High-power LED optical path heat dissipation combined system

A combination system and heat dissipation system technology, applied in the field of high-power LED optical path and liquid-cooled air-cooled heat dissipation combination system, can solve the problems of high energy consumption and limited heat dissipation efficiency, achieve high light efficiency, save space, and reduce design costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

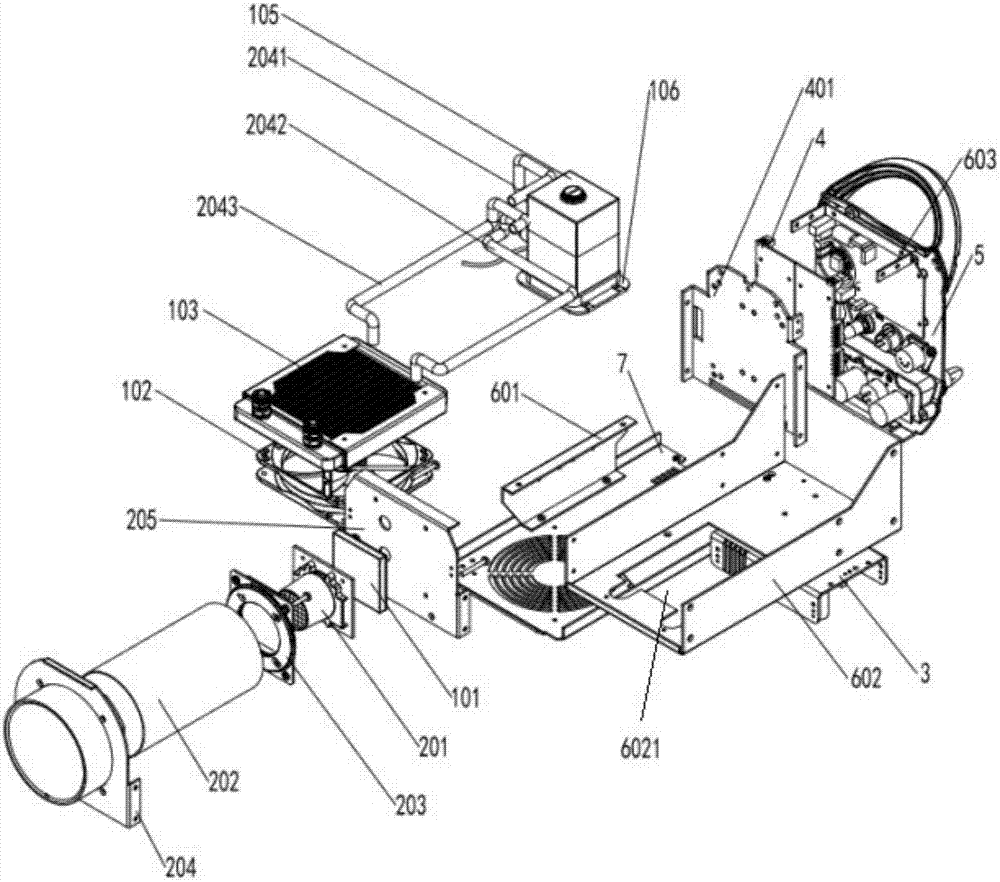

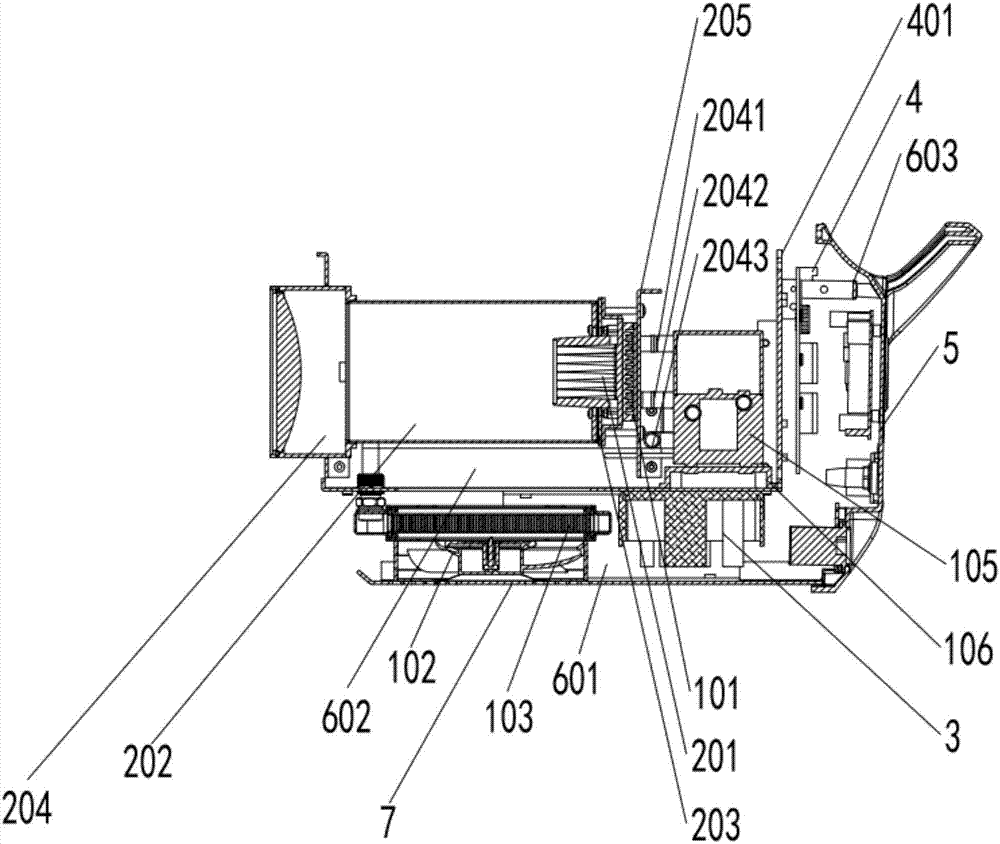

[0090] like Figure 1-9 As shown, this embodiment provides a high-power LED optical path heat dissipation combined system, including an optical path system and a heat dissipation system;

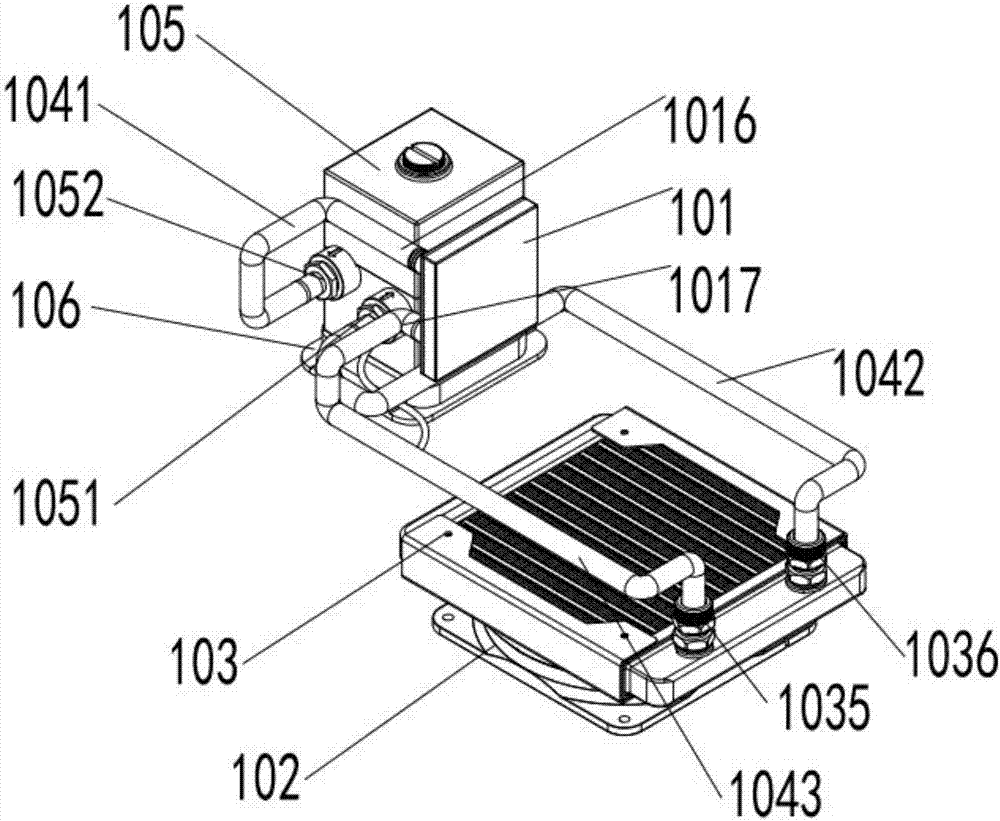

[0091] The heat dissipation system is a liquid-cooled and air-cooled combined heat dissipation system, which specifically includes: a heat absorbing device 101, a fan 102, a liquid-cooled radiator 103, a liquid-cooled pipeline 104, and a liquid circulation pump 105;

[0092] The inside of the heat absorbing device 101 in this embodiment is a hollow structure with diversion grooves, and the heat absorbing device inlet port 106 and the heat absorbing device outlet port 107 are arranged on the outside; it specifically includes: the heat absorbing device main body 1011 and a cover plate 1013, a sealing ring 1012 is arranged between the heat absorbing device main body 1011 and the cover plate 1013 and is fixedly connected by screws 1015, and a heat absorbing device liquid inlet port 1016 and a he...

Embodiment 2

[0121] like Figure 10-12 As shown, the difference between this embodiment and embodiment 1 is:

[0122] When the circulation pipeline 1033 adopts metal pipes such as aluminum pipes or copper pipes, it can be set as follows according to actual needs Figure 10 Metal circulation pipes of different shapes as shown; or, combined pipes with metal pipes or circulation lines embedded with profiled radiators.

[0123] The groove cylinder 10131 inside the cover plate 1013 of the heat absorbing device 101 in Embodiment 1 can also be set as an annular guide groove 10131 ′, and the boss cylinder 10111 in the heat absorbing device main body 1011 and the annular guide groove inside the cover plate 1013 The flow channels 10131' form interconnected flow channels. On the one hand, the boss cylinder 10111 and the annular diversion groove 10131' can increase the heat dissipation area in the cavity; on the other hand, the superconducting liquid can be shunted, so that the superconducting liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com