Large coal bunker blockage cleaning robot

A technology of robots and coal bunkers, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of warehouse wall damage, reduce the space used by coal bunkers, and inconvenient disassembly and maintenance, so as to achieve convenient installation, disassembly and maintenance, Guaranteed safety and high efficiency, low cost of installation and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

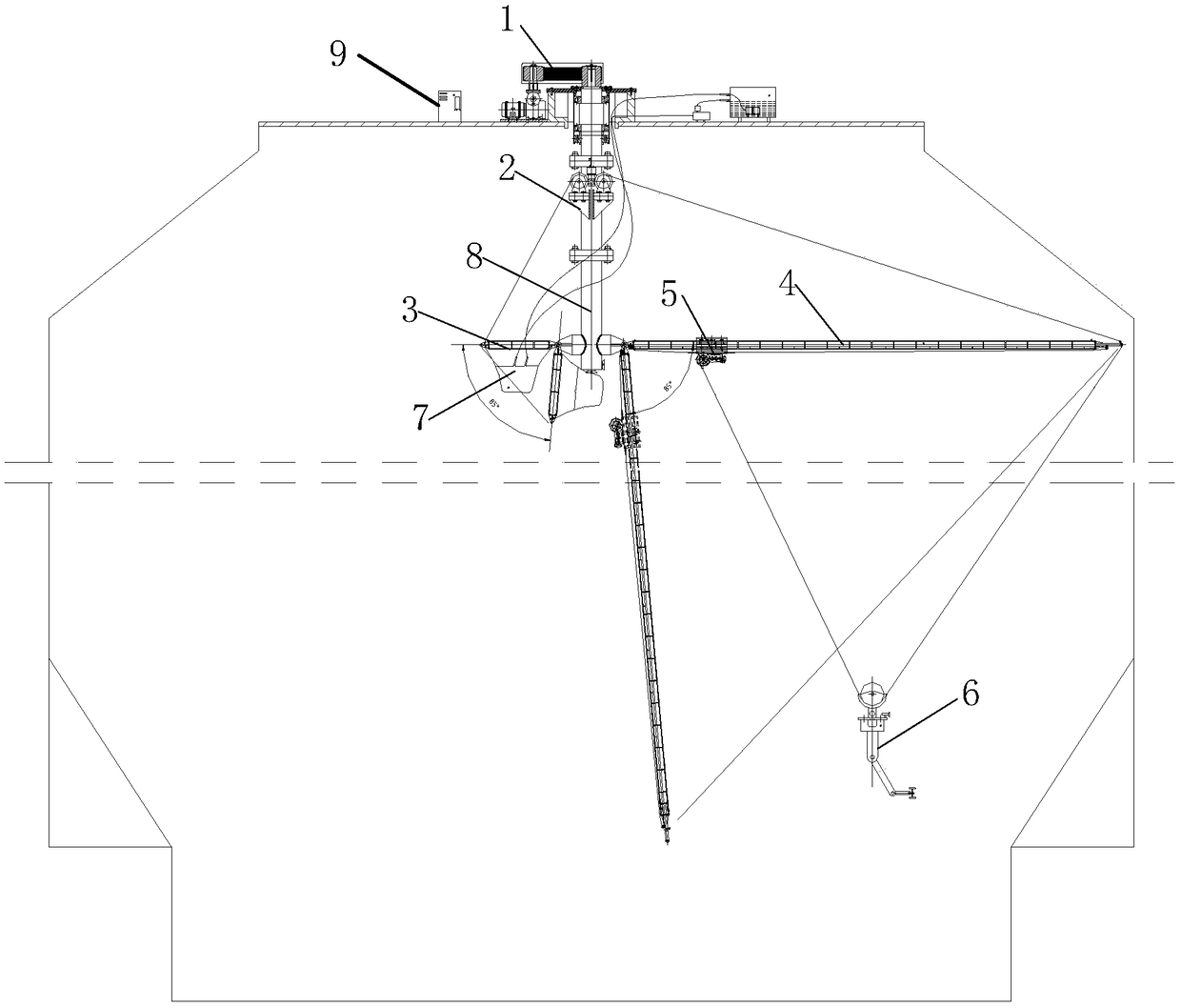

[0032] A large-scale coal bunker clearing robot specifically includes a rotary mechanism 1, a lifting mechanism 2, a left working arm 3, a right working arm 4, a walking trolley 5, a cleaning manipulator 6, a balancing device 7 and a column 8. The slewing mechanism 1 is connected to the upper end of the column 8 through gears, the lifting mechanism 2 is arranged on the column, and the lower end of the column 8 is provided with a connecting rod 803 . The left working arm 3 and the right working arm 4 are arranged on the connecting pole 803, the left working arm 3 is provided with a balance device 7, the right working arm 4 is provided with a walking trolley 5, the right working arm 4 is triangular prism, and the right working arm The arm 4 is provided with a walking track. The walking trolley 5 is provided with a winch 506, and the clearing manipulator 6 is connected with the walking trolley 5 by a wire rope. The coal bunker clearing robot adopts the structure of the working a...

Embodiment 2

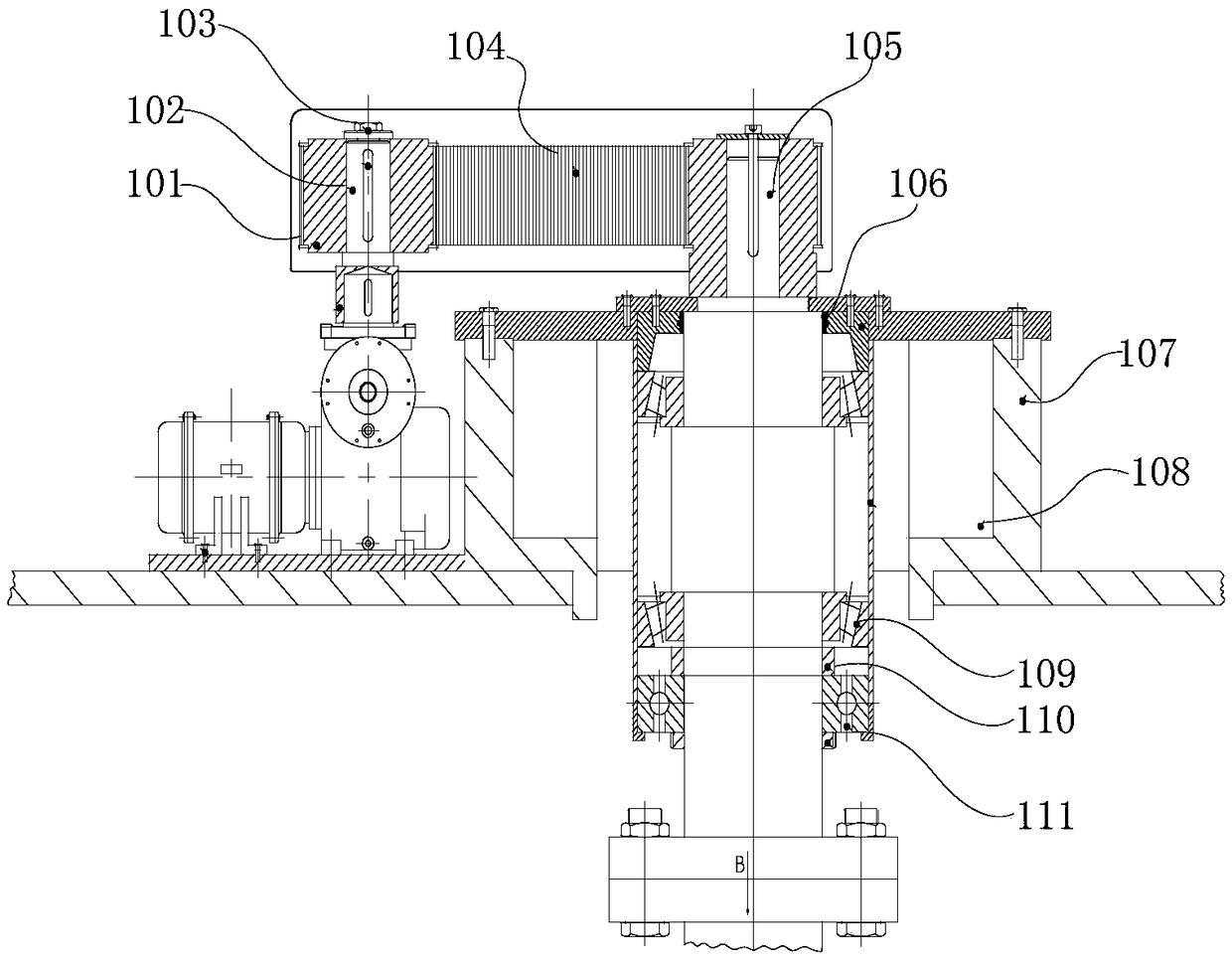

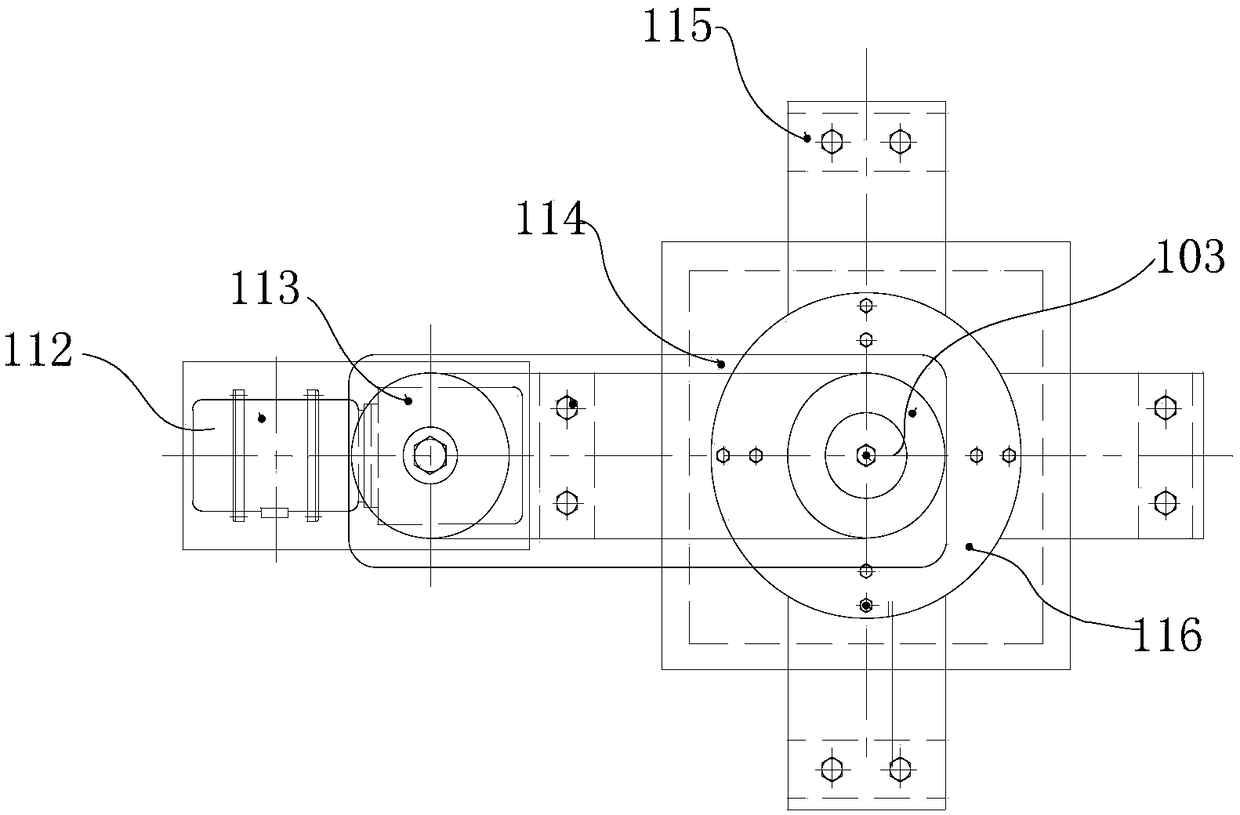

[0038] A large coal bunker clearing robot specifically includes an electric control cabinet 9, a slewing mechanism 1, a lifting mechanism 2, a left working arm 3, a right working arm 4, a walking trolley 5, a bin clearing robot 6, a balance device 7 and a column 8. Among them, the walking trolley 5 includes a vehicle frame 501, a roller group 502 and a hoist 506; a slewing mechanism 1, a lifting mechanism 2, a left working arm 3, a right working arm 4, a walking trolley 5, a clearing manipulator 6, a balance device 7 and a column 8; Slewing mechanism 1 includes explosion-proof motor 112, reducer 113, toothed belt 104, column joint rotary shaft 105, open gear 101, bracket and protective cover 114; balancing device 7 includes rubber water bag 703, water inlet and outlet pipe 704, water storage tank 705, submersible pump 706 and booster pump 707. The slewing mechanism 1 is connected to the upper end of the column 8 through gears, the lifting mechanism 2 is arranged on the column,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com