Distributed compression and cyclone ramjet engine

A ramjet, distributed technology, used in aero-engine and aviation fields, can solve the problems that ramjet cannot start at low speed, booster acceleration, ramjet cannot start by itself, etc., to reduce temperature, increase compression ratio, and reduce processing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

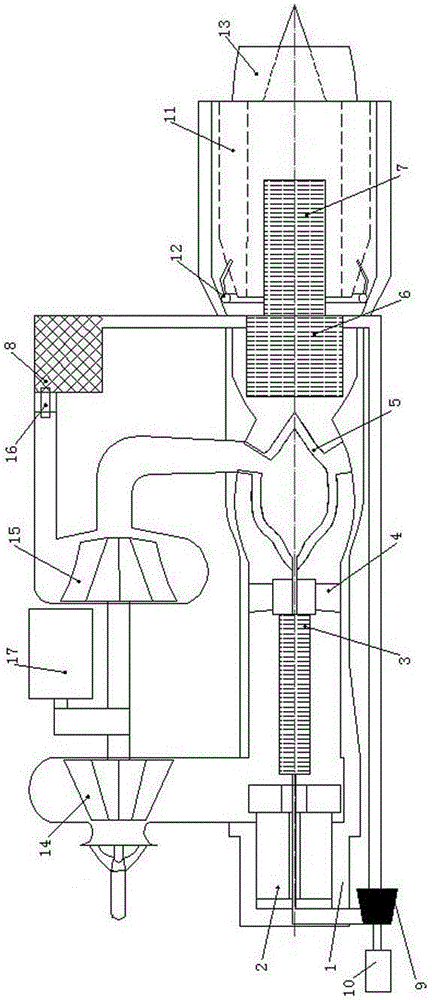

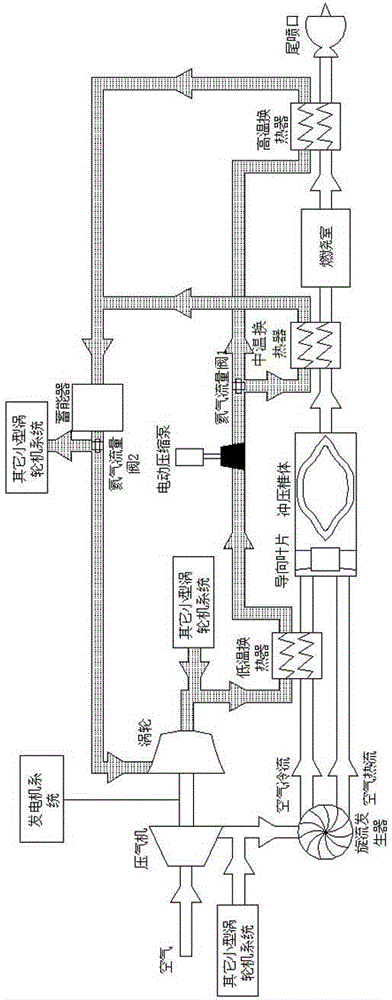

[0046] The distributed compression and swirl ramjet engine of this embodiment includes a turbine system, a casing 1, a swirl generator 2, a low-temperature heat exchanger 3, guide vanes 4, a stamping cone 5, a medium-temperature heat exchanger 6, and a high-temperature heat exchanger. Device 7, accumulator 8, electric compression pump 9, motor 10 for driving electric compression pump 9 to work, combustion chamber 11, fuel nozzle 12 arranged in combustion chamber 11, exhaust pipe 13 connected with combustion chamber 11 , the gas flow valve 16 arranged on the pipeline between the accumulator 8 and the turbine 15 .

[0047] Wherein, there are several turbine systems, and the turbine system includes a centrifugal compressor 14, a turbine 15, a generator 17 matched with the turbine 15, and the centrifugal compressor 14 and the turbine 15 are coaxially connected. Swirl flow generator 2 , low-temperature heat exchanger 3 , guide vane 4 , stamped cone 5 , and medium-temperature heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com