Combined heating fuel cell low-temperature starting system and working method

A start-up system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of serious energy consumption, waste, and increase the complexity of the system, so as to accelerate the heating rate and reduce low-temperature operation Effect of failure rate and guaranteed operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

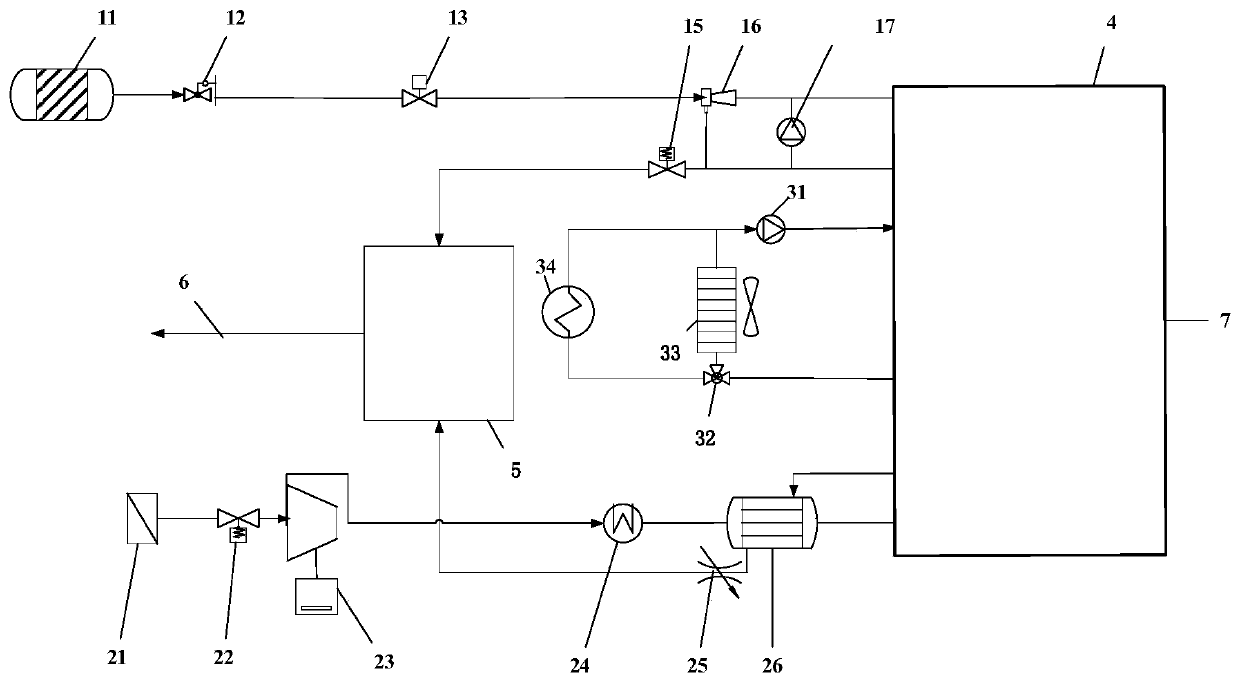

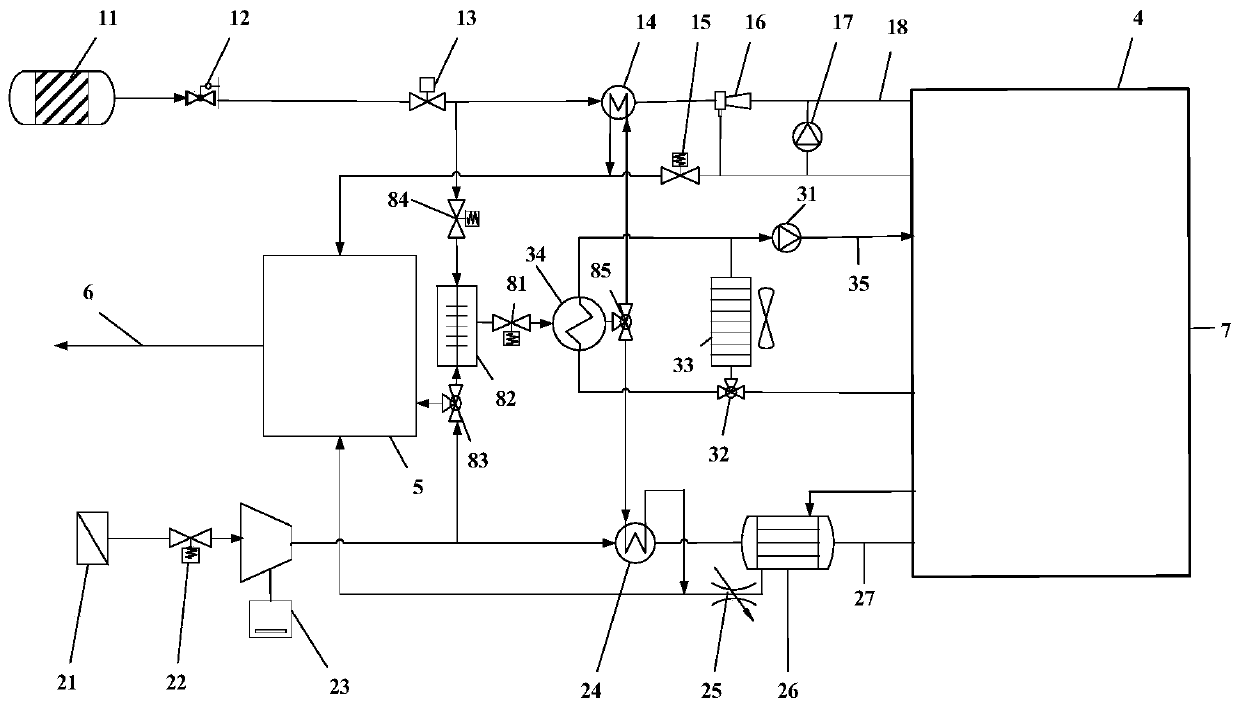

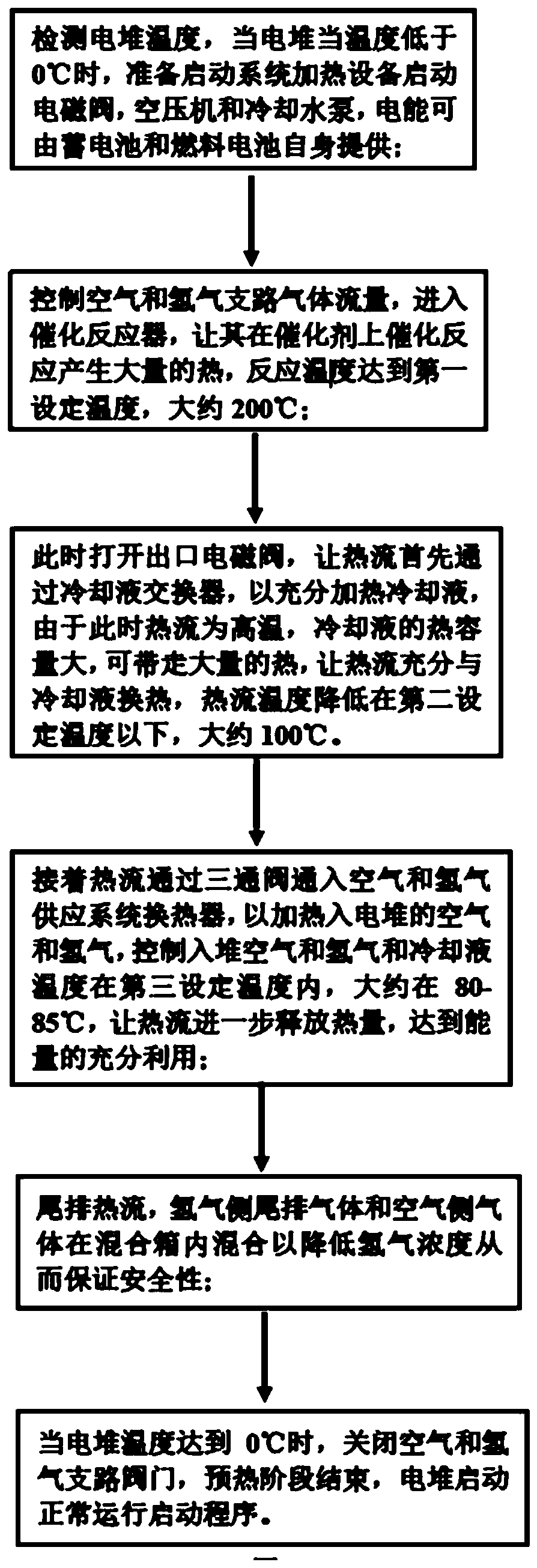

[0039] like figure 1 As shown, the fuel cell system of this embodiment is a fuel cell system in the prior art, and the fuel cell system includes an electric stack 4, an exhaust gas mixing box 5, an air supply pipeline, a hydrogen gas supply pipeline and a coolant circulation pipeline, The stack 4 is provided with a stack temperature sensor 7, and the air supply pipeline and the hydrogen gas supply pipeline are respectively connected to the cathode and the anode of the fuel cell stack 4, and are respectively connected to the exhaust gas mixing box 5, through the exhaust gas mixing box 5, at the end The air exhaust part 6 discharges the waste gas generated after the reaction of the fuel cell stack 4 to the atmosphere, and the cooling liquid circulation pipeline is connected with the electric stack 4 to circulate and provide cooling liquid.

[0040] The hydrogen gas supply pipeline includes a hydrogen tank 11, a pressure reducing valve 12, a hydrogen gas inlet valve 13 and an eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com