Split type mud gun vibrating source drilling tool

A split type, mud gun technology, applied in the field of drilling, can solve problems such as failure to apply, limit the excitation depth of mud guns, and inability to effectively download seismic waves, and achieve the effect of convenient loading, unloading and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

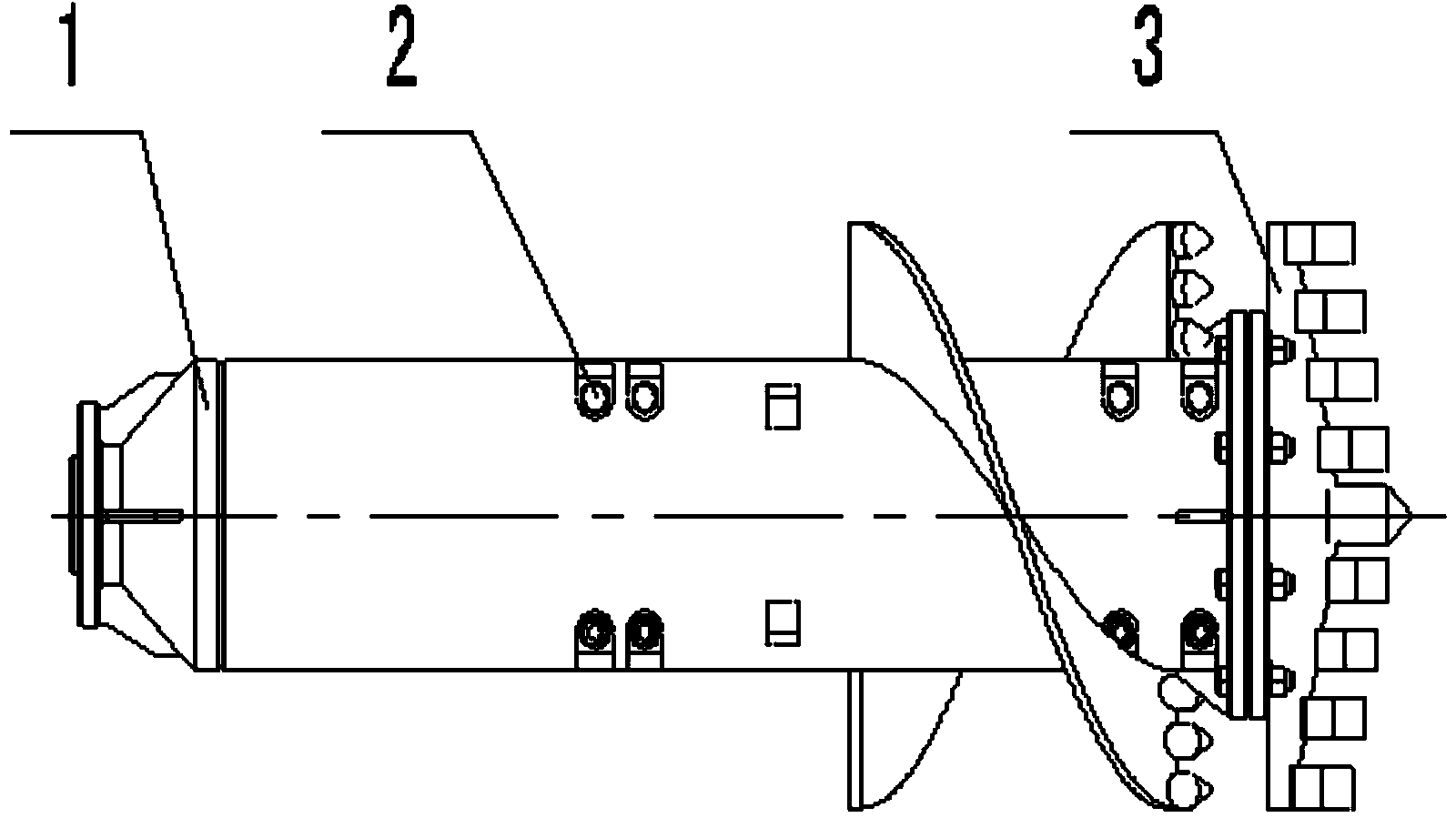

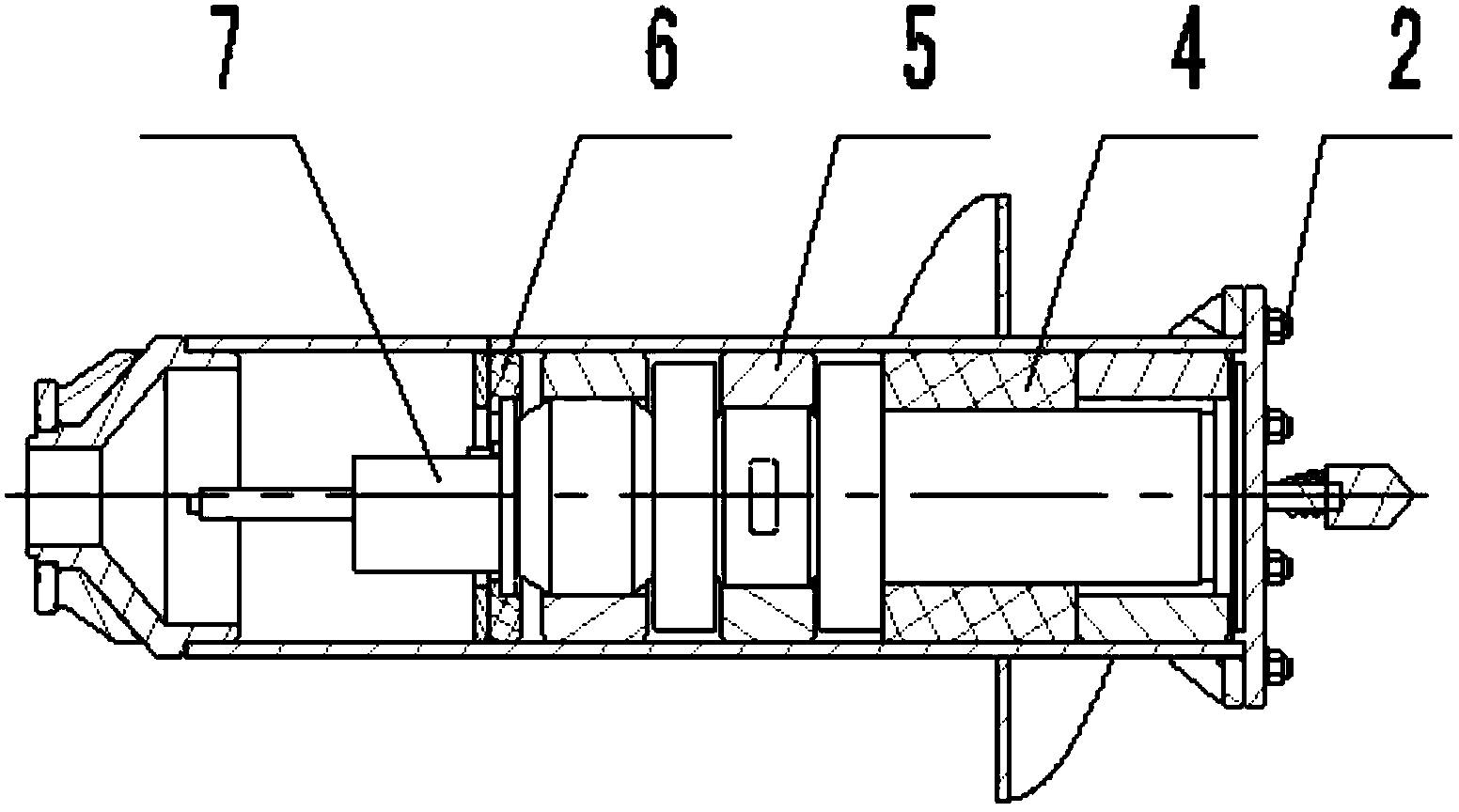

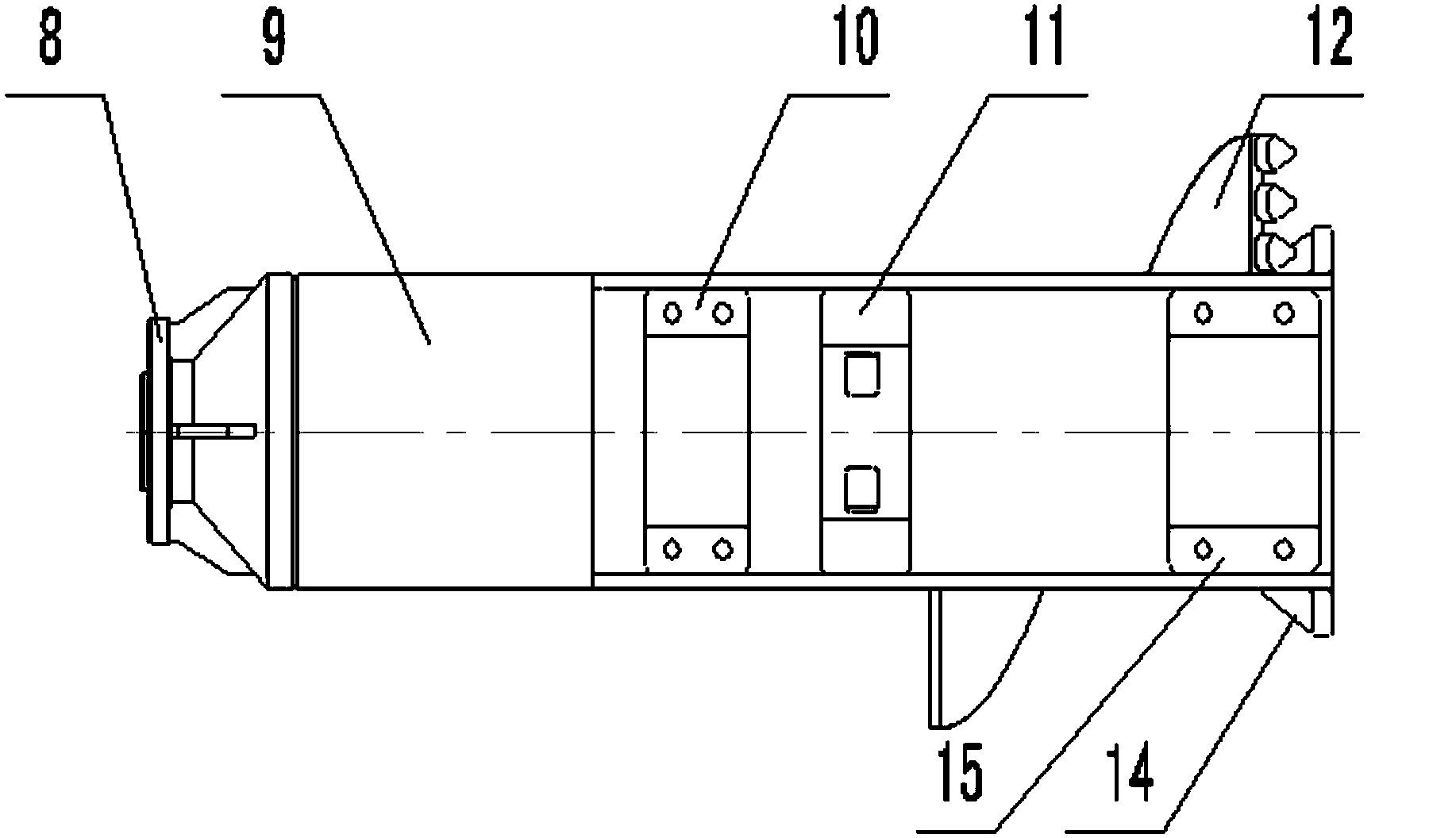

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown,

[0025] The present invention comprises main housing assembly 1, bolt 2, drill bit 3, lower rubber ring 4, auxiliary housing assembly 5, upper rubber ring 6, mud gun 7.

[0026] The main shell assembly 1 is a weldment, including the upper flange 8, the main shell 9, the upper connecting tile 10, the filling body 11, the spiral blade 12, the drill bit flange 13, the corner rib 14, the lower connecting tile 15, the retaining tile Circle 16, transition sleeve 17, rib plate 18. The main shell 9 is cylindrical, the inner diameter of the main shell 9 is φ200mm, and the thickness is 10mm. One end of the main shell is cut off in half. 17. The upper end of the transition sleeve 17 is welded to fix the upper flange 8, and four ribs 18 are evenly distributed between the transition sleeve 17 and the upper flange 8. Weld and fix the semi-circular upper connecting tile 10 on the lower side of t...

Embodiment 2

[0030] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown,

[0031] A split mud gun seismic source drilling tool includes a main shell assembly 1, bolts 2, drill bits 3, a lower rubber ring 4, an auxiliary shell assembly 5, an upper rubber ring 6, and a mud gun 7. The main casing assembly 1 includes an upper flange 8, a main casing 9, an upper connecting tile 10, a filling body 11, a spiral blade 12, a drill bit flange 13, corner ribs 14, a lower connecting tile 15, a retaining ring 16, and a transition sleeve 17, Rib 18. The sub-housing assembly 5 includes a sub-housing 19 , an upper connecting shoe 10 , a filling body 11 , a lower connecting shoe 15 , a spiral blade 12 , a drill bit flange 13 and corner ribs 14 .

[0032] The main shell 9 is cylindrical, one end of which is cut off in half, and a retaining ring 16 is welded at the incision of the inner cavity of the main shell 9, and a transition sleeve 17 is welded and fixed on the upper...

Embodiment 3

[0041] Embodiment 3: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a split type mud gun seismic source drilling tool, the split type mud gun drilling tool includes a main shell assembly, bolts, drill bits, a lower rubber ring, an auxiliary shell assembly, an upper rubber ring, and a mud gun.

[0042] The main shell is assembled into a weldment, including upper flange, main shell, upper connecting tile, filling body, helical blade, drill bit flange, corner rib, lower connecting tile, retaining ring, transition sleeve, rib plate. The main shell is cylindrical, one end of which is cut off in half, the inner cavity of the main shell is welded with a retaining ring, the upper end of the main shell is welded and fixed with a conical transition sleeve, the upper end of the transition sleeve is welded and fixed to the upper flange, and the transition sleeve and 4 ribs are evenly distributed between the upper flanges. Weld and fix the semi-annular upper conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com