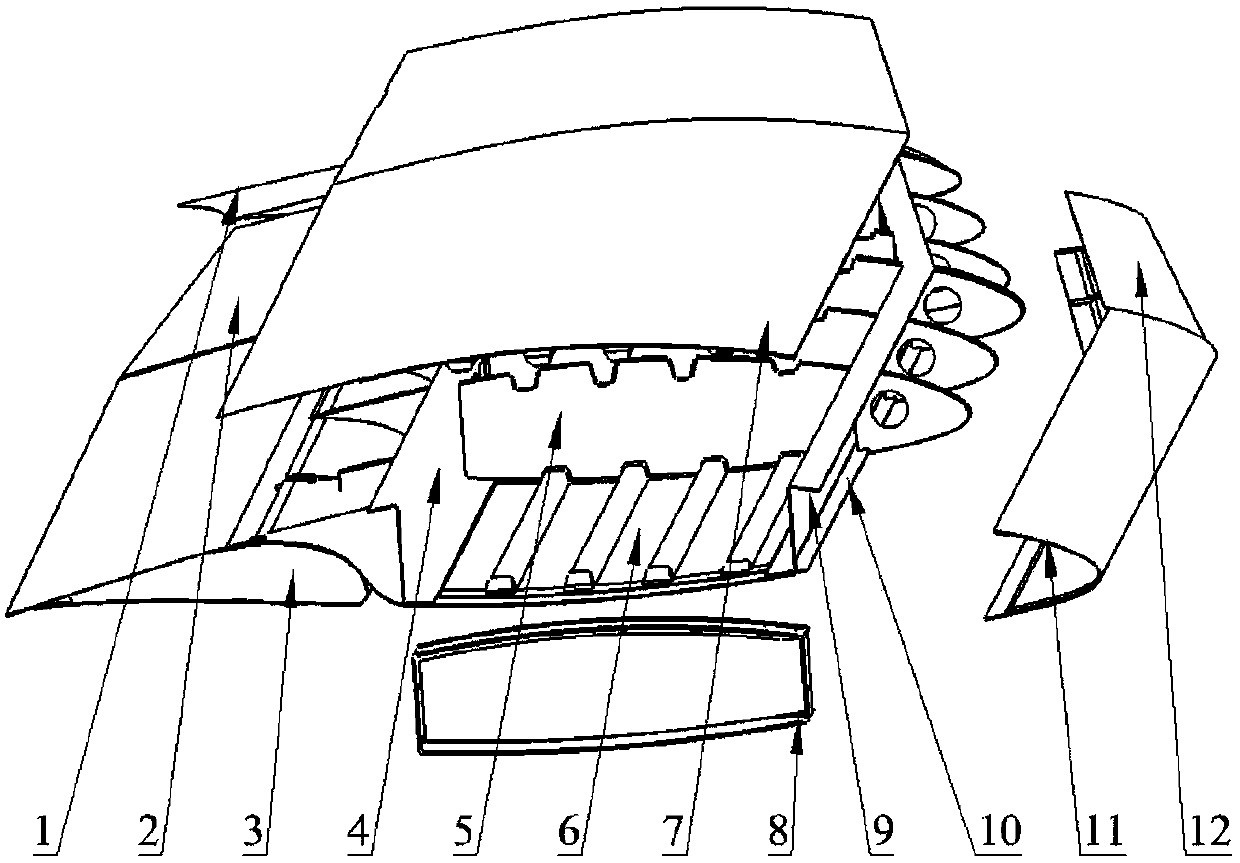

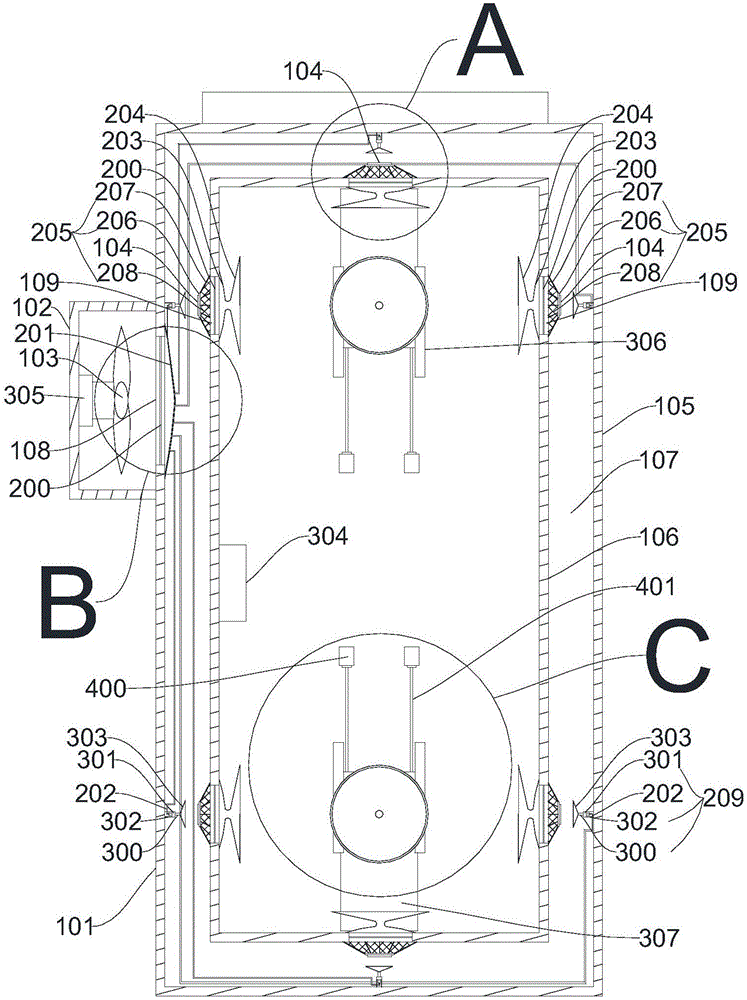

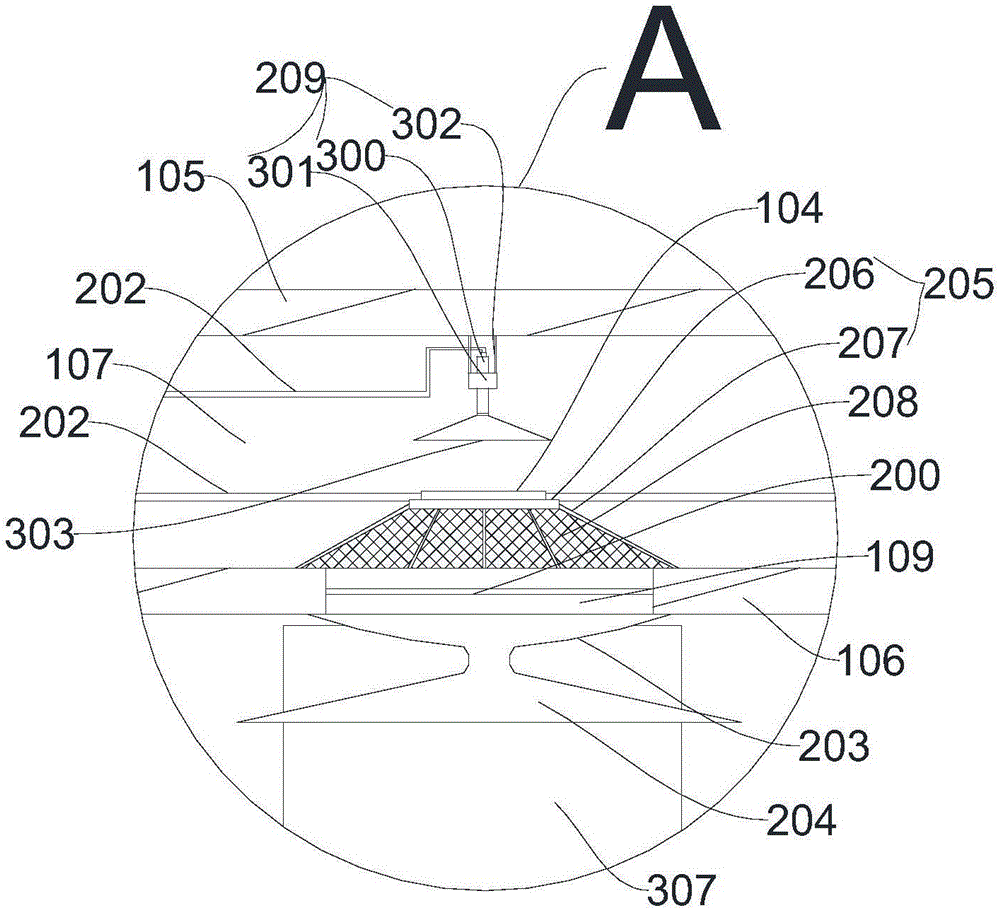

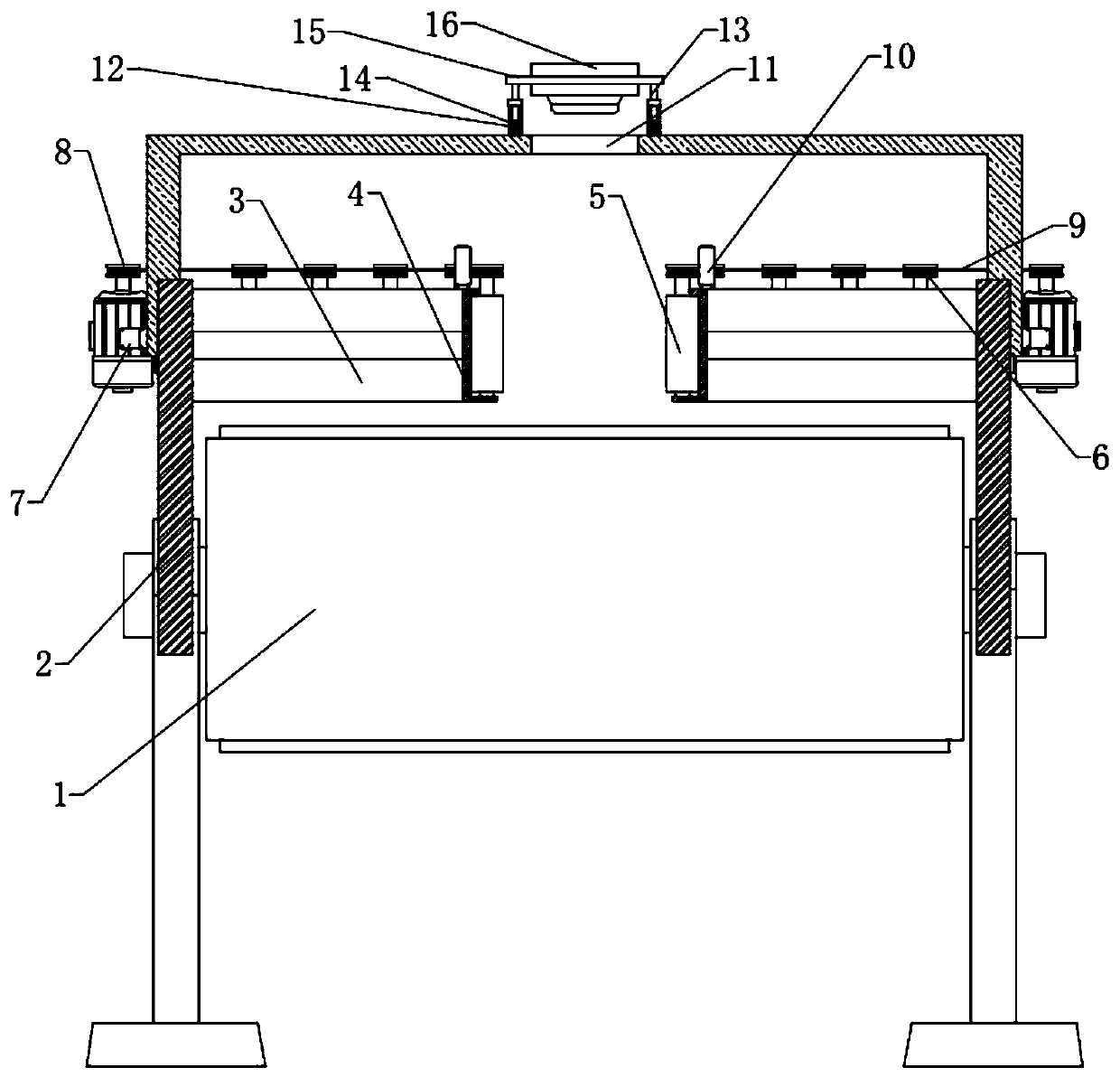

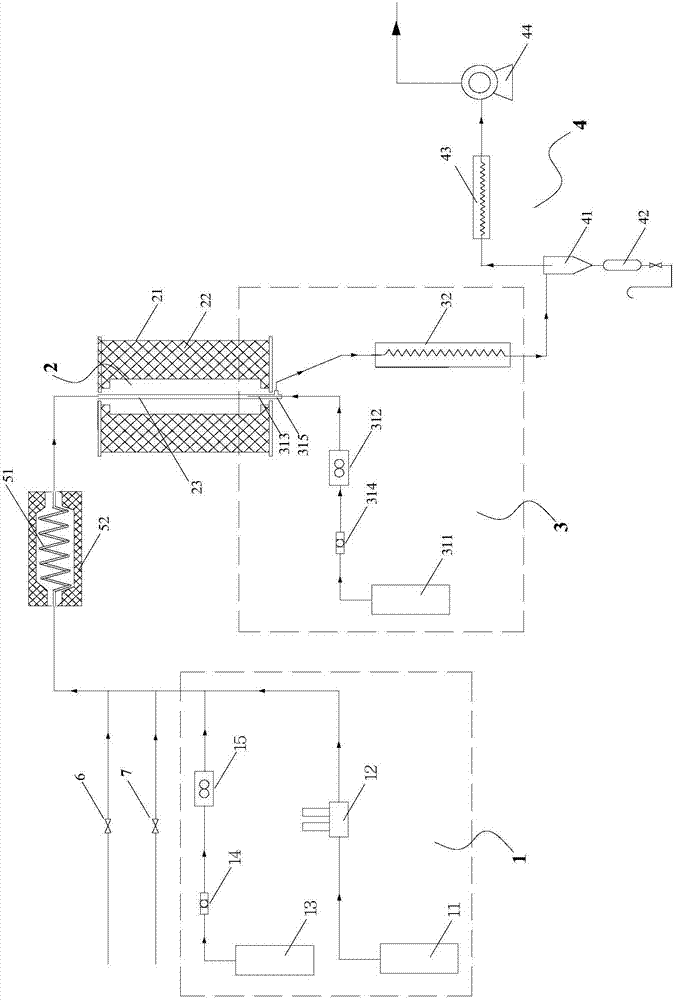

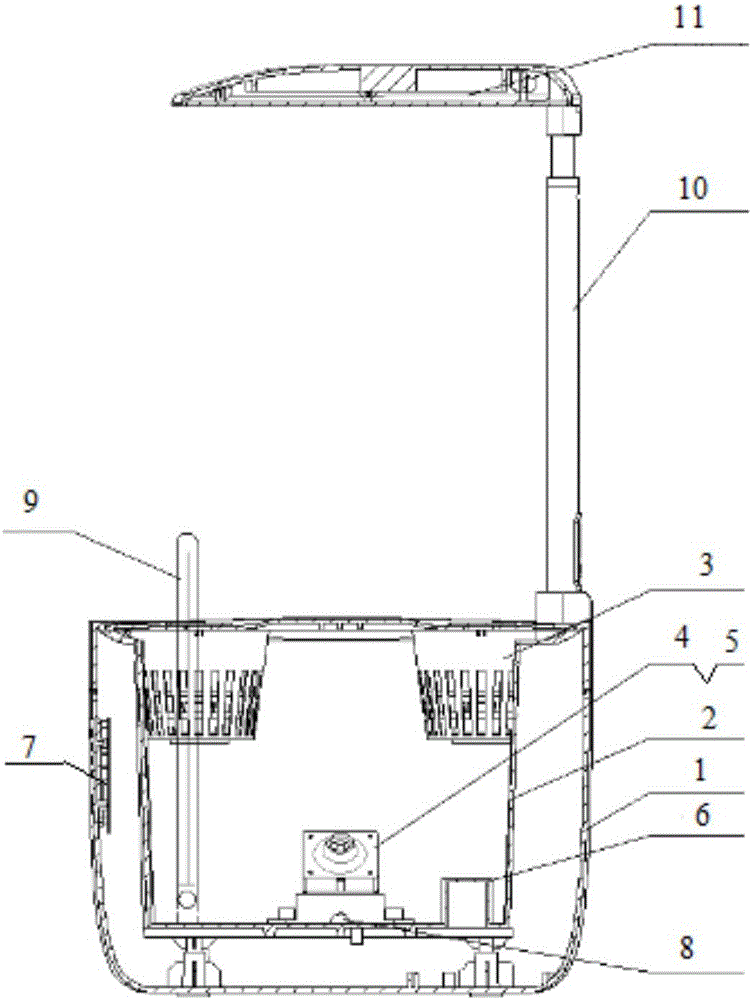

High-power LED optical path heat dissipation combined system

ActiveCN107091467AImprove cooling efficiencySave spaceLighting heating/cooling arrangementsProtective devices for lightingThermodynamicsCirculator pump

The invention provides a high-power LED optical path heat dissipation combined system. The system comprises an optical path system and a heat dissipation system; the heat dissipation system is a liquid cooling and air cooling combined heat dissipation system, and specifically comprises a heat absorbing device, a liquid cooling radiator, a fan, liquid cooling pipelines and a liquid circulating pump; the fan is fixedly mounted at the bottom of the liquid cooling radiator to form a liquid cooling and air cooling heat dissipation module; and the liquid circulating pump, the heat absorbing device and the liquid cooling radiator are connected through multiple liquid cooling pipelines to form a closed circulating loop. The liquid cooling heat dissipation system is applied to cool an LED light source, and is combined with the air cooling heat dissipation system to cool the LED light source, so that the heat dissipation efficiency can be improved, meanwhile, the space can be saved to a greater extent, and the design cost is reduced; and the system has the characteristics of convenience in disassembly and maintenance, high optical effect, low cost, excellent heat dissipation capacity and long service life.

Owner:HUNAN MINGHE OPTO TECH

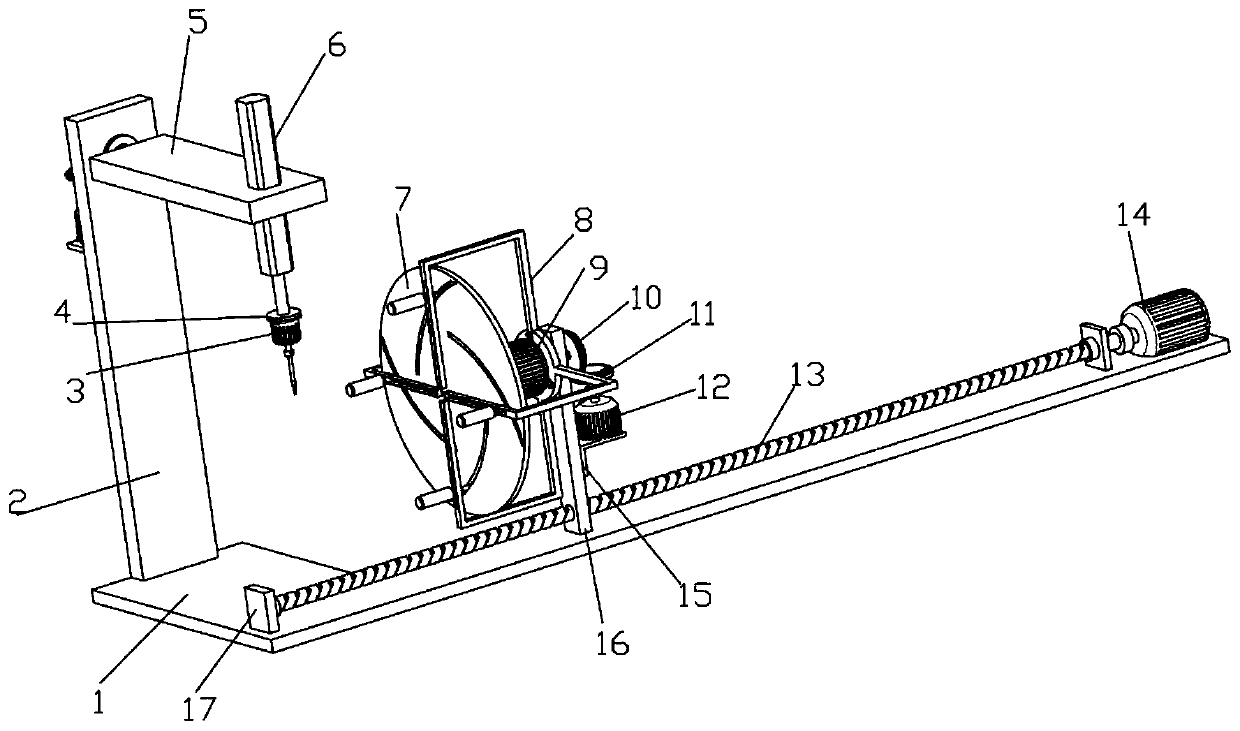

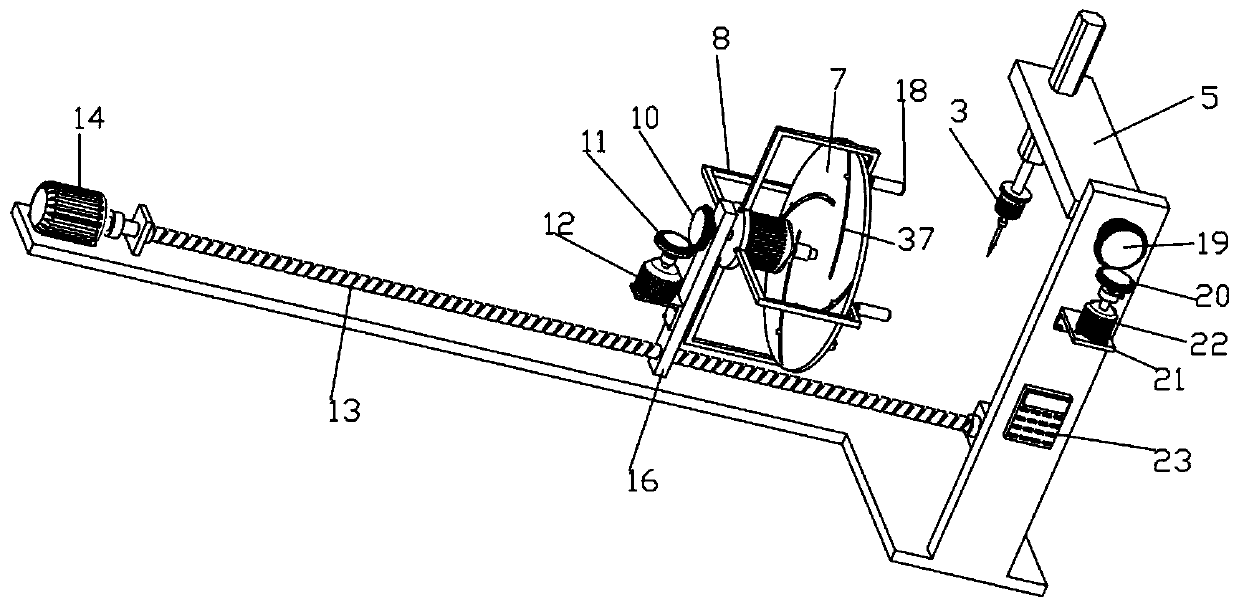

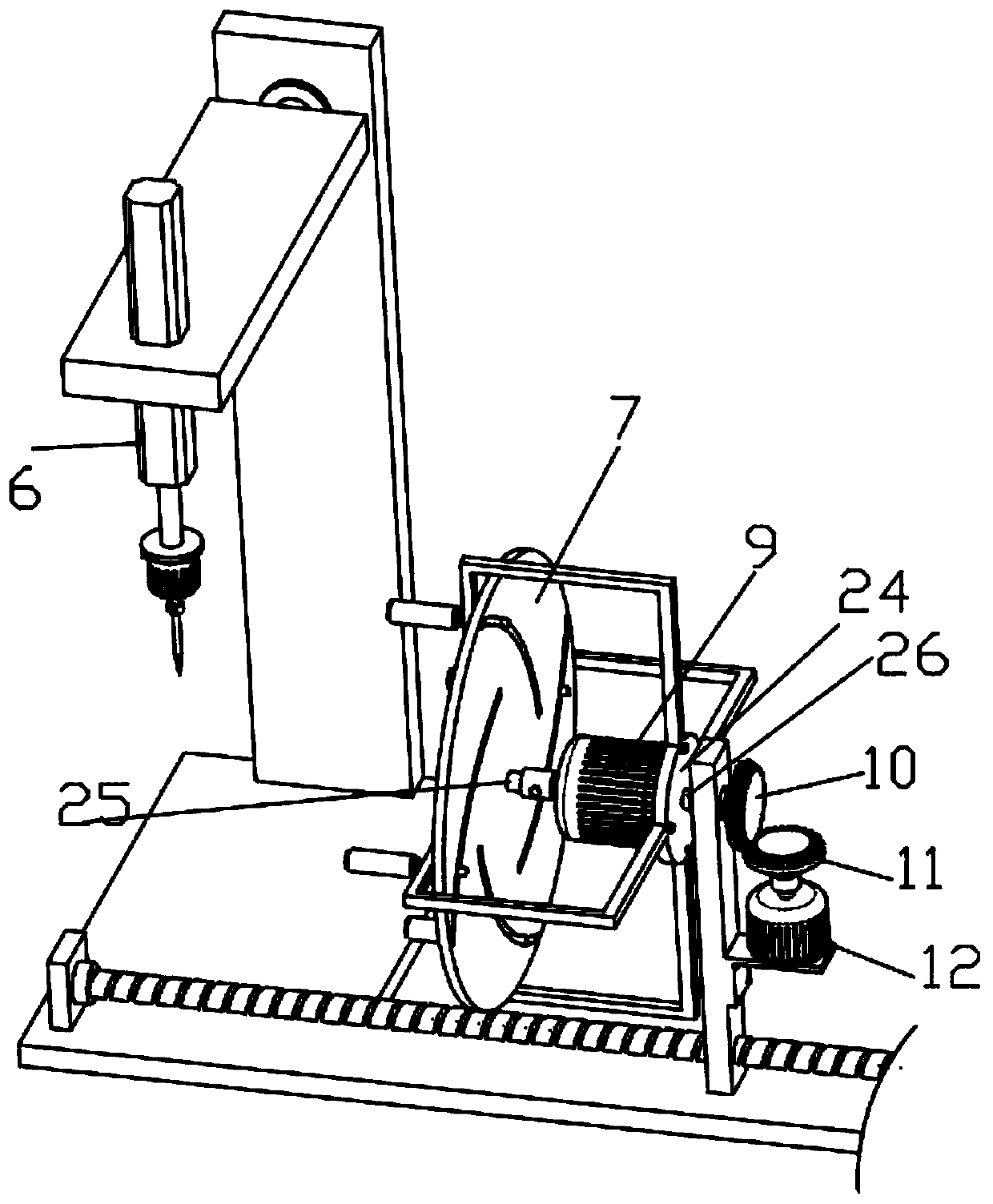

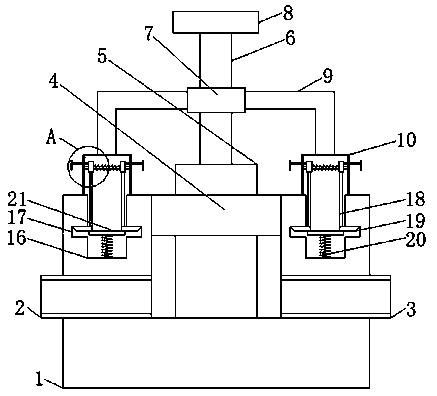

Pipe fitting machining device for electromechanical machining and machining method of pipe fitting machining device

PendingCN111468762AEasy to adjustEasy to drillWork clamping meansPositioning apparatusCircular discElectric machine

The invention relates to the technical field of electromechanical integration, in particular to a pipe fitting machining device for electromechanical machining. The device comprises an L-shaped bottomplate, the L-shaped bottom plate is provided with a straight plate, a driving motor and a straight block, the driving motor is provided with a threaded rod, the threaded rod is provided with a sliding plate, the sliding plate is provided with a second rotating rod, the second rotating rod is provided with a first bevel gear, a second rotating motor is provided with a second bevel gear, the secondbevel gear meshes with the first bevel gear, the second rotating rod is provided with a disc, the disc is provided with a clamping structure, the outer wall of the straight plate is connected with anangle adjusting structure for adjusting drilling angle and a controller, the angle adjusting structure is connected with a transverse plate, an electric push rod is fixedly connected in a through hole in the transverse plate, the bottom of the electric push rod is fixedly connected with a mounting plate, and the bottom of the mounting plate is fixedly connected with a drilling motor provided witha drill bit. According to the device, the drilling motor can be conveniently adjusted to the angle needed by drilling, the device can conveniently conduct drilling at different angles, and the adaptability of the device is improved.

Owner:周龙惠

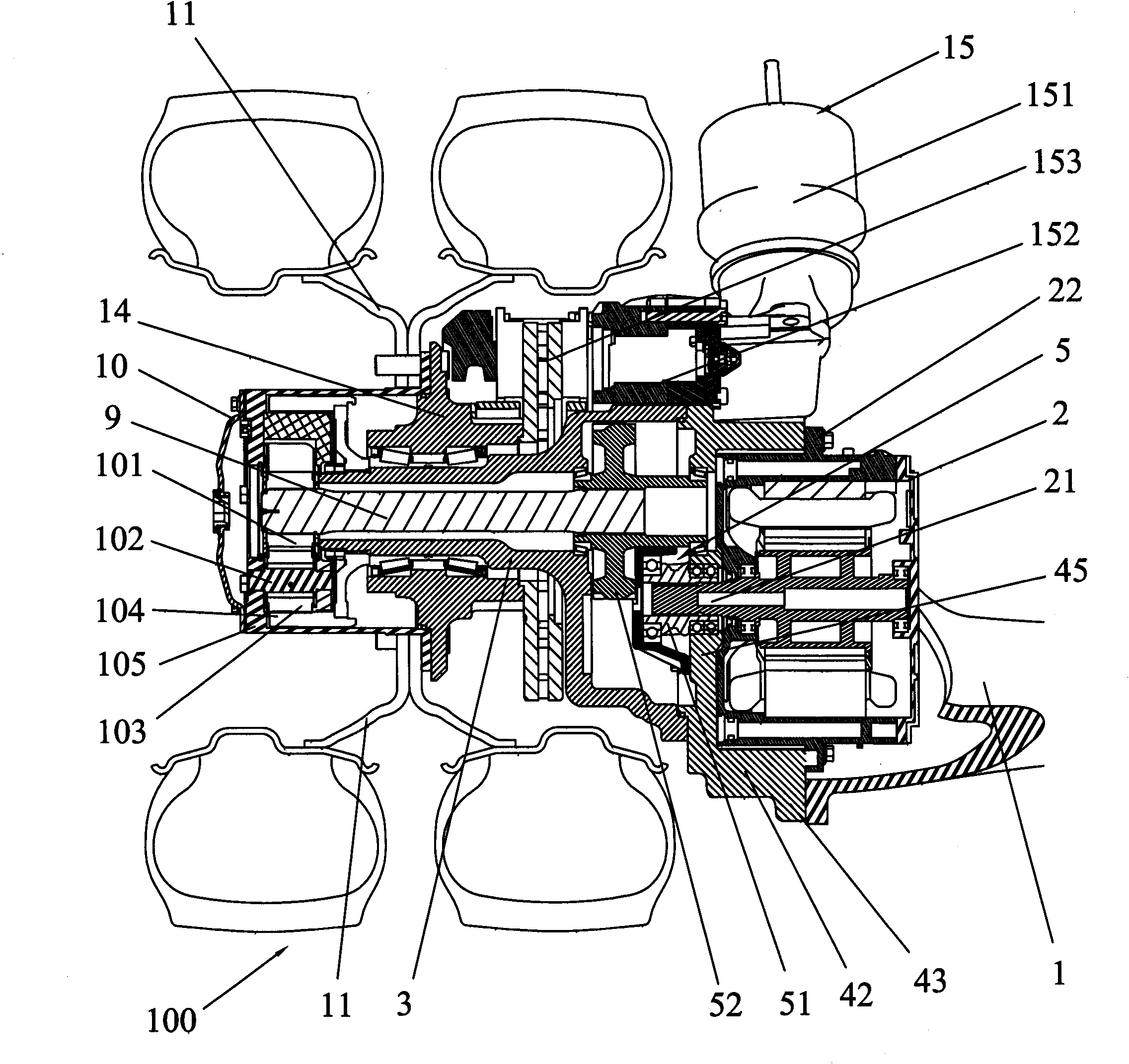

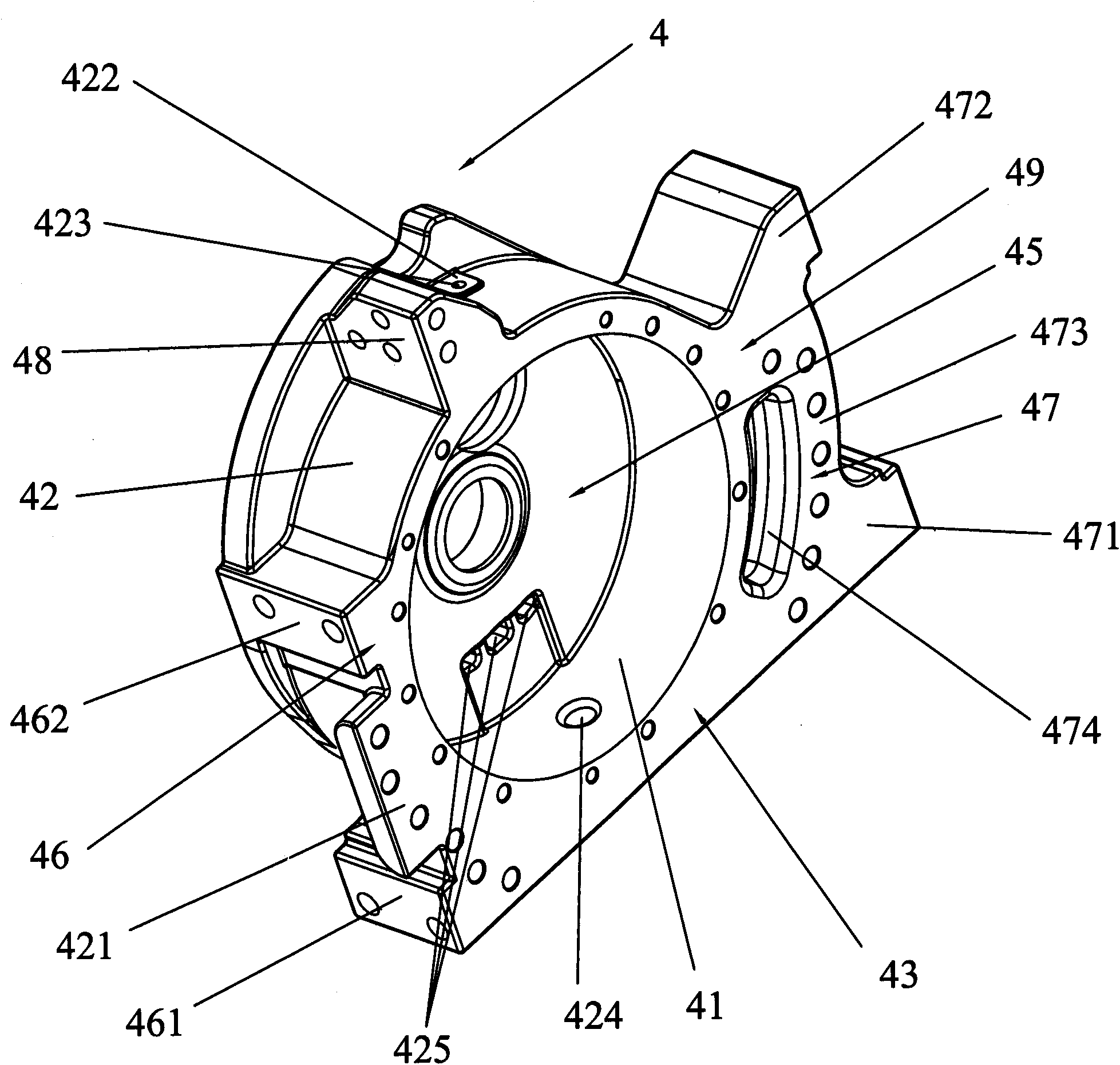

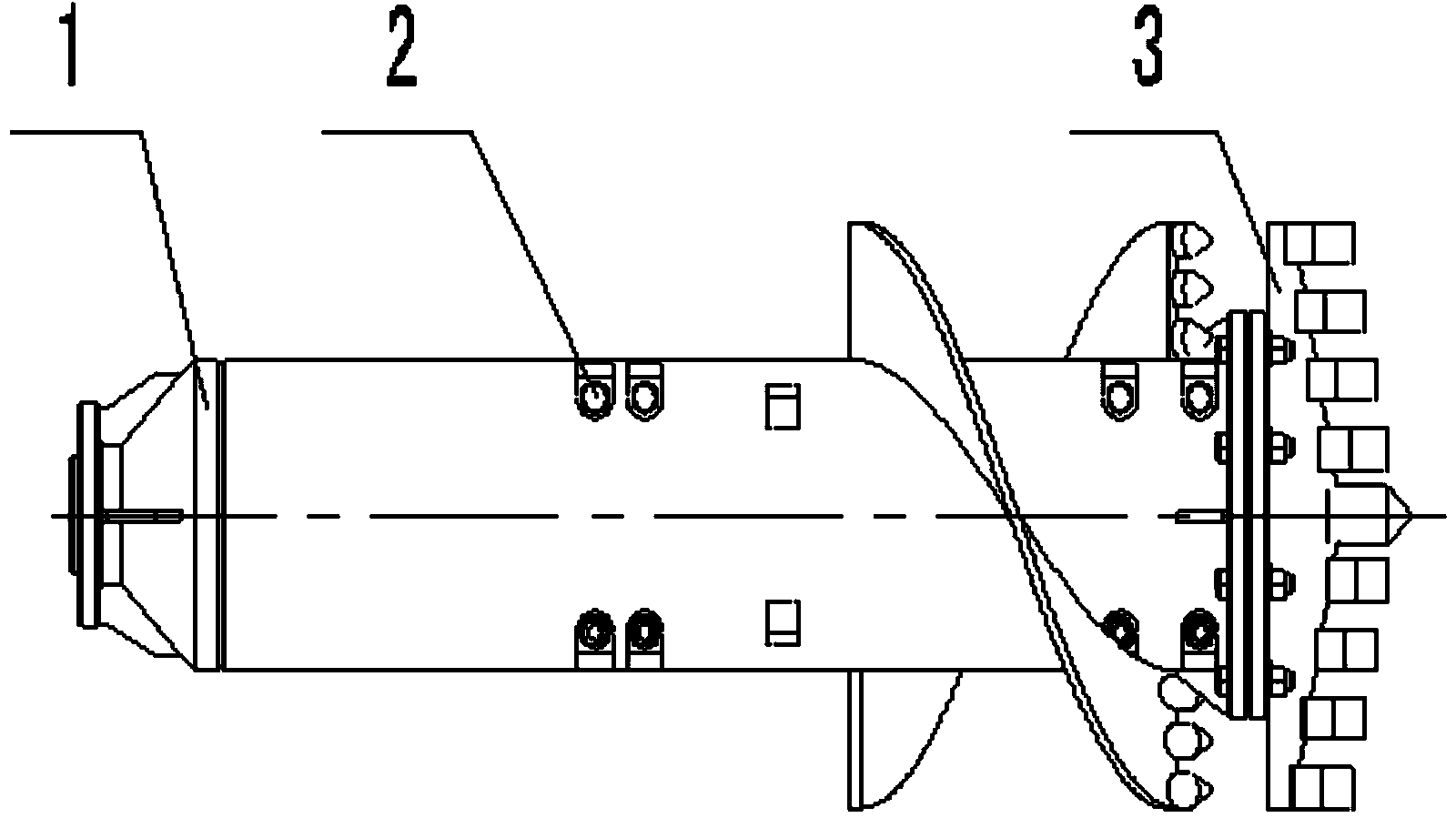

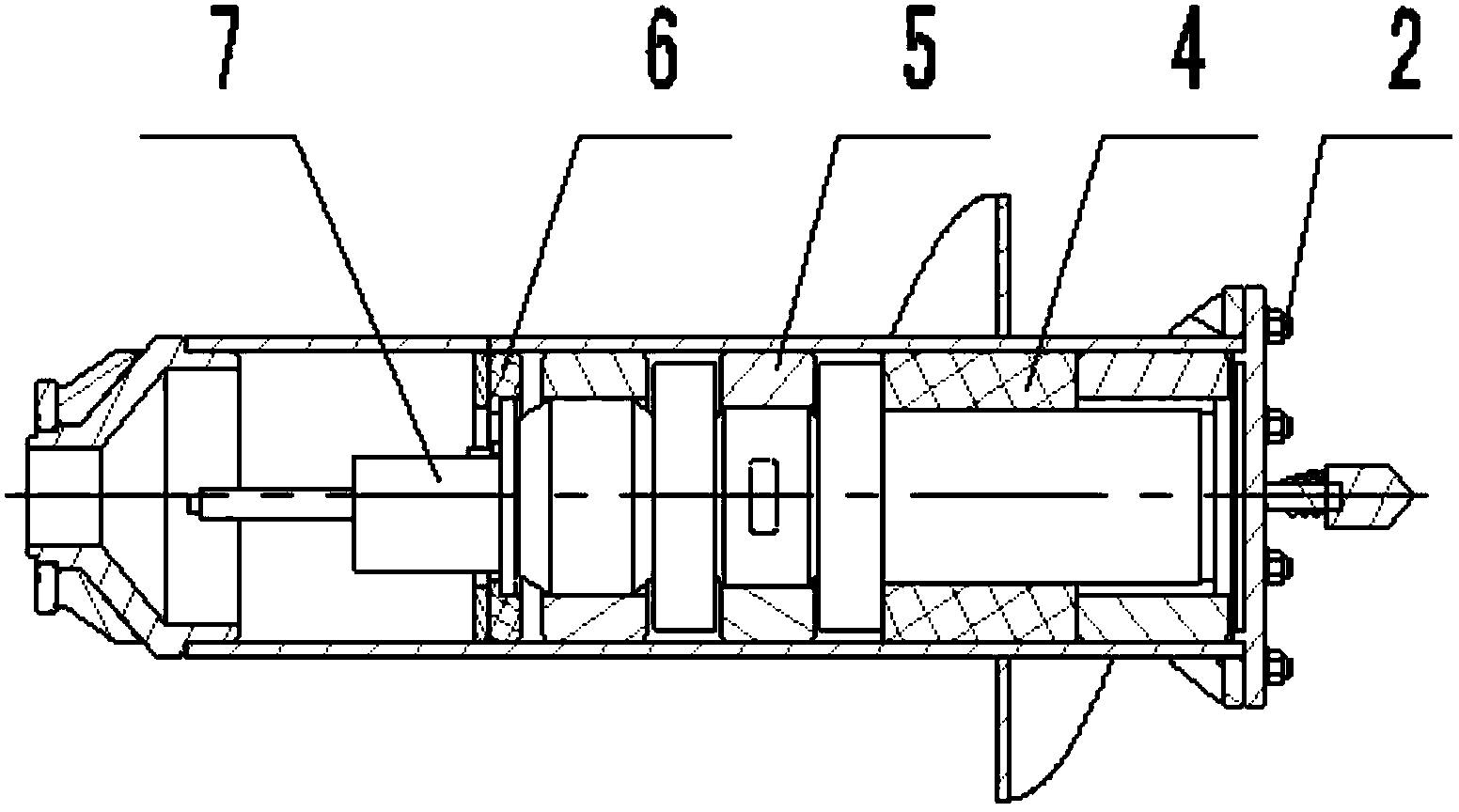

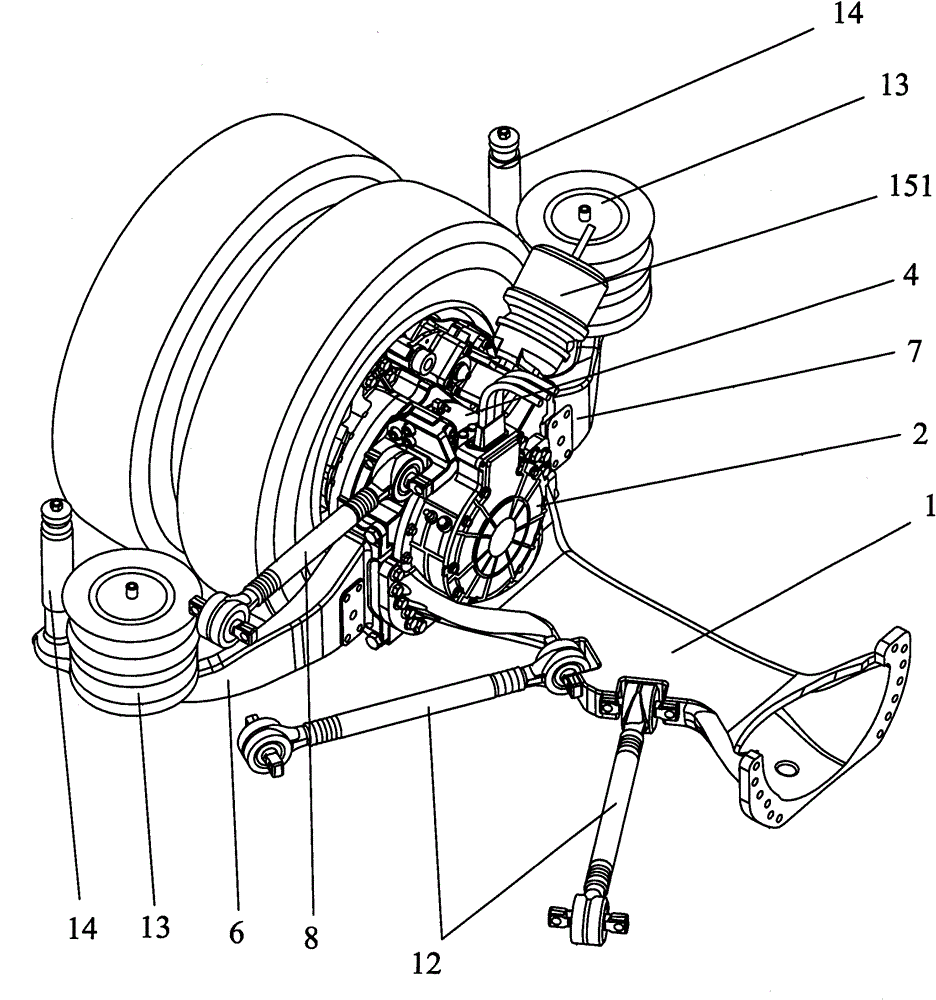

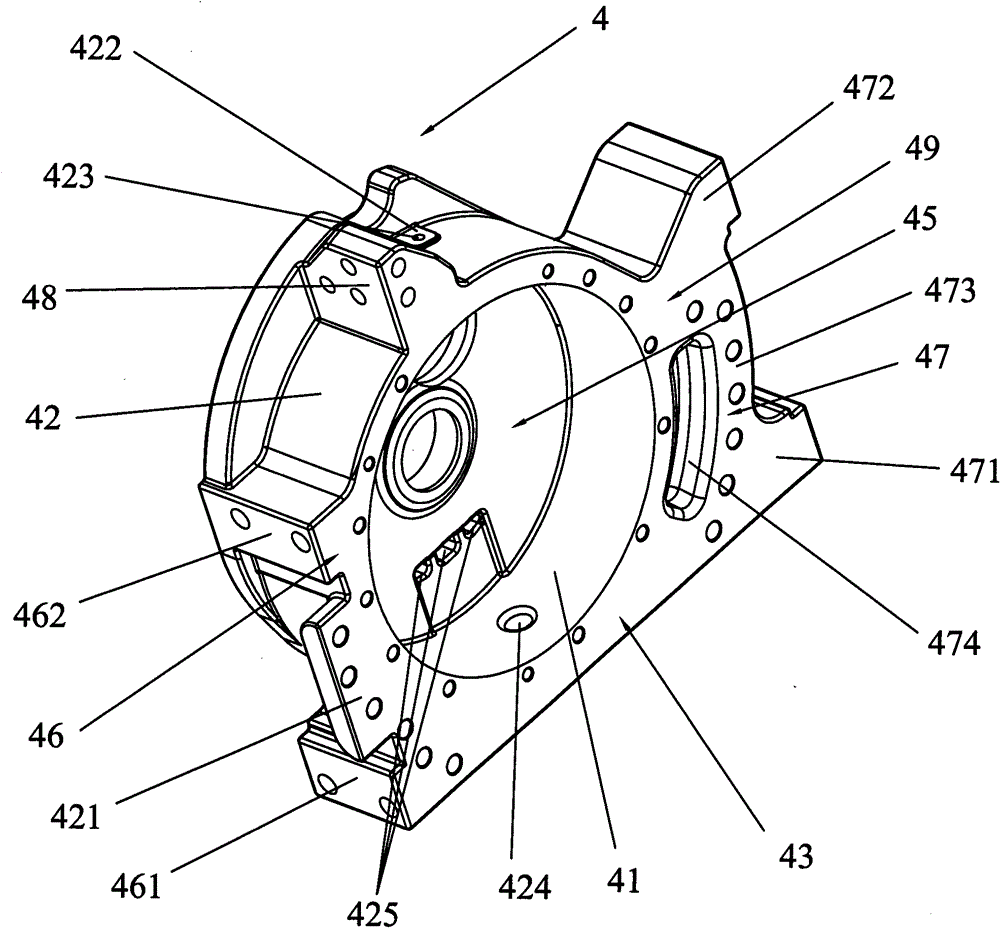

Wheel-side drive axle

ActiveCN102139628AEasy to disassemble and overhaulCompact structureMotor depositionControl devicesAutomotive engineeringElectric machine

The invention provides a wheel-side drive axle which comprises an axle housing and a first wheel-side driving system connected with one end of the axle housing; and the first wheel-side driving system comprises an electric machine and a half-axle casing pipe. The wheel-side drive axle is characterized in that the first wheel-side driving system also comprises an installing seat of the electric machine; one end of the installing seat of the electric machine is fixedly connected with the half-axle casing pipe; the other end of the installing seat of the electric machine is fixedly connected with the axle housing; the installing seat of the electric machine is provided with an inner chamber; an output shaft end of the electric machine is arranged in the inner chamber of the installing seat of the electric machine; and the electric machine is fixedly connected with the installing seat of the electric machine. The wheel-side drive axle is added with the installation seat of the electric machine so that the electric machine can be independently dismantled, and the axle housing does not need to be dismantled simultaneously so as to facilitate the assembling of the electric machine and the later-period disassembling and maintenance of the electric machine.

Owner:BYD CO LTD

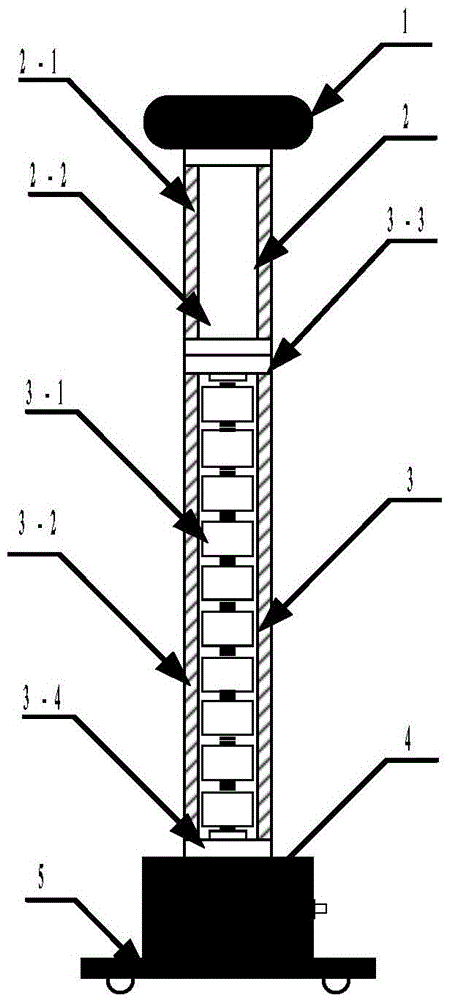

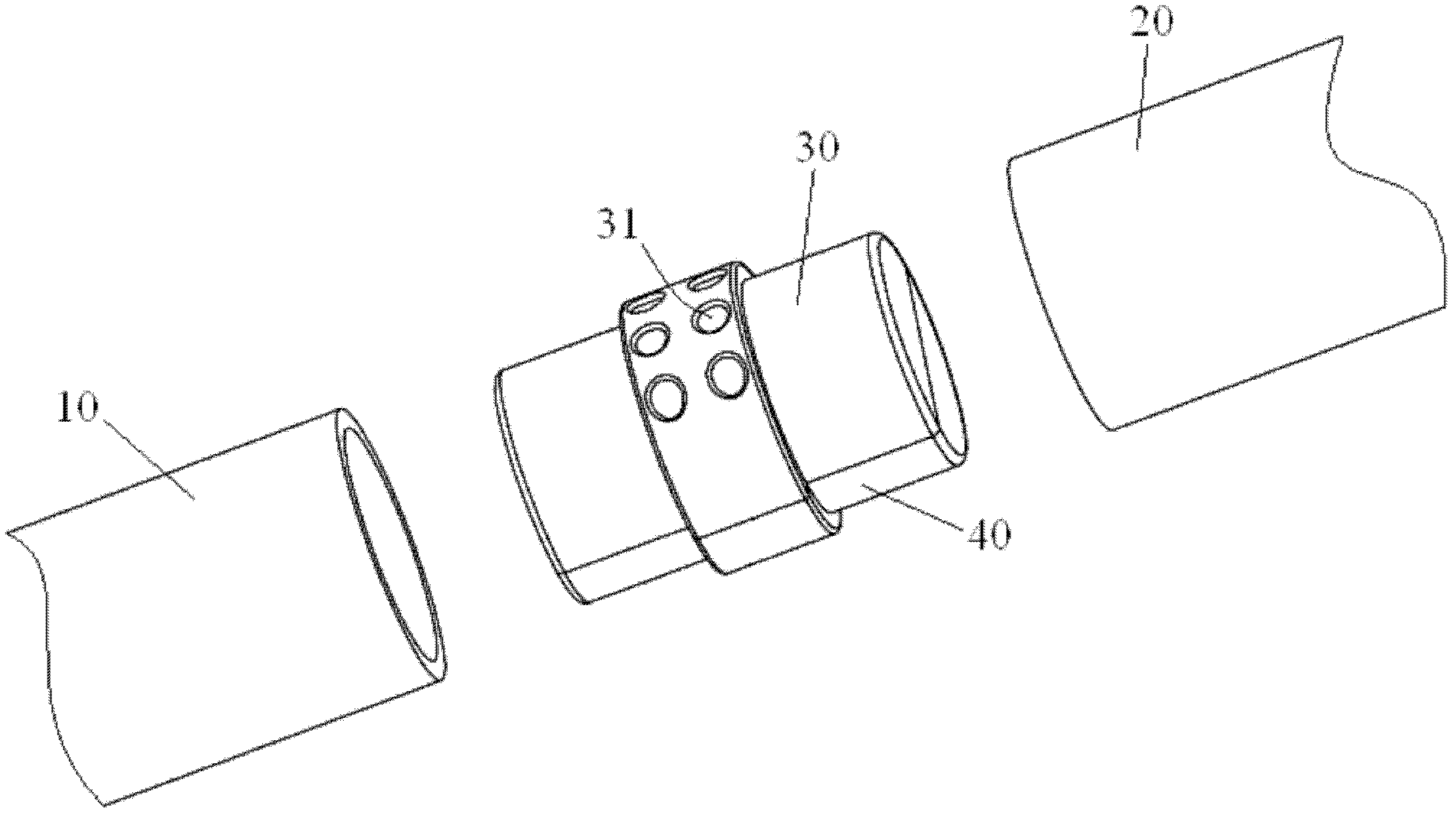

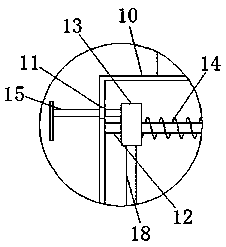

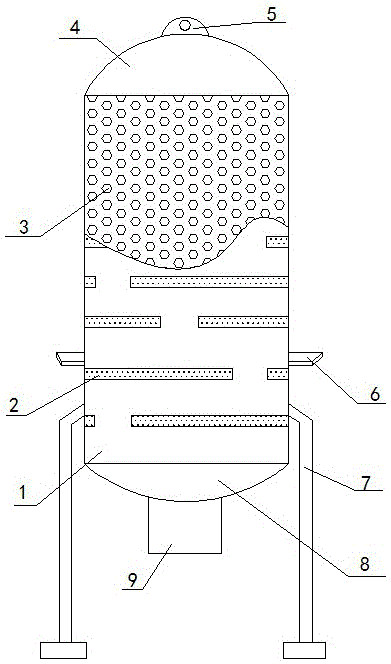

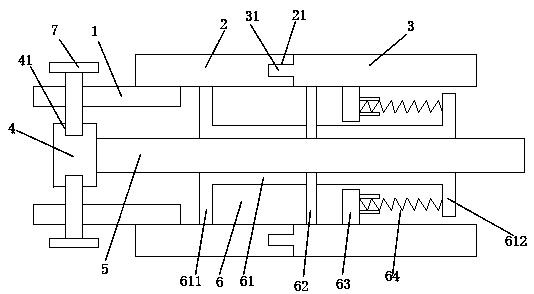

Small modularized resistance-capacitance divider

ActiveCN105629018ASimple structureReduce volumeVoltage dividersCapacitanceElectrical resistance and conductance

The invention provides a small modularized resistance-capacitance divider comprising an equalizing ring 1, a modularized resistor 2, a modularized distributed capacitive post 3, a modularized low voltage measurement system 4 and a base 5. The equalizing ring 1, the modularized resistor 2, the modularized distributed capacitive post 3, the modularized low voltage measurement system 4 and the base 5 are connected in turn. The modularized distributed capacitive post 3 is packaged in an organic glass shell 3-2. The modularized distributed capacitive post 3 is composed of multiple high voltage capacitors 3-1 through series connection, and the upper and lower ends 3-3 and 3-4 are metal covers. The modularized low voltage measurement system 4 is installed on the metal base 5. According to the small modularized resistance-capacitance divider, a modularized structure is adopted so that the divider is enabled to be simplified in structure and reduced in size and convenient for disassembling, adjustment and replacement of single modules, the measurement range of the divider is enabled to be easy to change to meet different experimental requirements, and disassembling, repair and maintenance are facilitated when faults occur.

Owner:STATE GRID CORP OF CHINA +3

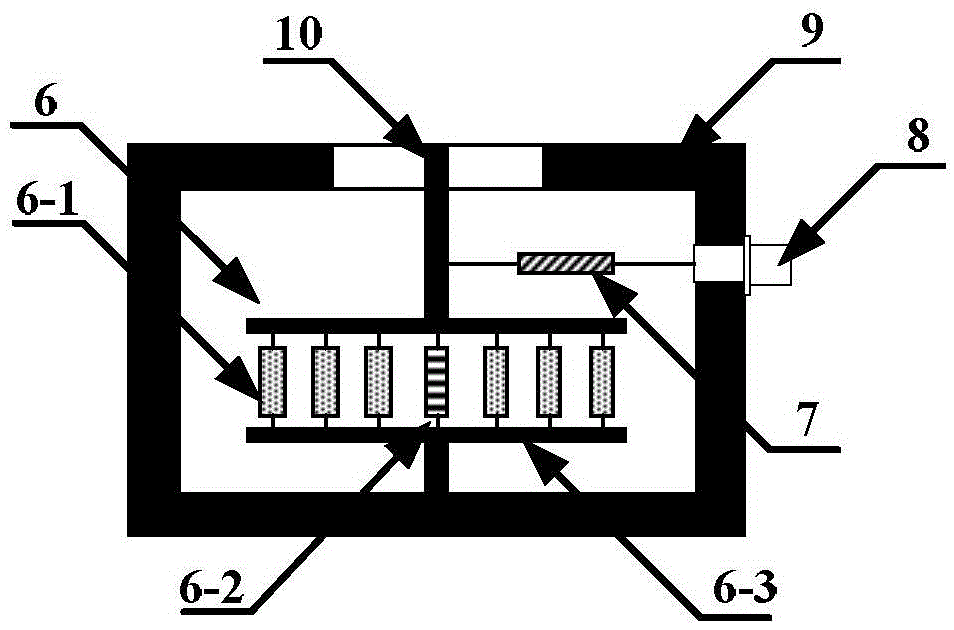

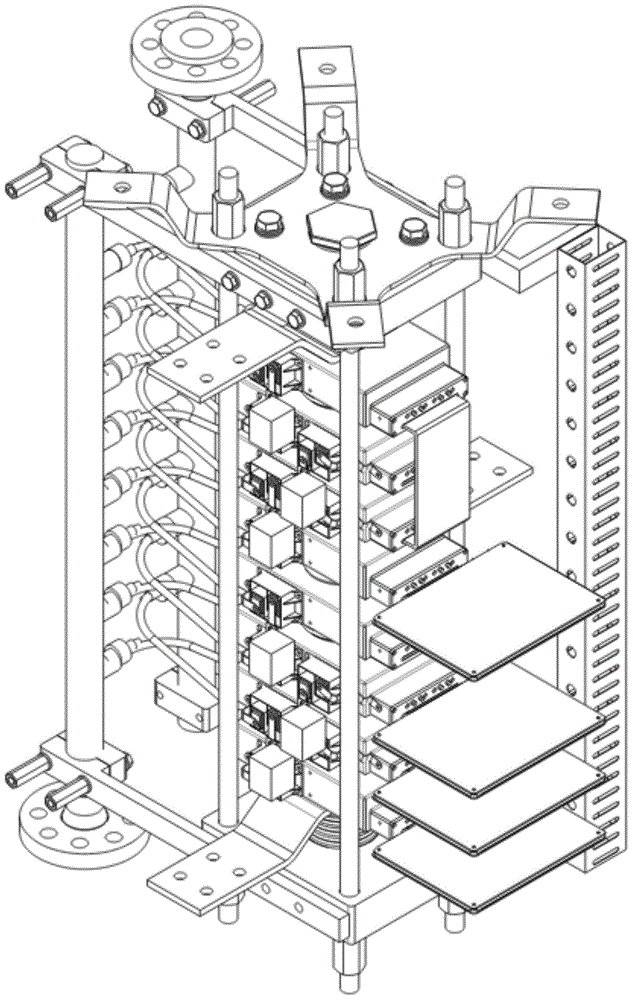

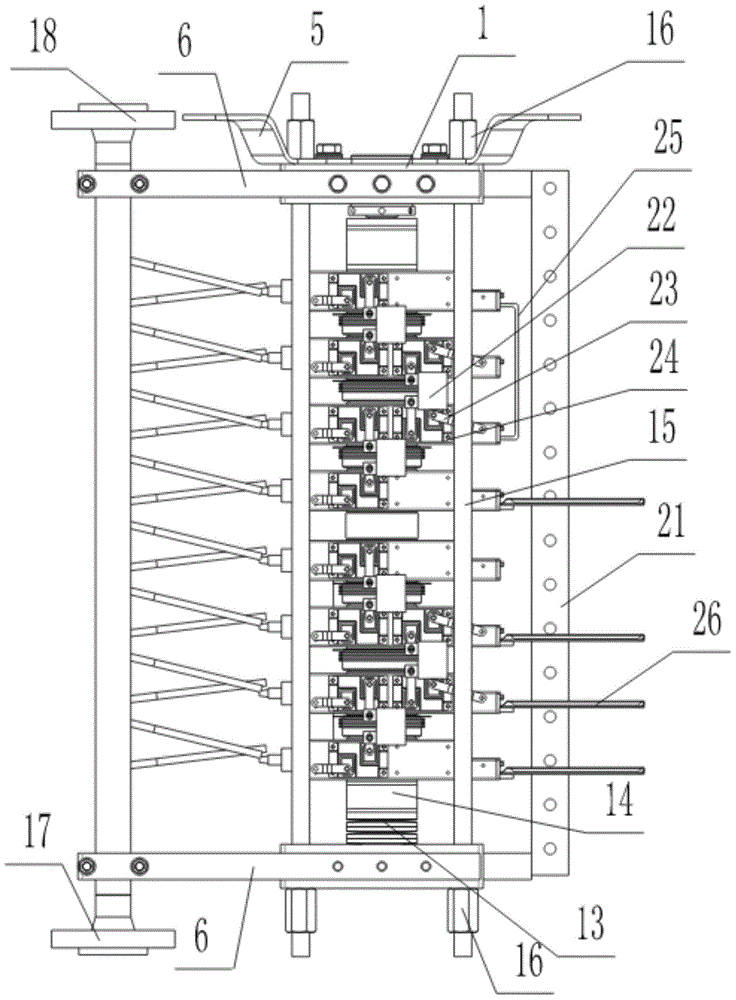

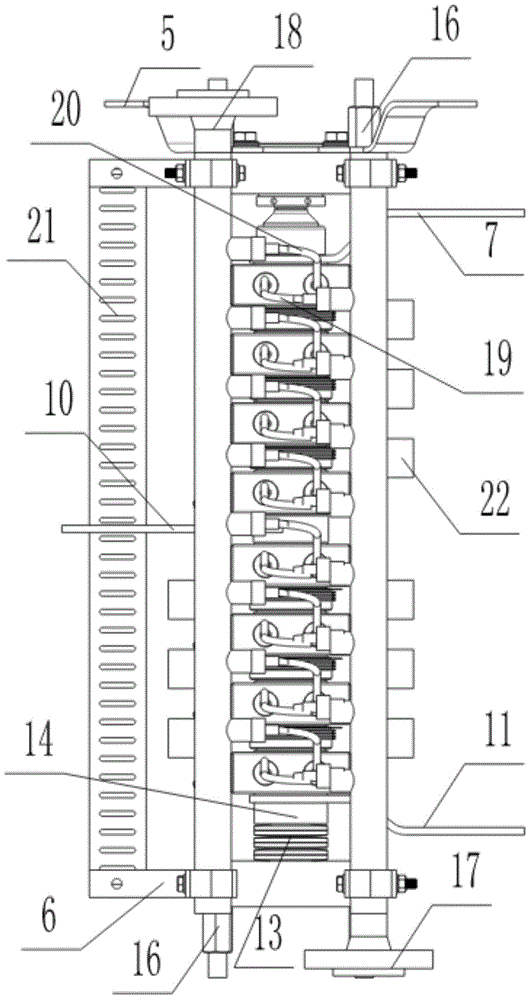

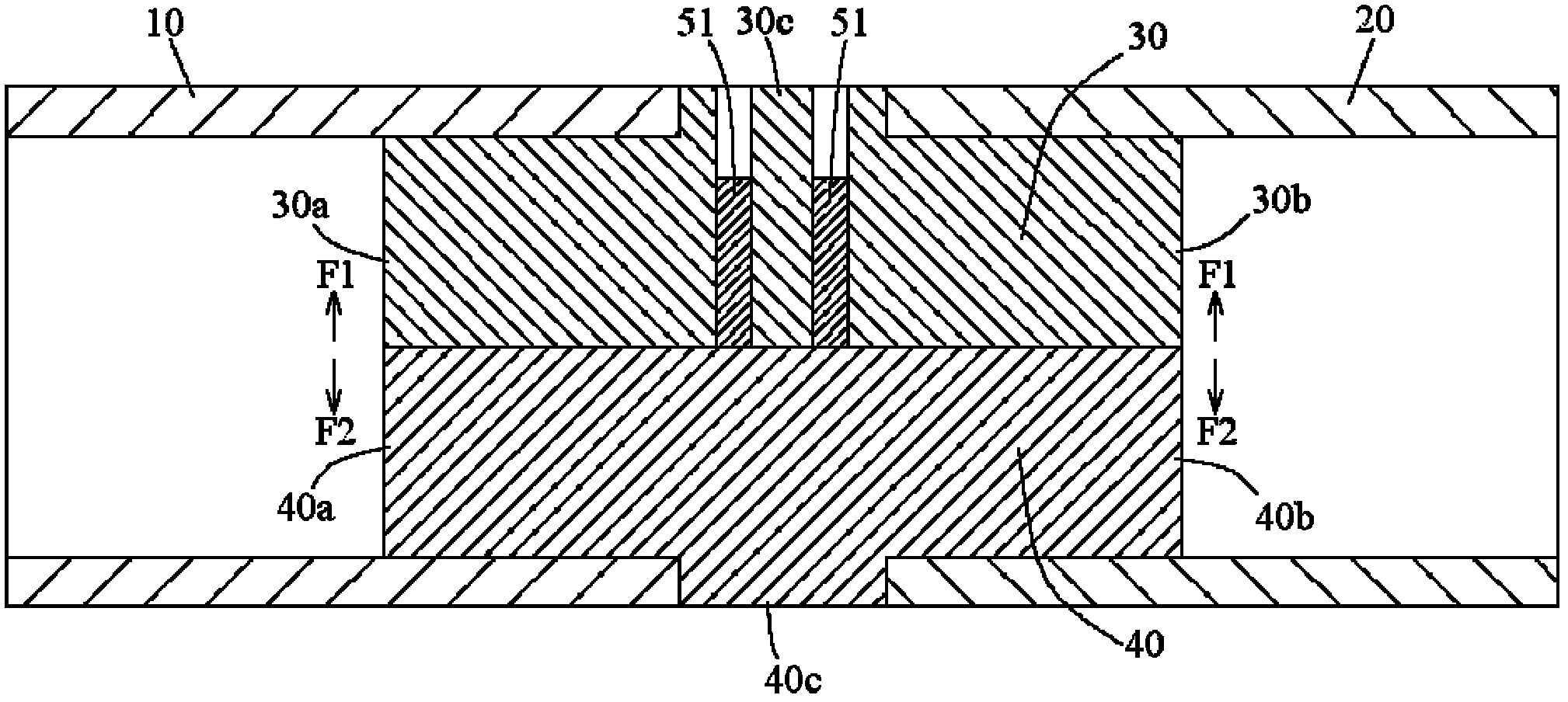

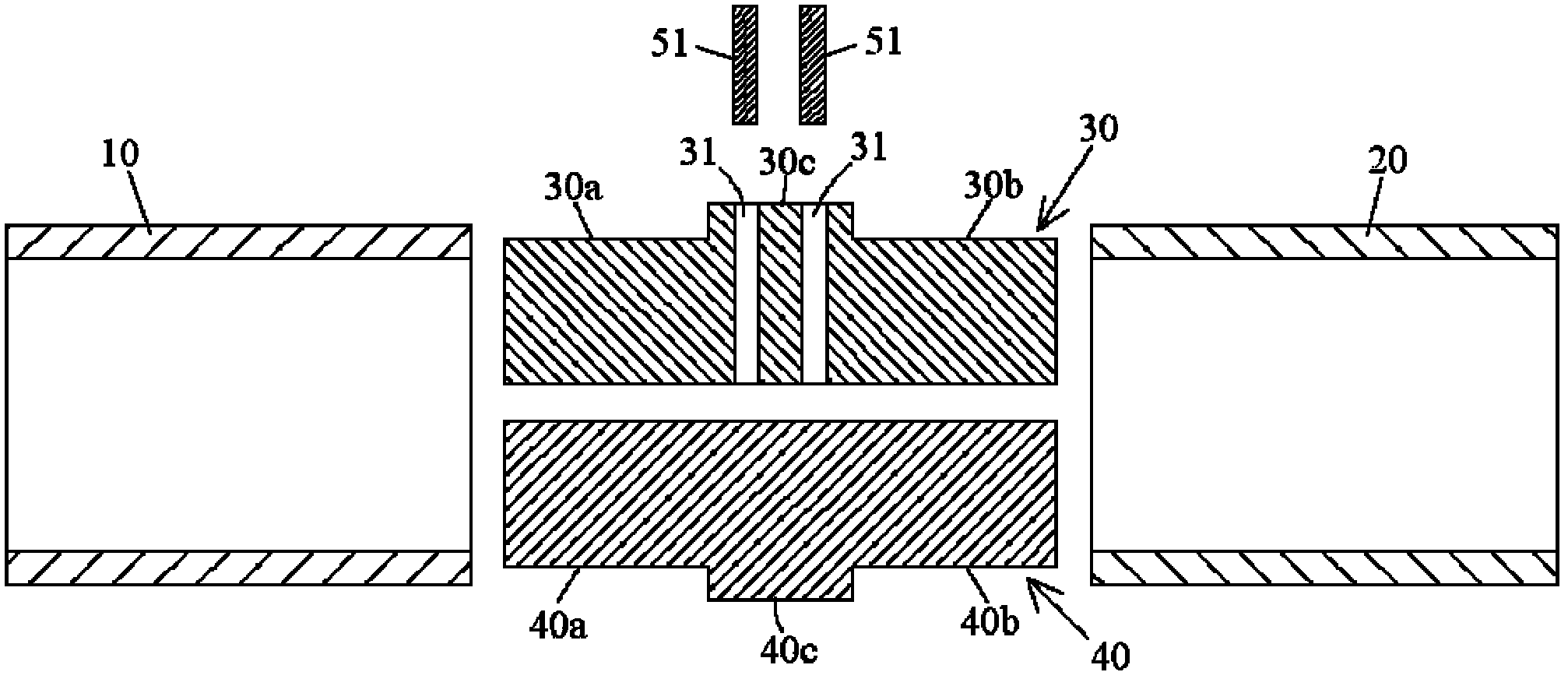

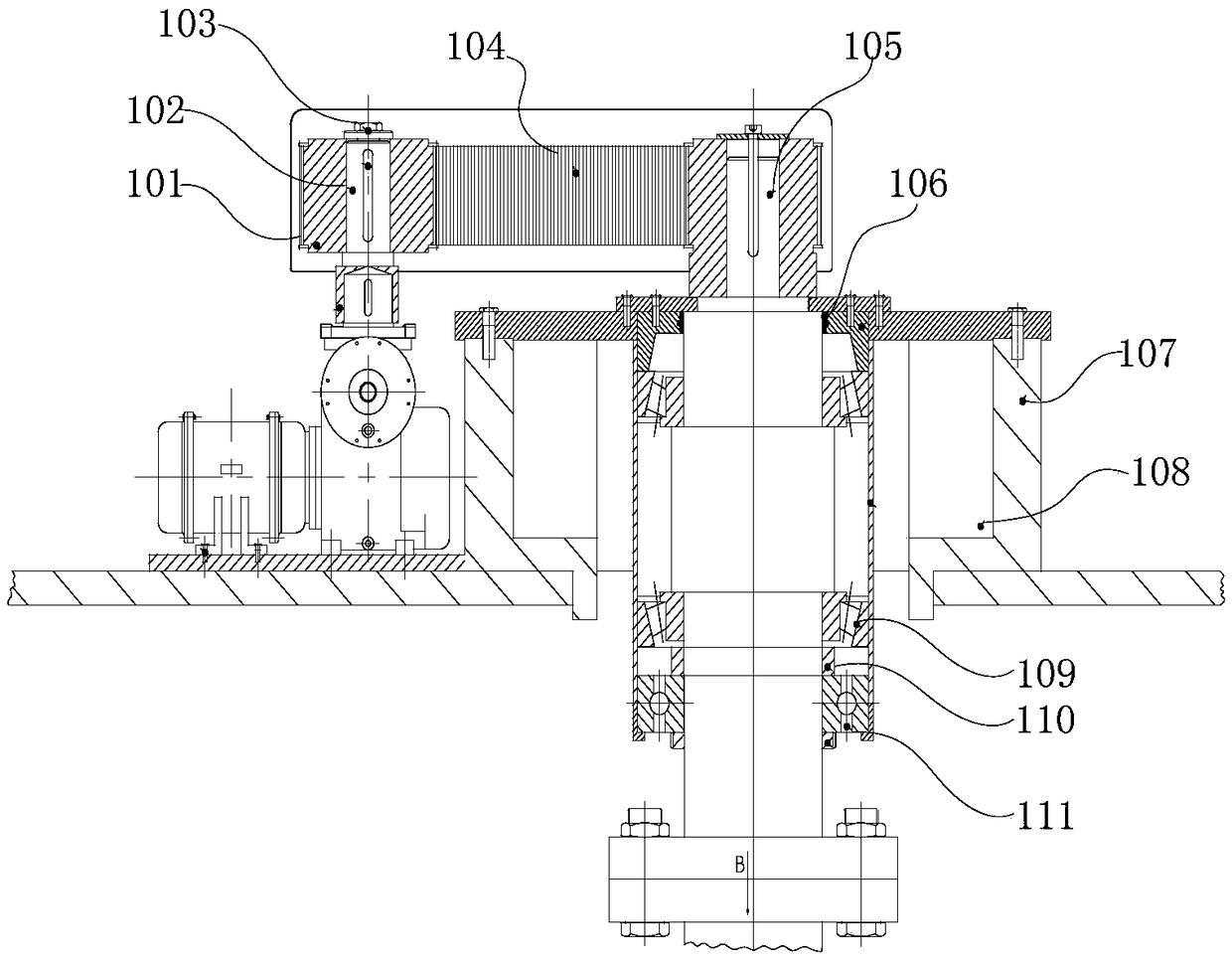

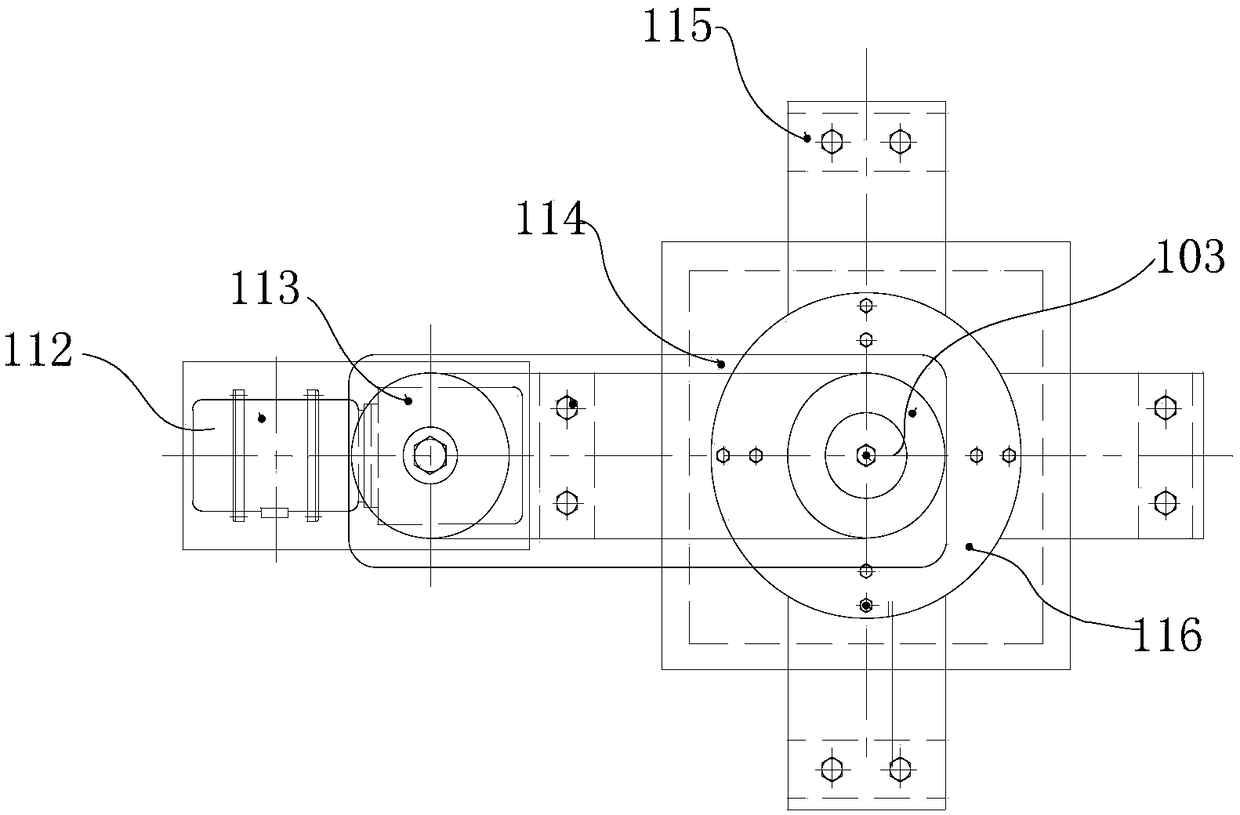

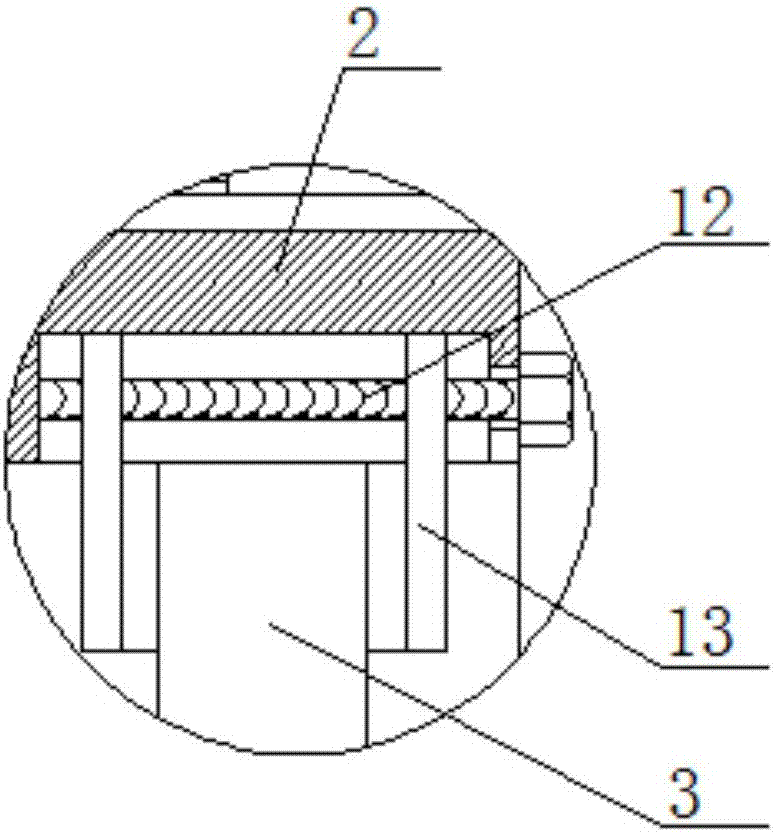

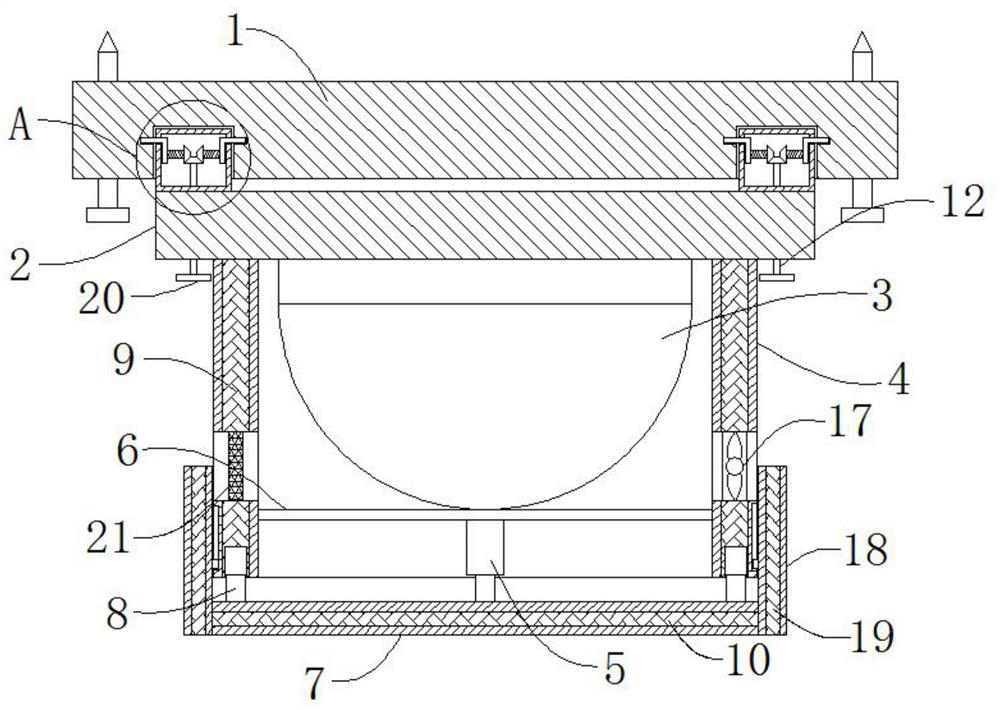

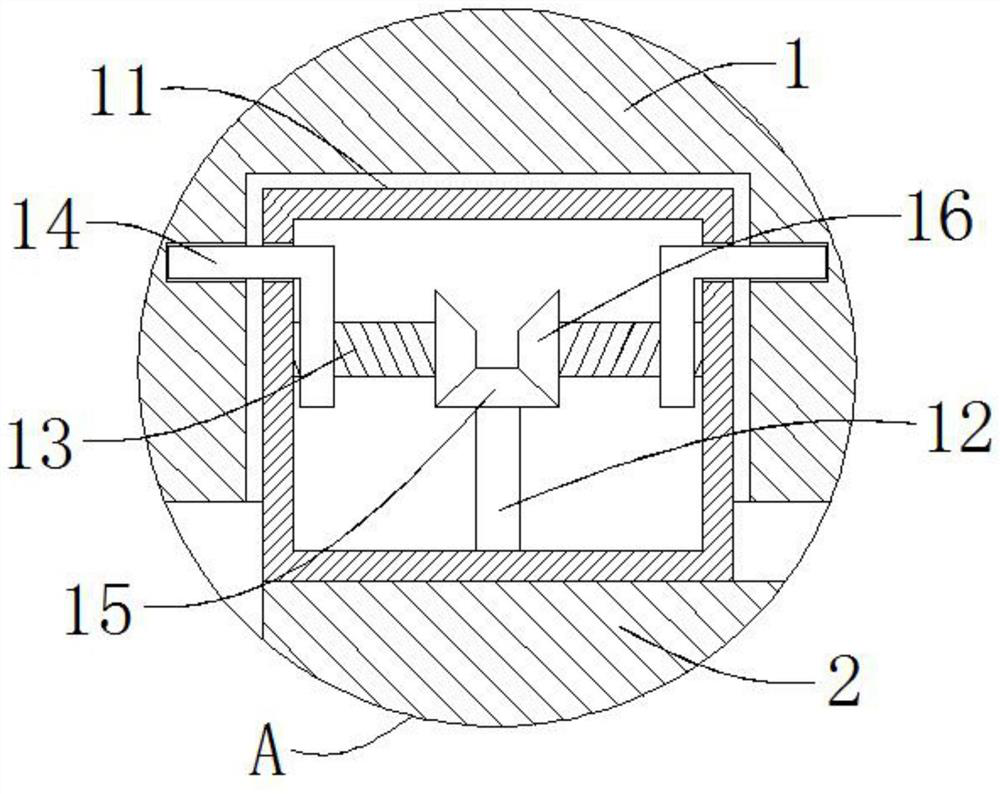

High-power crimping type IGBT encapsulation module fixture

ActiveCN104795348ASignificant progressCompact structureSemiconductor/solid-state device manufacturingCapacitanceComputer module

The invention provides a high-power crimping type IGBT encapsulation module fixture comprising an insulation supporting rod arranged vertically, and a lower end bearing flange component set, a lower end drainage bar, a lower water cooling component set, a middle drainage bar, an upper water cooling component set, an upper end drainage bar and an upper end fixture flange component set which are arranged from bottom to top sequentially and horizontally. Two sides of the upper and lower water cooling component sets are provided with capacitor components and damping resistor components, and the other two sides are provided with radiator waterway components, short circuit plates, drive plates and guide wire groove components; the upper and lower water cooling component sets comprise water cooling radiators which are parallel to each other vertically and which clamp a crimping type IGBT encapsulation module, and nickel is planted on the surfaces of the water cooling radiators. The fixture is simpler and more compacted in whole structure, more convenient to manufacture and assemble and more reasonable in layout and has higher reliability and better heat radiating performance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

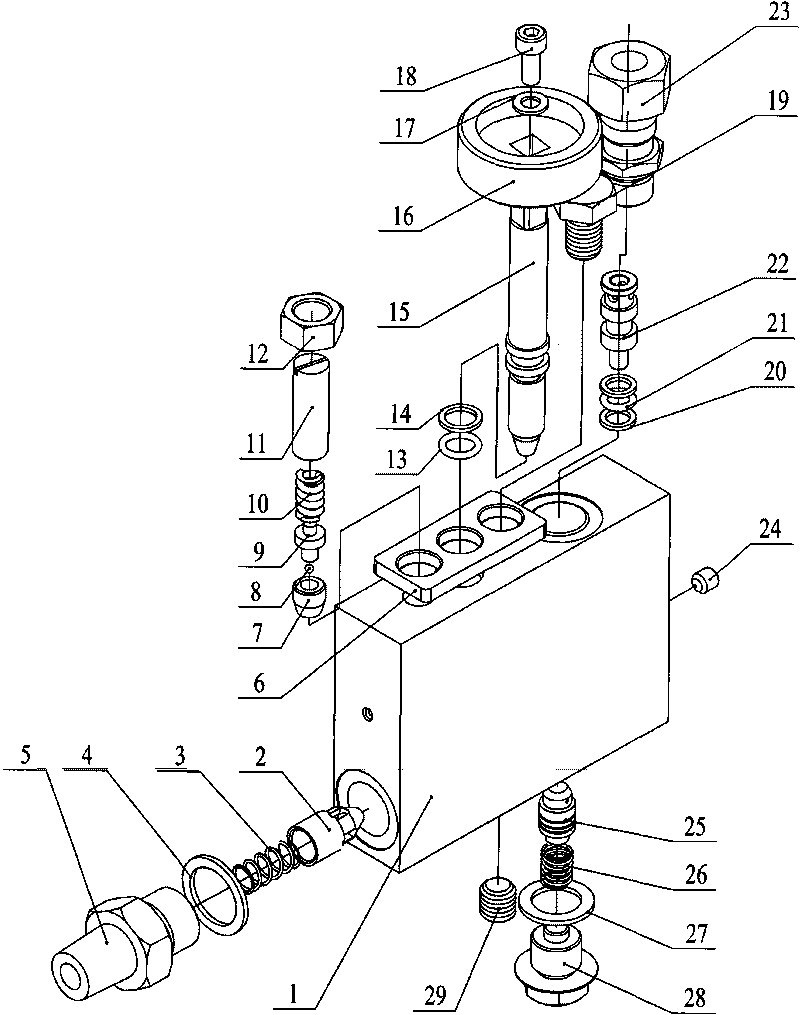

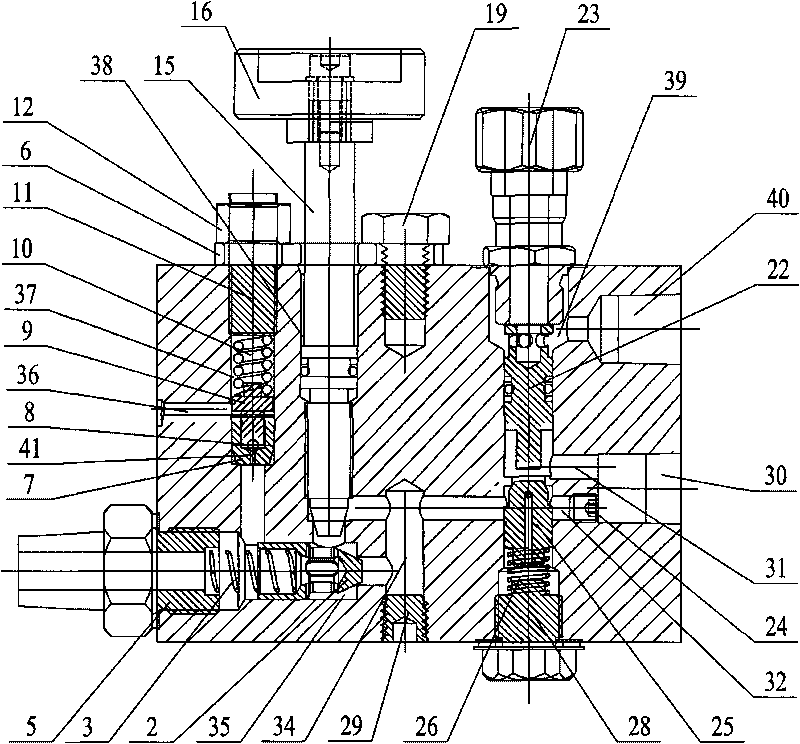

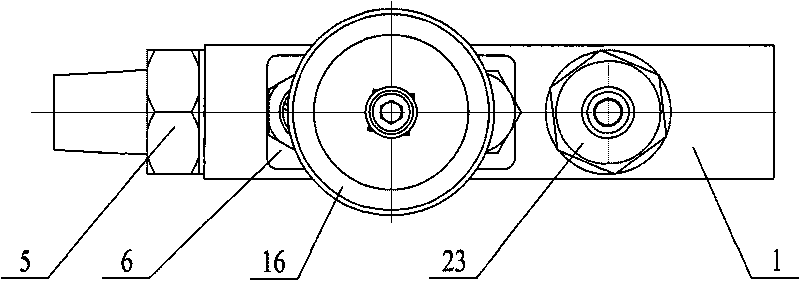

Combined valve

The invention belongs to the technical field of hydraulic elements, relates to a combined valve device, in particular to a combined valve integrating the functions of a hydraulic control one-way valve, a one-way throttle valve and a relief valve. The combined valve comprises a valve body, wherein a first check valve plug, a second check valve plug, a throttle core rod, a hydraulic control valve plug and an overflow component and other control parts are arranged in the valve body, so that actual requirement can be achieved by using combination of the control parts. The combined valve has smart structure, is compact and reasonable, has no inside connection thereby avoiding leakage point, has simple circuit connection, can be detached and maintained quickly and conveniently, improves production efficiency, has high rigidity and strength, can bear 70MPa hyperpressure, is safe and reliable, has wide application range, integrates the functions of the hydraulic control one-way valve, the one-way throttle valve and the relief valve, can effectively save space, and saves cost.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

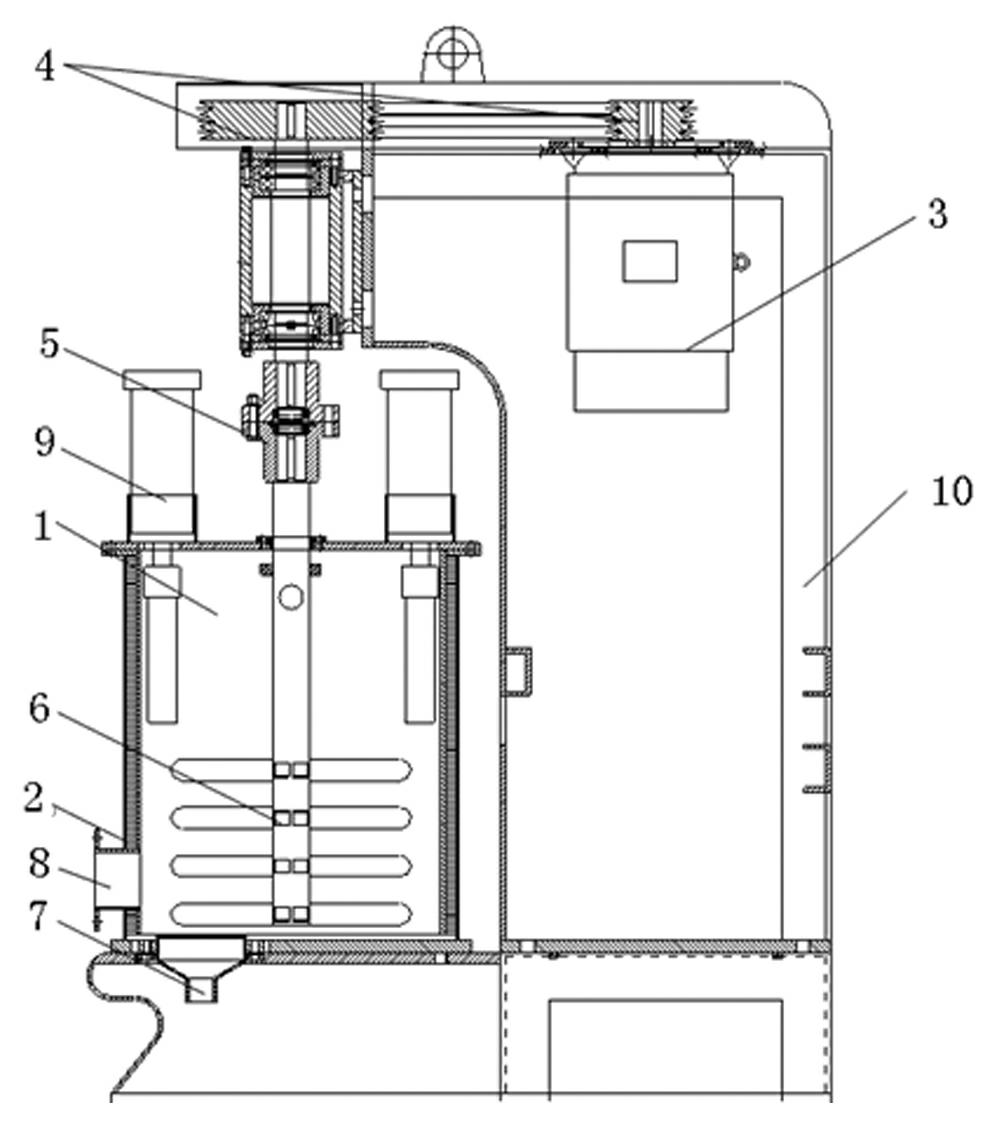

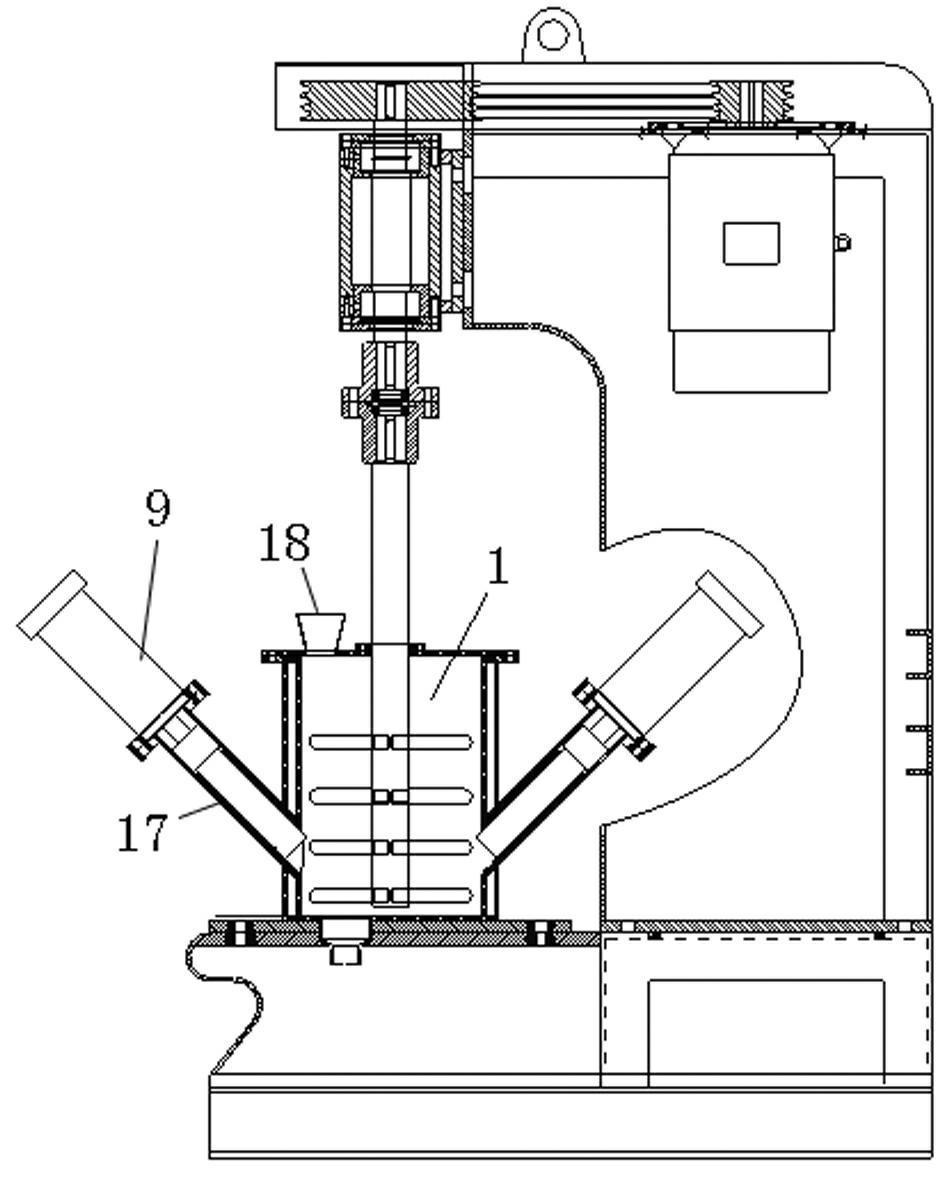

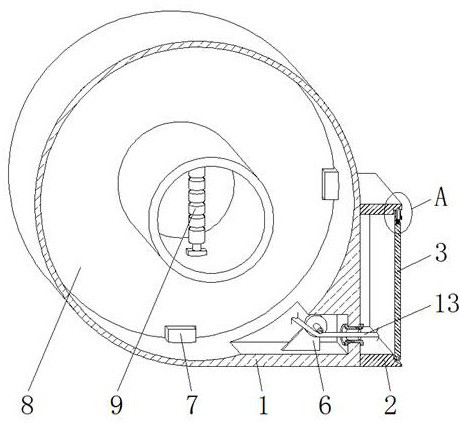

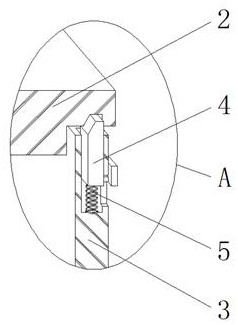

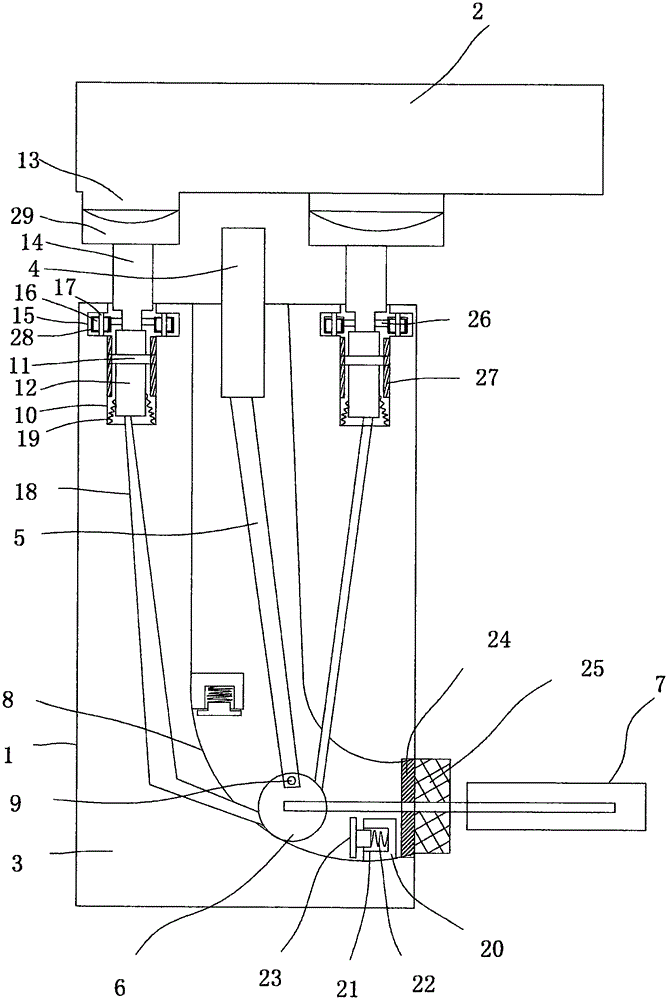

An ultrasonic ball mill

InactiveCN102284326AGet the most out of collision grindingMake full use of ultrasonic cavitation to promote collision grindingGrain treatmentsHigh densityMotor drive

The invention provides an ultrasonic ball mill pulverizer which comprises a frame, a mixing tank, a transmission motor driving a stirring shaft to rotate, the stirring shaft pushing mill balls to crush and grind a material, a material circulation system, as well as a cooling water jacket layer, a water inlet, a water outlet, a material inlet, a material outlet and a ball discharge port which are arranged on the mixing tank. The ultrasonic ball mill pulverizer is characterized in that: holes for inserting ultrasonic generators and an assembly bosses are formed on the upper cover or / and wall of the mixing tank; 1 to 12 sets of ultrasonic generators are vertically or / and obliquely inserted into the assembly bosses which are connected or welded on the cover or the wall of the mixing tank through threads or flanges; and probes of the ultrasonic generators are inserted deep into the mixing tank and contacted with the material, so that the material completely absorb strong ultrasonic energy. While performing stirring and ball milling to the material, the ultrasonic ball mill pulverizer applies strong ultrasonic field action to generate a high-density energy filed, so that micron-grade or sub-micron-grade (0.7-30mu m) powder can be crushed into nano-grade (20-600nm) powder. The ultrasonic ball mill pulverizer has the advantages of high yield and efficiency, simple process, is easy to operate and control and can eliminate local concentration unevenness, effectively prevent particle agglomeration, and is suitable for industrial production.

Owner:CHANGSHA SDLUBE SCI & TECH

Heating high temperature valve and uses thereof

InactiveCN101109448AAchieve closureSmooth rotationValve members for heating/coolingLift valveMagnesiumTitanium

A heating hi-temperature valve installed on the connection passage of an equipment, namely a reversed U-like reduction distilling combine furnace, for producing sponge titanium by magnesium method is provided, which comprises a valve body, a heater out the valve body and a valve clack. In the valve body, a circular valve seat is mounted, the valve clack is mounted in a support flange, and is connected with the valve body through a flange. The drive mechanism includes a handwheel, a water-cooled lead screw, a valve-rod connector, a valve rod and a valve clack. The outer surface of the valve clack is conic, is in linear contact with the circular valve seat, so as to guarantee reliable sealing. The heating hi-temperature valve can work under a high temperature up to 1000 centigrade, guarantee free closing, opening and reliable sealing. And as circulating cooling water is provided in the water-cooled lead screw, and cooling water jacket is provided in the flange for cooling the lead screw, the hand wheel is under room temperature, and is easy to operate.

Owner:中信钛业股份有限公司

Electric connecting device

InactiveCN102856677ACompact structureEasy to shield and wrap shieldsClamped/spring connectionsMultiple conductors connectorWrenchFirst insertion

The invention discloses an electric connecting device electrically connected with a tubular bus. The electric connecting device comprises a first conductive half body with a first insertion end, a second conductive half body with a second insertion end, and an expansion device. The expansion device is used for extruding the first insertion end and the second insertion end inserted into the tubular bus to the inner wall of the tubular bus towards mutually separated directions under predetermined expansion force, so that the outer walls of the first insertion end and the second insertion end are tightly jointed with the tubular bus, wherein, the expansion device comprises a threaded through hole formed in a raised part of at least one of the first and second conductive half bodies and a bolt screwed into the threaded through hole, and the bolt pushes the first conductive half body and the second conductive half body towards the mutually separated directions. Compared with the prior art, the electric connecting device has the advantages that the electric connecting device is convenient to install, the bus is not required to be machined, the electric connecting device can be installed only by using a screw wrench, special training for installation workers is not required, and special installation tools are also not required.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

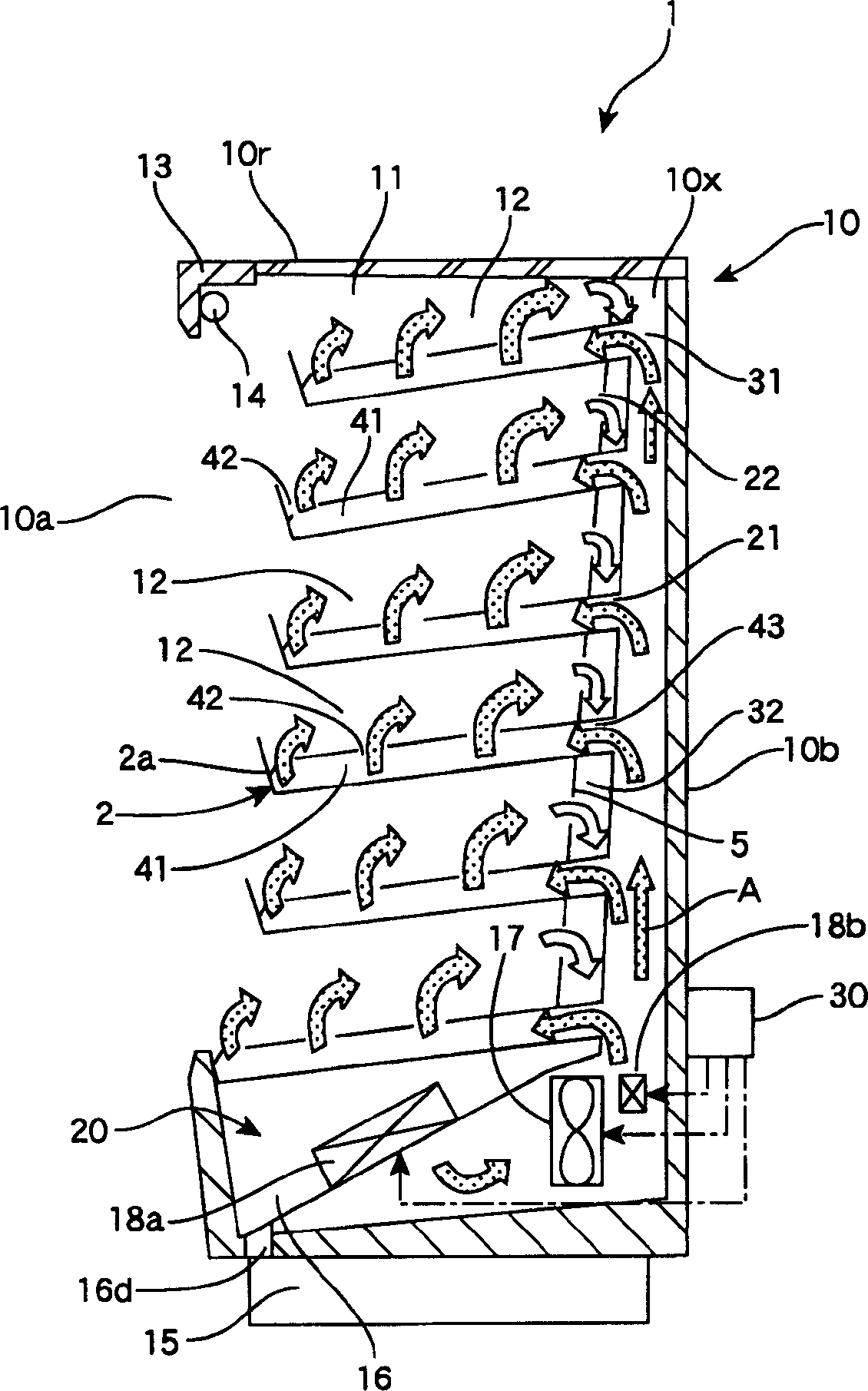

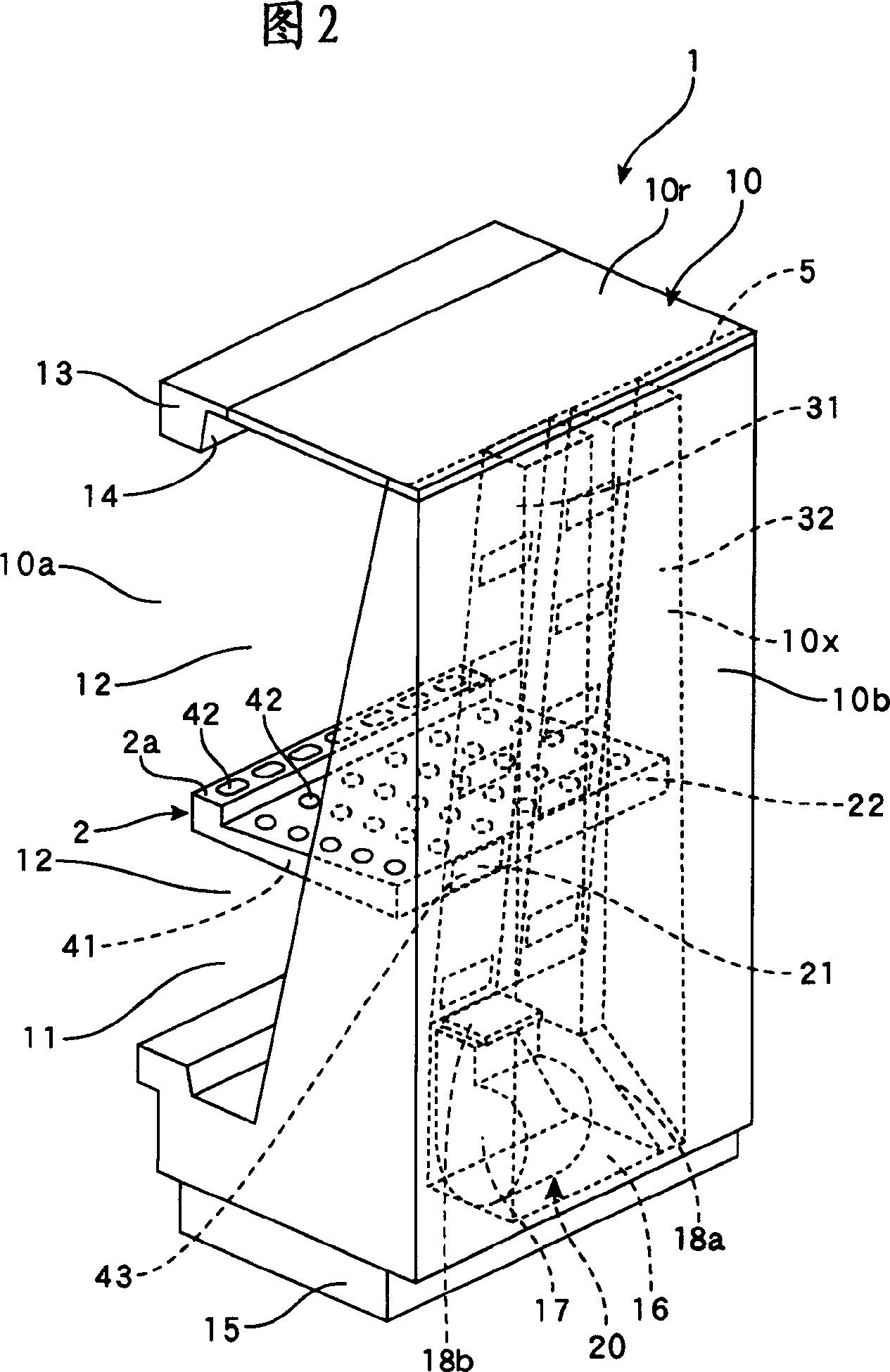

Storage device

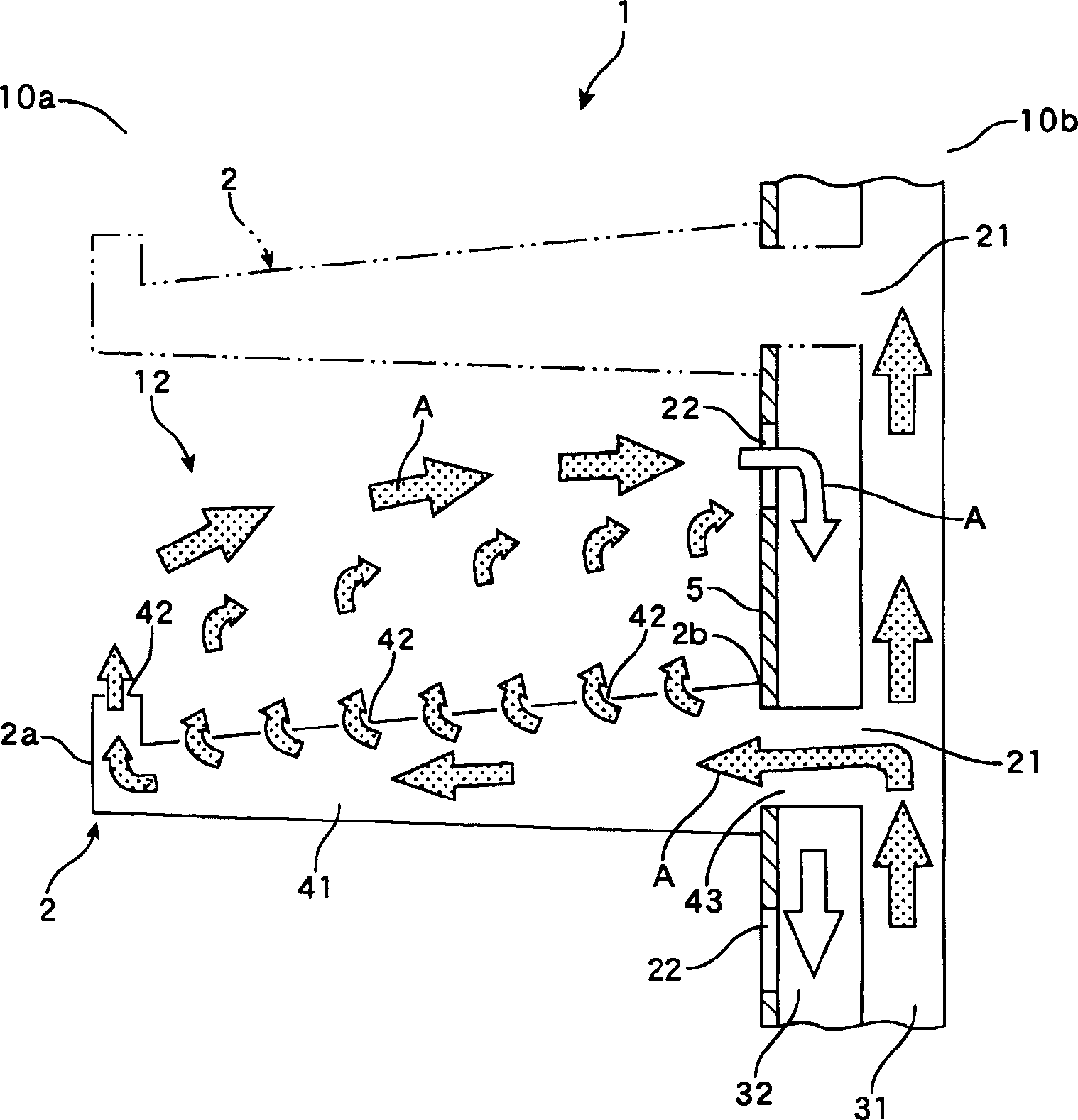

InactiveCN1608191ALighting means savedReduce outputShow cabinetsLighting and heating apparatusEngineeringLarge capacity

Provided is a storage device comprising: a display cabinet capable of dividing the interior into a plurality of storage areas; supply duct; exhaust duct connected to an exhaust outlet capable of drawing air from the storage area. With this storage device, air for conditioning such as cooling or heating is in a state of circulating in each storage area, and environmental conditions can be efficiently adjusted in a unit storage area. Therefore, the storage device provided with the open display cabinet can provide a storage device with a high storage capacity that can omit the air curtain covering the entire open surface.

Owner:GLOSTER

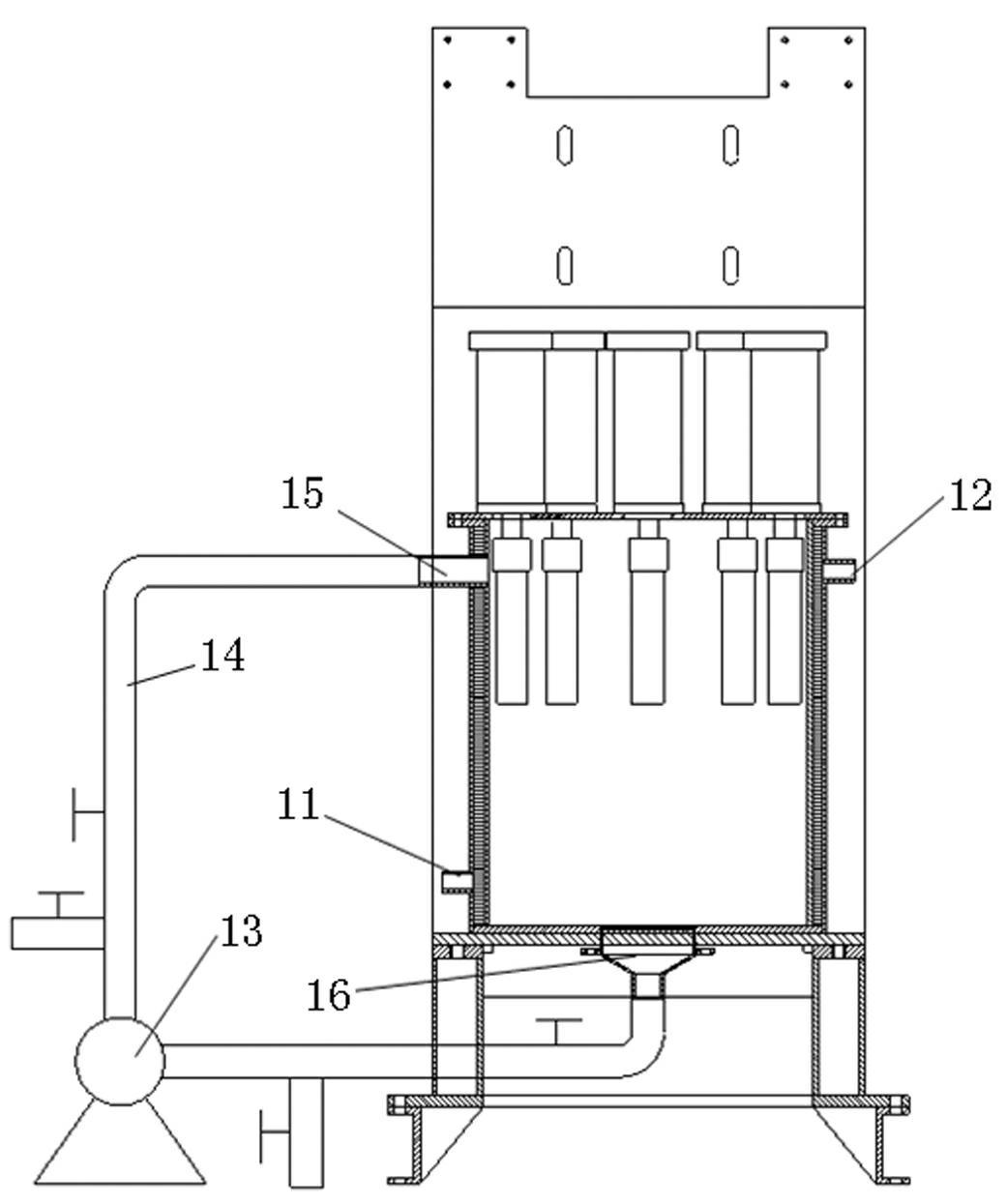

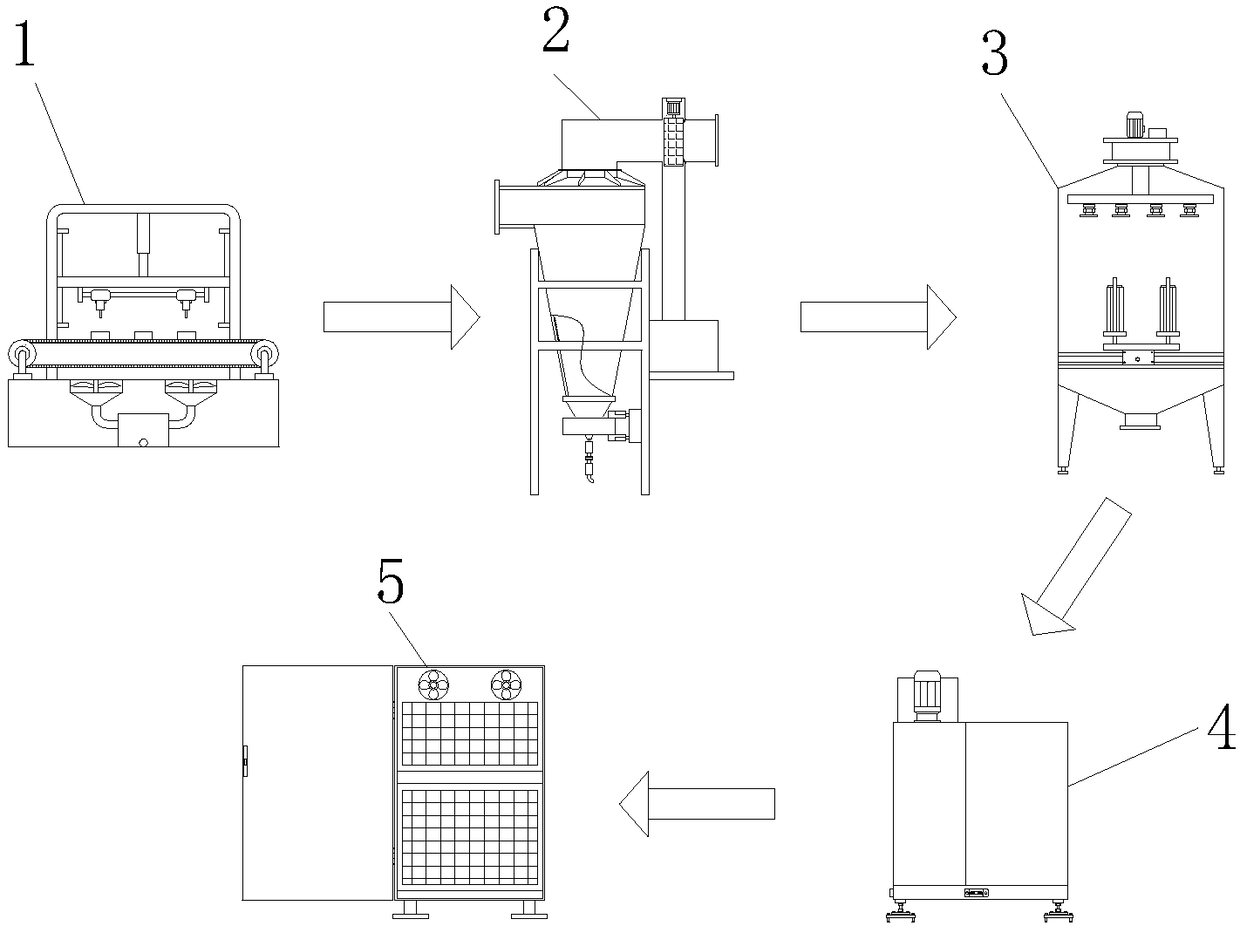

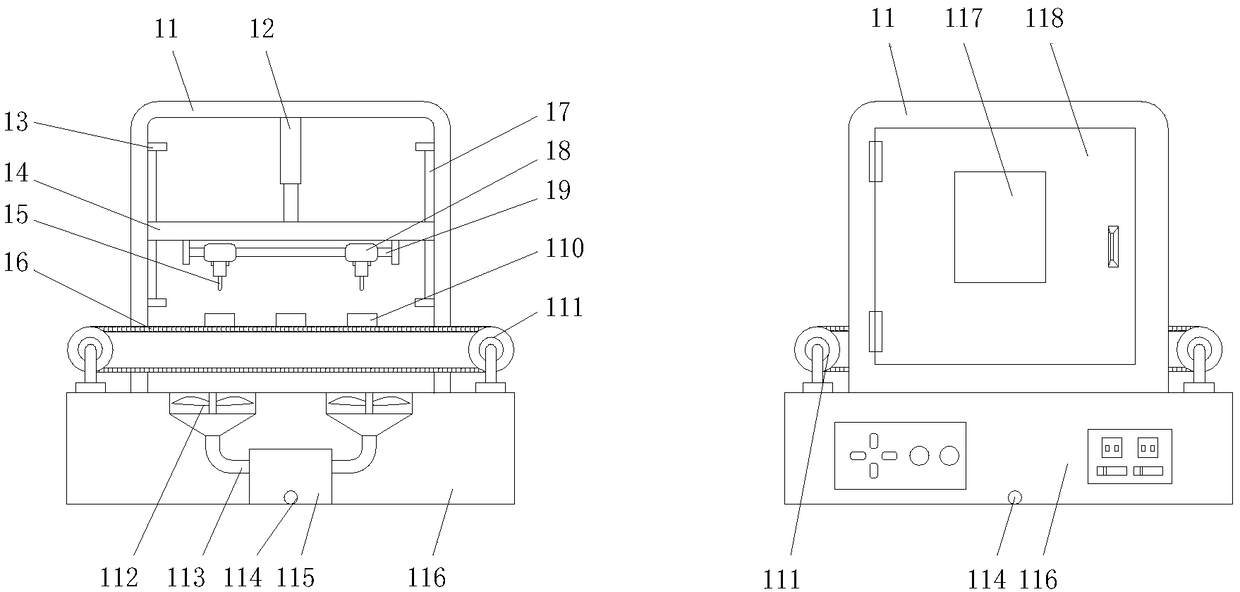

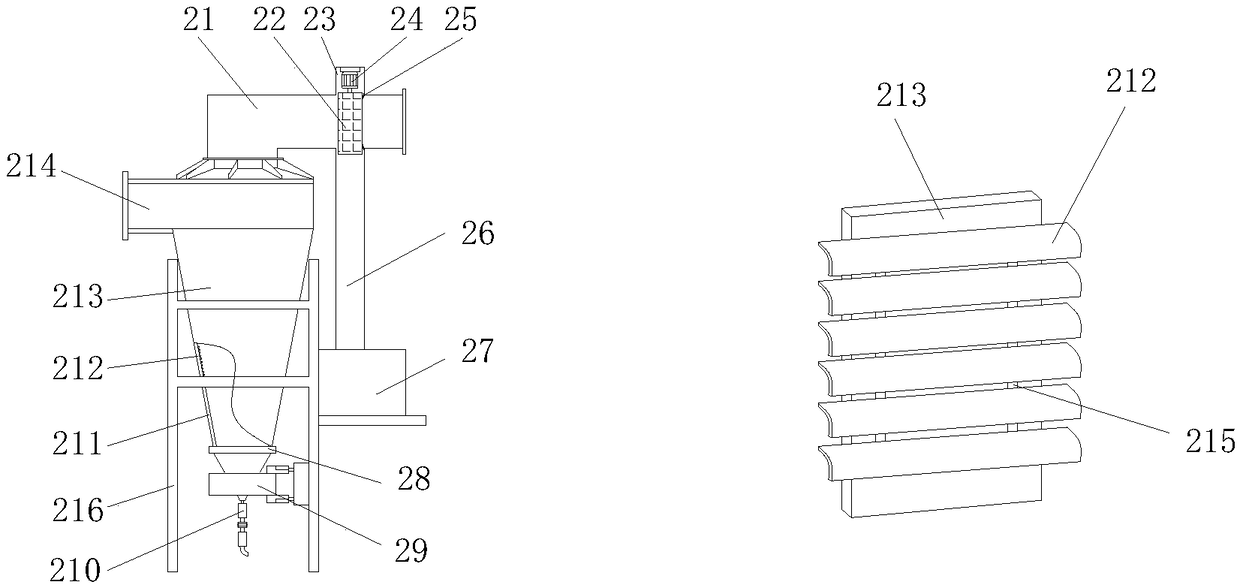

Fast color changing and spraying equipment for metal surfaces

InactiveCN108114839AAvoid environmental pollutionLow raw material costSpray boothsLeather beltMaterial storage

The invention discloses fast color changing and spraying equipment for metal surfaces. The equipment includes a coating device, a cyclone separation device, a filtering core recovery device, a powdersupply device and an electrical device. The spraying device includes a worktable, a spraying chamber, a hollow belt, an exhaust fan and a material storage box; the spraying chamber is formed in the upper portion of the worktable, vertical sliding tracks symmetric to each other are arranged on the inner wall of the spraying chamber, and limiting blocks symmetric to each other are arranged on the upper and lower sides of each vertical sliding track. The leakproofness of the spraying chamber of the spraying device is high, since the spraying device is communicated with the exterior through only one overhaul door, coloring particles can be effectively prevented from diffusing to the exterior air, and even if a small part of particles tend to diffuse outwards from gaps, the particles can be sucked by the exhaust fan. The exhaust fan can collect the coloring particles sprayed around a metal block into a material storage groove, environmental pollution is avoided on the one hand, recycle of resources can be achieved on the other hand, and the cost of raw materials for spraying is saved.

Owner:湖南三五二环保科技有限公司

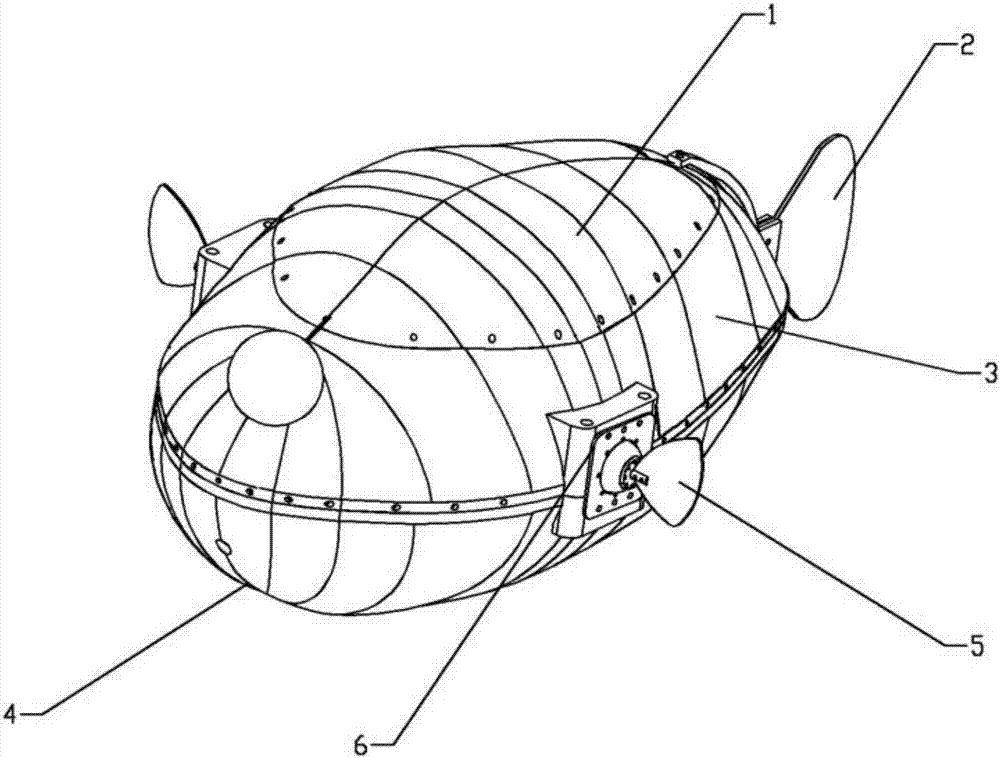

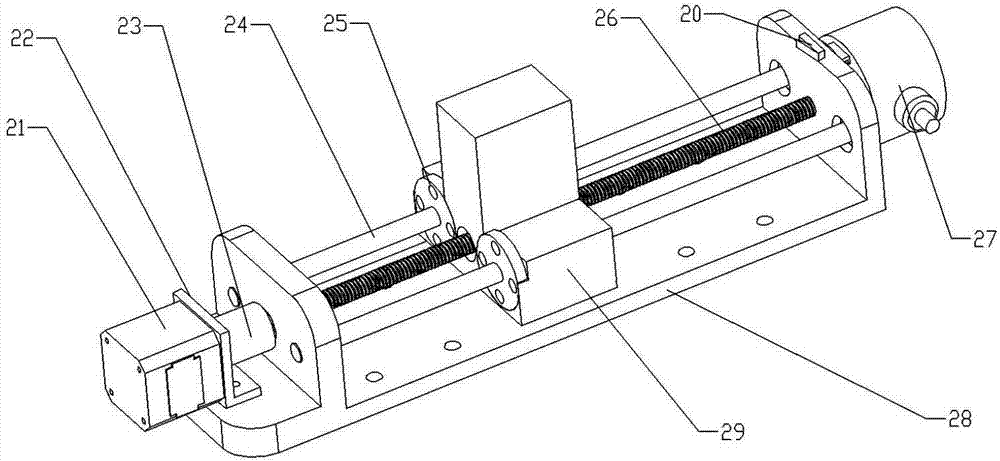

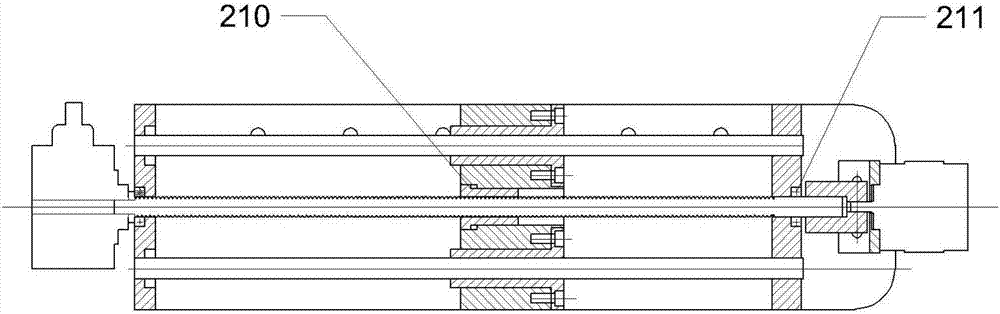

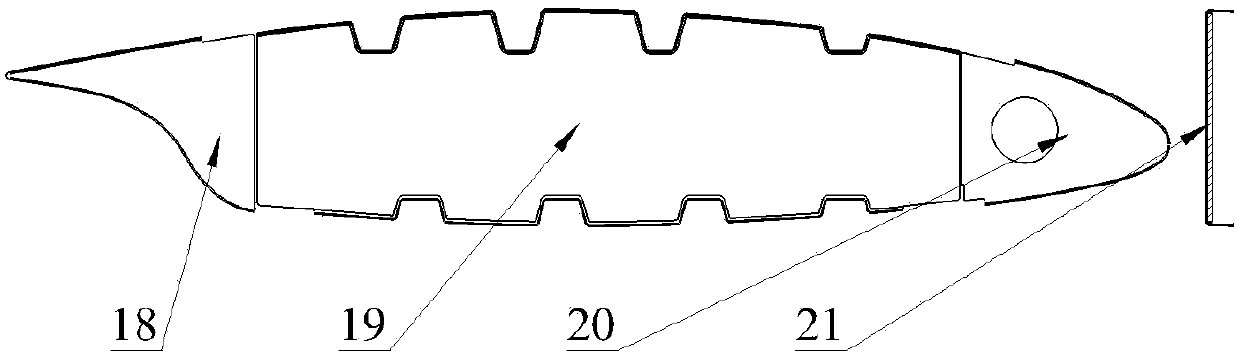

Ostraciidae-imitating autonomous robotic fish

PendingCN107161304ARealize diving and snorkelingImprove the ability of underwater sportsUnderwater vesselsUnderwater equipmentMarine engineeringUnderwater

The invention belongs to the technical field of underwater bio-mimetic robotic fishes, and particularly relates to ostraciidae-imitating autonomous robotic fish capable of achieving sink-and-swim motion. By adopting a gravity center adjusting method and a method of water suction and discharge, high speed underwater submerging and surfacing motion of the robotic fish is achieved, wherein the robotic fish can depend on a pectoral and a tail fin to propel and adjusts an angle of inclination through a heavy block to achieve the high-speed underwater submerging and surfacing motion, and further, submerging and surfacing motion of the robotic fish under a low-speed condition can be achieved through changing of the gravity of the robotic fish. Compared with a former mechanism, the adjusting range and the degree of precision of the robotic fish are greatly improved, the motion of direct swimming, steering, upward floating, diving and the like of the bio-mimetic robotic fish at various speeds can be achieved, and the capability of underwater motion of the robotic fish is improved. An upper shell body is divided into an upper shell body upper cover and an upper shell body connecting piece, the upper shell body connecting piece is connected with a lower shell body, the joint of the upper shell body connecting piece and the lower shell body is smeared with 703 silicone rubber, and static seal is formed between the two shell bodies. Deep-groove ball bearings are arranged at the two ends of a ball screw, a limiting switch and an encoder are arranged on a mechanism support, and the encoder is connected with the ball screw. Data of the movement condition of a balancing weight is sent back through the encoder, and a closed loop with a high precision is achieved. The situation that a fish head can adjust an angle of inclination of a fish body according to needs to reach to a set depth is guaranteed through the design.

Owner:LANZHOU JIAOTONG UNIV

Fixed-wing unmanned aerial vehicle outer wing structure and manufacturing method thereof

ActiveCN107651163AThe overall structure is light in weightReduce manufacturing costAircraft controlSpars/stringersLeading edgeUncrewed vehicle

The invention discloses a fixed-wing unmanned aerial vehicle outer wing structure and a manufacturing method thereof. The fuel economy and the market competitiveness of a fixed-wing unmanned aerial vehicle are effectively improved. The outer wing structure comprises a wing box, the rear end of the wing box is connected with a wing flap, an aileron and a winglet, the front end of the wing box is provided with a forward uplifted front edge inner section and a front edge outer section, the wing box is provided with an upper wall plate, a lower wall plate, a front beam, a rear beam, a wing rib anda joint, the joint is used for connecting an outer wing with a central wing, horizontally extending foam stringers are arranged on opposite surfaces of the upper wall plate and the lower wall plate,grooves matched with the foam stringers are formed in the upper end and the lower end of a middle wing rib, the front beam and the rear beam are in 'Z' shapes, lower plates of the front beam and the rear beam oppositely extend and are fixed onto the lower wall plate, upper plates of the front beam and the rear beam reversely extend and are fixed onto the upper wall plate, web plates of the front beam and the rear beam are connected between the upper plate and the lower plate, and the wing rib comprises a front wing rib, the middle wing rib and a rear wing rib.

Owner:CHONGQING GENERAL AVIATION IND GRP CO LTD

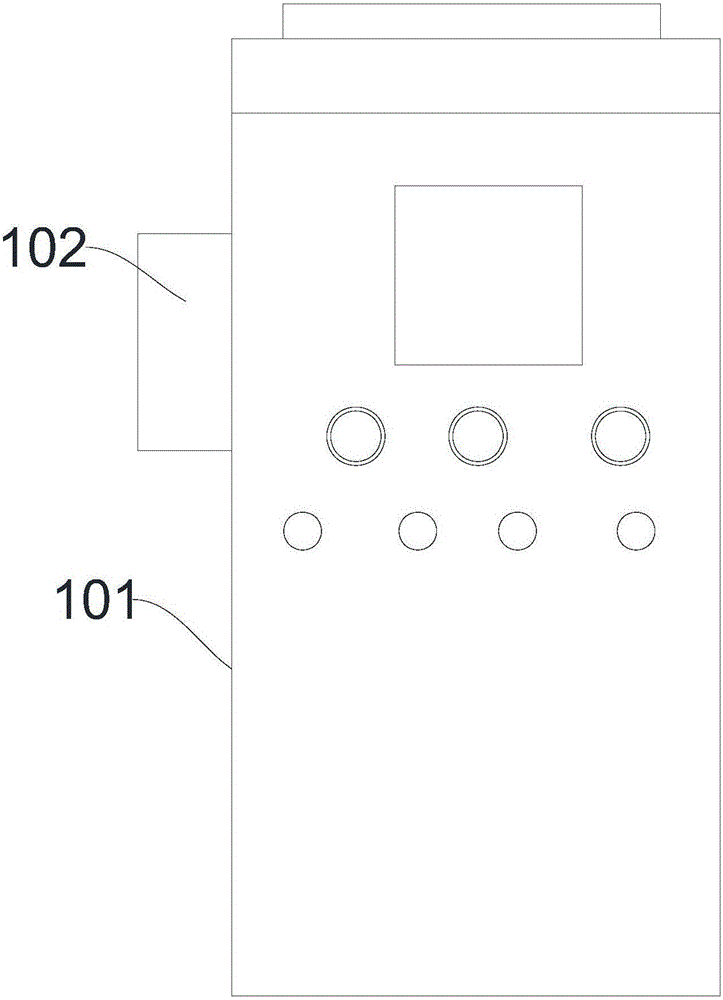

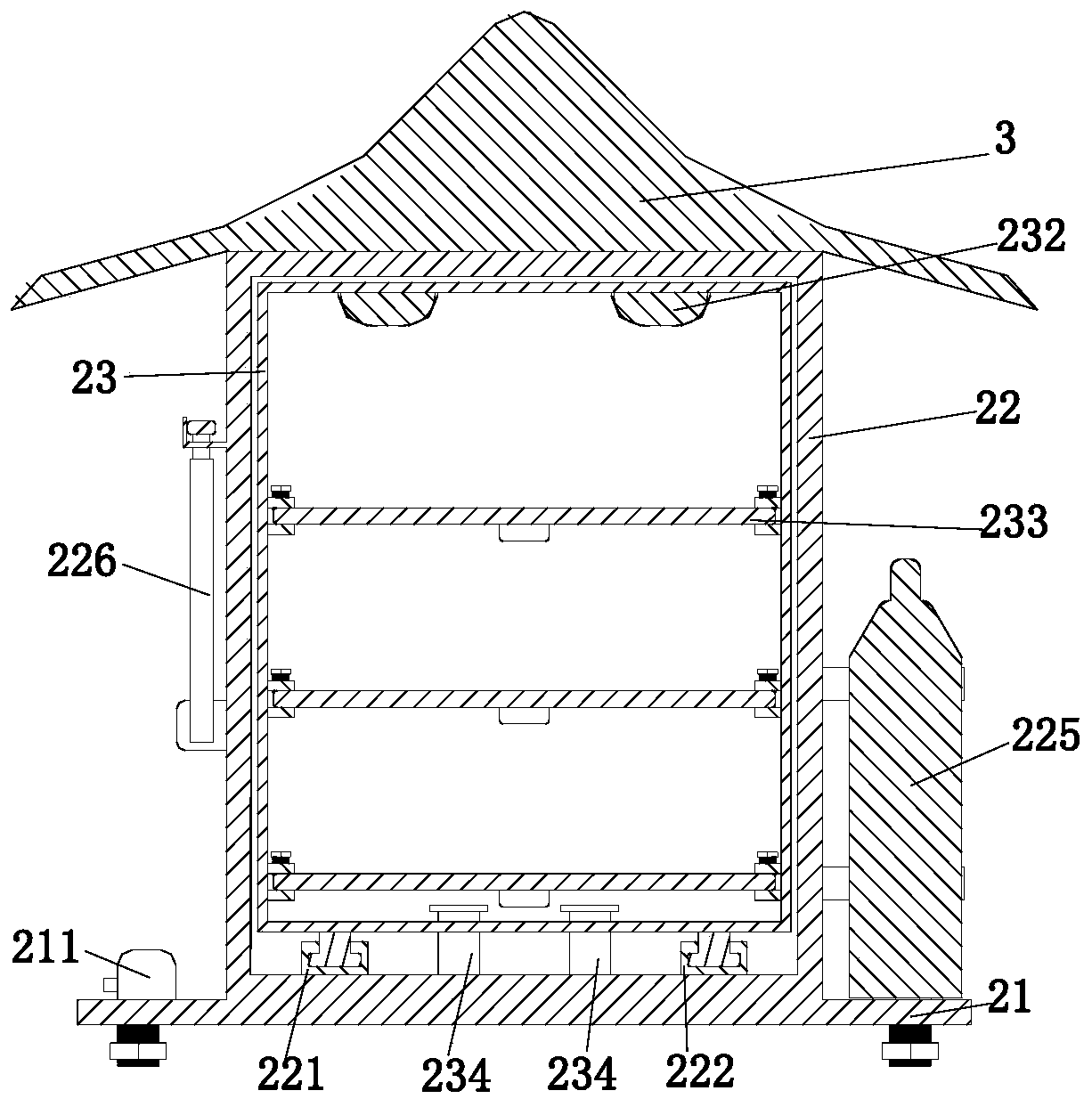

Electrical cabinet with moistureproof apparatus

InactiveCN106207767AImprove drying effectEvenly dispersedSubstation/switching arrangement casingsMicro motorEngineering

The invention provides an electrical cabinet with a moistureproof apparatus, and belongs to the field of the electrical cabinet. The electrical cabinet comprises a cabinet body, a mounting box, a micro-motor fan, PTC heating bodies, an air-supply assembly and an air-out component, wherein the cabinet body comprises an outer side wall and an inner side wall; an air-supply opening is formed in the outer side wall; at least one hot air outlet is formed in the inner side wall; the mounting box is arranged in the air-supply opening and connected with a sealed cavity; the micro-motor fan is arranged in the mounting box; the PTC heating bodies are arranged in the corresponding hot air outlets; the air-supply assembly comprises a cover shell and at least one air-supply branch pipe; the air-supply opening is covered with the cover shell; the air-supply branch pipes are connected with the cover shell; the air-out component is positioned on one side, far from the outer side wall, of the inner side wall; the air-out component comprises a collecting cavity and a horn-shaped air-out part which are connected mutually; and the collecting cavity covers the hot air outlets. The technical scheme of the invention provides the electrical cabinet, wherein water drop and moisture in the internal of the electrical cabinet can be uniformly dried, so that the internal of the electrical cabinet can be kept clean and dry, and short circuit of components in the electrical cabinet can be avoided.

Owner:JIANGXI ELECTRIC VOCATIONAL & TECHN COLLEGE +1

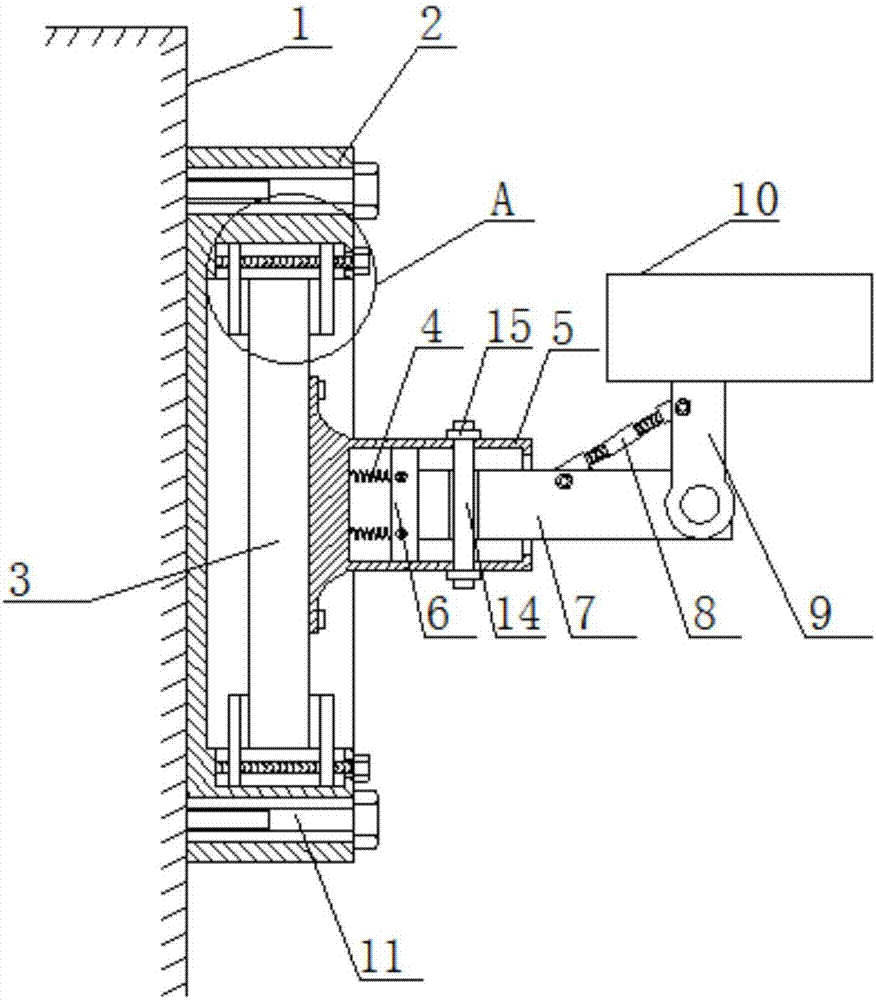

Conveniently detached adjusting valve

InactiveCN107701776AEasy to disassembleEasy to disassemble and overhaulValve housingsJoystickControl valves

The invention relates to the technical field of regulating valves, and discloses a regulating valve that is easy to disassemble, including a valve seat, both sides of the bottom of the U-shaped frame are connected with installation sleeves, and both sides of the installation sleeve are provided with openings , the inner side of the installation sleeve is connected with a movable shaft, both sides of the outer side of the movable shaft are sleeved with movable sleeves, a compression spring is connected between the two movable sleeves, and a control rod is connected to the movable sleeve away from the compression spring , Both sides of the top of the valve seat are provided with installation grooves, both sides of the inner wall of the installation groove are provided with card slots, and the right side of the top of the card block overlaps with the top of the inner wall of the card slot. The present invention cooperates with movable sleeve, compression spring, control rod, installation groove and block, so that when the control valve needs to be disassembled and overhauled, the control rod can be pressed to allow the block to disengage from the groove of the installation groove, thereby Allows the U-shaped bracket to be disassembled from the valve seat to facilitate removal of the baffle.

Owner:JOHNSTON FLOW TECH WUXI CO LTD

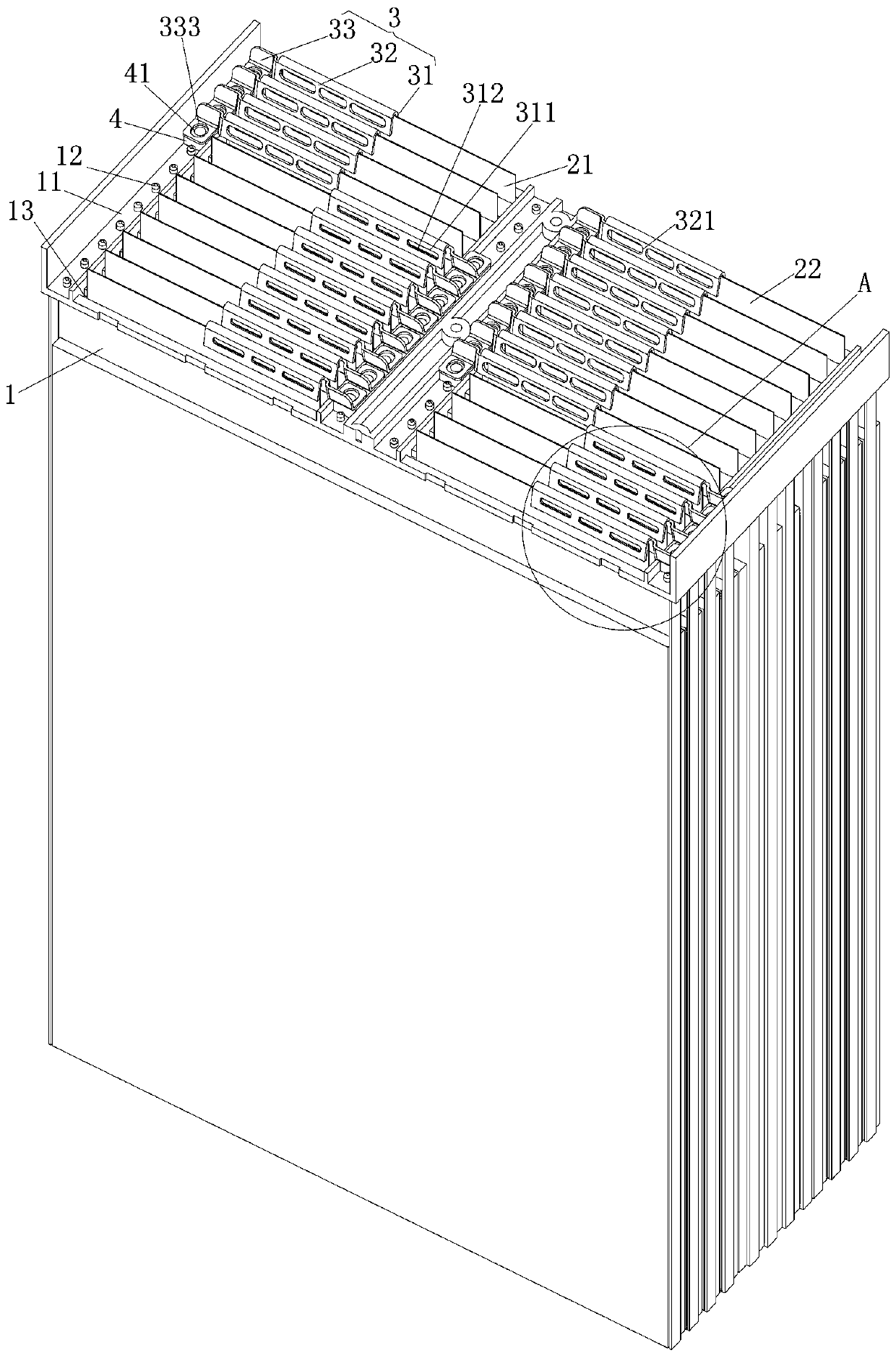

Soft package battery module with non-welding type tab connecting structure, and connecting method

ActiveCN110034265AReduce welding processImprove production and assembly efficiencyCurrent conducting connectionsBatteriesInterference fitBusbar

The invention discloses a soft package battery module with a non-welding type tab connecting structure; the soft package battery module comprises a battery frame, a plurality of single batteries stacked in the battery frame side by side, and at least two busbars arranged on the battery frame, wherein a connecting component is arranged between one tab of the single battery and the corresponding busbar; the connecting component comprises a first connecting piece, a second connecting piece and a third connecting piece which are connected in sequence; the third connecting piece is fixedly connected with the busbar; the tab is clamped between the first connecting piece and the second connecting piece; the first connecting piece is provided with at least one first clamping portion, and the second connecting piece is provided with at least one second clamping portion; and the tab is in interference fit between the first clamping portion and the second clamping portion through the buckled first connecting piece and second connecting piece. The soft package battery module is reasonable in structure, and the connecting mode of buckling and fixed connection between the connecting components and the tabs is adopted, so that the assembling, detaching and maintaining can be carried out conveniently, the assembling efficiency and the enterprise benefit are improved, and the wiring mode of different series-parallel connection of the lithium battery modules is met.

Owner:置富电子技术(东莞)有限公司

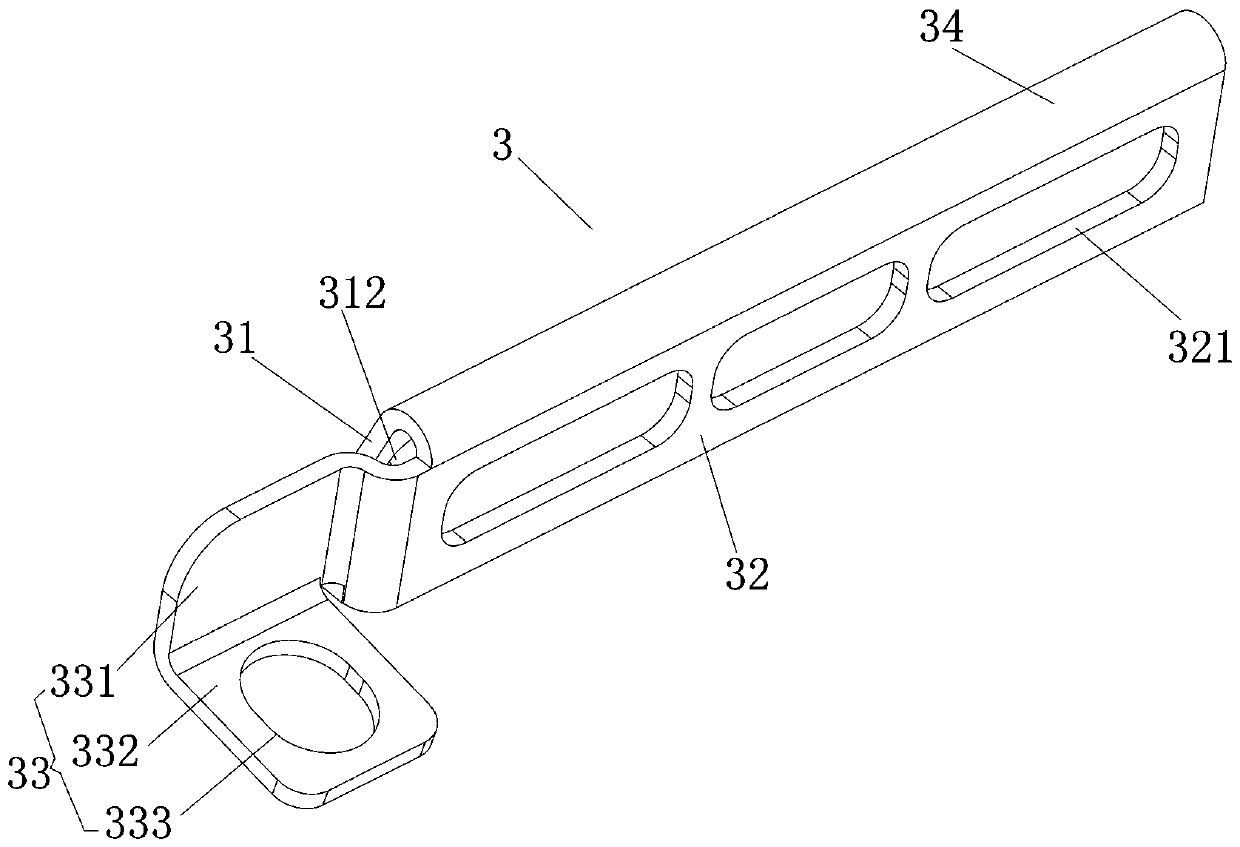

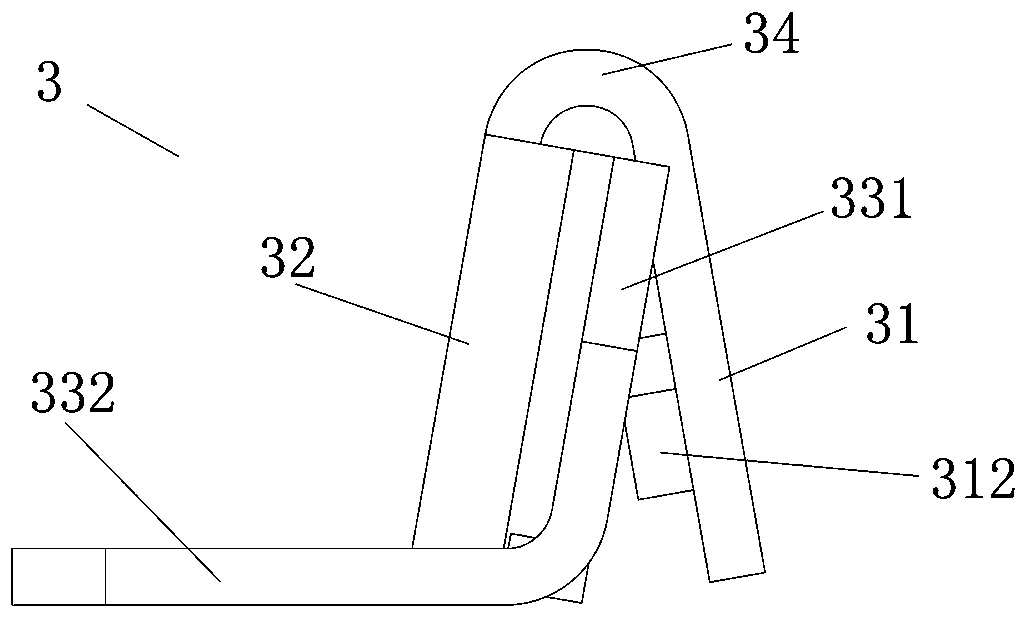

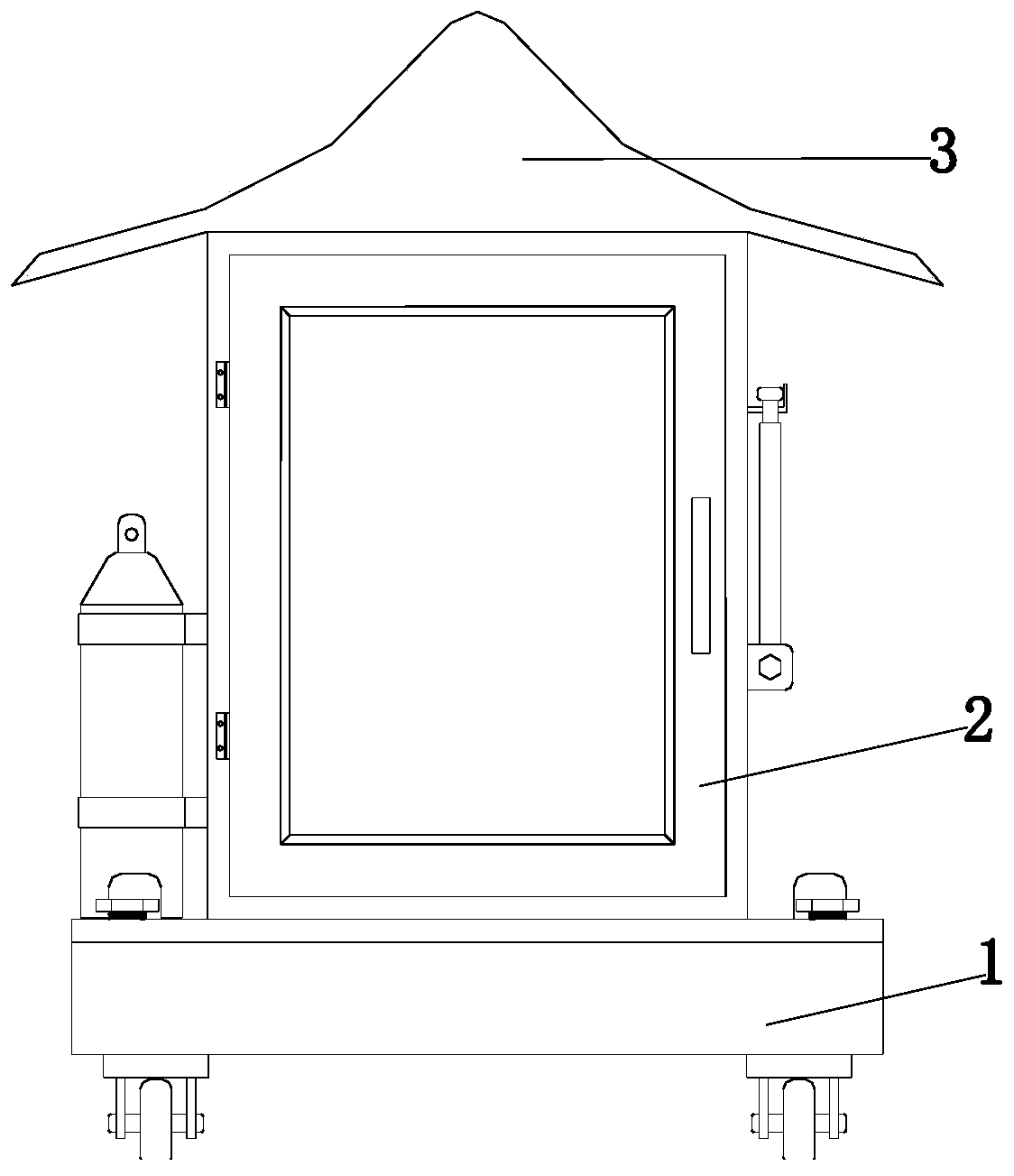

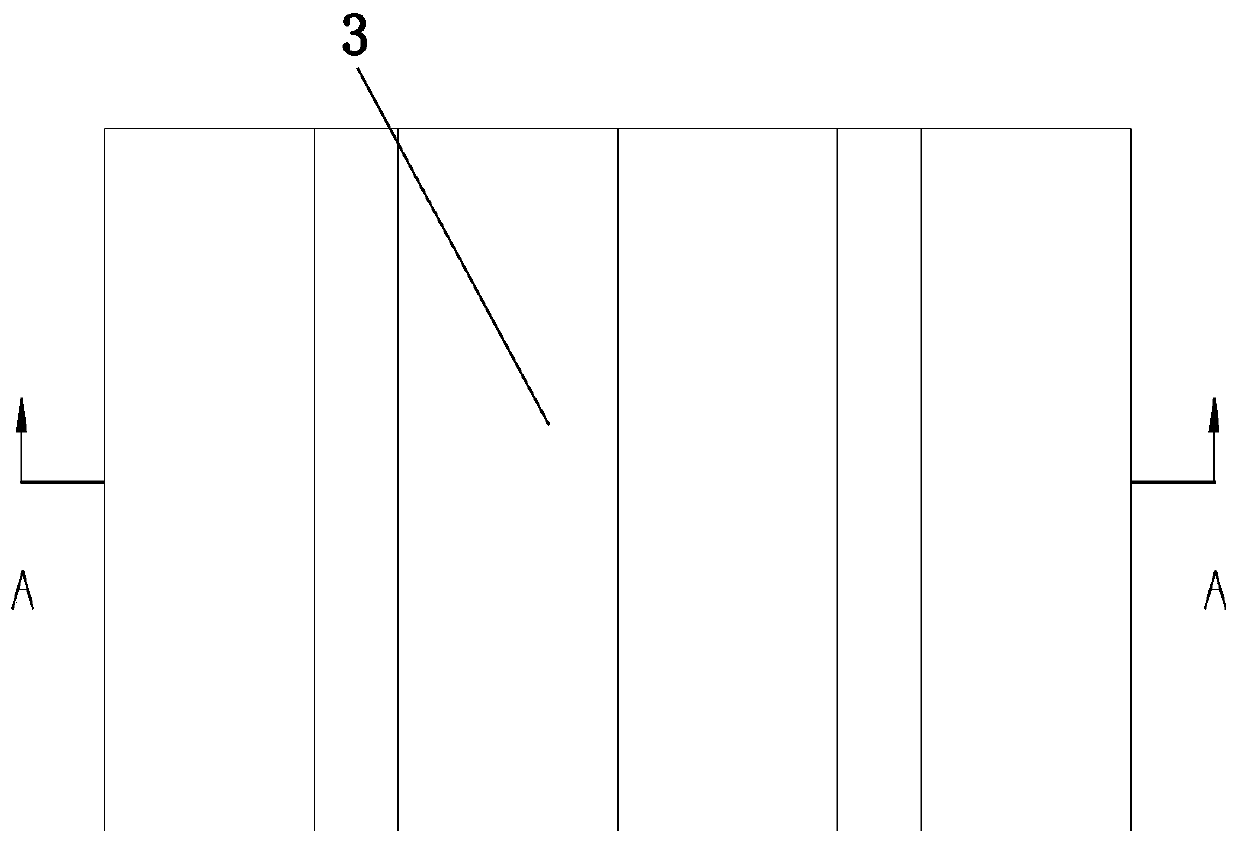

Multifunctional power distribution equipment

InactiveCN110364944ASolve the problem of not being able to movePrevent movementSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringScrew joint

The invention discloses multifunctional power distribution equipment and belongs to the technical field of power distribution equipment. The equipment comprises a movable base, a distribution box bodyand a top cover. The distribution box body is arranged on the top of the movable base. The movable base and the distribution box body are fixed in a screw joint manner. The top cover is located on the top of the distribution box body. The top cover and the distribution box body are fixed in a screw joint manner. The distribution box body comprises a bottom plate, a shell and a mounting box. The bottom plate is an insulating plate, and the bottom plate and the base are fixed in a screw joint mode. The shell is fixedly installed in the center of the upper portion of the bottom plate. The mounting box is arranged in the shell and is in sliding connection with the shell. Through the arrangement of the movable base, the power distribution equipment can be moved at any time and the problem thattraditional power distribution equipment cannot be moved is solved. Through sliding fit between the mounting box and the shell, the mounting box can be pulled out in a sliding mode at any time, so electrical elements in the mounting box can be disassembled and overhauled conveniently, and the problem that it is inconvenient to disassemble and maintain parts in a traditional power distribution boxis solved.

Owner:常德三欣电力电子科技有限公司

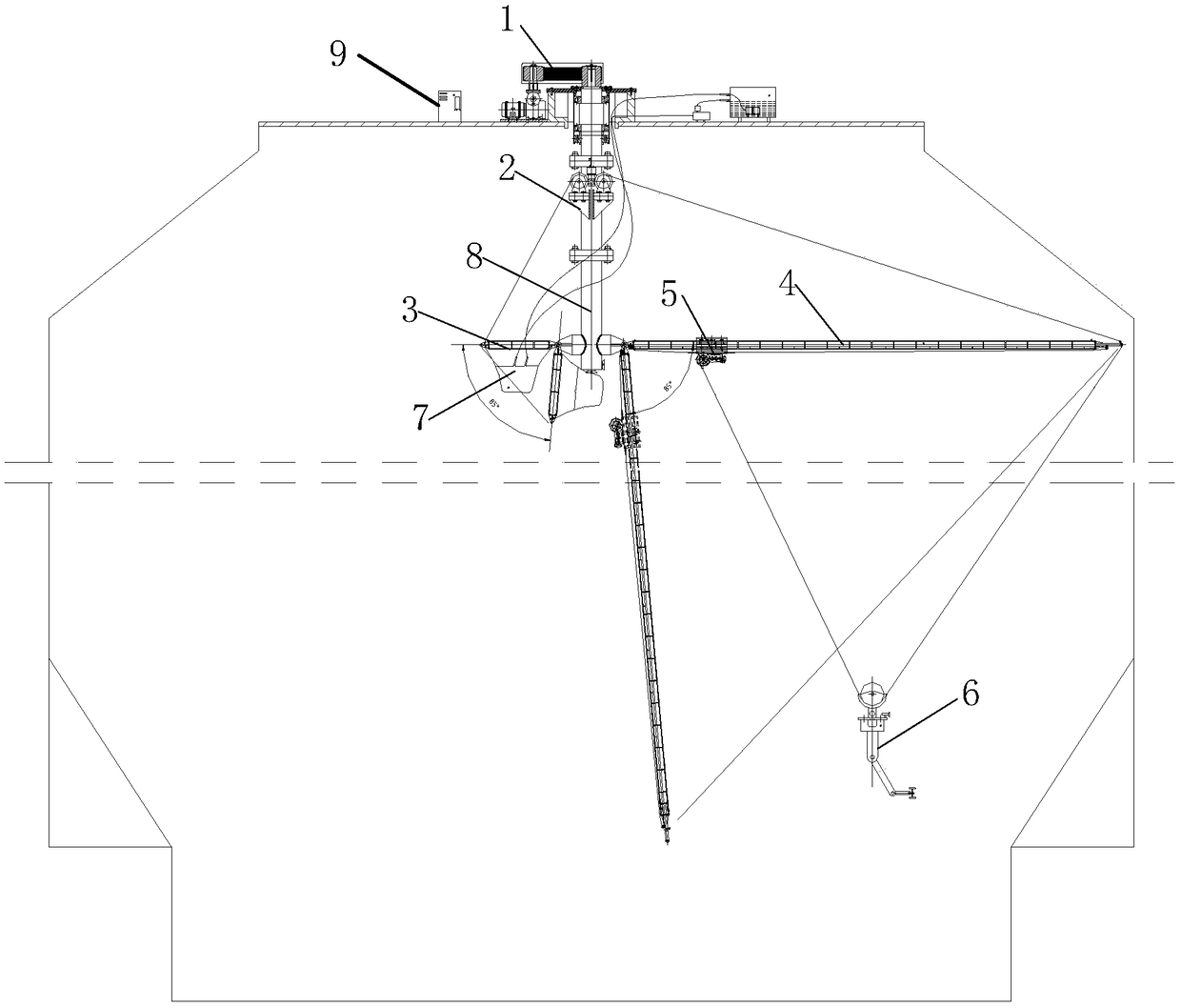

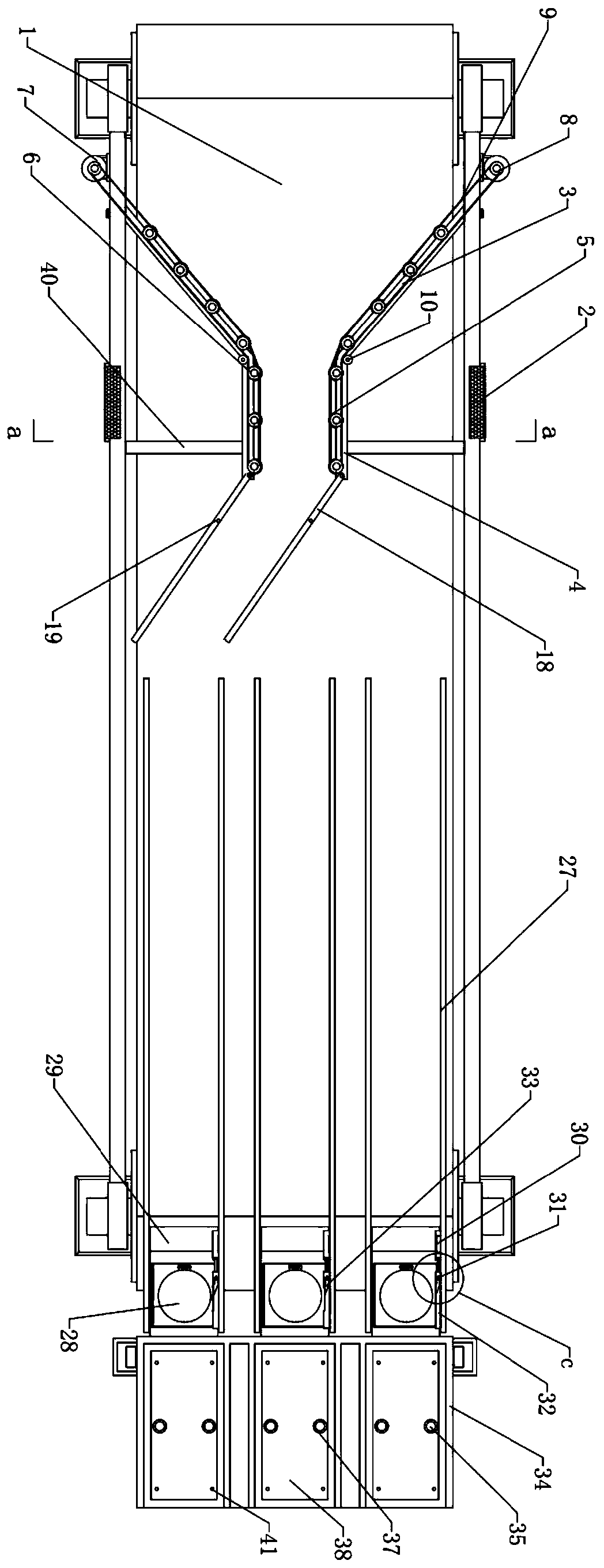

Large coal bunker blockage cleaning robot

ActiveCN109129431AEnsure safetyImprove efficiencyProgramme-controlled manipulatorWater storage tankEngineering

The invention provides a large coal bunker blockage cleaning robot, relates to the technical field of warehousing equipment, and solves the technical problem of mechanical cleaning in a coal bunker. The coal bunker cleaning robot comprises a revolving mechanism, a lifting mechanism, a water storage tank, a left working arm, a right working arm, a walking car, a bunker cleaning manipulator, a balance device and a stand column; the revolving mechanism is connected with the upper end of the stand column through a gear; the lifting mechanism is arranged on the stand column; a connecting support rod is arranged at the lower end of the stand column; the left working arm and the right working arm are arranged on the connecting support rod; the balance device is arranged on the left working arm; the walking car is arranged on the right working arm; a windlass is arranged on the walking car; the bunker cleaning manipulator is connected with the walking car through a steel wire rope; and the steel wire rope is used for adjusting rotation of the left working arm and the right working arm and the position of the bunker cleaning manipulator to finish internal cleaning of a coal bunker. In addition, the coal bunker cleaning robot has the advantages of safe and efficient cleaning, wide application range and convenience for installation and disassembly.

Owner:SHANDONG UNIV OF SCI & TECH

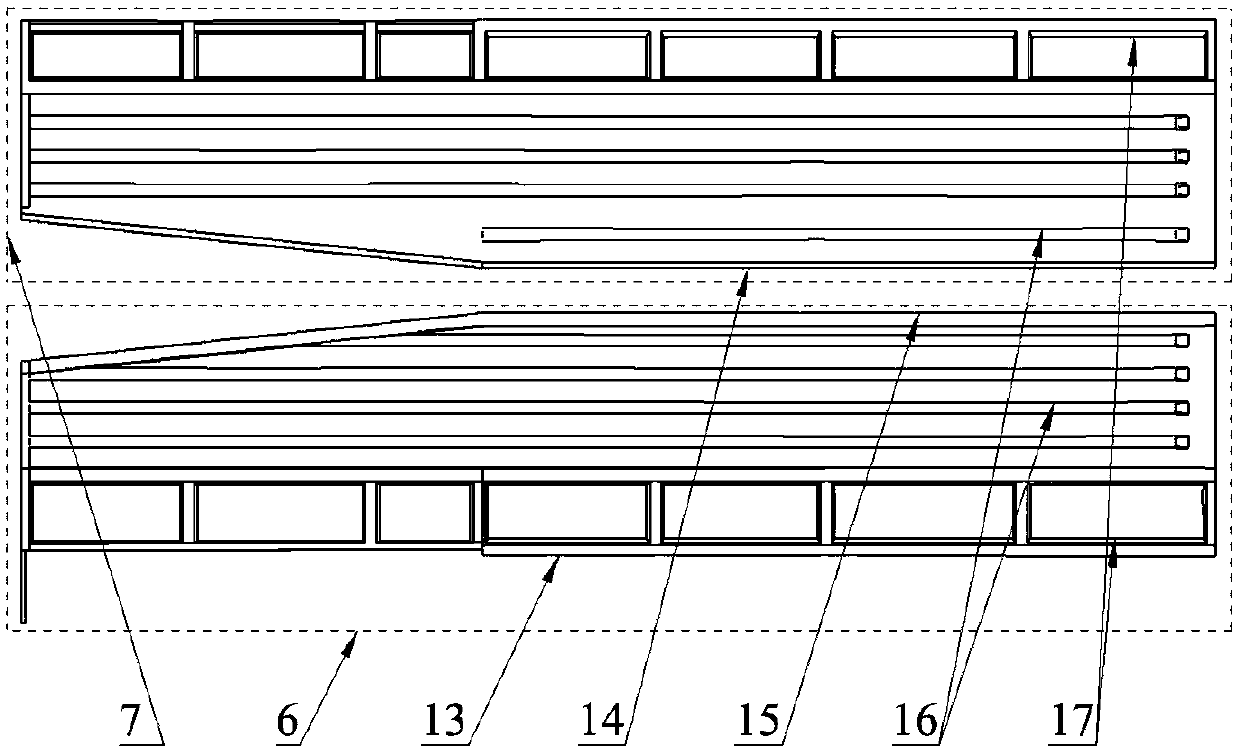

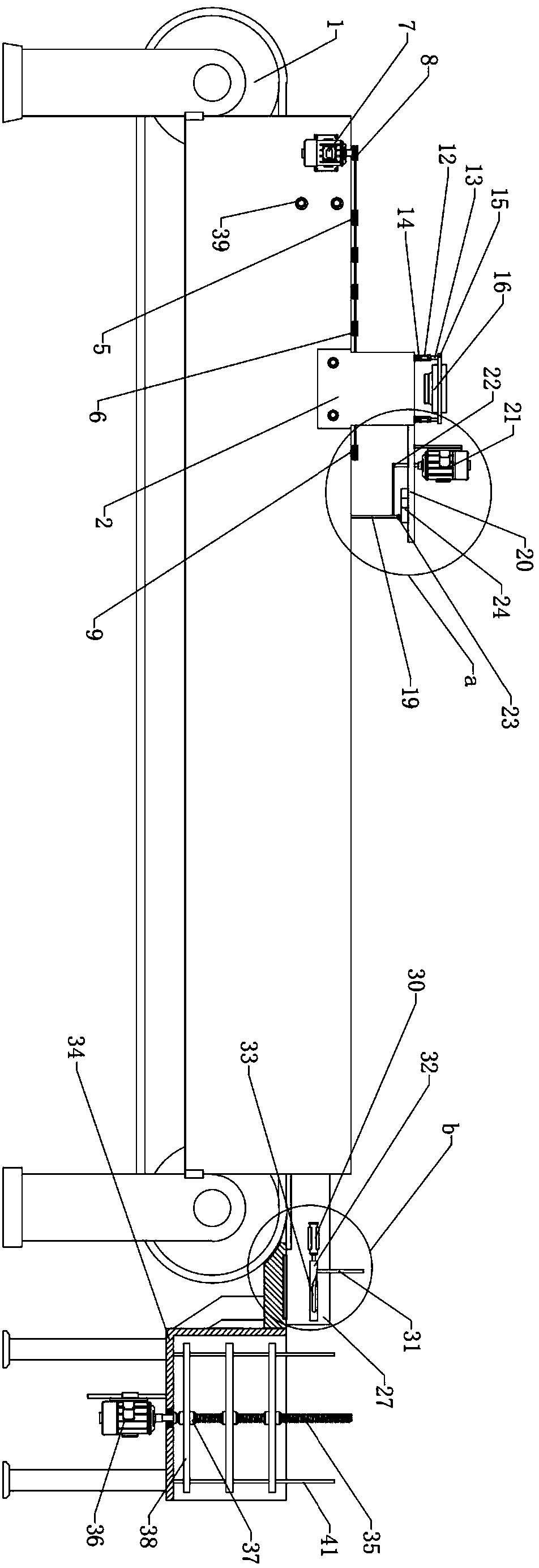

Logistics storage conveying equipment with automatic screening function

PendingCN111014074ASimple compositionReduce deliverySortingLogistics managementIndustrial engineering

The invention relates to logistics storage conveying equipment with an automatic screening function. The logistics storage conveying equipment comprises a main conveying belt, a feeding mechanism, a first-stage sorting mechanism and a plurality of second-stage sorting mechanisms of the same structure, the feeding mechanism is installed on one side of the main conveying belt, the first-stage sorting mechanism is arranged on the main conveying belt, and the multiple second-stage sorting mechanisms are arranged on one side of the first-stage sorting mechanism. The logistics storage conveying equipment has the beneficial effects that the logistics storage conveying equipment is simple in composition, adopts modular design, is simple to install and assemble, is divided into the feeding mechanism, the first-stage sorting mechanism and the second-stage sorting mechanisms, achieves miniaturization of sorting equipment through cooperation of the structures, overall takes the conveying belt as amain body and is simple in structure; and the feeding mechanism, the first-stage sorting mechanism and the second-stage sorting mechanism are all mounted in a split mode, disassembly and maintenanceare convenient, two times of sorting are used, express items are classified according to regions, weights and the like, delivery by couriers is facilitated, and meanwhile the express items are effectively protected.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

Silencer for safety valve for chemical plant

InactiveCN105065767ASimple structureEasy and fast assemblyValve members for absorbing fluid energyAcoustic waveEngineering

The invention discloses a silencer for a safety valve for a chemical plant. The silencer comprises a silencer barrel, a partition plate, through holes, an upper end socket, a lifting lug, a support, a base, a lower end socket and an air inlet. The two ends of the silencer barrel are provided with the upper end socket and the lower end socket. The lifting lug is arranged on the upper end socket. The through holes are evenly formed in the outer wall of the silencer barrel. The support is arranged at the portion, close to the lower end, of the outer side of the silencer barrel. The air inlet is arranged in the lower end of the lower end socket. The silencer for the safety valve for the chemical plant has the beneficial effects that the structure is simple, compact and reasonable, assembling is convenient and rapid, and connection is reliable; the purpose of silencing is achieved by disturbing airflow and sound waves of the silencer, and noise is lowered; internal intake and exhaust are smooth, power losses are small, and the silencing effect is good; the working reliability of the silencer is greatly improved, and use and application are easy; an exhaust pipe will not bear large external force due to the fact that the silencer is placed, disassembling and overhauling are convenient, and displacement, taking-off and returning of the safety valve are not affected.

Owner:WUXI YUEFENG CHEM

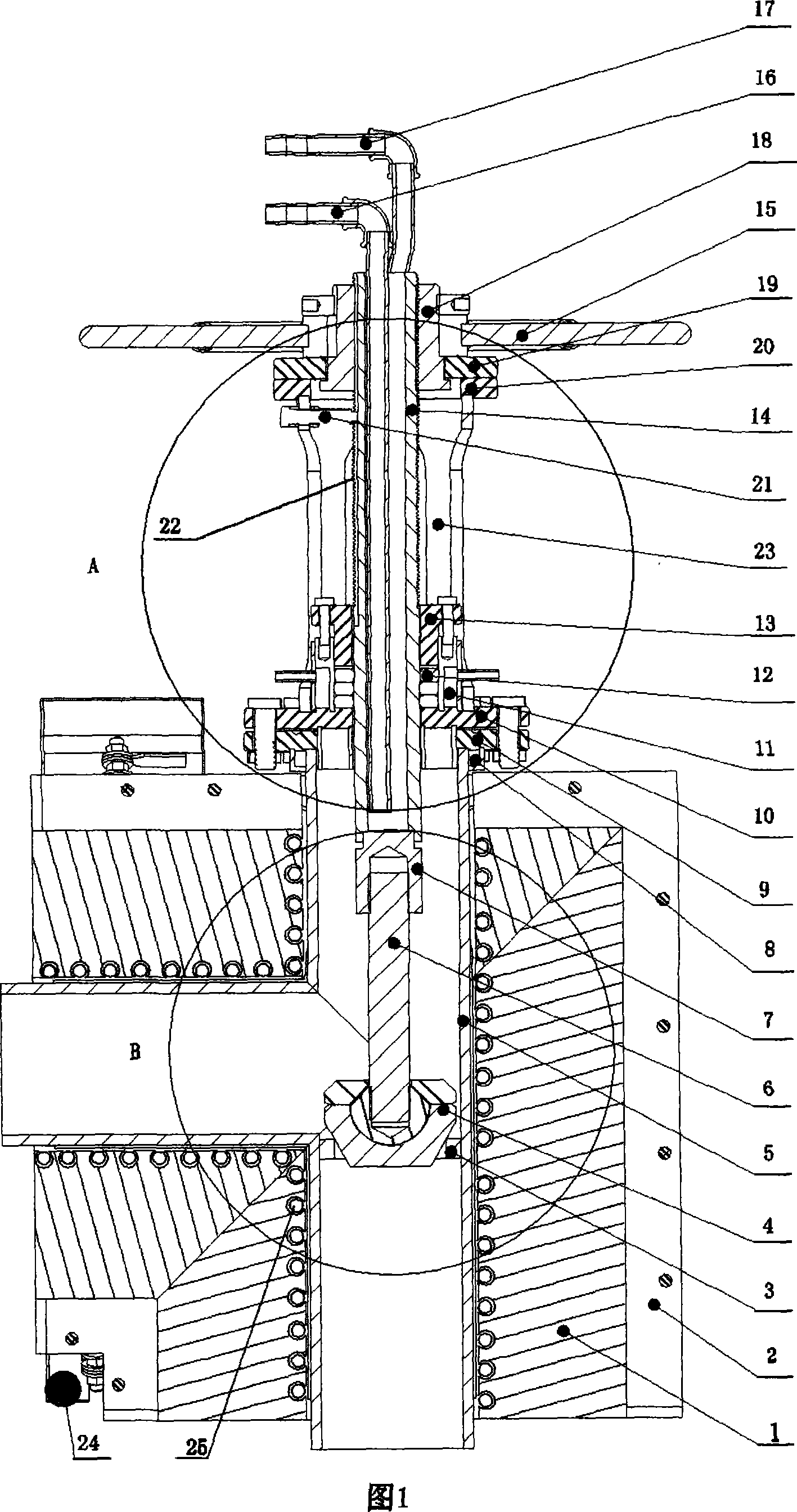

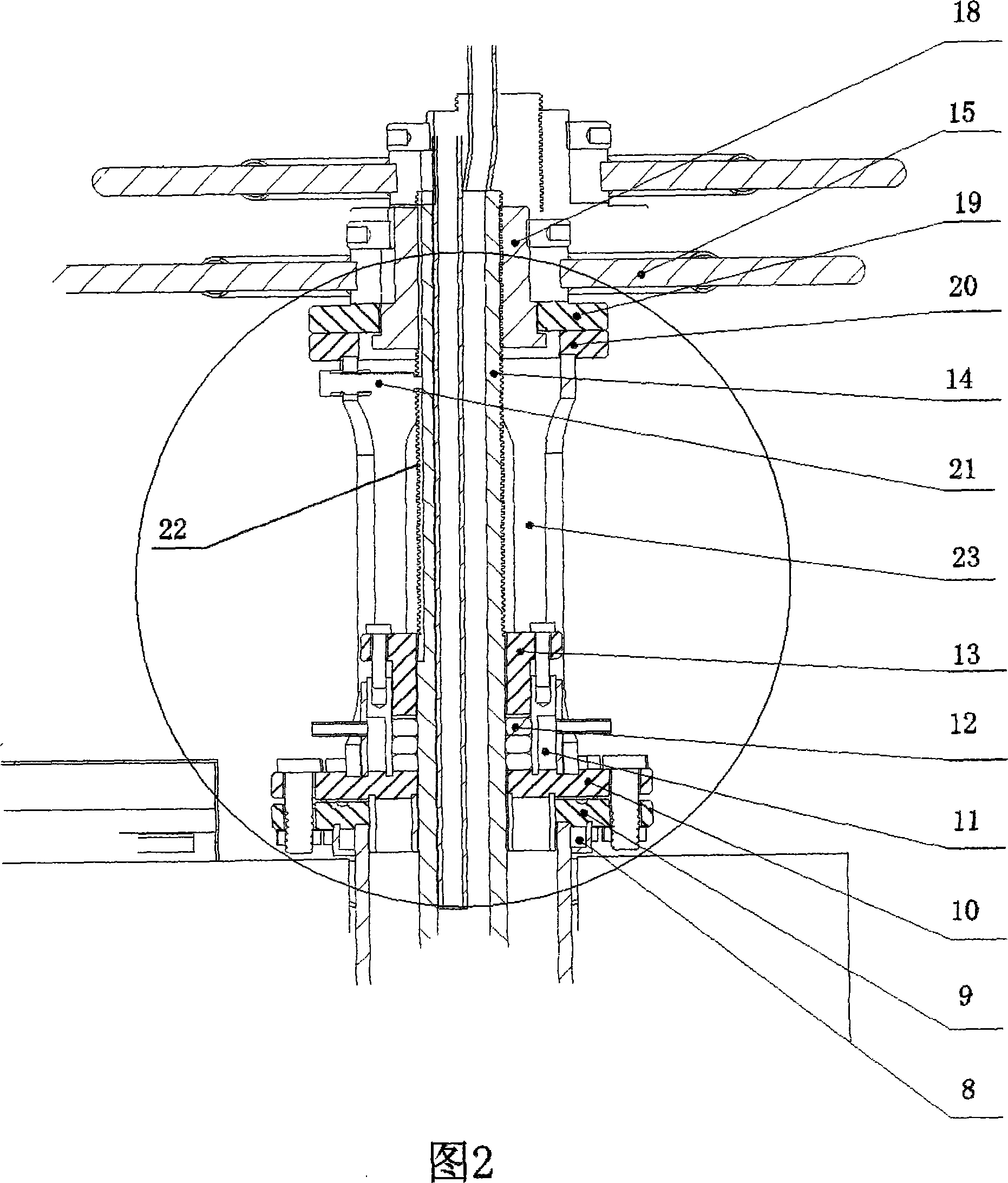

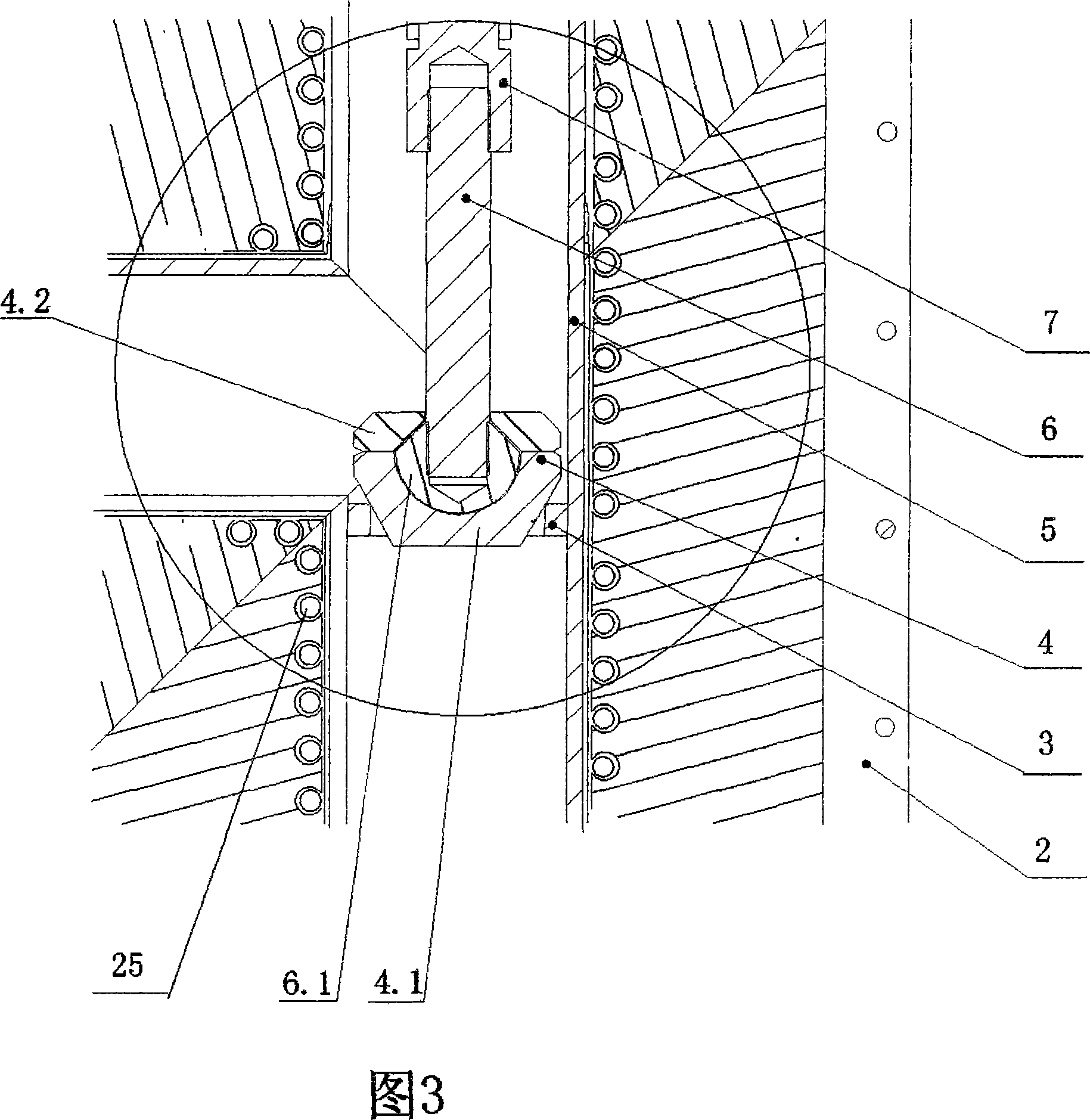

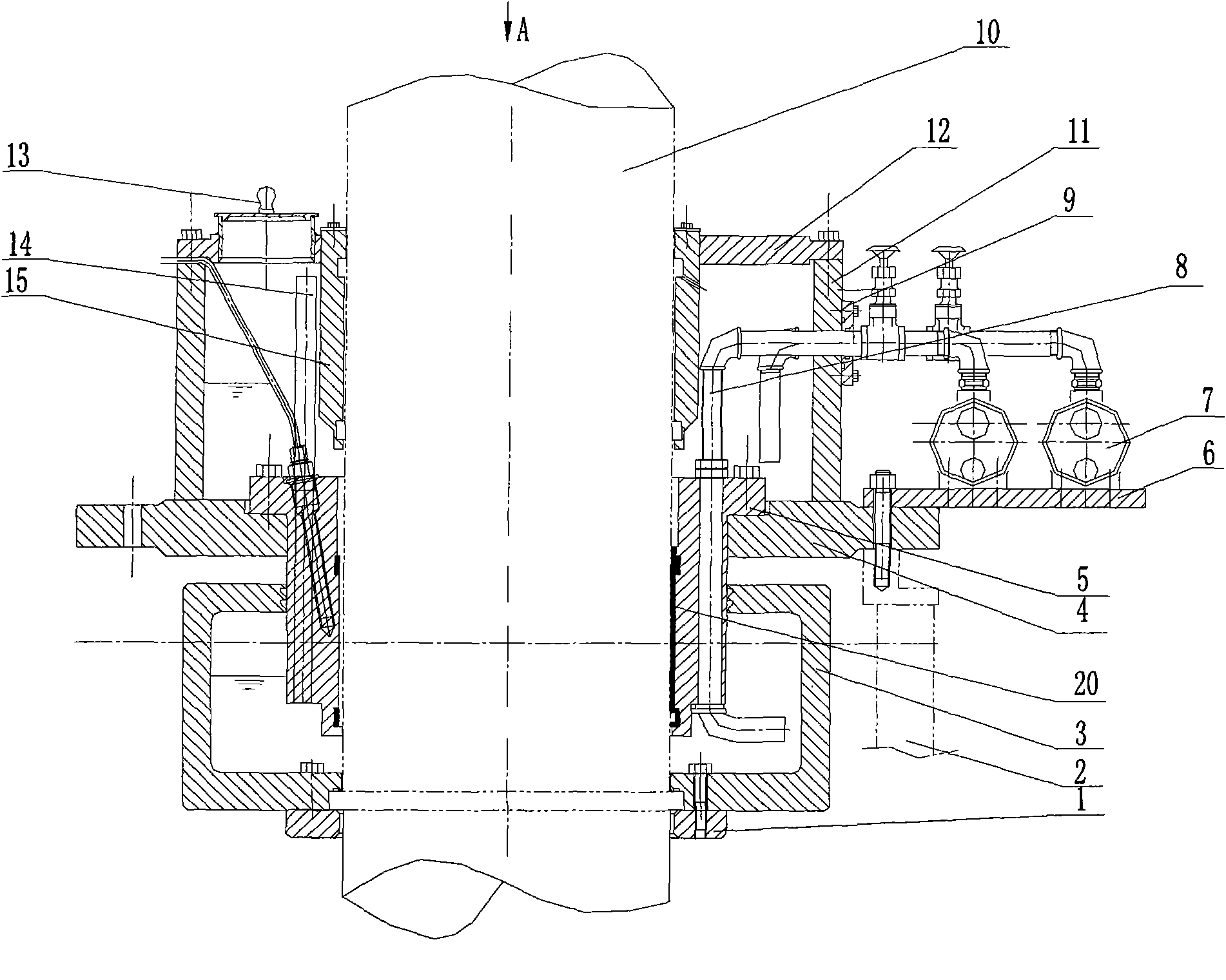

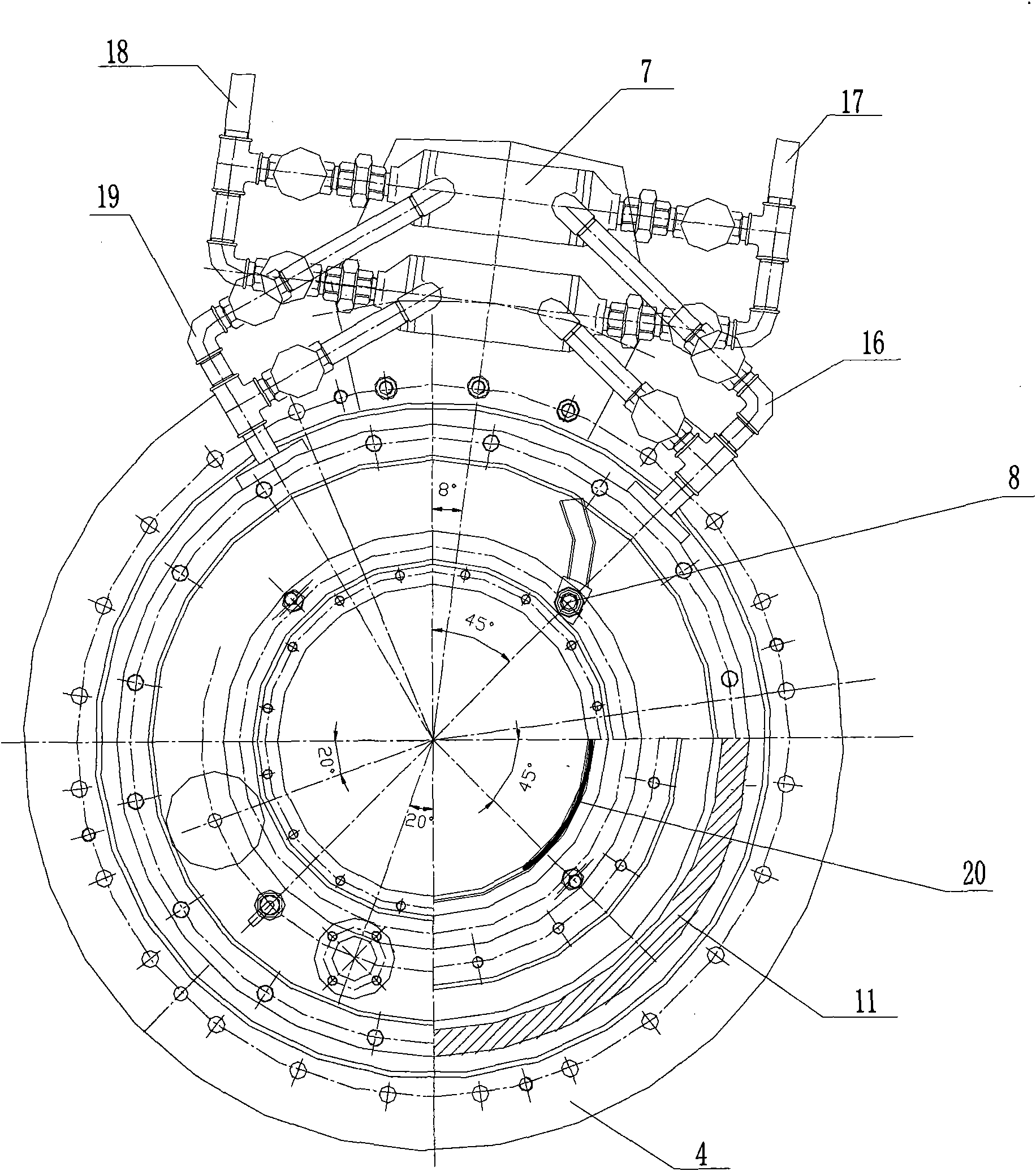

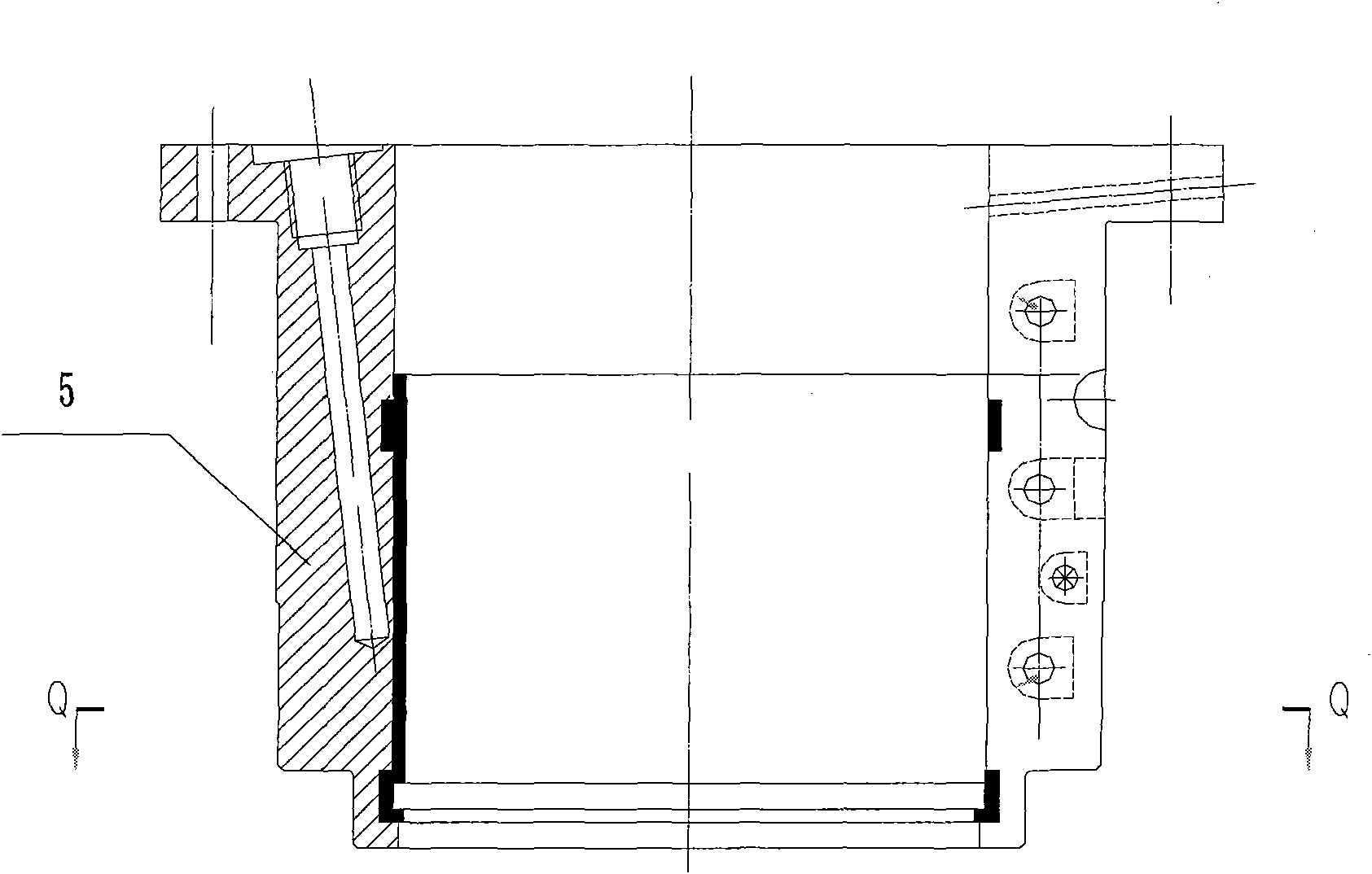

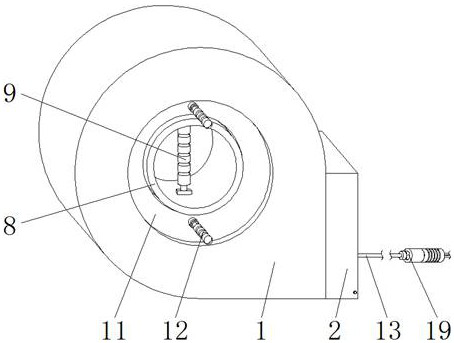

Parabolic pad guide bearing for main shaft of vertical water turbine

InactiveCN101576044AEasy to disassemble and overhaulExcellent dynamic hydraulic performanceFinal product manufactureHydro energy generationWater turbineEngineering

The invention relates to a parabolic pad guide bearing for a main shaft of a vertical water turbine, which is characterized in that: a bearing base is arranged on the top cover of the water turbine; a bearing body consisting of four circular arc bodies is fixed on the bearing base; a bearing bush of the main shaft is embedded in the bearing body; the bearing bush takes the shape of a parabolic surface; a rotating oil basin which is positioned at the lower end of the bearing body is arranged on the main shaft; an upper oil tank is welded at the upper end of the bearing base; an oil tank cover is sealed on the upper oil tank; a pitot tube is arranged on the side wall of the bearing body; the lower end of the pitot tube is communicated with the rotating oil basin, while the upper end thereof is connected with a cooler which is arranged outside the upper oil tank by pipelines; and the oil outlet of the cooler is communicated with the upper oil tank by pipelines. The invention solves the problem that the cooler is inconvenient for maintenance. The bearing bush on the bearing body can directly face to the polished journal of the main shaft and the main shaft does not need to be provided with a shaft neck or an enlarged diameter. In addition, the invention has the advantages of simple structure, easy manufacture, being capable of bearing large radial force.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Convenient conduit threading auxiliary device for building power construction

ActiveCN112290467AQuick install connectionEasy to fixApparatus for laying cablesArchitectural engineeringStructural engineering

The invention discloses a convenient conduit threading auxiliary device for building power construction. The device comprises an outer protection shell and a storage box, the storage box is welded tothe outer surface of the right side wall of the outer protection shell, a box cover is hinged to the lower end of the right side of the storage box, and a mounting base is mounted on the inner side ofthe rear end of the outer protection shell. A handle is fixedly connected to the inner side wall of the middle of the mounting base, cranks are rotatably connected to the upper end and the lower endof the front side wall of a winding wheel, a connecting block is fixedly connected to the right end of a steel wire rope, the outer side of the left end of the mounting column is sleeved with a firstpipe sleeve, and a limiting groove is formed in the outer side wall of the right end of the mounting column; and a connecting hole is formed in the inner side of the right end of the mounting column.According to the convenient conduit threading auxiliary device for building power construction, rapid installation and connection of cables are facilitated, the installed cables are fixed conveniently, the practicability is improved, in addition, the convenient conduit threading auxiliary device has the characteristics of being small in size, convenient to wind and the like, and the convenience isimproved.

Owner:CHINA HUADIAN ENG

Damping device for building

The invention discloses a damping device for a building. The damping device comprises a vibration support and a vibration table. The vibration support comprises a base, a vibration rotating wheel and a vibration movable rod. A driving wheel is arranged between the vibration movable rod and the bottom of the base. A transverse oil cylinder is also arranged at the bottom of the base. The bottom of the base is an arc face. The top face of the base is provided with a damping clamping groove. A shaft rod is arranged in the damping clamping groove. The middle of the shaft rod is provided with a damping eccentric wheel. The bottom face of the vibration table is provided with a damping lug connected with the damping eccentric wheel. Movable wheel grooves are symmetrically formed in the inner side wall of the damping clamping groove. Movable wheels are arranged in the movable wheel grooves. A synchronous connecting rod is arranged between the wheel side of the damping eccentric wheel and the driving wheel. A buffer pressure spring is arranged between the damping eccentric wheel and the damping clamping groove. The damping device is simple in structure, good in using stability, capable of effectively reducing noise produced by vibration and convenient to assemble, disassemble and overhaul, the using reliability and using stability are improved, the installation cost is greatly reduced, the using stability is good, and applicability is high.

Owner:江苏华轩建设工程有限公司

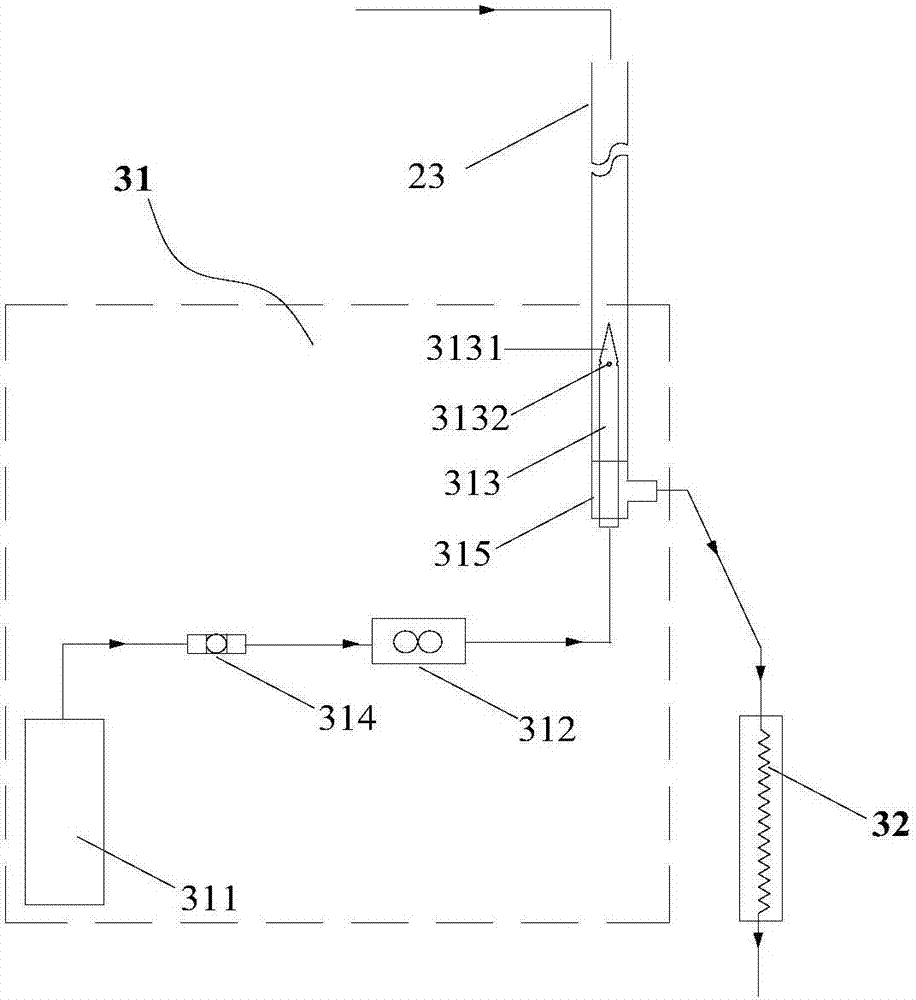

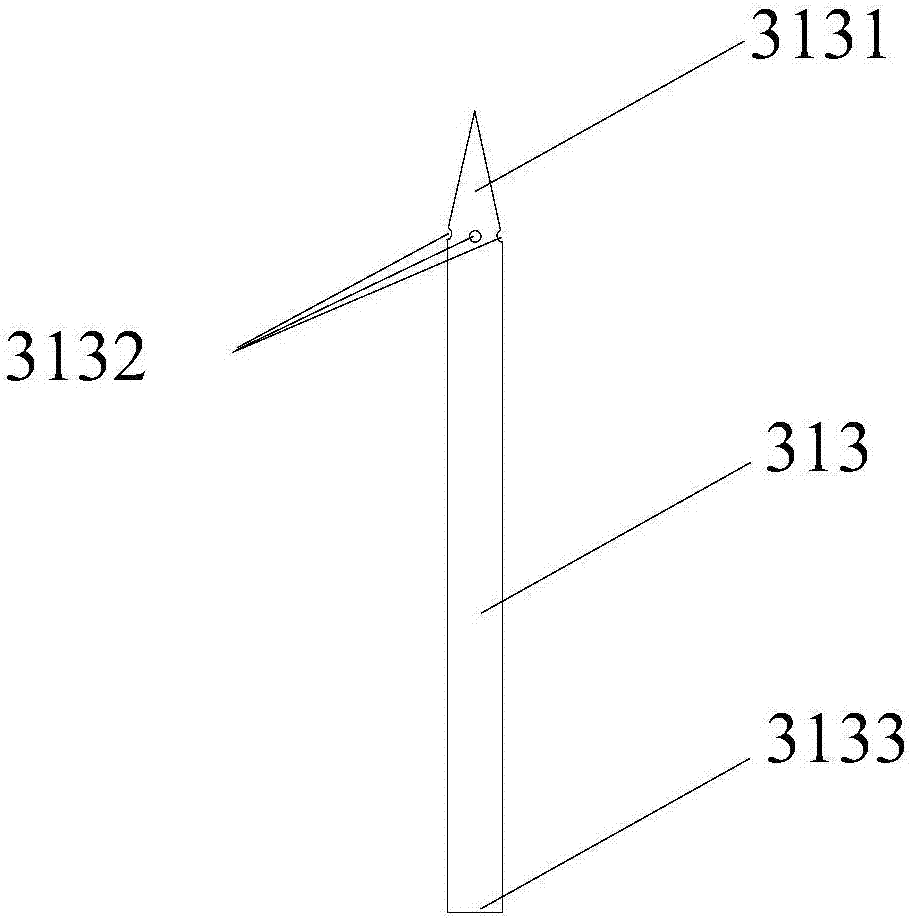

Steam thermal cracking simulating experiment apparatus and technology

ActiveCN107541240AGuarantee the normal operation of the experimentSmall pressure lossThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingCircular coneEngineering

The invention provides steam thermal cracking simulating experiment apparatus and a technology. The apparatus comprises a raw material inlet device, a cracking furnace, a product quick cooling deviceand a product separation and recovery device, wherein the raw material inlet device, the cracking furnace, the product quick cooling device and the product separation and recovery device are connectedsequentially, the product quick cooling device comprises a direct cooling system and an indirect quick cooling device, an operation method of the direct cooling system comprises the following steps:a quick-cooling water injecting pipe is inserted vertically into a material outlet of a cracking furnace pipe, the end part of an inserted end is in the shape of a circular cone, water injecting holesare uniformly arranged in the bottom surface circumference of the end part of the circular cone shape, quick cooling water is directly sprayed into the cracking furnace pipe through the water injecting holes, and high-temperature pyrolysis gases subjected to quick cooling through the quick cooling water enter the indirect quick cooling device. The apparatus has the advantages that the novel product quick cooling device is adopted, thus quick cooling of the high-temperature pyrolysis gases is facilitated, pressure loss of the pyrolysis gases in the furnace pipe is reduced, coking near the quick-cooling water injecting holes is effectively prevented, smooth operation of the simulating apparatus is guaranteed, and at the same time simulation effect accuracy of the cracking furnace is improved.

Owner:PETROCHINA CO LTD

Plant atomization and water-replenishing planting device

InactiveCN106613435AGuaranteed normal growthAvoid freezing to deathLighting and heating apparatusSelf-acting watering devicesElectricityBarrel Shaped

The invention discloses an atomization and water-replenishing planting device suitable for planting of plants of orchid and the like with roots easy to rot. The planting device comprises a barrel-shaped body, wherein at least one cultivation basket is detachably arranged at the upper part of the body, a controller is arranged on the body, a water pump is arranged in the position, close to the bottom wall, of the inside of the body and is electrically connected with the controller, an atomization device which is connected with the water pump is further arranged in the body and is electrically connected with the controller, and a heating plate which is electrically connected with the controller and a temperature sensor which is electrically connected with the controller and used for controlling the working state of the heating plate are arranged in the positions, close to the bottom wall, of the inside of the body.

Owner:SUZHOU RUITENG ECOLOGICAL TECH CO LTD

Movable clamping type electronic connector

InactiveCN109411912AEasy to disassemble and overhaulAchieve axial movementElectric connection structural associationsClamped/spring connectionsSize changeEngineering

The invention discloses a movable clamping type electronic connector. The movable clamping type electronic connector comprises a first connection ring, a breakover block, a second connection ring, a flexible breakover rod, a standby start / stop assembly and a clamping screw. The breakover block is clamped and connected in the first connection ring through the clamping screw, so that the operation is more convenient and rapid when the breakover needs to be dismounted for size change or overhauling.

Owner:东台市高科技术创业园有限公司

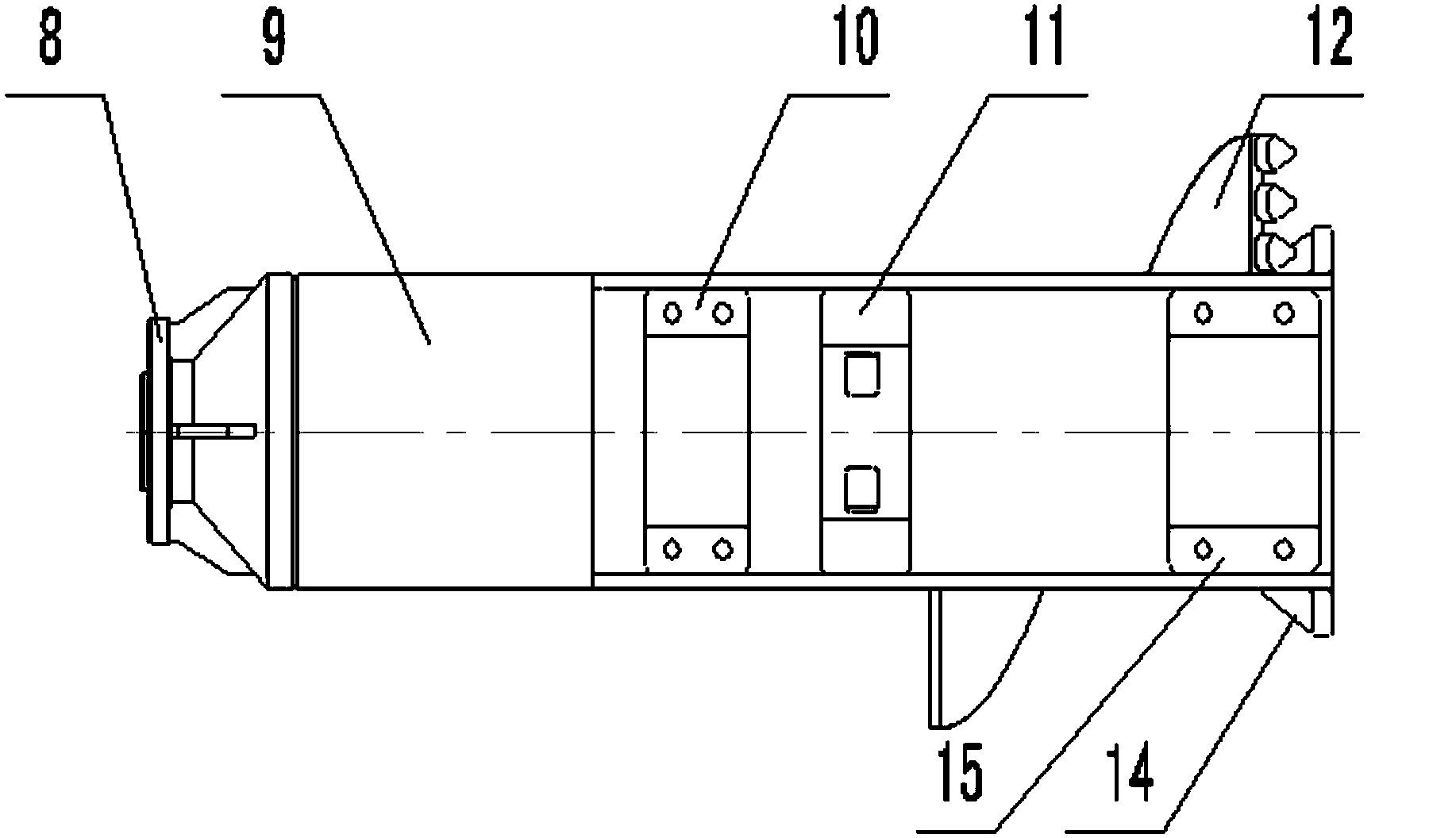

Split type mud gun vibrating source drilling tool

The invention discloses a split type mud gun vibrating source drilling tool, and belongs to the technical field of drilling. A main shell is cylindrical, a half of one end of the main shell is cut, a check ring is welded to a notch of an inner cavity of the main shell, a transition sleeve is fixedly welded to the upper end of the main shell, and an upper flange is fixedly welded to the upper end of the transition sleeve so that the upper end of the transition sleeve can be connected with a drill rod. A drill bit flange is fixedly welded to the outer circle of the lowest end of the main shell, the lower end face of the drill bit flange is flush with the lower end face of the main shell, and angle ribs are welded between the drill bit flange and the main shell. A screw blade with a half lead is fixedly welded to the lower side of a square hole of the outer circle of the main shell, the lead of the screw blade is 800 mm, and the external diameter phi of the screw blade is 600 mm. A semi-circular-ring-shaped upper connecting tile is fixedly welded to the lower side of the check ring of the inner cavity of the main shell, a bolt connecting hole is machined in the upper connecting tile, a semi-circular-ring-shaped filling body is fixedly welded to the lower side of the upper connecting tile, and square holes are machined in the positions, corresponding to air vents of a mud gun, of the filling body and the main shell. A lower connecting tile is welded to the inner cavity of the lowest side of the main shell.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

Monitor convenient to mount

InactiveCN107396070AWide range of monitoringEasy to install and disassembleClosed circuit television systemsBiochemical engineering

Owner:肇庆高新区鹰眼科技有限公司

Building intelligent fire automatic alarm device

PendingCN112820055AEasy to useAvoid damageFire alarm electric actuationStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of building security and protection, and discloses a building intelligent fire automatic alarm device, which comprises a mounting plate, a base and an alarm device body, and is characterized in that the upper end of the alarm device body is fixedly connected with the lower end of the base; the left side and the right side of the upper end of the base are both connected with clamping mechanisms and are jointly connected with the mounting plate through the two clamping mechanisms, the base is connected with a protection mechanism, the protection mechanism comprises a frame body, an electric push rod and a fixing rod, and the fixing rod is fixedly arranged on the lower portion in the frame body. When the temperature is too high, the alarm device body can be separated from the external high temperature in time, the alarm device body is prevented from being damaged due to the too high temperature, the alarm device body can give an alarm continuously, the use effect of the automatic fire alarm device is improved, meanwhile, people can disassemble and overhaul the alarm device body conveniently, and mounting and dismounting are convenient and fast.

Owner:西安千心网络科技有限公司

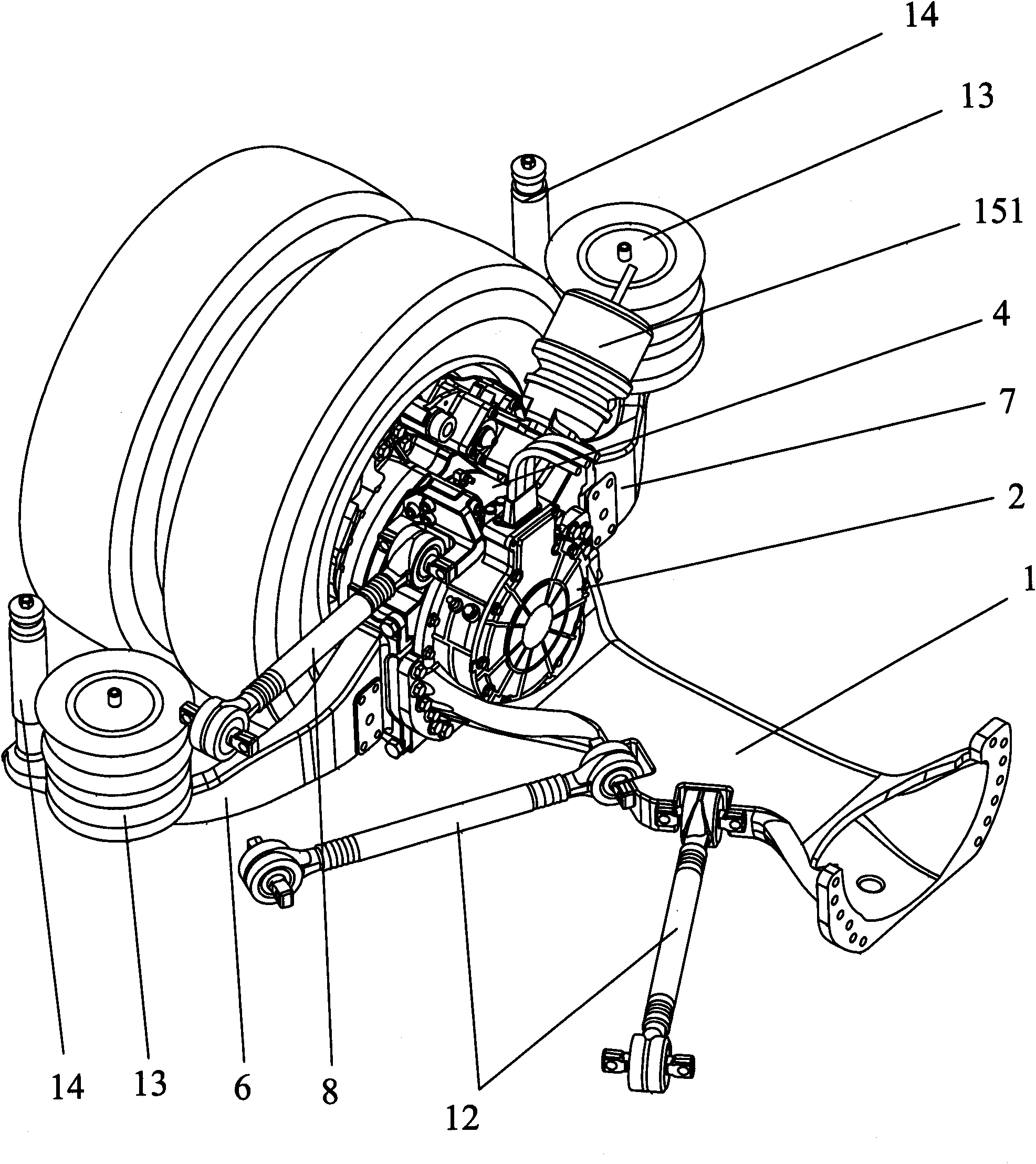

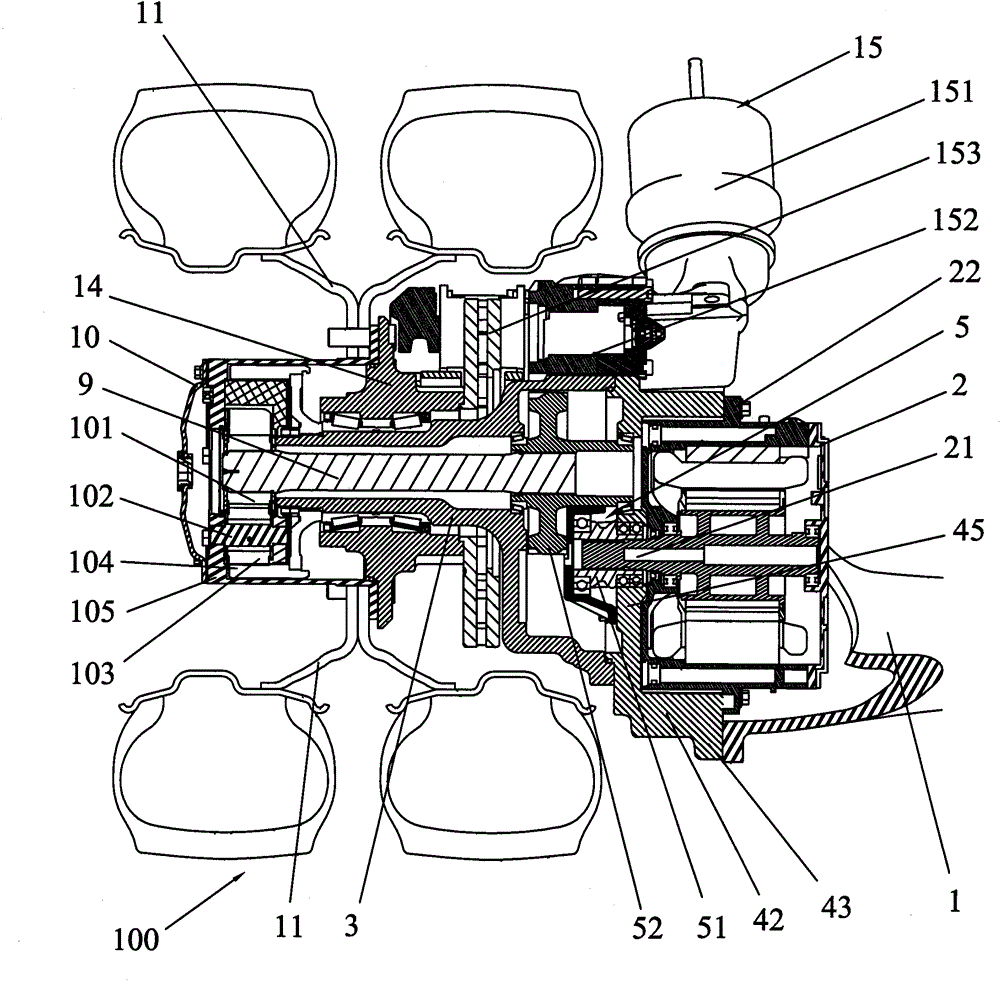

Wheel drive axle

ActiveCN102139629BSimple structureCompact structureMotor depositionControl devicesControl theoryWheel drive

The invention provides a wheel drive axle which comprises a first wheel drive system. The first wheel drive system comprises a motor and a primary speed reducer which is connected with an output shaft of the motor, wherein the primary speed reducer comprises an input shaft gear, an output shaft gear, an intermediate shaft driven gear and an intermediate shaft drive gear; a rotating shaft of the output shaft gear is coaxial with a wheel rotating shaft; a rotating shaft of the input shaft gear is coaxial with an output shaft of the motor; the output shaft of the motor is fixedly connected with the input shaft gear so as to drive the input shaft gear; the input shaft gear is meshed with the intermediate shaft driven gear so as to drive the intermediate shaft driven gear and the intermediate shaft drive gear which are fixed on the same shaft as the intermediate shaft driven gear; and the intermediate shaft drive gear is meshed with the output shaft gear so as to transfer driving force to the output shaft gear. In the wheel drive axle, the primary speed reducer has simple structure and is easy to process and assemble.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com