Logistics storage conveying equipment with automatic screening function

A technology of automatic screening and conveying equipment, applied in the field of logistics and warehousing, can solve the problems of inapplicability to various secondary sites, increase the labor intensity of workers, reduce the efficiency of express sorting, etc., to achieve convenient classification and packaging, simple structure, convenient The effect of disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

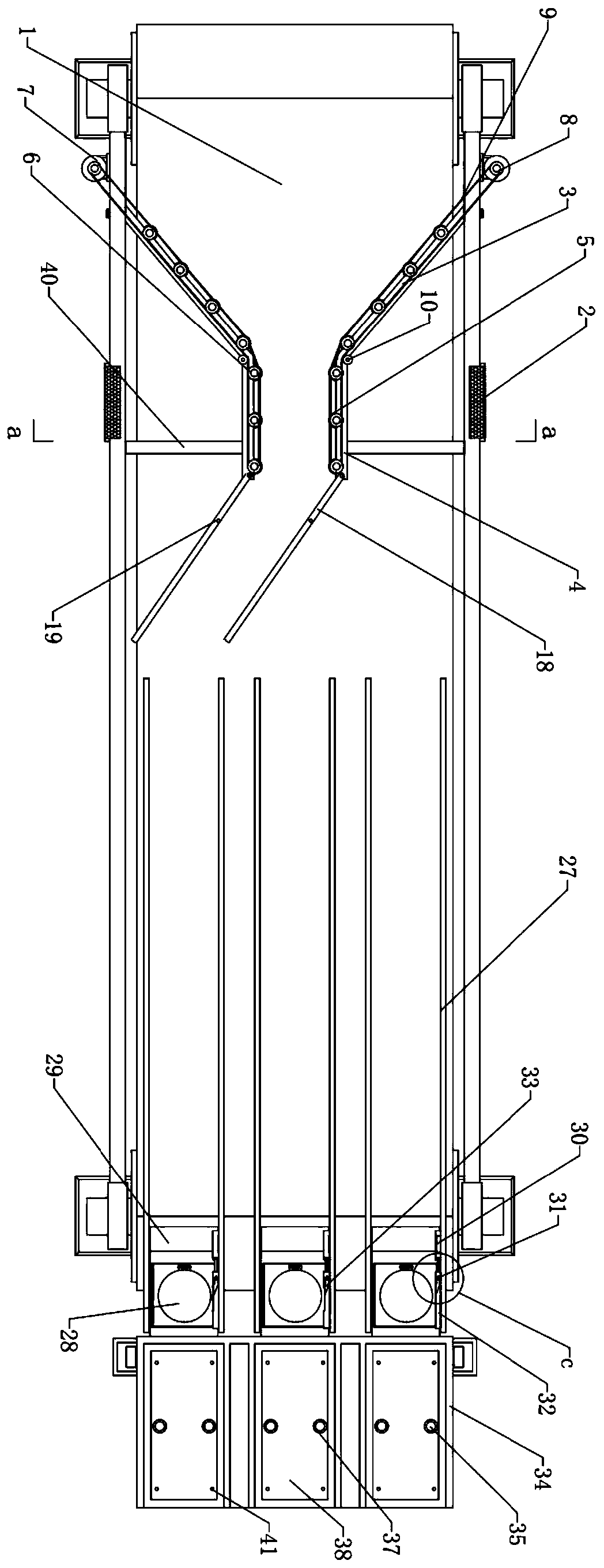

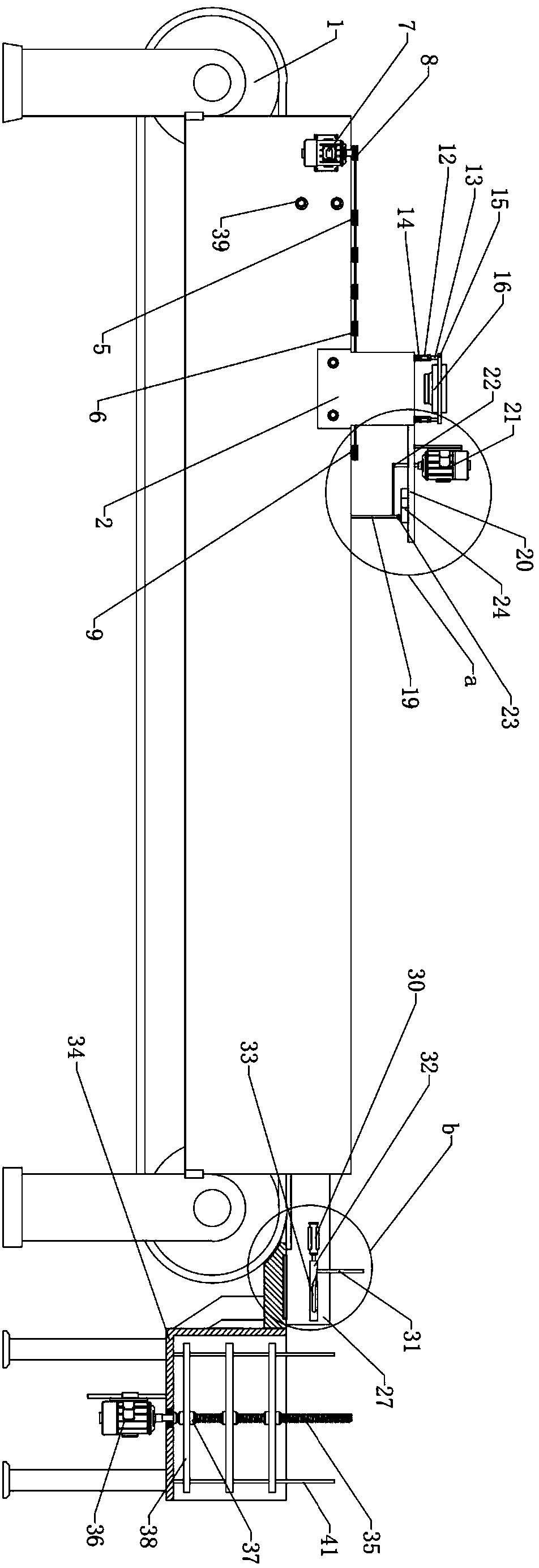

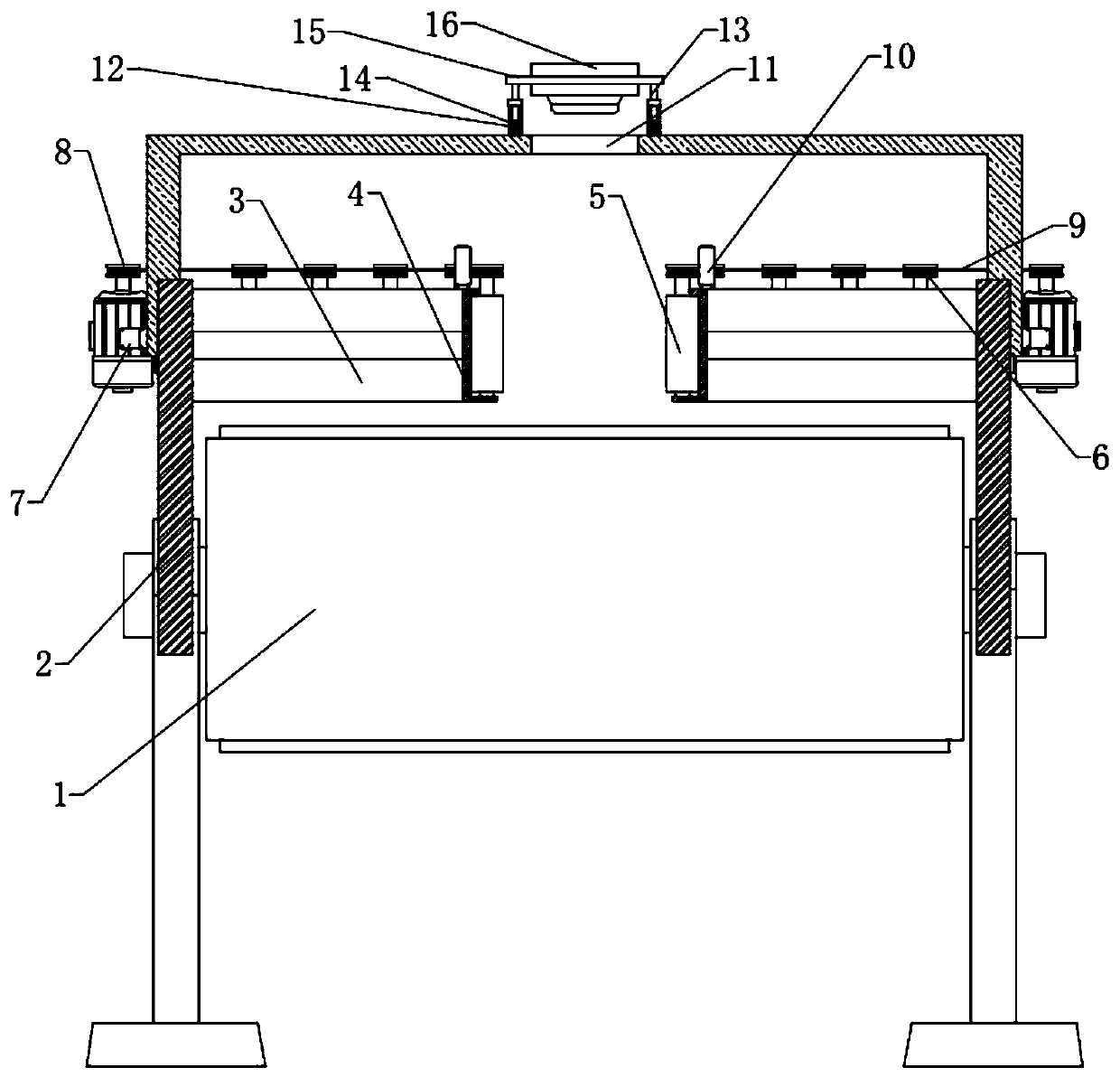

[0038] Embodiment: according to specification Figure 1-10 It can be seen that this case is a conveyor equipment for logistics and warehousing with automatic screening function, including a main conveyor belt 1, a feeding mechanism, a primary sorting mechanism, and several secondary sorting mechanisms with the same structure. The feeding mechanism is installed on the main conveyor belt 1 On one side, the primary sorting mechanism is placed on the main conveyor belt 1, and several secondary sorting mechanisms are placed on the side of the primary sorting mechanism. Placement, place the courier on one side of the main conveyor belt 1, comb through the feeding mechanism, so that the courier passes through the first-level sorting mechanism one by one, and distributes it to several secondary sorting agencies according to the region for secondary sorting. The weight and the type identified by scanning the code are received hierarchically, and the specific structure and operation ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com