Patents

Literature

1154results about "Jet type power plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

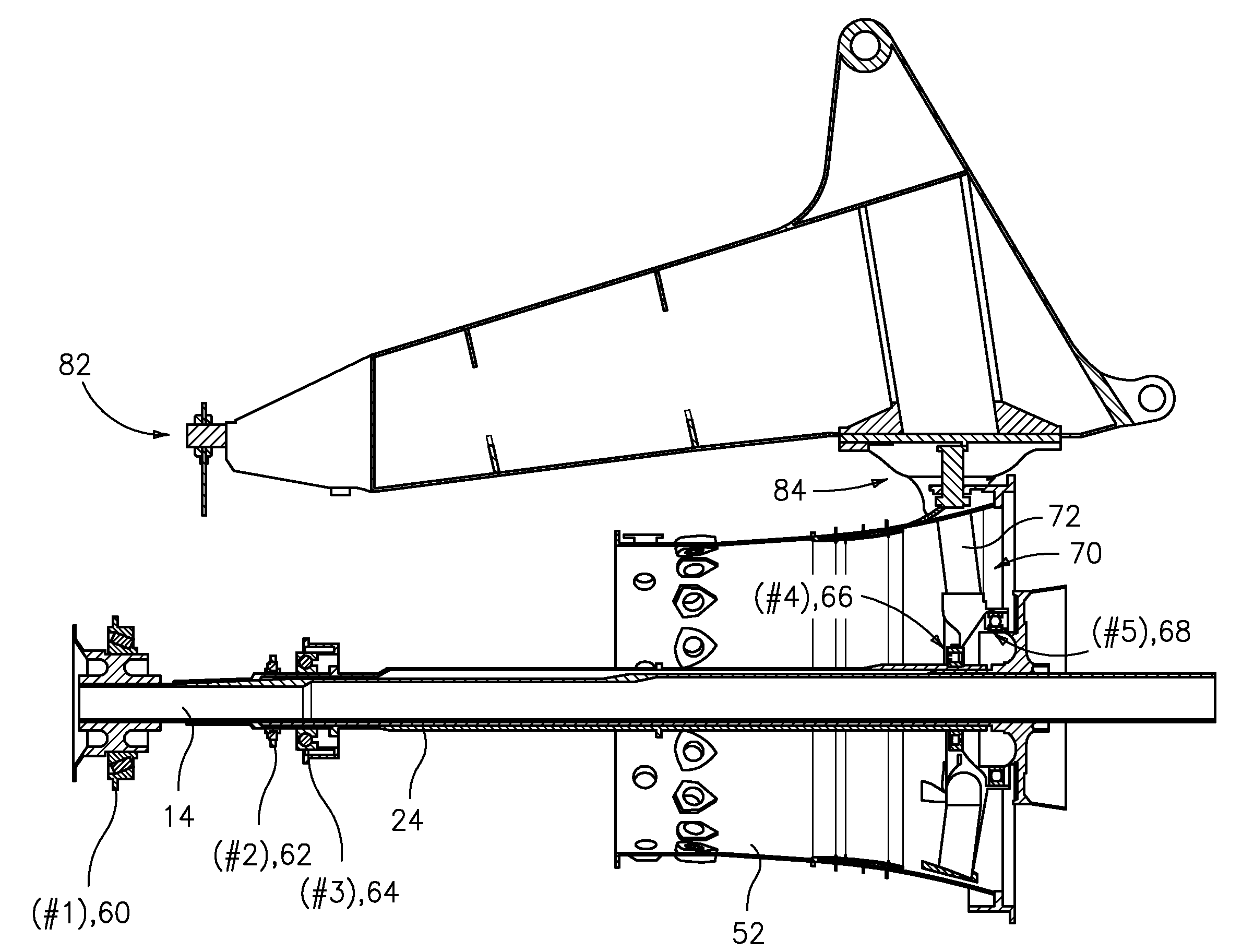

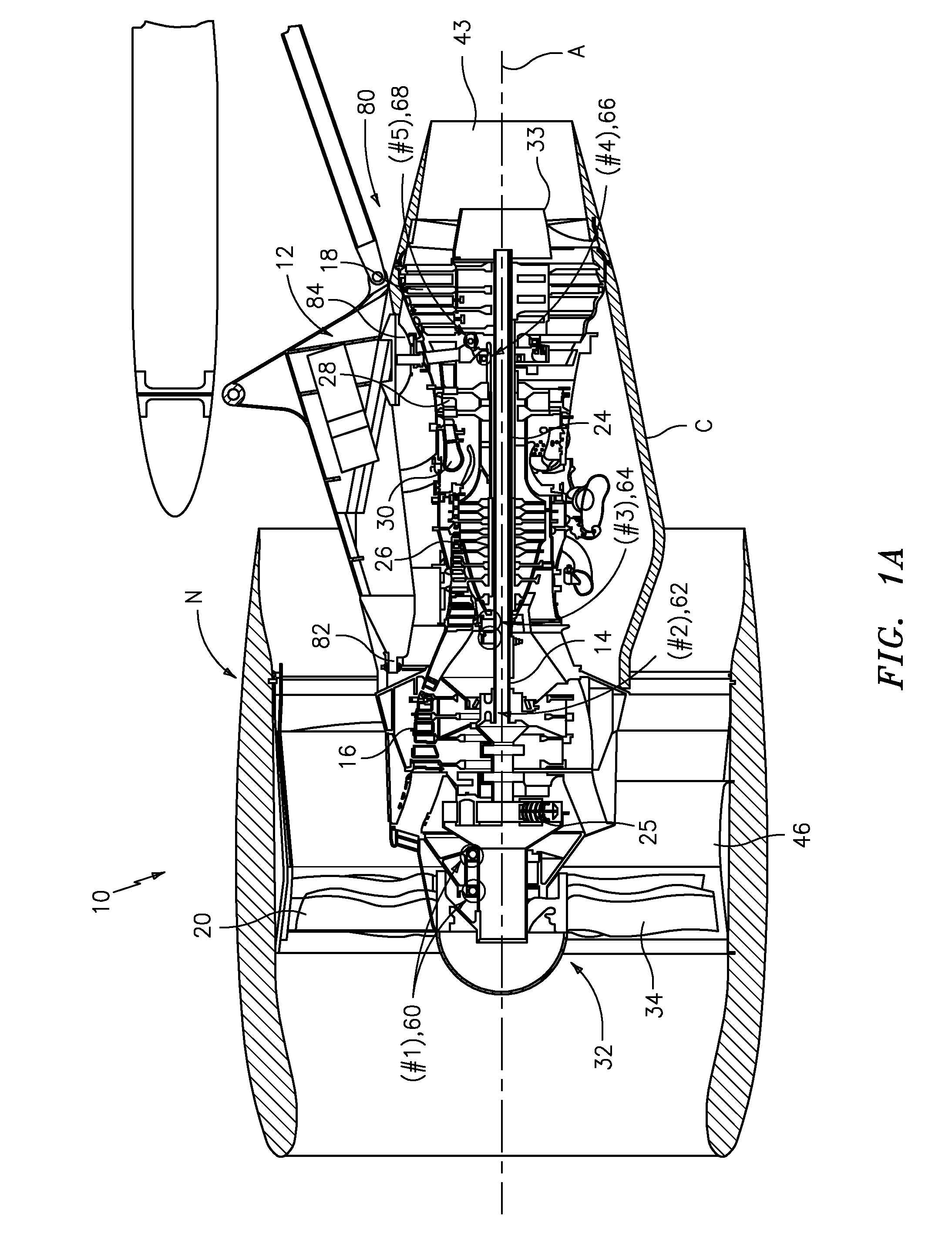

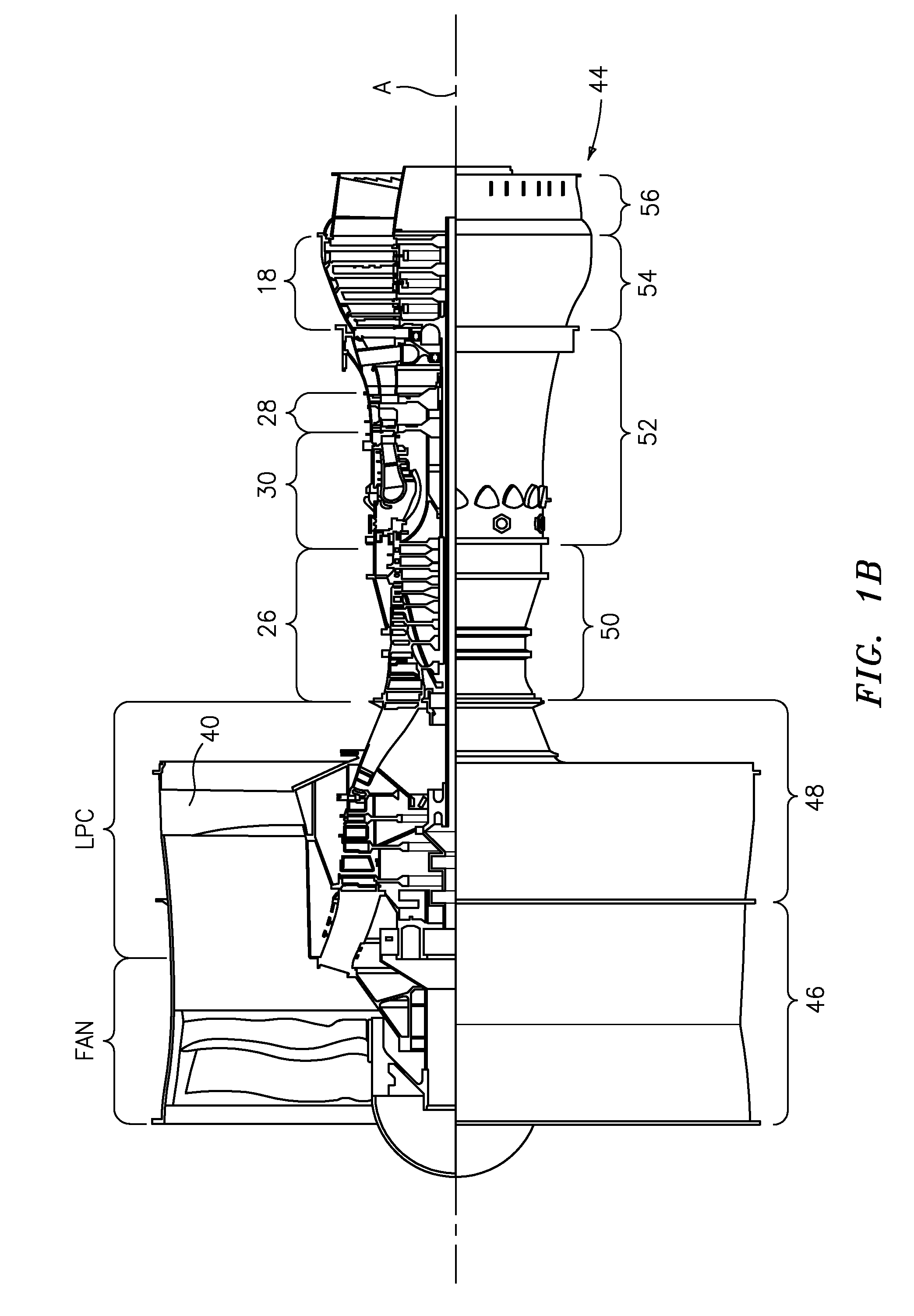

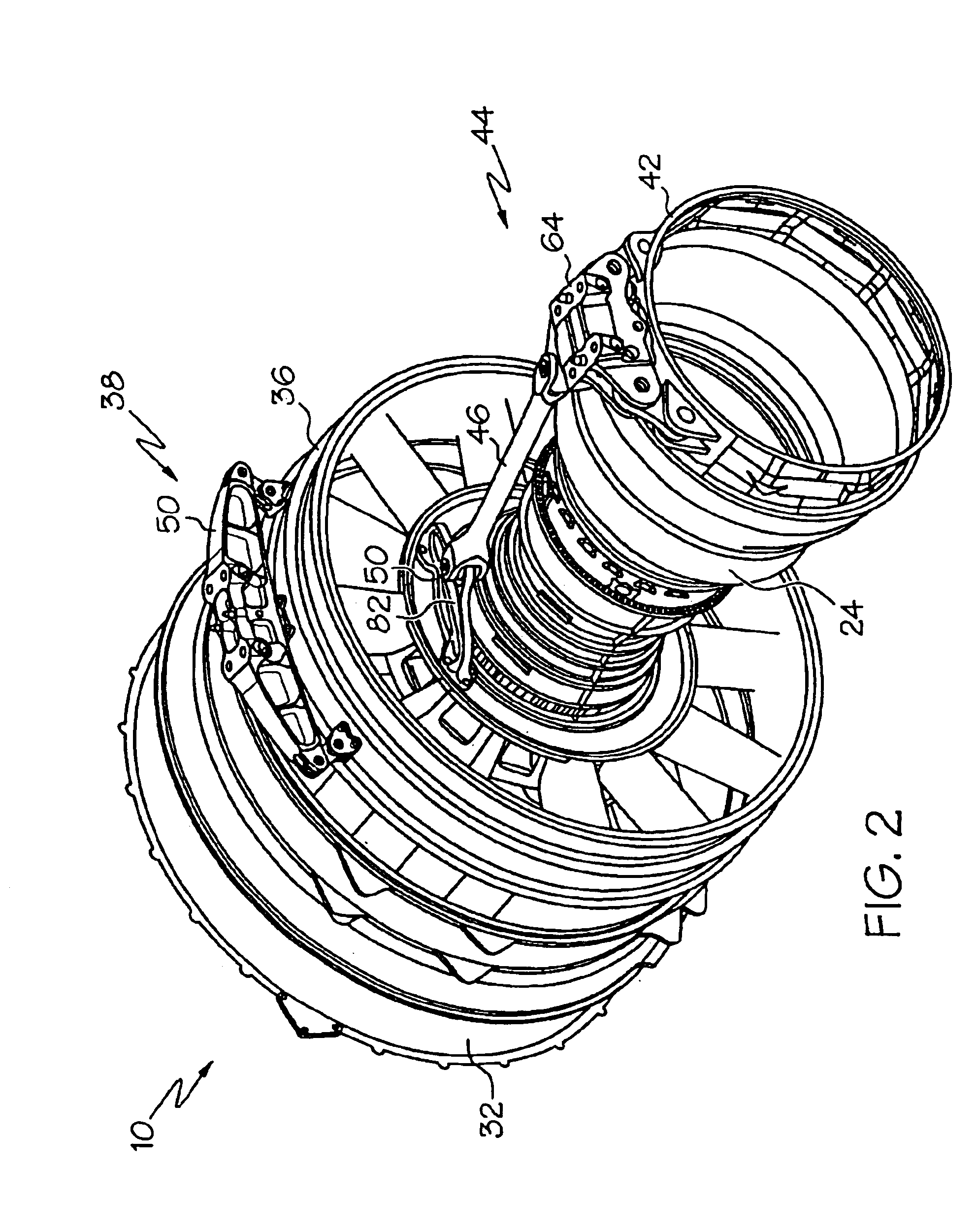

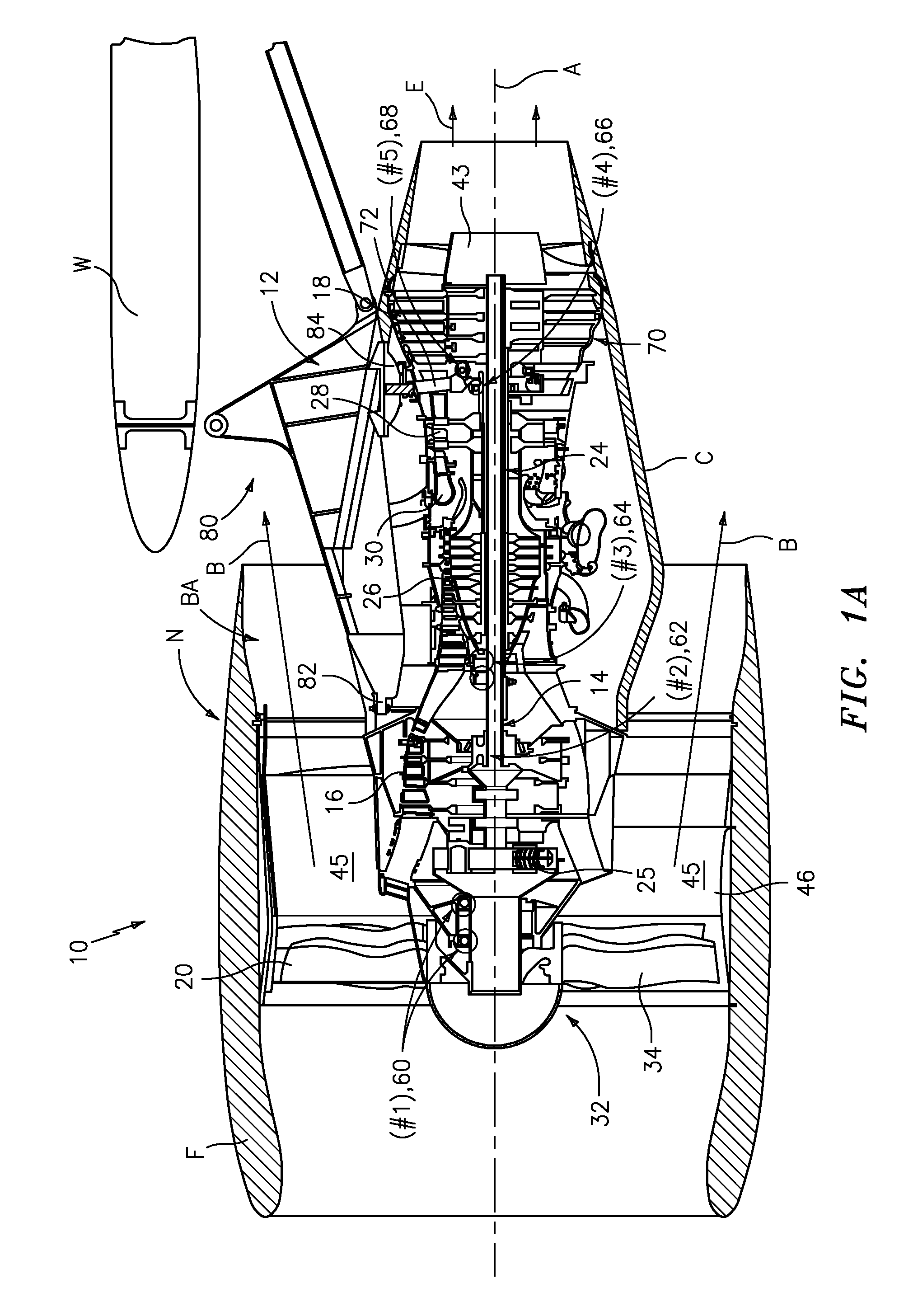

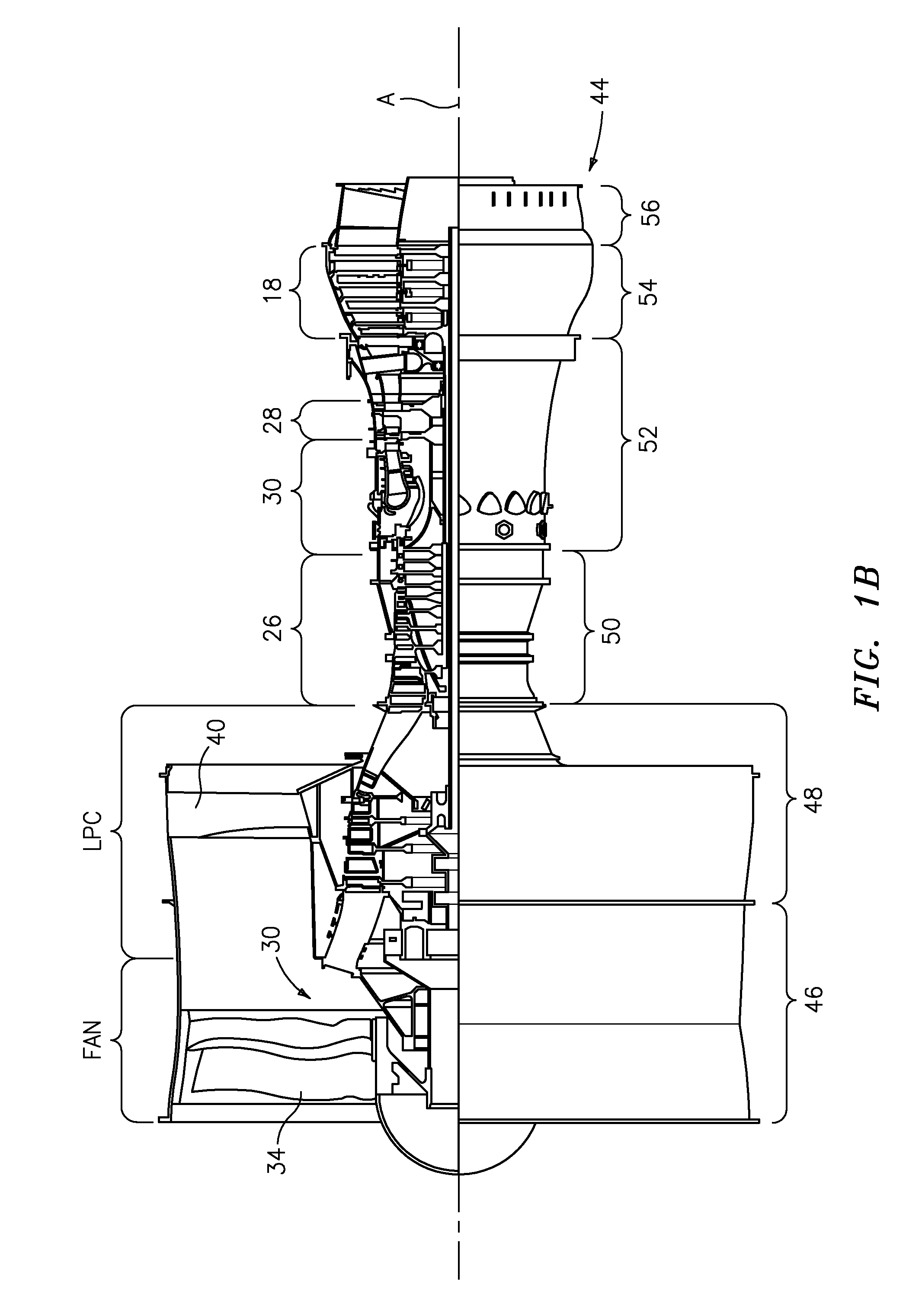

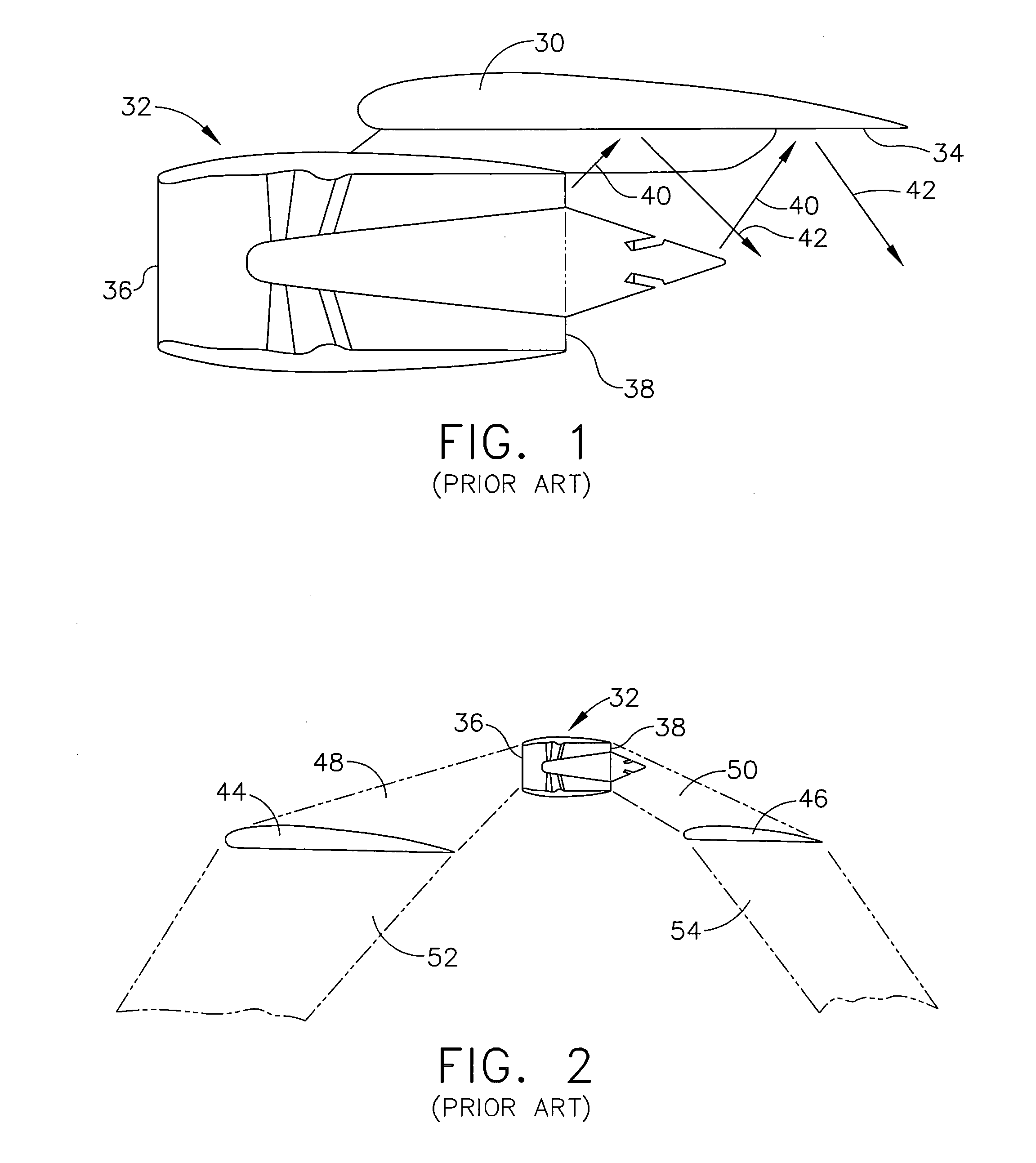

Engine mounting configuration for a turbofan gas turbine engine

ActiveUS20090056343A1Minimizes backbone bendingMinimizes engine case distortionPower plant constructionJet type power plantsNacelleEngine mount

An engine mounting configuration reacts engine thrust at an aft mount. The engine mounting configuration reduces backbone bending of the engine, intermediate case distortion and frees-up space within the core nacelle.

Owner:RAYTHEON TECH CORP

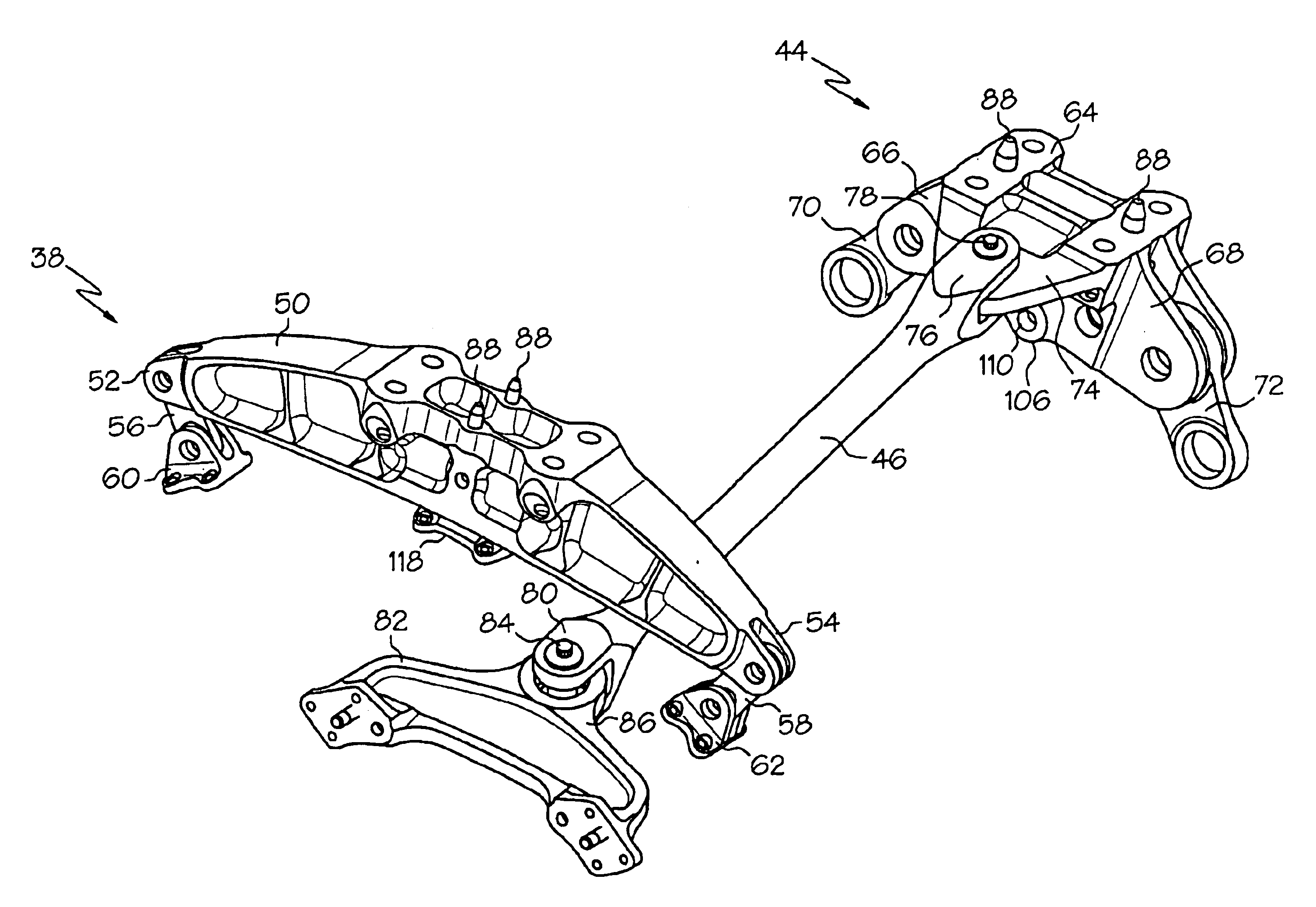

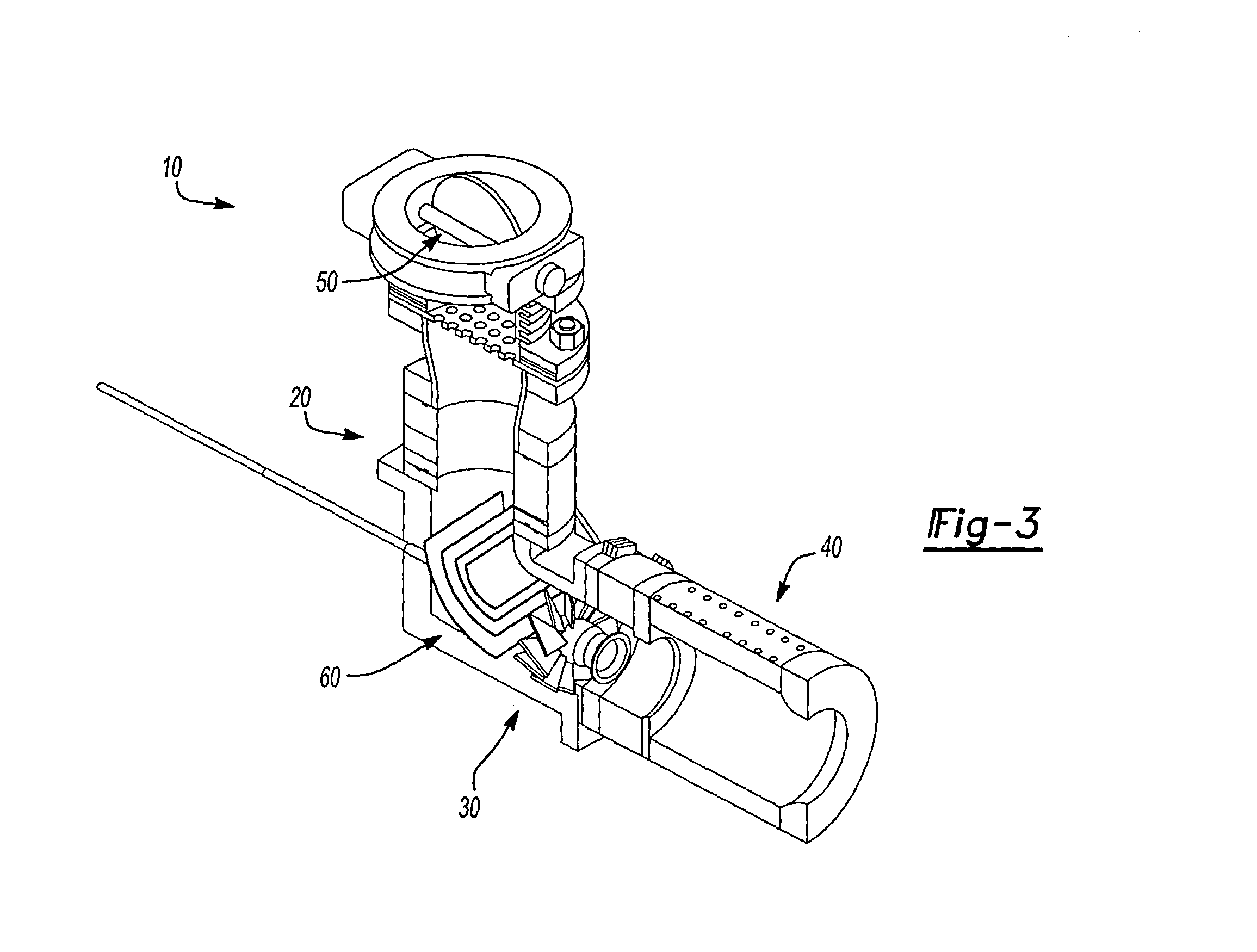

Fail-safe aircraft engine mounting system

A fail-safe lug is carried by an engine frame member and receives a clevis carried by an engine mount member. The mount member includes side links that transmit transverse loads between the engines and the airframe and a thrust link that transmits axial, engine thrust loads between the engine and the airframe. A fail-safe pin is carried by the clevis and has an outer diameter that is smaller than an aperture in the lug and through which the pin passes, so that no loads are imposed on the fail-safe pin in normal operation. When one or more of the links are no longer capable of transmitting loads, the fail-safe arrangement becomes operative to accommodate the loads transmitted between the engine and the airframe.

Owner:GENERAL ELECTRIC CO

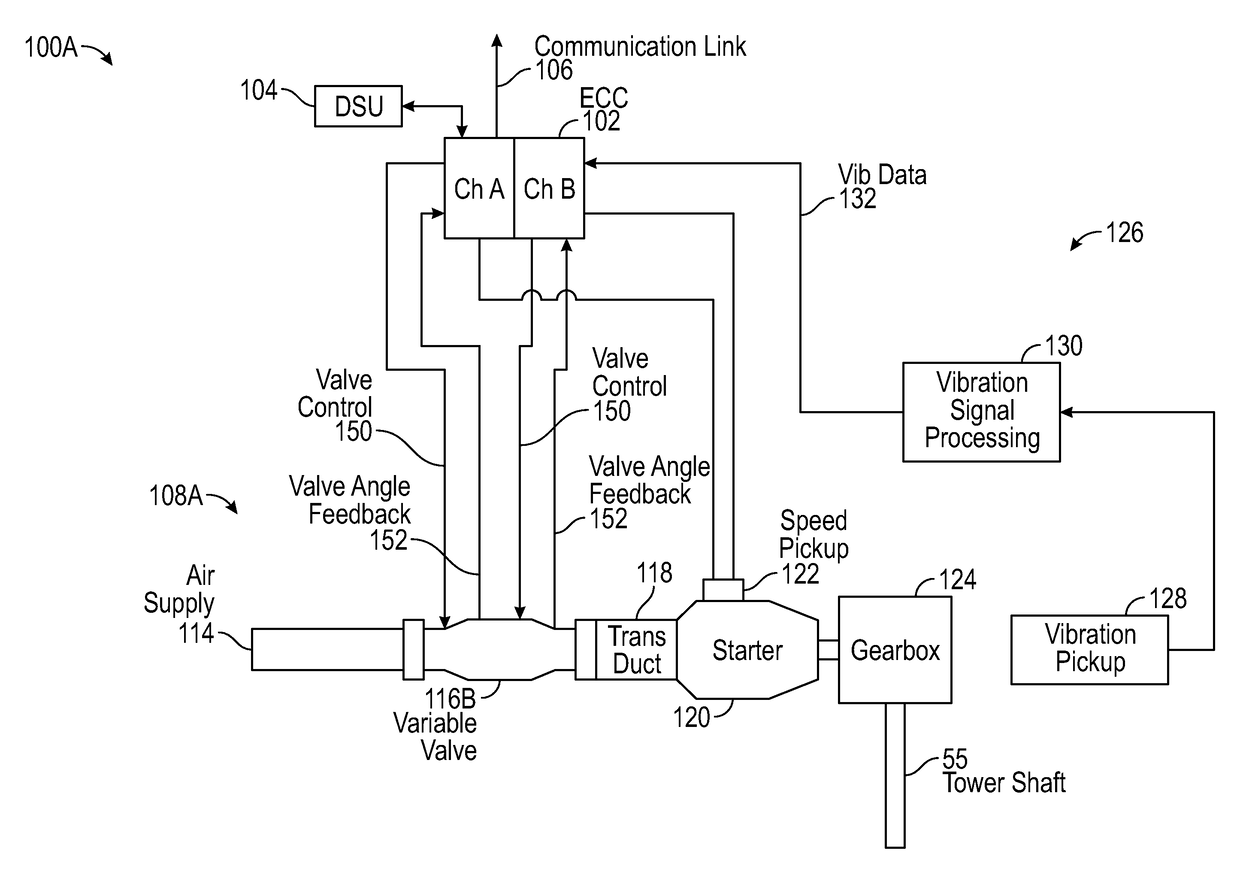

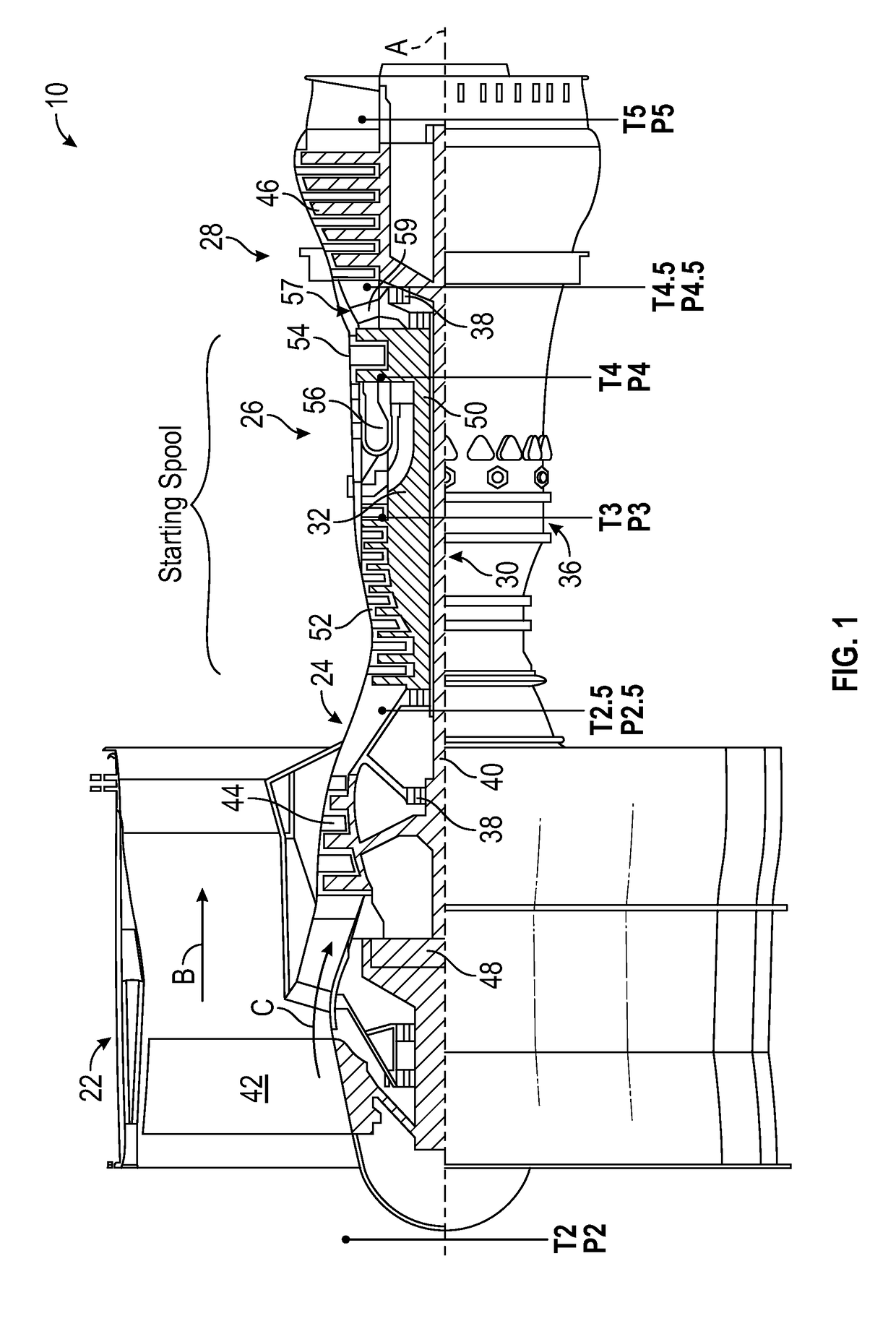

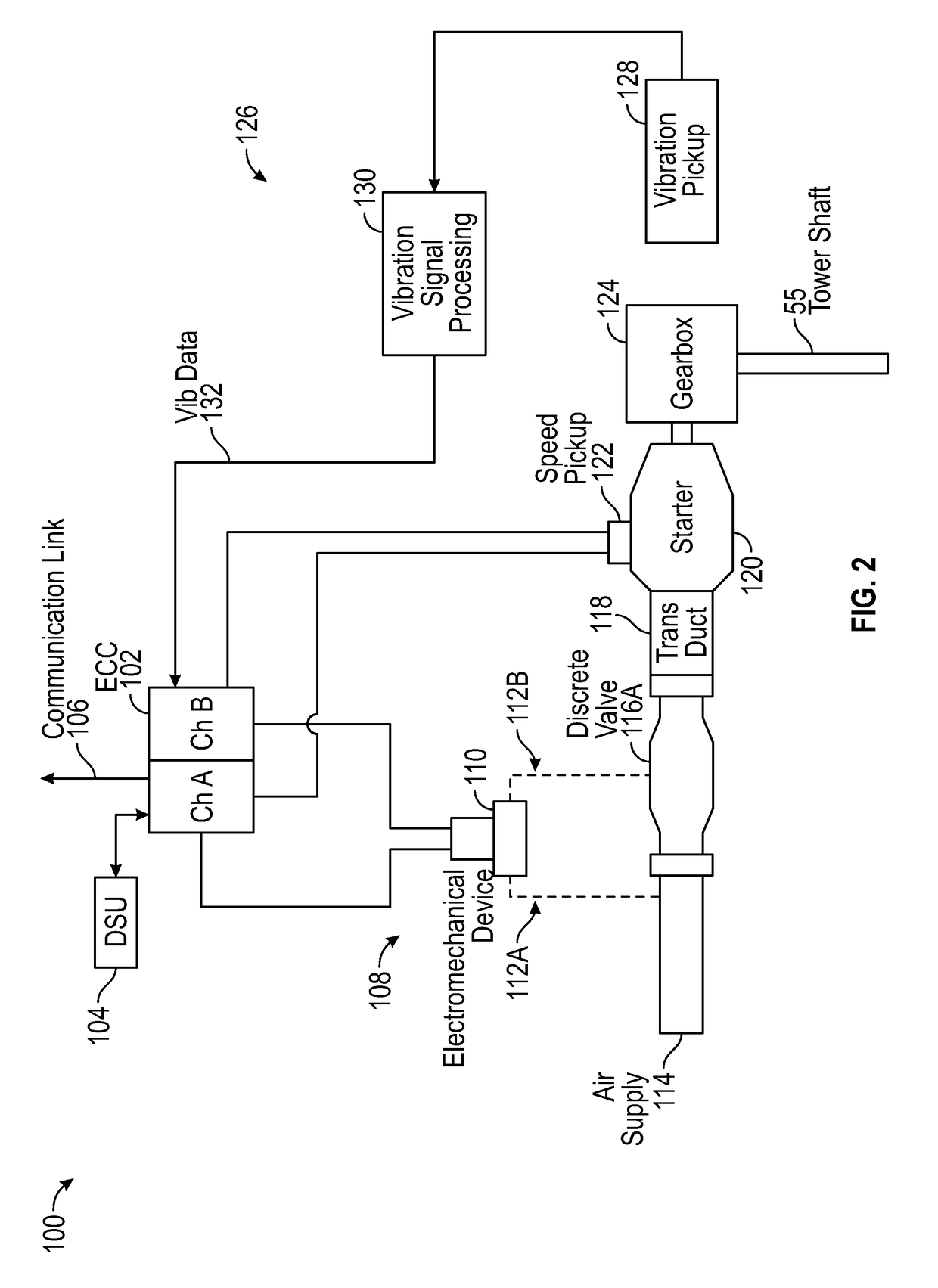

Modified start sequence of a gas turbine engine

ActiveUS20170233103A1Increase rotation speedEngine fuctionsJet type power plantsIdle speedEngineering

A system for starting a gas turbine engine of an aircraft is provided. The system includes a pneumatic starter motor, a discrete starter valve switchable between an on-state and an off-state, and a controller operable to perform a starting sequence for the gas turbine engine. The starting sequence includes alternating on and off commands to an electromechanical device coupled to the discrete starter valve to achieve a partially open position of the discrete starter valve to control a flow from a starter air supply to the pneumatic starter motor to drive rotation of a starting spool of the gas turbine engine below an engine idle speed.

Owner:RAYTHEON TECH CORP

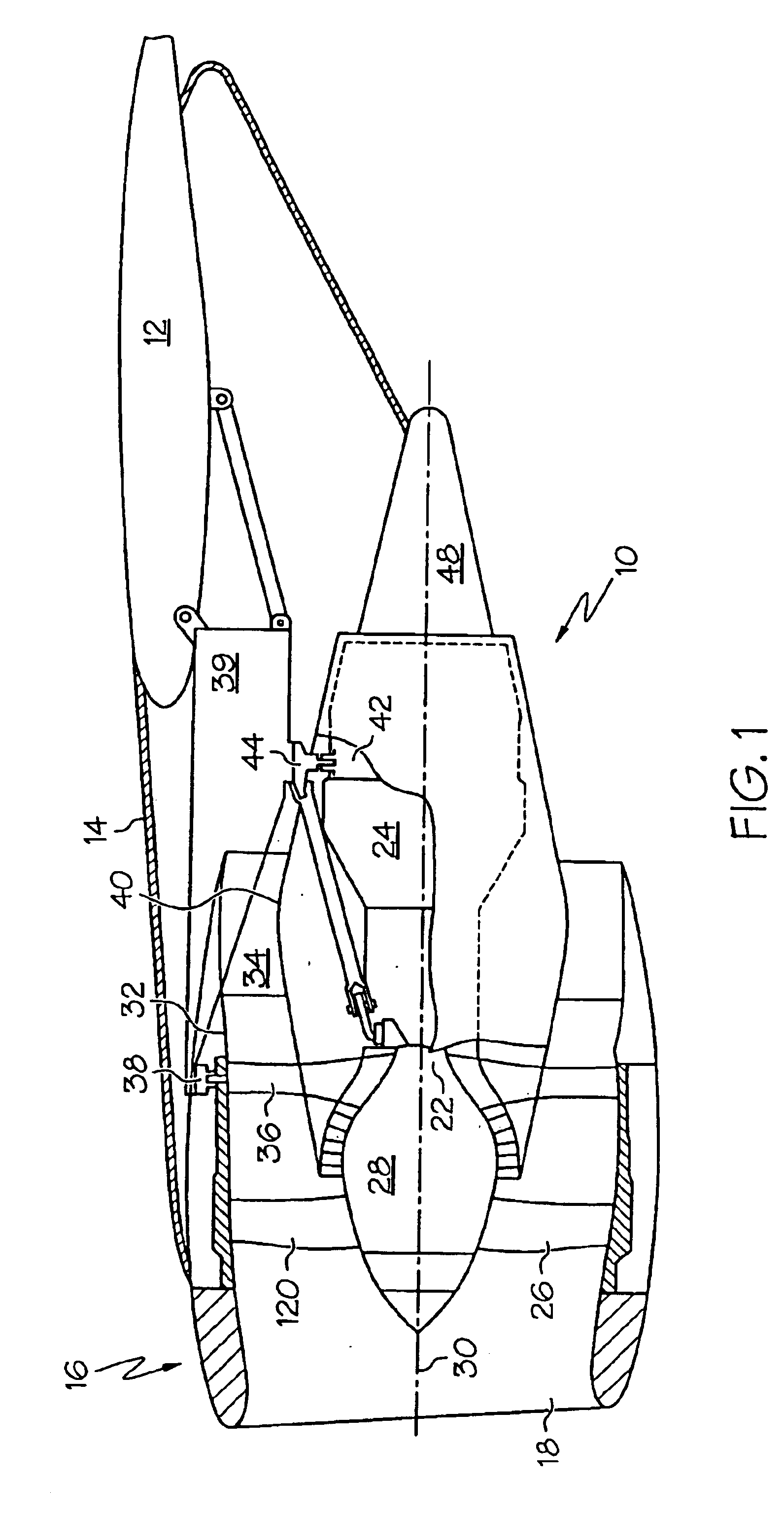

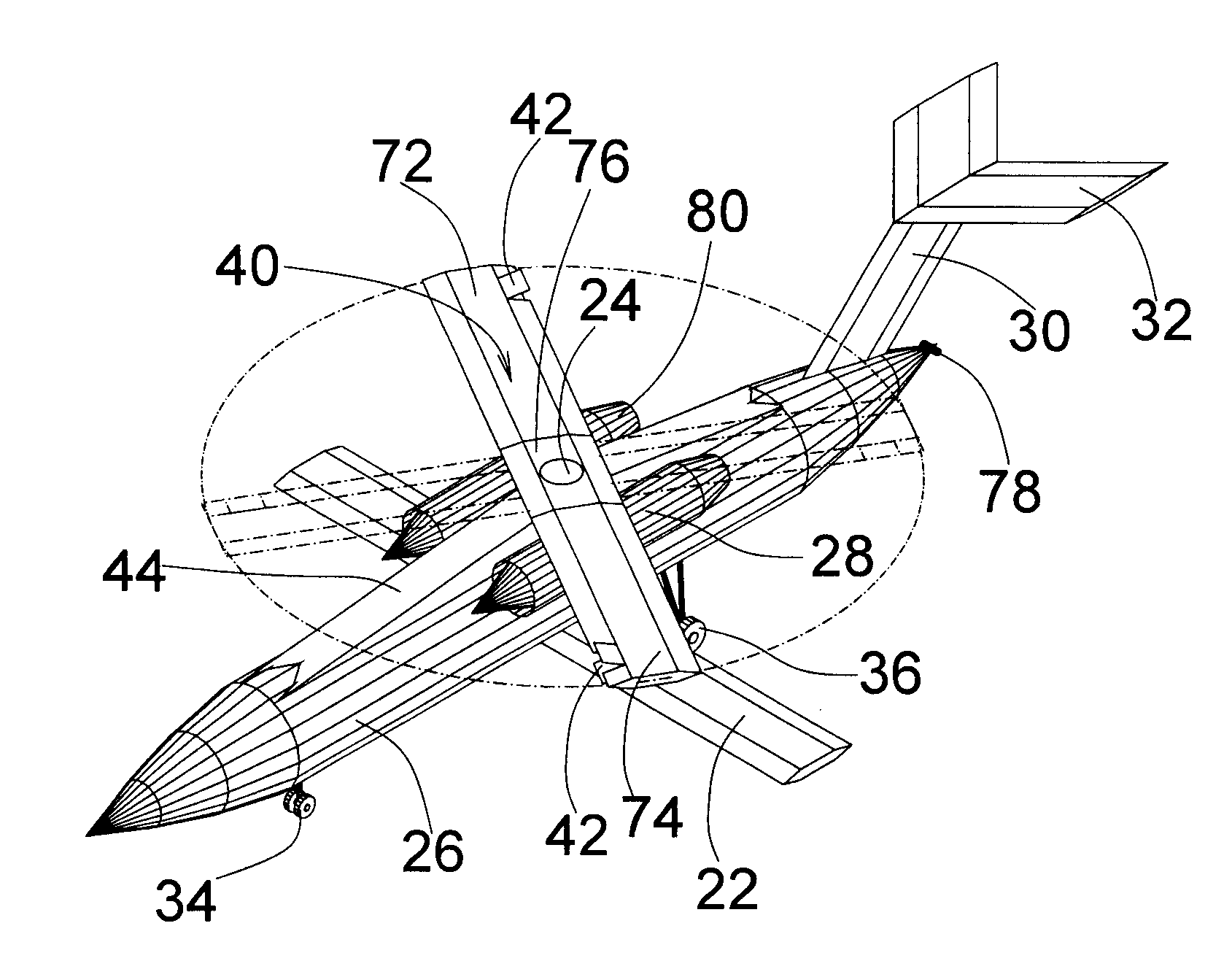

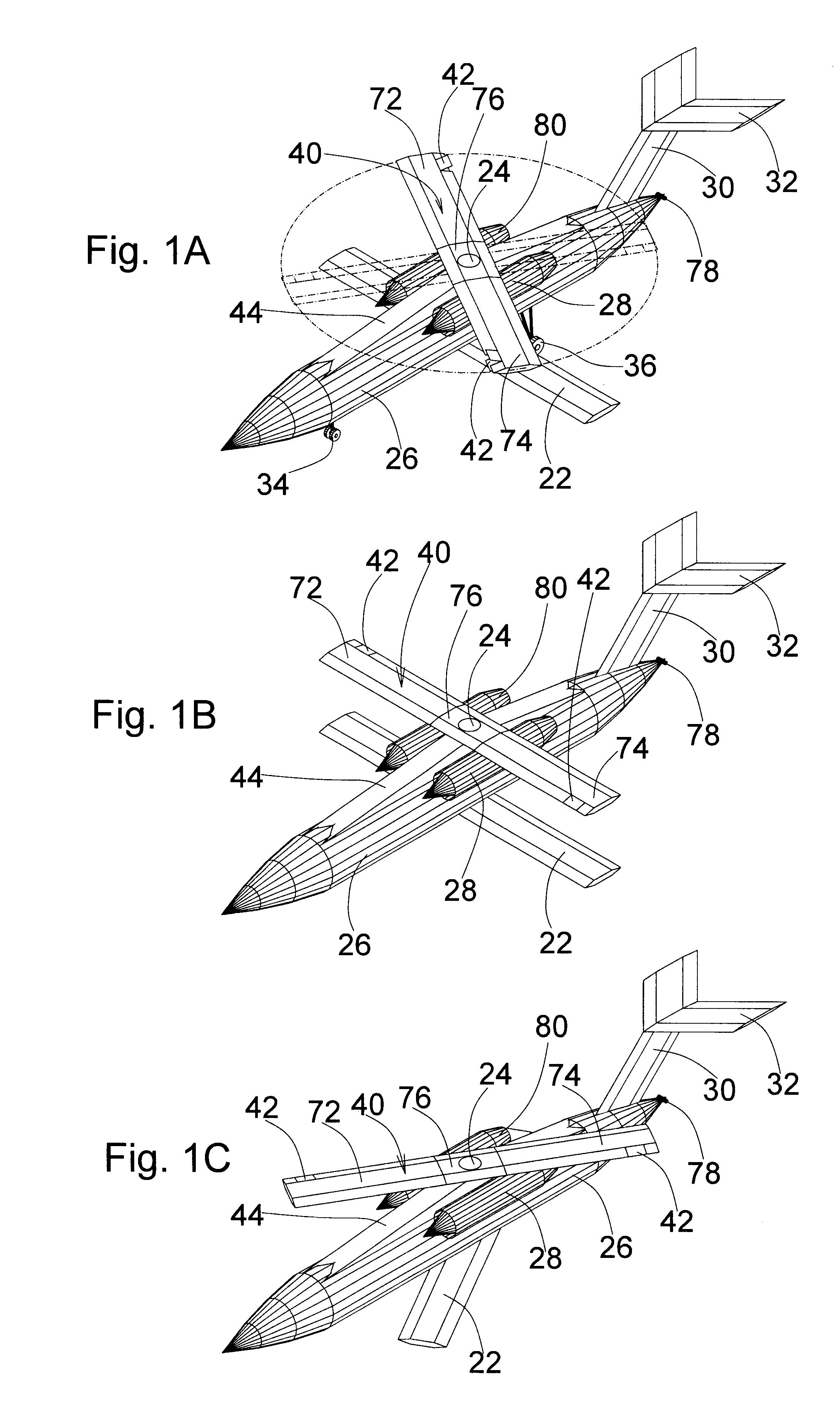

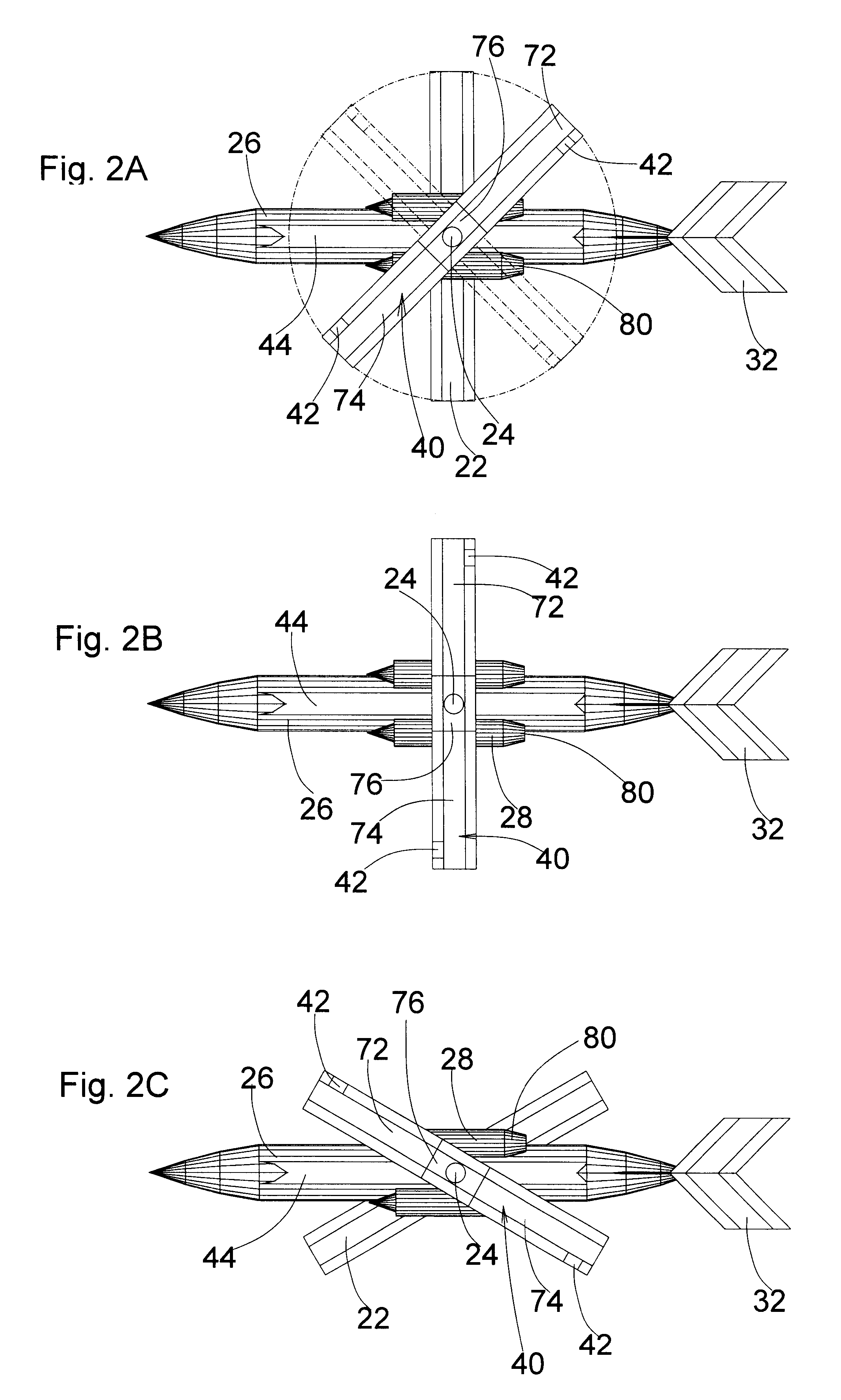

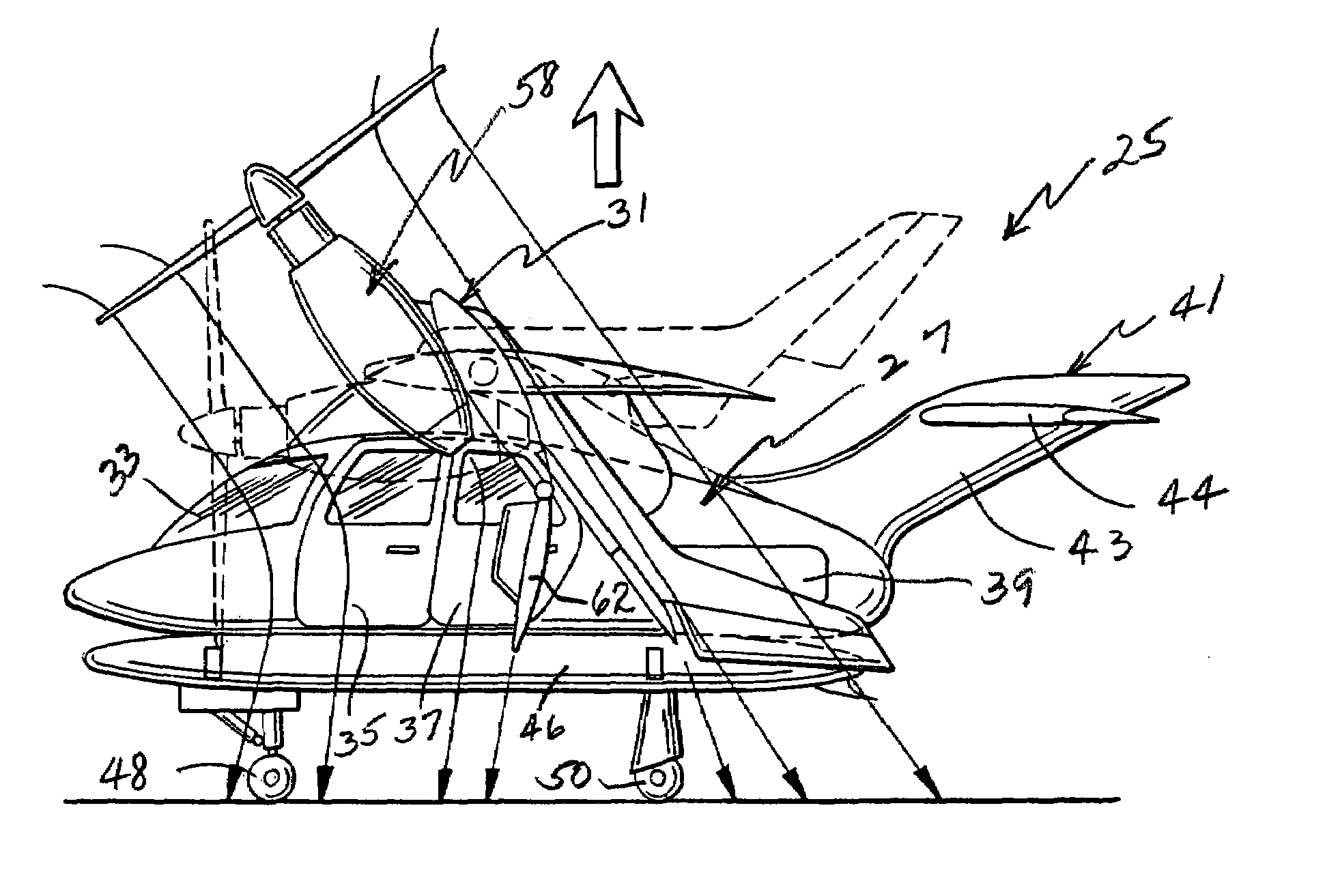

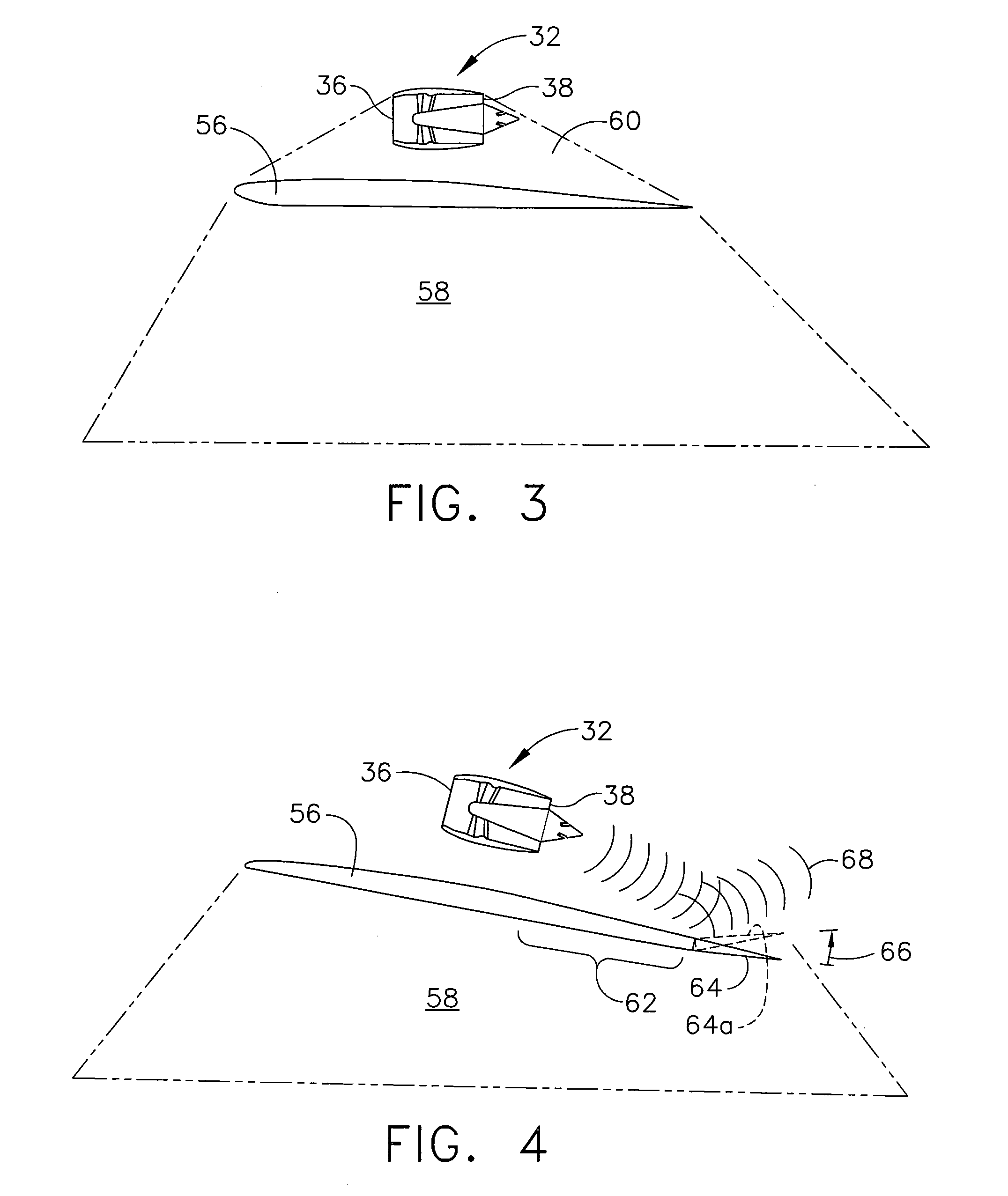

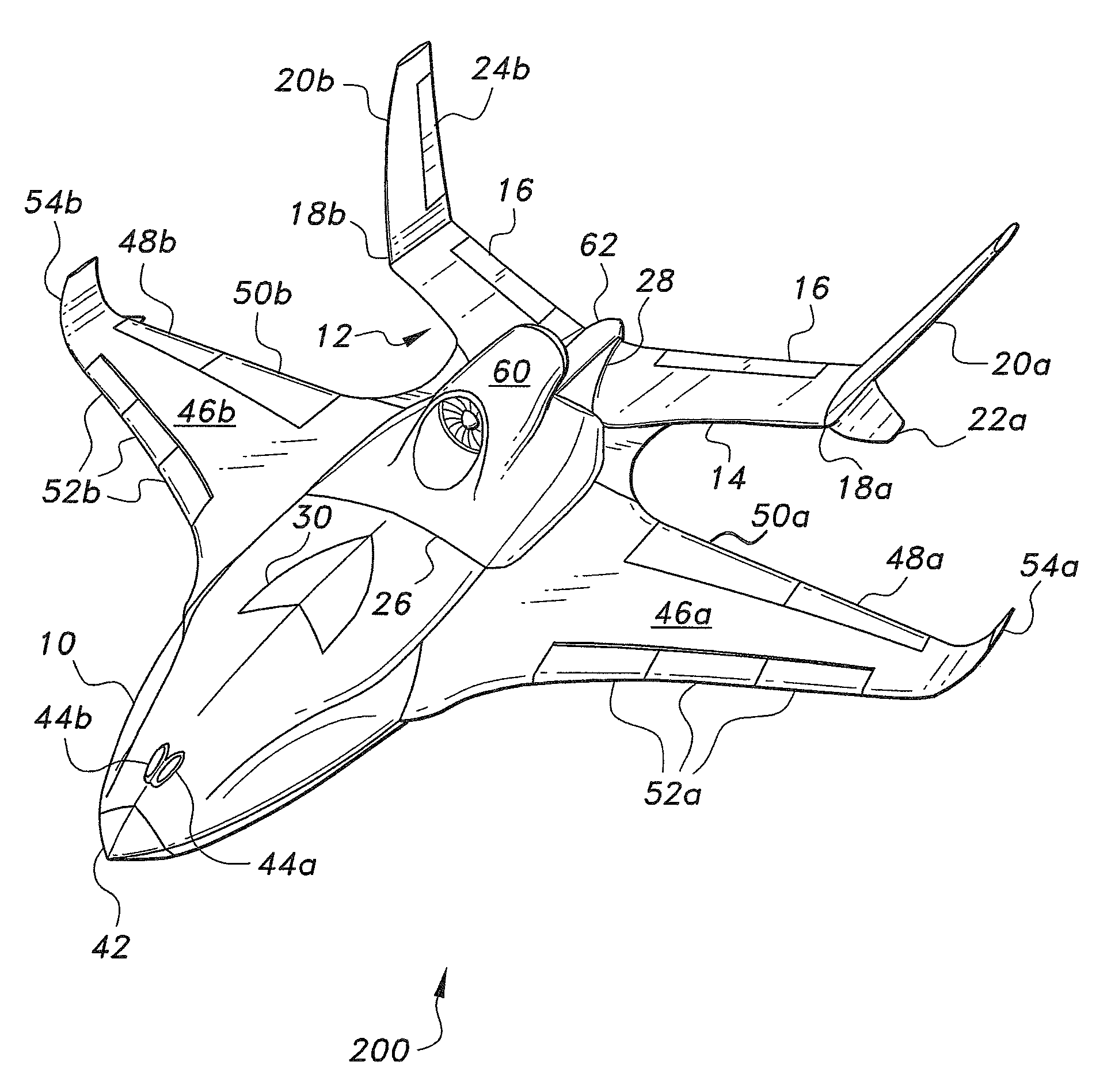

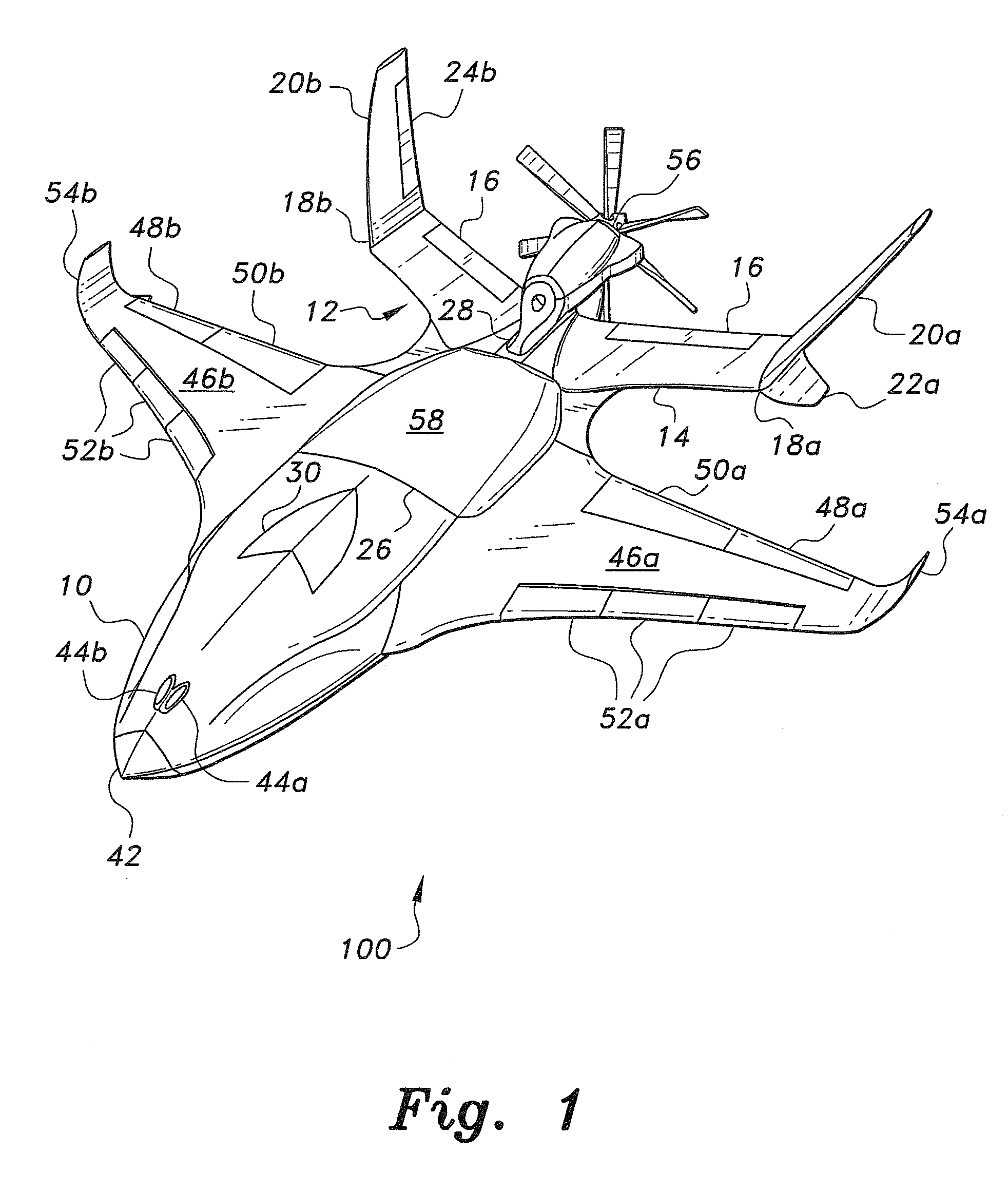

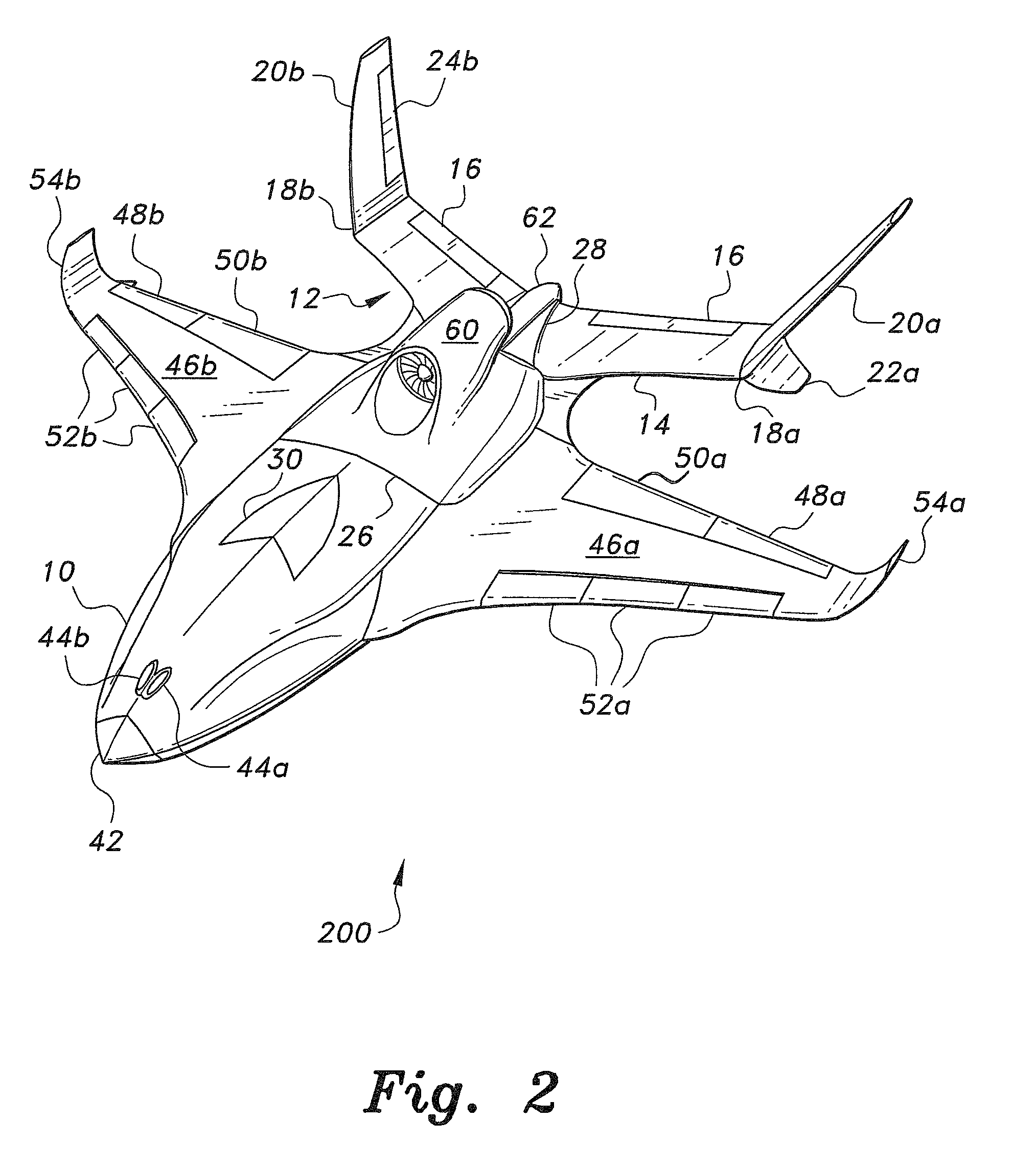

Air vehicle having rotor/scissors wing

InactiveUS6669137B1Easy to convertEfficiently and effectively flyJet type power plantsEfficient propulsion technologiesLow speedReverse order

An air vehicle, such as a manned or unmanned air vehicle, has a fuselage, a rotor / scissors wing, and a scissors wing. At helicopter mode, the rotor / scissors wing rotates to make the air vehicle fly like a helicopter to achieve vertical and / or short take-off and landing, hovering, and low speed flying. At airplane mode, the rotor / scissors wing and scissors wing form a scissors wings configuration to maximize the air vehicle's flying efficiency at a wide range of speed and flying conditions by adjusting the yaw angle of the rotor / scissors wing and scissors wing. During the conversion from helicopter mode to airplane mode, the scissors wing generates lift to offload the rotating rotor / scissors wing and eventually the offloaded rotor / scissors wing's rotating speed is slowed and stopped so that the rotor / scissors wing can be locked at a specific position and the conversion can be achieved. In a reverse order, the air vehicle can convert from airplane mode to helicopter mode. Either turbofan or turbojet engine, or turboshaft / turbofan convertible engine can be used to power the air vehicle.

Owner:CHEN ZHUO

Integrated bypass turbojet engines for air craft and other vehicles

InactiveUS6966174B2Reduce complexityReduce weightJet type power plantsEfficient propulsion technologiesRam air turbineTurbojet engine

Turbojet engines and aircraft configurations for advantageous use of the turbojet engines; the turbojet engines utilizing ram air turbine units that centrifugally compress air isothermally for use in various combustion configurations designed for stoichiometric combustion, wherein a stream of by-pass ram-air jets is mixed with combustion gas jets for discharge in a common discharge nozzle.

Owner:PAUL MARIUS A

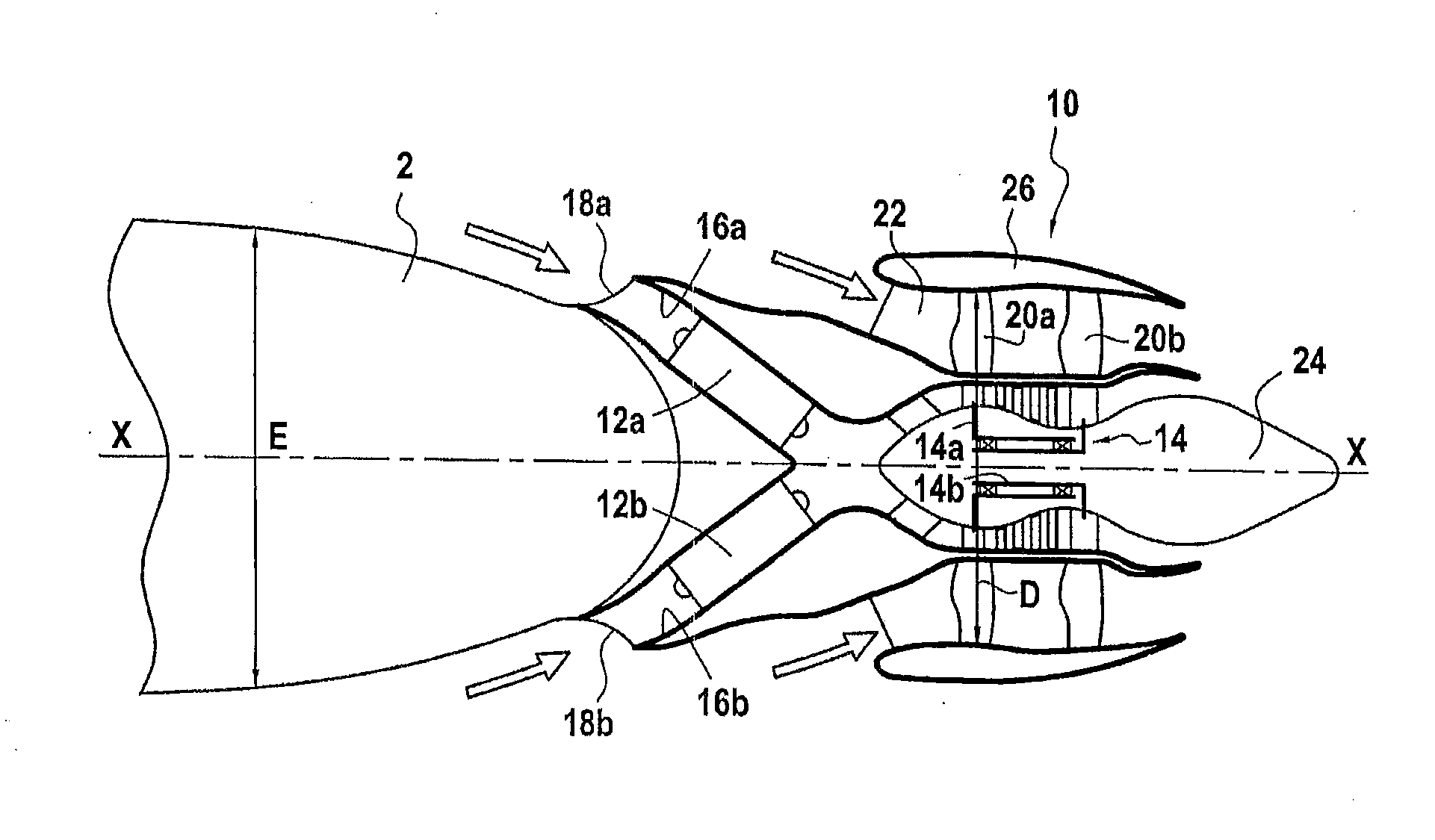

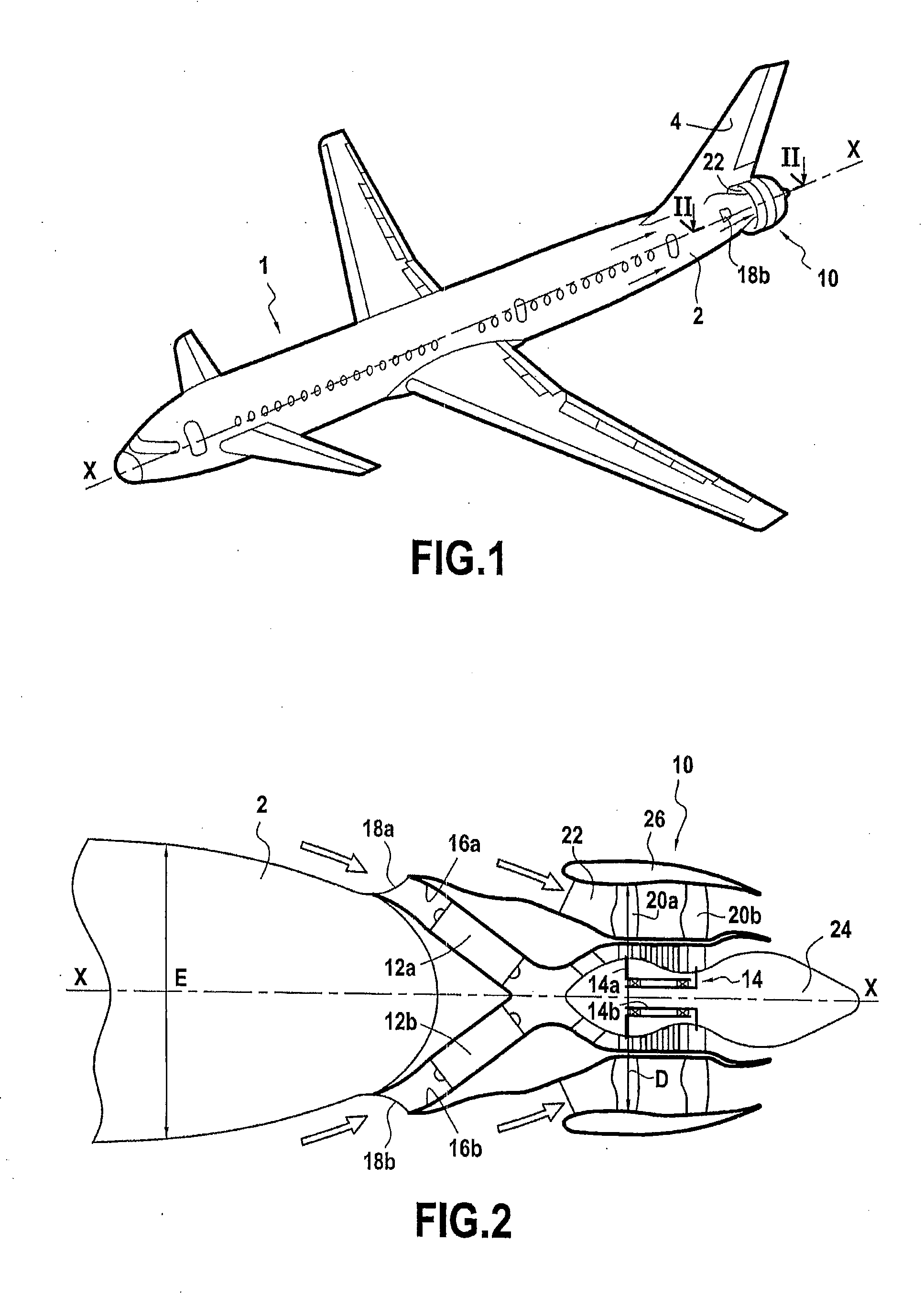

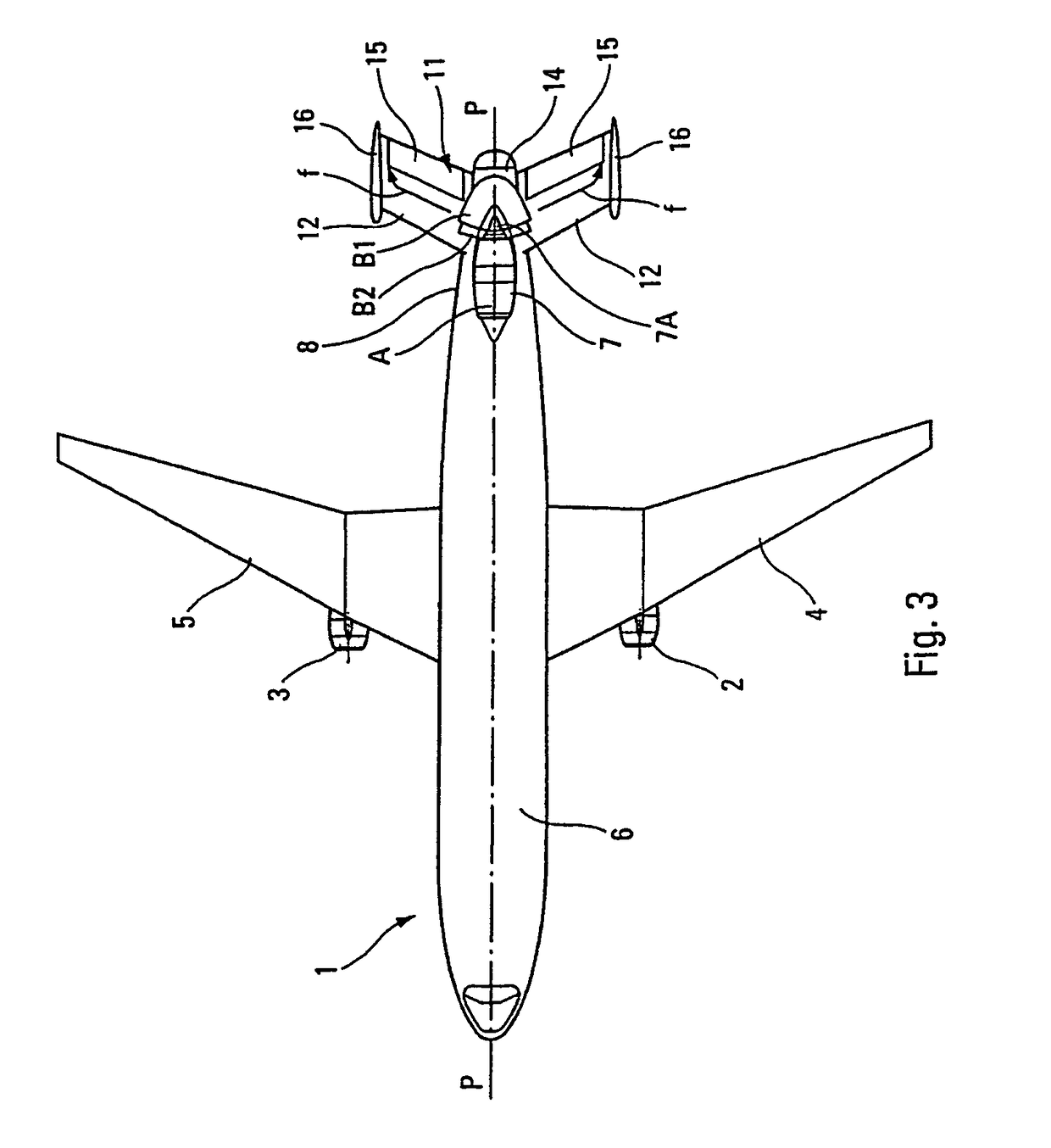

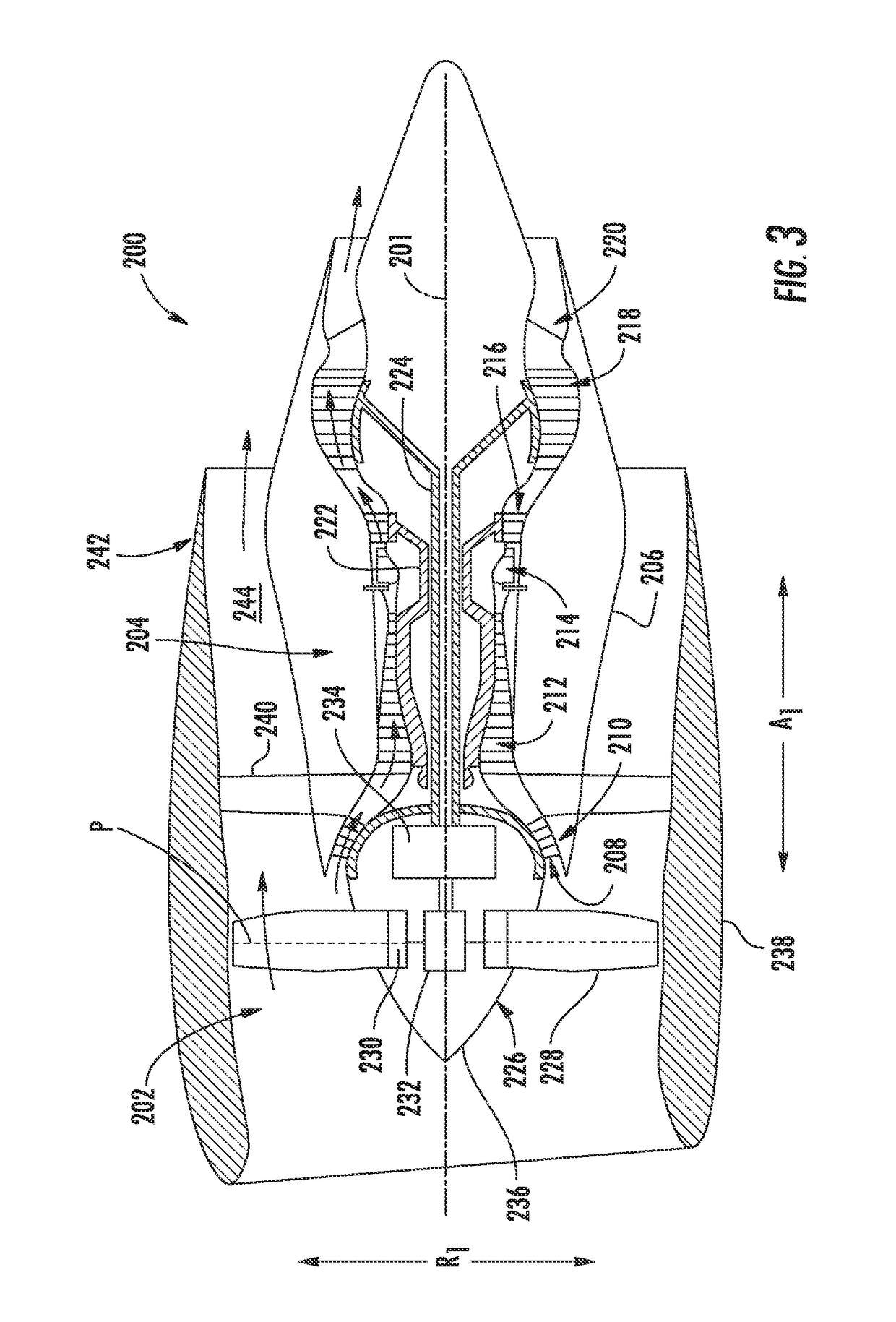

Aircraft propelled by a turbojet engine with contrarotating fans

ActiveUS20150291285A1Reduce fuel consumptionLimiting aerodynamic dragGas turbine type power plantsCombination enginesJet aeroplaneFuselage

An aircraft propelled by a turbojet having contrarotating fans, the turbojet being incorporated at the rear of a fuselage of the aircraft and in line therewith and including two gas generators that feed a working turbine having two contrarotating turbine rotors for driving two fans arranged downstream from the gas generators, and distinct air intakes for feeding each gas generator, the air intakes being connected to the fuselage of the aircraft so as to take in at least a portion of the boundary layer formed around the fuselage of the aircraft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

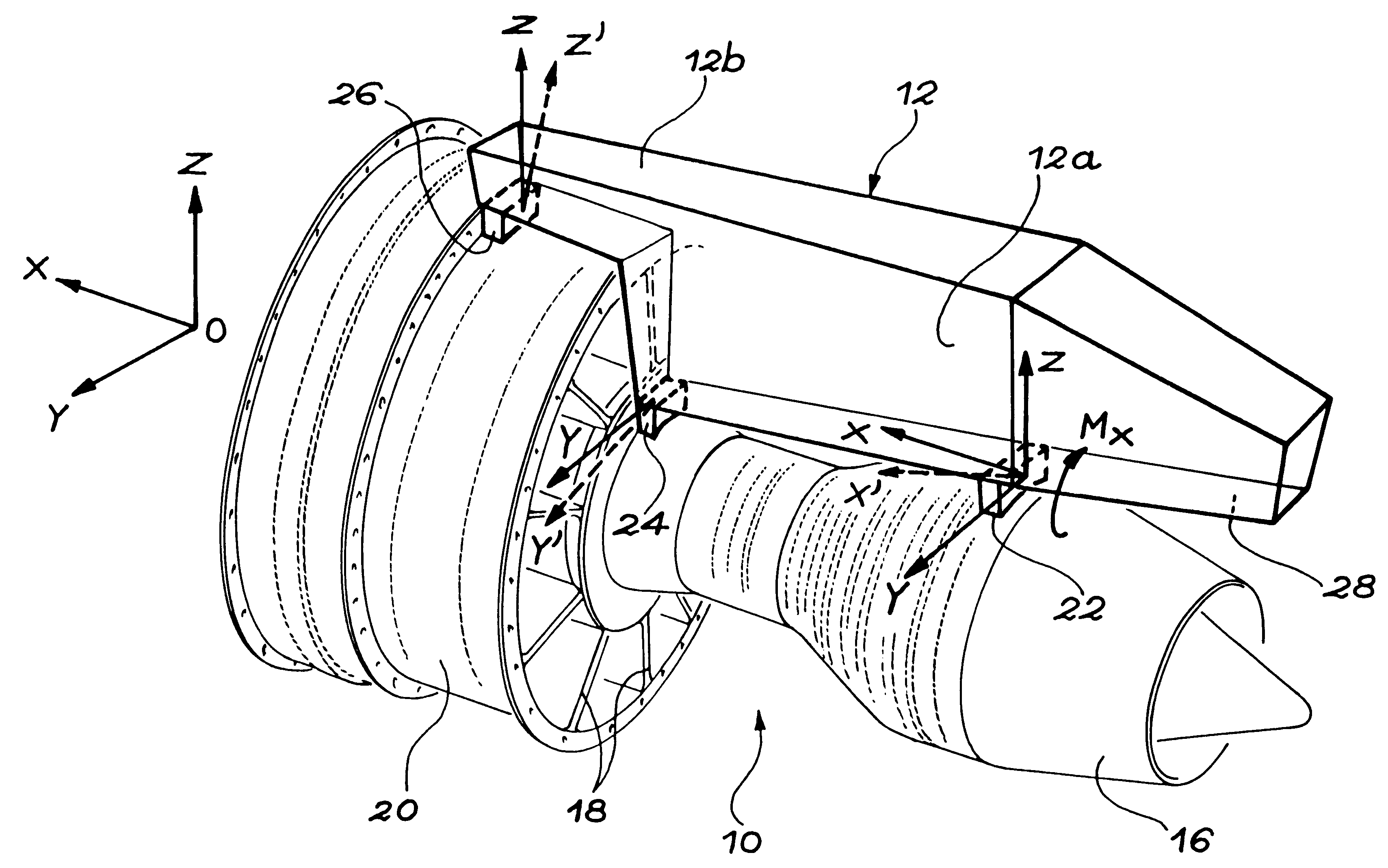

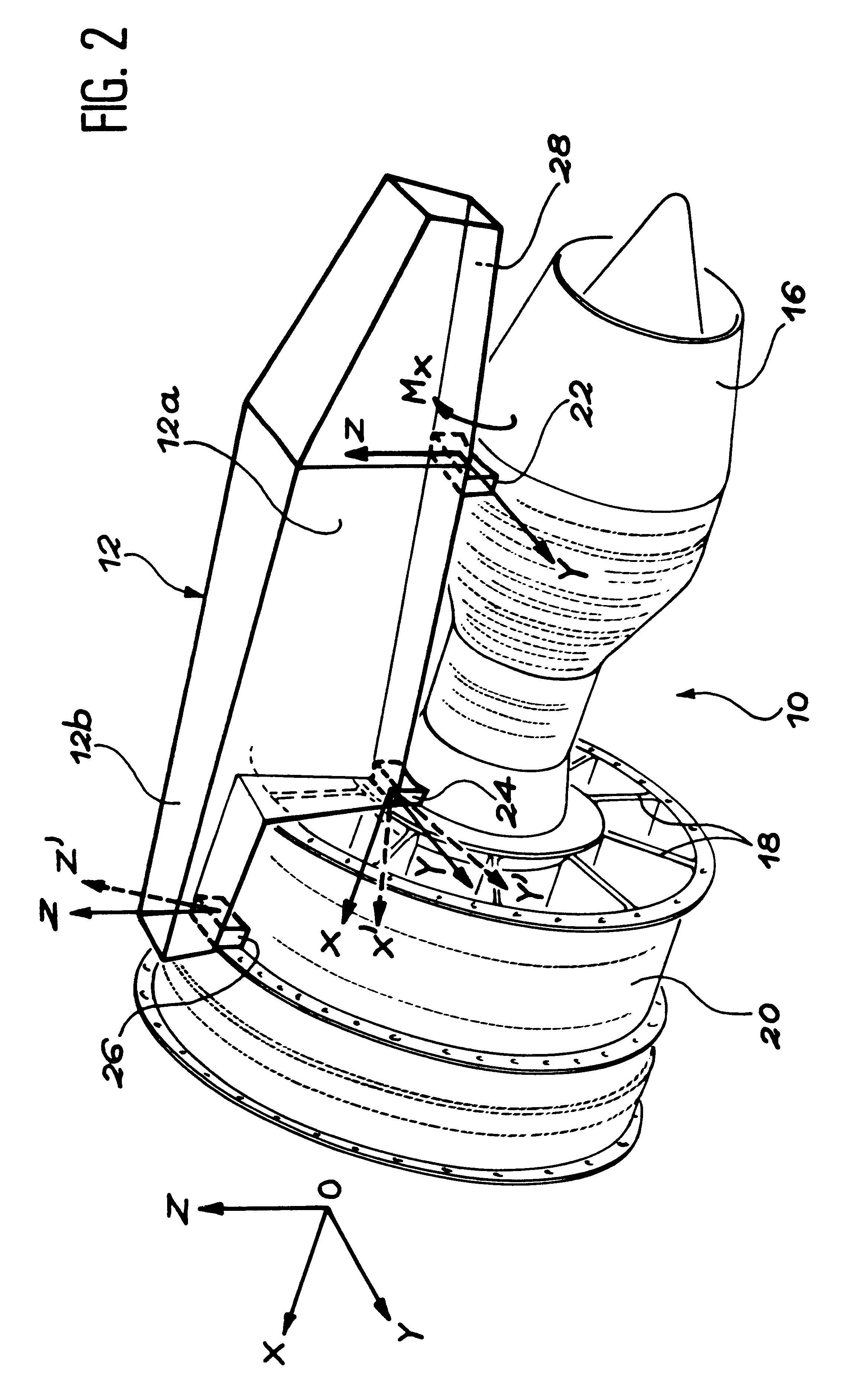

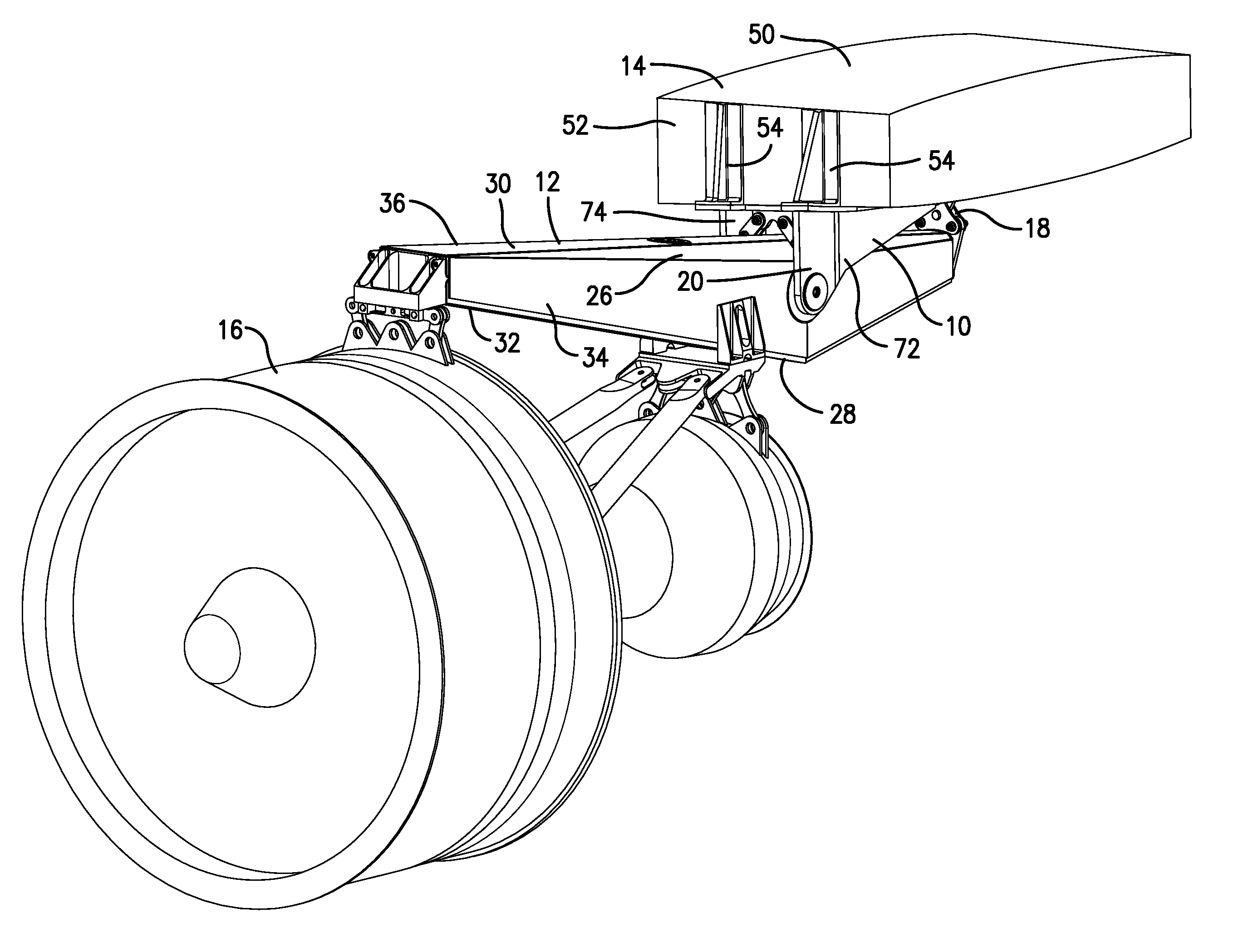

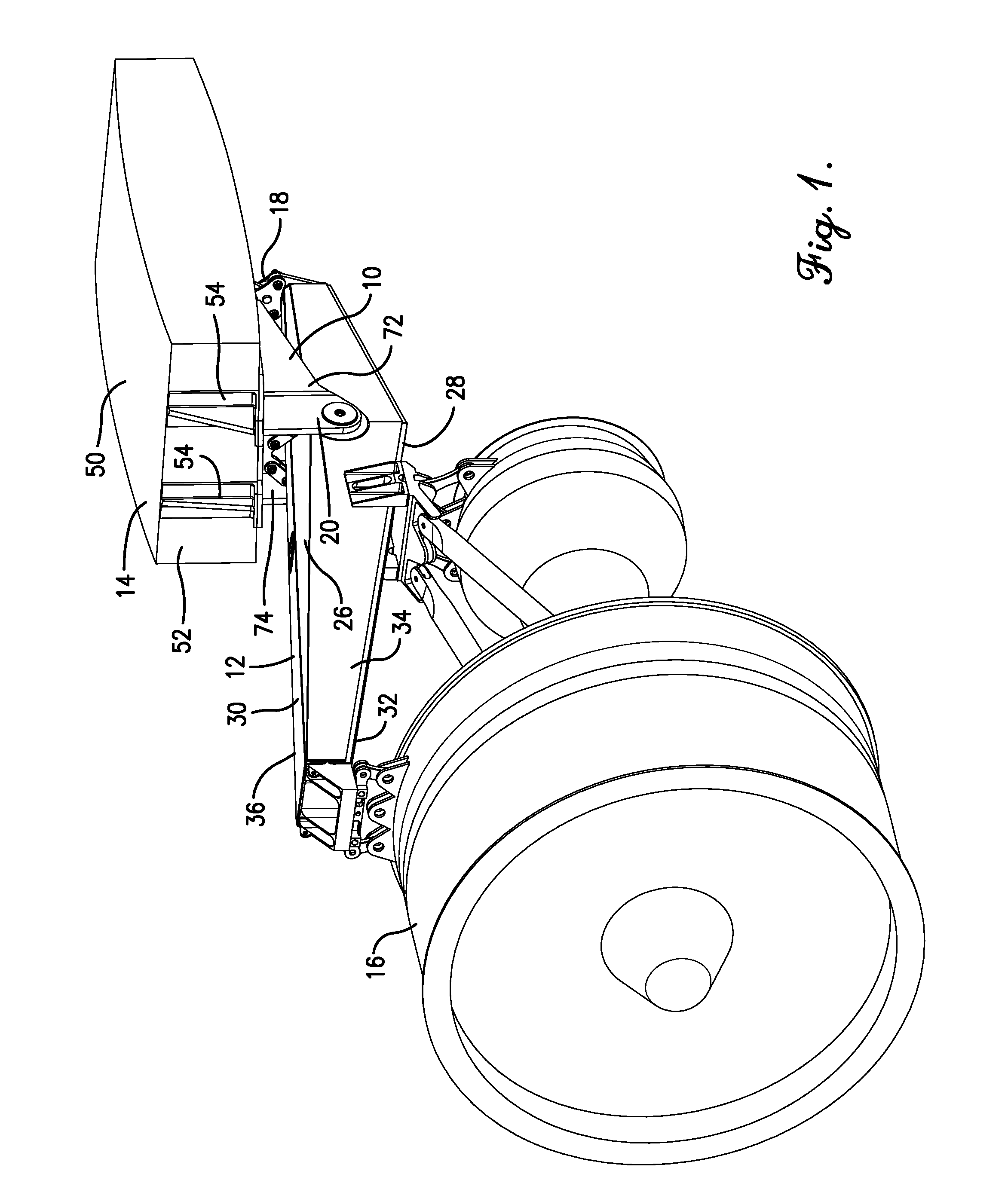

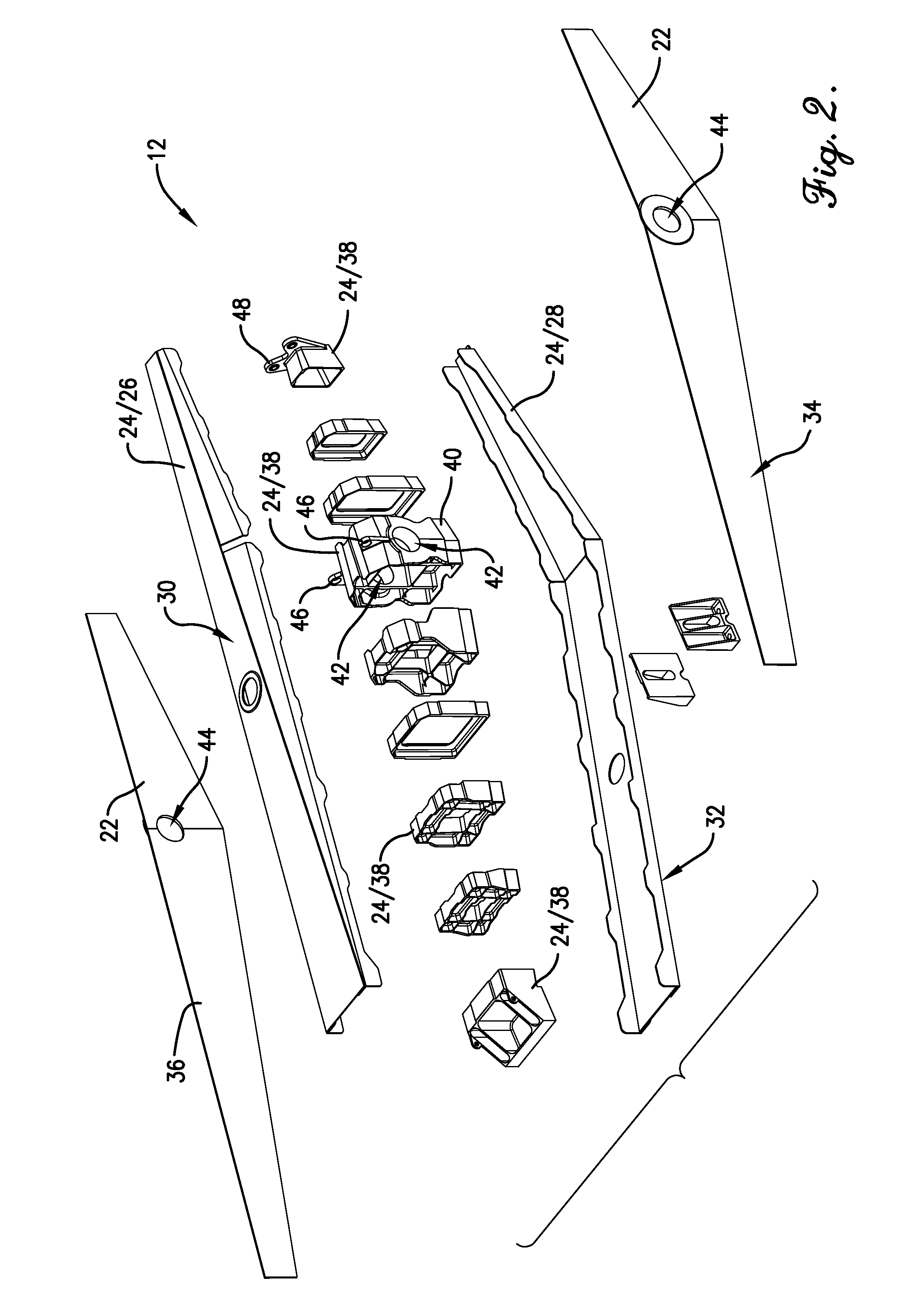

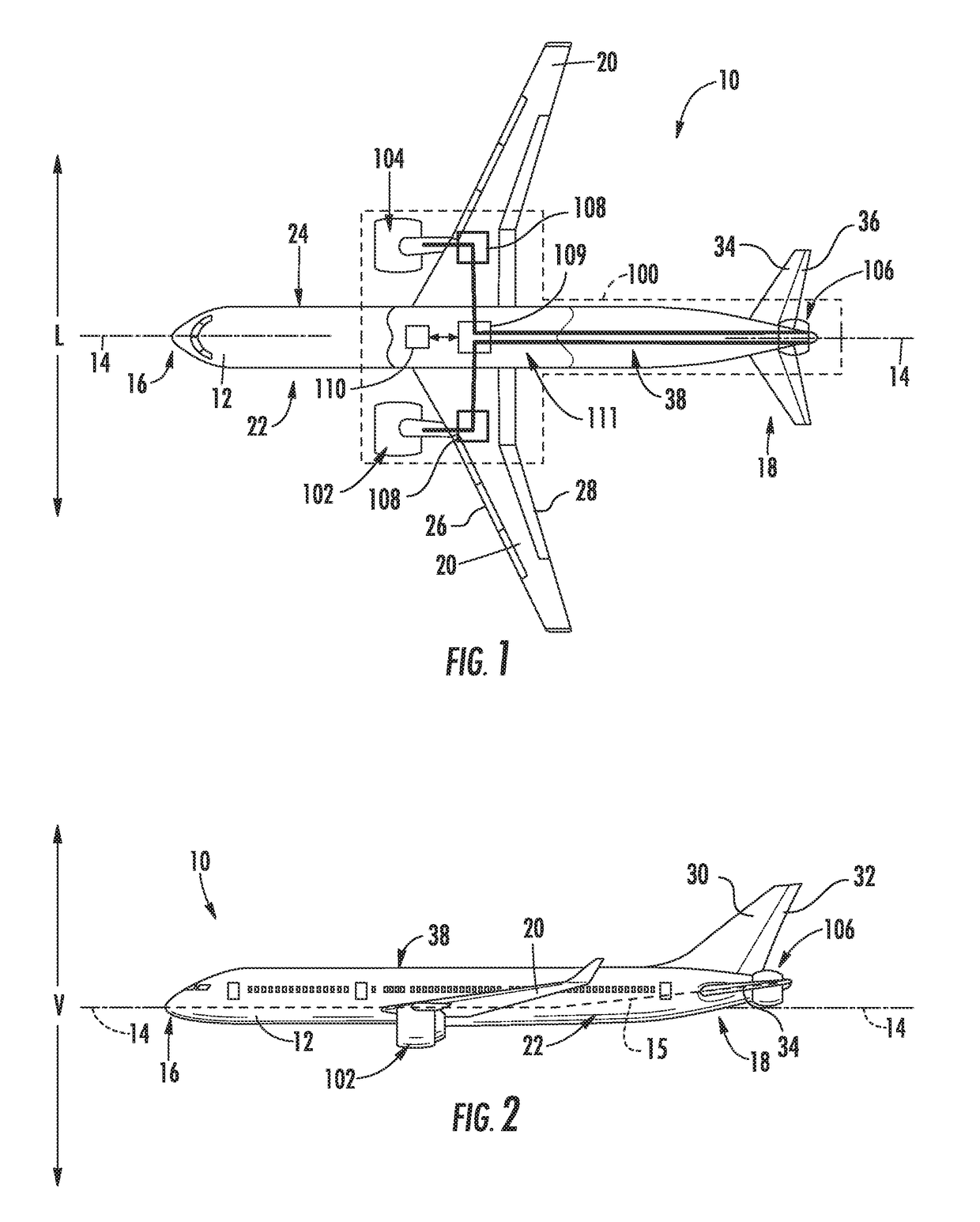

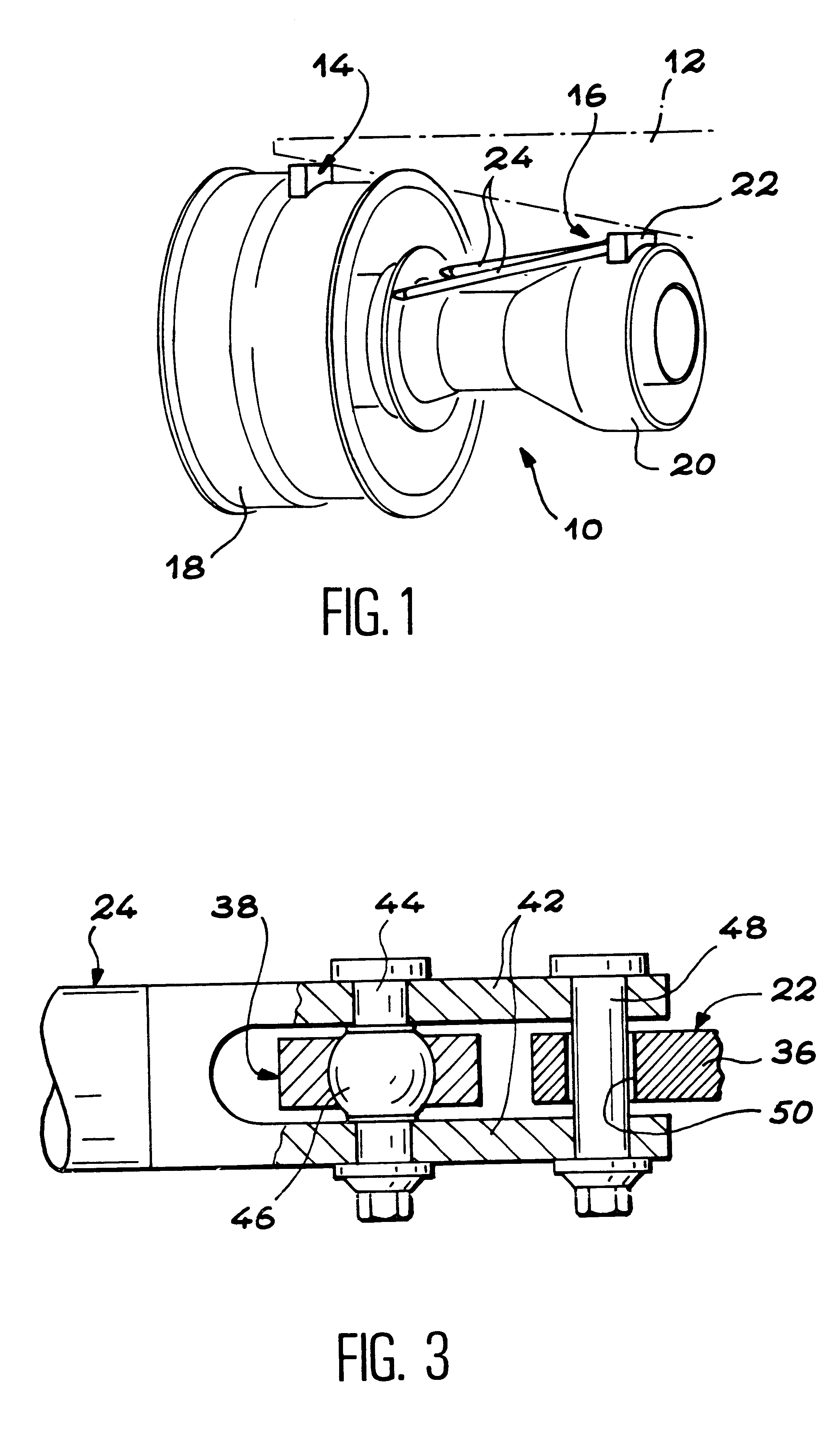

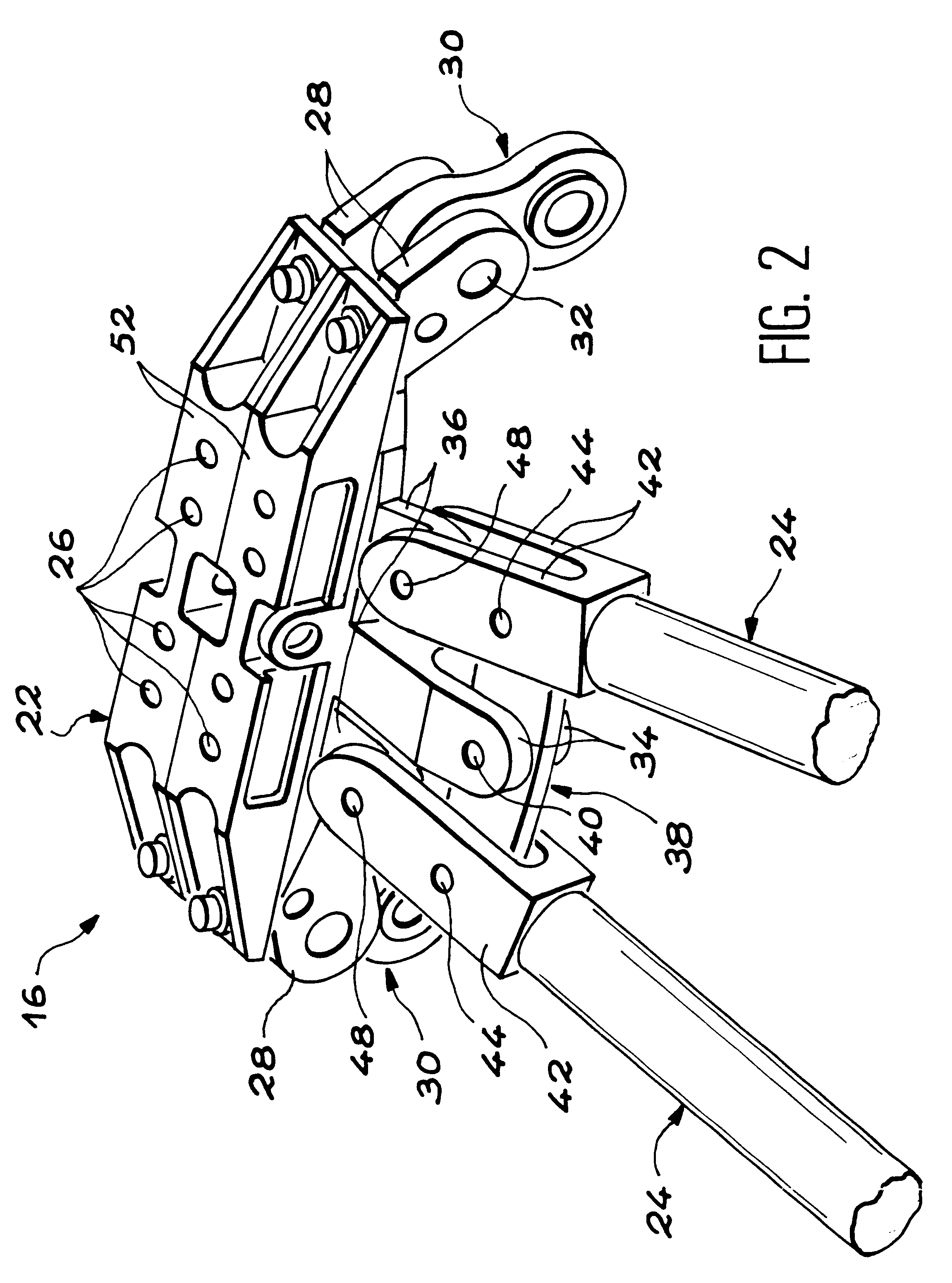

Device for fixing an aircraft propulsion system to a strut and a strut adapted to said device

An aircraft propulsion system (10) is connected to a strut, fixed to the wing or fuselage, by a fixing device comprising at least one rear mount (22) and two front mounts (24, 26). The rear mount (22) and a first (24) of the front mounts connect a main part (12a) of the frame (12) of the strut to the central casing (16) of the engine. The other front mount (26) connects a front part (12b) projecting from the strut frame (12) to the fan stator case (20) and mainly takes up the vertical forces (Z). Thus, the first front mount (24) can be simplified and bending or sagging of the engine is reduced.

Owner:AEROSPATIALE AIRBUS

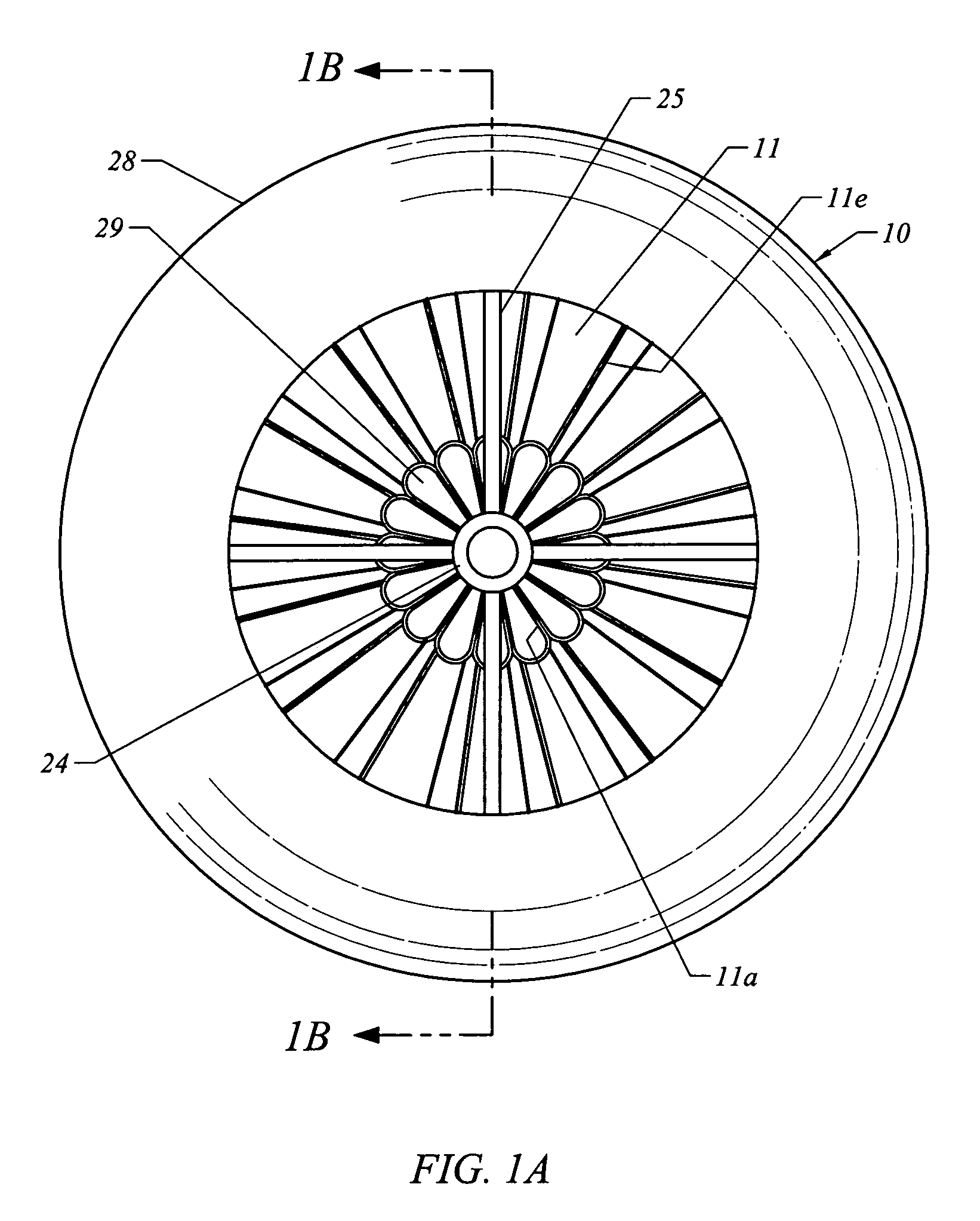

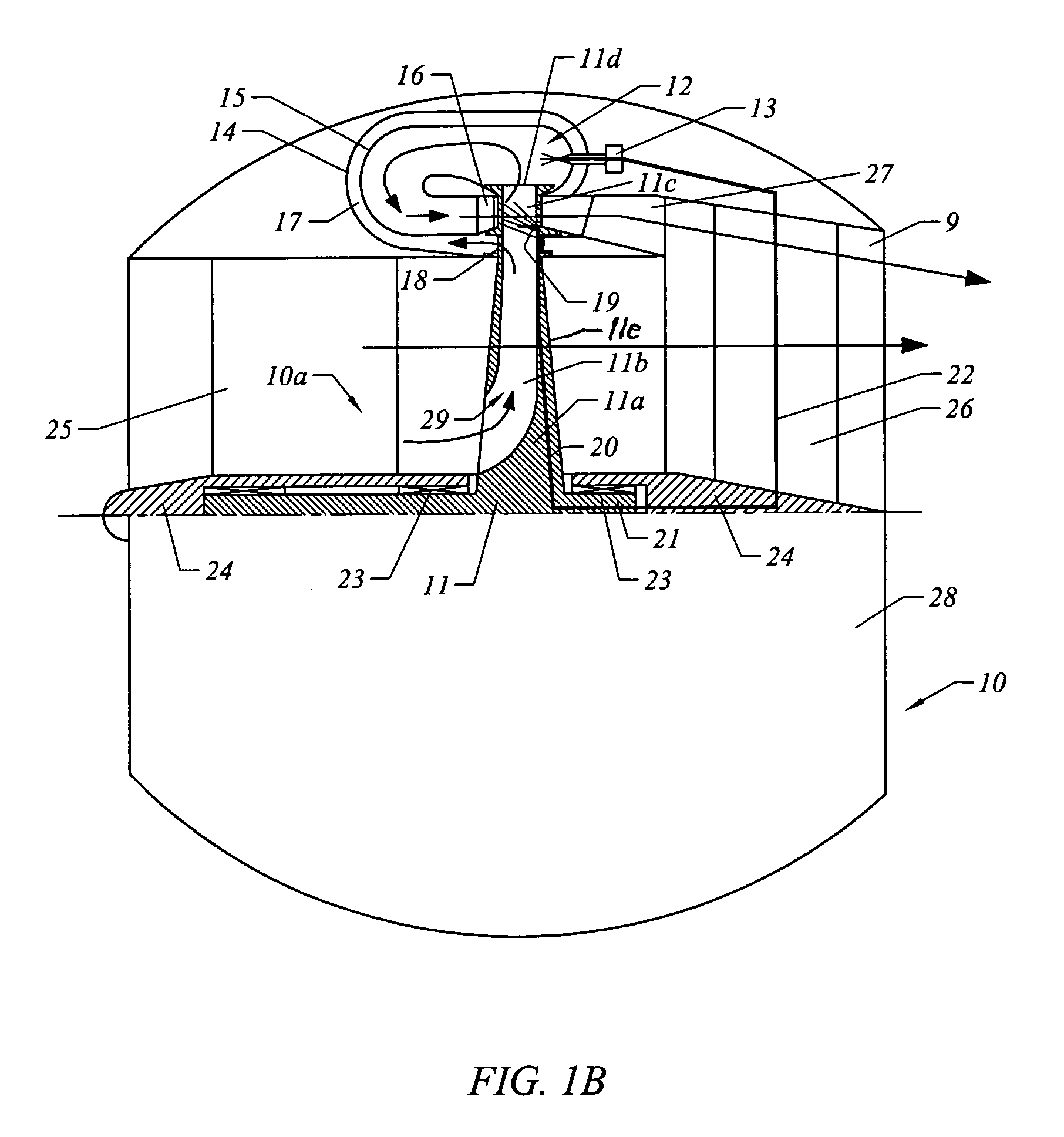

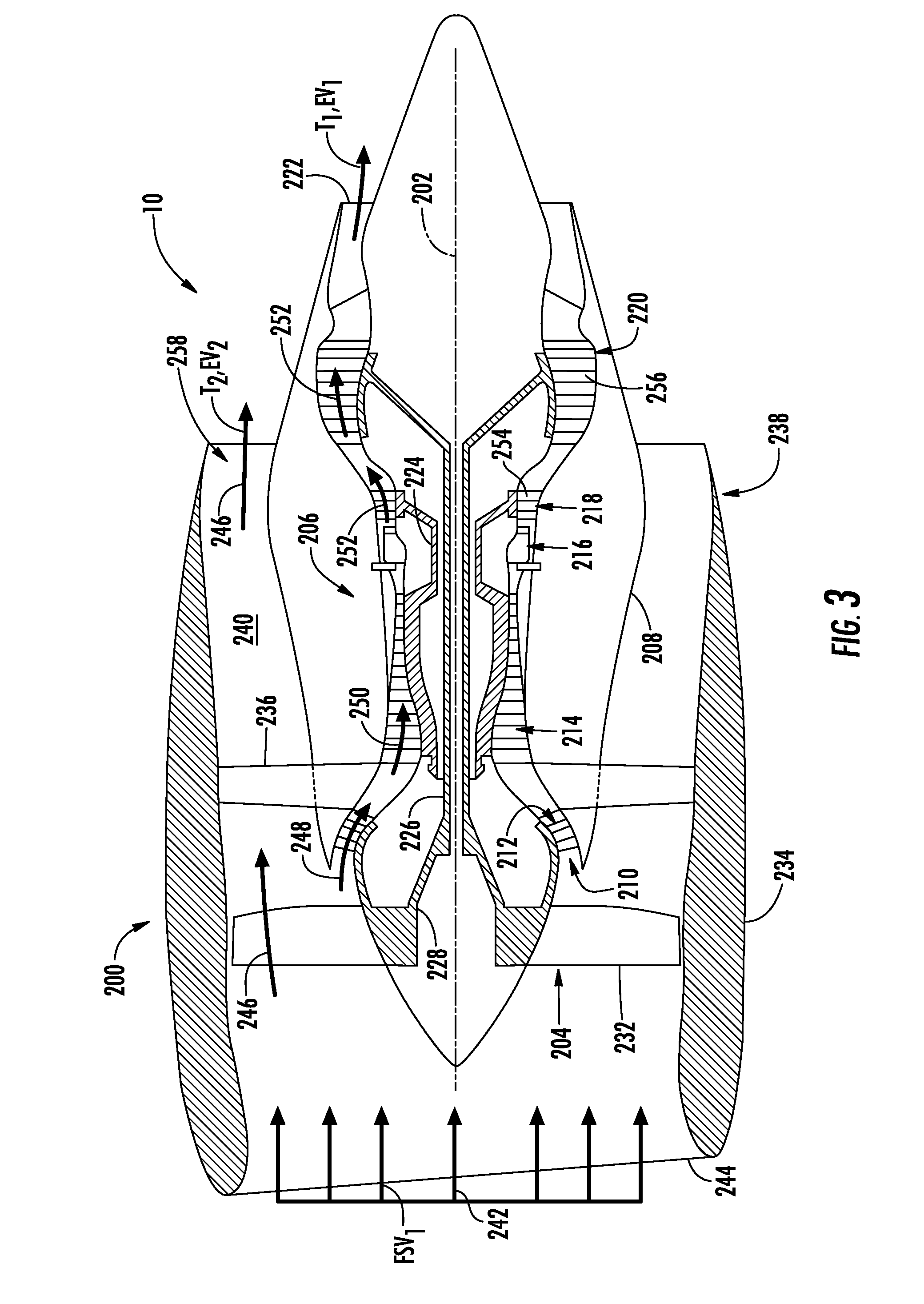

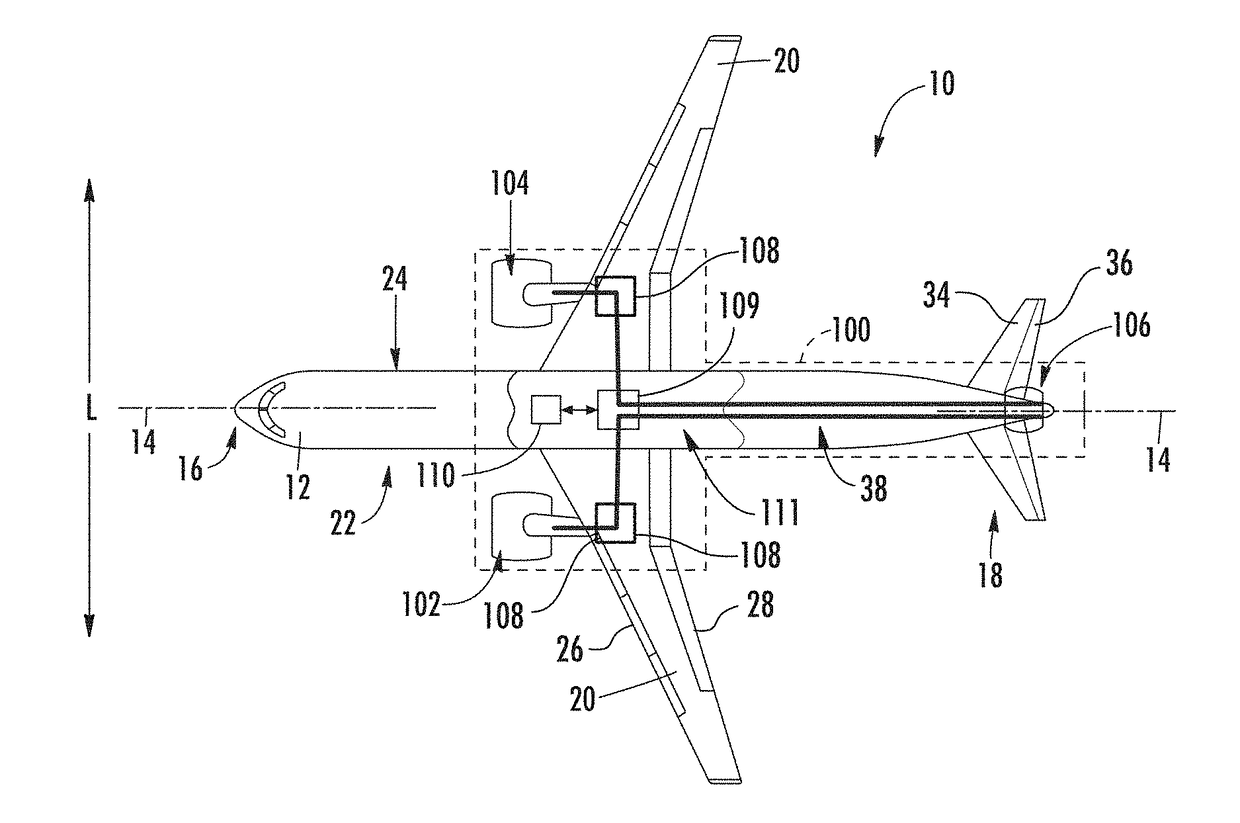

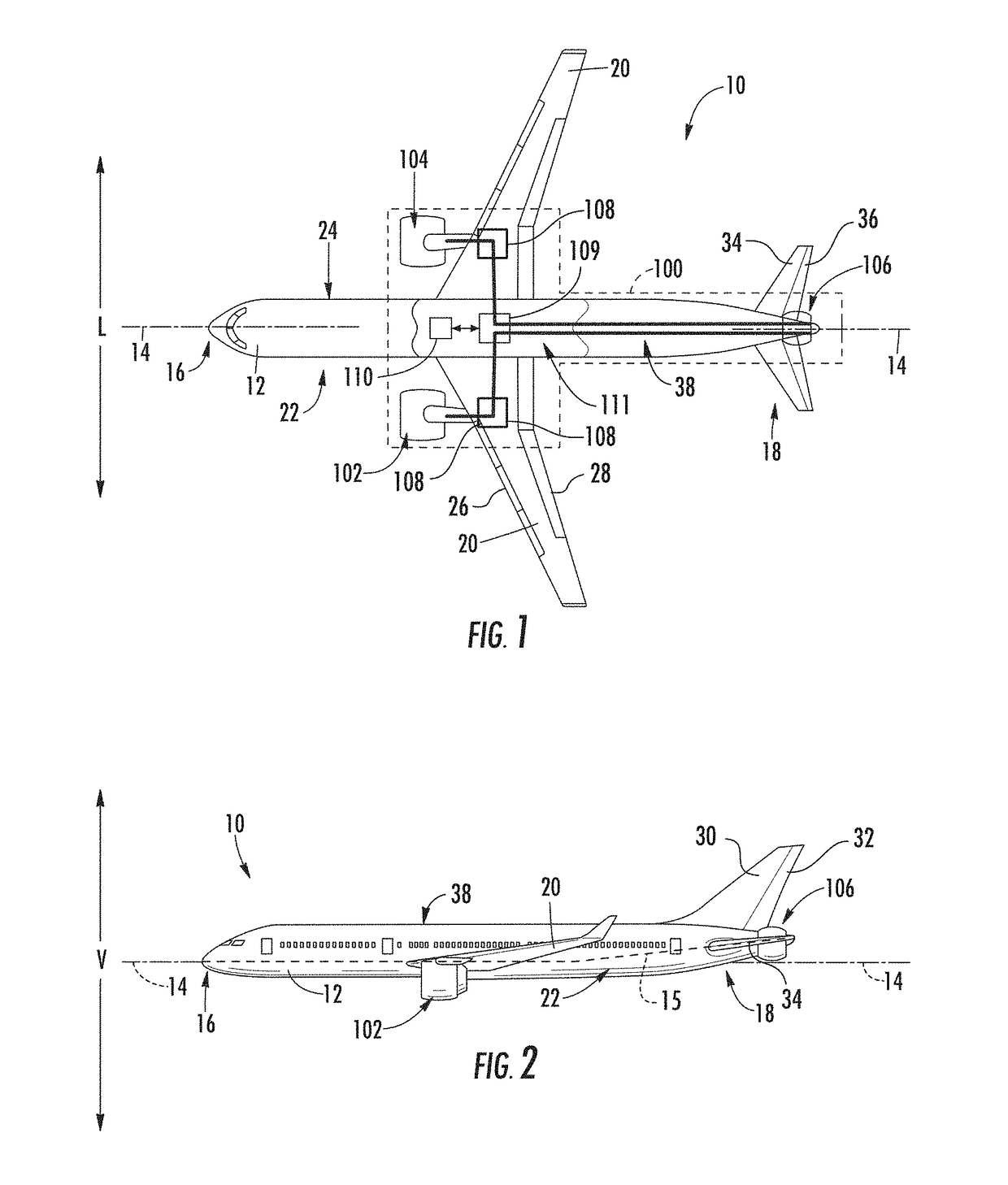

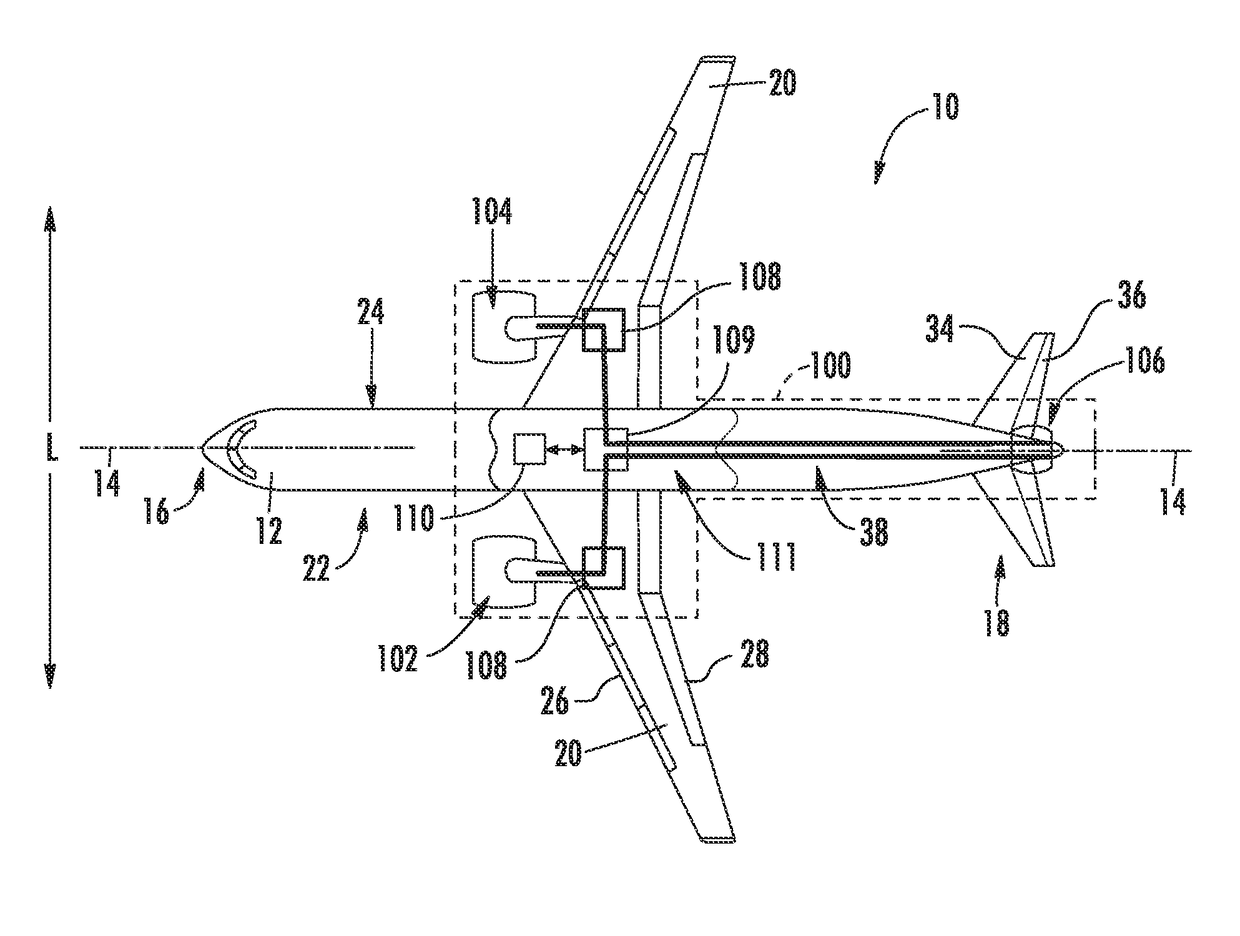

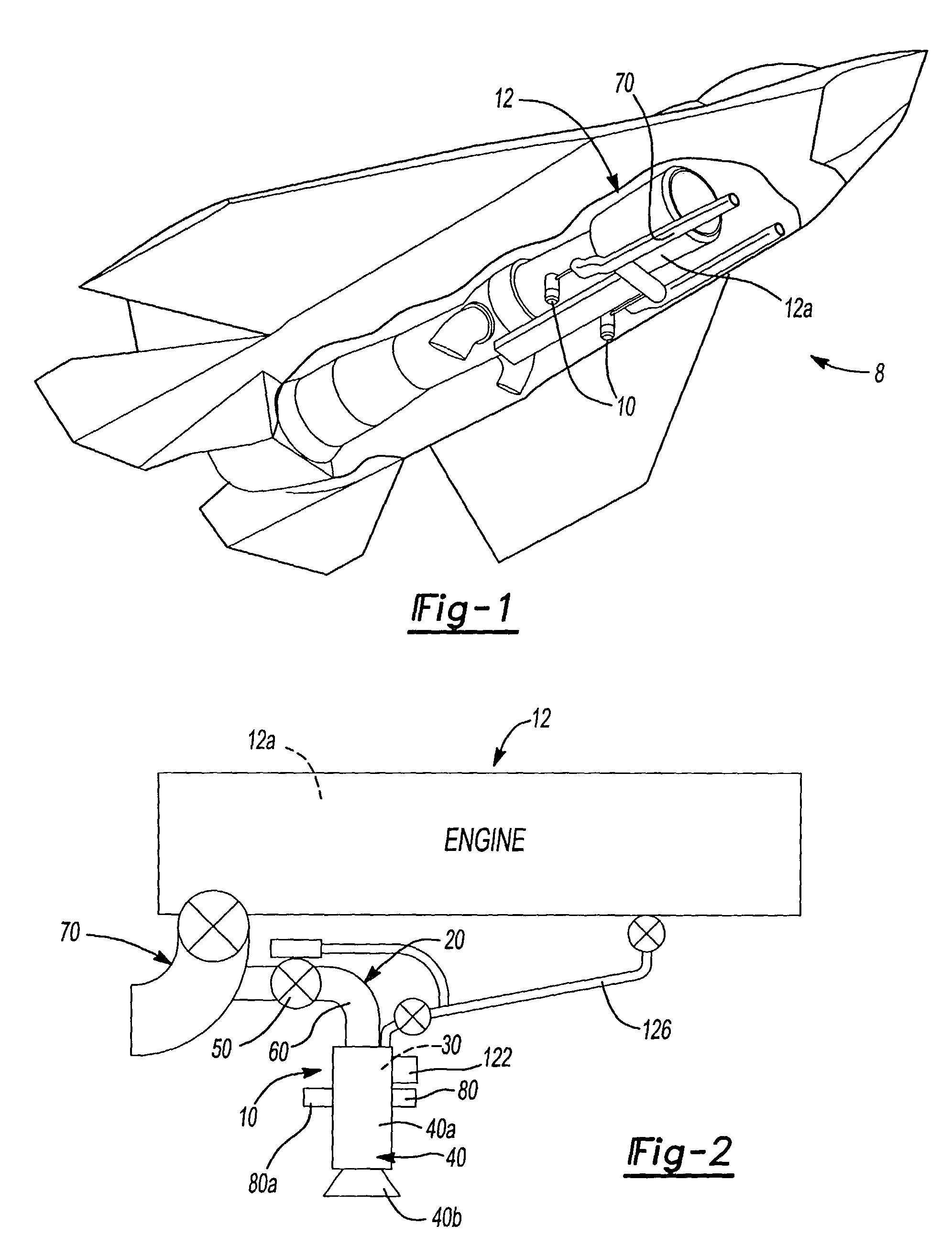

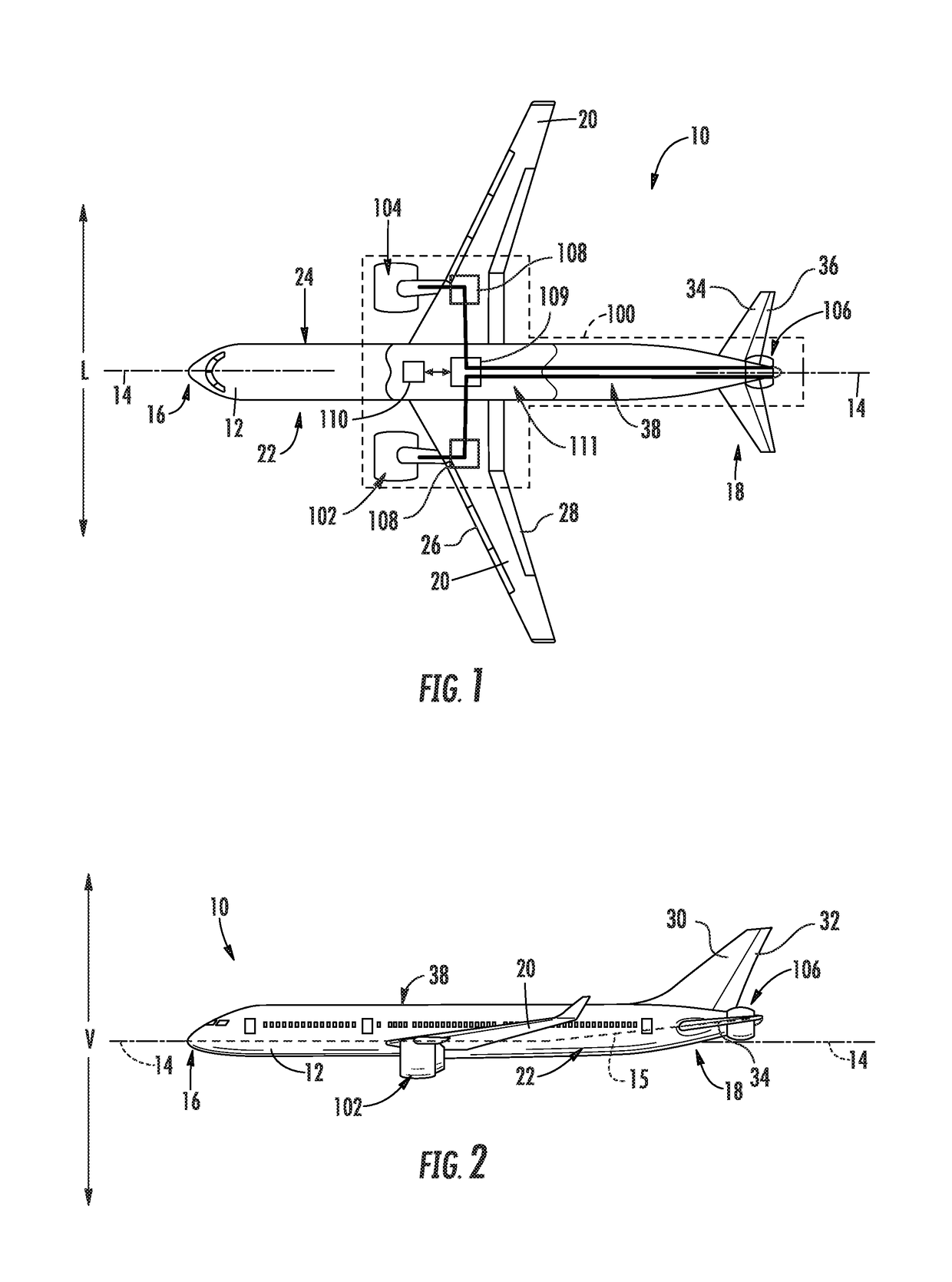

Gas-electric propulsion system for an aircraft

In one aspect the present subject matter is directed to a gas-electric propulsion system for an aircraft. The system may include a turbofan jet engine, an electric powered boundary layer ingestion fan that is coupled to a fuselage portion of the aircraft aft of the turbofan jet engine, and an electric generator that is electronically coupled to the turbofan jet engine and to the boundary layer ingestion fan. The electric generator converts rotational energy from the turbofan jet engine to electrical energy and provides at least a portion of the electrical energy to the boundary layer ingestion fan. In another aspect of the present subject matter, a method for propelling an aircraft via the gas-electric propulsion system is disclosed.

Owner:GENERAL ELECTRIC CO

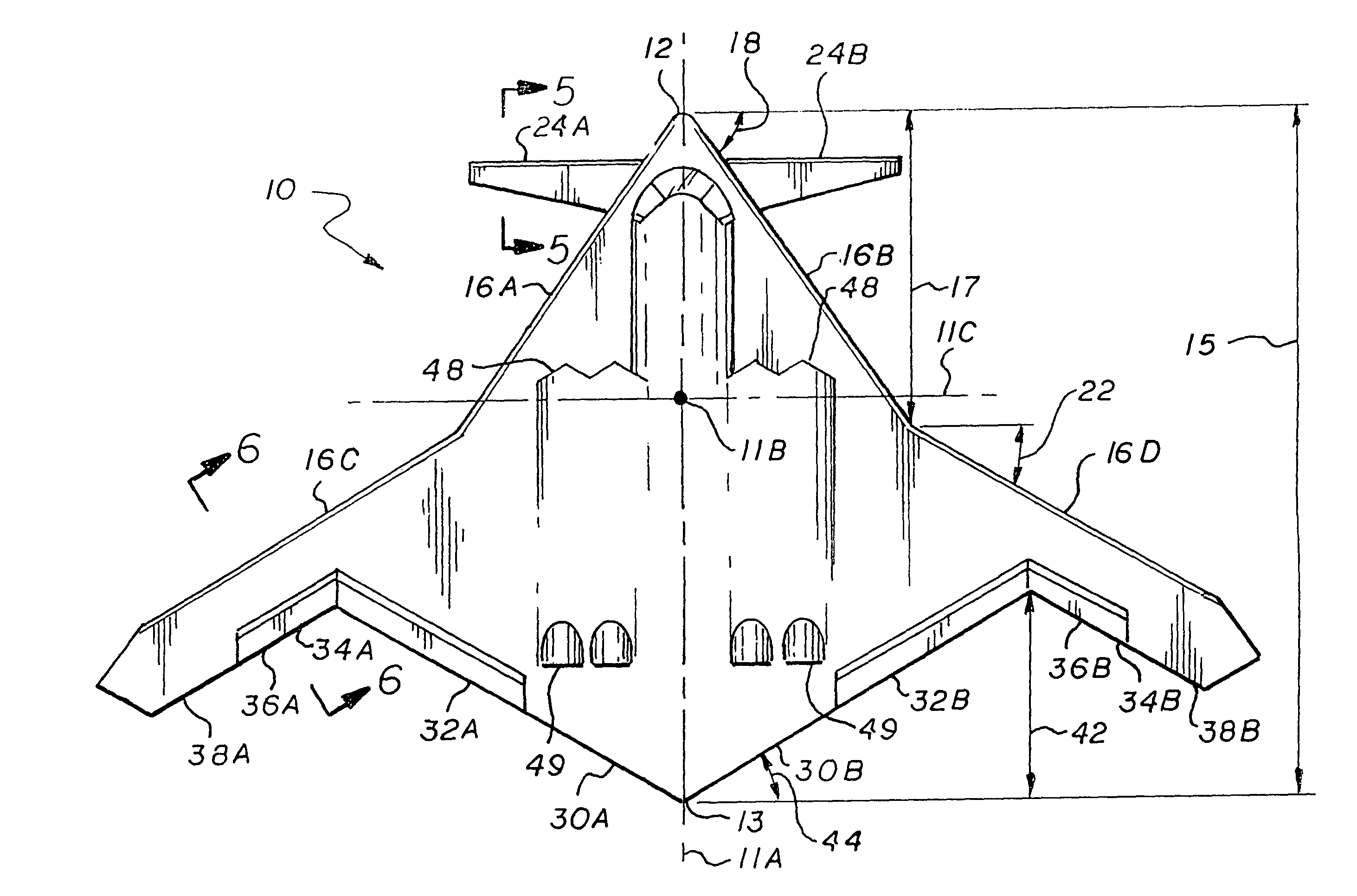

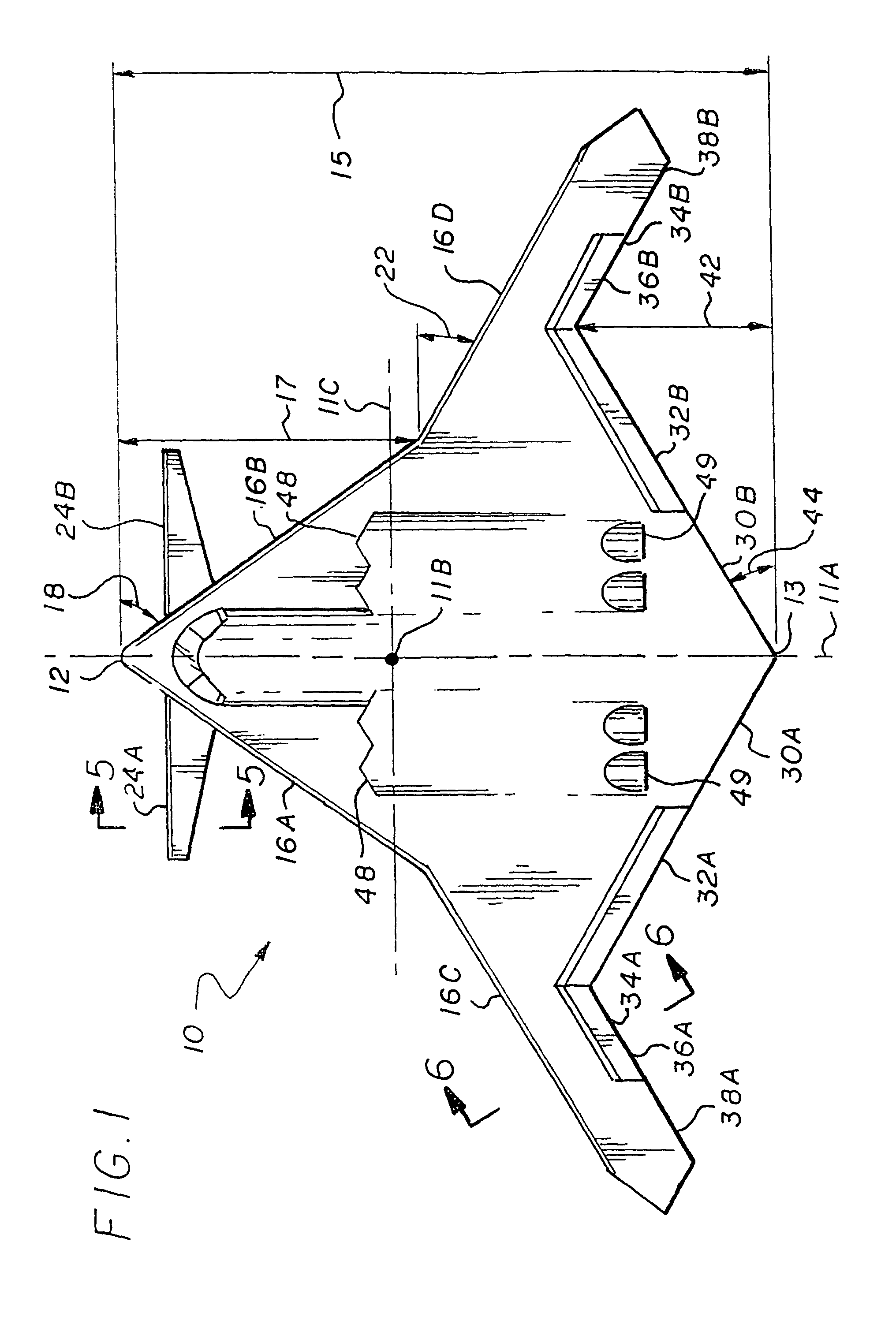

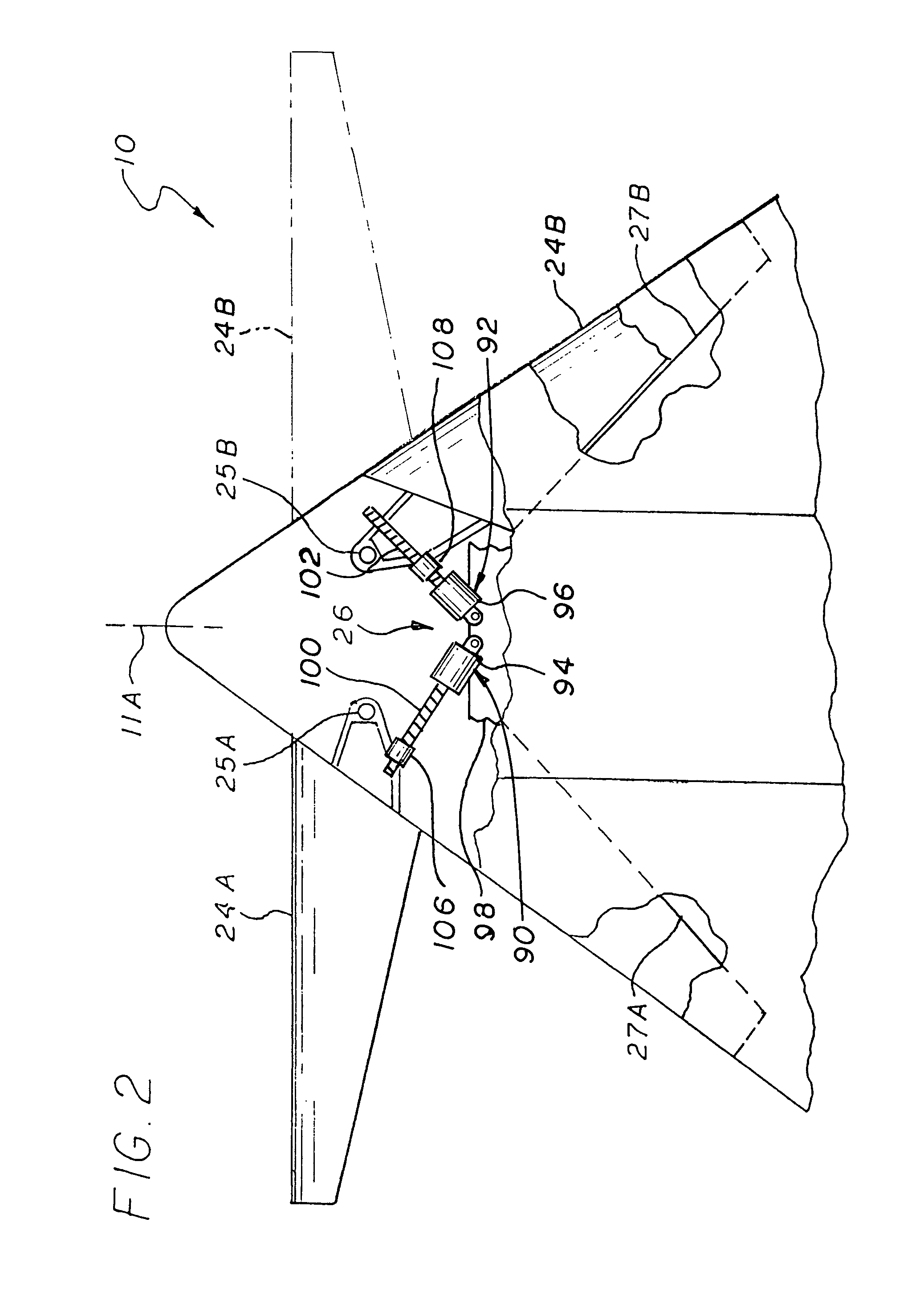

Flying wing aircraft

The invention is an aircraft that includes a flying wing having a plurality of extendable flaps mounted on the trailing edge of the flying wing. A canard is mounted on the nose of said flying wing. A system is mounted in the flying wing for providing high pressure air over the canard and the flaps. A second system is provided for controlling the flow of air over the canard to provide pitch control of the aircraft.

Owner:NORTHROP GRUMMAN SYST CORP

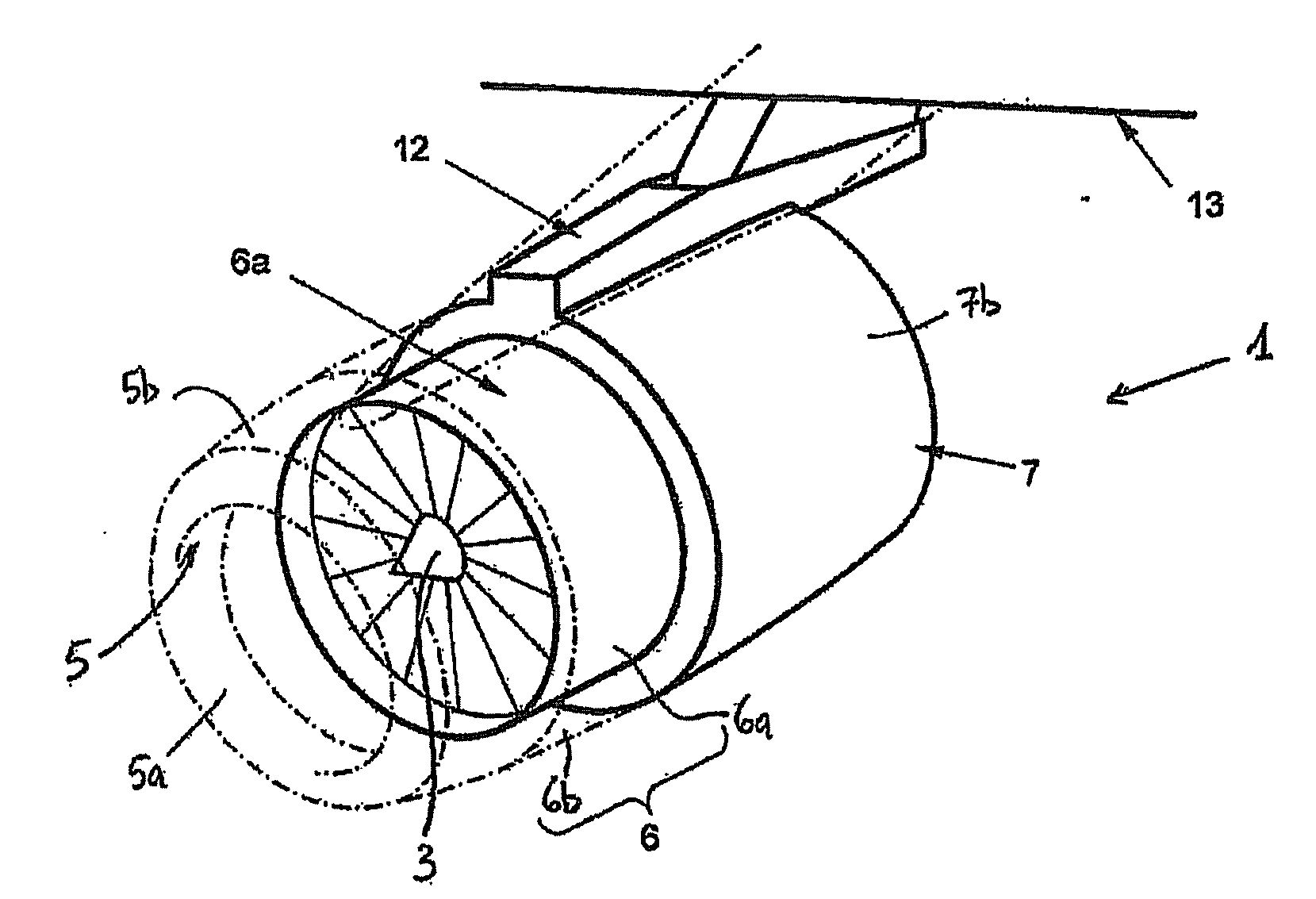

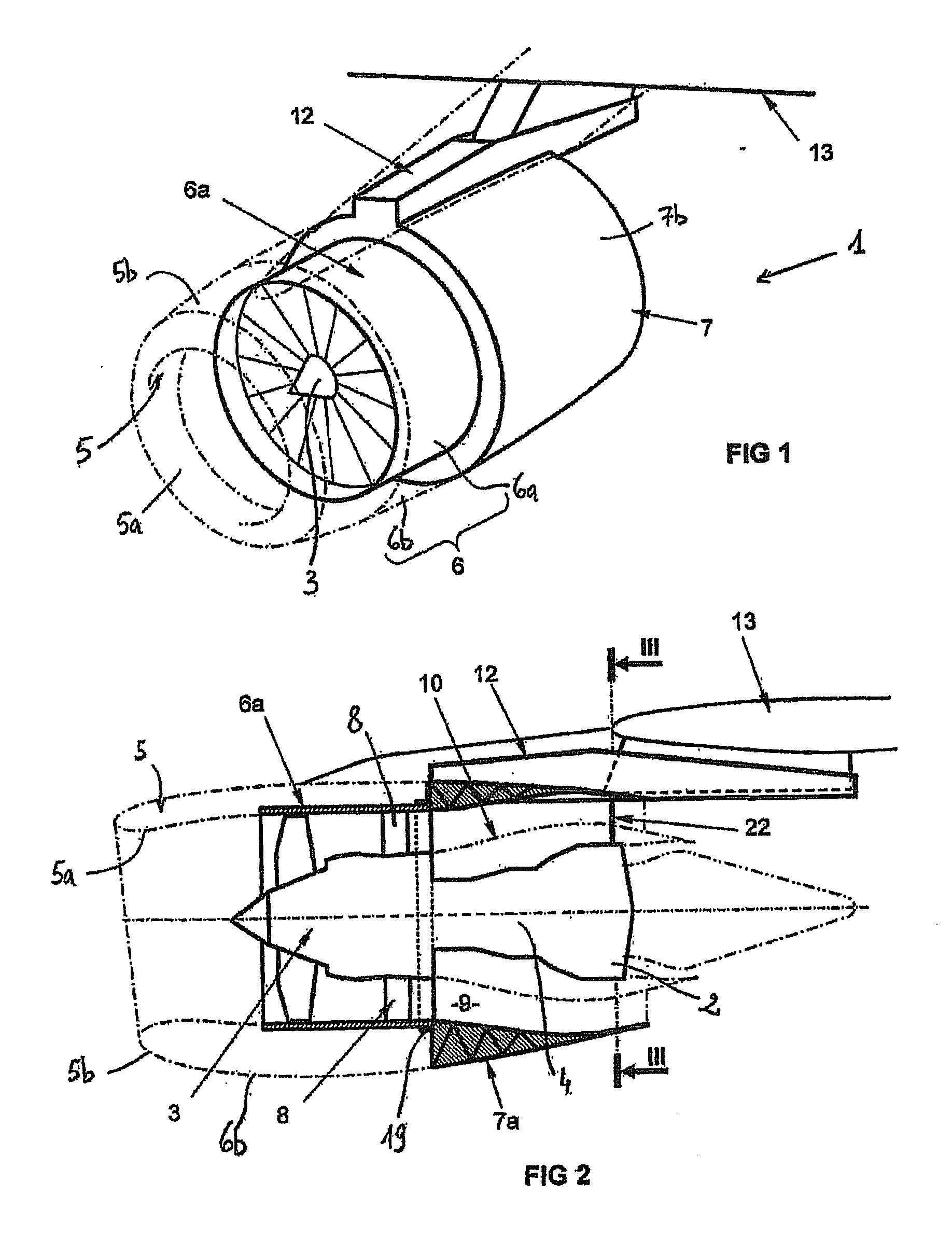

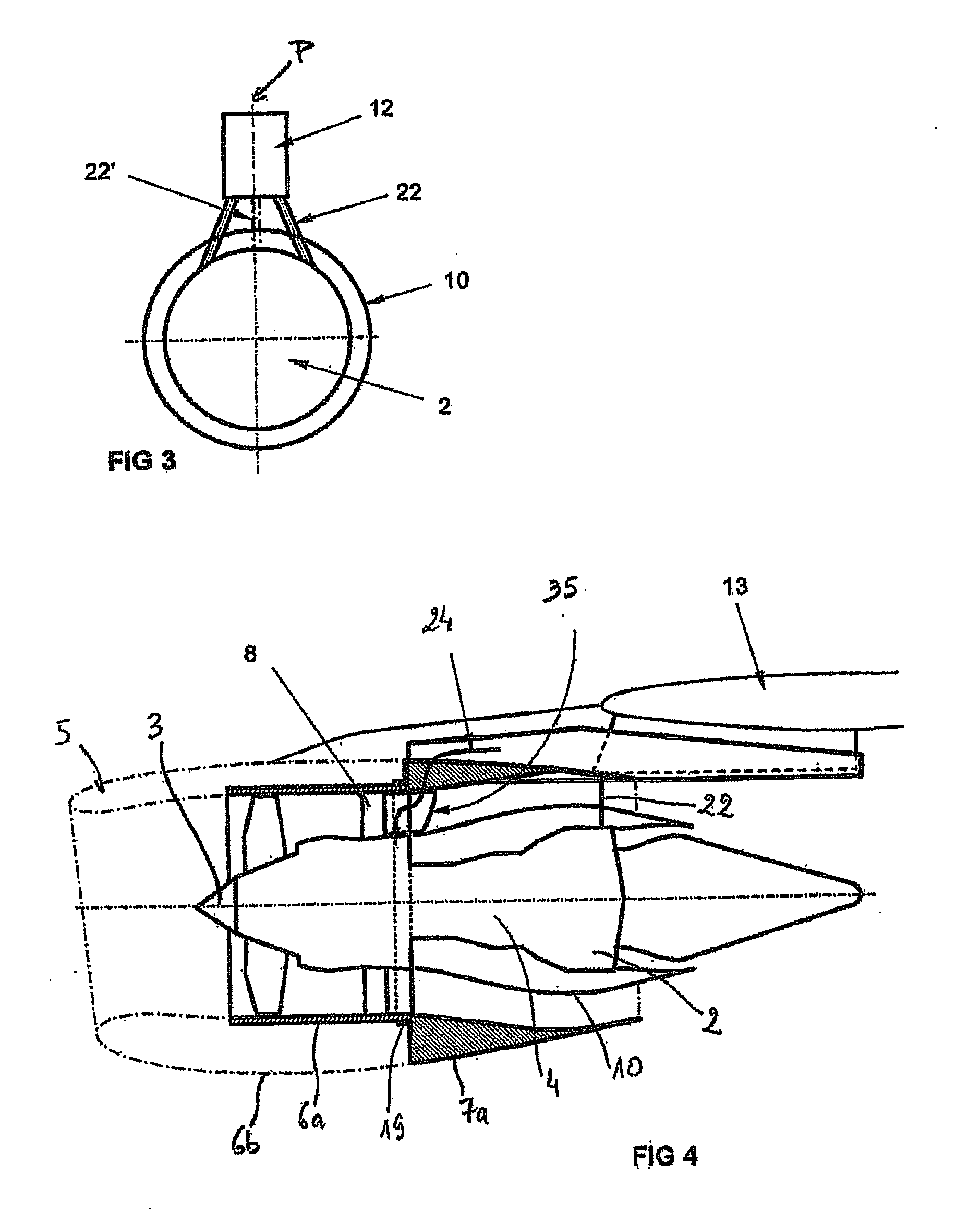

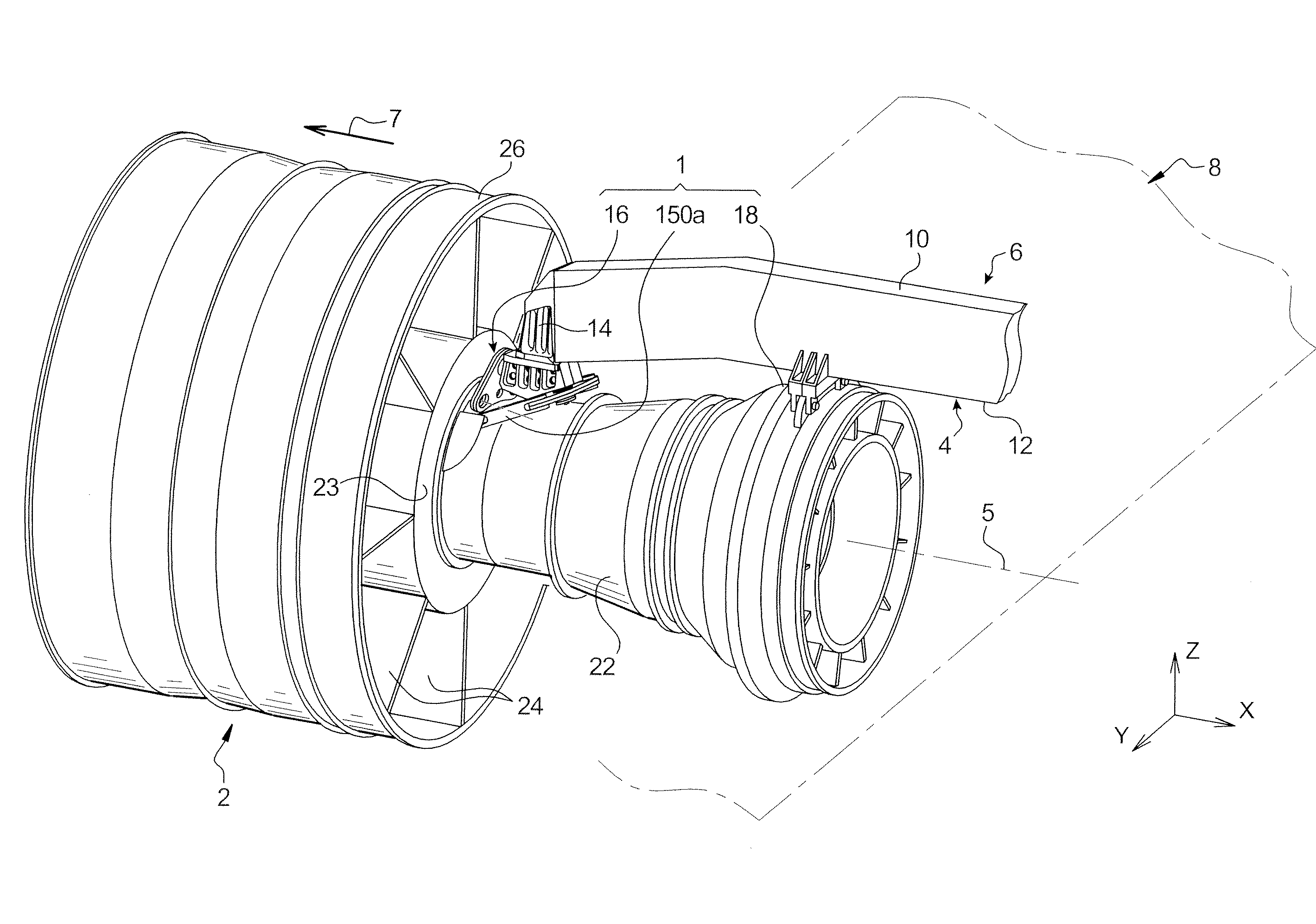

Bypass turbojet engine nacelle

InactiveUS20100040466A1Avoid disadvantagesImprove performancePower plant arrangements/mountingGas turbine plantsNacelleJet engine

The nacelle (1) comprises an air intake (5) upstream of the turbojet engine (2), a middle section (6) an internal casing (6a) of which is intended to surround a fan (3) of the turbojet engine (2), and a downstream section (7) comprising an external structure (7a)which is rigidly connected to a downstream part of the casing (6a) of the fan (3) so as to support the turbojet engine (2) and has means of attachment to a strut (12) intended to be connected to a fixed structure (13) of an aeroplane.

Owner:AIRCELLE

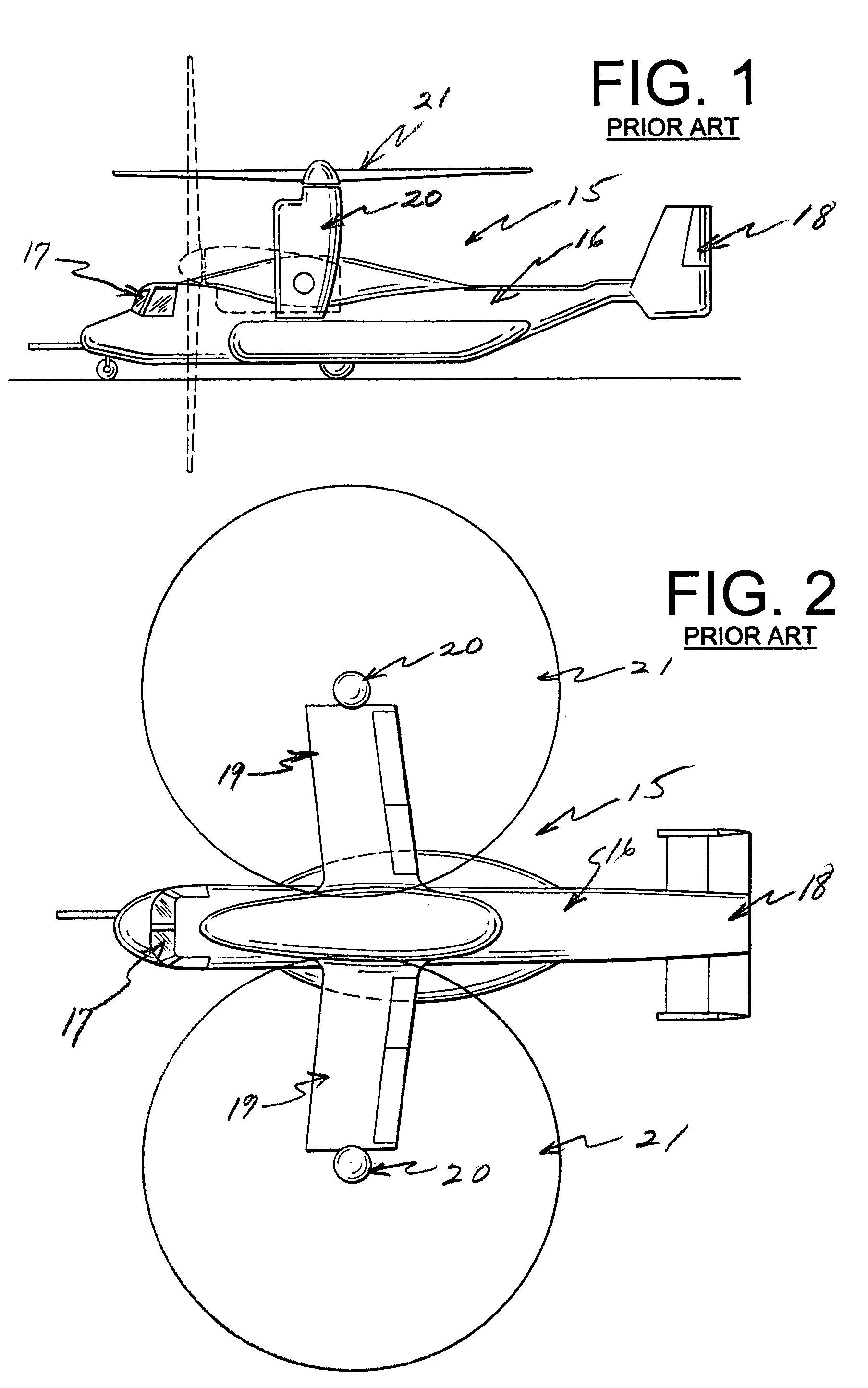

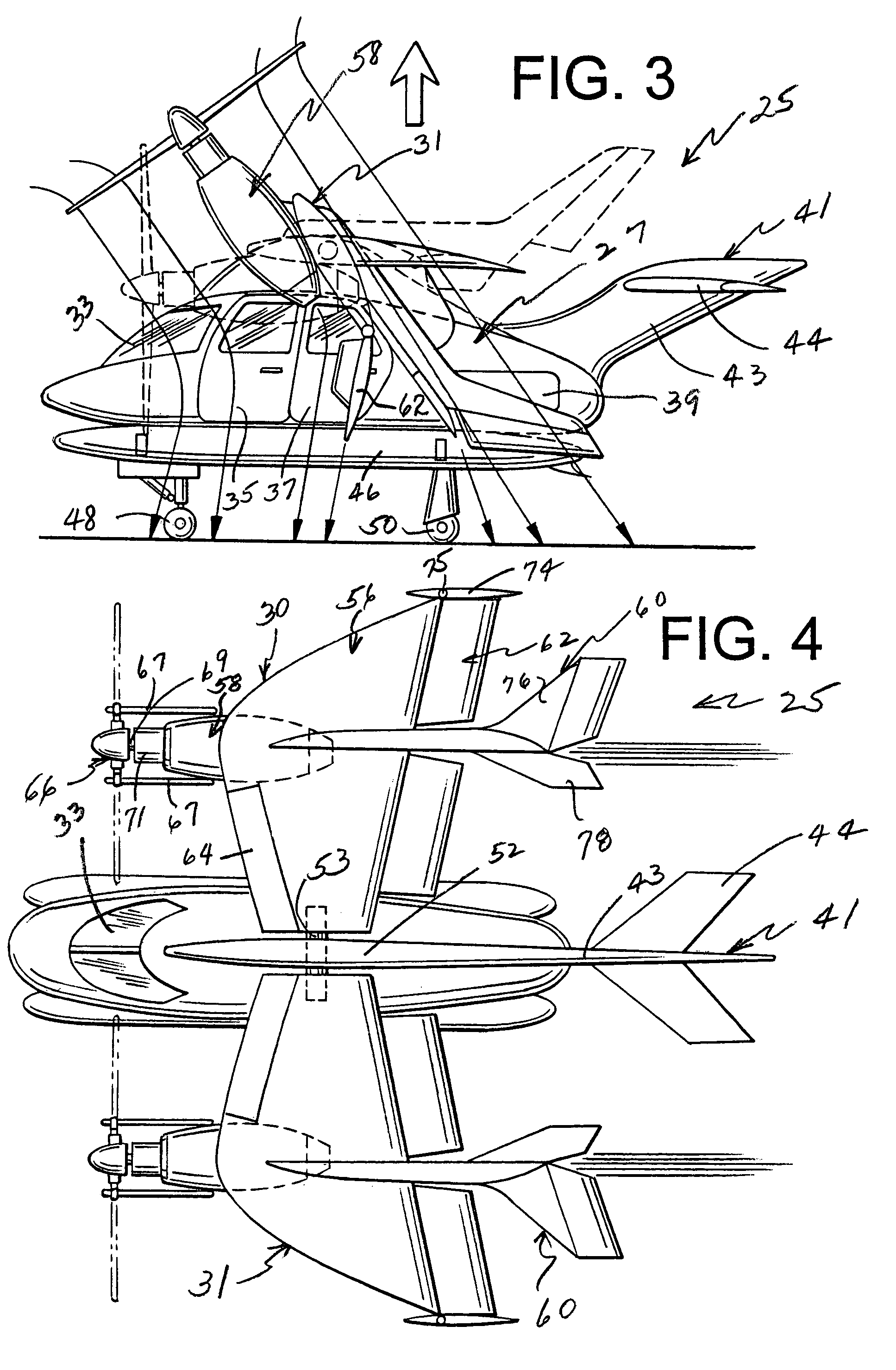

Vertical takeoff and landing aircraft

InactiveUS6896221B1Provide stabilityWithout damaging any partAircraft navigation controlAircraft stabilisationVertical take off and landingAirplane

A vertical takeoff and landing aircraft, which includes pivotal wing and engine assemblies on a fuselage with tail assemblies extending from each of the wing assemblies and the engines being operable in turbo prop or pure jet mode, wherein the aircraft is configured such that it can be landed or taken off vertically or in a horizontal mode along a runway.

Owner:ZICKERT LLOYD L 1 2 INTEREST

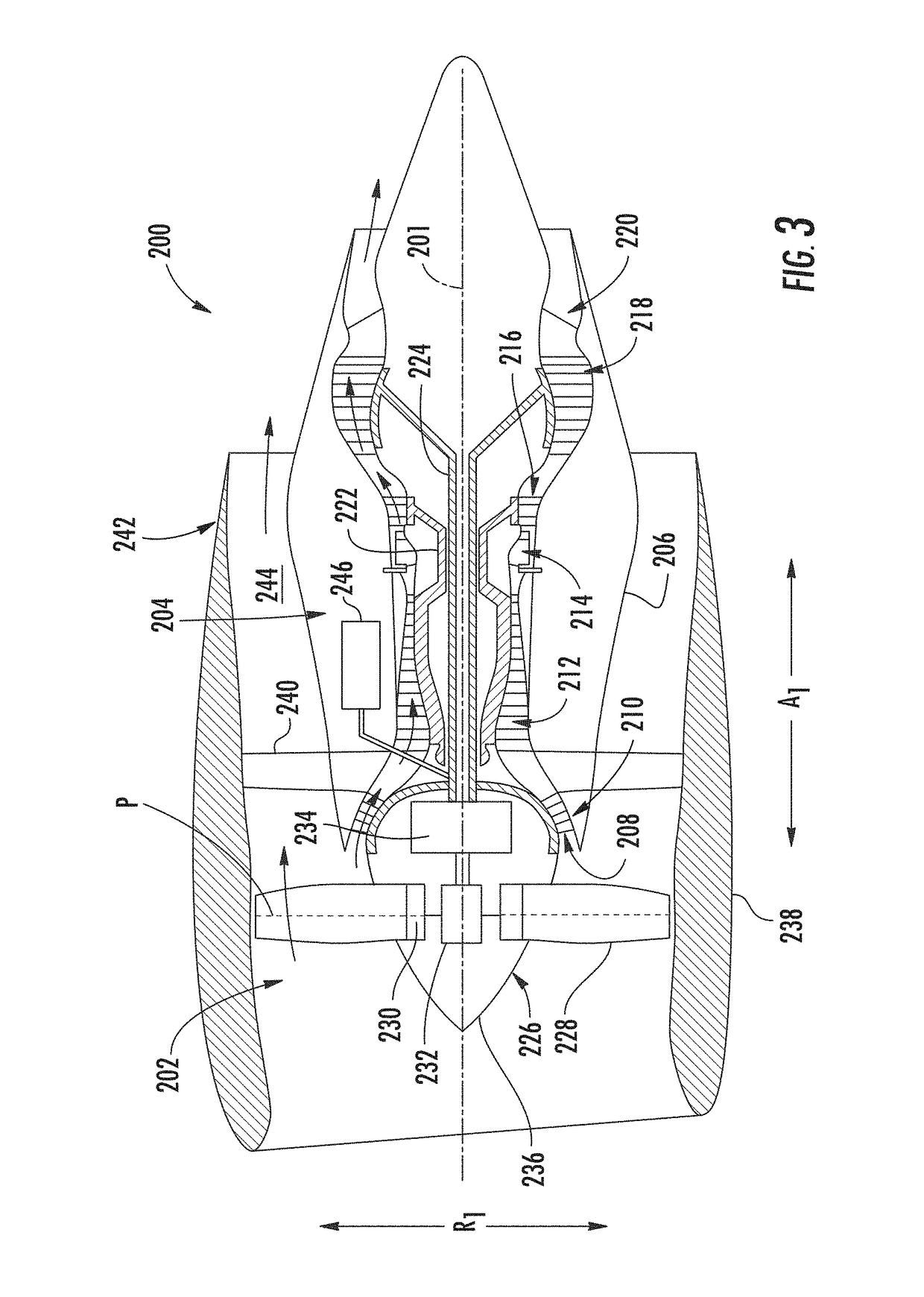

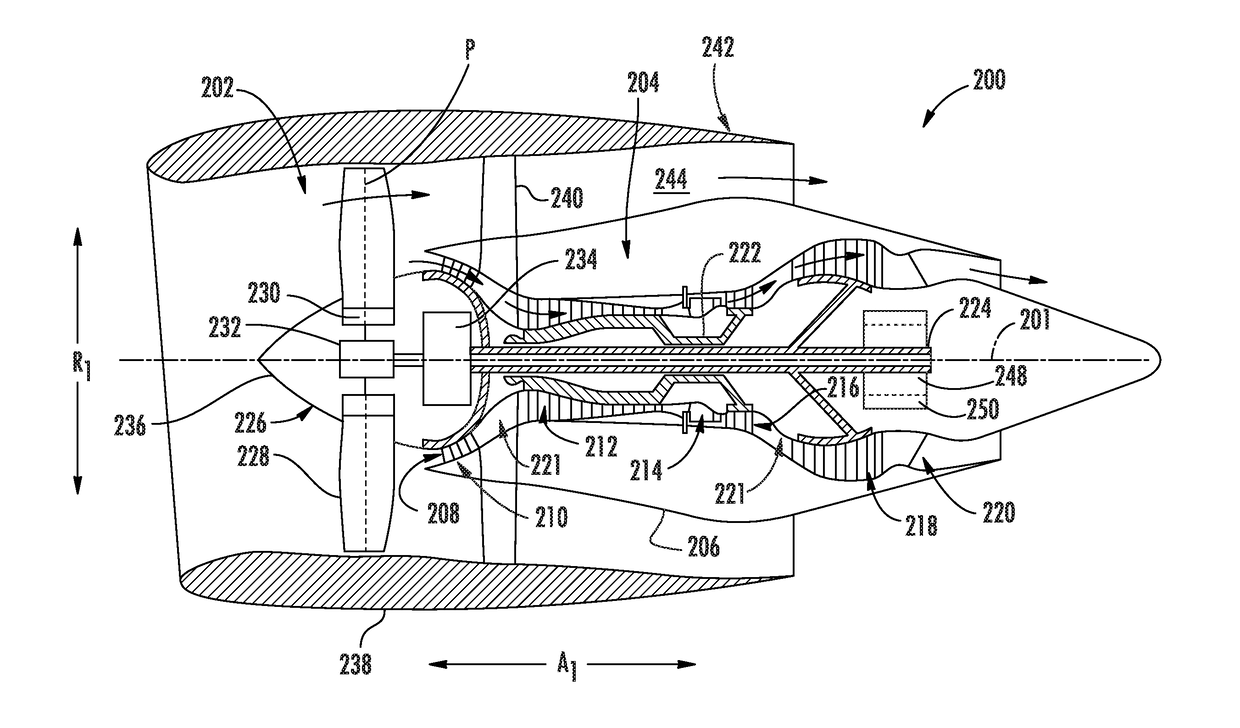

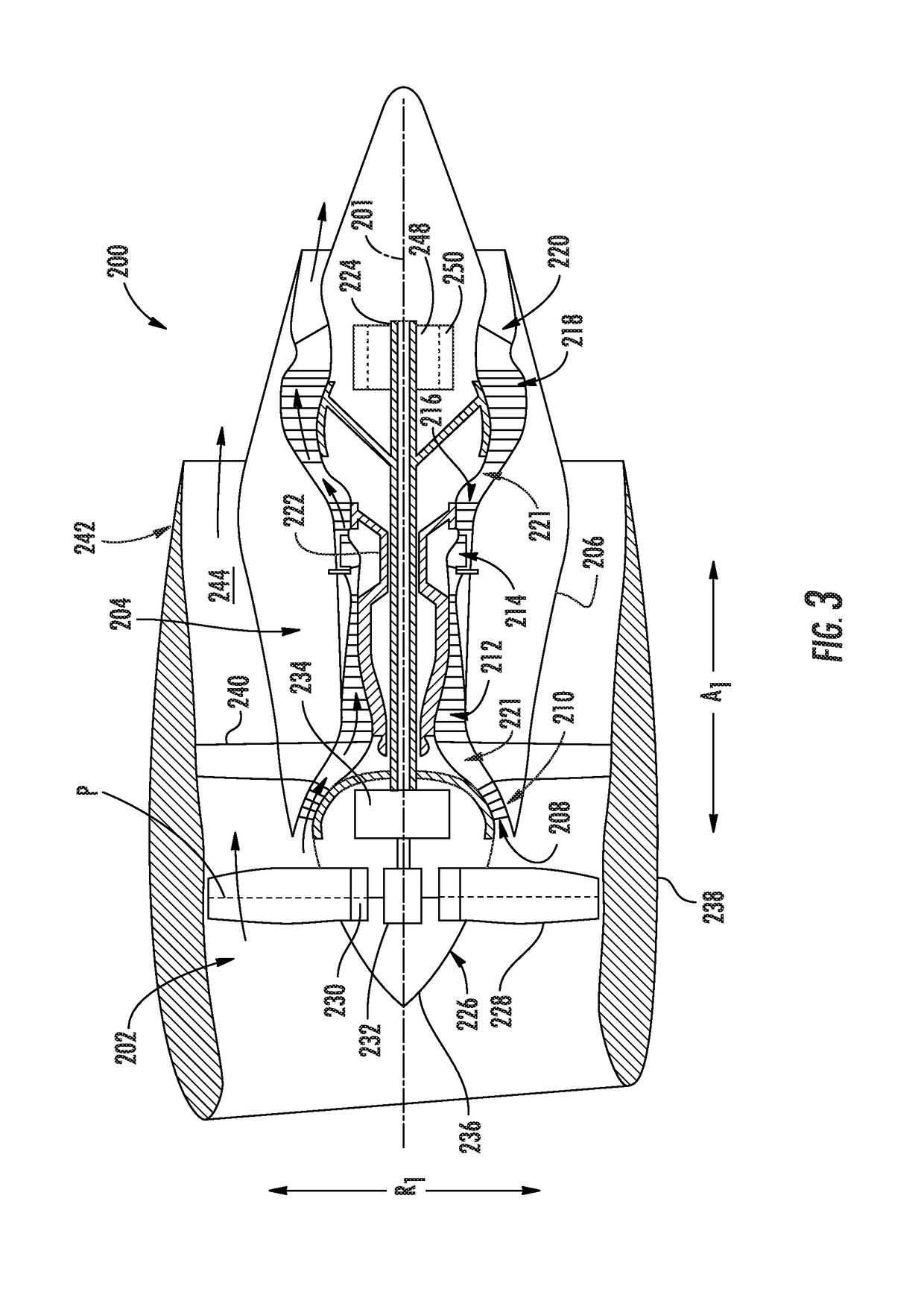

Propulsion engine for an aircraft

ActiveUS20180050811A1Power plant cooling arrangmentsJet type power plantsElectricityThermal management system

A propulsion system for an aircraft includes a gas turbine engine and an electric propulsion engine defining a central axis. The electric propulsion engine includes an electric motor and a fan rotatable about the central axis of the electric propulsion engine by the electric motor. The electric propulsion engine additionally includes a bearing supporting rotation of the fan and a thermal management system including a thermal fluid circulation assembly. The thermal fluid circulation assembly is in thermal communication with at least one of the electric motor or the bearing and is further in thermal communication with a heat exchanger of a thermal management system of the gas turbine engine.

Owner:GENERAL ELECTRIC CO

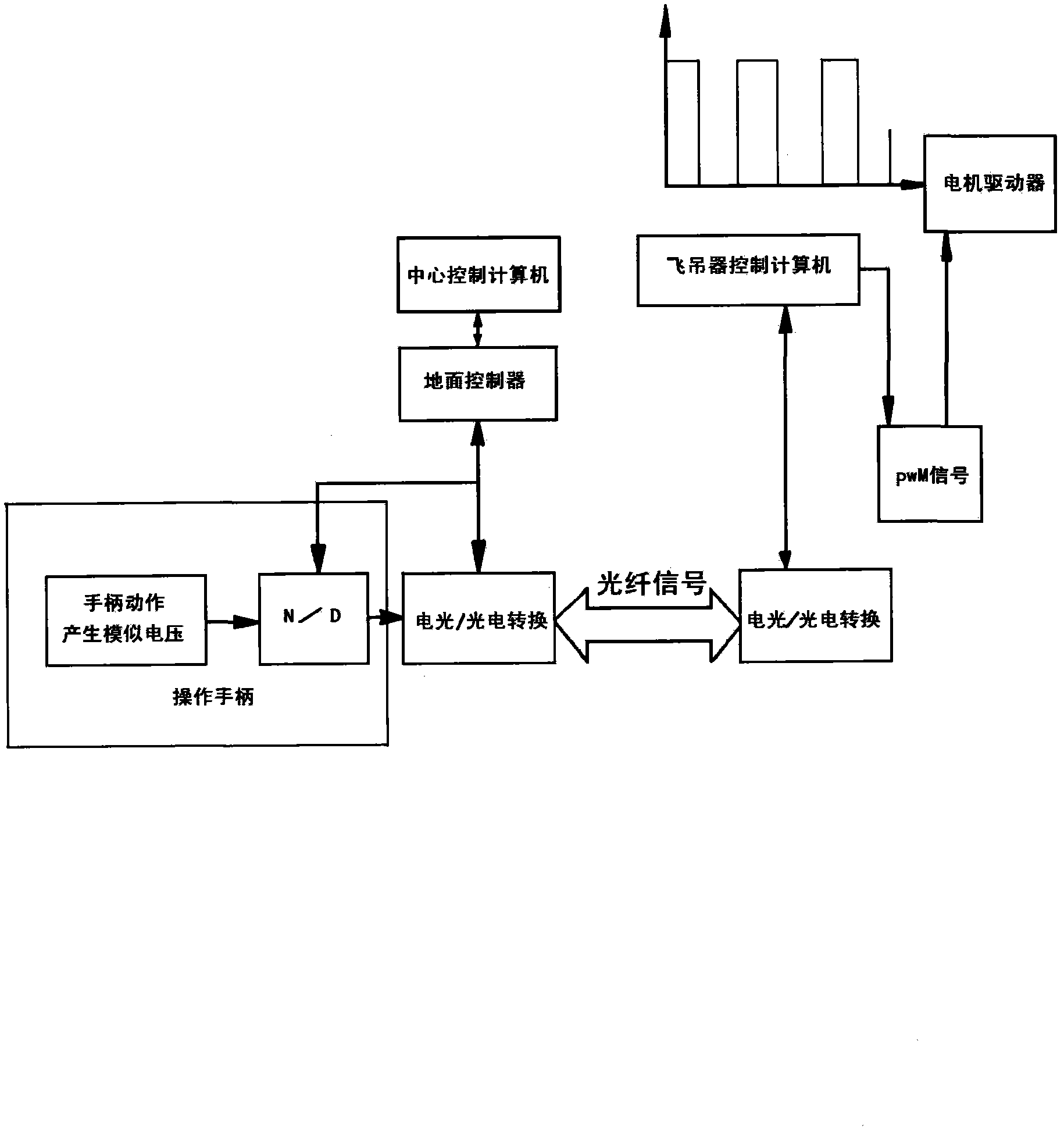

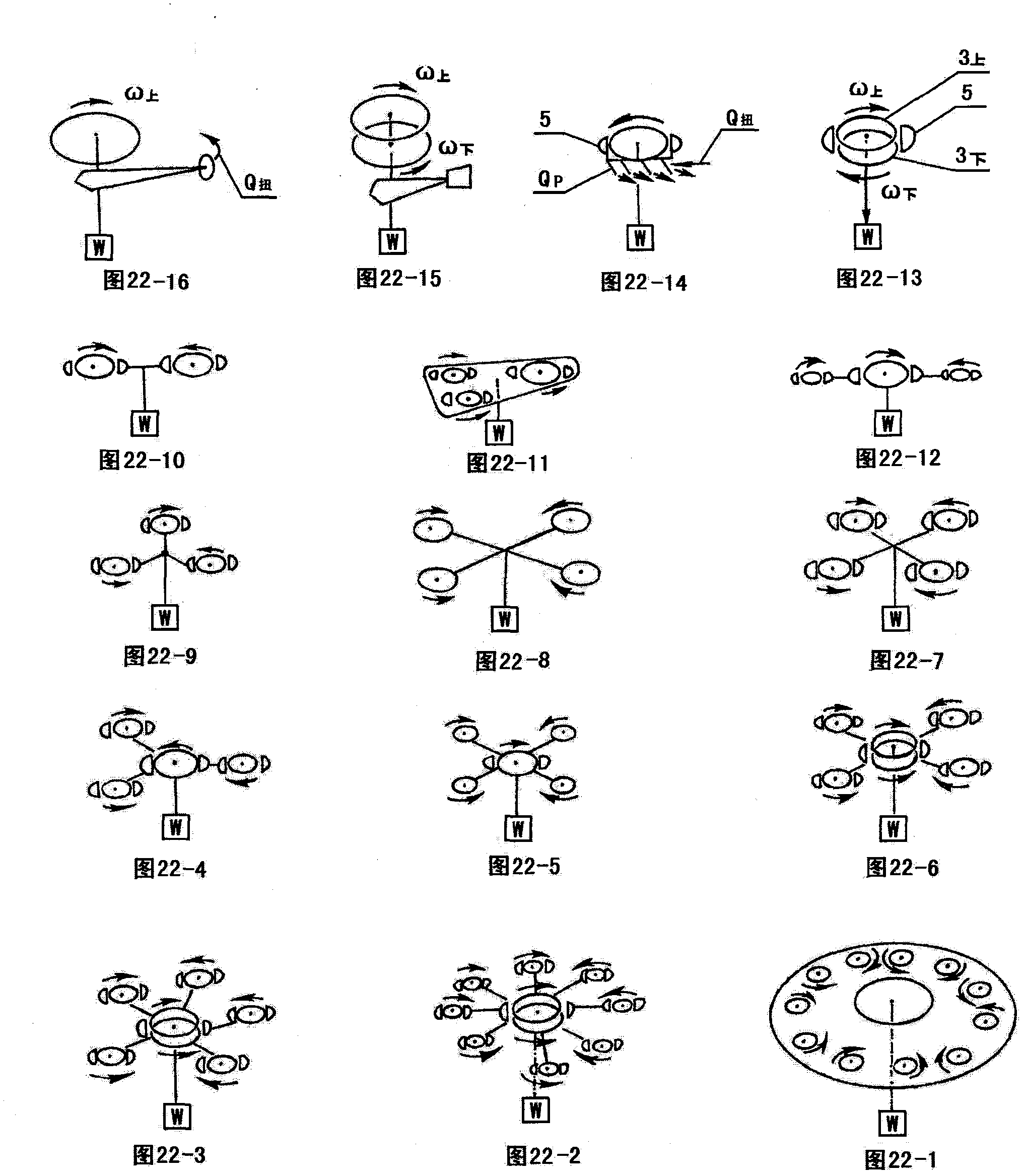

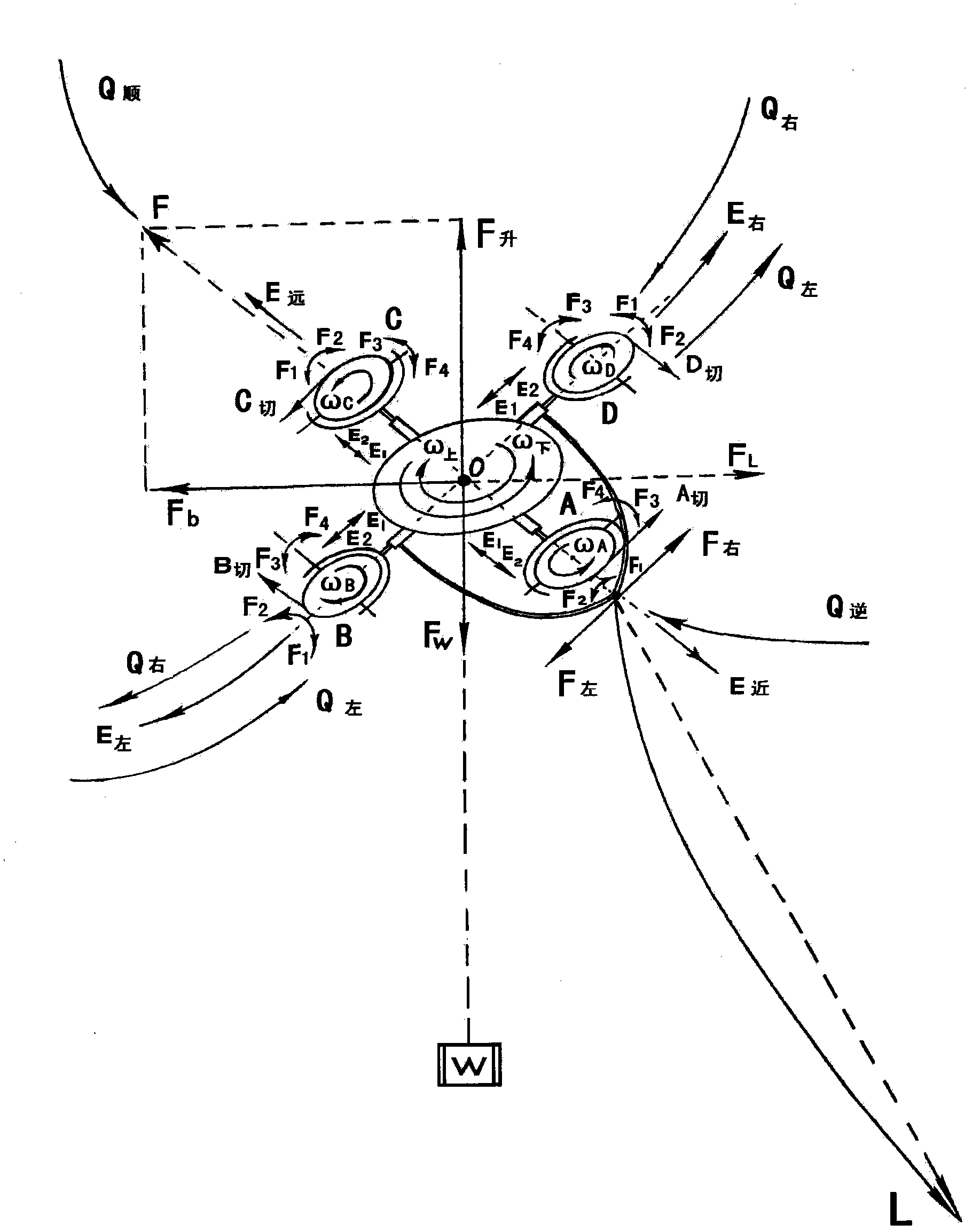

Traction energy transmission type duct rotor wing fly lifter

The invention relates to a fly lifter, in particular to a duct rotor wing fly lifter mainly used for lifting heavy articles. A pneumatic structure bears the main lifting force by taking a large-diameter main duct coaxial positive and negative rotation dual rotor wing as a center; a variable inertia device is arranged in a rotor wing system, so that the rotor wing system generates differential variable inertia, induces to generate the rigidity of gyroscopic effect and has the capability of resisting turbulence transition wind; a plurality of small-diameter duct rotor wings are arranged outside a multi-ring-layer duct; a connecting arm can do telescopic torsional swing to do four-degree-of-freedom action and bear the auxiliary lifting force, direction and posture control and vortex ring prevention; a main nozzle is arranged at the lower end of the main duct; side nozzles are arranged at the periphery of lower end of the main duct; a swing wind guide plate is inbuilt and used for regulating and controlling direction and performing active type vortex ring prevention; and a plasma energy wave generator is provided and used for performing active type vortex ring prevention and improving Reynolds number. The fly lifter transmits power or fuel in a wireless traction mode and is driven by a power machine with energy to perform wireless remote control, so that the fly lifter has dead wind resistance and high suspended load capacity and can perform durable operation under severe environment and weather conditions.

Owner:郑鹏

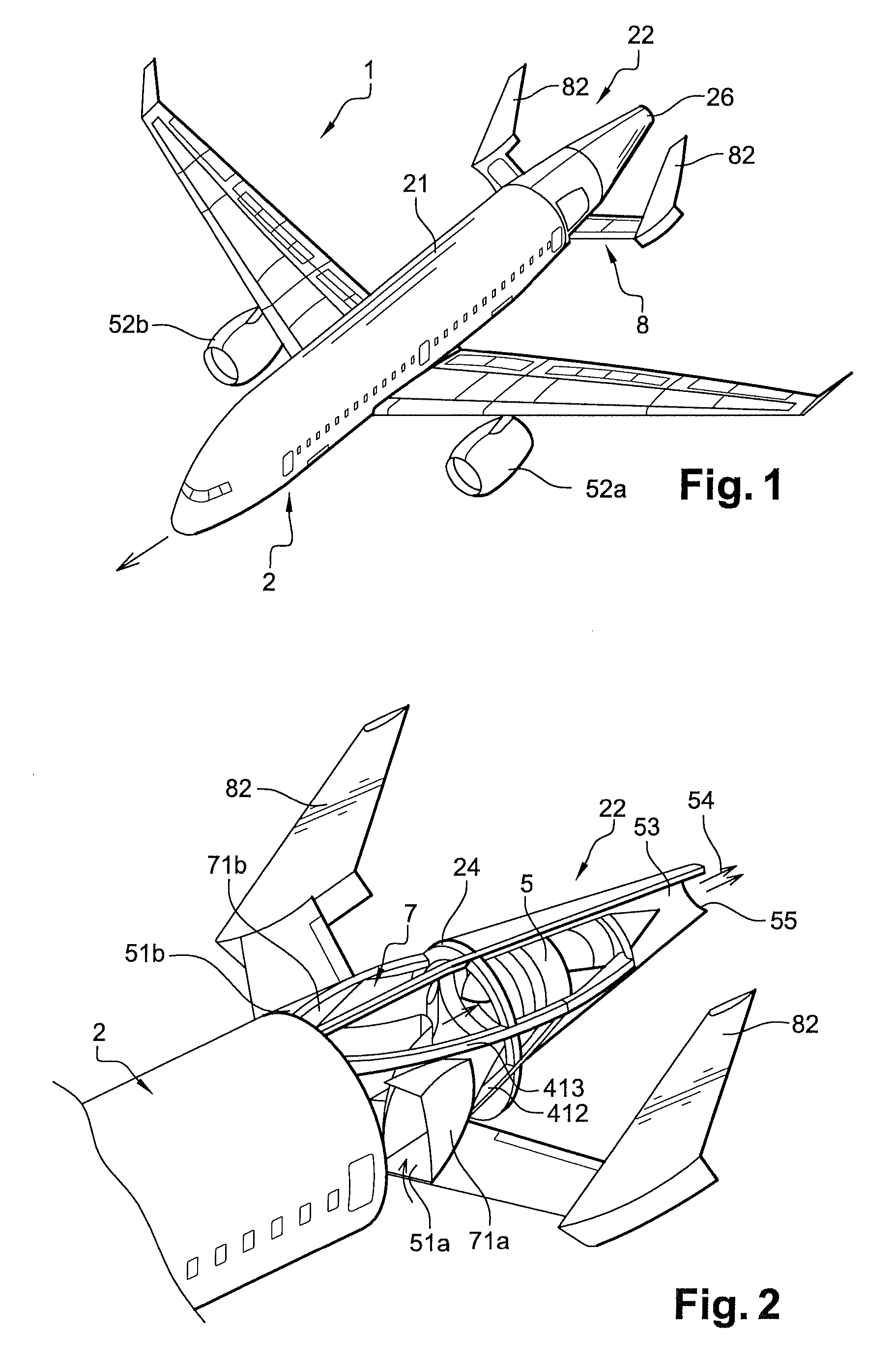

Multi-engine aircraft

InactiveUS7905449B2Reduce previous acoustic problemLess noisyPower plant exhaust arrangementsPower installationsJet aeroplaneLongitudinal plane

A multi-engine aircraft includes at least two first engines and a third engine located at a rear part of the fuselage, containing rear tail sections, along a vertical longitudinal plane of symmetry of the fuselage. The rear tail sections define a channel which is symmetrical with respect to the longitudinal plane of the fuselage. The third engine is arranged in the plane of symmetry of the channel corresponding to the longitudinal plane and is mounted on the upper part of the fuselage in a raised manner and in front of the tail sections, so that the outlet of the third engine is situated substantially at the inlet of the channel defined by the tail sections.

Owner:AIRBUS OPERATIONS (SAS)

Method for mounting a pylon to an aircraft

An assembly and method for attaching an engine pylon to an aircraft wing. The method may include attaching a first forward wing-mounted fitting to the pylon at a first side of the pylon between upper and lower spars of the pylon and attaching a second forward wing-mounted fitting to the pylon at a second side of the pylon between the upper and lower spars of the pylon. The second side of the pylon is located opposite of the first side of the pylon. Mechanical attachment devices may be inserted through holes on the sides of the pylon aligned with holes formed through the forward wing-mounted fittings. The mechanical attachment devices may be made of steel and the forward wing-mounted fittings may be made of composite or aluminum material.

Owner:SPIRIT AEROSYSTEMS

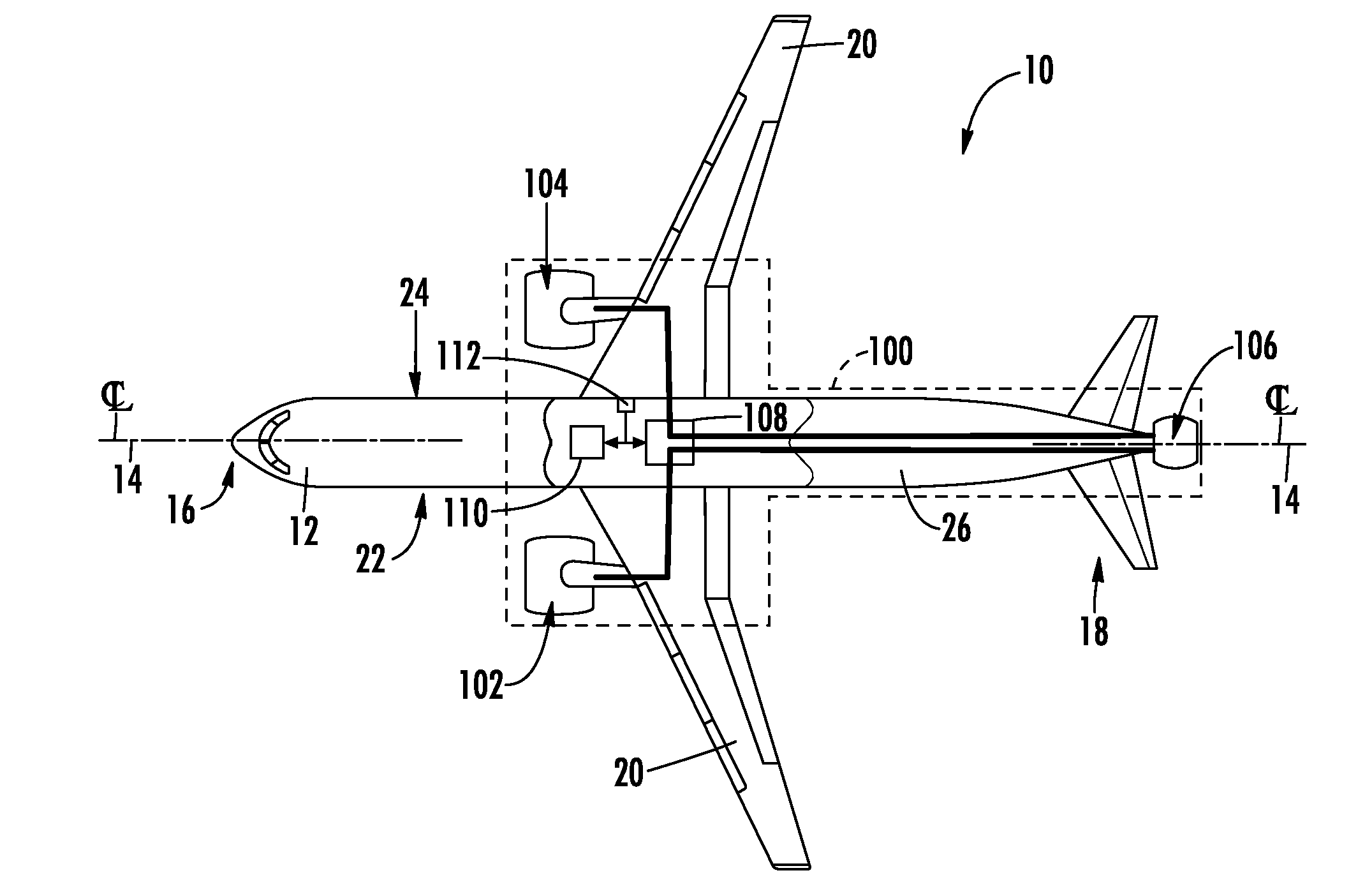

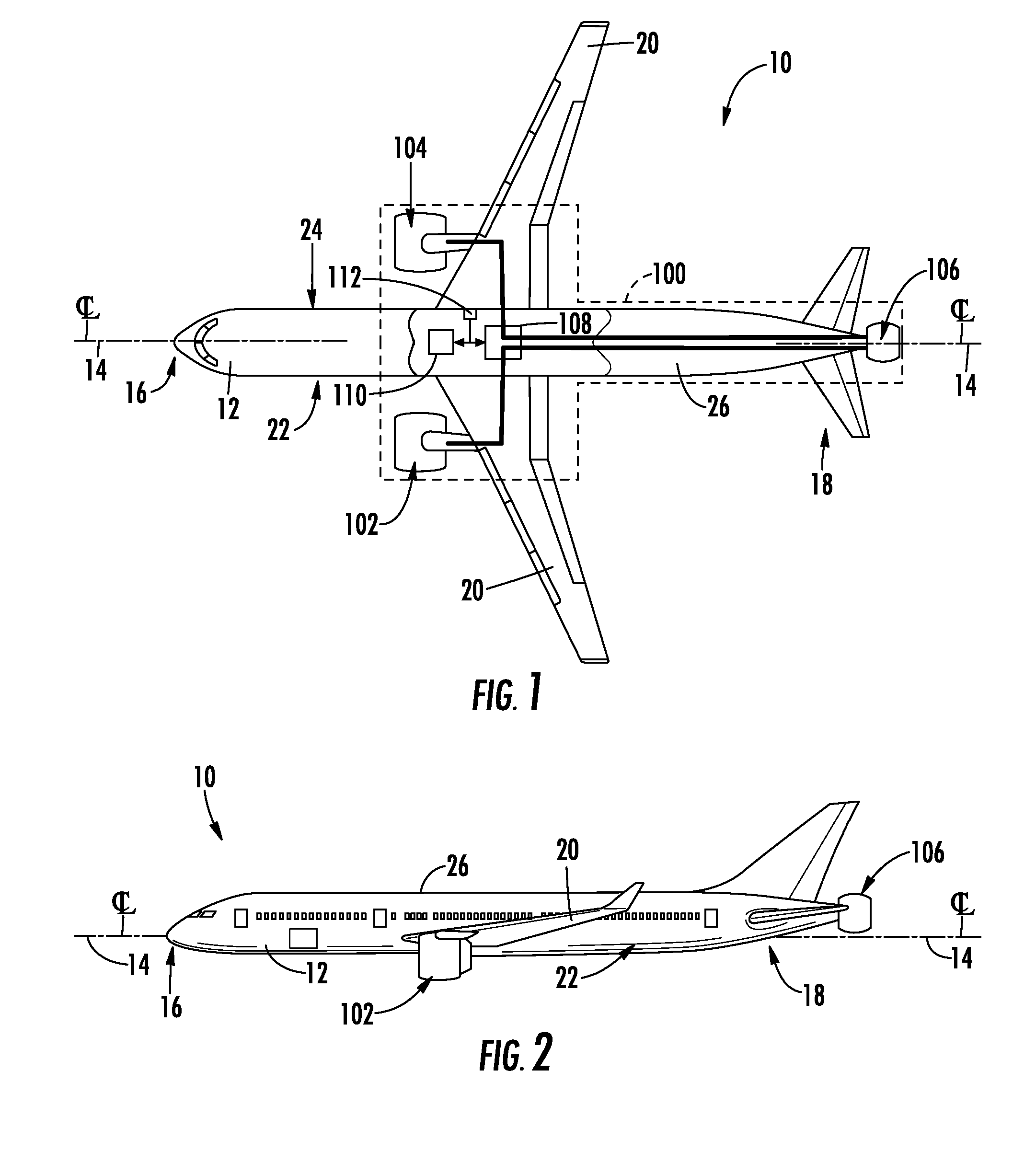

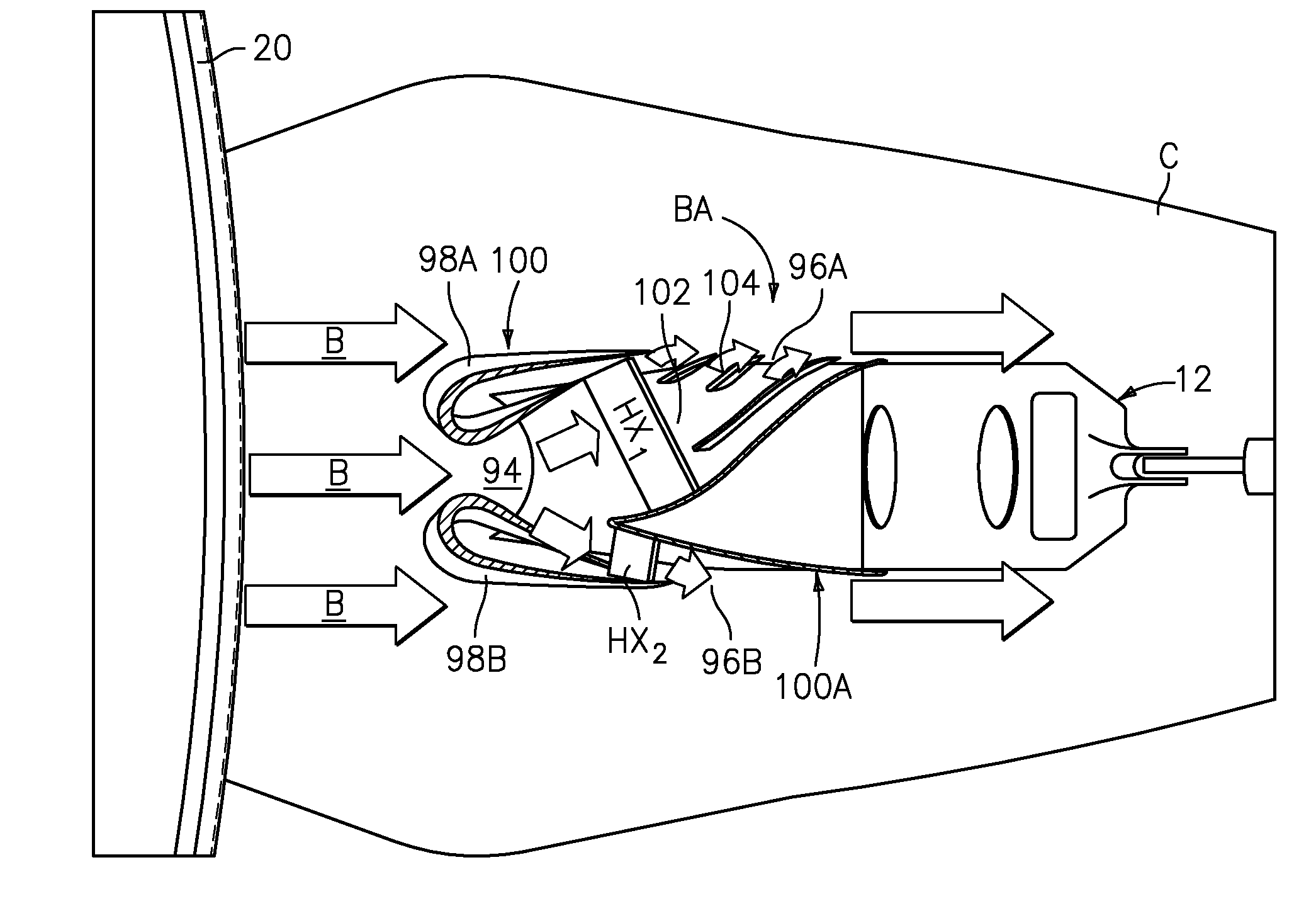

Thermal management system integrated pylon

ActiveUS20090188232A1Power plant cooling arrangmentsTurbine/propulsion engine coolingEngineeringThermal management system

A thermal management system includes at least one heat exchanger in communication with a bypass flow of a gas turbine engine. The placement of the heat exchanger(s) minimizes weight and aerodynamic losses and contributes to overall performance increase over traditional ducted heat exchanger placement schemes.

Owner:RAYTHEON TECH CORP

Propulsion engine for an aircraft

A propulsion system for an aircraft is provided having a propulsion engine configured to be mounted to the aircraft. The propulsion engine includes an electric machine defining an electric machine tip speed during operation. The propulsion system additionally includes a fan rotatable about a central axis of the electric propulsion engine with the electric machine. The fan defines a fan pressure ratio, RFP, and includes a plurality of fan blades, each fan blade defining a fan blade tip speed. The electric propulsion engine defines a ratio of the fan blade tip speed to electric machine tip speed that is within twenty percent of the equation, 1.68×RFP−0.518, such that the propulsion engine may operate at a desired efficiency.

Owner:GENERAL ELECTRIC CO

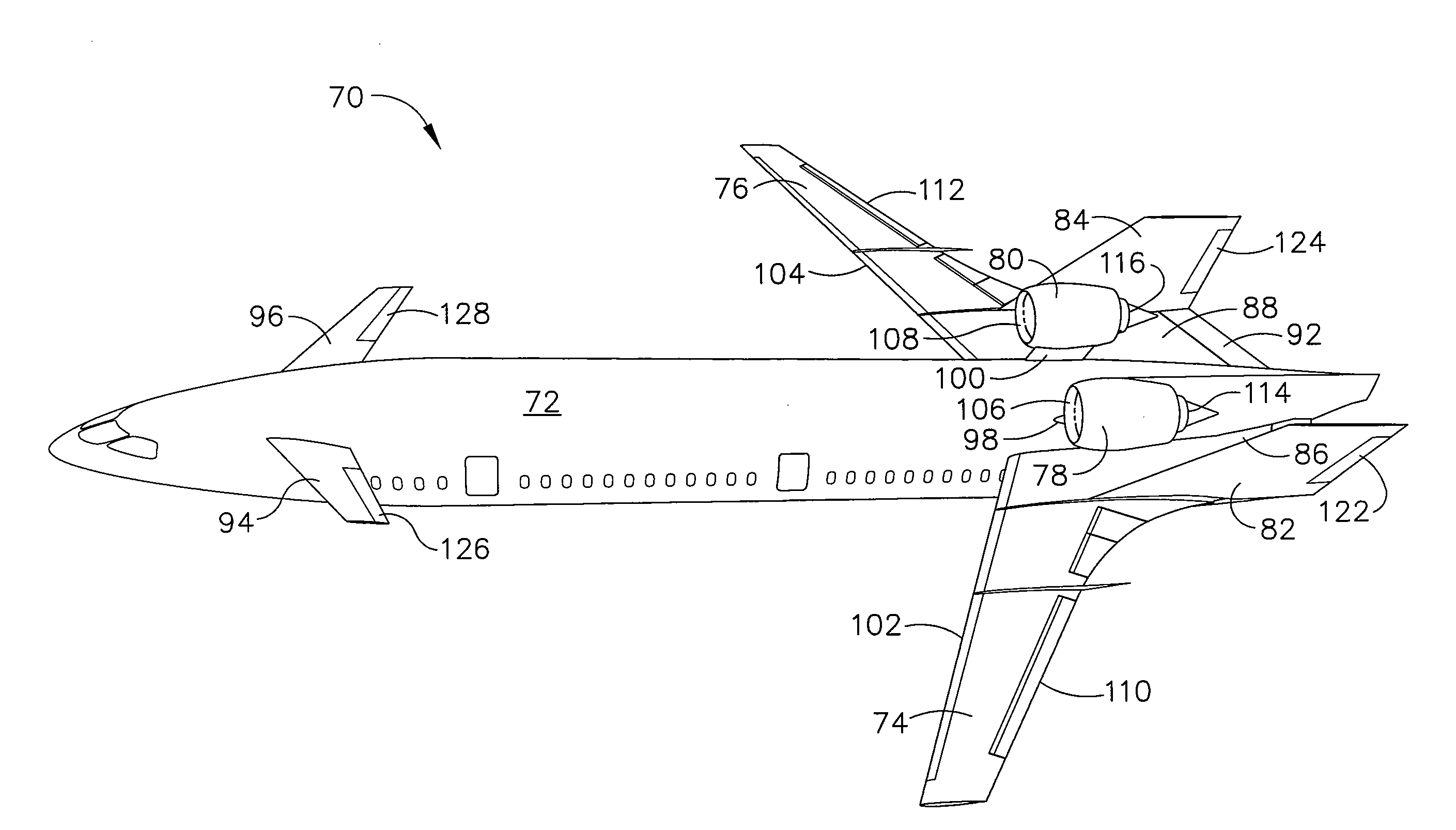

Airplane configuration

InactiveUS20080142641A1Lower Level RequirementsReduced aircraft noiseGas turbine type power plantsAircraft stabilisationJet aeroplaneLeading edge

An aircraft configuration that may reduce the level of noise, infrared radiation, or combination thereof directed towards the ground from an aircraft in flight. An embodiment of an aircraft includes a fuselage, two forward swept wings, at least one engine mounted to the aircraft and higher than the wings, and vertical stabilizers mounted on each wing outboard of the outermost engine. The leading edge of the wing may extend forward of the leading end of the engine, and the trailing edge of the aft deck may extend aft of the trailing end of the engine. The aft deck may include an upwardly rotatable pitch control surface at the trailing edge of the deck. Engine types may vary, including but not limited to turbofans, prop-fans, and turbo-props. Main wings may be mounted above the longitudinal axis of the fuselage, and canards may likewise be mounted above or below the axis.

Owner:THE BOEING CO

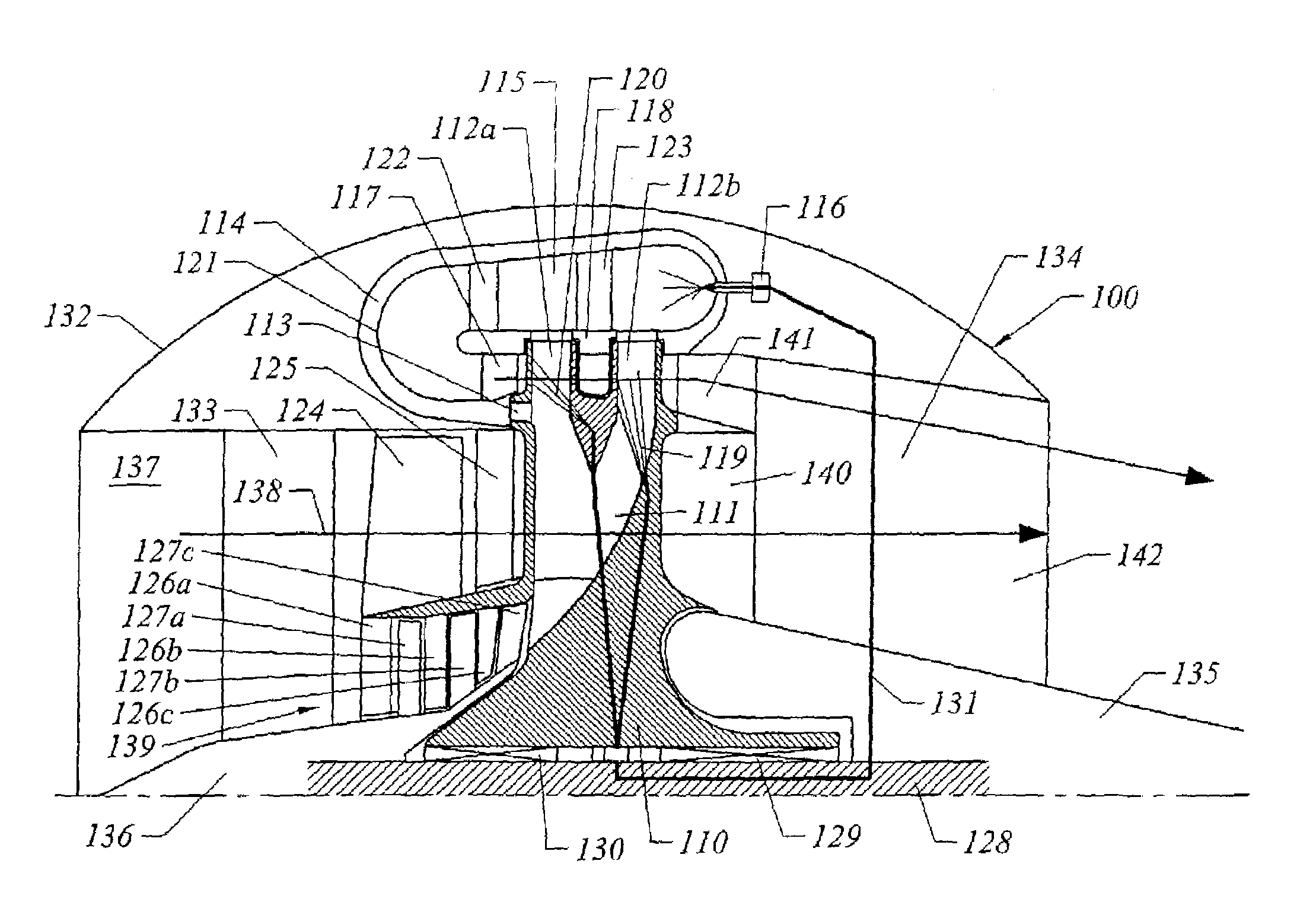

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS6907724B2Shorten the lengthFast atomizationContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

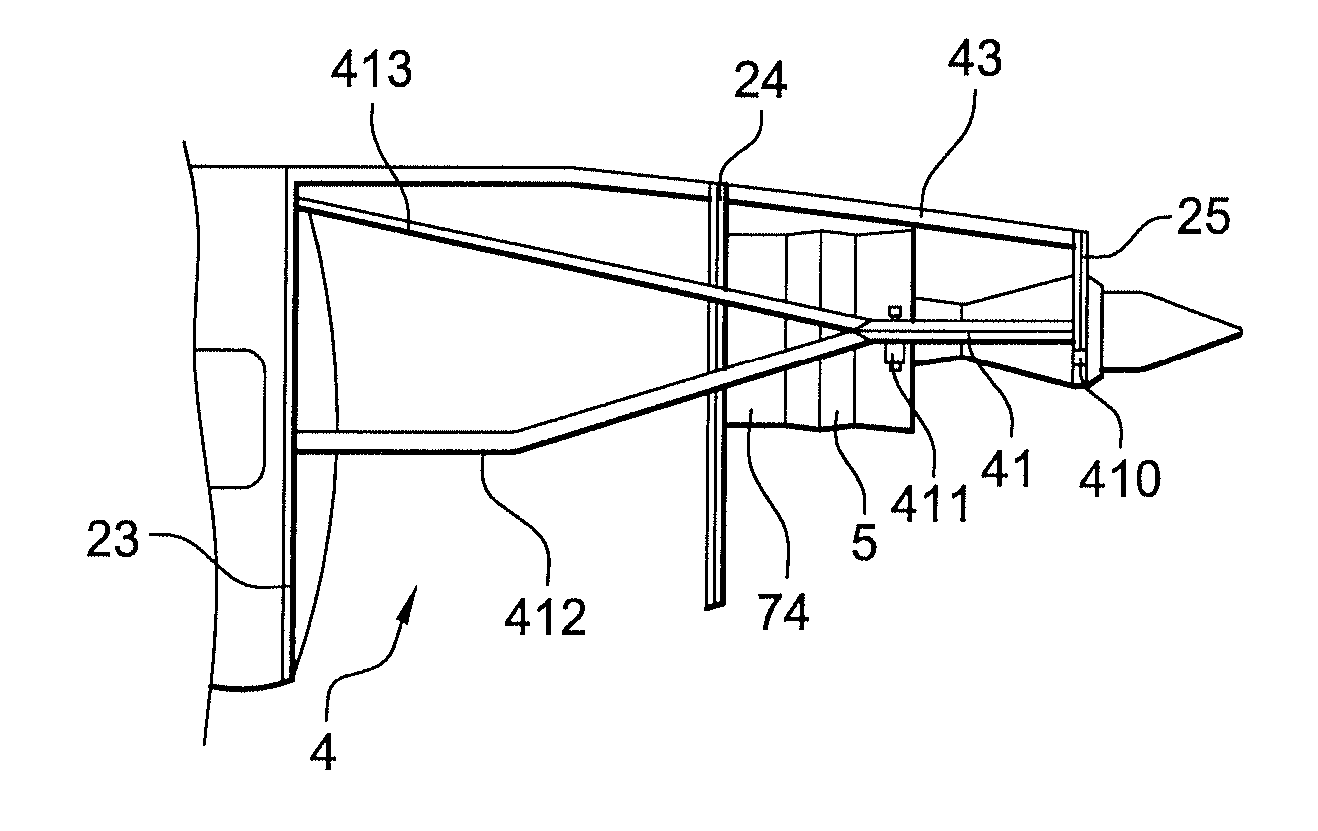

Beam mounted rear propulsion system for an aircraft and aircraft with such system

ActiveUS8220739B2Easy to operateAvoid mechanical interferencePower installationsAircraft power plant componentsJet engineFuselage

A propulsive system for an aircraft including an auxiliary jet engine is integrated into a tail cone of a fuselage. A carrying structure of the jet engine is primarily formed with beams and frames or half-frames to which the auxiliary jet engine is fixed by lateral beams. The beams are interdependent of the frames and half-frames, and the beams are overhanging behind a frame behind which is fixed the engine. Each beam includes a lower half-beam and a higher half-beam, separated on at least a part of its length ahead from attachments of the jet engine to determine a space free of structure impediment for lateral air intakes.

Owner:AIRBUS OPERATIONS (SAS)

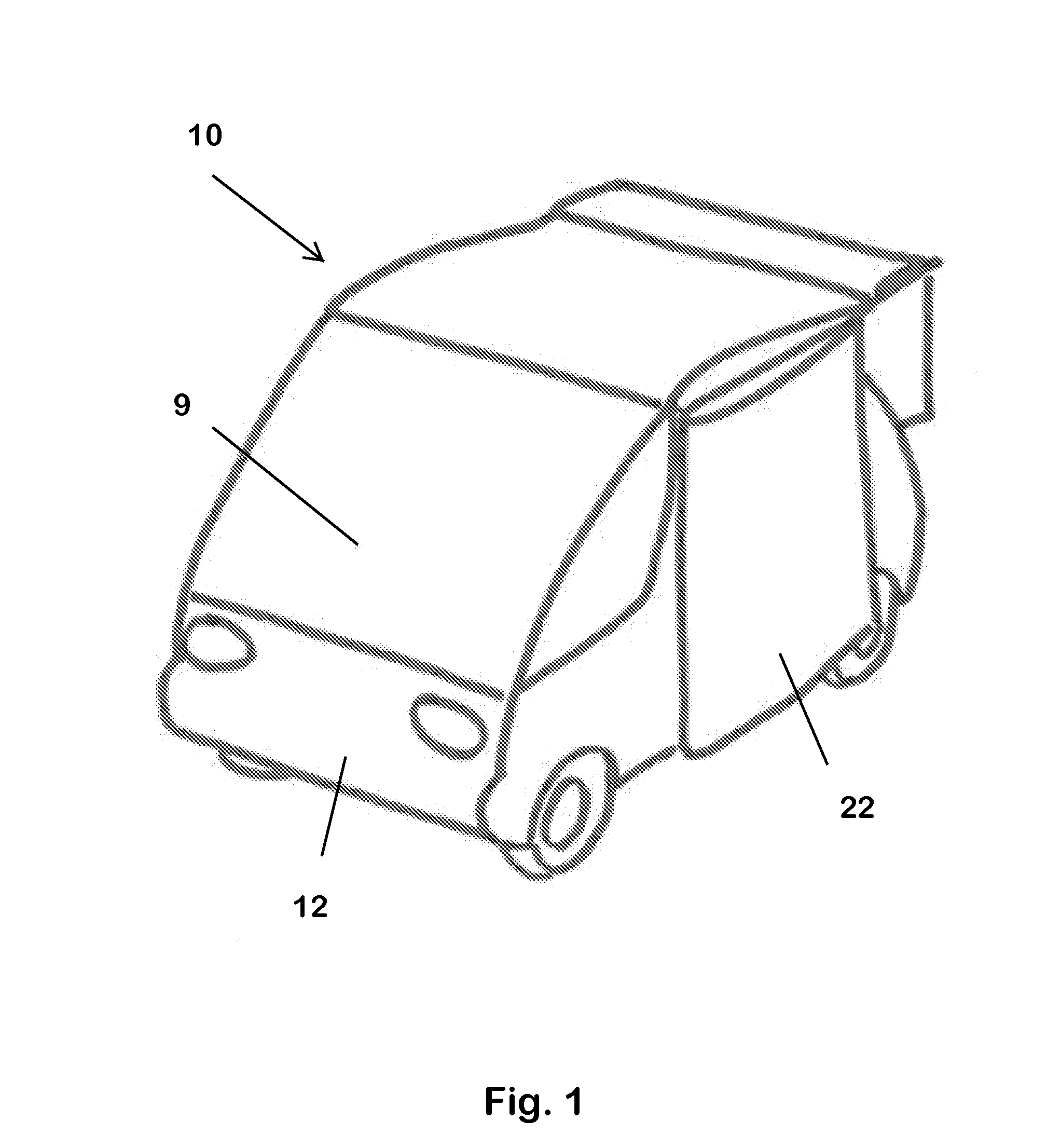

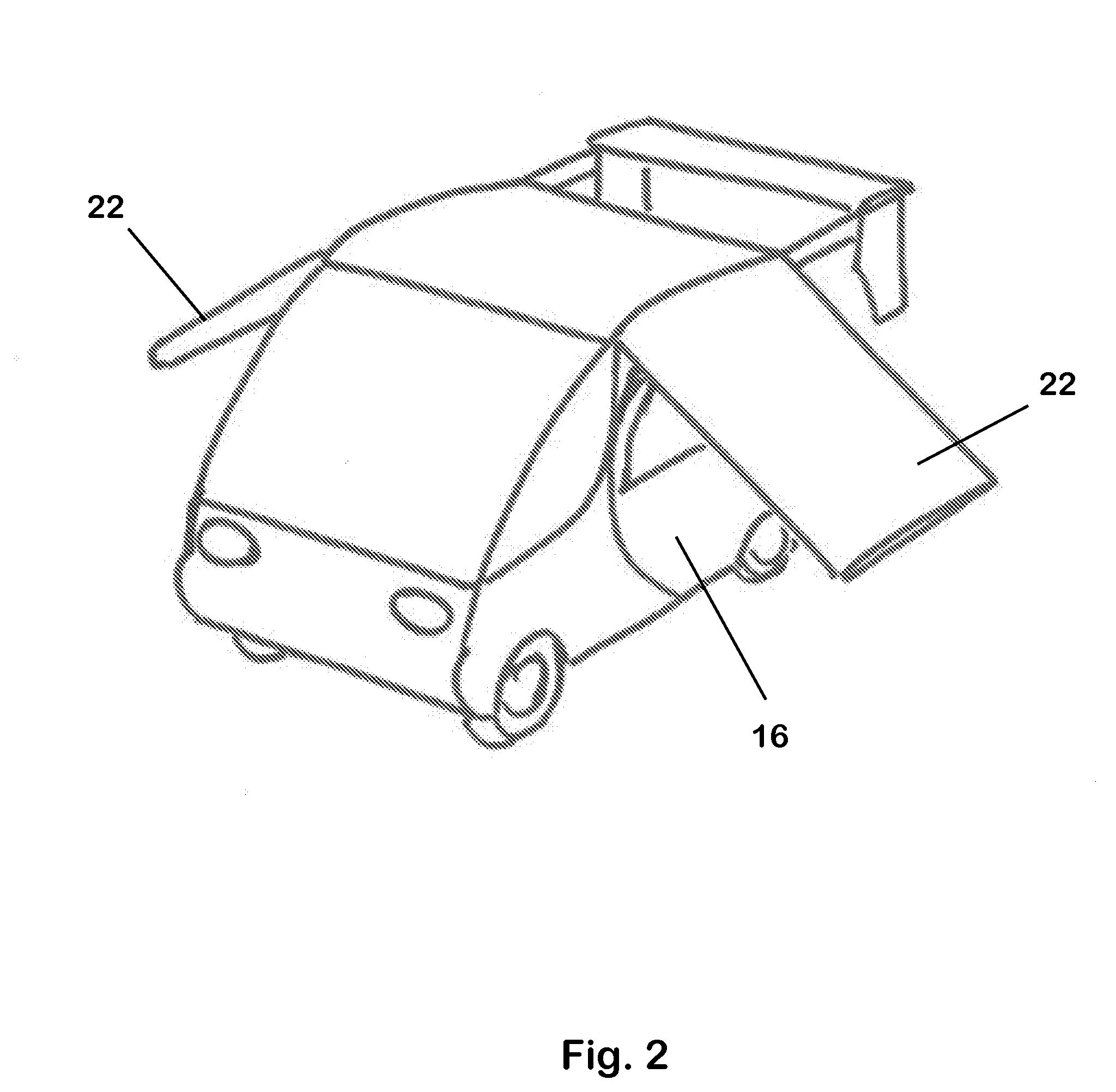

Flying Car or Drone

InactiveUS20160272314A1Improve performanceImprove efficiencyHybrid vehiclesConvertible aircraftsAerospace engineering

Owner:RADU BOGDAN

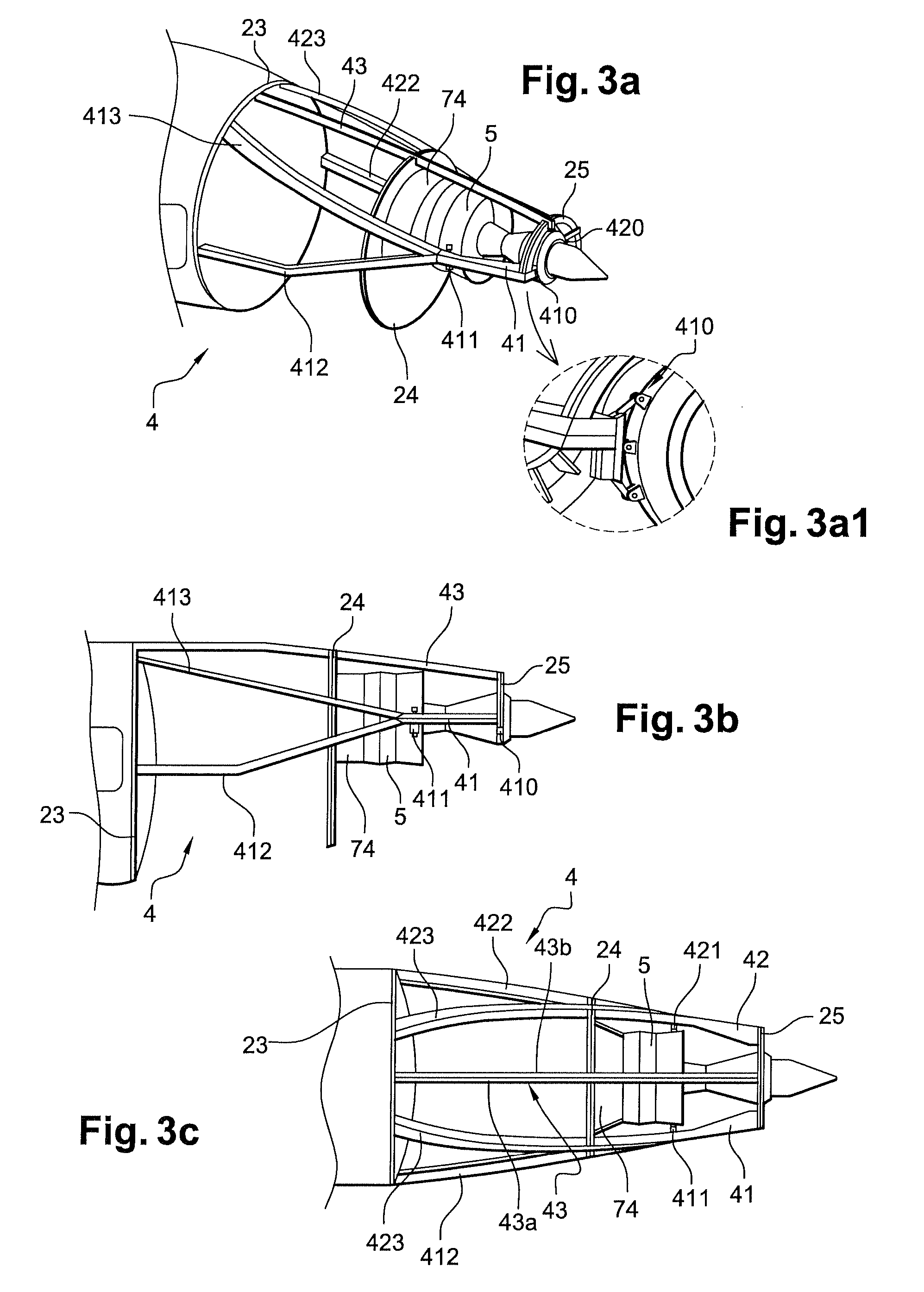

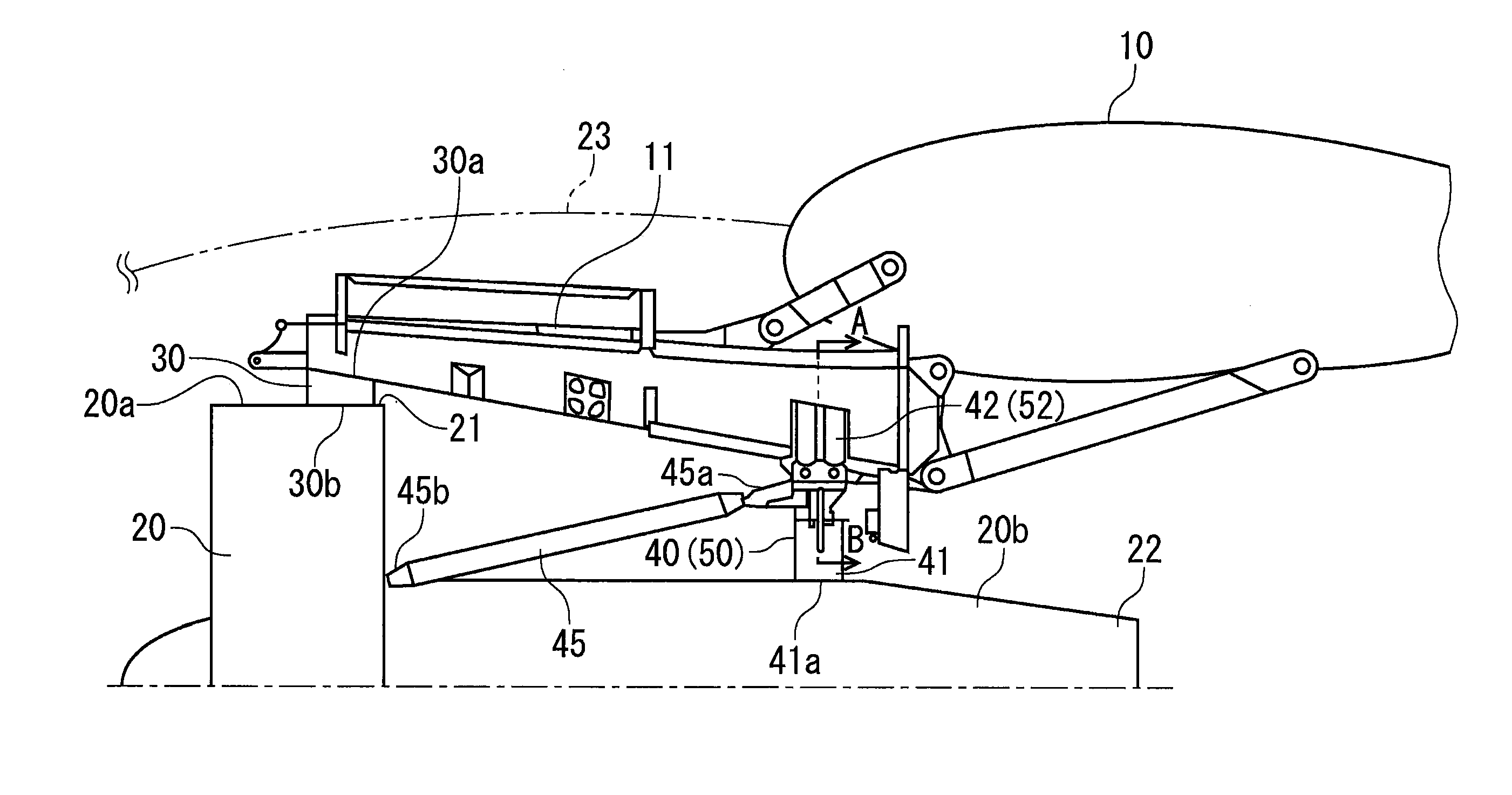

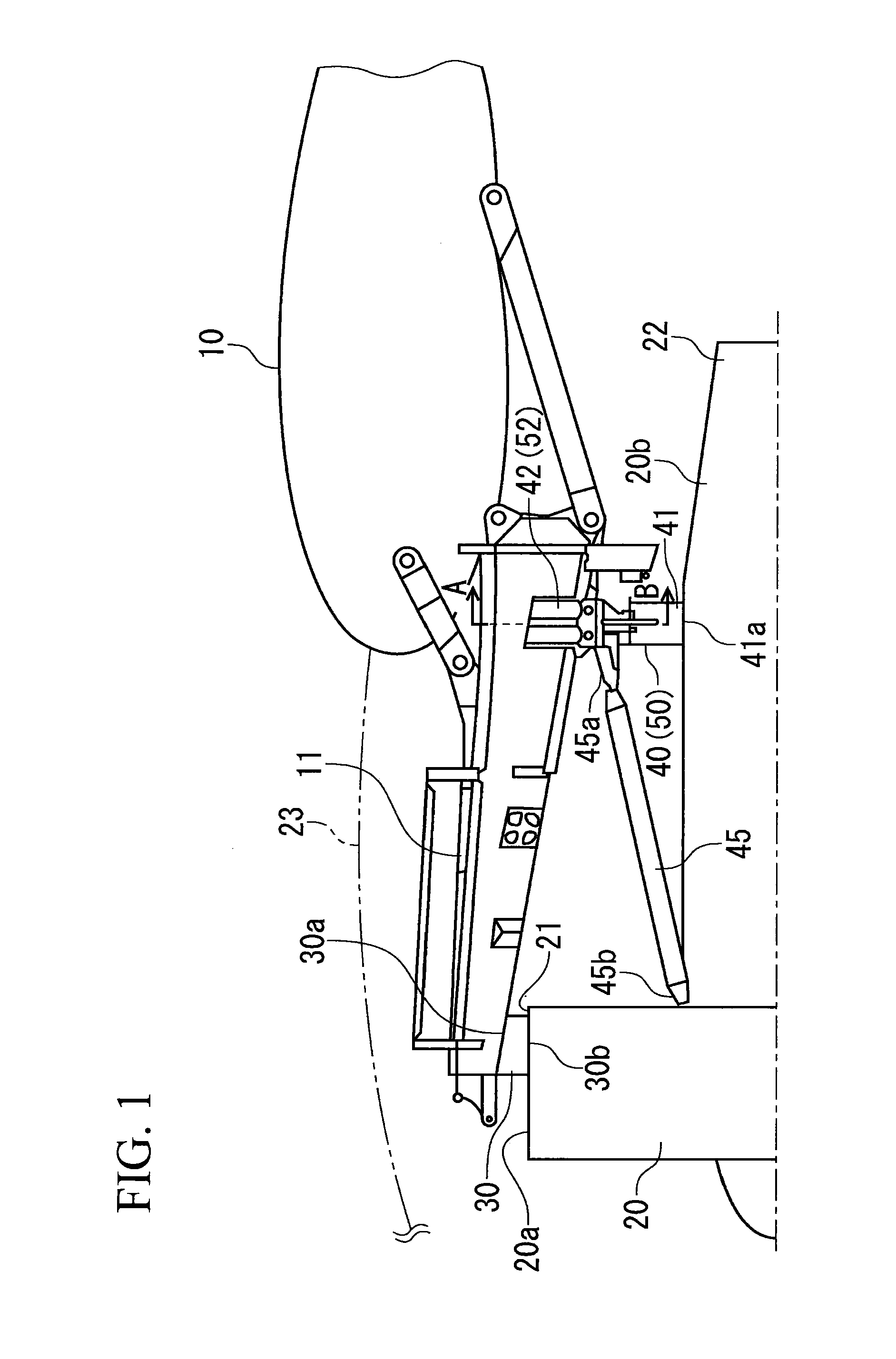

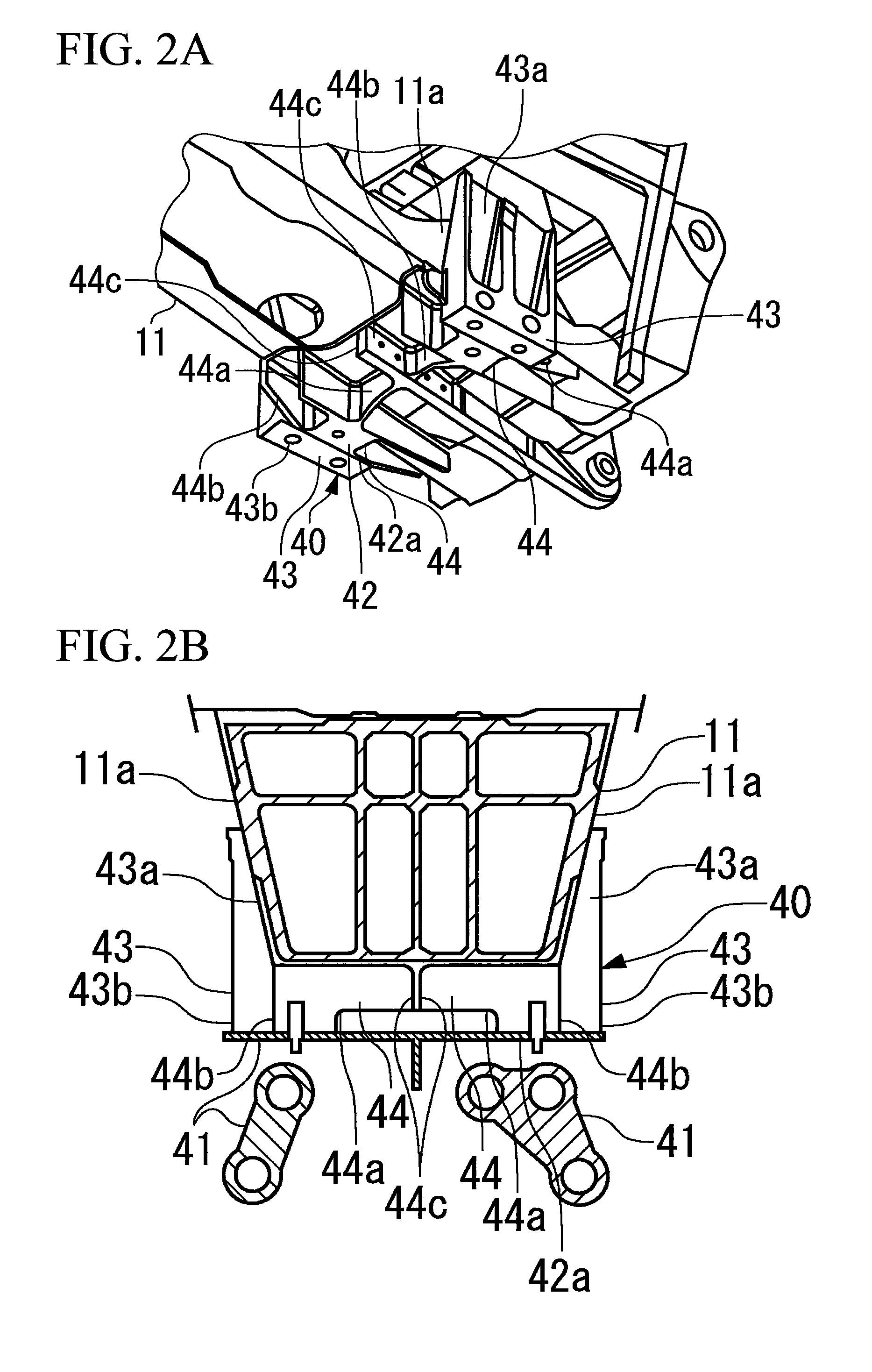

Engine mount of aircraft and aircraft

ActiveUS20110127371A1Small sizeIncrease the use of spacePower plant constructionJet type power plantsNacelleBypass ratio

An engine mount of an aircraft and an aircraft are provided, which can reduce a size of an engine mount and can effectively use a space in an engine nacelle even in an engine with a high bypass ratio. An engine core section 20b at a rear of an engine 20 is supported by a rear engine mount 40 comprising an engine side mount member 41 fixed to a side of the engine 20 and a strut side mount member 42 fixed to a side of a pylon strut 11. The rear engine mount 40 is divided into the engine side mount member 41 and the strut side mount member 42, and thereby, even in the engine 20 with a high bypass ratio in which an outside diameter of the fan section 20a and the outside diameter of the engine core section 20b significantly differ, the lengths in the vertical direction of the engine side mount member 41 and the strut side mount member 42 are suppressed.

Owner:MITSUBISHI AIRCRAFT

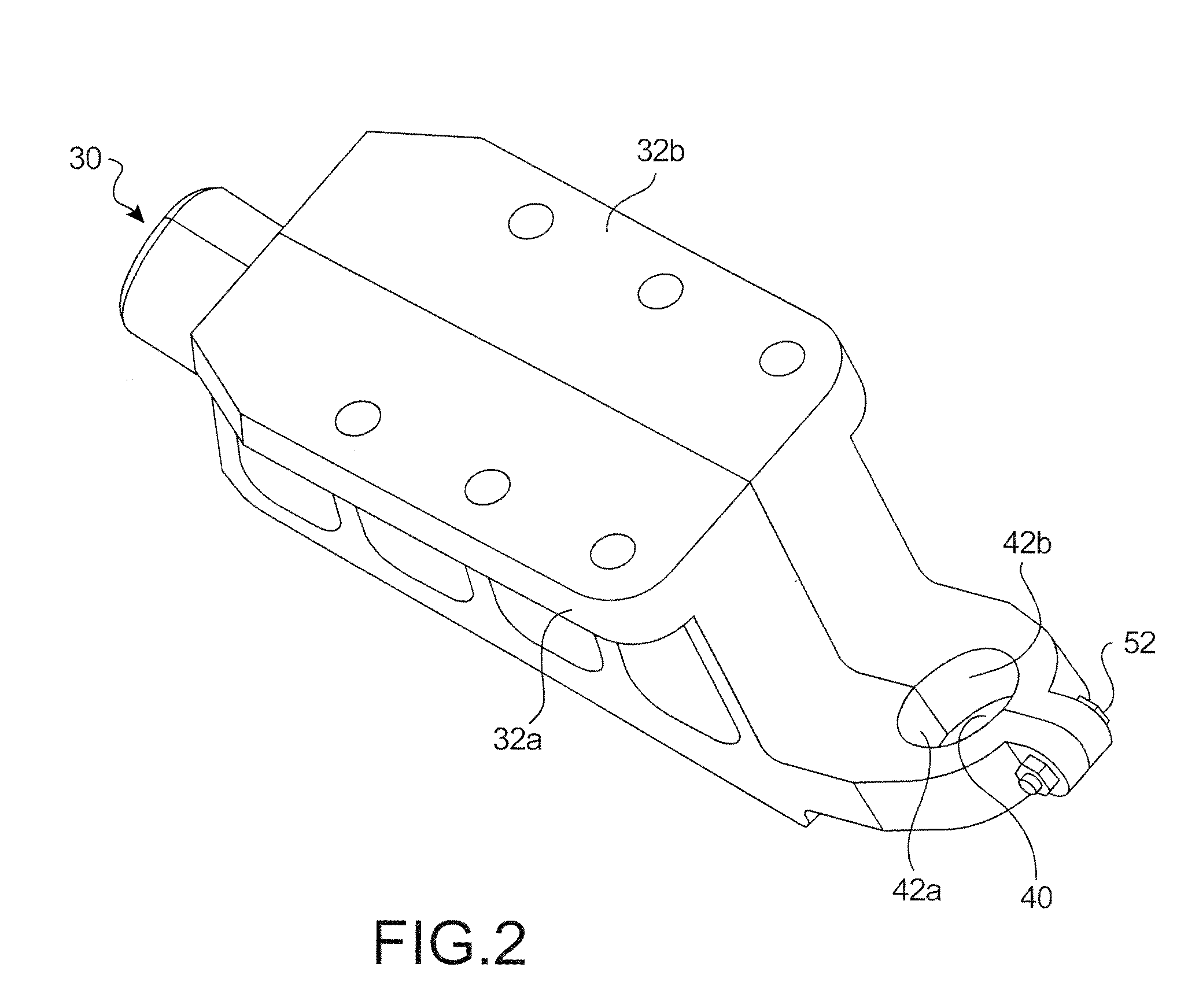

Engine Fastener Of A Mounting System Interposed Between An Attachment Strut And An Aircraft Engine

ActiveUS20080169378A1Reduction in overall weight and sizeIncrease in sizeGas turbine type power plantsPower plant constructionEngineeringRigid structure

An engine attachment for an assembly system configured to be mounted between a rigid structure of an attachment strut of an aircraft engine and an engine. The attachment includes a main body, a rudder bar on an articulated mounting on the main body by a hinge pin, and two thrust absorption rods each with one end connected to the rudder bar. The main body includes a first main brace and a second main brace superimposed on the first brace. The hinge pin is formed by a first portion and a second portion, wherein the first portion is made in one piece with the first brace and the second portion is made in one piece with the second brace. Furthermore, the braces define a stop limit surface configured to limit rotation of the rudder bar.

Owner:AIRBUS OPERATIONS (SAS)

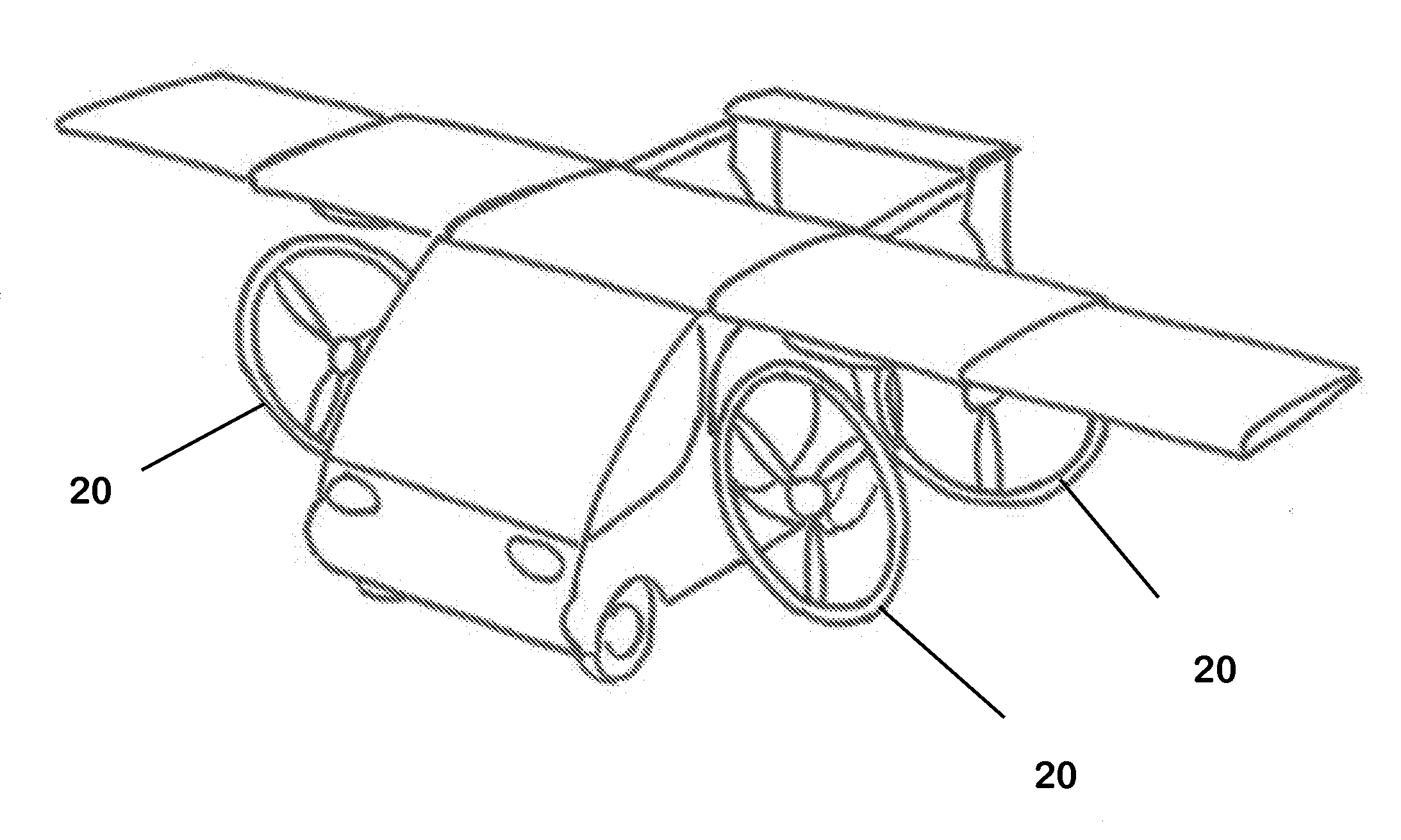

Modular aircraft system

ActiveUS9505484B1Easy constructionImprove aerodynamic performanceActuated automaticallyDe-icing equipmentsCarrying capacityFlight vehicle

The modular aircraft system includes a single fuselage having a permanently installed empennage and plural sets of wing modules and engine modules, with each wing and engine module optimized for different flight conditions and missions. The fuselage and each of the modules are configured for rapid removal and installation of the modules to minimize downtime for the aircraft. Short wings having relatively low aspect ratio are provided for relatively high speed flight when great endurance and / or weight carrying capacity are not of great concern. Long wings having high aspect ratio are provided for longer range and endurance flights where speed is not absolutely vital. A medium span wing module is also provided. Turboprop, single turbojet, and dual turbojet engine modules are provided for installation depending upon mission requirements for any given flight. The aircraft is primarily adapted for use as an autonomously operated or remotely operated unmanned aerial vehicle.

Owner:AL SABAH NASSER M

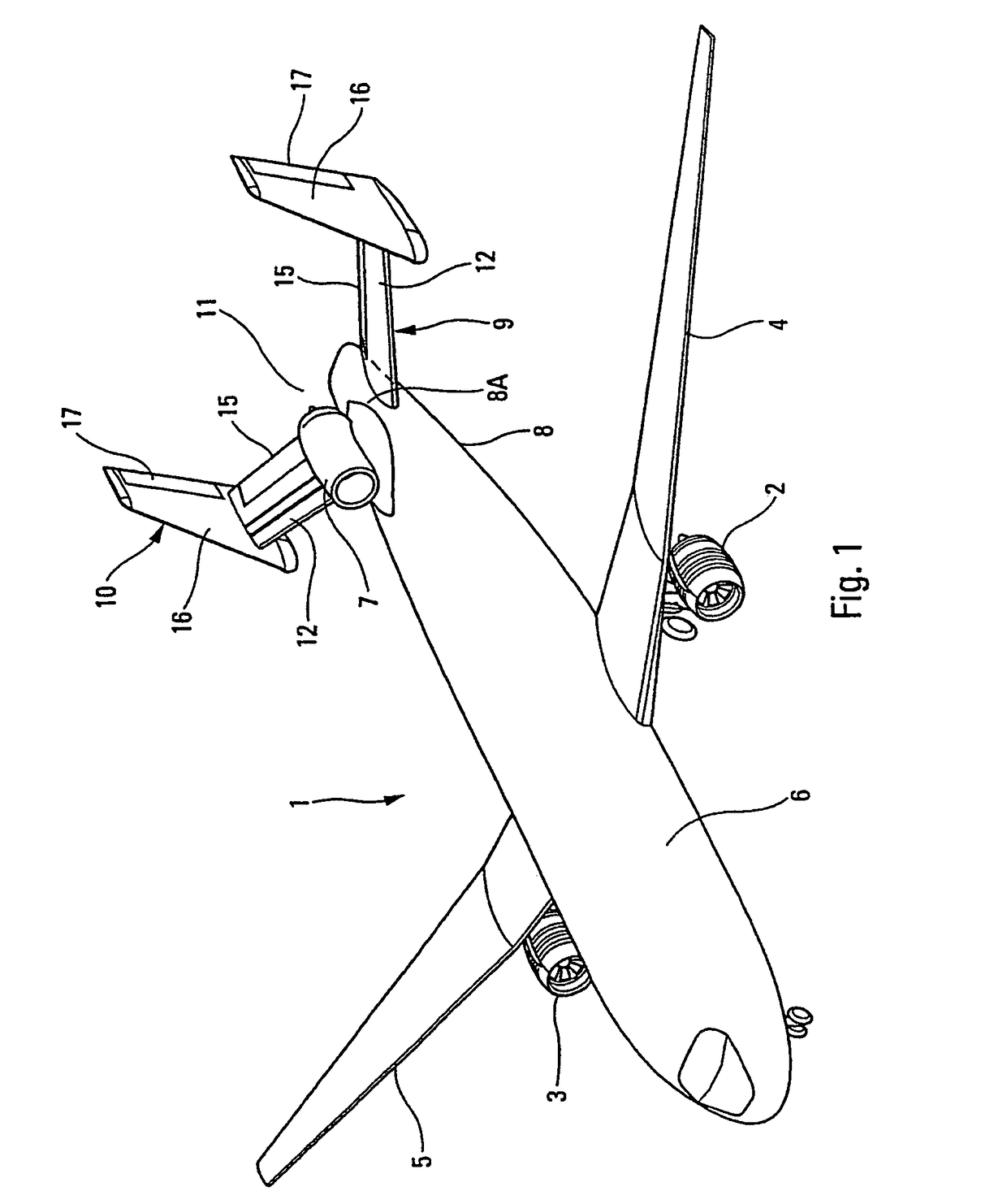

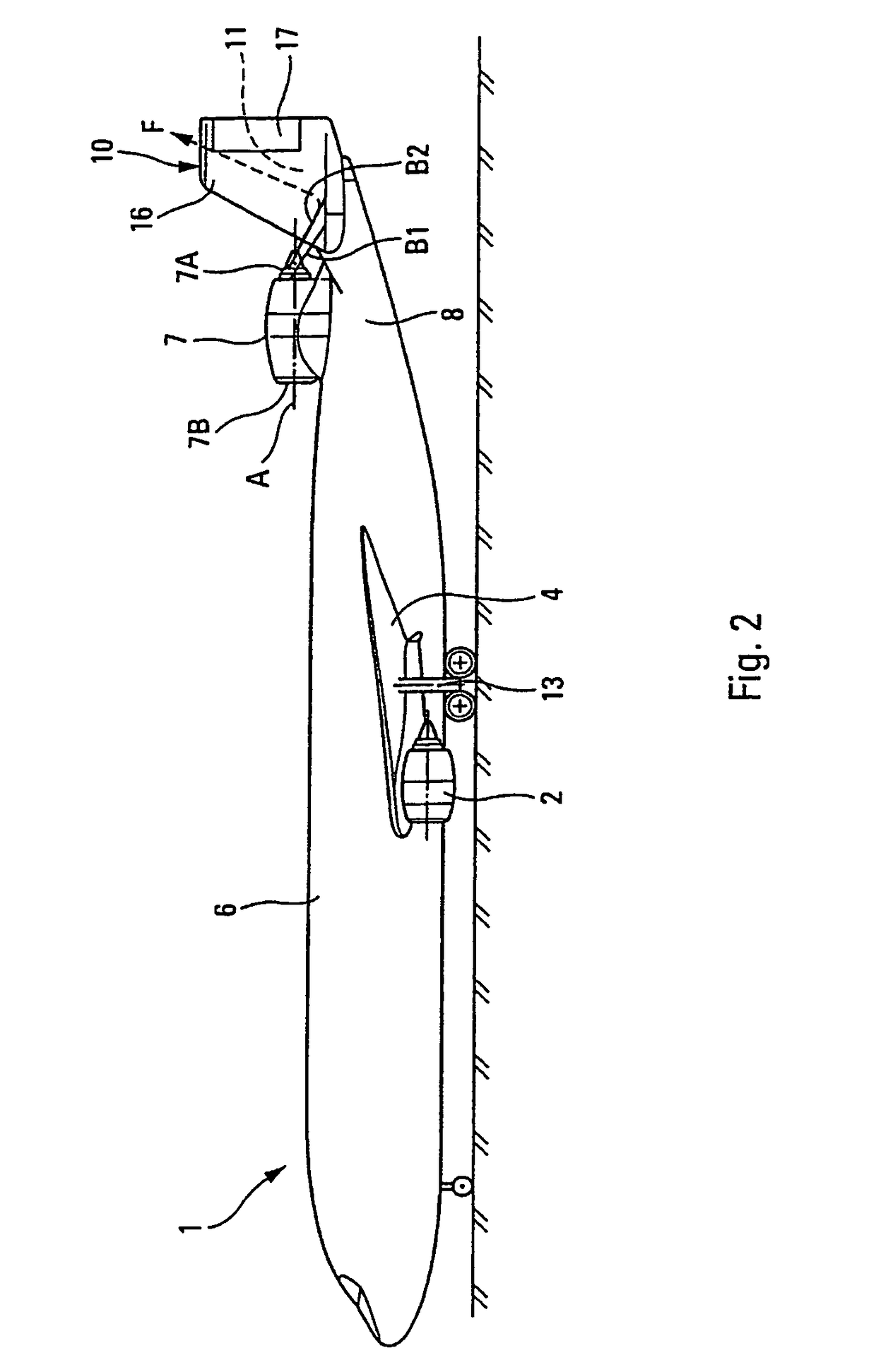

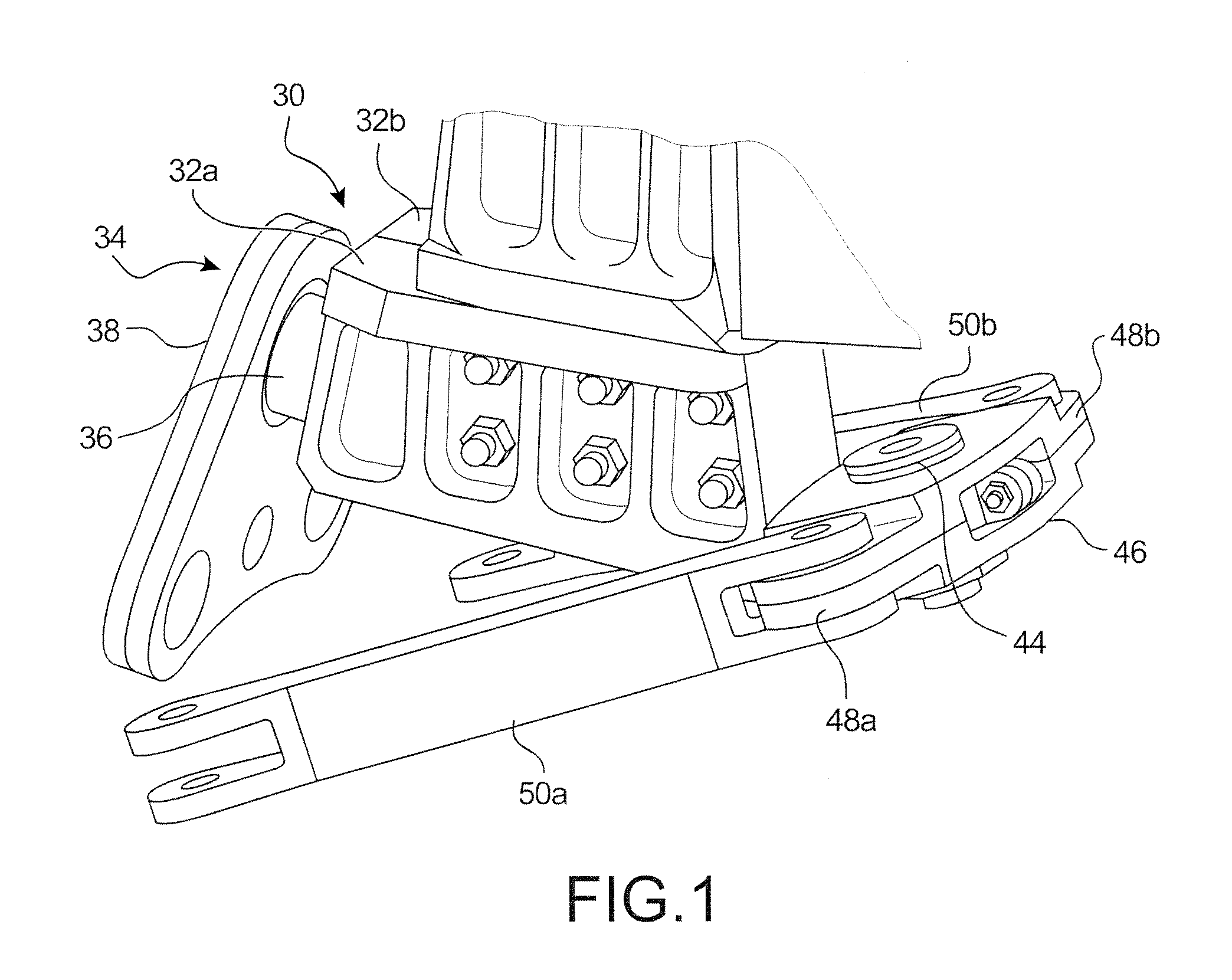

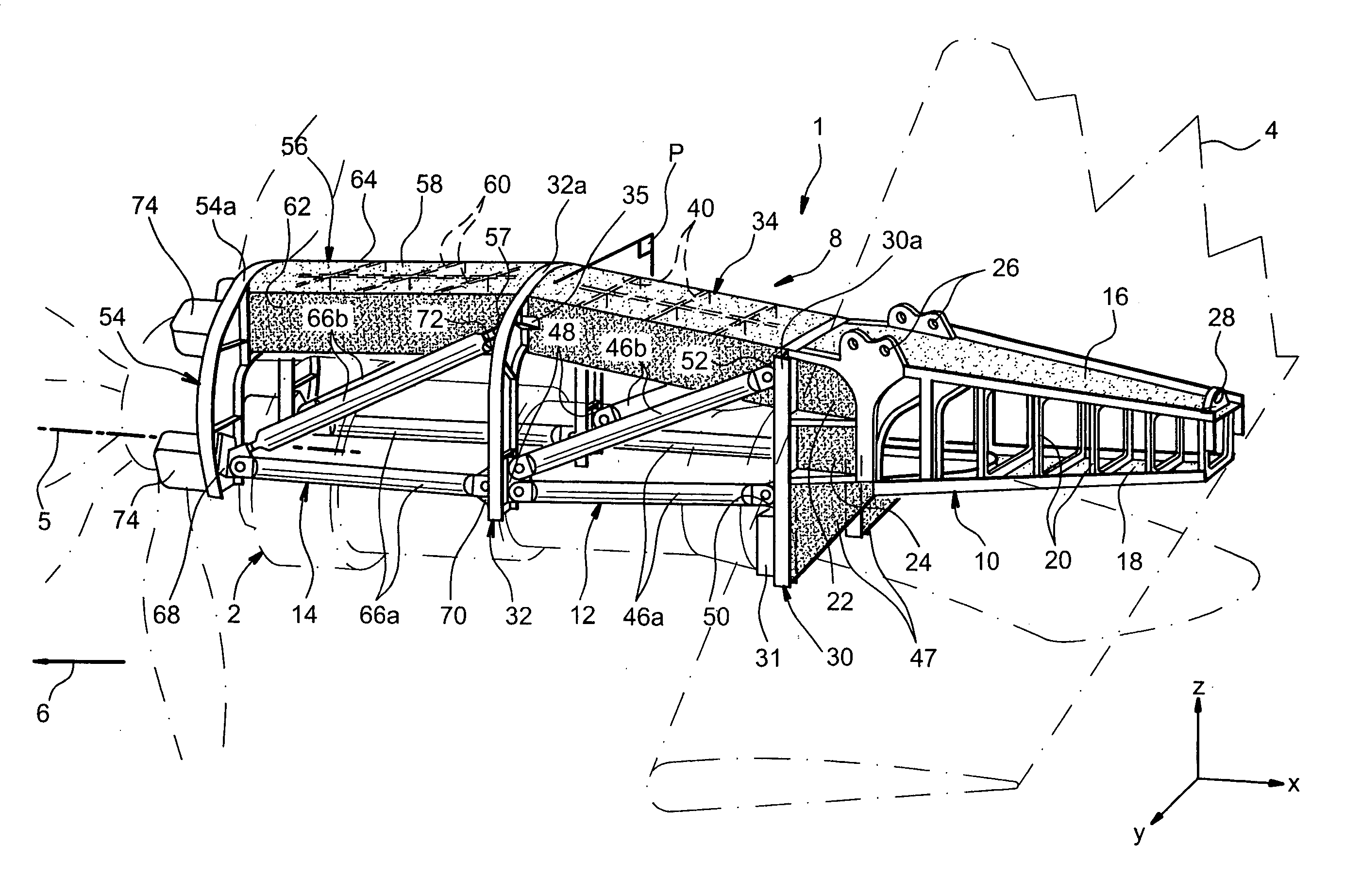

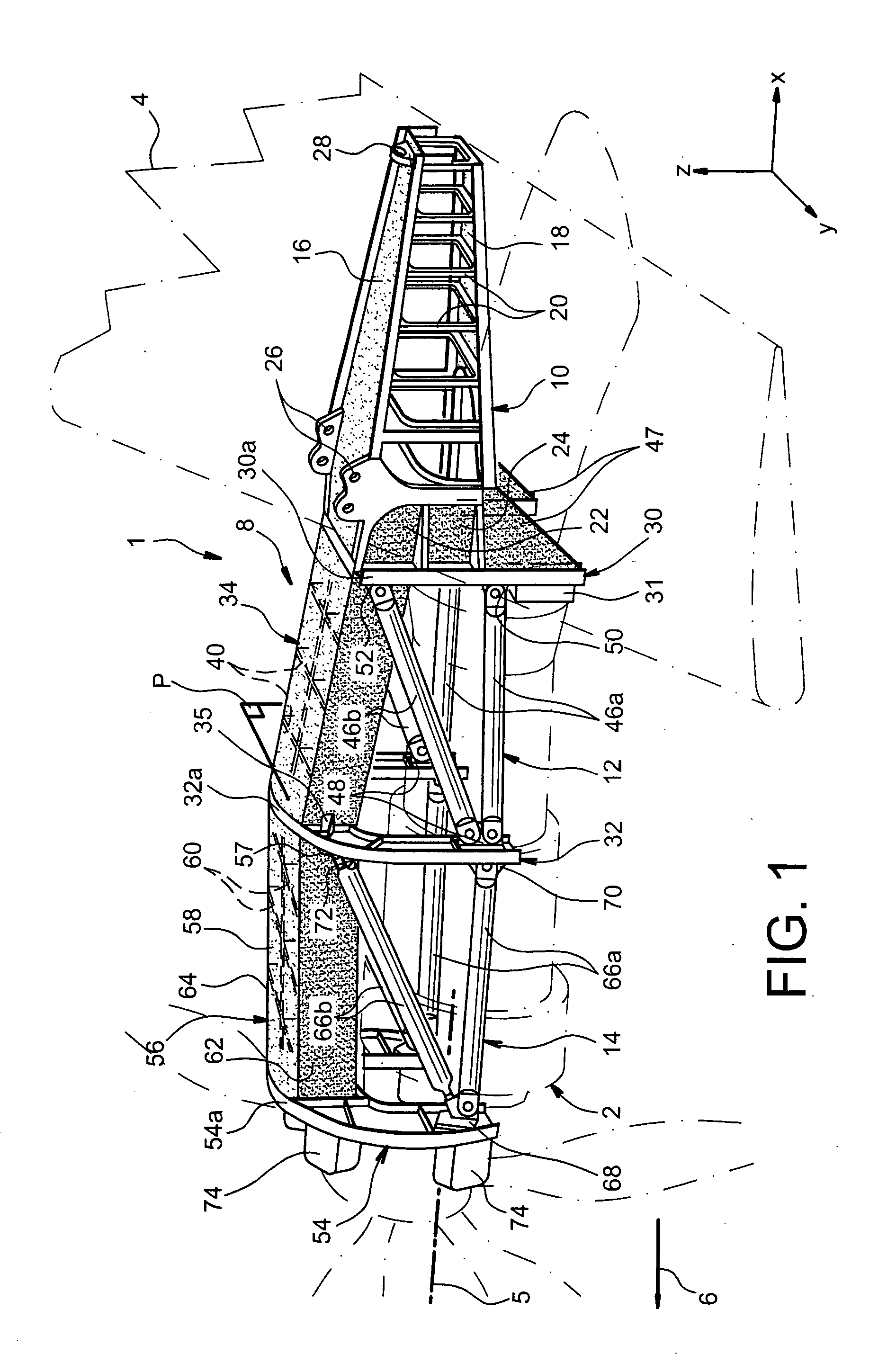

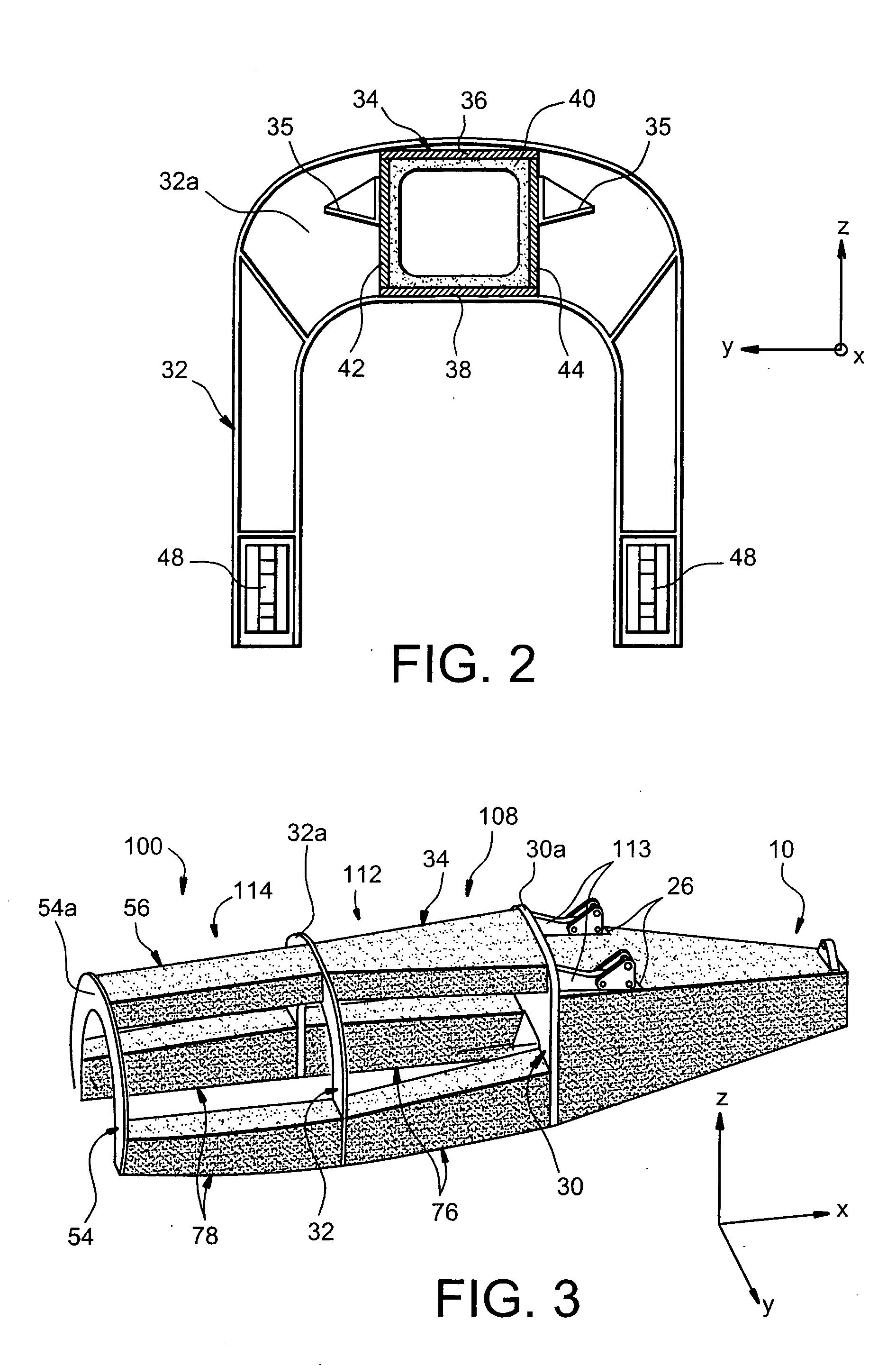

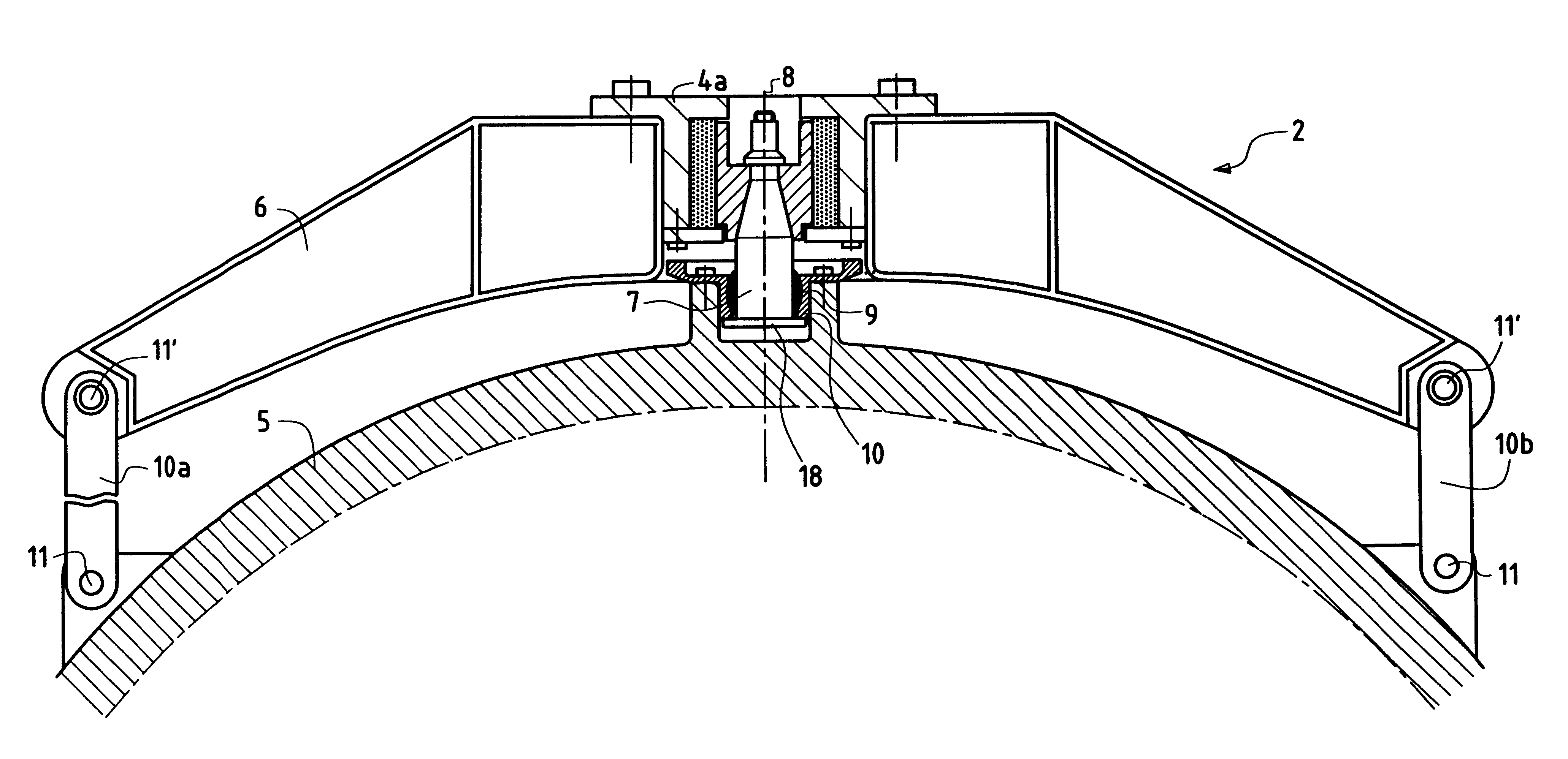

Mounting structure for mounting a turboprop under an aircraft wing

ActiveUS20050116093A1Easy resistanceGood geometric continuityGas turbine type power plantsPower plant constructionRigid structureAirplane

This invention relates to a mounting structure (1) for mounting a turboprop (2) under an aircraft wing (4), the structure comprising a rigid structure (8) provided with an aft underwing box (10), and at least one forward rigid segment (12, 14), each forward rigid segment having two transverse frames (30, 32, 54) at a spacing from each other. According to the invention, at least one forward rigid segment (12, 14) of the rigid structure also comprises at least one forward upper box (34, 56) connecting a top part (30a, 32a, 54a) of the two transverse frames (30, 32, 54) of the forward rigid segment.

Owner:AIRBUS OPERATIONS (SAS)

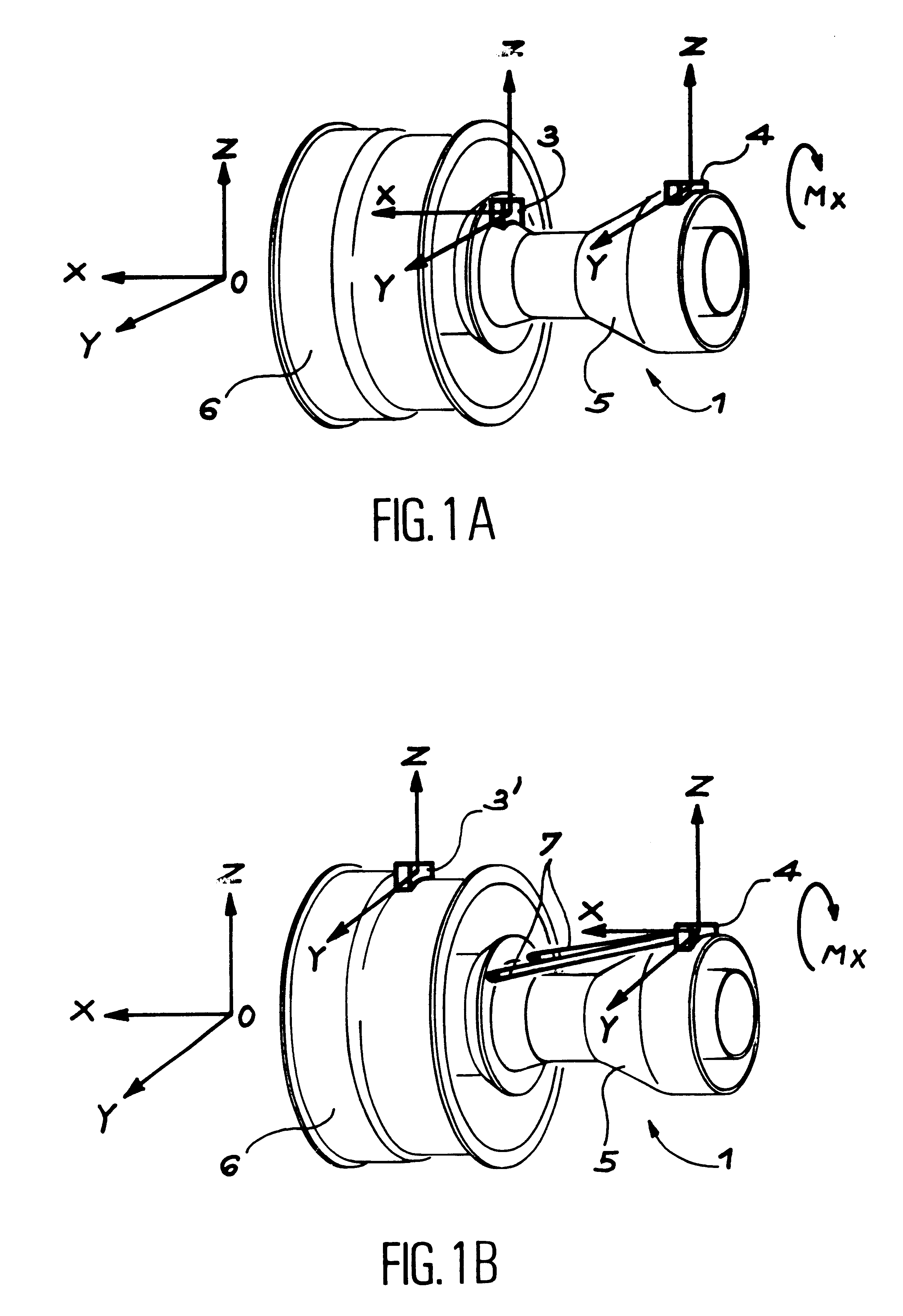

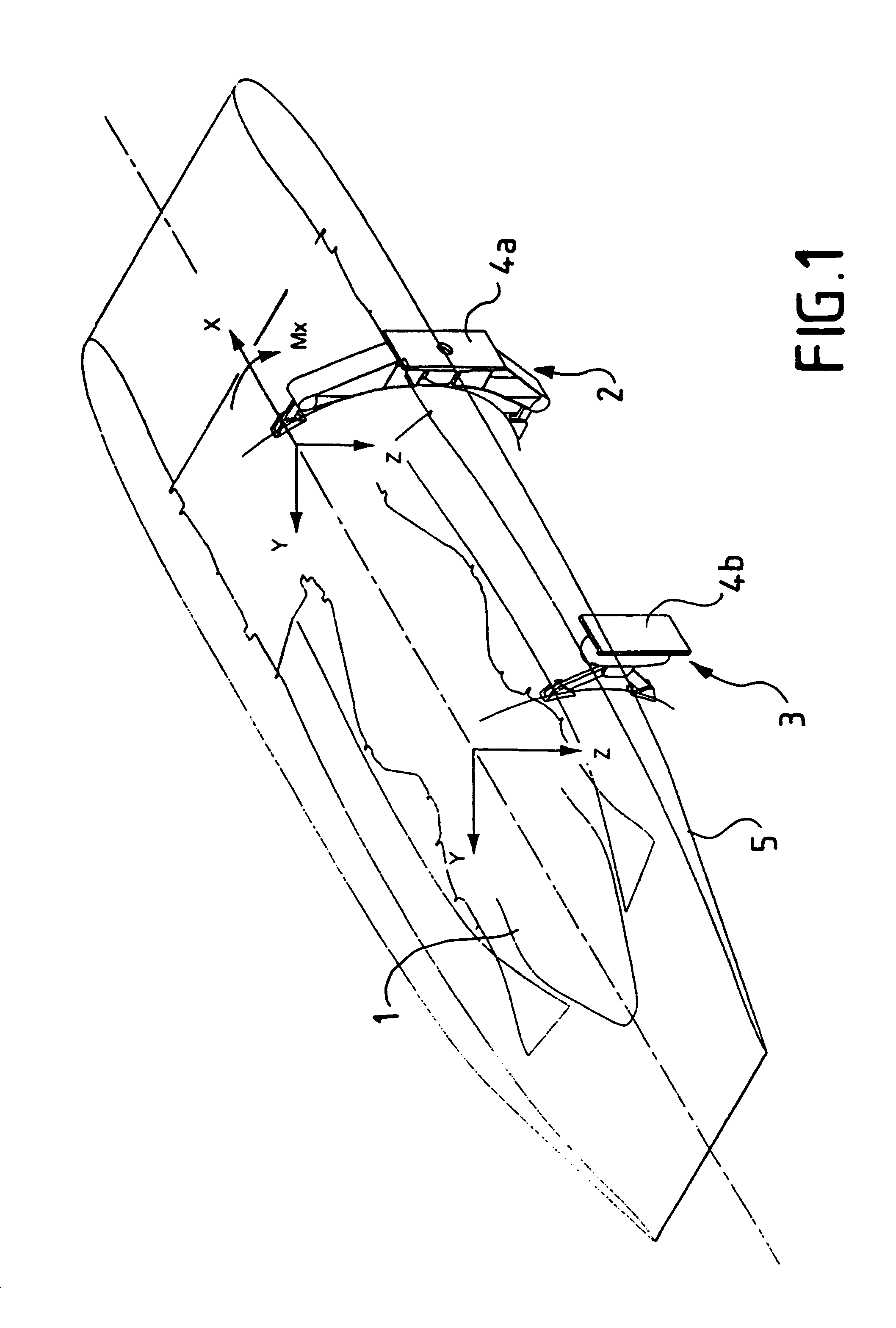

Suspension system with intrinsic safety features for aircraft powerplants

InactiveUS6474596B1Easily integrates safety featureModificationFuselage framesPower plant constructionIntrinsic safetyAirplane

A suspension system for an aircraft powerplant attached to an aircraft frame and having a housing. The suspension system includes a spindle mounted in a spindle support rigidly joined to the aircraft frame, a bearing cage affixed to the housing and having a bearing positioned therein, a pair of suspension arms connected to the spindle support, and a pair of lateral linkrods configured to link the housing and the suspension arms. The side surfaces of the bearing cage and the suspension arms define a clearance therebetween concentric to the Y-axis. The bearing cage is configurable along the spindle such that the bearing cage is limited to displacement relative to the longitude of the spindle while maintaining contact with the spindle.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

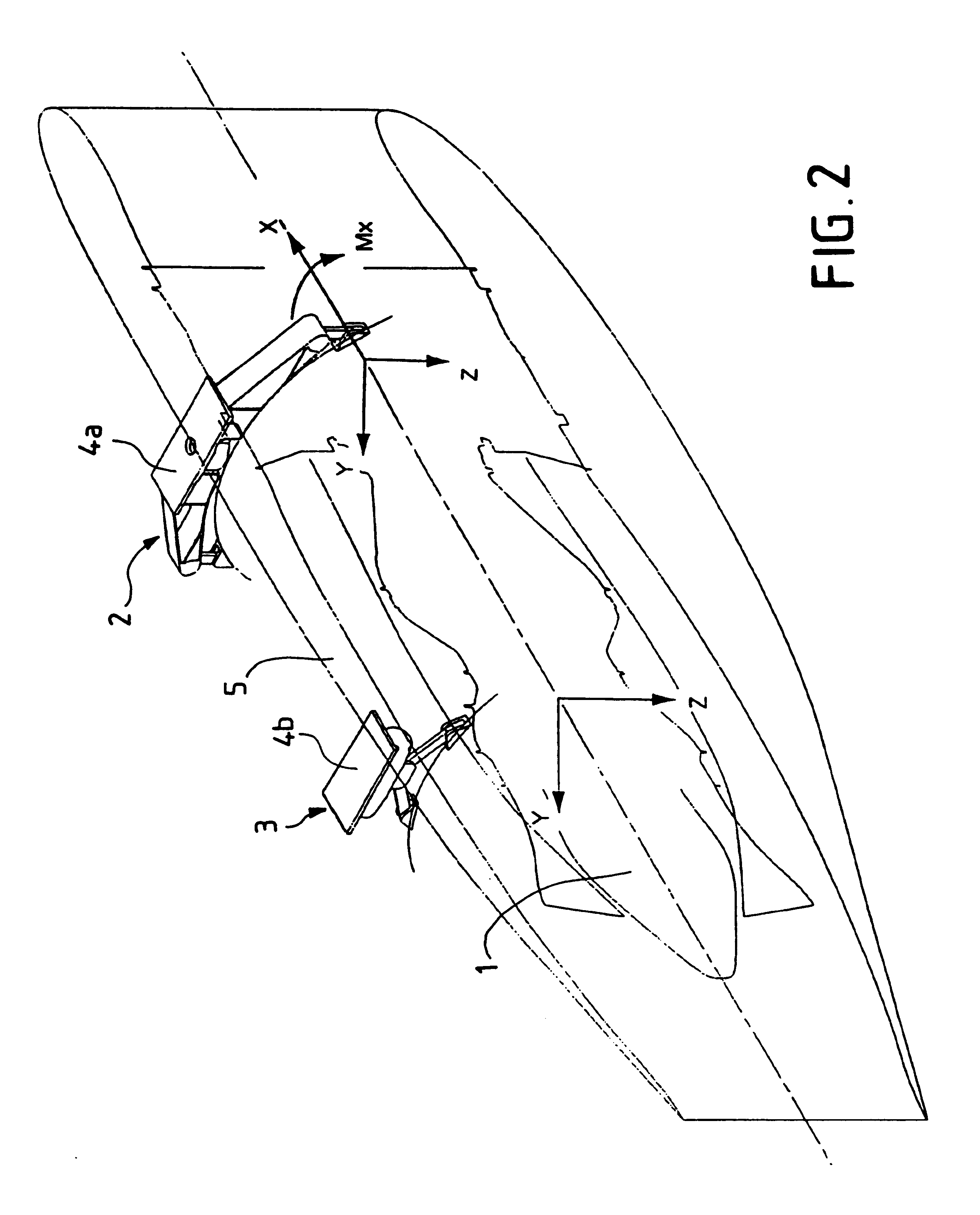

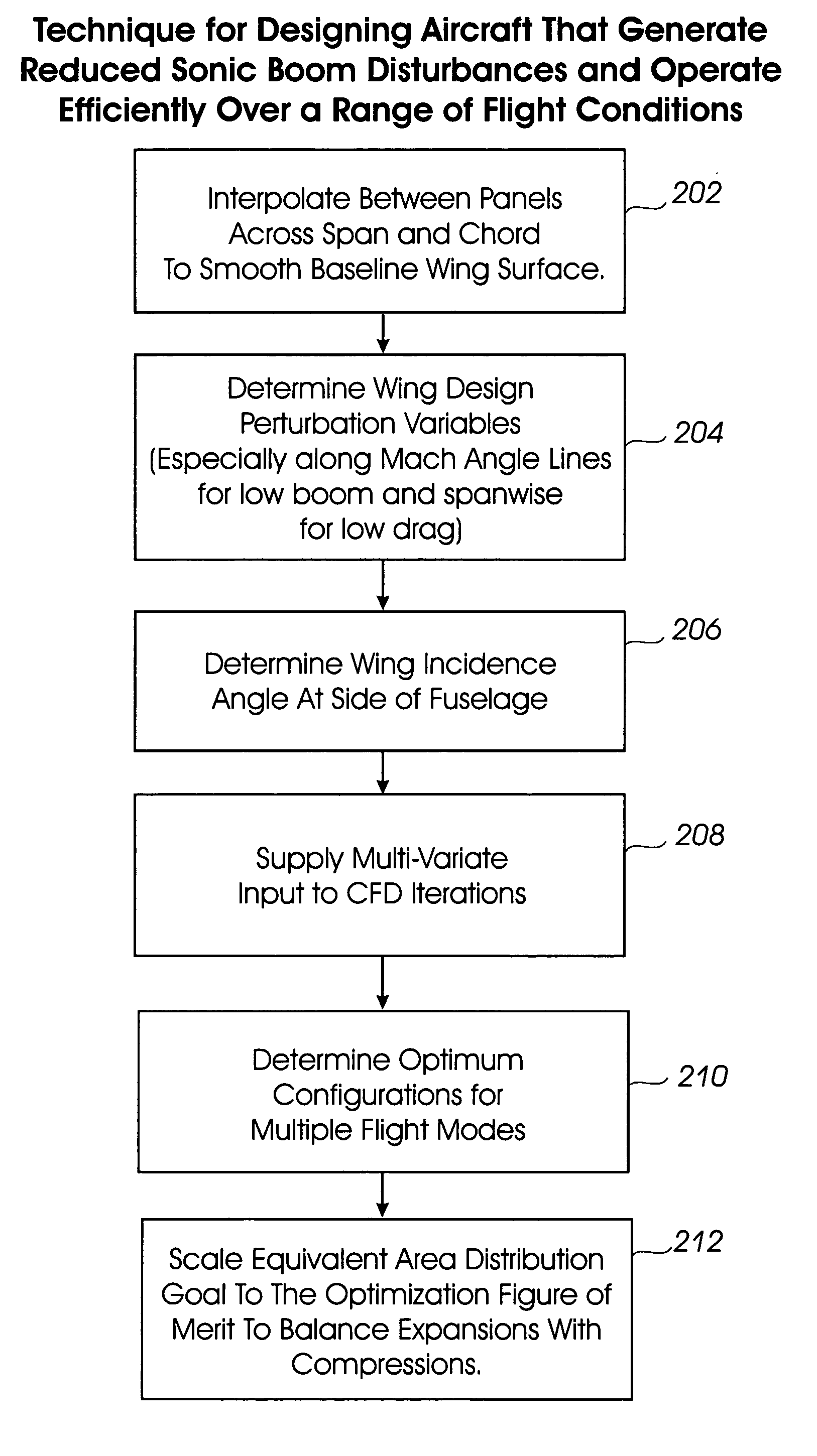

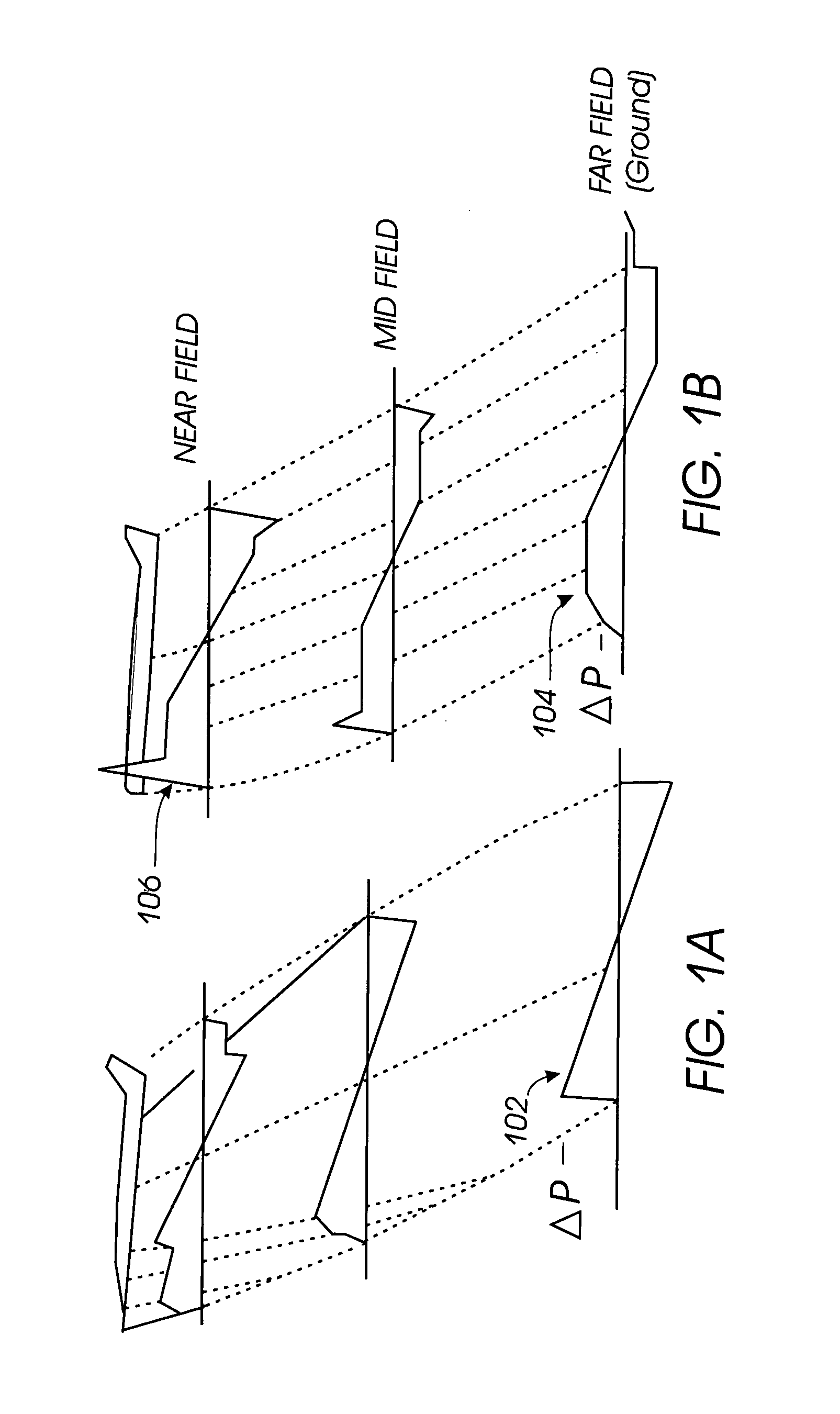

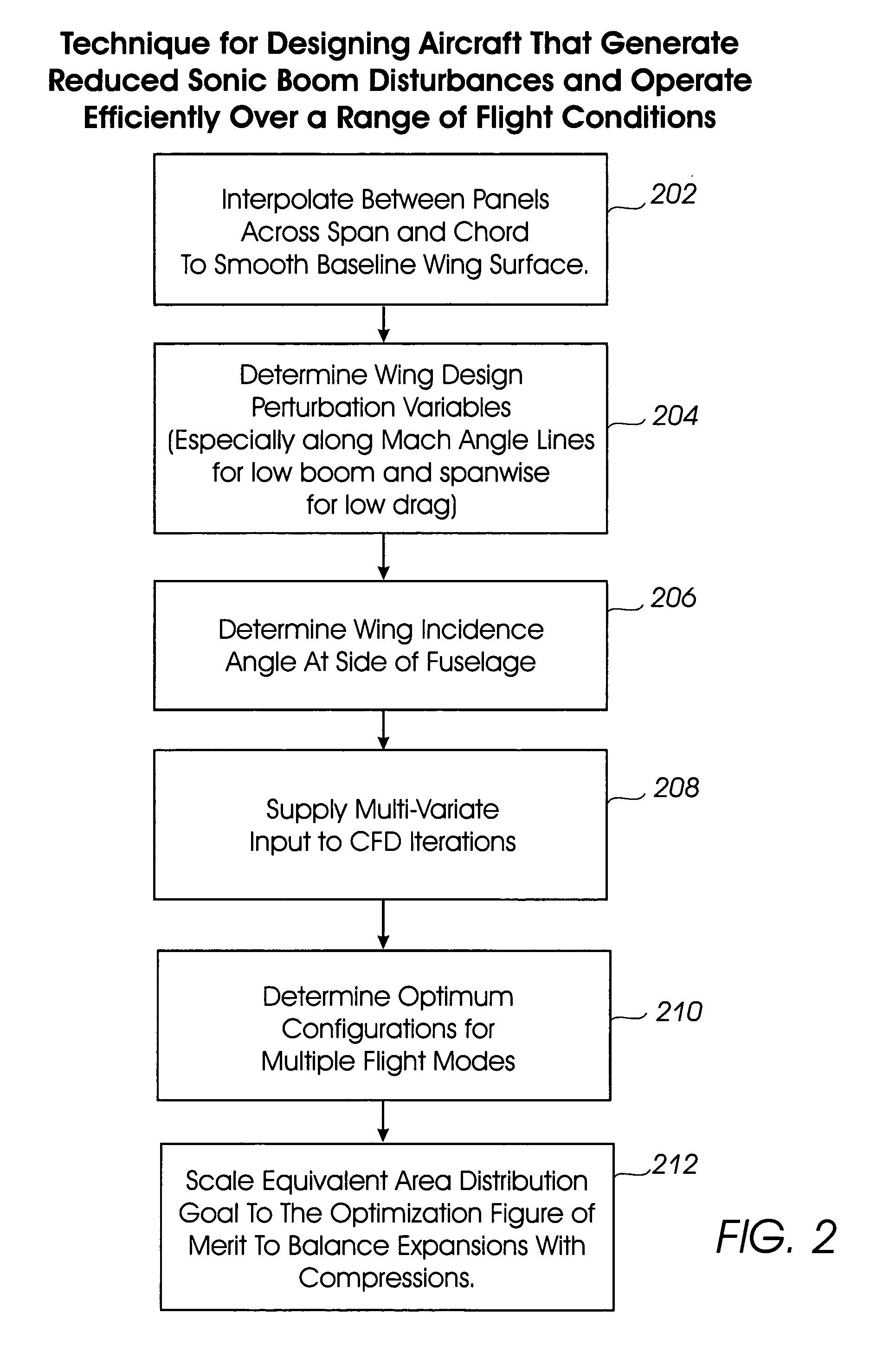

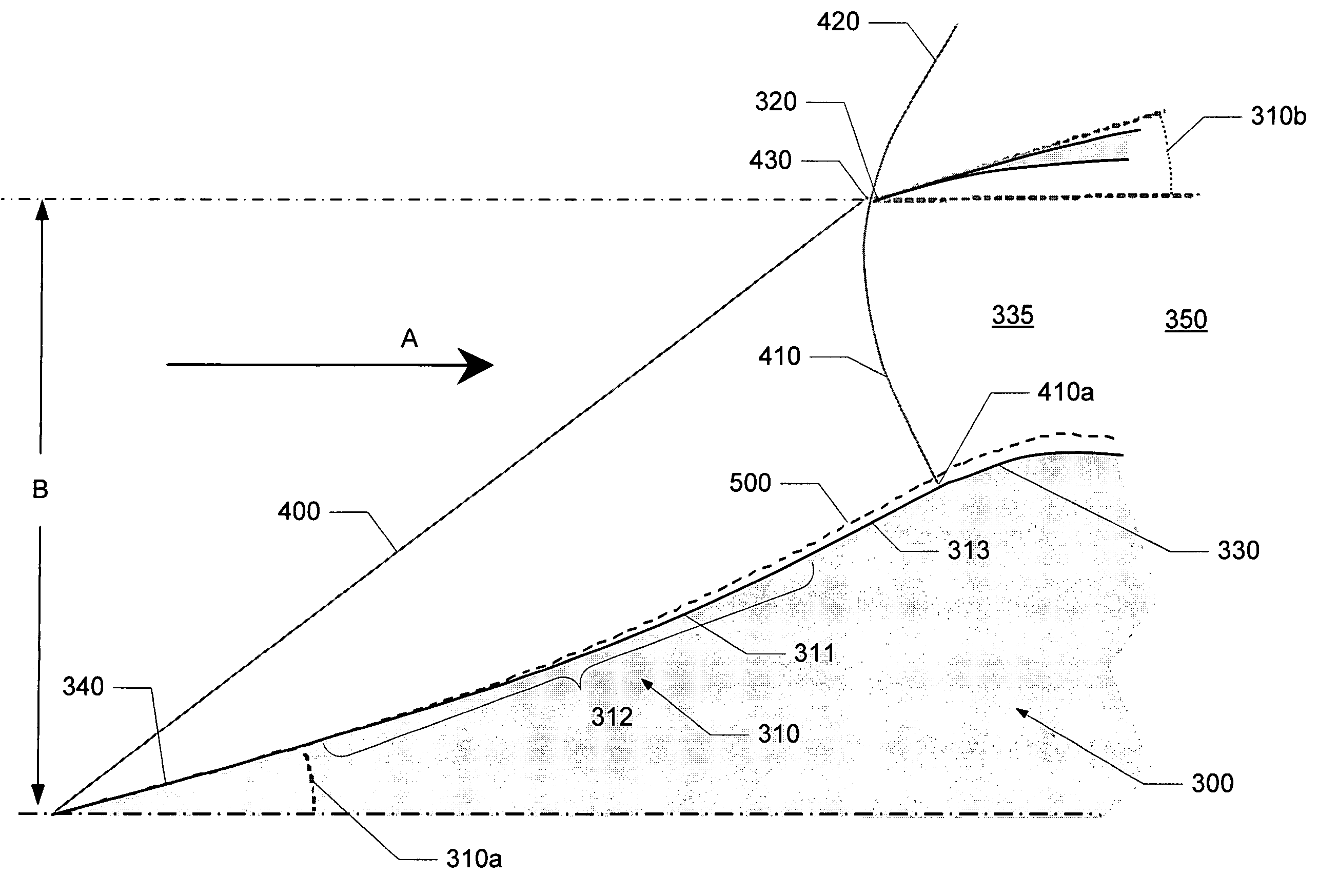

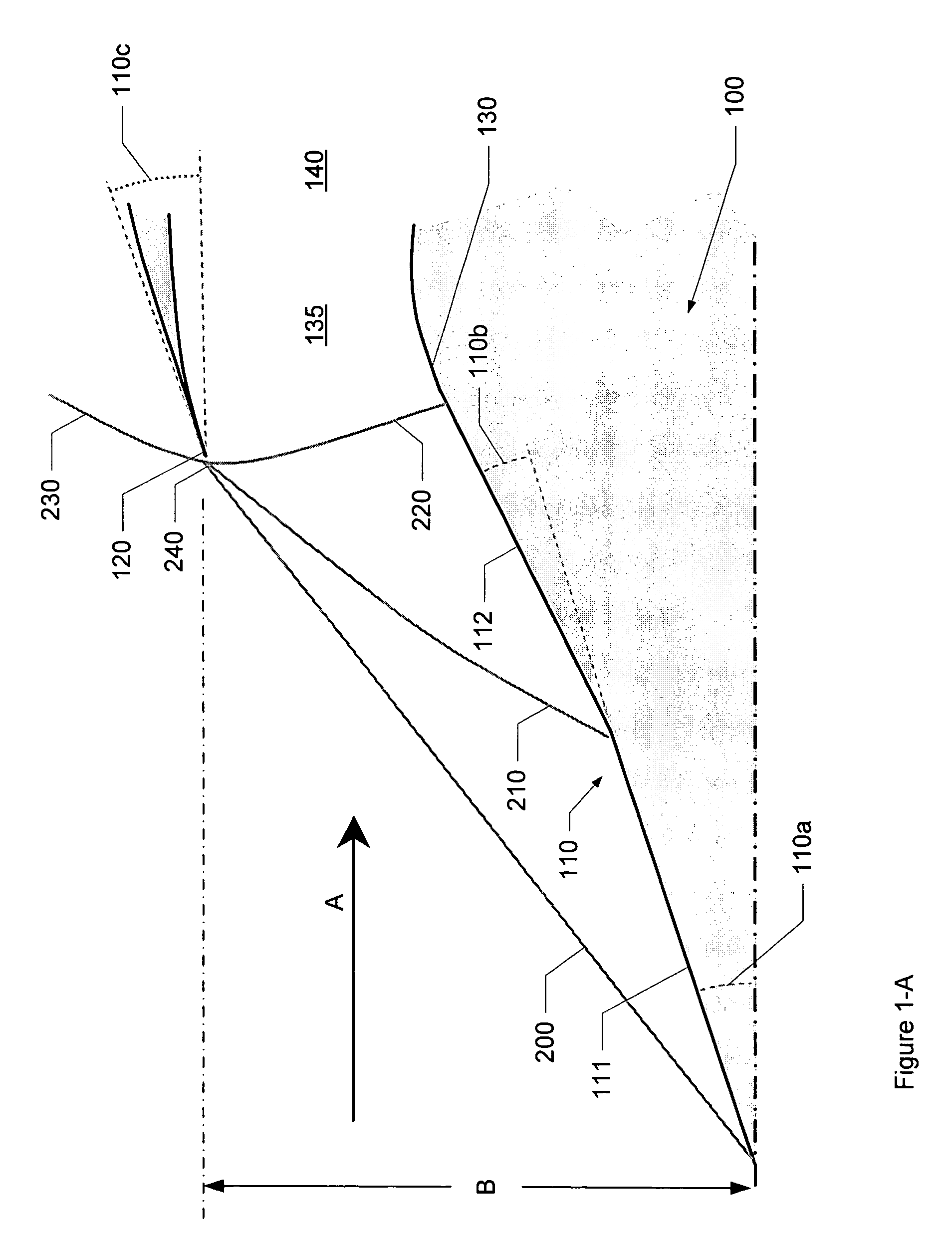

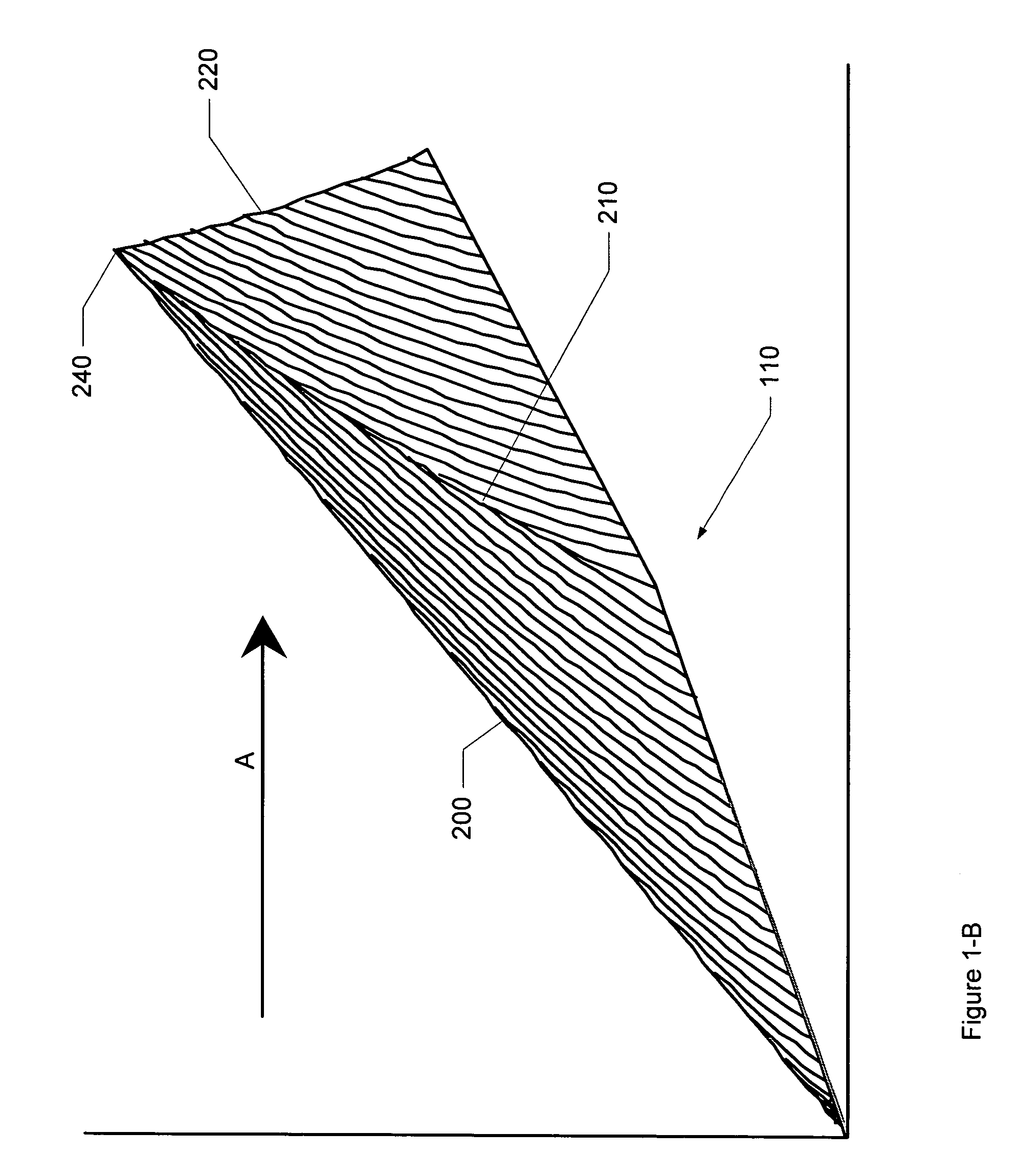

System, apparatus, and method for redistributing forces to meet performance goals and shock wave disturbance constraints

A system and method for configuring an aircraft for low sonic boom supersonic flight conditions includes redistributing lift of a wing by configuring the wing with one or more areas of far-field expansion ahead of areas of far-field compression. An equivalent area distribution goal curve is scaled to account for the equivalent area reduction due to excursions below to goal curve. A relaxed constraint allows the equivalent area distribution of the aircraft to be at or below the equivalent area distribution goal curve to enable multiple parameters to be configured to meet the equivalent area distribution constraint, as well as other constraints. The system and method can be adapted to aid in the design of any type of vehicle whose surfaces are subject to supersonic fluid flow, especially to reduce sonic boom.

Owner:SUPERSONIC AEROSPACE INT

Embedded electric machine

A gas turbine engine includes a compressor section and a turbine section together defining a core air flowpath. The rotary component is rotatable with the compressor section and the turbine section. The gas turbine engine additionally includes an electric machine rotatable with the rotary component and positioned coaxially with the rotary component at least partially inward of the core air flowpath. The electric machine is flexibly mounted to a static frame member, or flexibly coupled to the rotary component, or both, such that the electric machine is mechanically isolated or insulated from various internal and external forces on the gas turbine engine.

Owner:GENERAL ELECTRIC CO

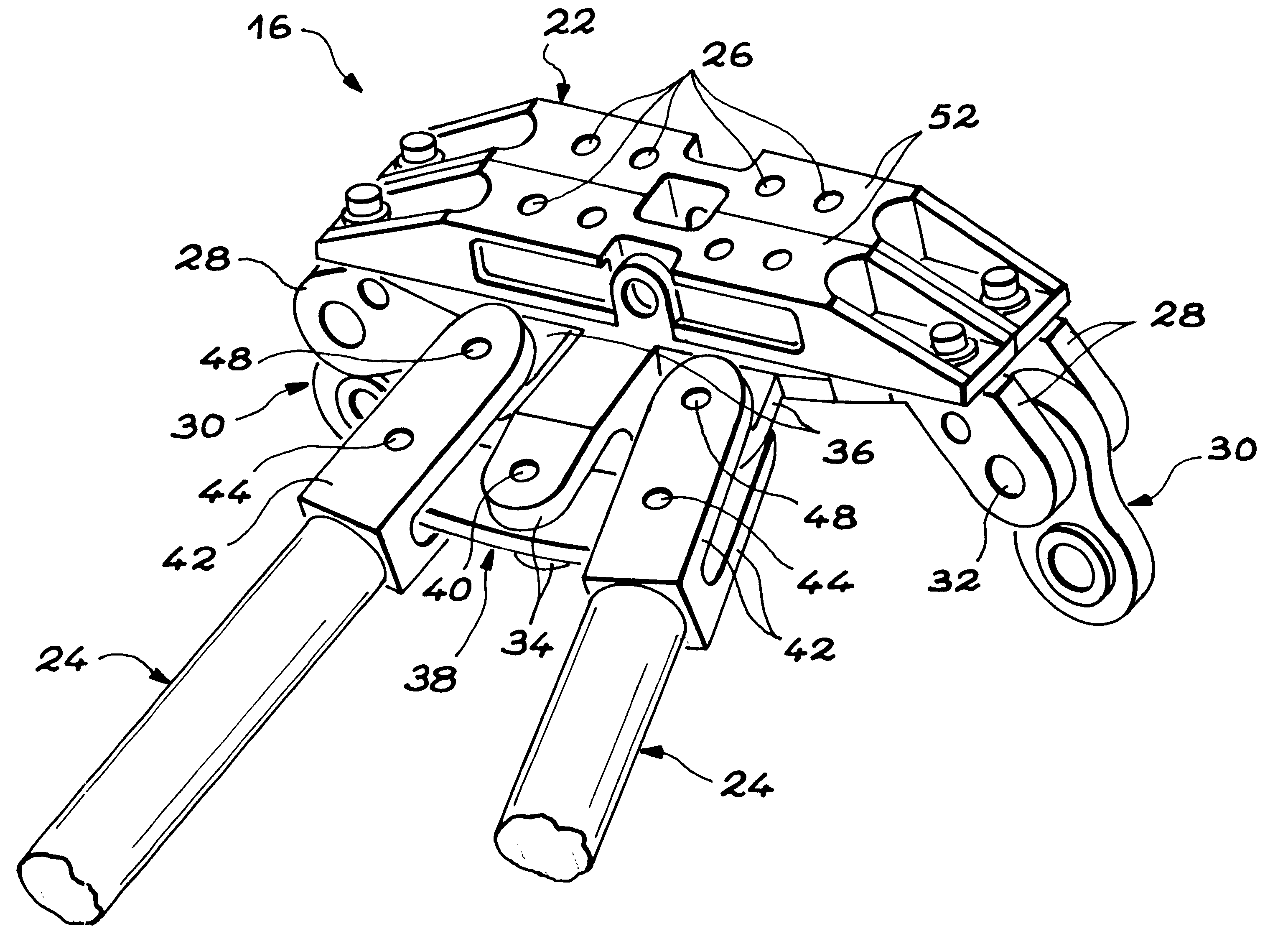

Device for aircraft thrust recovery capable of linking a turboshaft engine and an engine strut

Device for aircraft thrust reovery capable of linking a turboshaft engine and an engine strut.A device for thrust recovery (16) linking a turboshaft engine to an aircraft engine strut comprising an attachment fitting (22) fixed to an engine strut, a control bar (38) articulated on the attachment fittings (22) and two coupling rods (24) linking the control bar (38) to the central engine casing, almost along the longitudinal axis of the latter. Links with play are envisaged between each of the coupling rods (24) and the attachment fitting (22), to ensure transmission of thrust forces in the event of rupture of one of the parts of the device. These links with play comprise pivoting axes (48) which intersect the longitudinal axes of the corresponding coupling rods (24).

Owner:EADS AIRBUS

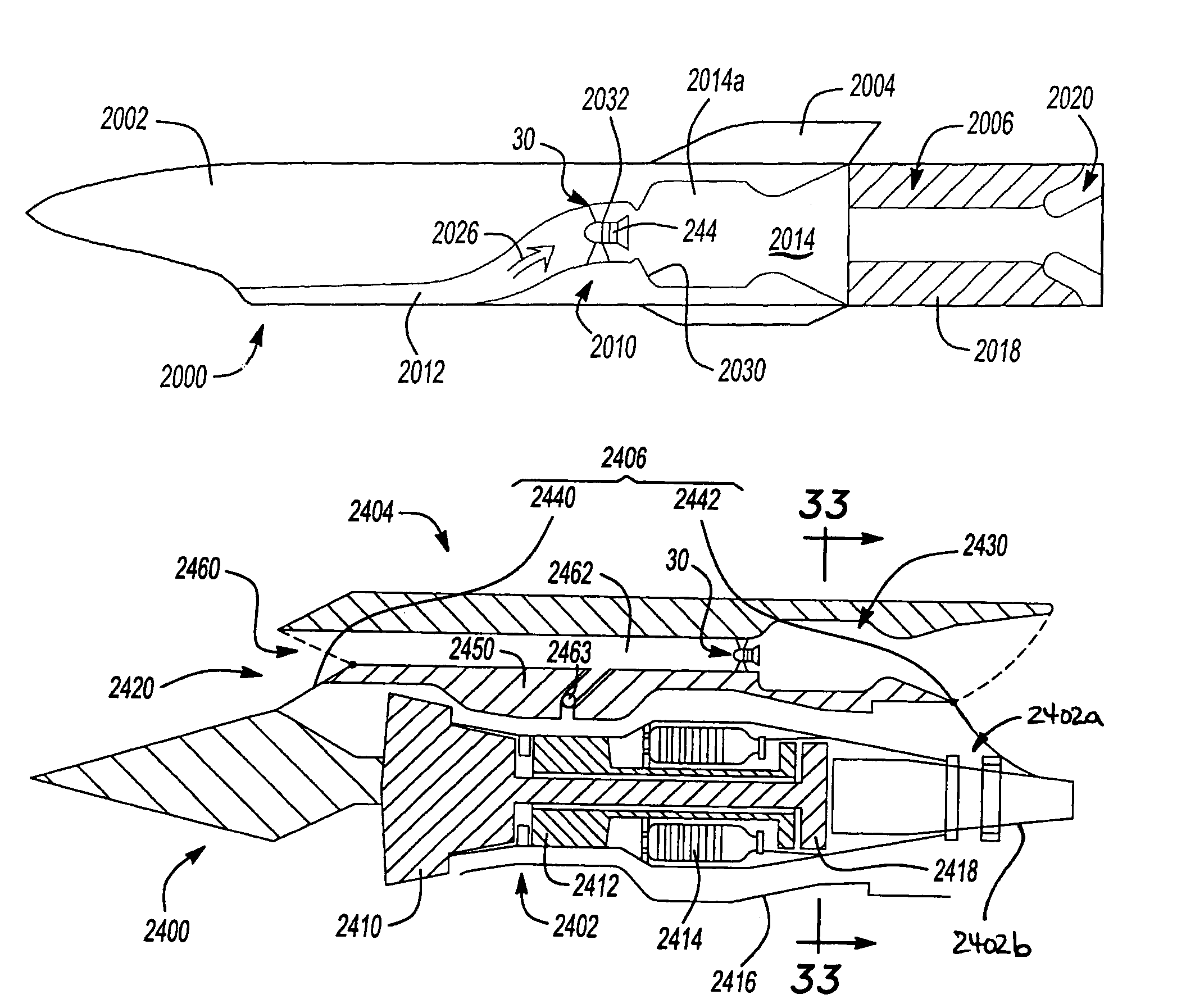

Isentropic compression inlet for supersonic aircraft

ActiveUS20080271787A1Improve performanceInherent shock stabilityCosmonautic vehiclesEngine manufactureEngineeringAirplane

Embodiments of the invention relate to a supersonic inlet employing relaxed isentropic compression to improve net propulsive force by shaping the compression surface of the inlet. Relaxed isentropic compression shaping of the inlet compression surface functions to reduce cowl lip surface angles, thereby improving inlet drag characteristics and interference drag characteristics. Using supersonic inlets in accordance with the invention also demonstrated reductions in peak sonic boom overpressure while maintaining performance.

Owner:GULFSTREAM AEROSPACE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com