Soft package battery module with non-welding type tab connecting structure, and connecting method

A soft-pack battery and connection structure technology, which is applied to battery components, batteries, and conductive connections, can solve the problems of inconvenient disassembly and maintenance of lithium battery modules, increased weight of lithium battery modules, and cumbersome production processes, etc., to achieve Improve assembly efficiency and enterprise benefits, improve connection stability, and facilitate the production and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

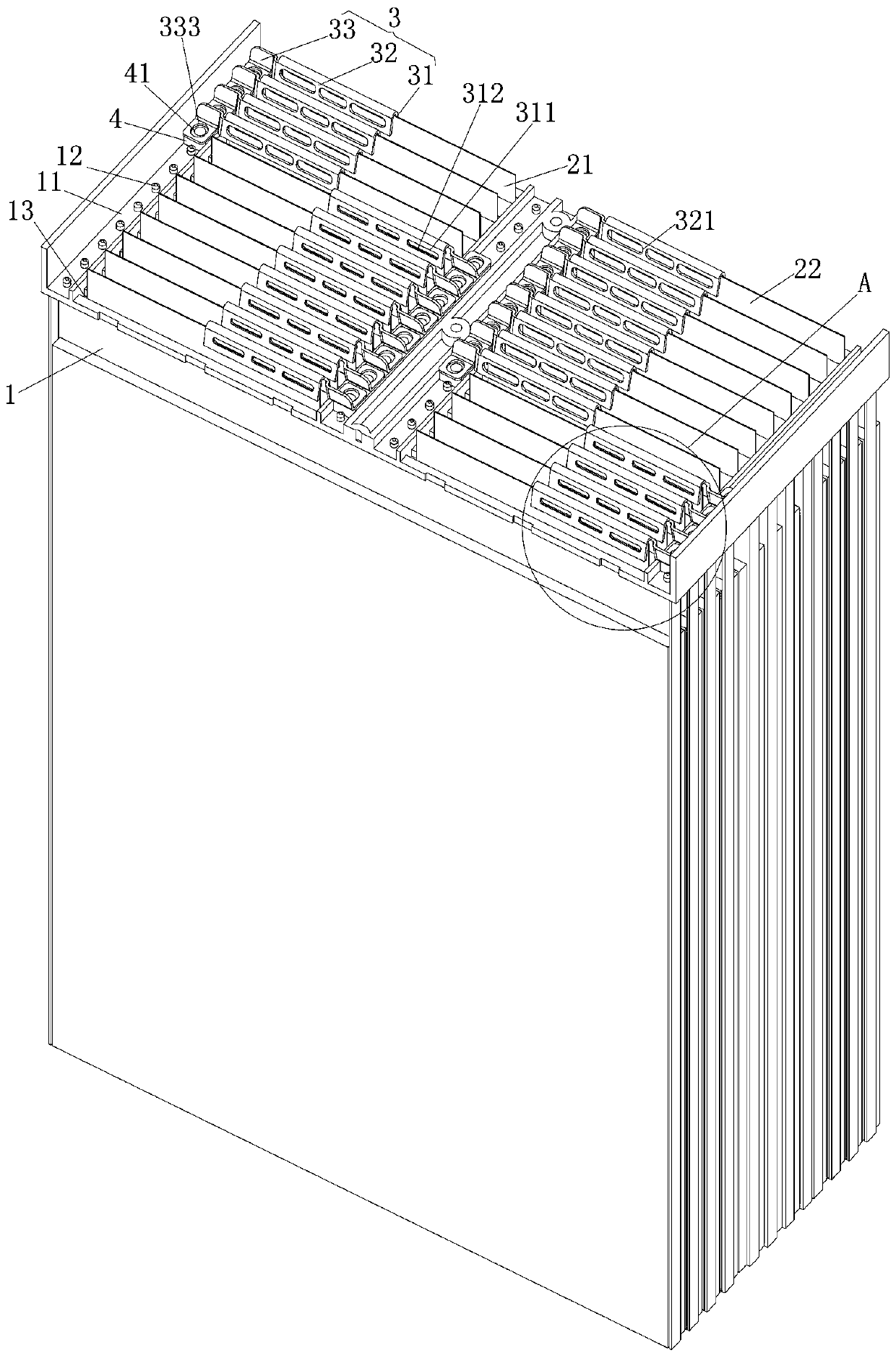

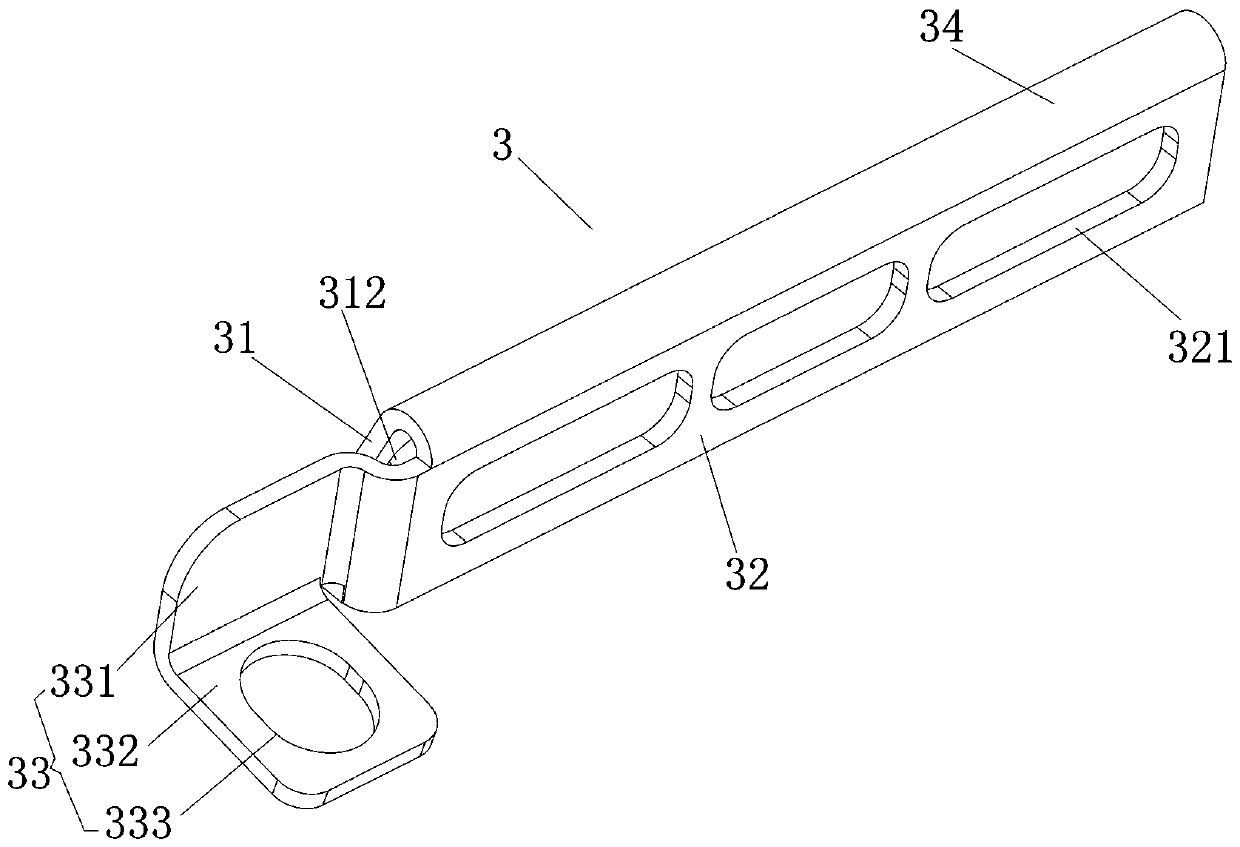

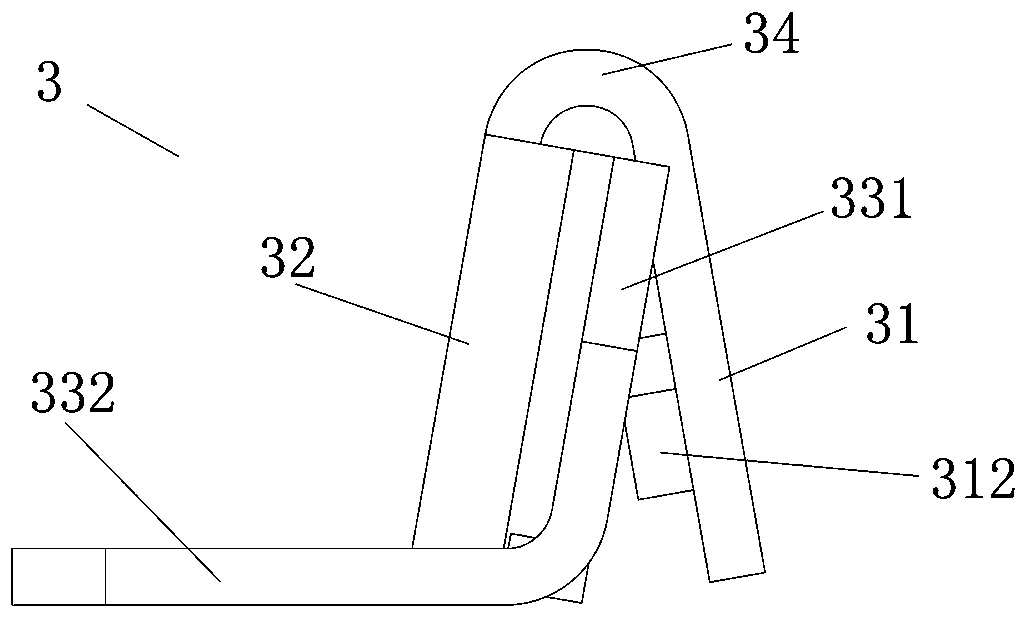

[0030] Such as Figure 1-4 As shown, a pouch battery module with a non-welded tab connection structure includes a battery frame 1, 12 battery cells stacked side by side in the battery frame 1, and four bus bars arranged on the battery frame 1. 4. A connection member 3 is provided between a tab of the battery cell and a corresponding bus bar 4, and the connection member 3 includes a first connection piece 31, a second connection piece 32 and a third connection piece 33 connected in sequence, and the third connection piece 3 The connecting piece 33 is fixedly connected to the bus bar 4, and the tabs are sandwiched between the first connecting piece 31 and the second connecting piece 32. The first connecting piece 31 is provided with three first clamping parts, and the second connecting piece 32 is provided with three There is a second clamping part, and the pole lug is interference-fitted between the first clamping part and the second clamping part through the fastened first con...

Embodiment 2

[0047] The difference from the first embodiment above is that the first engaging part is a through hole 321 formed on the first connecting part 31, the second engaging part is a block protruding toward the first connecting part 31, and the locking part is The shape of the block matches the shape of the through hole 321; when the first connector 31 and the second connector 32 are engaged, there is a gap with a width smaller than the thickness of the lug between the inner wall of the through hole 321 and the outer wall of the block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com