Combined valve

A combination valve and valve body technology, applied in the field of hydraulic components, can solve the problems of easy leakage of joint joints, inconvenient maintenance and repair, complicated line connection, etc., and achieve the effects of quick and convenient disassembly and maintenance, cost saving, and simple line connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

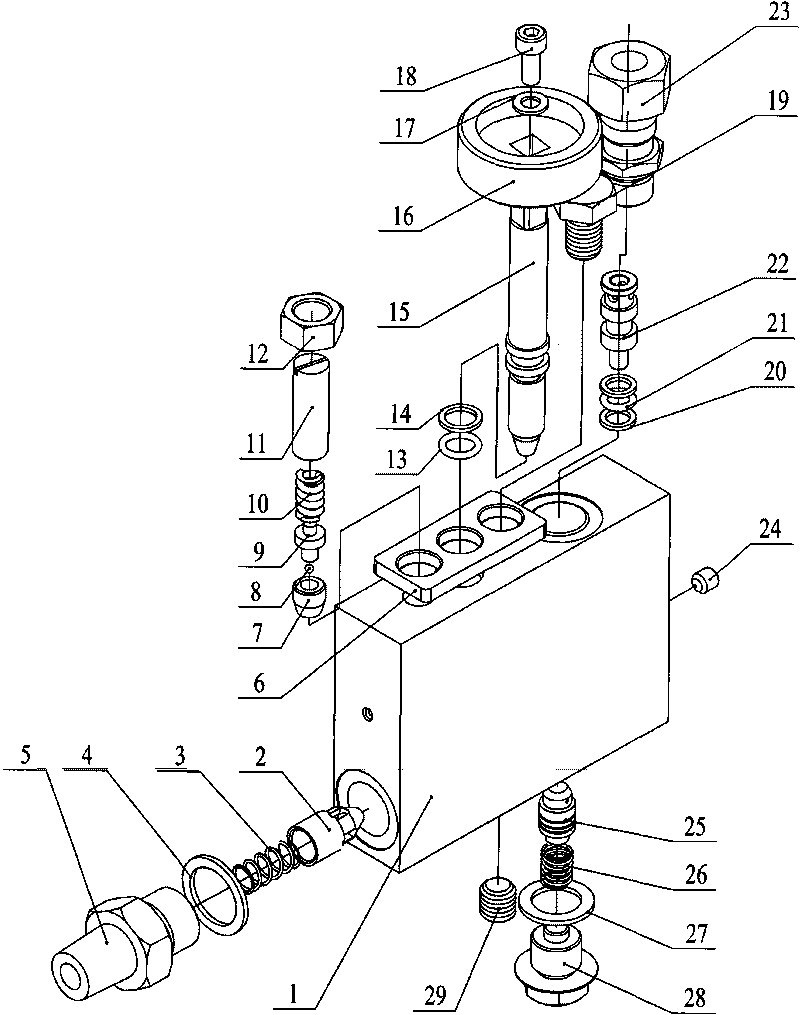

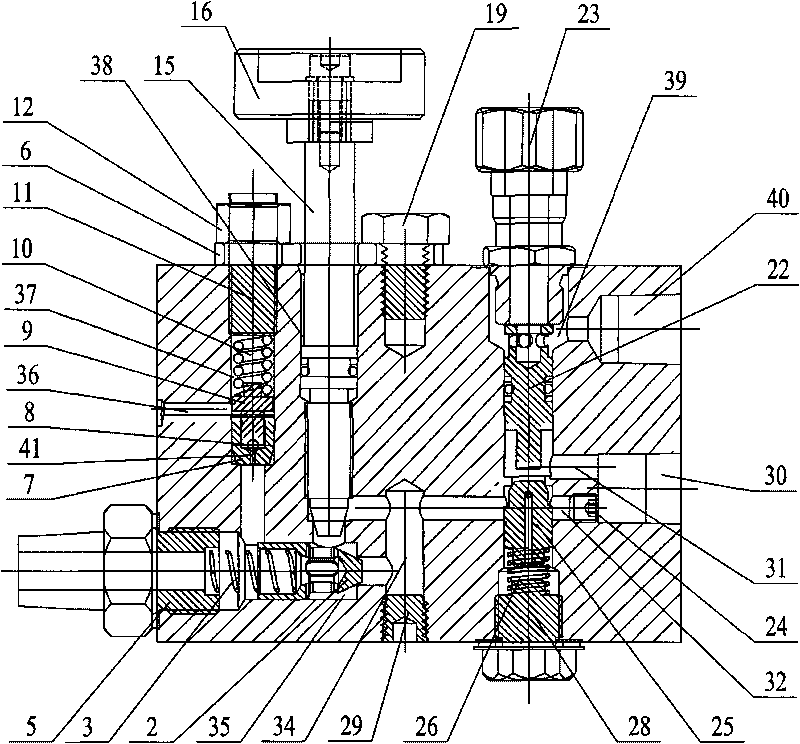

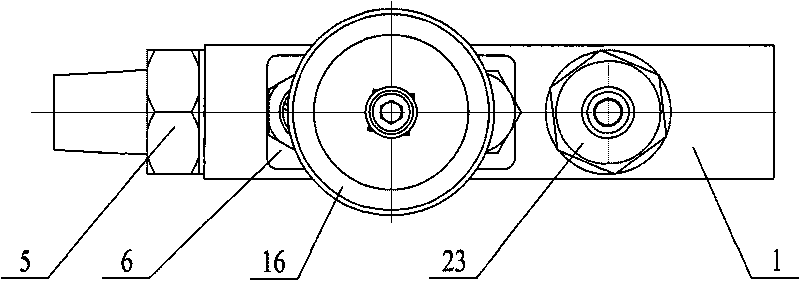

[0022] Such as Figure 1 ~ Figure 3 As shown, the present invention mainly consists of a valve body 1, a first one-way valve core 2, a return spring 3, a first sealing gasket 4, a working pipe joint 5, a pressing plate 6, a steel ball seat 7, a steel ball 8, a thimble 9, and a safety valve. Spring 10, push rod 11, lock nut 12, O-ring 13, first retaining ring 14, throttle mandrel 15, adjusting nut 16, washer 17, screw 18, bolt 19, O-ring 20, second gear Ring 21, hydraulic control valve core 22, control pipe joint 23, first plug 24, second one-way valve core 25, thrust spring 26, second sealing washer 27, locking bolt 28, second plug 29, etc. Parts composition.

[0023] Such as figure 2 As shown, the valve body 1 is provided with a first working oil hole 30, a check hole 33, a main oil hole 34, a second working oil hole 35, an overflow hole 36, an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com