Ejector based engines

A jet engine, injector technology, applied in the direction of machine/engine, ramjet engine, combined engine, etc., can solve problems such as no injector type engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following details the best presently contemplated modes of carrying out the invention. These descriptions are not intended to be limiting, but merely to illustrate the basic principles of the invention.

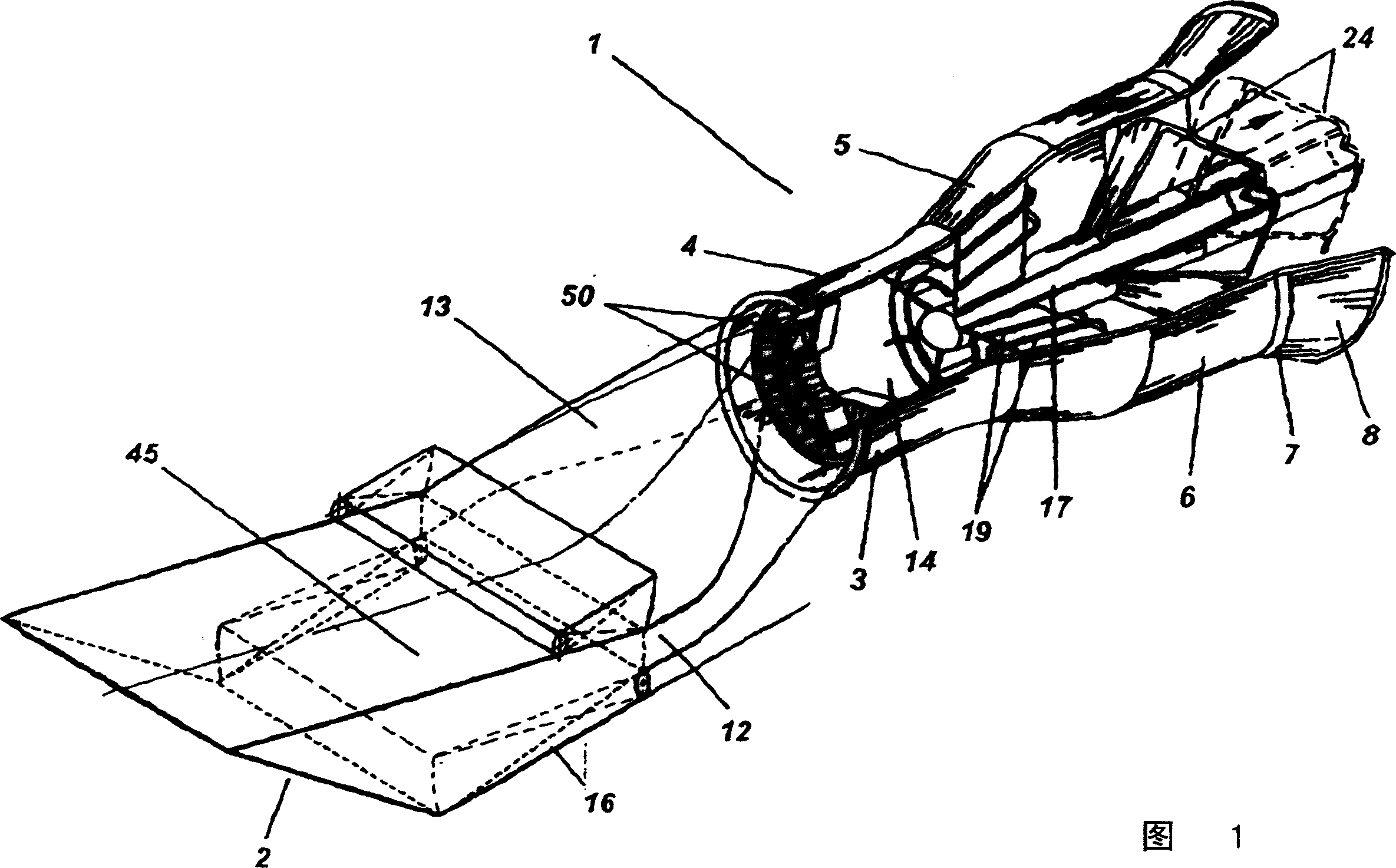

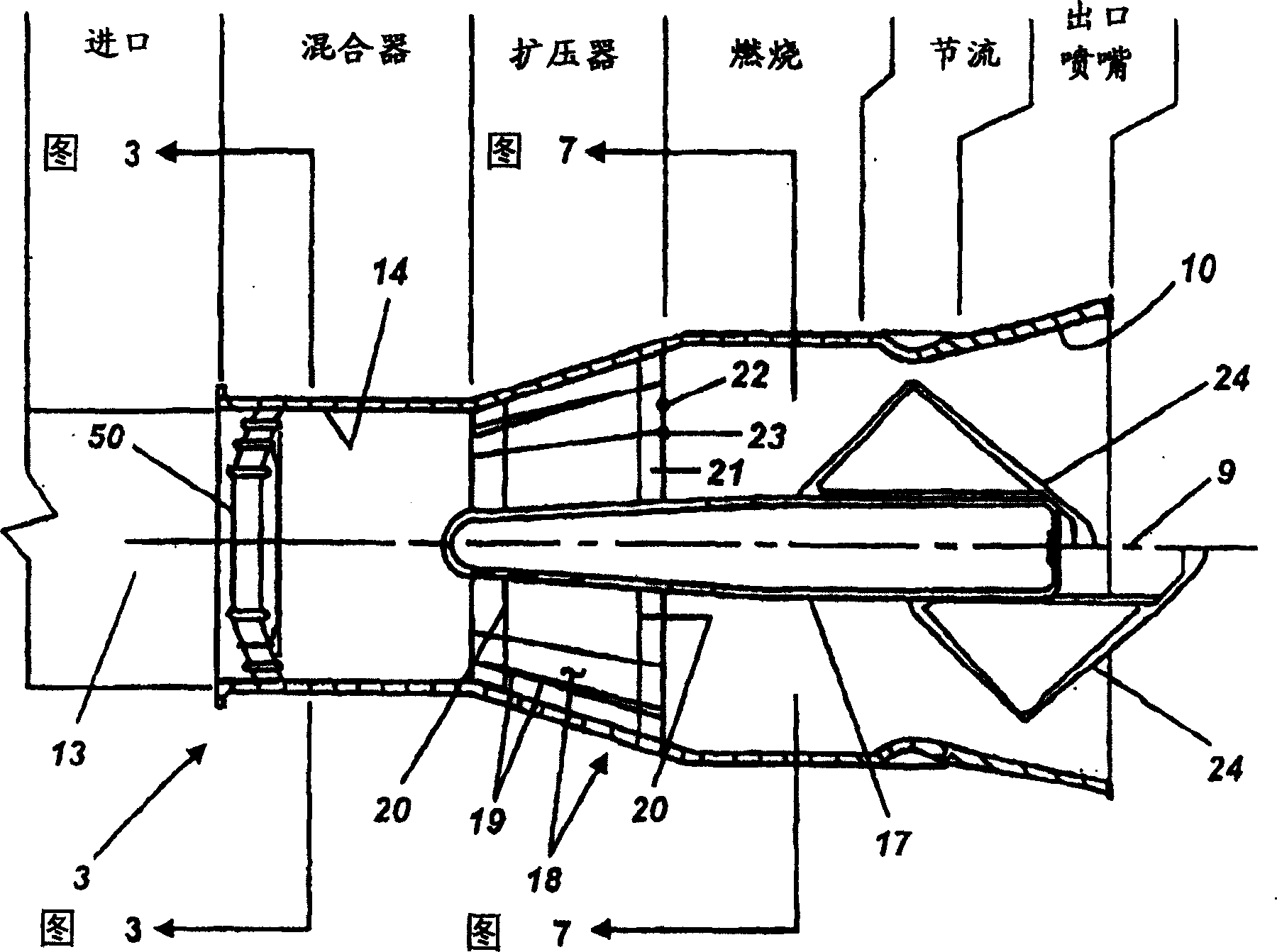

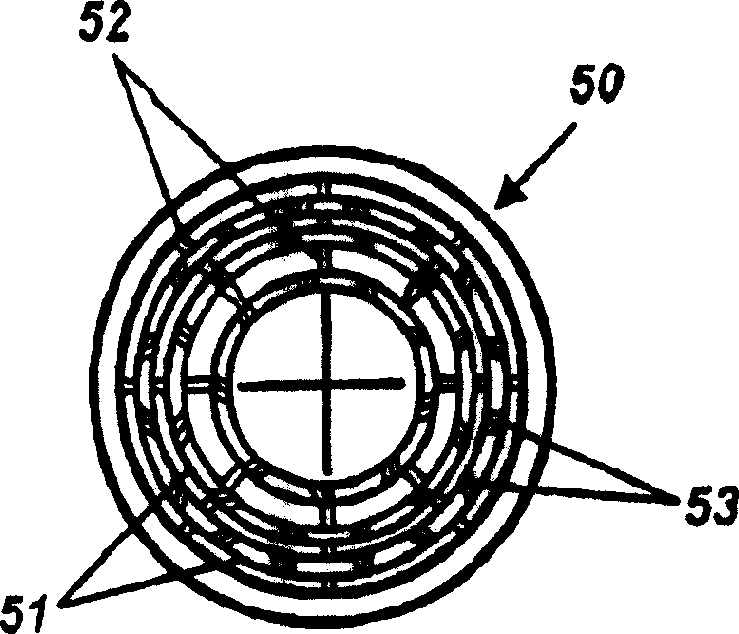

[0031] The injector ramjet propulsion system or engine may be a geometrically expandable ramjet engine having inlet, mixer, diffuser, combustor, and outlet nozzle elements or sections as commonly known , they are connected in sequence from the inlet to the outlet nozzle to form a whole. The engine can be of any shape to facilitate vehicle installation and facilitate the performance of each component over the engine duty cycle. As stated in the examples, a circular cross-section engine may be assumed, with a rectangular inlet cowling. The injector structure having the injector cavity therein may be mounted at the upstream end of the mixer section, normal to the longitudinal axis of the engine, to form an injector assembly. The injector element may be connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com