Traction energy transmission type duct rotor wing fly lifter

A flying crane and rotor technology, which is applied in the field of traction energy transmission type ducted rotor flying crane, can solve the problems of not perfecting the gas field of the precursor vortex ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

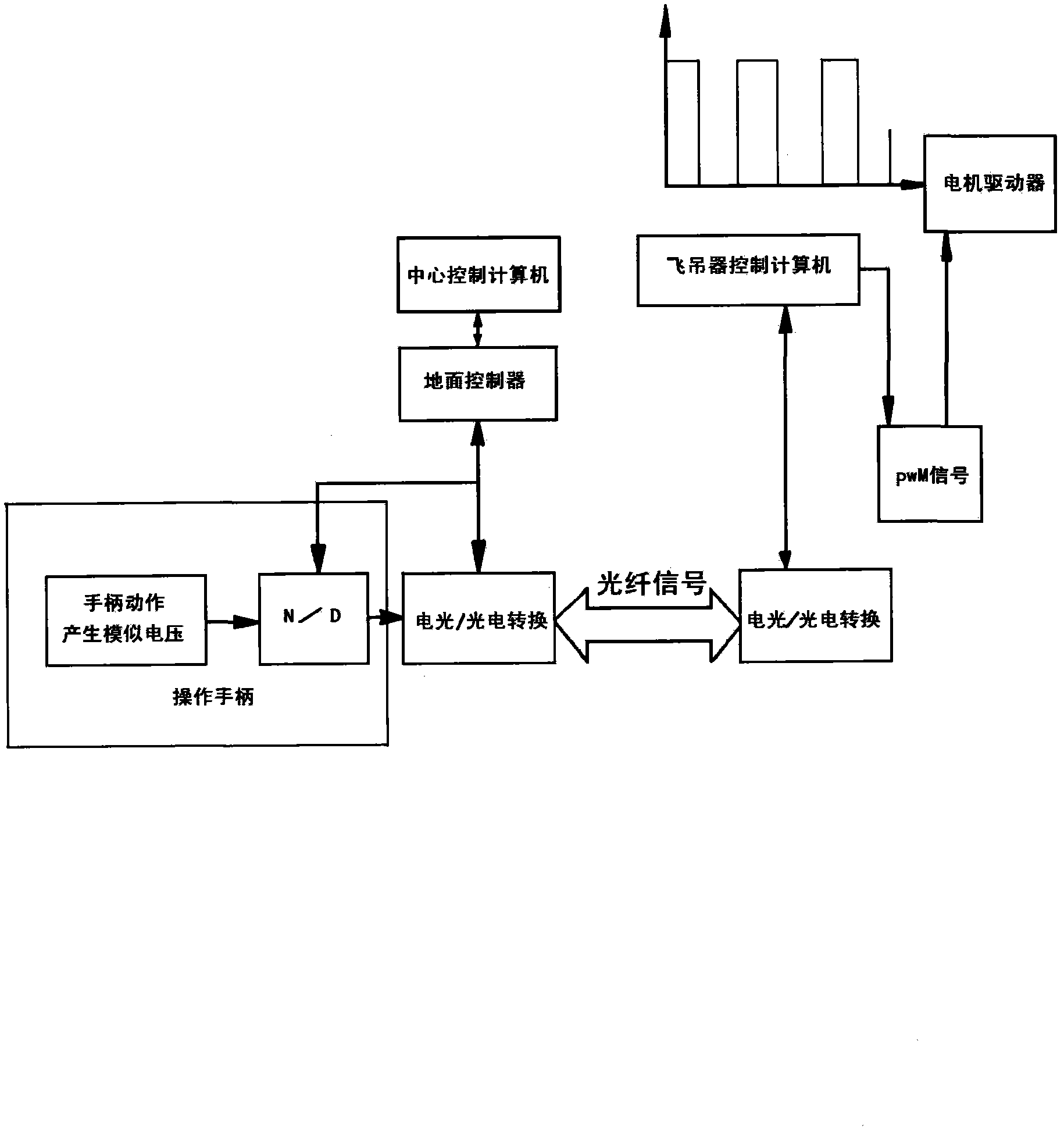

Method used

Image

Examples

Embodiment Construction

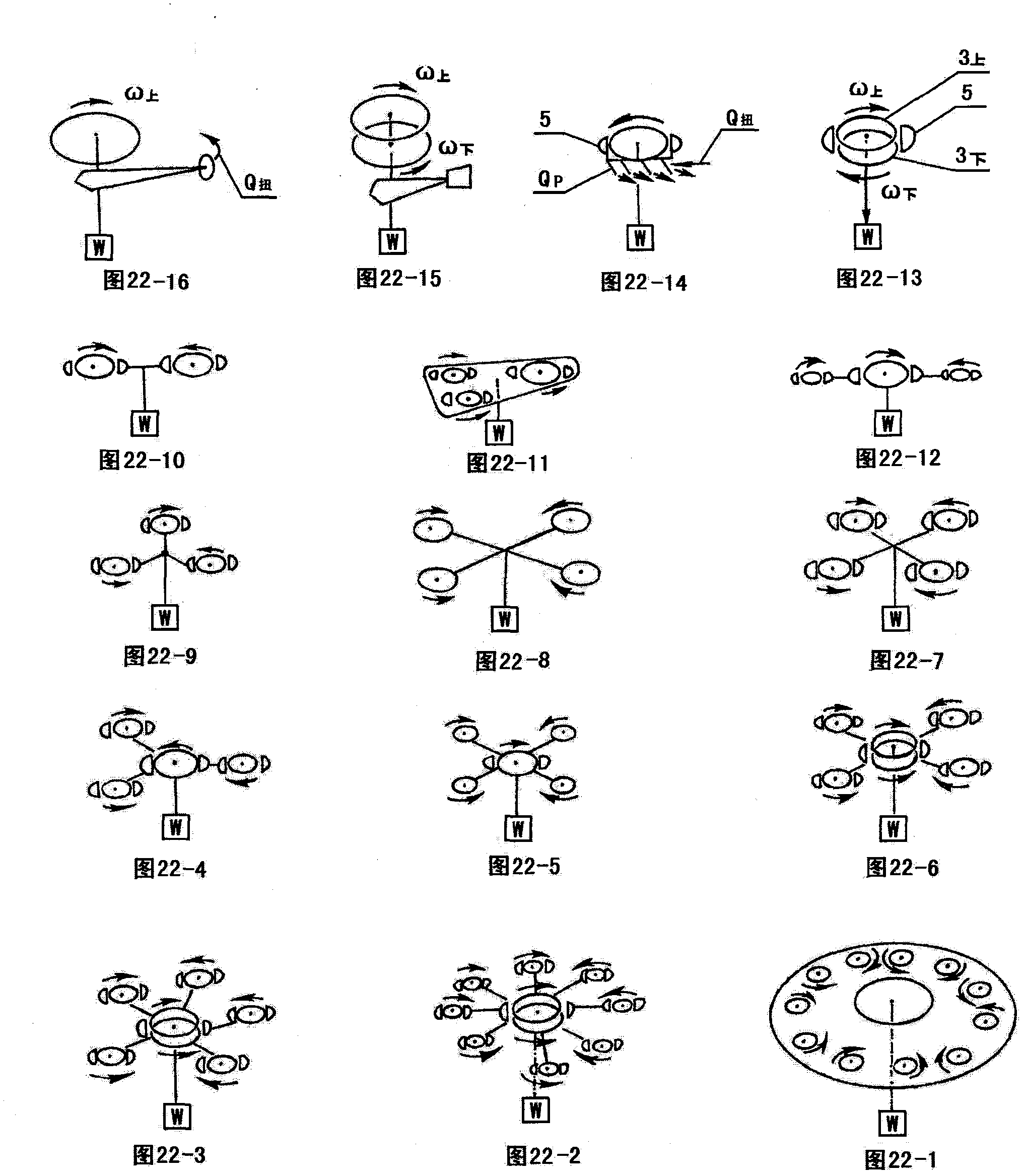

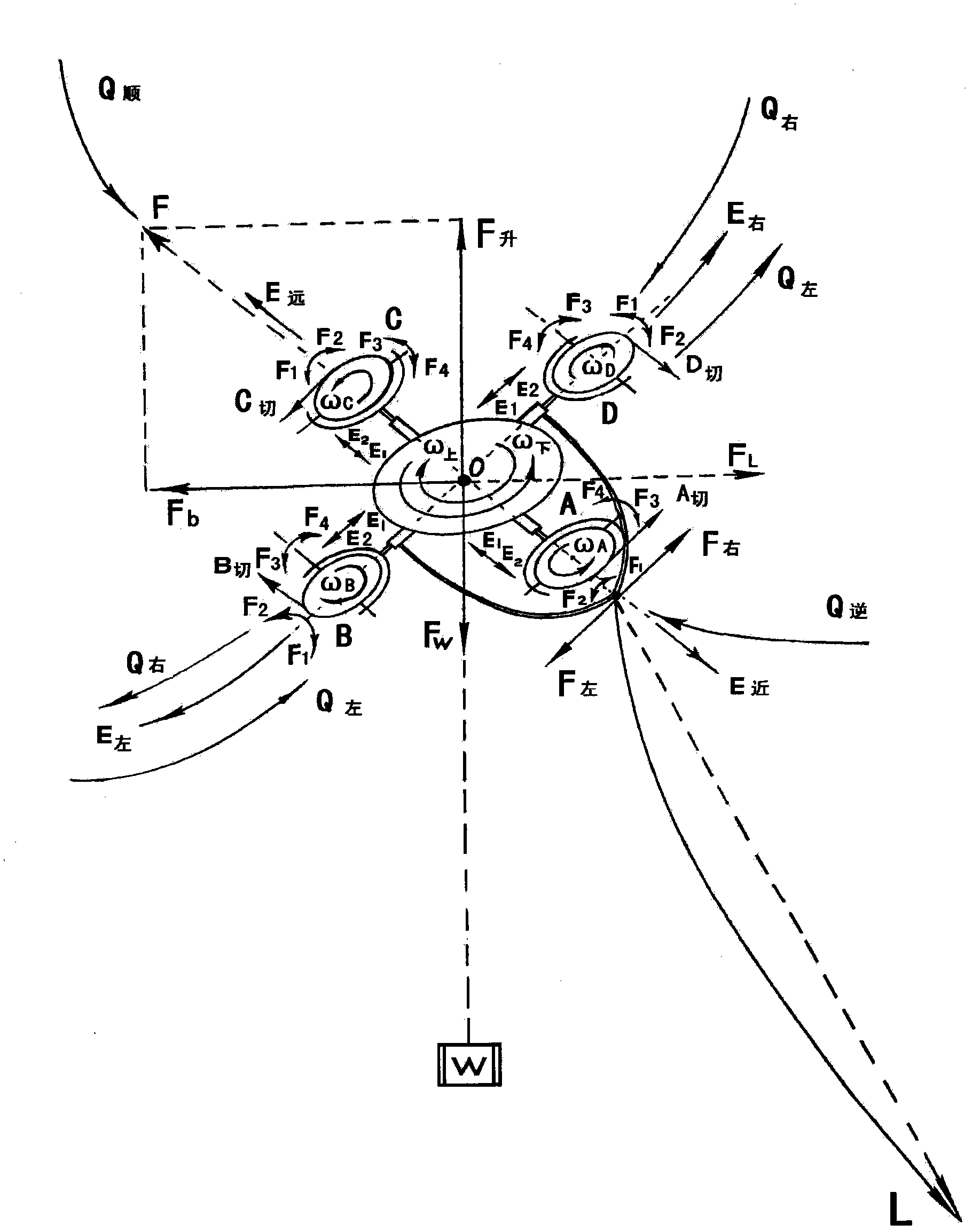

[0781] 1. Specific implementation options for the pneumatic mechanism and layout of the flying crane:

[0782] (1). The preferred scheme of the large-diameter main duct rotor body 5 of the flying crane:

[0783] 1. The large-diameter main duct rotor body 5 of the flying hanger looks like a partial drum shape 29, and the body cavity 14 is provided with an annular mouth-shaped main beam 28 between the partial drum-shaped shell 29 and the main duct H1 of the outer ring layer. The inner wall of the large-diameter main duct in the single-ring layer is marked as 11 with the upper and lower linear ring walls. It is preferable to set the inner wall of the outer ring main duct H1 of the double-ring layer main duct as an up and down linear ring inner diameter wall 11, which is combined with the drum-shaped surface of the main culvert body 5 shell 29, and is collectively called the outer ring main duct H1. The main second duct H2 of the inner ring layer is a linear inner diameter wall 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com