Patents

Literature

109results about How to "Guaranteed operating life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises

InactiveCN101955282AHigh salt contentReduce evaporationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectrochemical responseChemistry

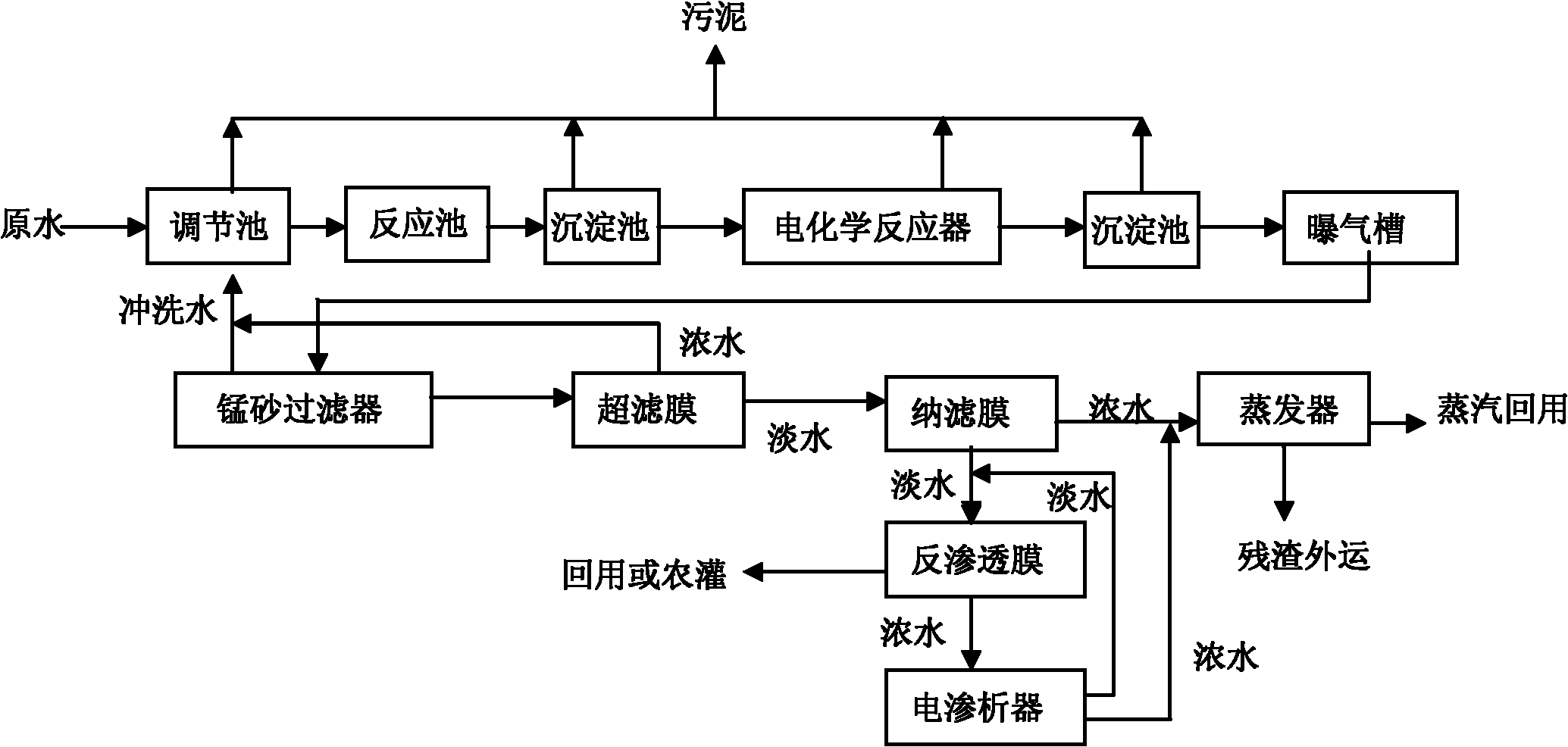

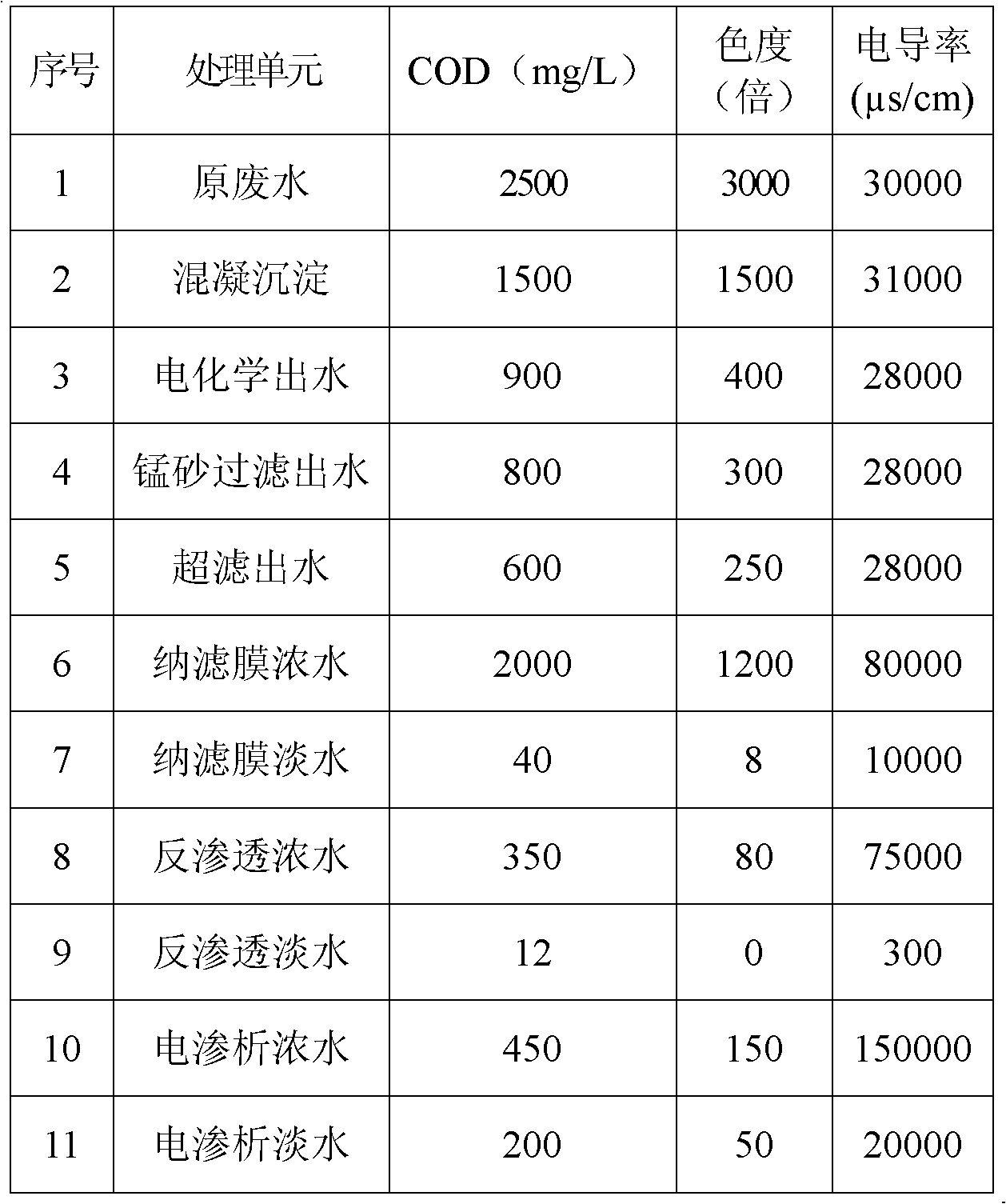

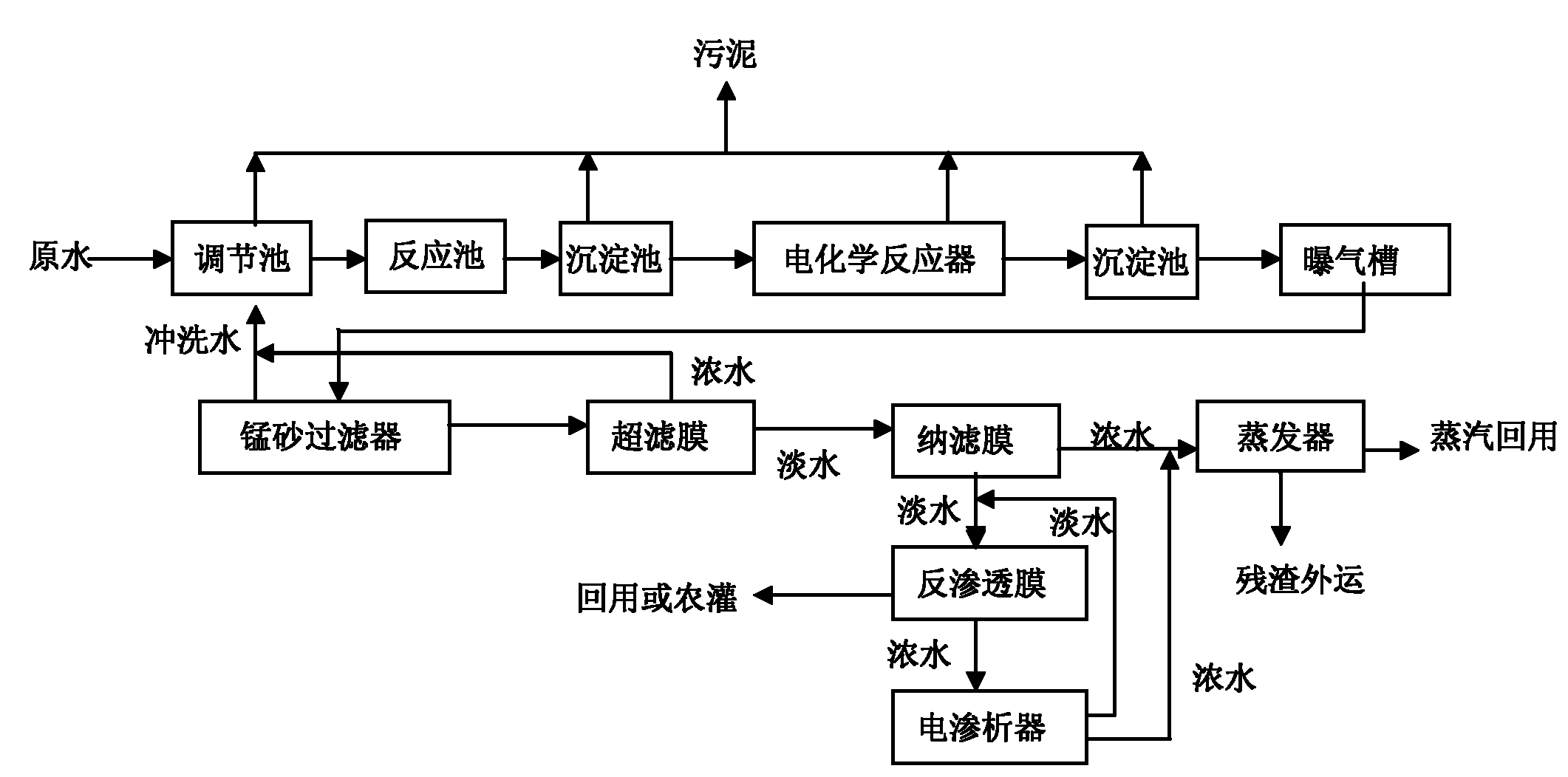

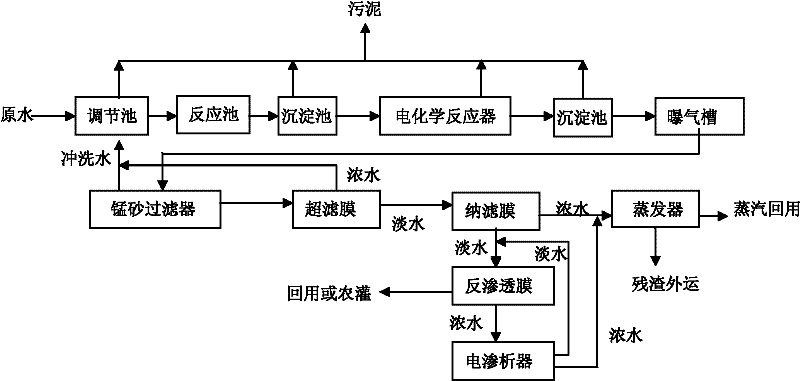

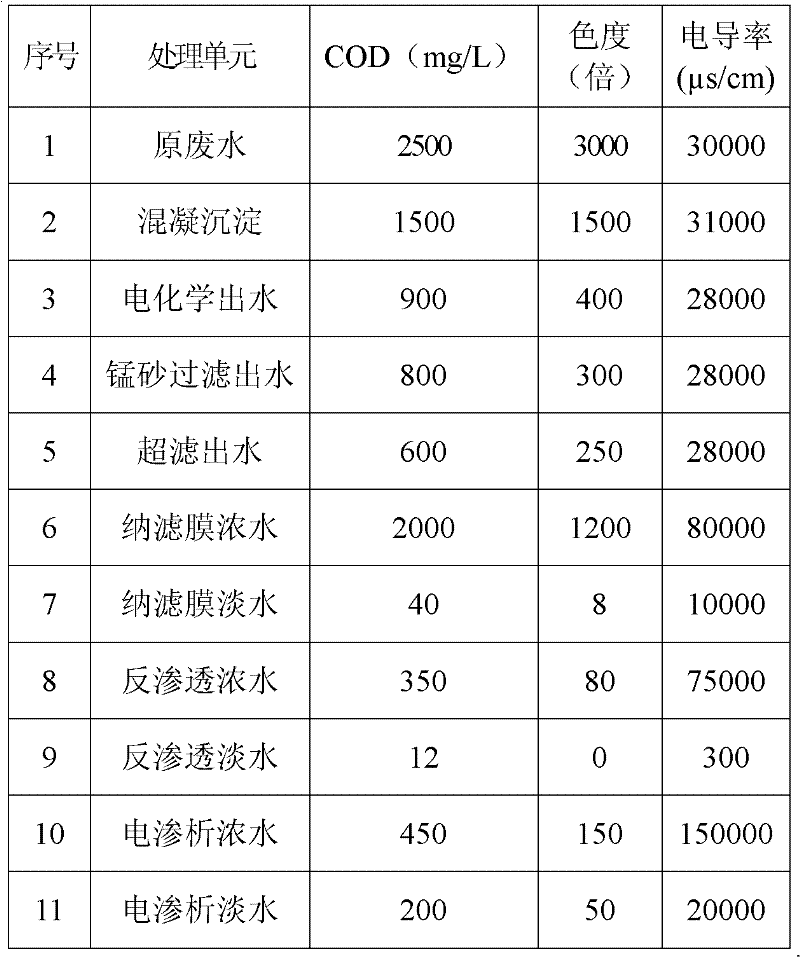

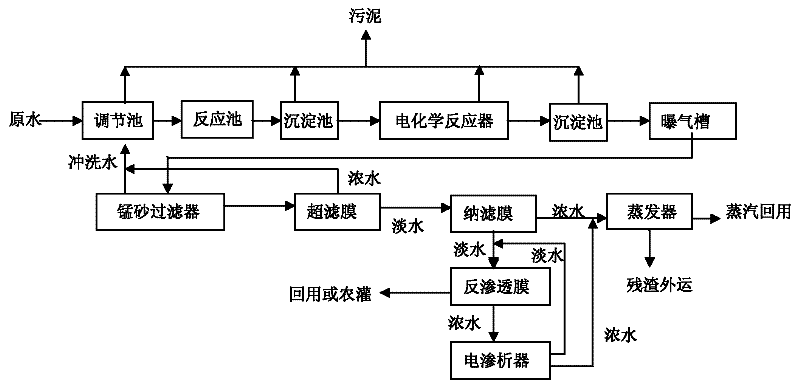

The invention discloses a method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises. The method comprises the following steps that: the wastewater enters a regulating reservoir first for homogenizing, and then enters a reaction tank, ferrous sulfate is added into the reaction tank to regulate the pH value and perform a coagulation reaction, effluent enters a sedimentation basin for precipitating after the reaction, supernate of the sedimentation basin is treated by an electrochemical reactor, enters a secondary sedimentation basin so as to remove scummings and dregs and enters an aeration tank for aerating, and the supernate is filtered by a manganese sand filter for deferrization after the aerating; the filtered effluent is treated by using an ultrafiltration membrane, concentrated water of the ultrafiltration membrane returns to the regulating reservoir, and fresh water enters a nanofilter membrane for treating; the fresh water outputted by the nanofilter membrane enters a reverse osmosis membrane, the outputted concentrated water returns to the regulating reservoir or is evaporated directly; and concentrated water of the reverse osmosis membrane enters an electrodialyzer, electrodialytic fresh water is refluxed to be used as inflow of the reverse osmosis membrane, and electrodialytic concentrated water enters an evaporator for evaporating. Vapor generated by evaporating can be used for printing and dyeing production, residues generated by the evaporating are used as solid wastes, and water pollutants are not discharged in the whole process.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +3

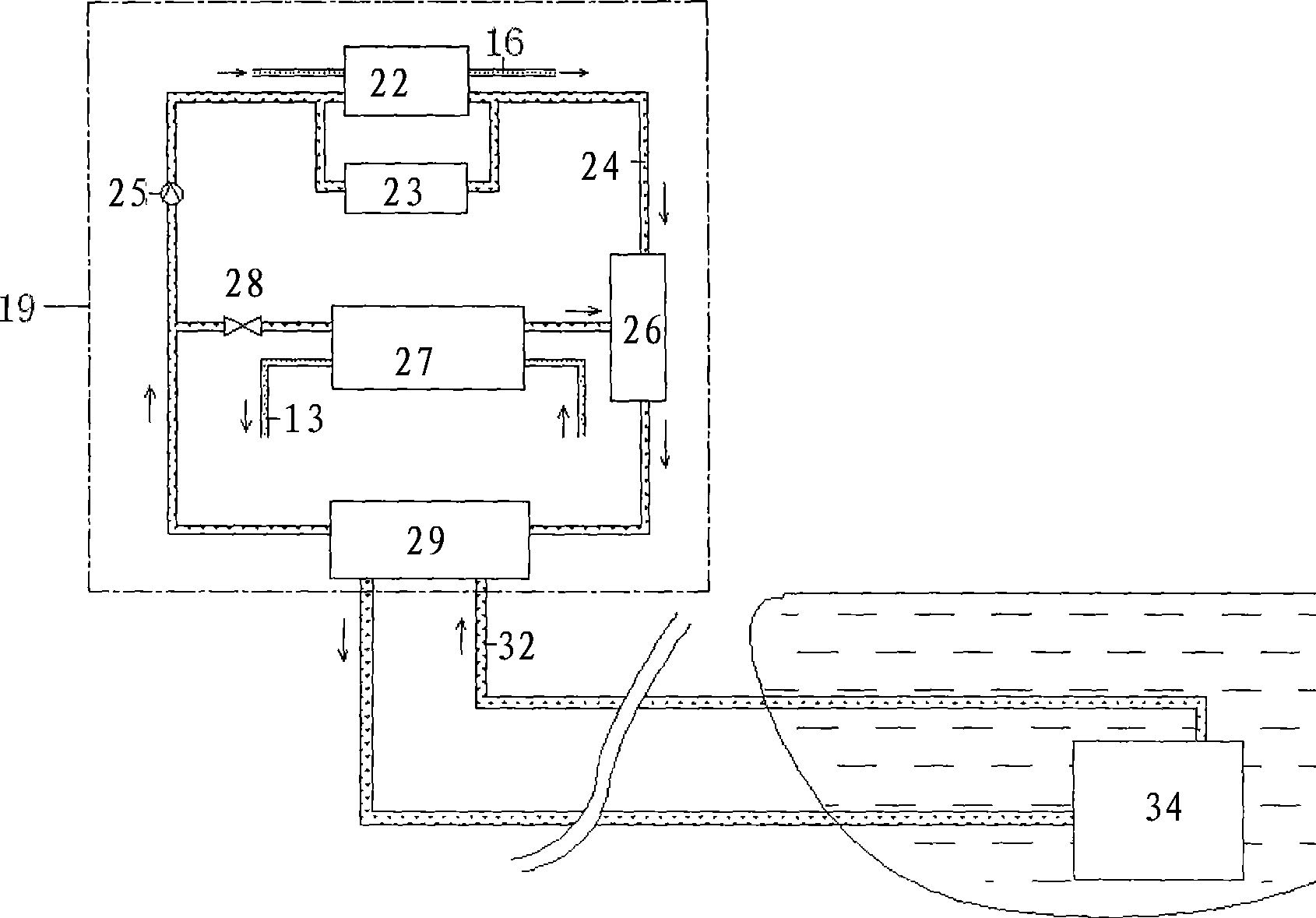

Underground pipe gallery wireless monitoring system

InactiveCN107333113AGuaranteed operating lifeEnsure safetyMeasurement devicesTransmission systemsWireless dataSystem maintenance

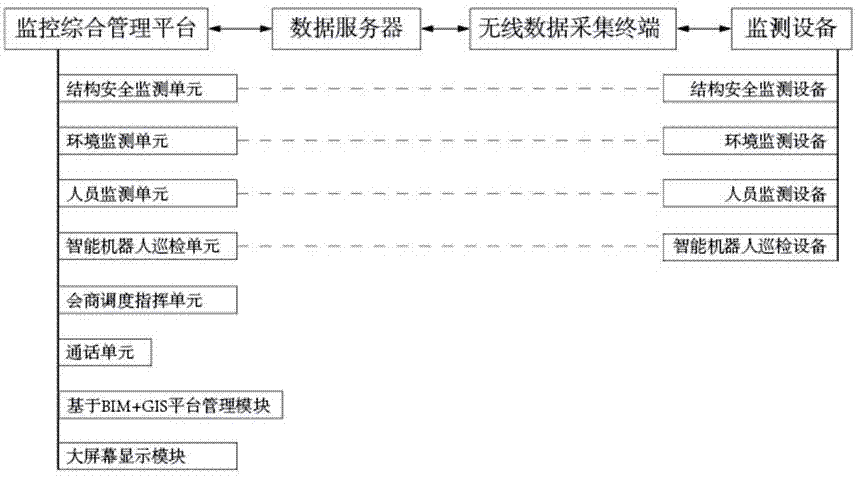

The invention discloses an underground pipe gallery wireless monitoring system, comprising a remote management platform, a data server, a wireless data collection terminal and monitoring devices which can carry out two-way data transmission in sequence. The remote management platform comprises a structure safety monitoring unit, an environment monitoring unit, a personnel monitoring unit, a smart robot inspection unit, a consultation scheduling command unit, a call unit, a BIM+GIS-based platform management module and a large-screen display module. The data server is mainly used for collecting and storing real-time data and processing results of various units, and allocating and storing all business data. According to the system, gallery structure safety monitoring, environment monitoring, personnel positioning, personnel health monitoring, smart robot inspection and wireless communication are integrated; the safety of a pipe gallery and personnel is ensured; the construction wiring is reduced; and the system maintenance is facilitated.

Owner:长沙变化率信息技术有限公司

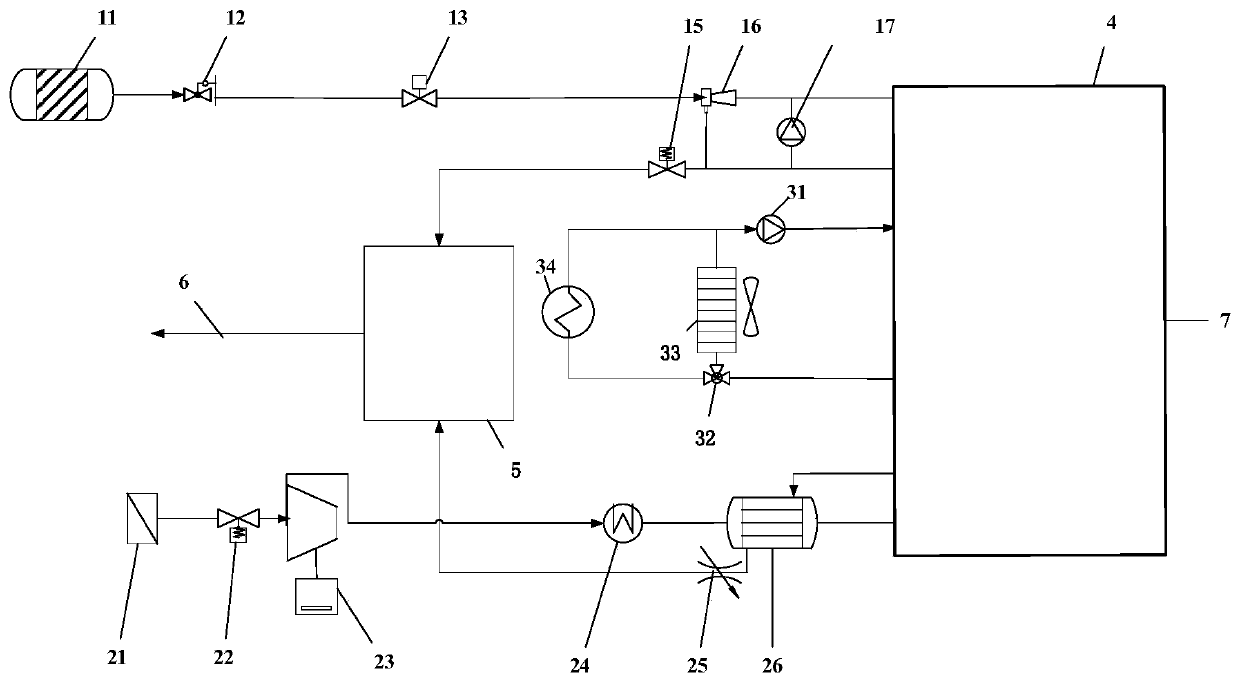

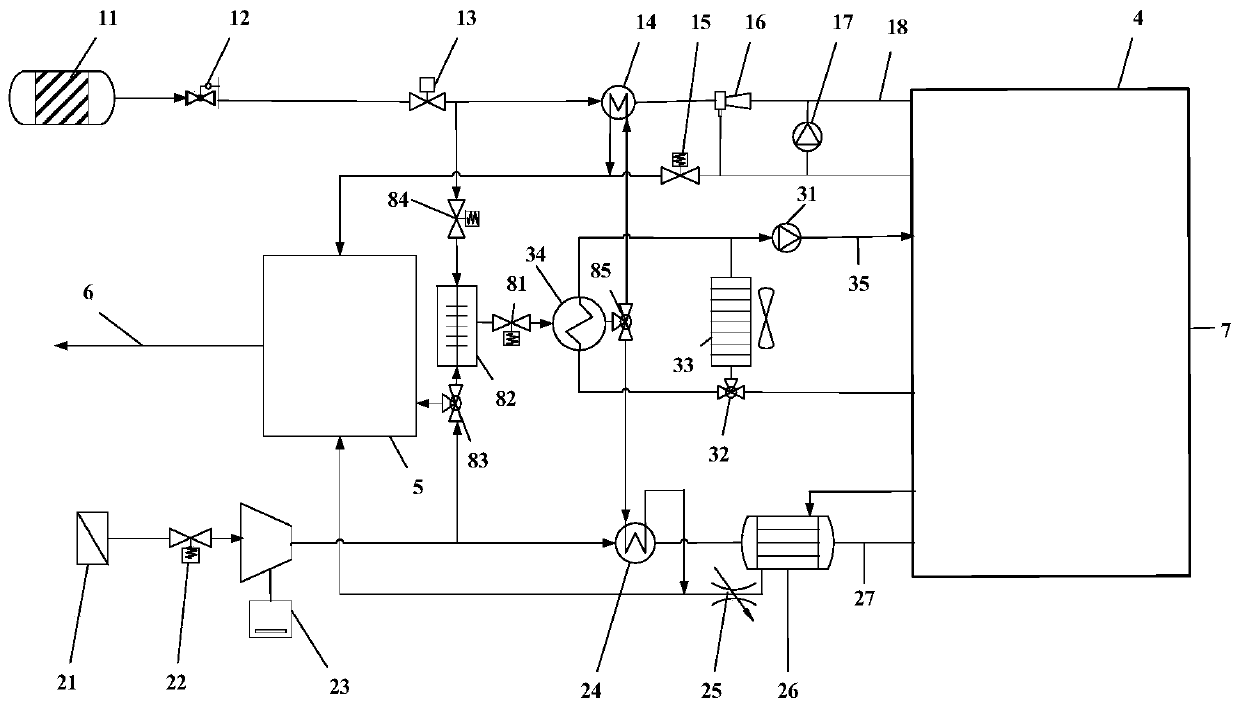

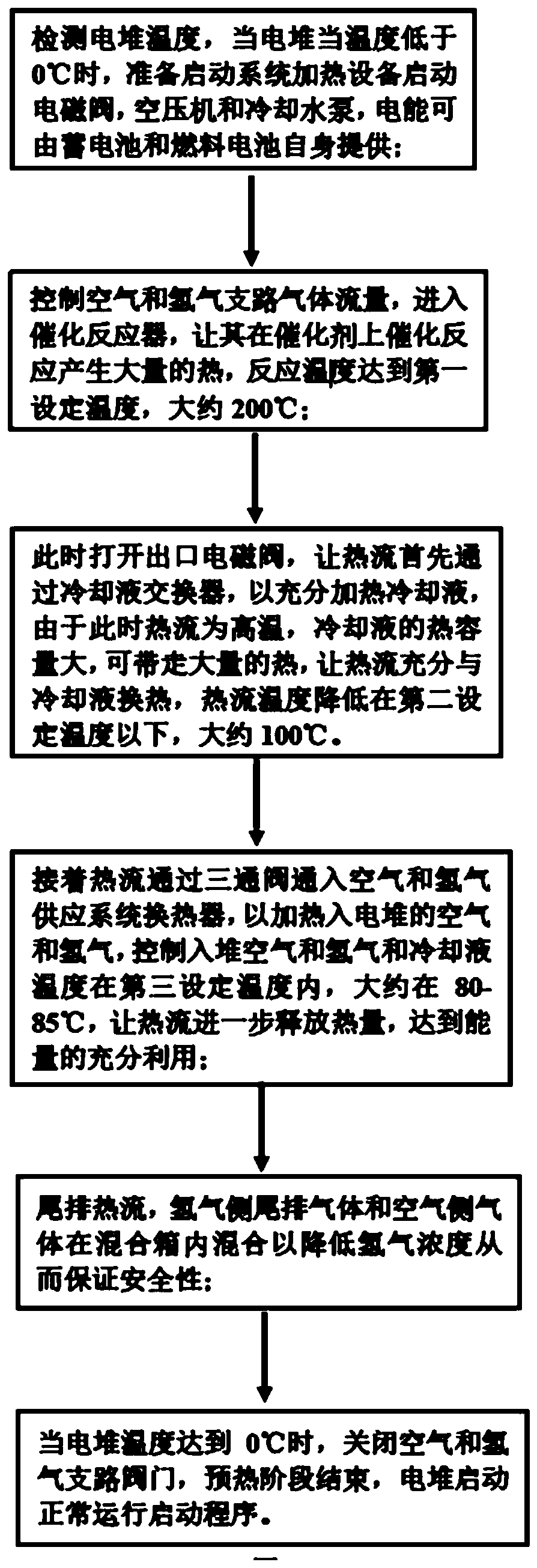

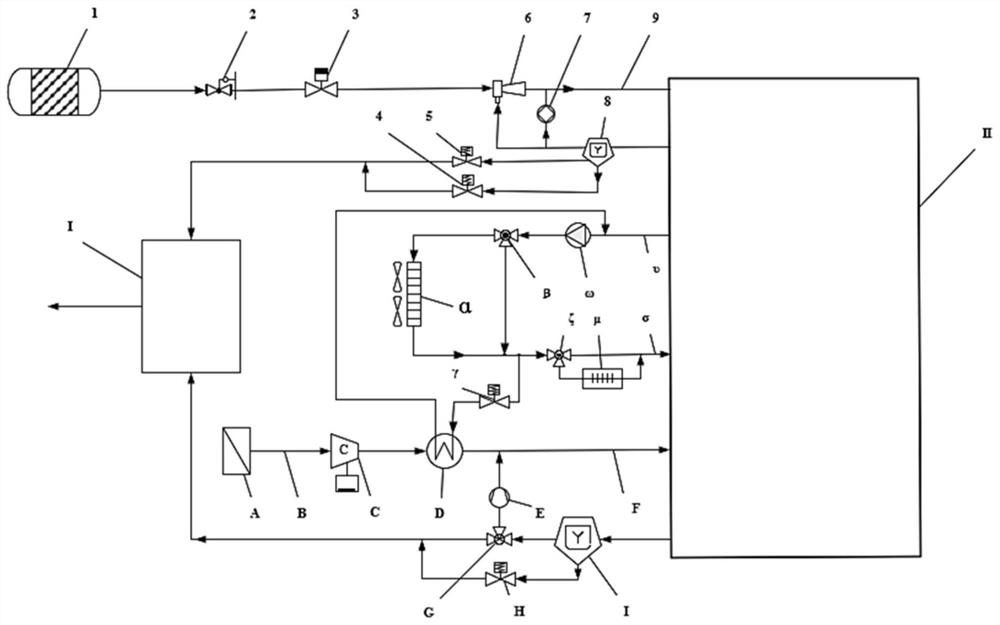

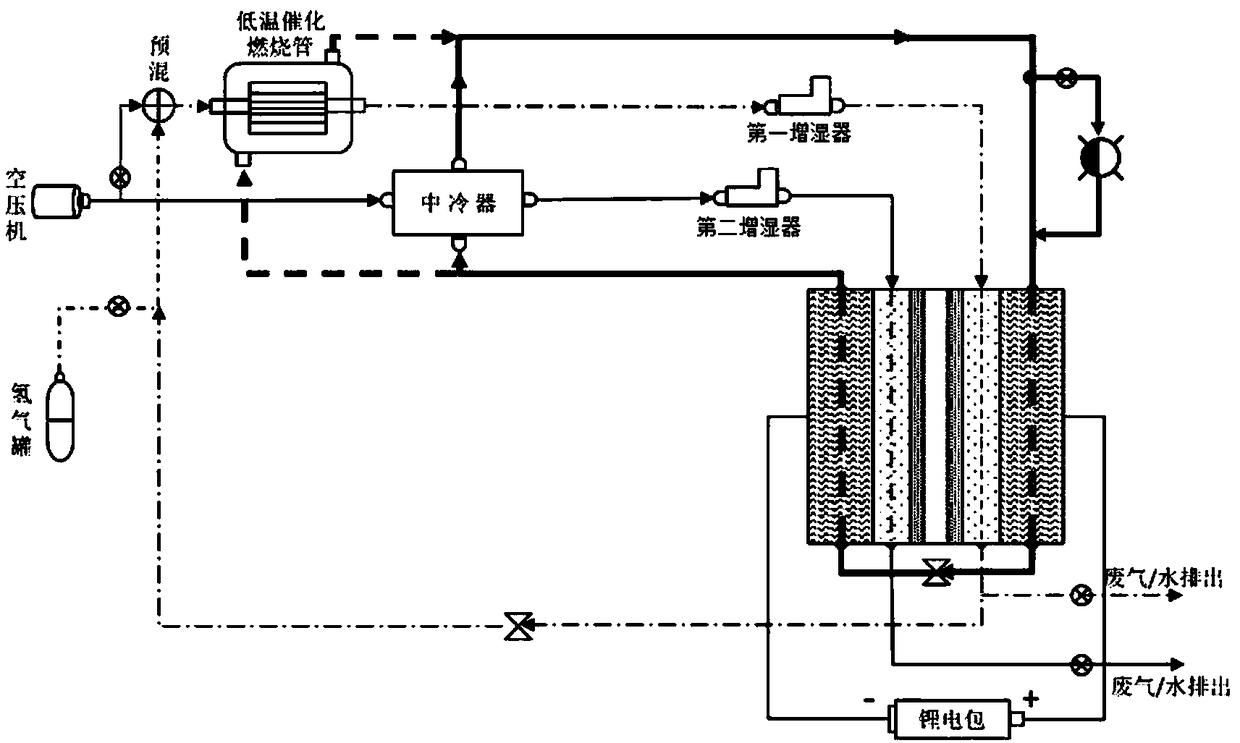

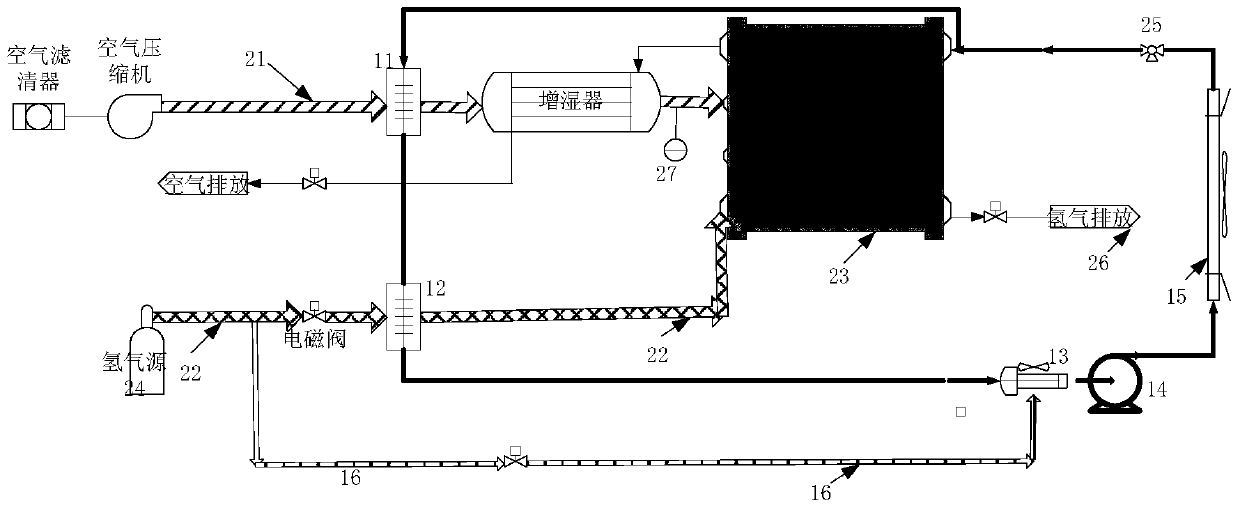

Combined heating fuel cell low-temperature starting system and working method

The invention relates to a combined heating fuel cell low-temperature starting system comprising a cooling liquid circulating pipeline, an electric pile, a waste gas mixing box, and an air supply pipeline and a hydrogen supply pipeline which are connected with the electric pile and the waste gas mixing box. The cooling liquid circulating pipeline is connected with the electric pile; the waste gasmixing box is communicated with the atmosphere to exhaust waste gas. The low-temperature starting system further comprises a heating assembly. The cooling liquid circulating pipeline comprises a cooling liquid heat exchanger; the air supply pipeline comprises an air heat exchanger, the hydrogen supply pipeline comprises a hydrogen heat exchanger, and the heating assembly is connected with the cooling liquid heat exchanger, the air heat exchanger and the hydrogen heat exchanger. Compared with the systems in the prior art, the system has the advantages that the fuel cell can be rapidly started in a low-temperature environment and the energy utilization rate is high.

Owner:TONGJI UNIV

Method and system for active power control of wind turbines

ActiveCN105515061AGuaranteed operating lifeGuaranteed stabilitySingle network parallel feeding arrangementsWind energy generationElectricityTurbine

The embodiment of the invention discloses a method and system for active power control of wind turbines. The method comprises the steps of classifying the wind turbines according to the capability of the wind turbines participating in wind power plant automatic gain control (AGG) boost / reduction power control, and dividing the wind turbines into boost power wind turbines, reduction power wind turbines and power-nonadjustable wind turbines; setting a boost power priority sequence of the boost power wind turbines according to boost power stability, and setting a boost power priority sequence and distribution strategy; setting a reduction power priority sequence of the reduction power wind turbines according to reduction power stability, and setting a reduction power priority sequence and distribution strategy; and controlling the wind turbines to execute boost power or reduction power operation according to the wind power plant AGG boost / reduction power control requirements. According to the wind turbine active power control scheme, factors affecting the service lives of the wind turbines can be fully considered, grouping is performed according to the characteristics of the factors, and corresponding control sequences and strategies are selected to perform active power regulation on the wind turbines, and thus the aging of the wind turbines is slowed down.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

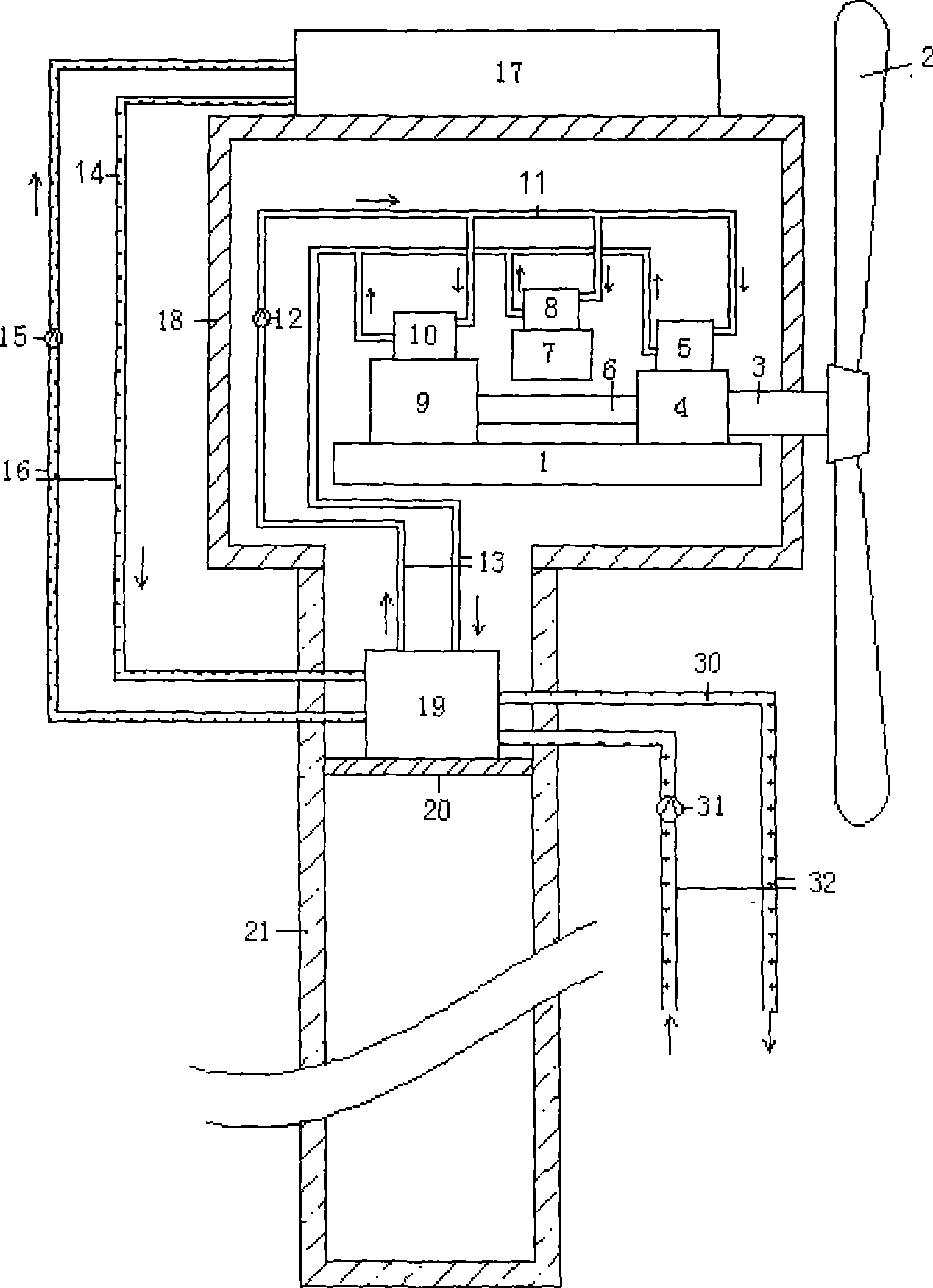

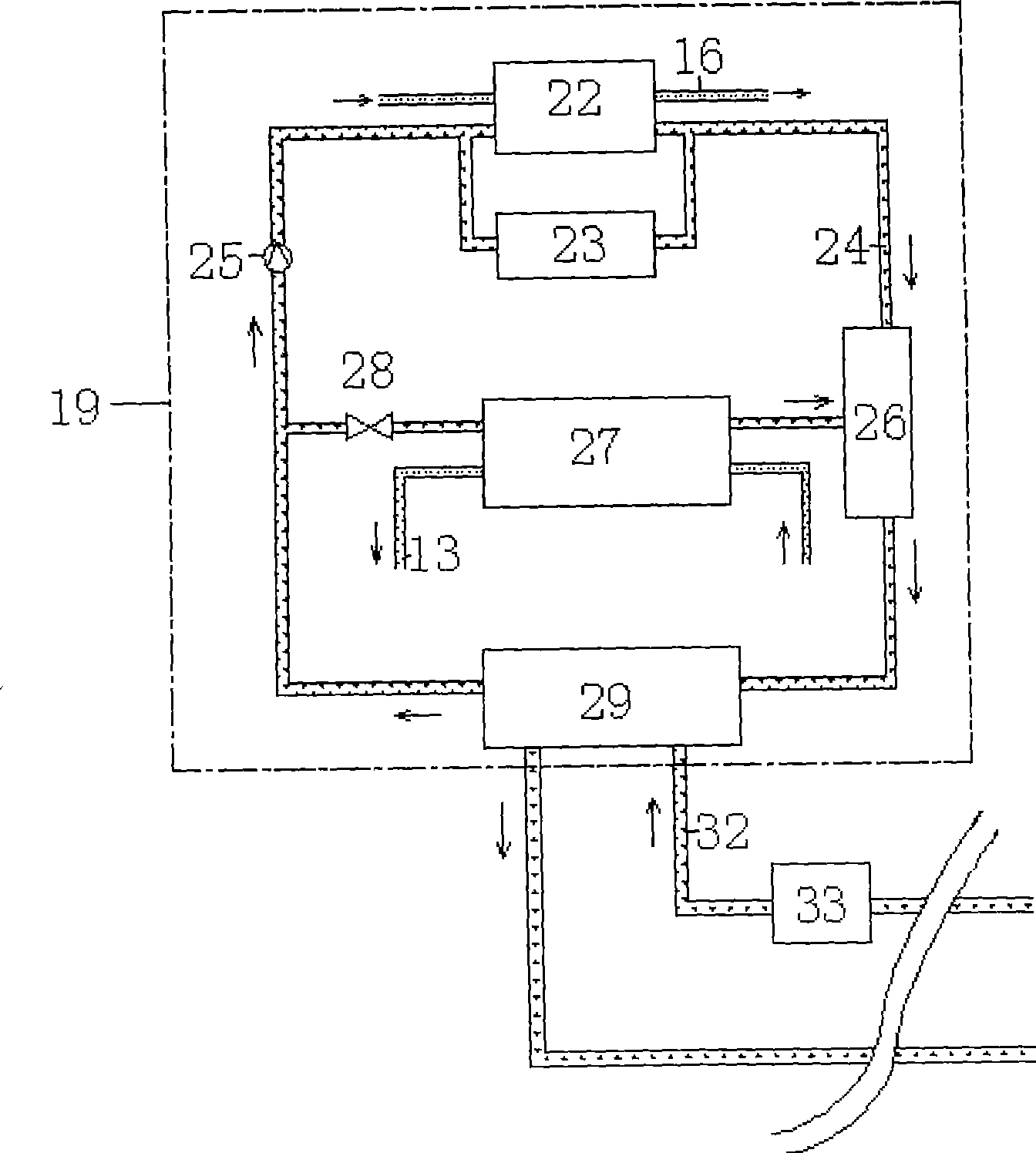

Wind power generator cooled by solar injection

InactiveCN101392729AImprove cooling effectGood environmental benefitsMachines/enginesWind motor combinationsCooling effectElectric generator

The invention discloses a wind power generator adopting solar ejecting type cooling, which belongs to the technical field of wind power generator. The wind power generator mainly comprises a desk frame (1), a wind wheel (2), a slow-speed shaft (3), a gear box (4), a gear box heat exchanger (5), a high speed shaft (6), a controlling frequency converter (7), a controlling frequency converting heat exchanger (8), a generator (9), a generator heat exchanger (10), secondary refrigerants (11), a secondary refrigerant transportation pipe (13), a heat accumulator (14), a heat accumulator transportation pipe (16), cooling media (30), and a cooling media transportation pipe (32). The winder power generator is characterized in that the winder power generator also comprises a solar thermal collector (17) arranged on the outer surface of an engine room cover, and an ejecting type refrigerating machine (19) for cooling and cycling the secondary refrigerants (11) running through the gear box, the controlling frequency converter, and the generator heat exchanger (10). The wind power generator has the advantages of low electric energy consumption, good cooling effect, excellent environmental protection benefit, and the like.

Owner:南京韩威南冷制冷集团有限公司

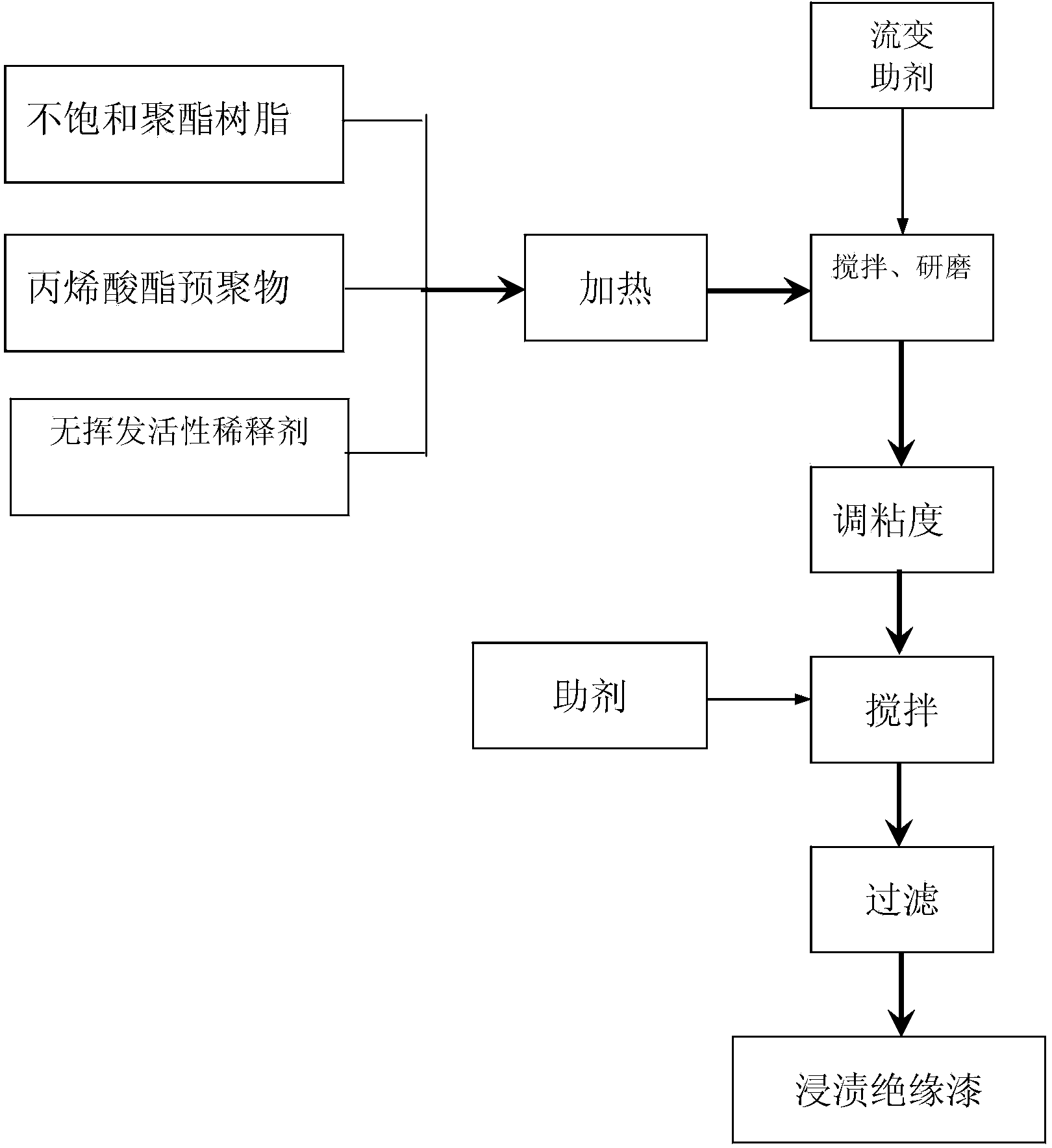

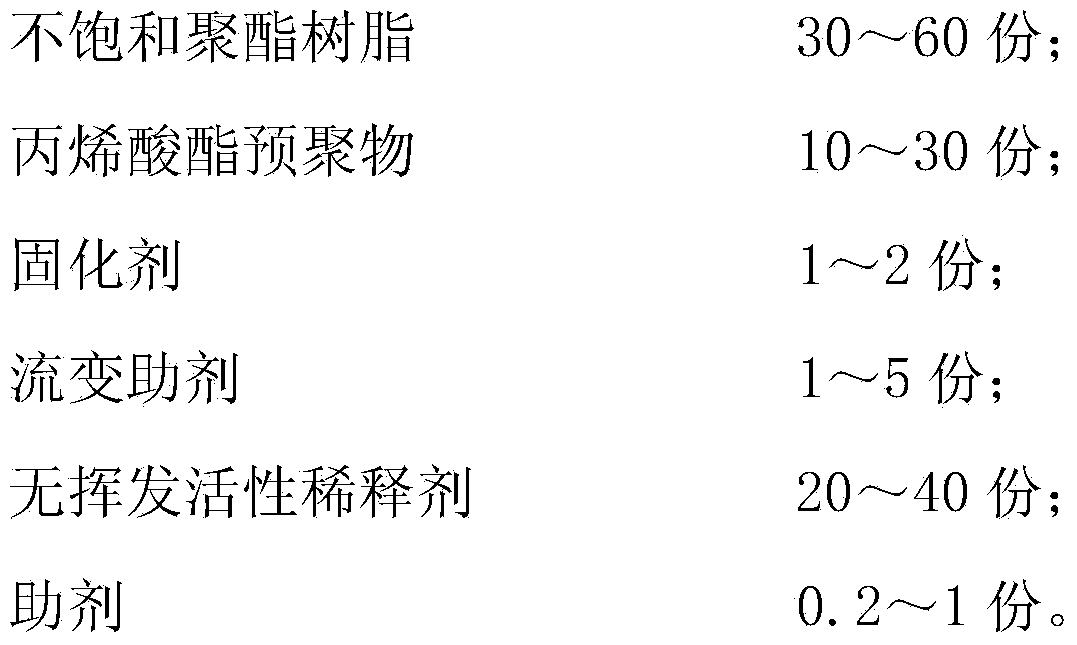

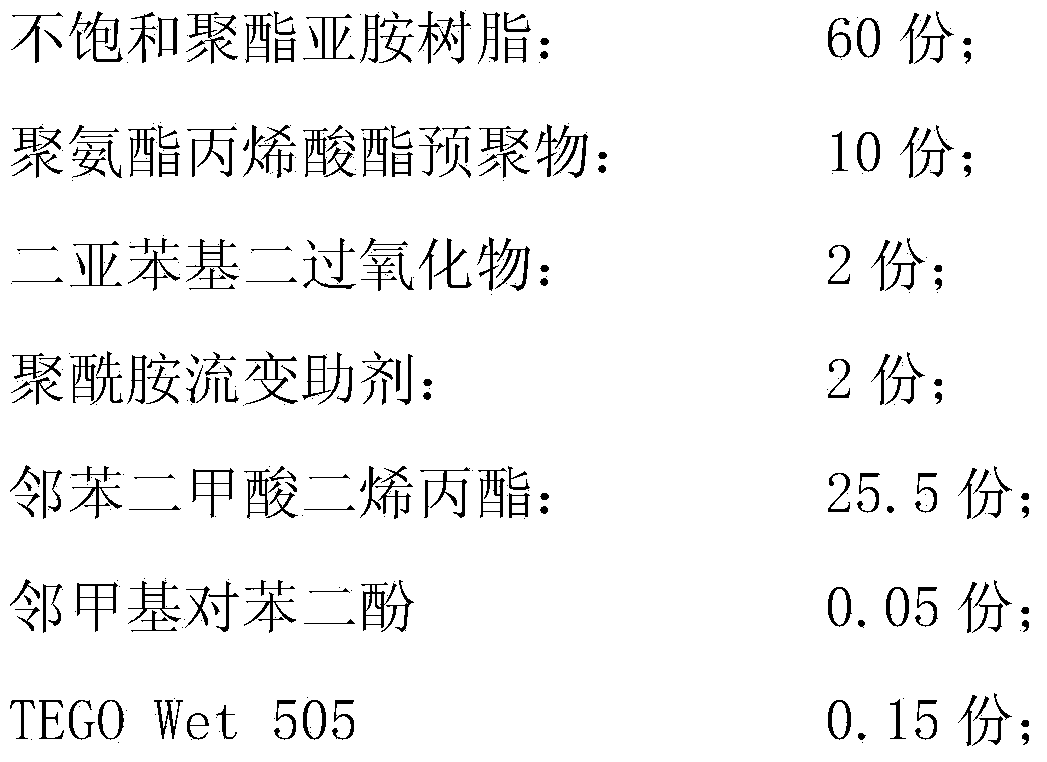

Dipping insulating paint and preparation method therefor

InactiveCN103614053AFast curingShort curing timePolyurea/polyurethane coatingsEpoxy resin coatingsEnvironmental resistancePrepolymer

The invention provides a dipping insulating paint, and relates to an insulating paint for a motor. The dipping insulating paint is prepared from the following raw materials, by weight, 30-60 parts of unsaturated polyester resins, 10-30 parts of acrylic ester prepolymers, 1-2 parts of curing agents, 1-5 parts of rheological additives, 20-40 parts of diluters without volatilization activity, and 0.2-1 part of auxiliary agents. The invention also provides a preparation method for the dipping insulating paint. The dipping insulating paint is environmentally friendly, nontoxic and low baking loss amount, and therefore raises the painting amount of a motor.

Owner:GUANGZHOU BETTER NEW MATERIALS

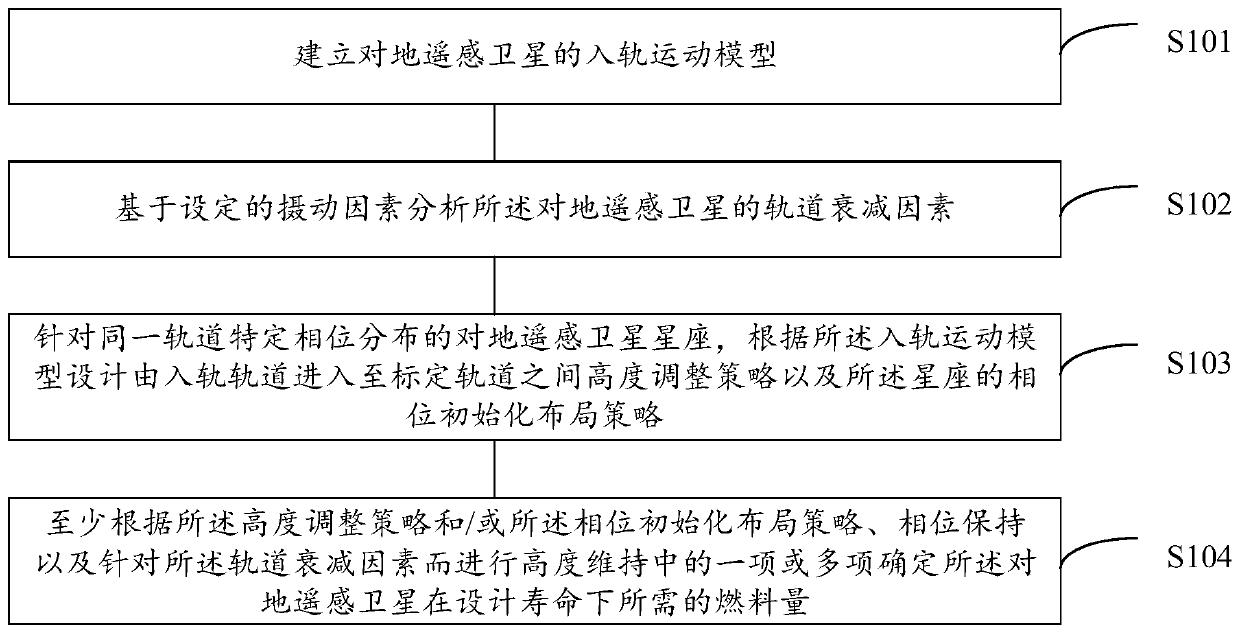

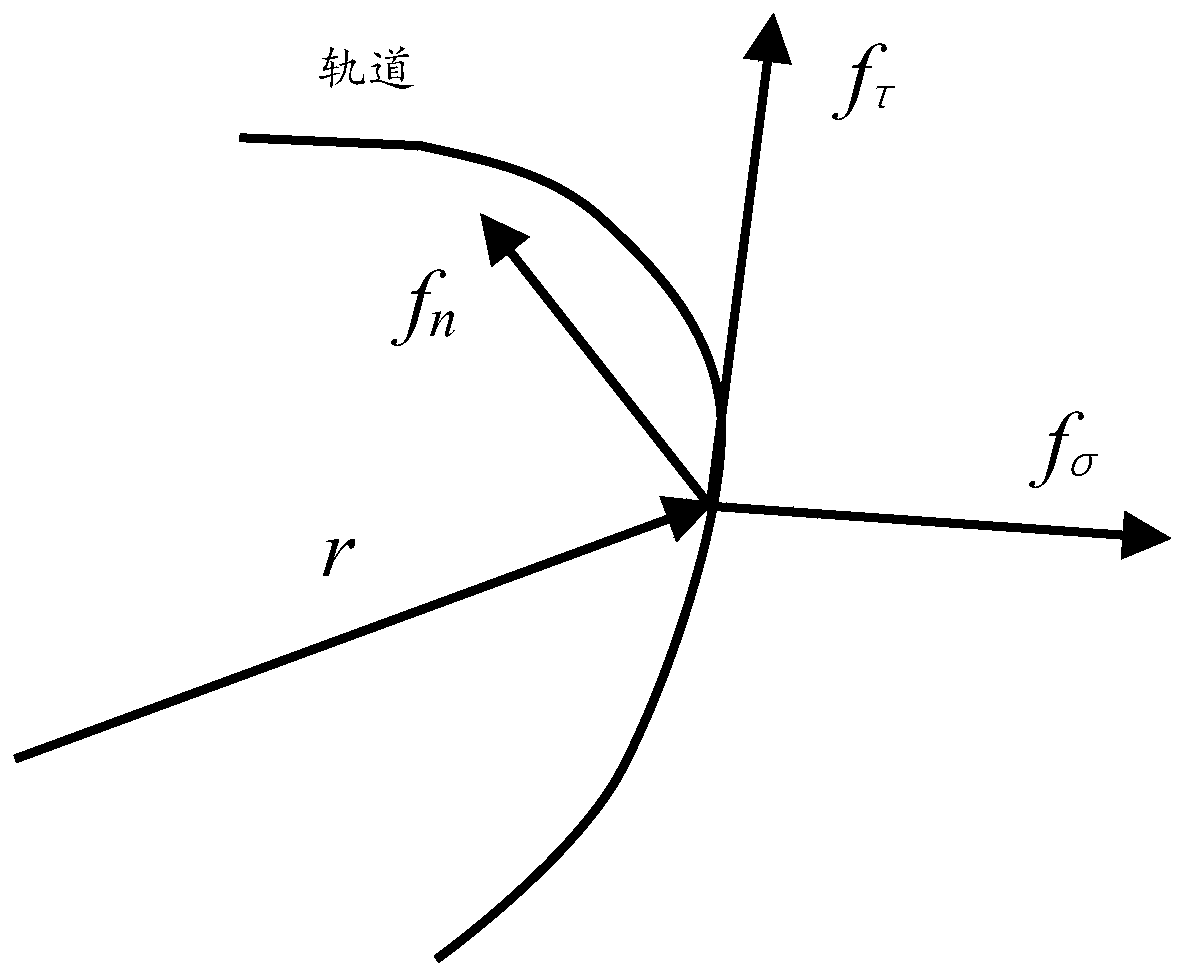

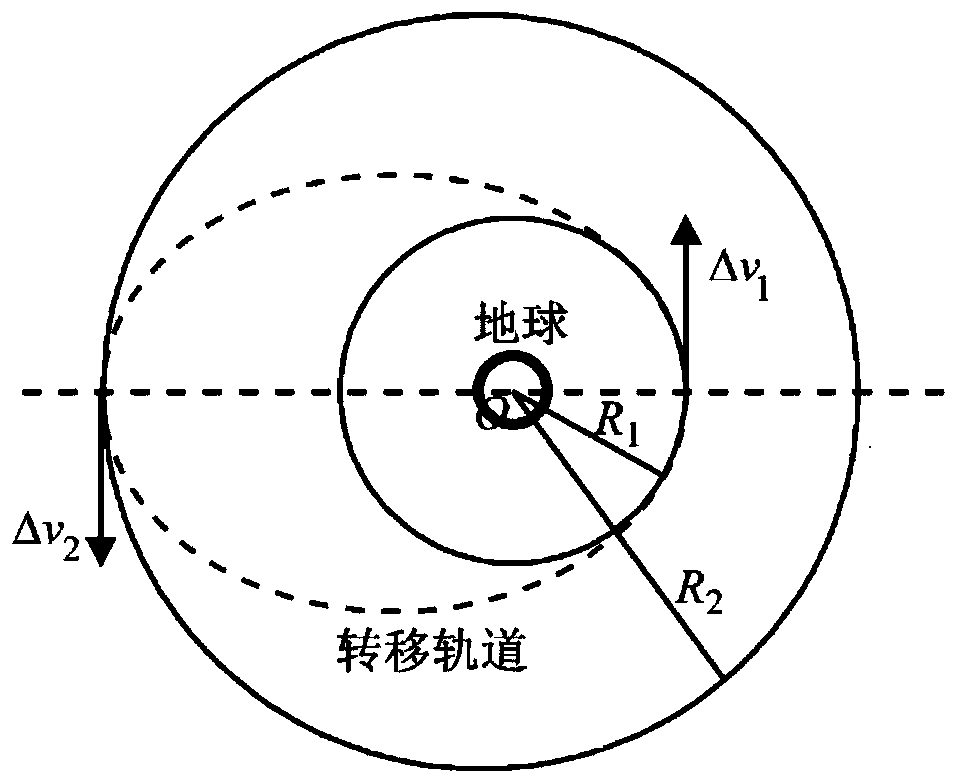

Same-orbit specific phase distribution constellation layout and orbit adjustment method and device based on Hohmann orbital transfer, and computer storage medium

ActiveCN111301715AGuaranteed on-orbit operating lifeGuaranteed operating lifeArtificial satellitesSpacecraft guiding apparatusOrbital decaySatellite constellation

The embodiment of the invention discloses a same-orbit specific phase distribution constellation layout and orbit adjustment method and device based on Hohmann orbital transfer, and a computer storagemedium. The method comprises the following steps: establishing an orbit injection motion model of an earth remote sensing satellite; analyzing an orbit attenuation factor of the earth remote sensingsatellite based on a preset perturbation factor; aiming at the earth remote sensing satellite constellation with specific phase distribution on the same orbit, designing a height adjustment strategy from an injection orbit to a calibration orbit and a phase initialization layout strategy of the constellation according to the orbit injection motion model; and determining the fuel quantity requiredby the earth remote sensing satellite under the designed service life at least according to one or more of the height adjustment strategy and / or the phase initialization layout strategy, phase maintenance and height maintenance for the orbit attenuation factor.

Owner:HARBIN INST OF TECH

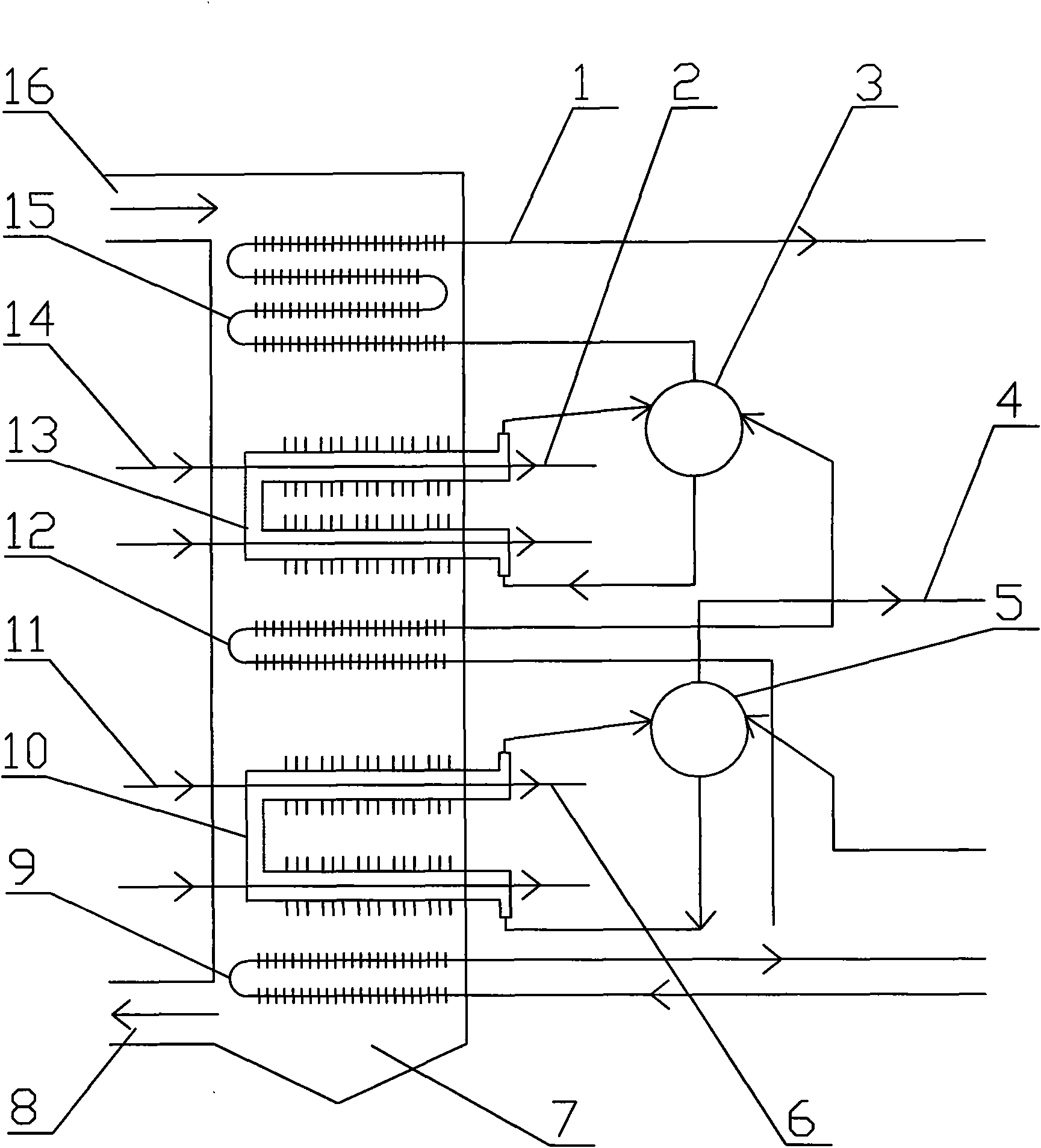

Double-working substance heat source sintering cogeneration-type boiler system

ActiveCN101832718ALarge self-generated electricityImprove heat transfer effectEnergy industryIncreasing energy efficiencyElectricityFlue gas

The invention relates to an afterheat boiler system, in particular to a double-working substance heat source sintering cogeneration-type boiler system. The system comprises a vertical cooling machine, a sintering machine, a cogeneration-type boiler, a steam condensing and compensating turbine and a generator, wherein hot air produced by the vertical cooling machine is introduced into the upper part of the cogeneration-type boiler through a pipeline; warm flue gas in the sintering machine is introduced into a sleeve-type medium-pressure evaporator on the upper-middle part of the cogeneration-type boiler through the pipeline; low-temperature flue gas of the sintering machine is introduced into a sleeve-type low-pressure evaporator on the lower-middle part of the cogeneration-type boiler through the pipeline; medium-pressure over-heat steam produced by the cogeneration-type boiler is introduced into a main steam port of the steam condensing and compensating turbine through the pipeline; and low-temperature saturated steam produced by the cogeneration-type boiler is introduced into the steam compensating port of the steam condensing and compensating turbine through the pipeline so that the steam condensing and compensating turbine drives the generator to generate electricity. By taking energy cascade utilization as a theoretical basis and taking heat exchange equipment of the vertical cooling machine as source equipment, the system integrates and recoveries the afterheat of sintering flue gas efficiently and realizes the maximum generated electricity converted from heat power.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

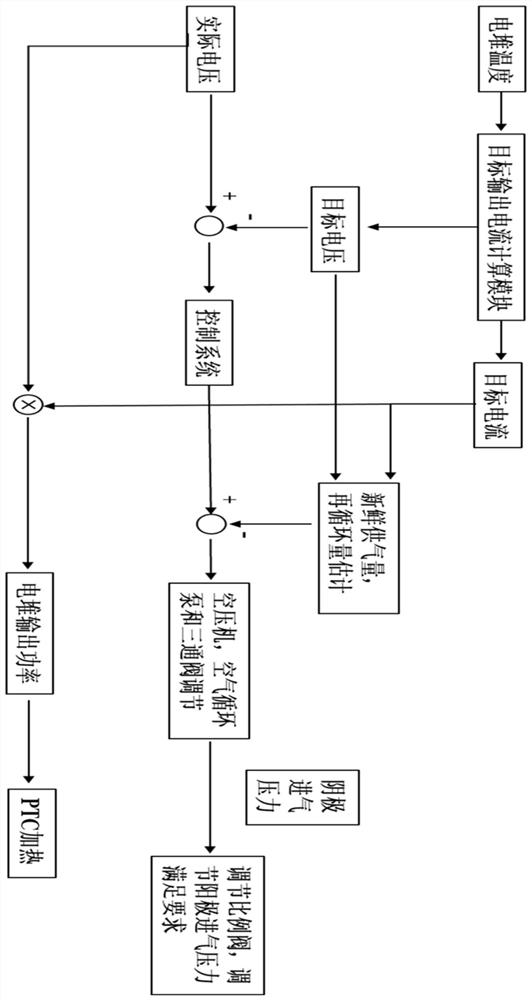

Fuel cell system and low-temperature starting control method thereof

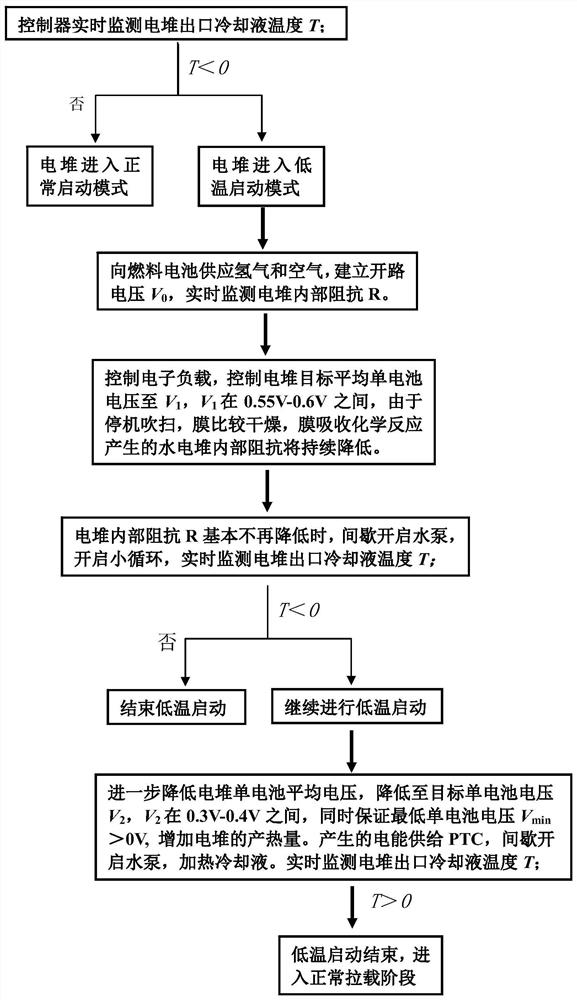

ActiveCN113629269AImprove performanceIncrease drynessFuel cell heat exchangeFinal product manufactureElectronic loadFuel cells

The invention relates to a fuel cell system and a low-temperature starting control method thereof. In the low-temperature starting process, the voltage of a galvanic pile is controlled in a staged mode through an electronic load, the output current of the galvanic pile is controlled in a staged mode, a drying film can absorb generated water easily, the performance of the galvanic pile is improved, and the heat yield of the galvanic pile is further increased by controlling the voltage of the galvanic pile. The galvanic pile is heated, and pore spaces of the catalyst layer and the diffusion layer are fully utilized; besides, the generated electric energy is directly supplied to the PTC to heat the cooling liquid, and in order to prevent the PTC from being overheated and discontinuously starting a water pump, the opening degree of a thermostat is controlled to enable the fuel cell system to work in a small cycle, and the PTC directly heats the cooling liquid. Compared with the prior art, quick start of the fuel cell in a low-temperature environment is facilitated, the low-temperature starting success rate of the fuel cell is improved, and the service life of the fuel cell at a low temperature is prolonged.

Owner:TONGJI UNIV

Method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises

InactiveCN101955282BHigh salt contentReduce evaporationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectrochemical responseUltrafiltration

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +3

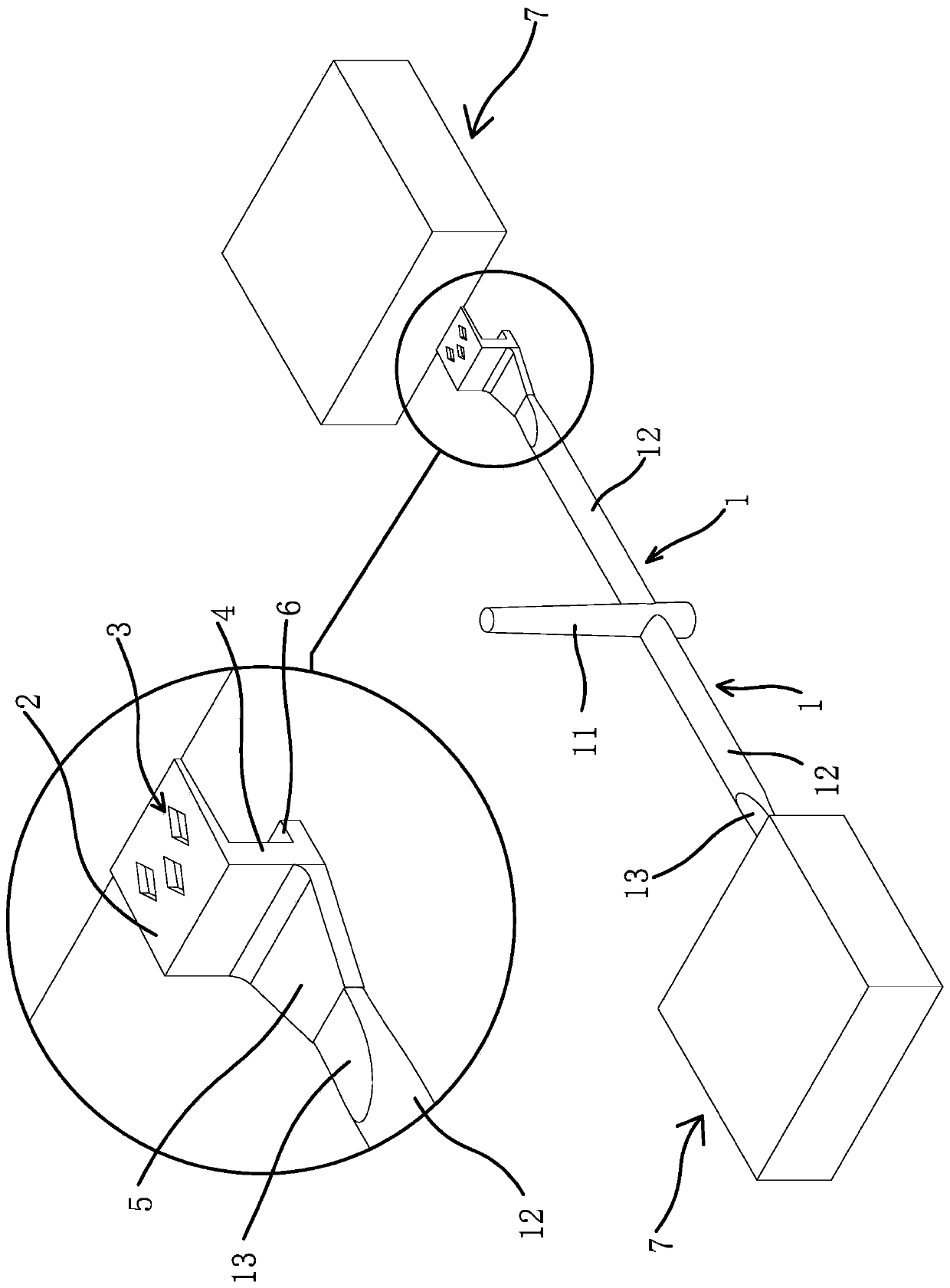

Variable-pitch air door mechanism for vertical-axis wind power generation device

InactiveCN111520281ASimple structureEasy to operateWind motor controlRenewable energy generationExtreme weatherNew energy

The invention relates to the technical field of new energy, and discloses a variable-pitch air door mechanism for a vertical-axis wind power generation device. The variable-pitch air door mechanism comprises a variable-pitch air door mechanism body, an air door upper guard belt, an air door lower guard belt and air door panels, wherein the variable-pitch air door mechanism body is located on the peripheries of a movable blade rotor and a guide blade stator, a plurality of movable blades are arranged on the movable blade rotor, guide blades are arranged on the guide blade stator, the variable-pitch air door mechanism body is provided with the air door panels, a plurality of air collection section side plates are arranged on the outer side of the air door panels, the movable blades, the guide blades, the air door panels and the air collection section side plates are in one-to-to-one correspondence, the air door panels are annularly distributed and rotatably arranged between the air doorupper guard belt and the air door lower guard belt, and every two adjacent air door panels, the air door upper guard belt and the air door lower guard belt form a gradually-shrunk channel. According to the variable-pitch air door mechanism, variable pitch adjustment of the vertical-axis wind power generation device can be completed, the power of a wind turbine is effectively and safely adjusted according to the set working condition, and the effect of protecting the vertical-axis wind power generation device in extreme weather states such as storm wind is achieved.

Owner:BEIJING HENGJU CHEM GRP +1

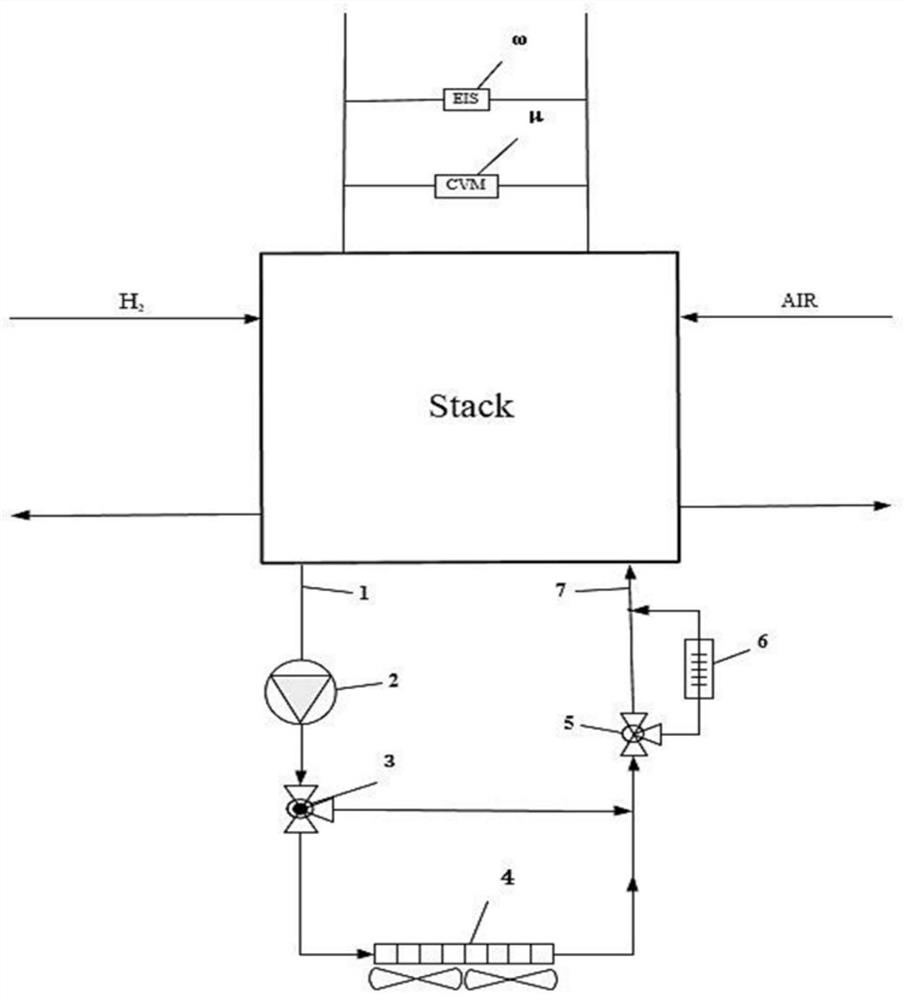

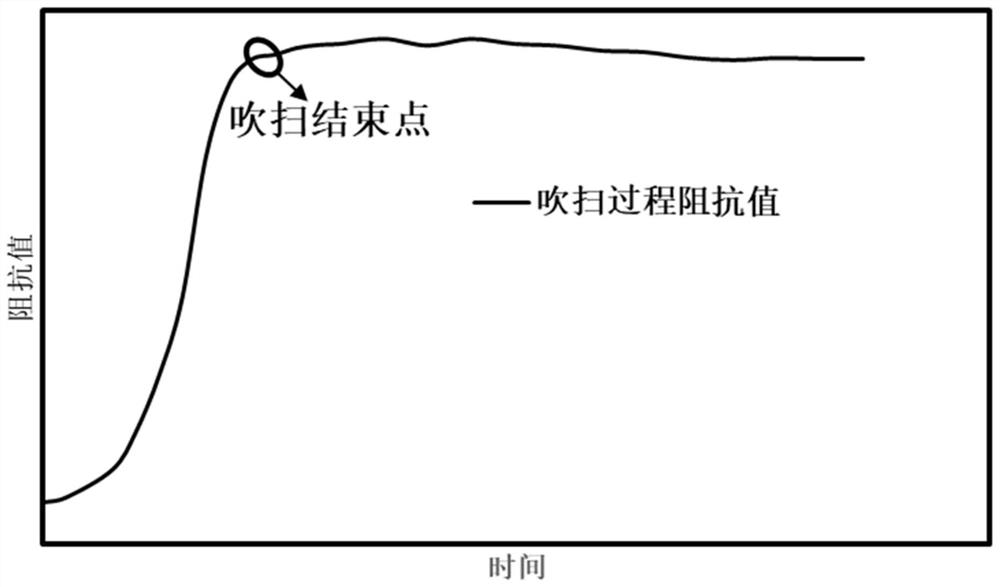

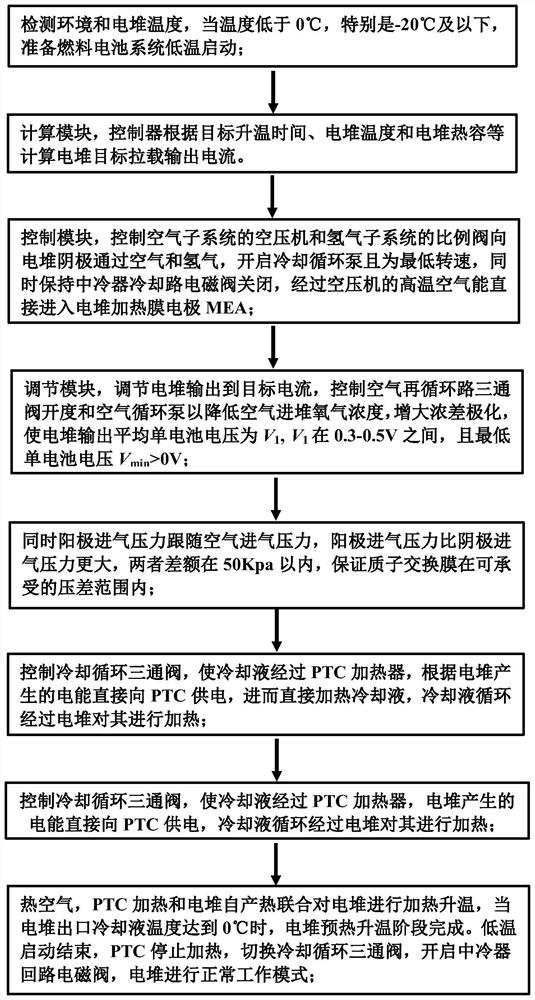

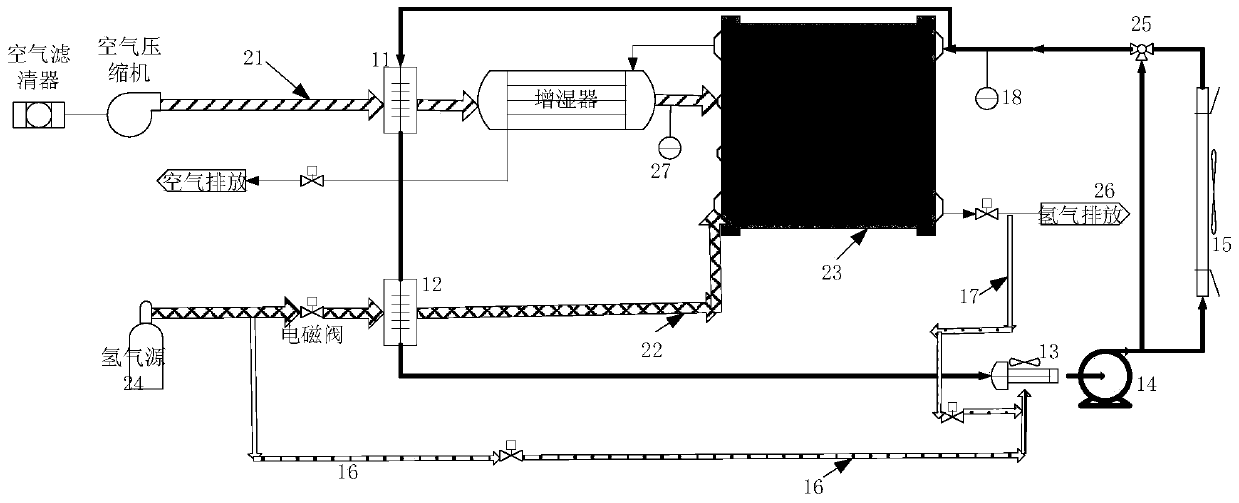

Fuel cell cathode recirculation low-temperature starting system and control method thereof

ActiveCN113629270AGuaranteed operating lifeNormal startFuel cell heat exchangeReactant parameters controlThermodynamicsProcess engineering

The invention relates to a fuel cell cathode recirculation low-temperature starting system and a control method thereof. The system comprises an air supply subsystem, a hydrogen supply subsystem and a cooling circulation subsystem. Through system control, hot air directly heats an MEA, electric energy output by a galvanic pile enables a PTC to heat cooling liquid, the operation conditions of the galvanic pile are controlled to increase self-produced heat, so that the galvanic pile is jointly heated, energy is utilized to the maximum extent to heat the galvanic pile, and the low-temperature starting capability is enhanced; when the temperature of the cooling liquid at the outlet of the galvanic pile reaches 0 DEG C, the galvanic pile preheating temperature rise stage is completed. Compared with the prior art, the method is beneficial to realizing quick start of the fuel cell in a low-temperature environment, the failure rate of low-temperature start of the fuel cell is reduced, and the service life of the fuel cell at a low temperature is prolonged.

Owner:TONGJI UNIV

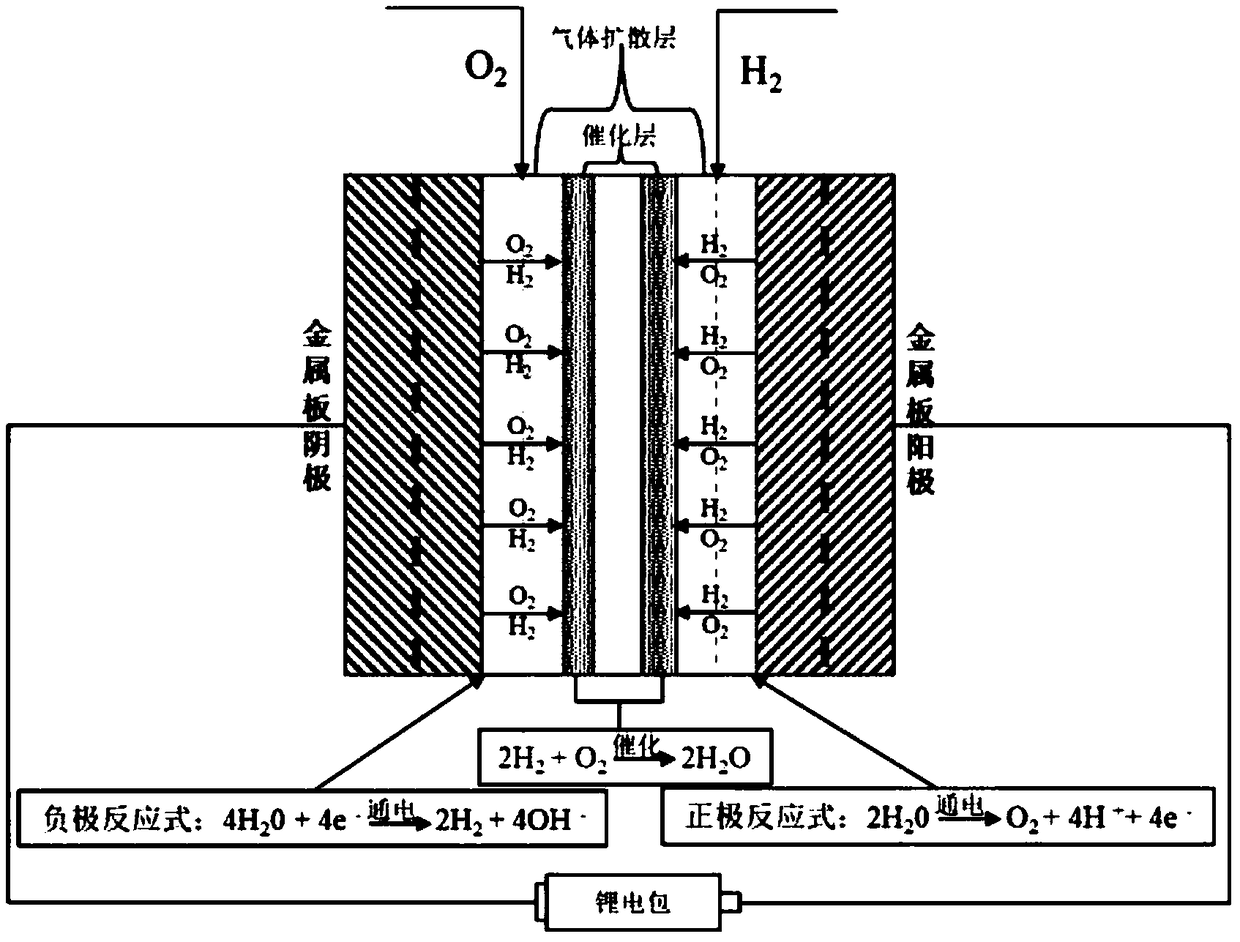

A metal stack fuel cell low-temperature start-up thermal control system and operation method

The invention discloses a metal stack fuel cell low-temperature start-up heat control system and an operation method. The metal stack fuel cell low-temperature start-up heat control system comprises an external heat source heating system, an internal heat source heating system, a pressure / temperature patrol inspection system and a control system. The external heat source heating system is used forheating the metal stack from the outside; the internal heat source heating system is used for heating the metal stack from the inside; the pressure / temperature patrol inspection system is used for patrol inspection of the pressure and temperature on the metal stack fuel cell; the control system is used for integrated control of the metal stack fuel cell before and after the low temperature start-up is completed. The invention effectively enables the metal stack fuel cell to start quickly by utilizing the heat system integrating an external heat source and an internal heat source without usingtoo much auxiliary equipment, and effectively alleviate the permanent damage to the metal stack caused by the start-up failure.

Owner:SHANGHAI UNIV

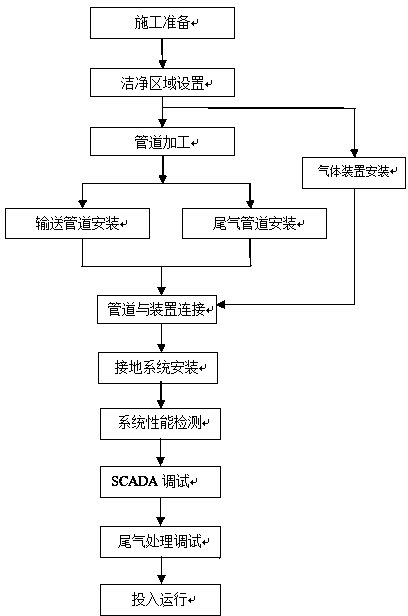

Installing construction method for semiconductor manufacture procedure gas conveying pipelines

ActiveCN104455722AQuick disassemblyGuaranteed stabilityPipe laying and repairShielding gasMass spectrometry

The invention discloses an installing construction method for semiconductor manufacture procedure gas conveying pipelines. The installing construction method includes the following steps that (1), a clean region is preset on a construction site, and a clean space is constructed; (2), all apparatuses used for construction are retested and sealed to prevent contamination; (3), the pipeline is cleanly machined in a sealed mode unit by unit in the clean space, and pipe orifices are sealed immediately after machining is completed; (4), the conveying pipeline is installed, protective gas is continuously injected in the pipeline in the installing process and at the operation intervals; (5), the tail gas pipeline is installed according to the structure of a plasma and washing processing system; (6), a gas device is installed, and the pipelines are connected with the gas device in a radial face seal connecting mode; (7), an electrostatic grounding system and an outdoor anti-thunder electric induction grounding system are installed; (8), pressure detection, helium mass spectrum leakage detection, moisture detection, cleanliness detection and oxygen detection are carried out until all results are qualified; (9), a tail gas treatment test is carried out until a test result is qualified.

Owner:成都建工第三建筑工程有限公司 +1

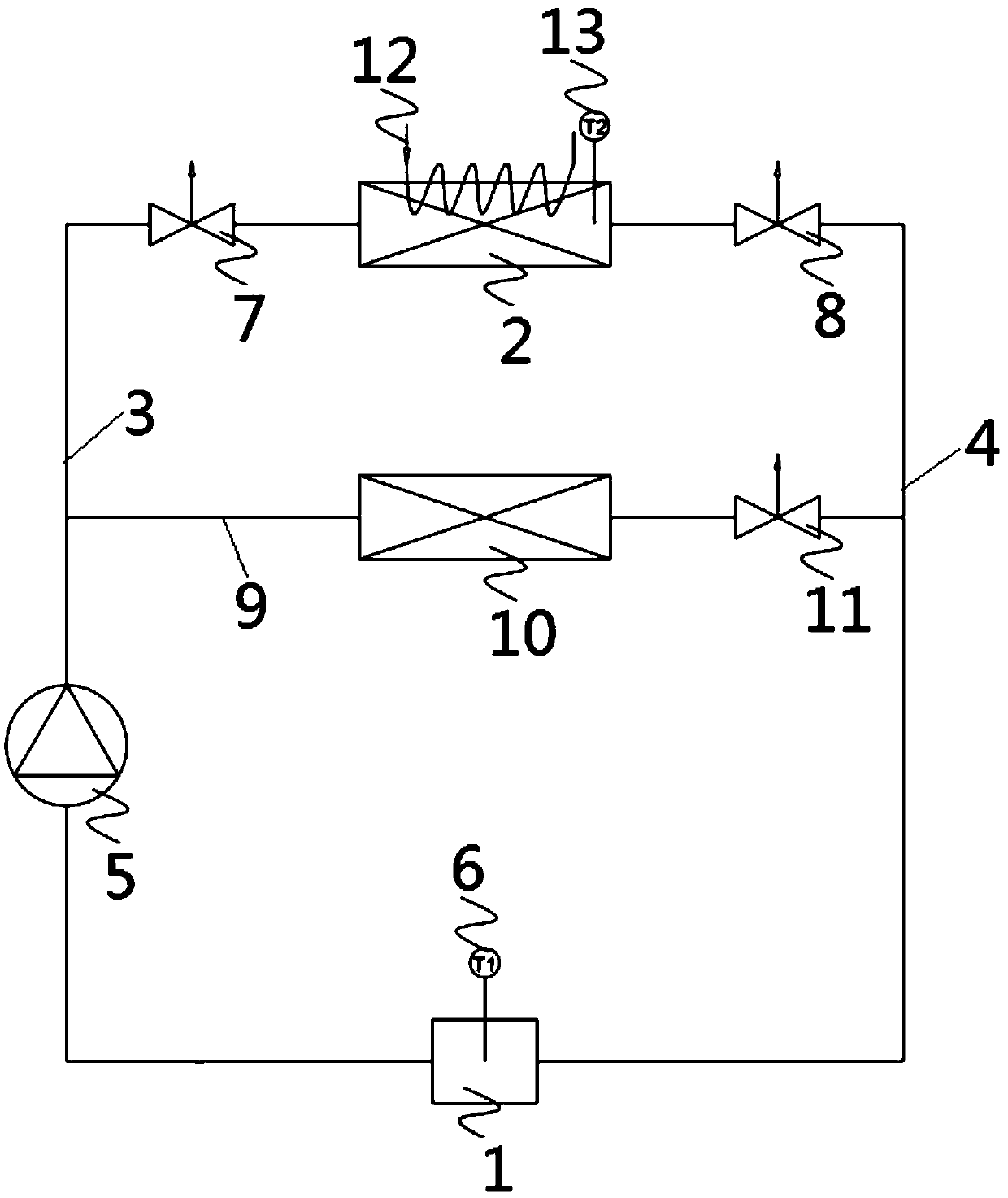

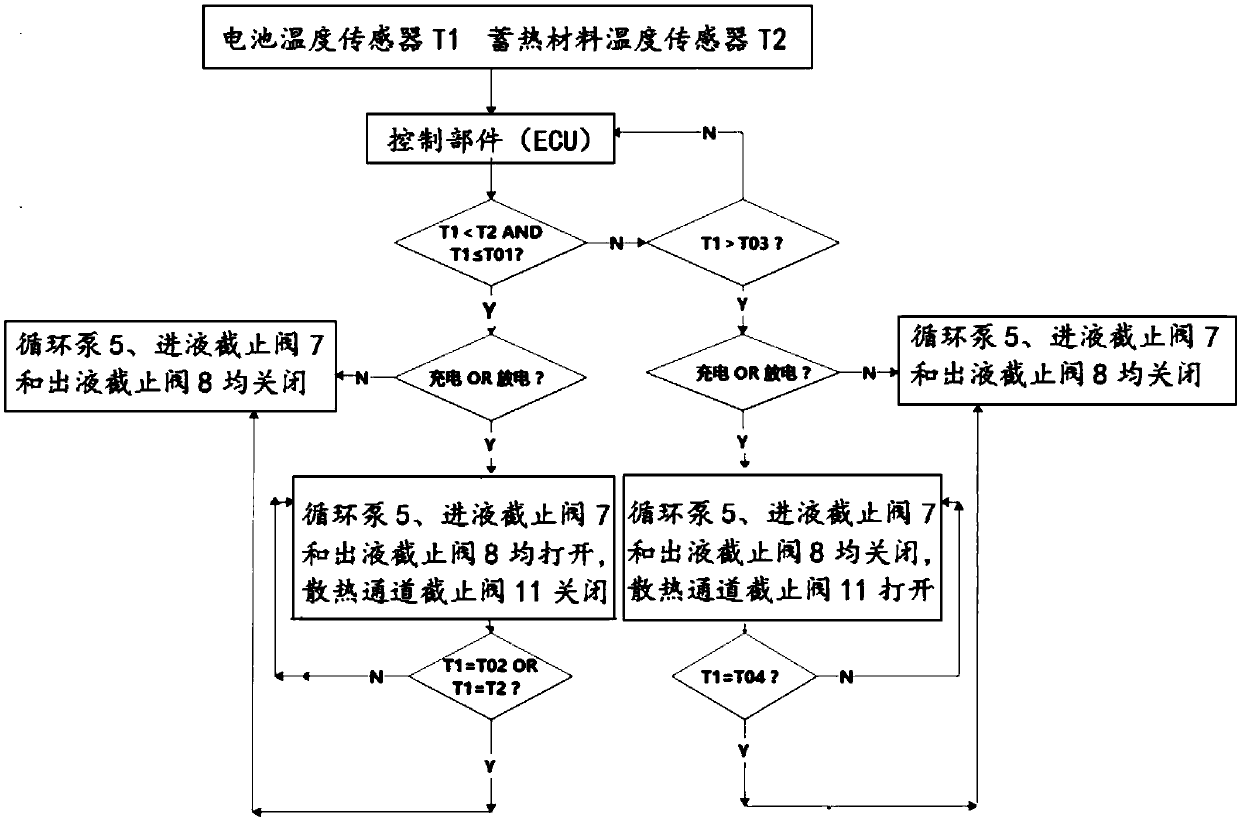

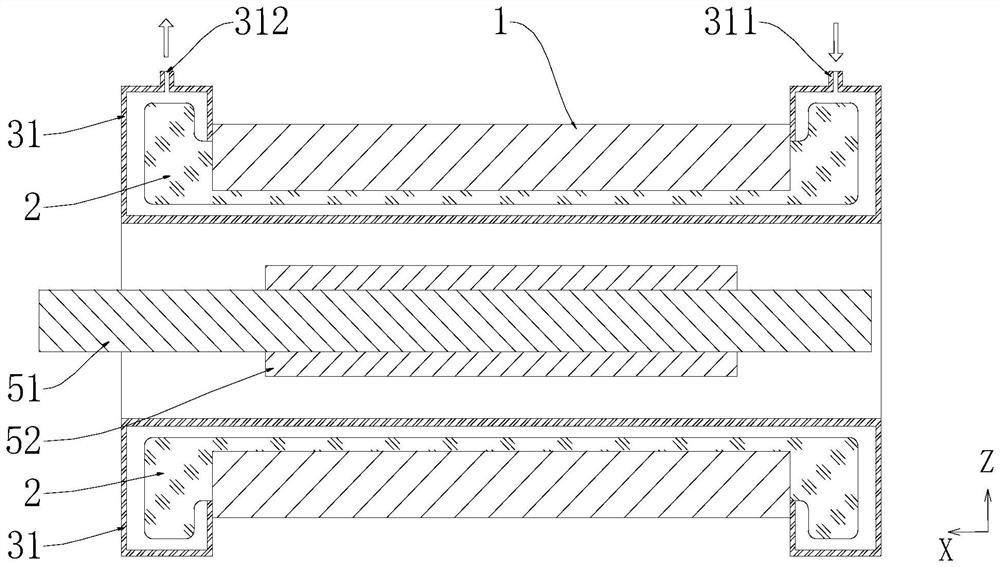

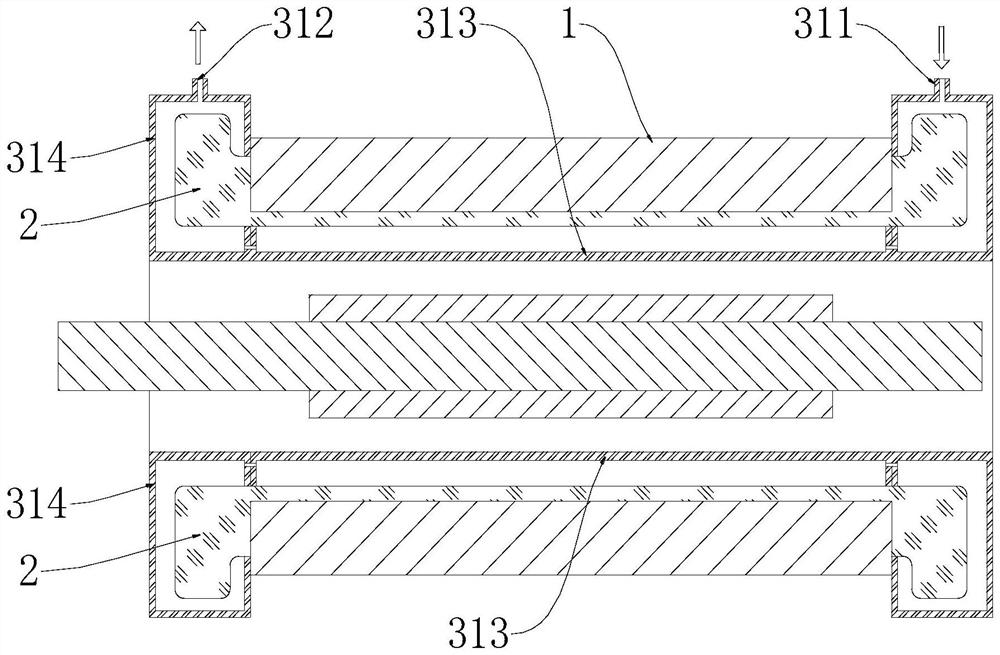

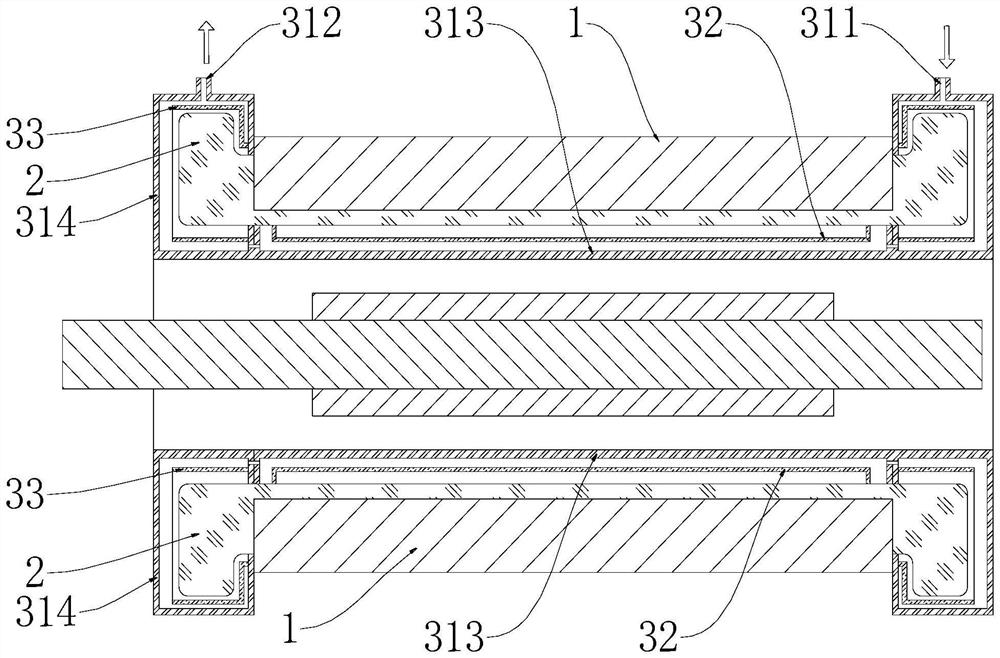

Battery pack temperature control device for electric automobile and control method thereof

ActiveCN109616706AExchangeHigh latent heat of phase changeBatteries circuit arrangementsSecondary cells servicing/maintenanceTemperature controlElectrical battery

The present invention provides a battery pack temperature control device for an electric automobile applied to the technical field of electric automobile parts, and also relates to a control method ofthe battery pack temperature control device for an electric automobile. One end of a regenerative heat exchanger (2) of the battery pack temperature control device for an electric automobile communicates with one end of a battery pack (1) through a connection line I (3); the other end of the regenerative heat exchanger (2) communicates with the other end of the battery pack (1) through a connection line II (4); a connection line III (9) is arranged between the connection line I (3) and the connection line II (4); and the connection line III (9) is provided with a heat dissipation exchanger (10) and a heat dissipation channel globe valve (11). Through the battery pack temperature control device for an electric automobile and the control method of the invention, the battery module in the battery pack can be charged and discharged in the temperature range with high efficiency, the input and output efficiency of the battery module is improved, and the service life and endurance mileage are improved.

Owner:JAPHL POWERTRAIN SYST

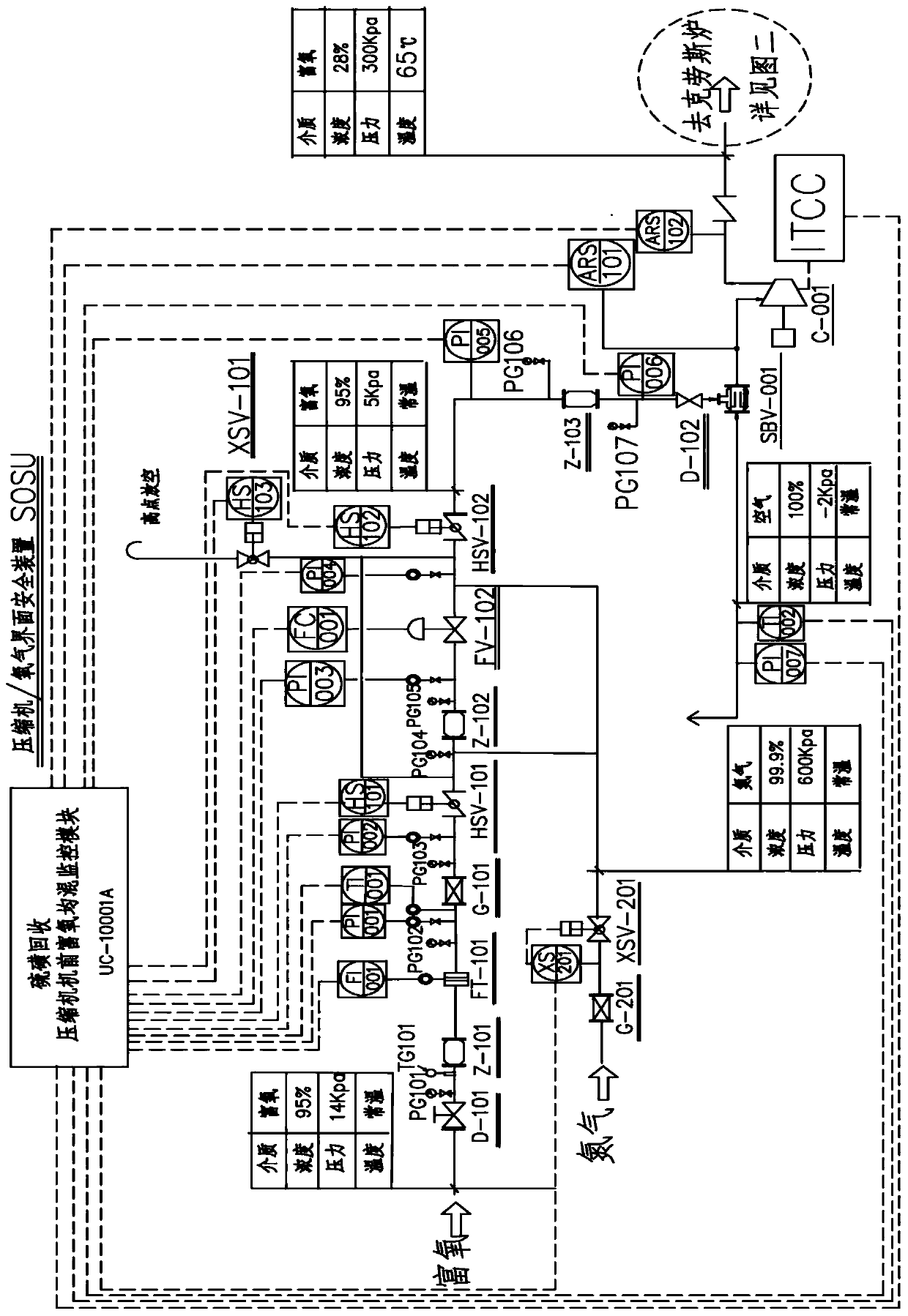

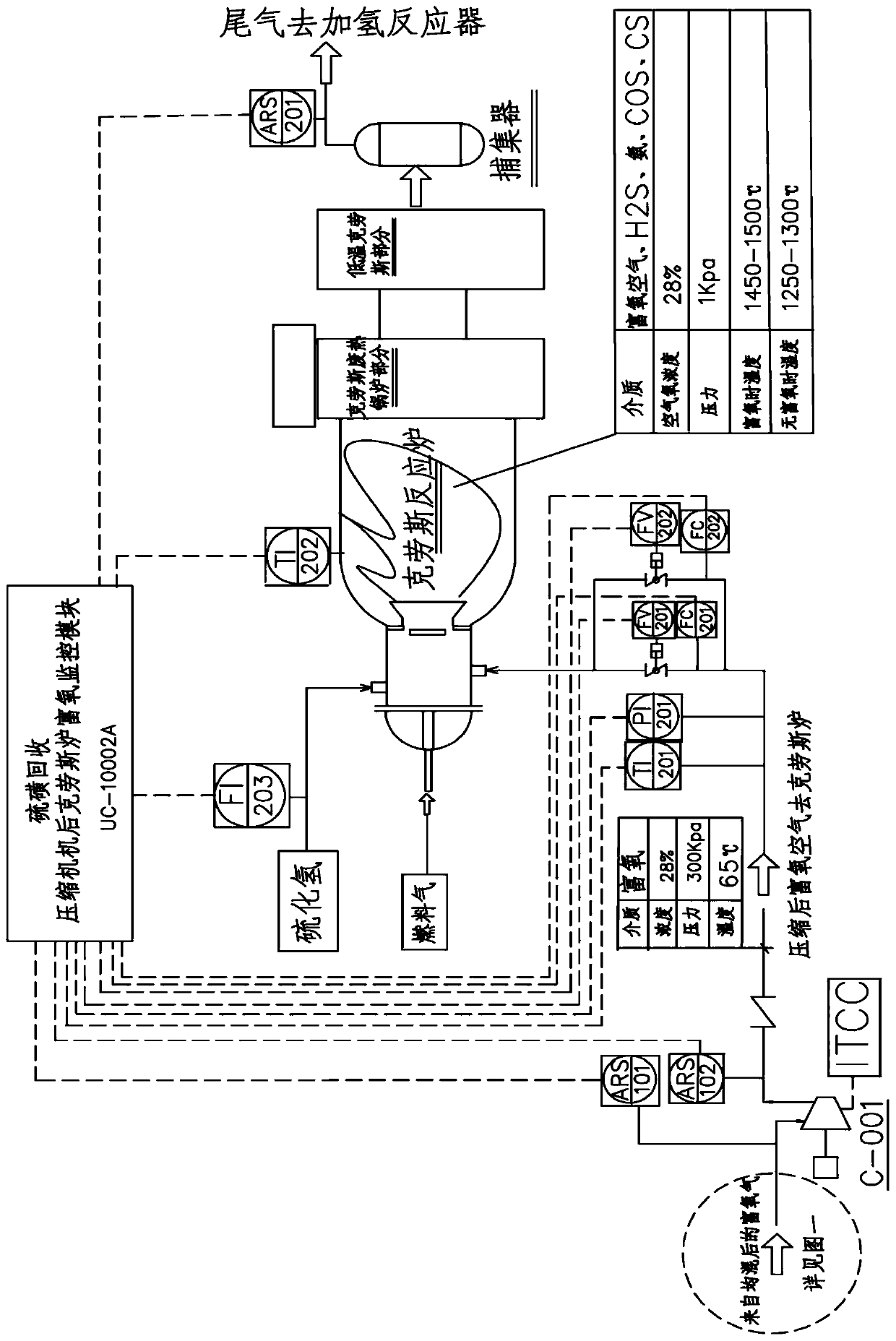

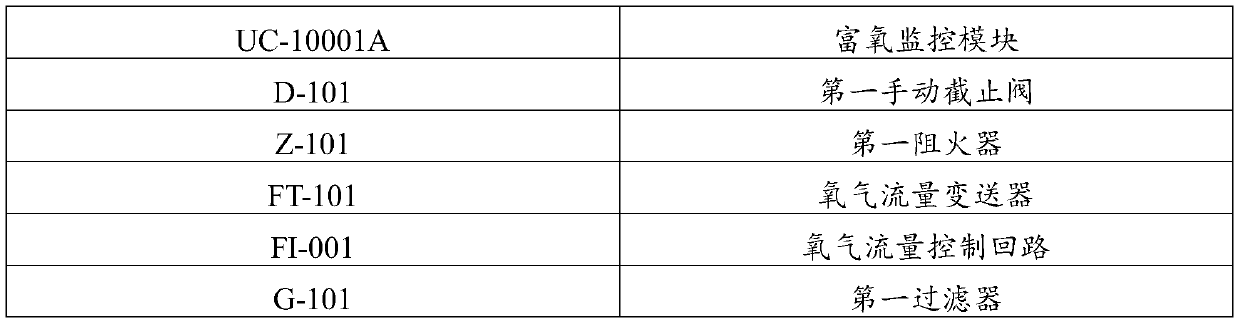

Sulfur recovery Klaus furnace oxygen-enriched blast management system and method

ActiveCN111470477ASafe and reliable mixingLow costAir supply regulationSulfur preparation/purificationPhysicsCoal chemical industry

The invention relates to the technical field of petrochemical and coal chemical industry, and provides a sulfur recovery Klaus furnace oxygen-enriched blast management system and method. The sulfur recovery Klaus furnace oxygen-enriched blast management system comprises a compressor front oxygen interface safety device, a compressor and a compressor rear oxygen-enriched monitoring system; the compressor front oxygen interface safety device can mix oxygen and air in front of the compressor, and the process can be completed by using low pressure oxygen, no oxygen booster is needed, mixing is uniform, safe, and reliable, and cost is low; and the concentration, the flow rate, the temperature, the pressure, the electrostatic discharge and the particle filtration of oxygen can be strictly monitored and managed; optimization is realized through calculation using an oxygen-enriched uniform mixing monitoring module. According to the system provided by the invention, the whole oxygen enrichmentprocess is monitored through the compressor front oxygen interface safety device and the compressor rear oxygen-enriched monitoring system, so that the safe operation and the service life of the Klausfurnace can be ensured, and the hydrogen sulfide treatment capacity of the Klaus furnace is improved.

Owner:上海轻叶能源股份有限公司

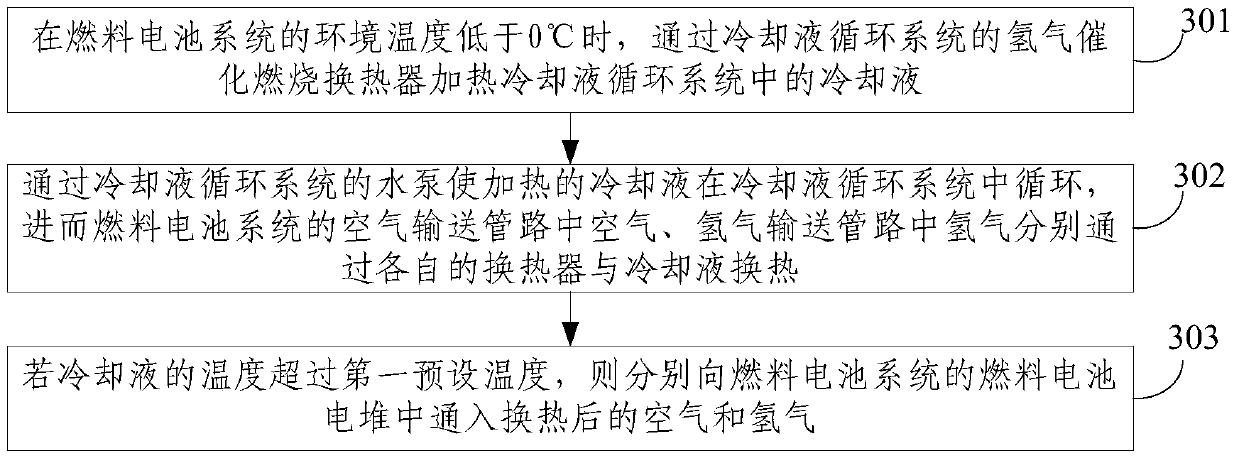

A fuel cell low temperature starting system and operation method

The invention provides a fuel cell low-temperature startup system and an operation method. The low-temperature startup system includes: a fuel cell system and a coolant circulation system; the coolant circulation system includes: an air-coolant heat exchanger, a hydrogen ‑Coolant heat exchanger, hydrogen catalytic combustion heat exchanger, water pump, radiator; air‑coolant heat exchanger on the air delivery line of the fuel cell system; hydrogen‑coolant heat exchanger on the hydrogen delivery line; hydrogen The catalytic combustion heat exchanger is used to heat up the cooling liquid circulating in the cooling liquid circulation system and communicate with the hydrogen source of the fuel cell system through the first hydrogen delivery branch; circulate in the circulatory system. The above-mentioned low-temperature start-up system can realize rapid start-up of the fuel cell in a low-temperature environment, and ensure the operating life of the fuel cell at low temperature, which can effectively reduce the failure rate of the fuel cell in low-temperature operation.

Owner:BEIJING SINOHYTEC

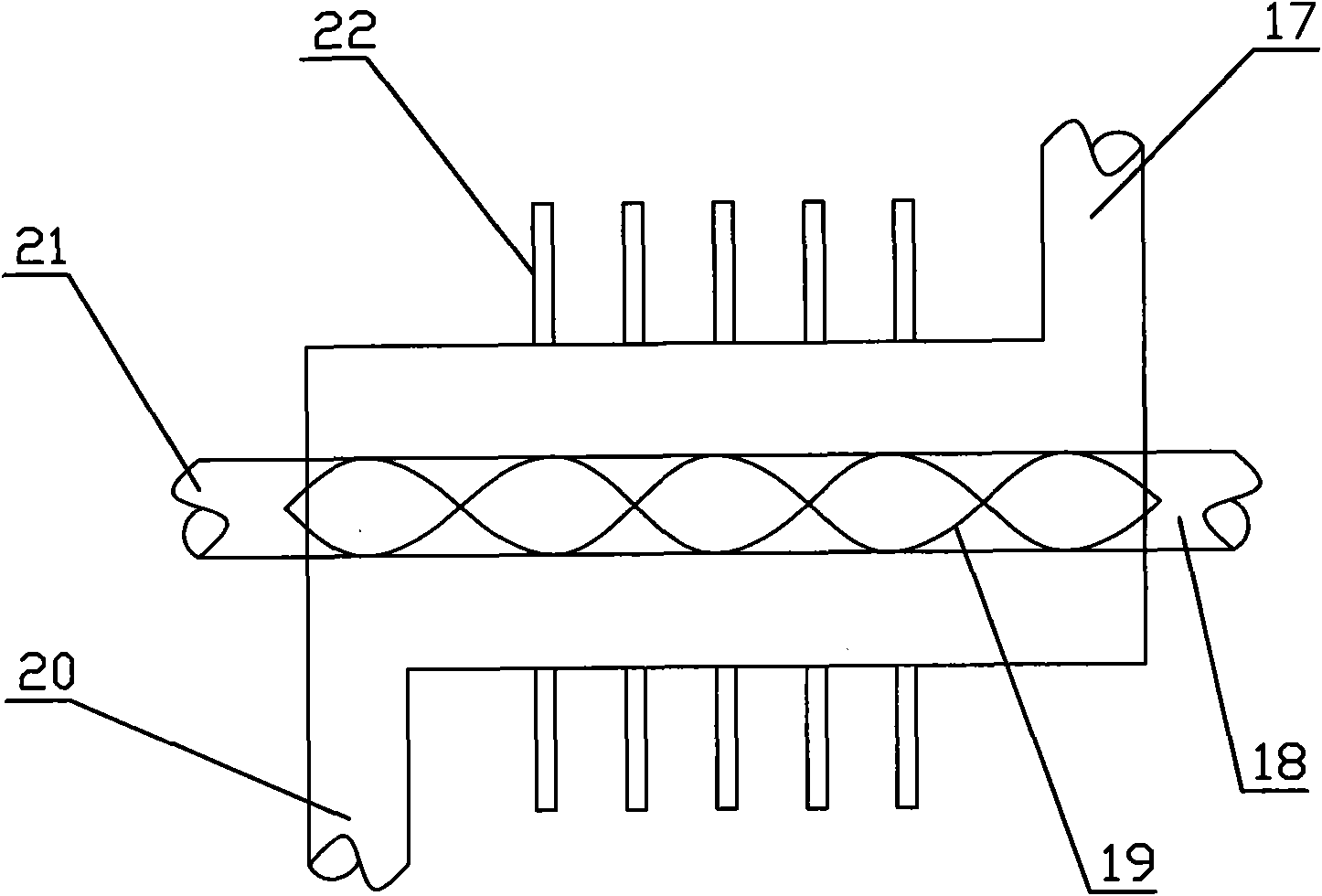

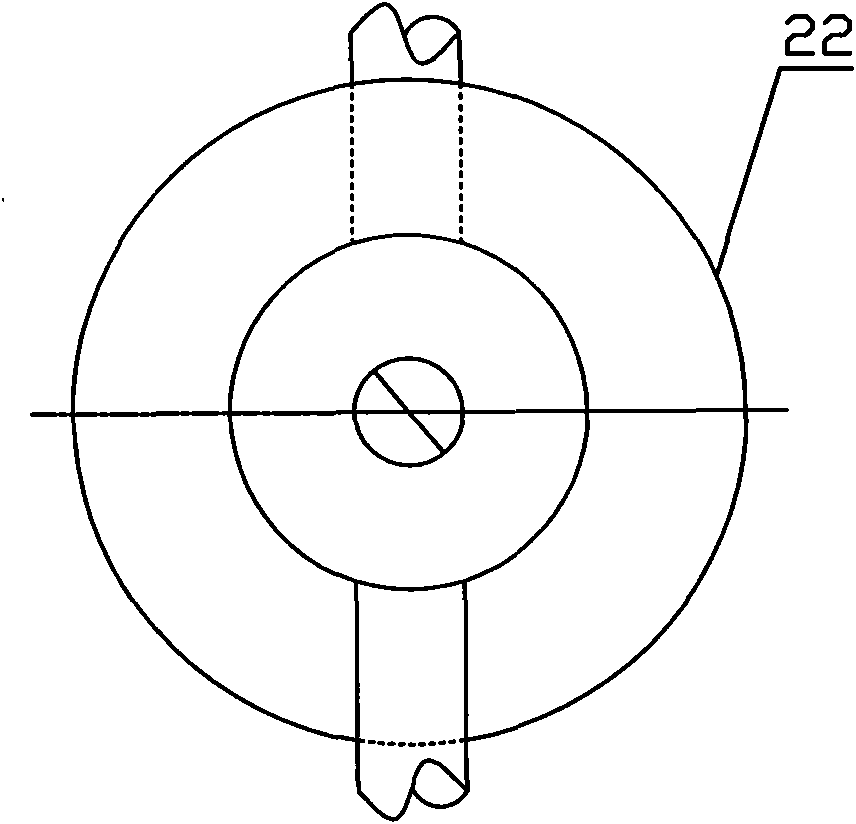

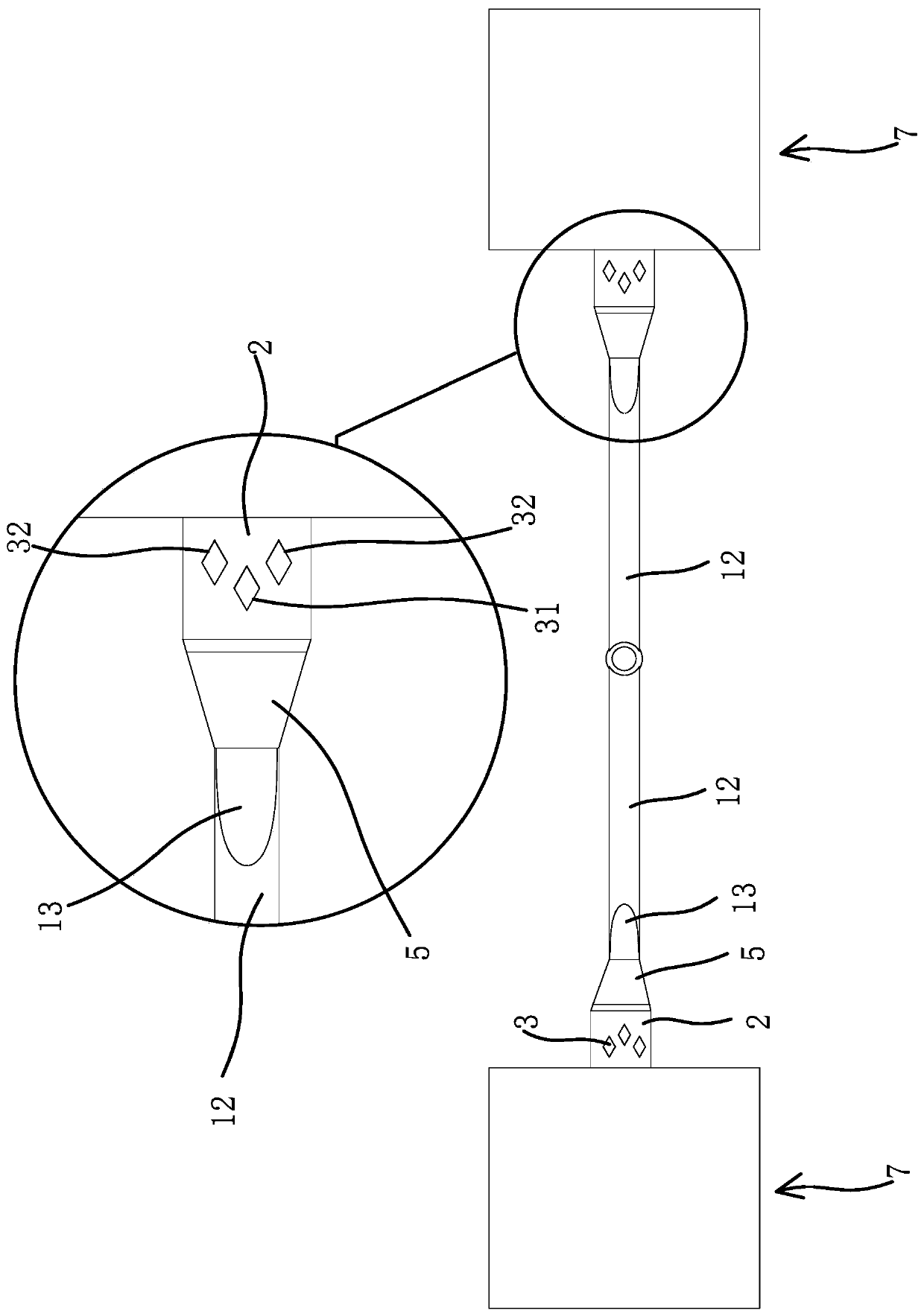

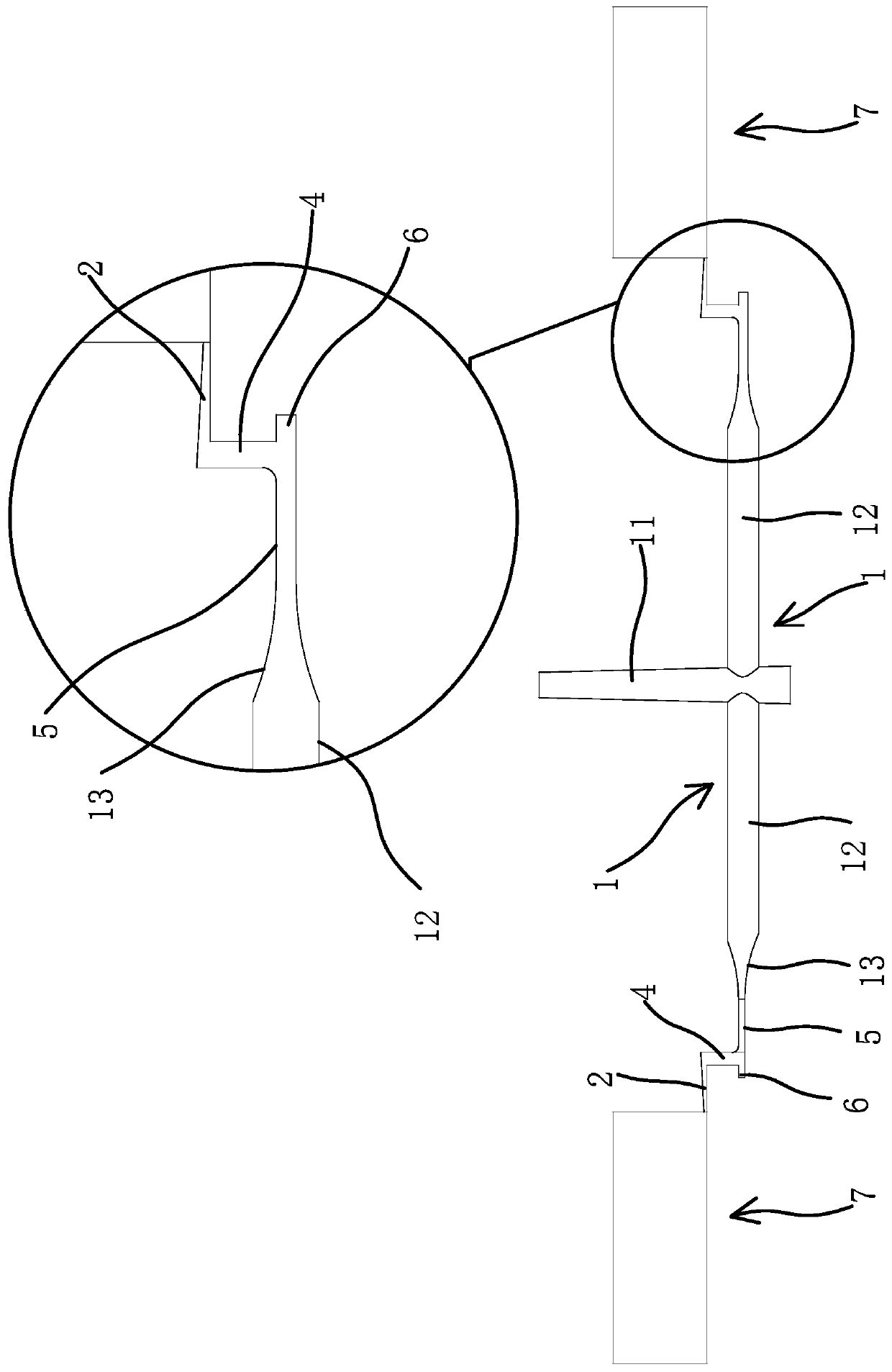

Self-flow-disturbing injection mold pouring system

The invention provides a self-flow-disturbing injection mold pouring system, belongs to the technical field of injection molding processing, and solves the technical problem that existing thick-walledtransparent plastic parts are susceptible to flow marks and other injection molding defects. The self-flow-disturbing injection mold pouring system comprises a tubular runner for being connected withan external plastic melt and a gate for enabling the runner to communicate with a mold cavity, wherein a plurality of pin fins arranged at intervals are arranged in the gate. The system is characterized in that the runner communicates with the gate by a flat buffer pipe for leading the plastic melt to flow upwards, the gate is used for guiding the plastic melt to flow downwards and is flat tubular, the pin fins are arranged in at least one row, and each row of the pin fins is arranged in the width direction of the gate. The flow marks of the thick-walled transparent plastic parts are effectively prevented by improvement of the pipe structure and the arrangement manner of the pin fins of the pouring system.

Owner:ZHEJIANG SAIHAO IND CO LTD

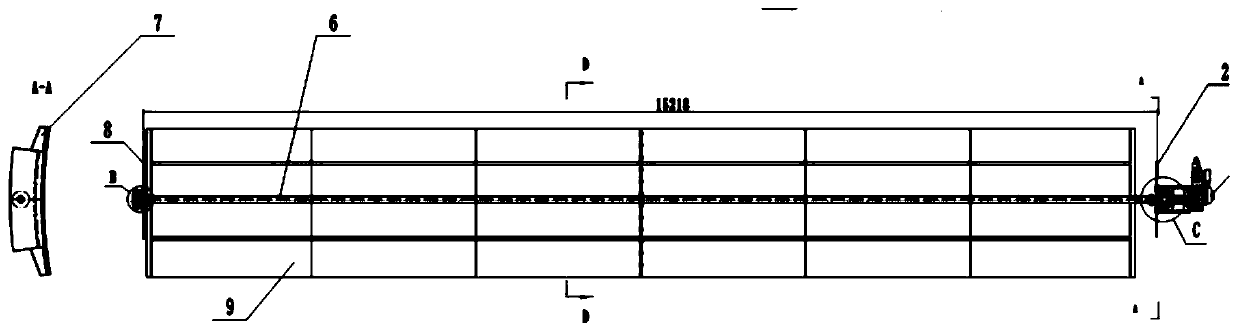

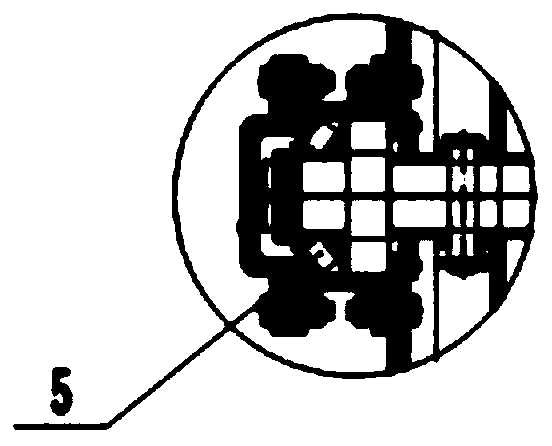

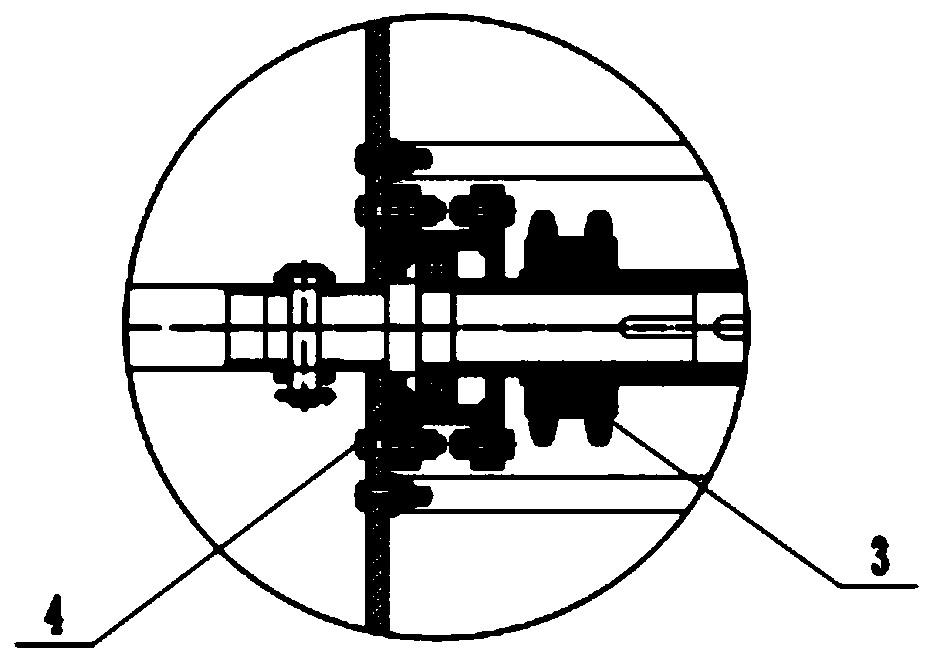

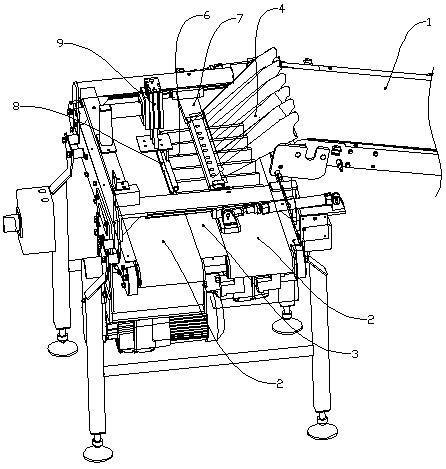

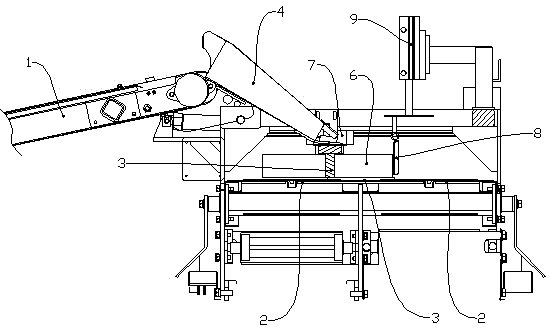

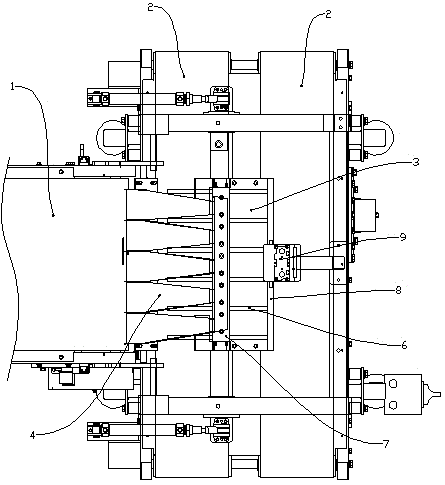

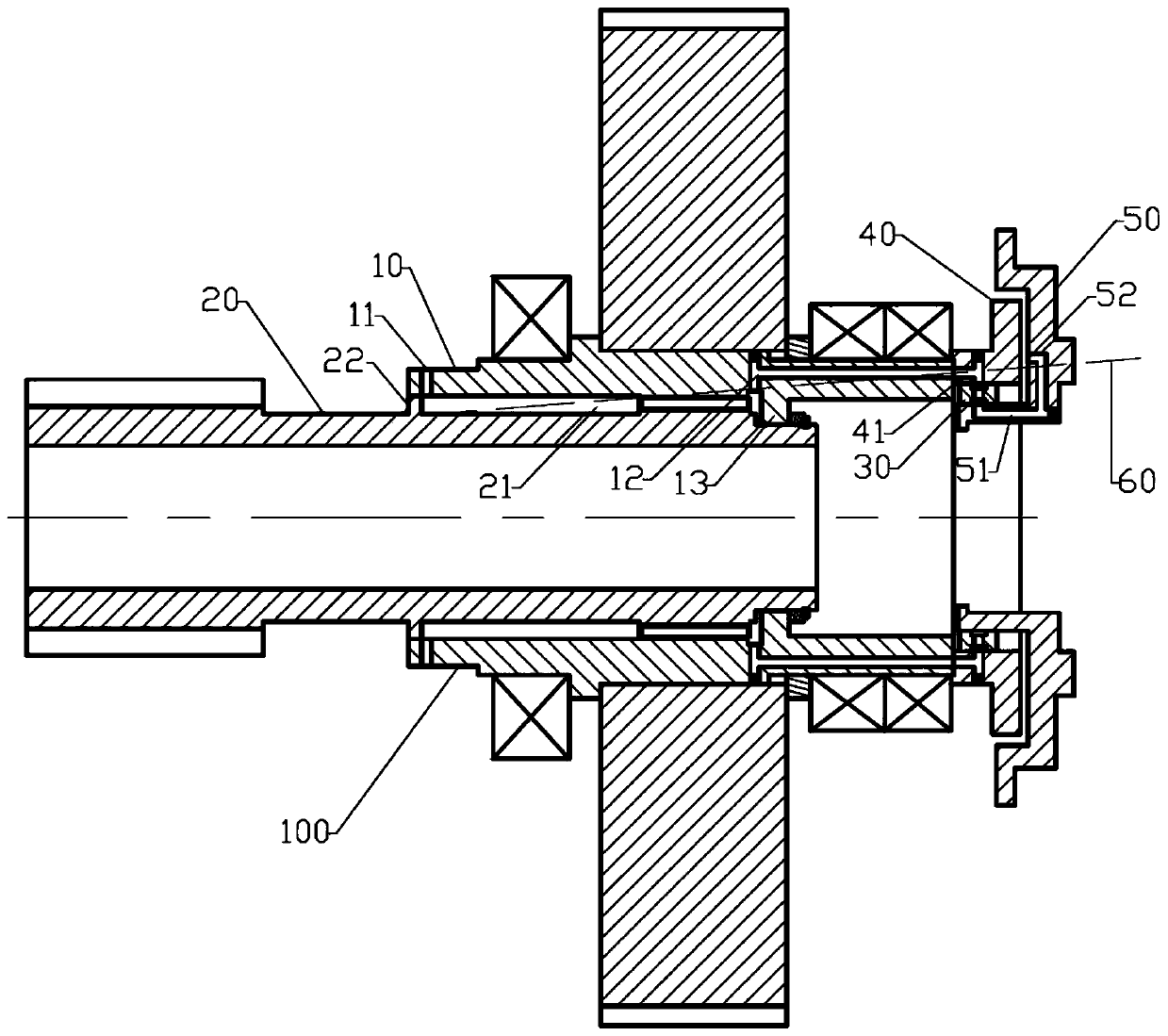

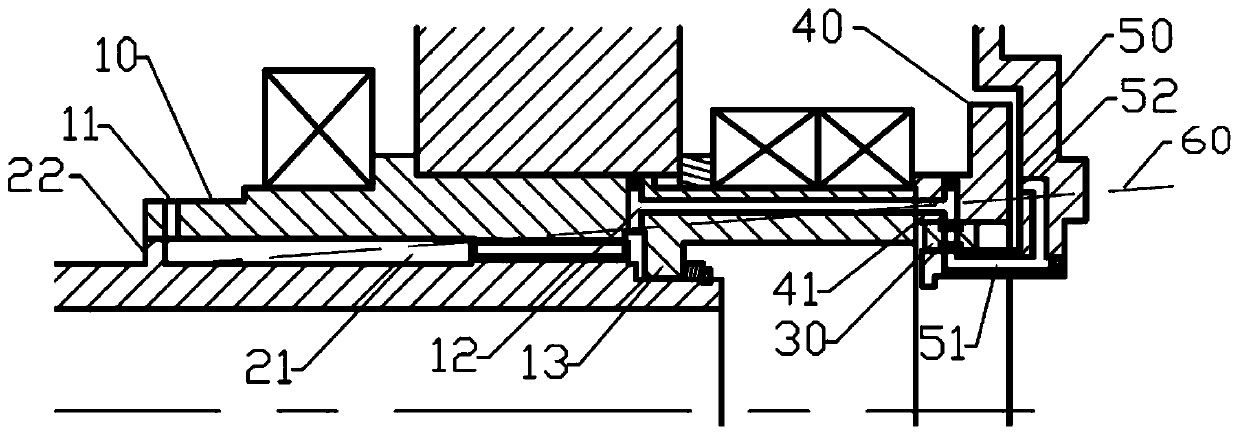

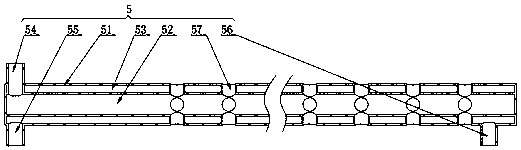

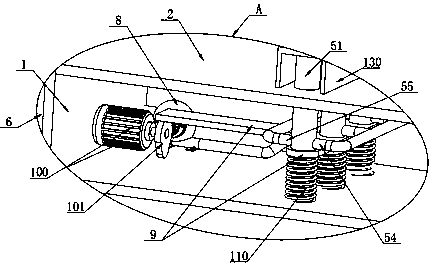

Quantitative product output mechanism of packaging equipment

InactiveCN105292586AGuaranteed operating lifeImprove operational efficiencyPackagingEngineeringMechanical engineering

The invention relates to a component of packaging equipment, and in particular to a quantitative product output mechanism of the packaging equipment. The quantitative product output mechanism is used for counting products conveyed one by one and then quantitatively outputting the products. The quantitative product output mechanism comprises a conveying belt capable of conveying the products one by one. Two transverse discharging conveying belts perpendicular to the conveying direction of the conveying belt are arranged below the tail end of the conveying belt. A fixed material collecting platform is arranged between the two discharging conveying belts. Material guiding troughs connected with the tail end of the conveying belt are arranged above the material collecting platform. A material pushing plate capable of moving between the two discharging conveying belts back and forth is arranged above the material collecting platform. The products on the material collecting platform can be pushed to the two discharging conveying belts respectively through back-and-forth movement of the material pushing plate. The conveying belt continuously runs, and high reliability and running efficiency are achieved.

Owner:JOYEA CORP

Wind power speed increasing box spline connection lubricating and cooling system

PendingCN109899503AGuaranteed operating lifeReduce heat and wearGear lubrication/coolingWind energy generationElectricityReturn channel

The invention discloses a wind power speed increasing box spline connection lubricating and cooling system which comprises a spline shaft, a sun gear, an oil pump gear and a permeable cover; an oil storage cavity is arranged between the spline shaft and the sun gear; the spline shaft is provided with a first oil return channel communicated to the oil storage cavity and used for discharging oil inthe oil storage cavity; the oil pump gear is provided with a second oil return channel which is communicated with the first oil return channel and is used for discharging oil in the first oil return channel; and the permeable cover is provided with a third oil return channel communicated with the second oil return channel and used for discharging oil in the second oil return channel and an oil outlet used for discharging oil in the third oil return channel. Oil enters the oil storage cavity from the oil inlet, sequentially flows through the first oil return channel, the second oil return channel and the third oil return channel and is discharged from the oil outlet; and splines of the spline shaft and the sun gear are submerged with lubricating oil. The wind power speed increasing box spline connection lubricating and cooling system has the beneficial effects that heating abrasion of internal and external splines in the running process are effectively reduced, and the service life of spline connection is ensured.

Owner:NANJING HIGH SPEED GEAR MFG

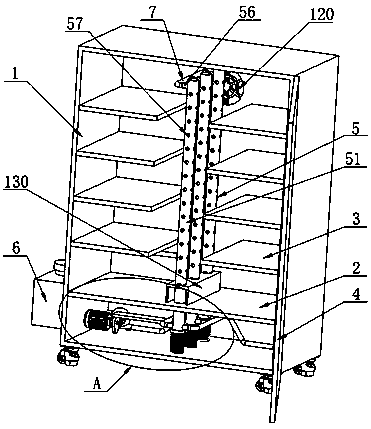

Portable network hard disk based on cloud server

PendingCN111163616AGood effectImprove cooling effectCooling/ventilation/heating modificationsPhysicsElectric machinery

The invention discloses a cabinet type computer network server, and particularly relates to the technical field of computer servers. The cabinet type computer network server comprises a cabinet body,a partition plate is fixedly connected to the lower portion of the interior of the cabinet body, and a plurality of carrying plates are arranged at the two sides of the upper portion of the partitionplate respectively. One ends of the carrying plates are fixedly connected with the two sides of the cabinet body respectively, a cabinet door is arranged at one side of the front portion of the cabinet body, and one side of the cabinet door is hinged to the side wall of the cabinet body. According to the present invention, by arranging a heat dissipation pipe, a water tank, a connecting hose, a water pump, an exhaust fan, a T-shaped plate, a driving motor, a cam and a spring, the heat dissipation of the devices in a cabinet is facilitated, and the air blown out of an air outlet passes throughthe water in a water cavity to be cooled when the air is in the air cavity, so that the air cooling effect is better. During heat dissipation, the heat dissipation pipe can move up and down, so that the air outlet can blow air up and down, the heat dissipation effect is improved, and the normal operation and the service lives of the devices are guaranteed.

Owner:扬州网桥软件技术有限公司

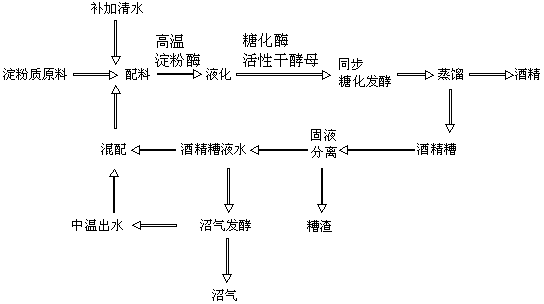

Method for fermenting alcohol by reusing alcohol grain liquid and medium-temperature anaerobic effluent

InactiveCN103382490AImprove fermentation efficiencyLow costBiofuelsWaste based fuelAmmonium hydroxideEnvironmental chemistry

The invention discloses a method for fermenting alcohol by reusing alcohol grain liquid and medium-temperature anaerobic effluent. According to the process method, burdening liquid is added according to the feed liquid weight ratio of 1:1.5-2.4, the burdening liquid is composed of the alcohol grain liquid, the medium-temperature anaerobic effluent and supplemented clean water, the effluent is reused, and ammonium hydroxide or sulfuric acid are not required, so that the effluent treatment cost can be reduced. By controlling the feed water ratio and adjusting the proportion of alcohol grain liquid and the medium-temperature anaerobic effluent to control the pH value, the complex cost-increasing procedures of conducting acid radical removing, ammonia nitrogen removing and additionally adding of acid or alkali to adjust the pH value and the like on the medium-temperature anaerobic effluent in the traditional process are avoided, the production efficiency is greatly improved, the production cost is reduced, sewage discharge in alcohol production is greatly reduced, feed mixing water use cost and sewage treatment cost are saved, more additional products are produced, and considerable market economical benefit is brought.

Owner:HENAN TIANGUAN GRP

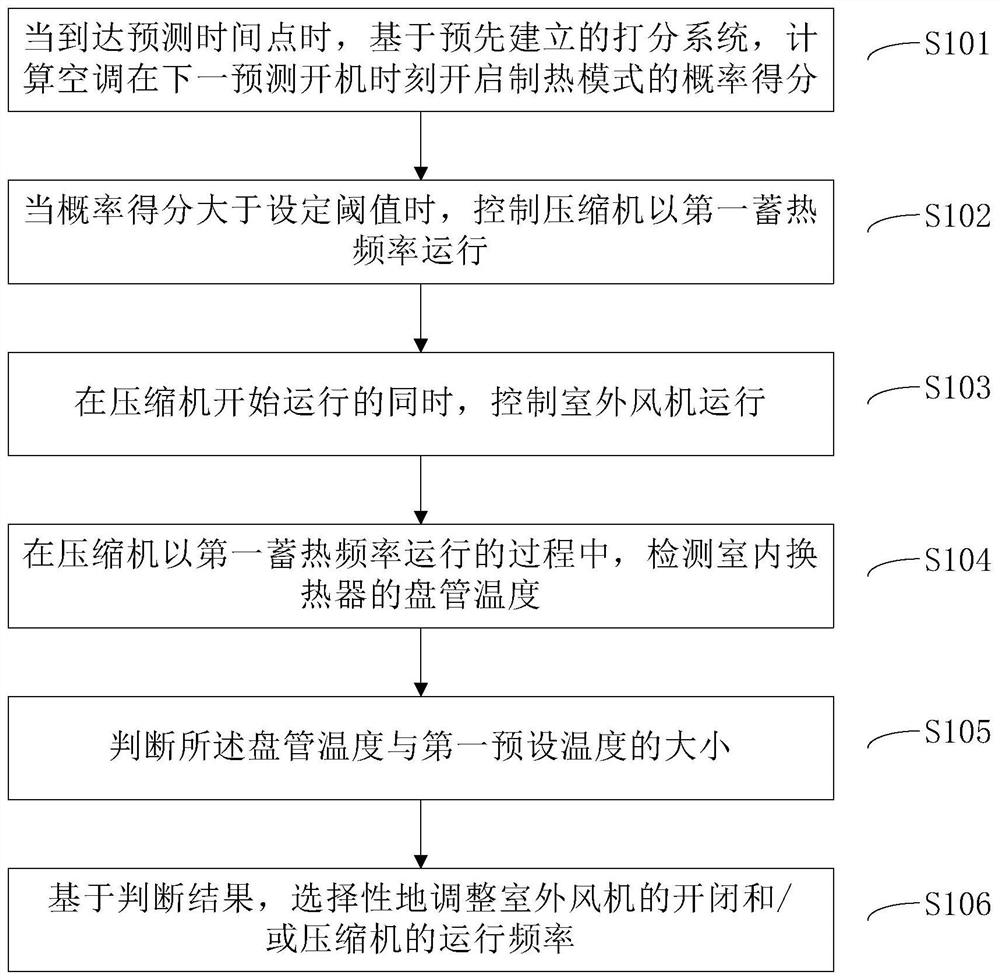

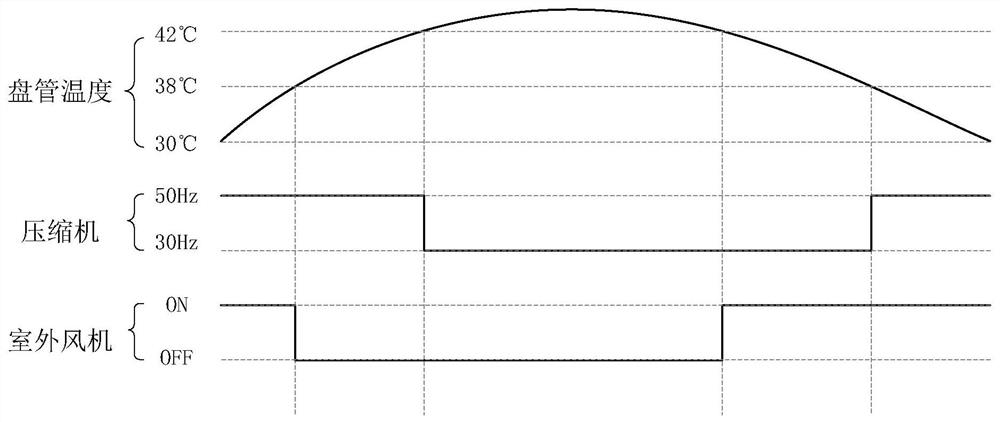

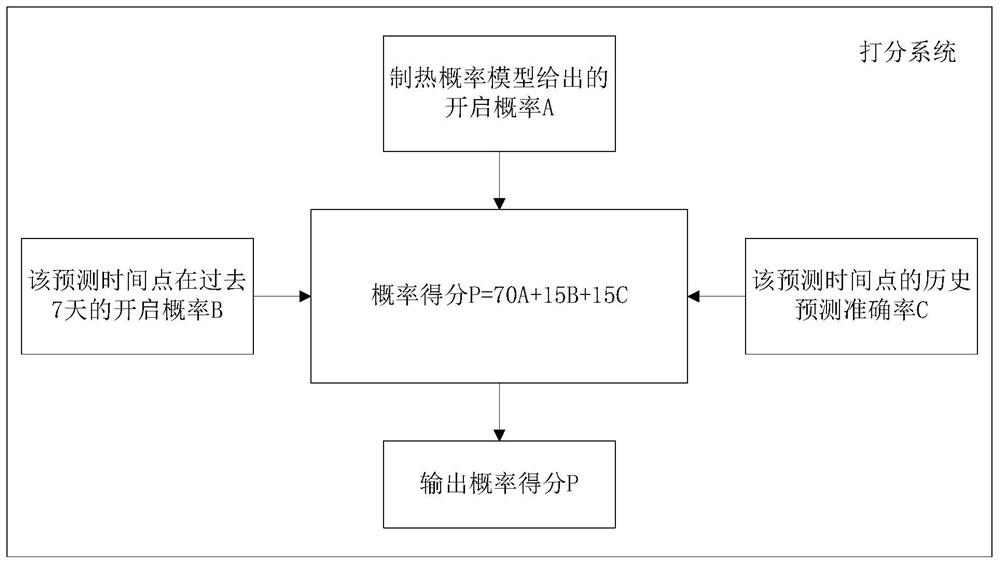

Air conditioner heat storage control method

ActiveCN112032949ASmall fluctuationEasy to adjustMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeat control

The invention relates to the technical field of air conditioning, in particular to an air conditioner heat storage control method and aims at solving the problems that according to an existing preheating scheme, the service life of a compressor is short, and coil pipe temperature fluctuation is large. In order to achieve the purpose, the heat storage control method comprises the steps that when aprediction time point is reached, based on a pre-established scoring system, the probability score of starting a heating mode of an air conditioner at the next prediction starting moment is calculated; when the probability score is larger than a set threshold value, the compressor is controlled to run at a first heat storage frequency, and an outdoor draught fan is controlled to run; In the running process of the compressor, the coil pipe temperature of an indoor heat exchanger is detected; the coil pipe temperature and a first preset temperature are judged; and based on a judgment result, theopening and closing of an outdoor draught fan and / or the running frequency of the compressor are / is selectively adjusted. According to the heat storage control method, the service life of the compressor can be prolonged, fluctuation of the coil pipe temperature in the air conditioner heat storage process is reduced, and user experience is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

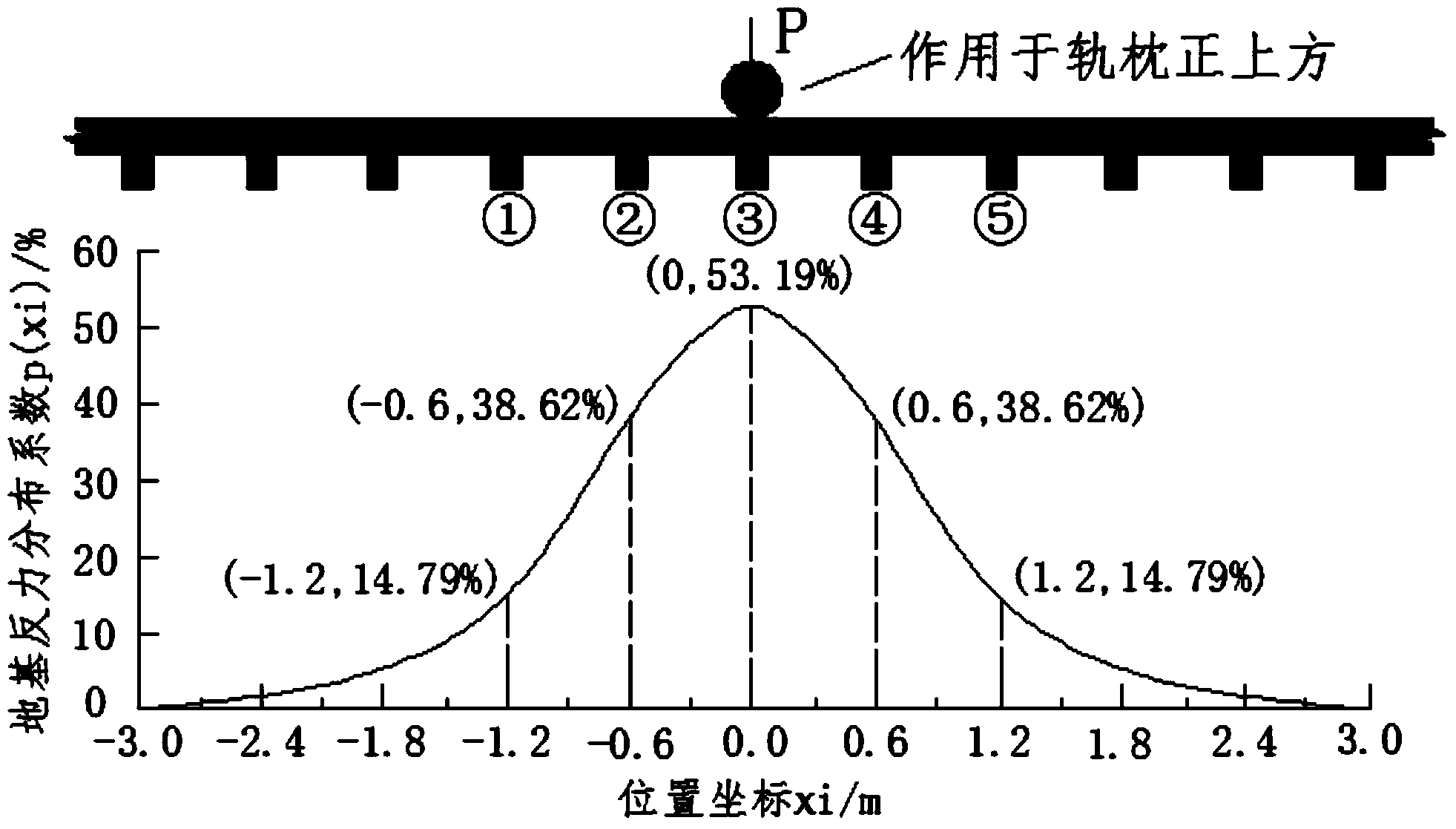

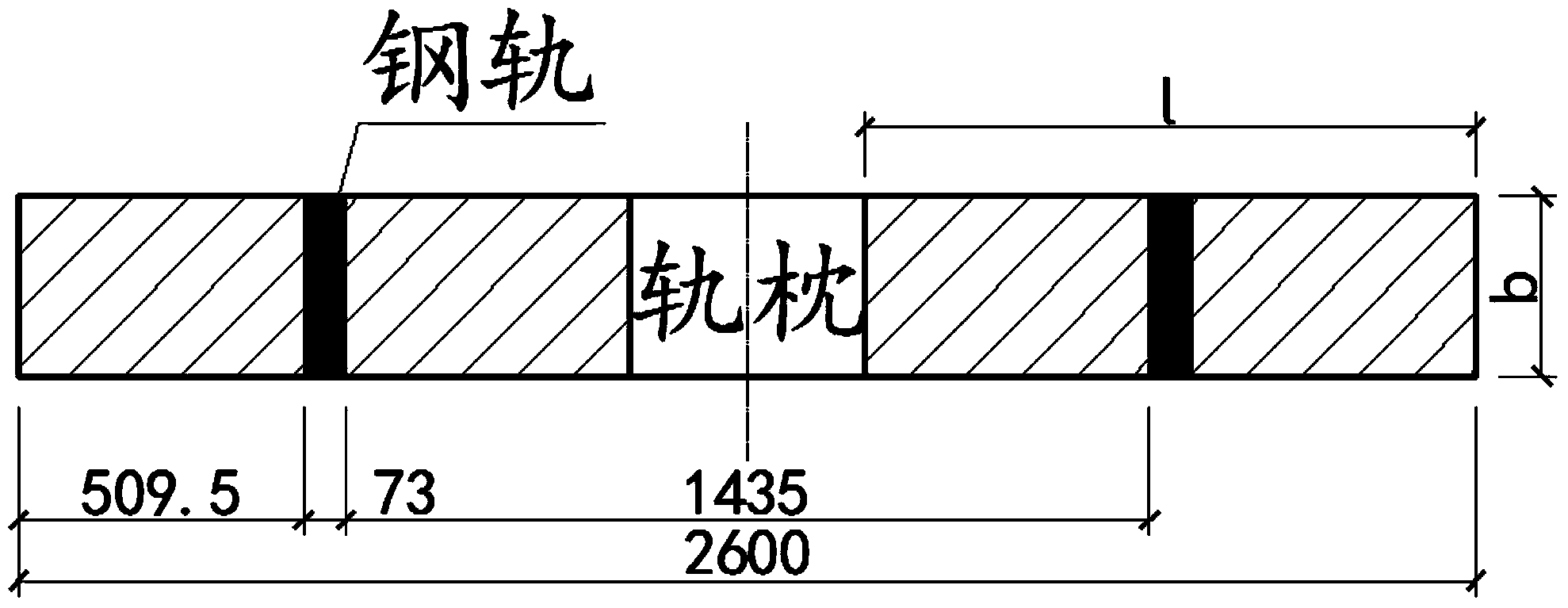

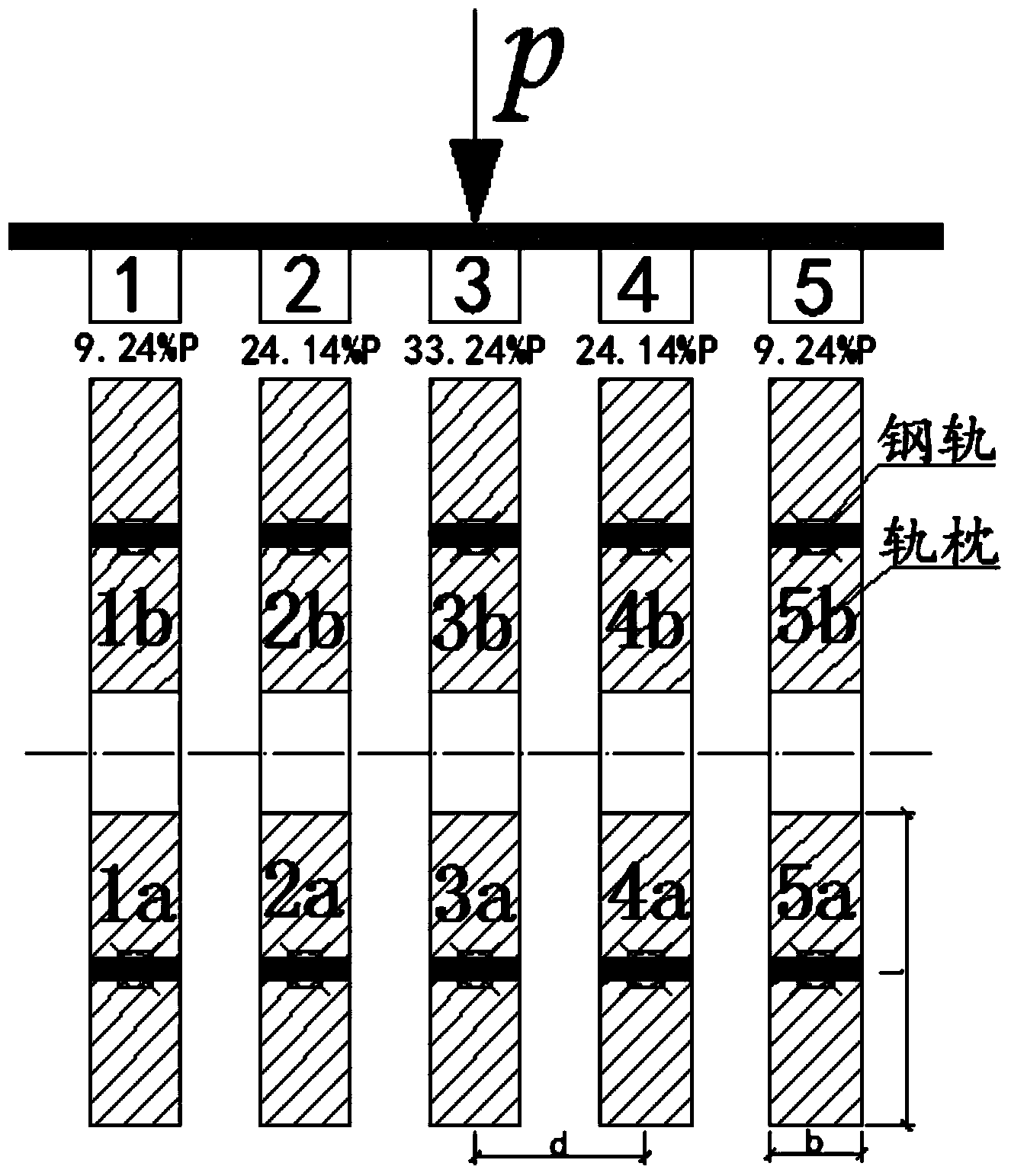

Method for determining thickness of high speed railway bedding structure of ballast track

ActiveCN103866664AHigh share ratio accuracyCalculation method is simpleRoadwaysBallastwayEngineeringWheel load

The invention relates to a method for determining the thickness of a high speed railway bedding structure of a ballast track. The method mainly comprises the steps of determining the wheel loading force of the adjacent sleeper and the average pressure of the left side of the bottom of a sleeper 3 based on the normal distribution curve; considering the vertical diffusion of the wheel loading force of one sleeper side (left side) right below a wheel, the stress of a position right below the center of the sleeper bottom (left side), diffused obliquely by the wheel loading force of the other sleep side (right side), and the stress of a position right below the center of the sleeper bottom (left side), diffused obliquely by the wheel loading force of the bottoms of the left side and the right side of the adjacent sleeper, so as to obtain the relation of the total load stress of the vehicle in a depth position right below the wheel at left side and the depth and further obtain the thickness of the bedding structure. The method has simplicity in calculation and accurate result, thus further ensuring the service life of the railway and the safety operation of a train, and also reducing the railway repairing and maintaining costs and preventing waste.

Owner:SOUTHWEST JIAOTONG UNIV

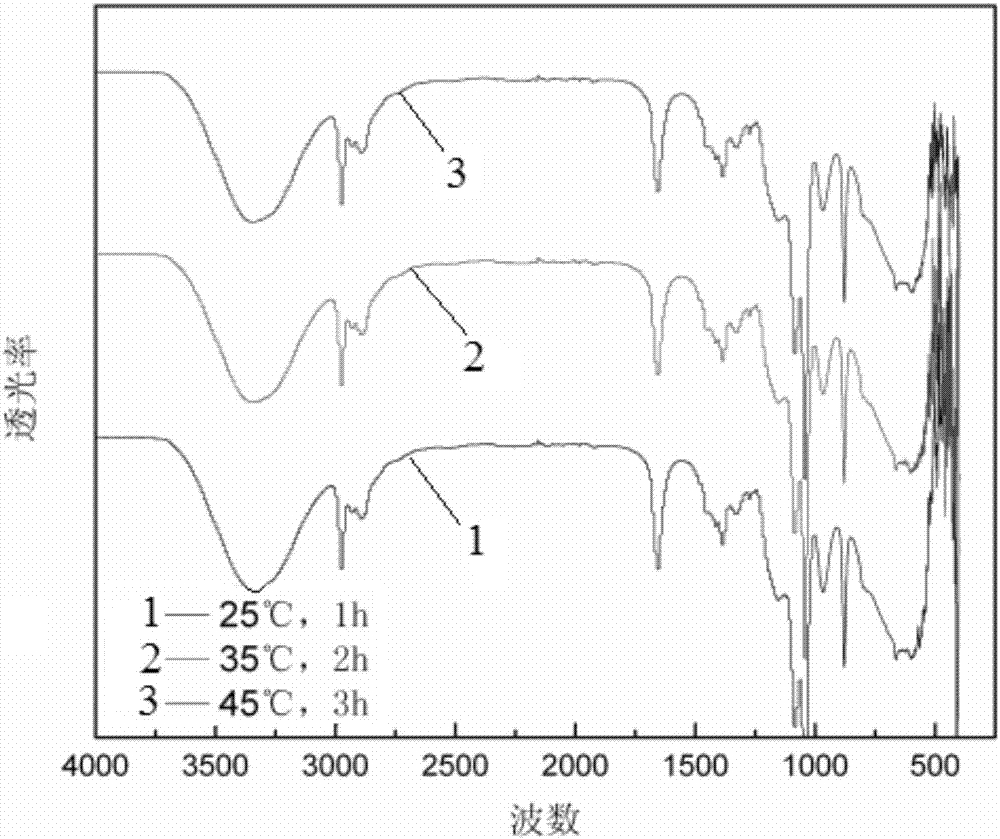

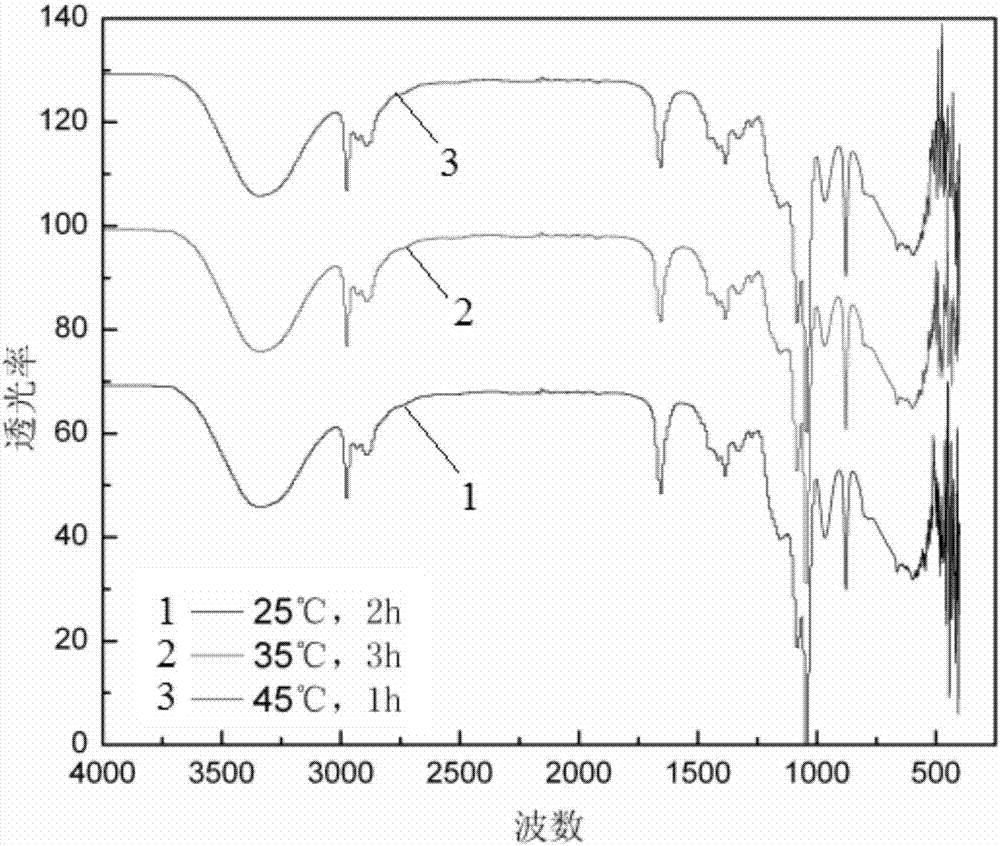

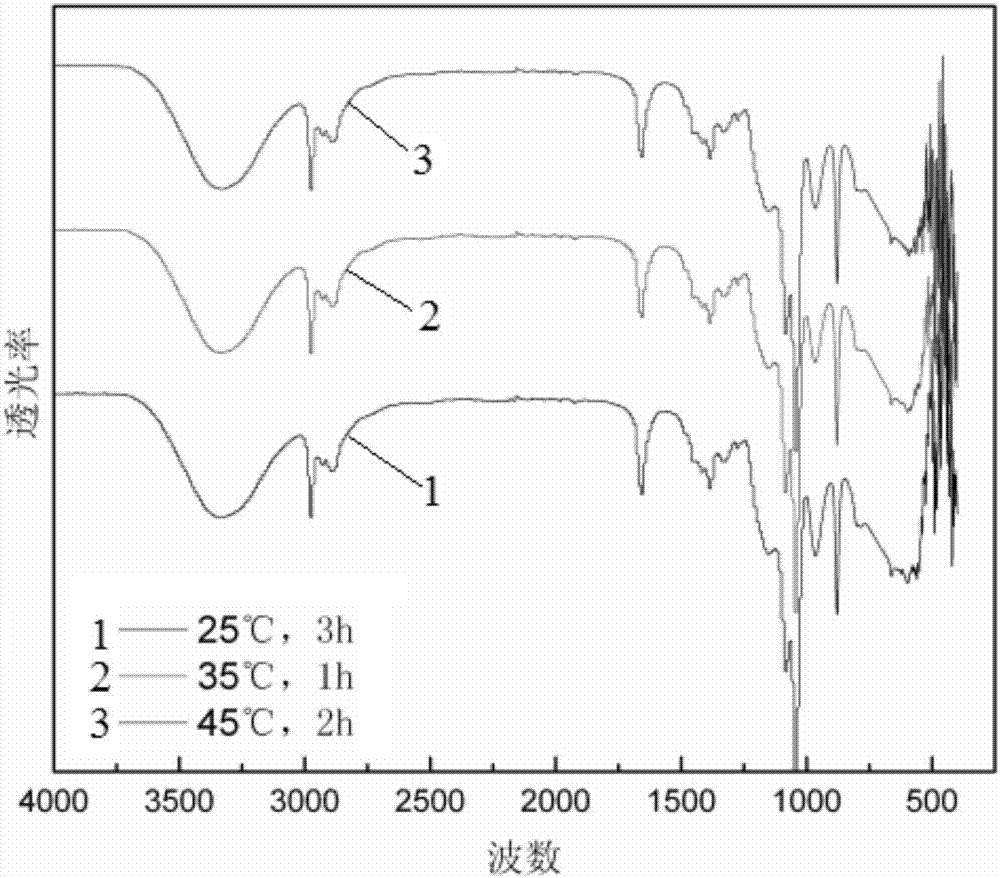

Silicon dioxide coating resisting to high temperature and corrosion and preparation method and application thereof

ActiveCN106884158ALow viscosityGood adhesionLiquid/solution decomposition chemical coatingWater bathsSilica coating

The invention discloses a silicon dioxide coating resisting to a high temperature and corrosion and a preparation method and application thereof, and belongs to the technical field of silicon dioxide coatings. The silicon dioxide coating resisting to the high temperature and corrosion and the preparation method and application thereof solve the technical problems that current preparation of silicon dioxide coatings is usually conducted under the condition of a high temperature, industrial production is thus not facilitated, generally the hydrophobic performance is poor, the coatings are easily affected by steam in air, and the service life is short. The preparation method comprises the steps that absolute ethyl alcohol is equally divided into two parts, one part of absolute ethyl alcohol and tetraethoxysilane are mixed and stirred to prepare a solution A, the other part of absolute ethyl alcohol and deionized water are mixed and stirred and then fluorosilane coupling agents are added dropwise to prepare a solution B, the solution A and the solution B are mixed and stirred under the conditions of heating in a water bath and reflux condensation, N,N-dimethyl formamide is slowly added dropwise, then nitric acid is added and stirred for reaction to prepare a glue solution, and a silicon steel sheet with an oxidation film removed is subjected to dipping and pulling through the glue solution and then subjected to secondary thermal treatment. The silicon dioxide coating resisting to the high temperature and corrosion is used as a turbine blade surface wear-resisting coating.

Owner:哈尔滨金氙科技有限公司

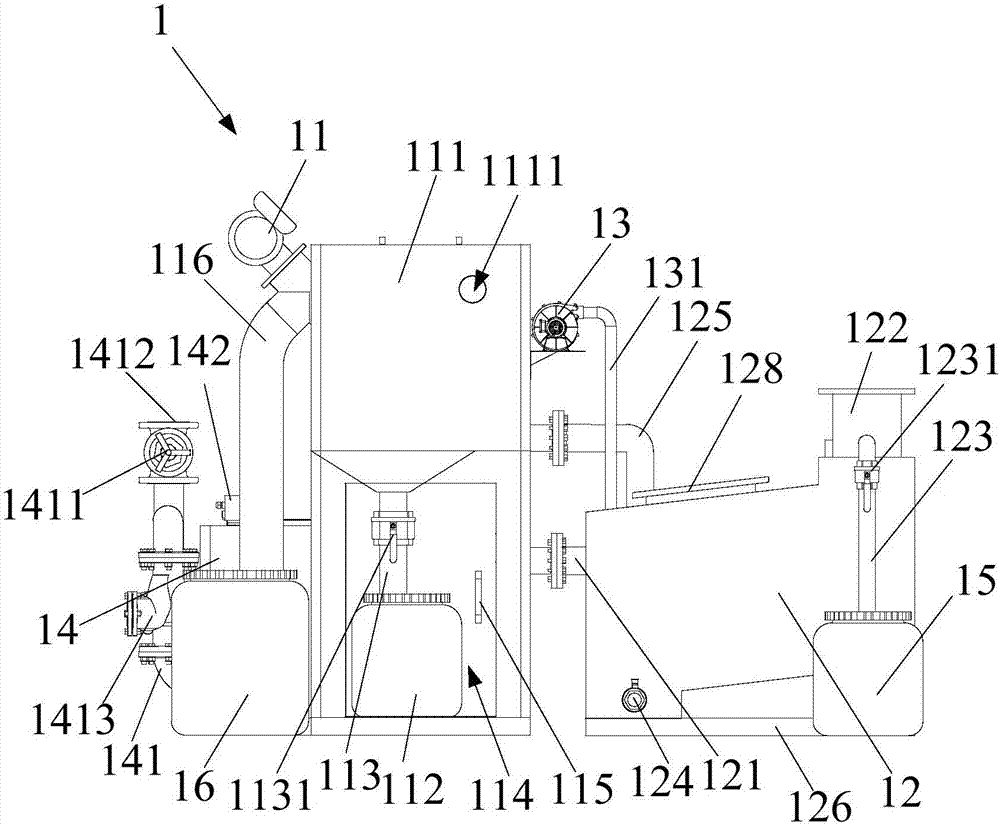

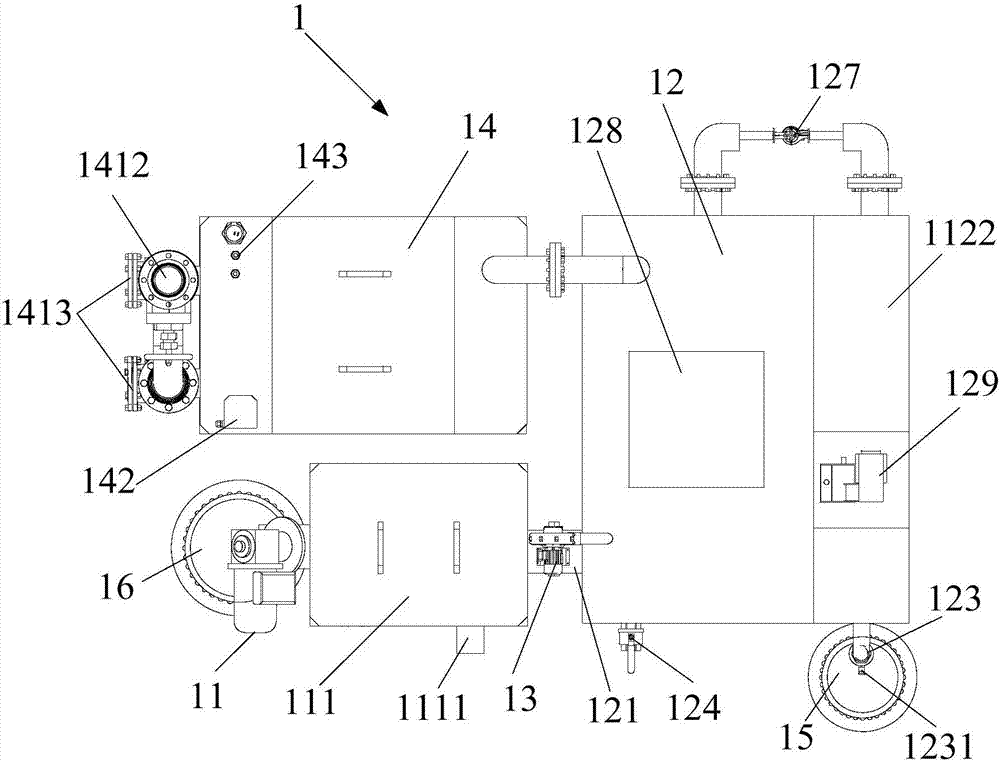

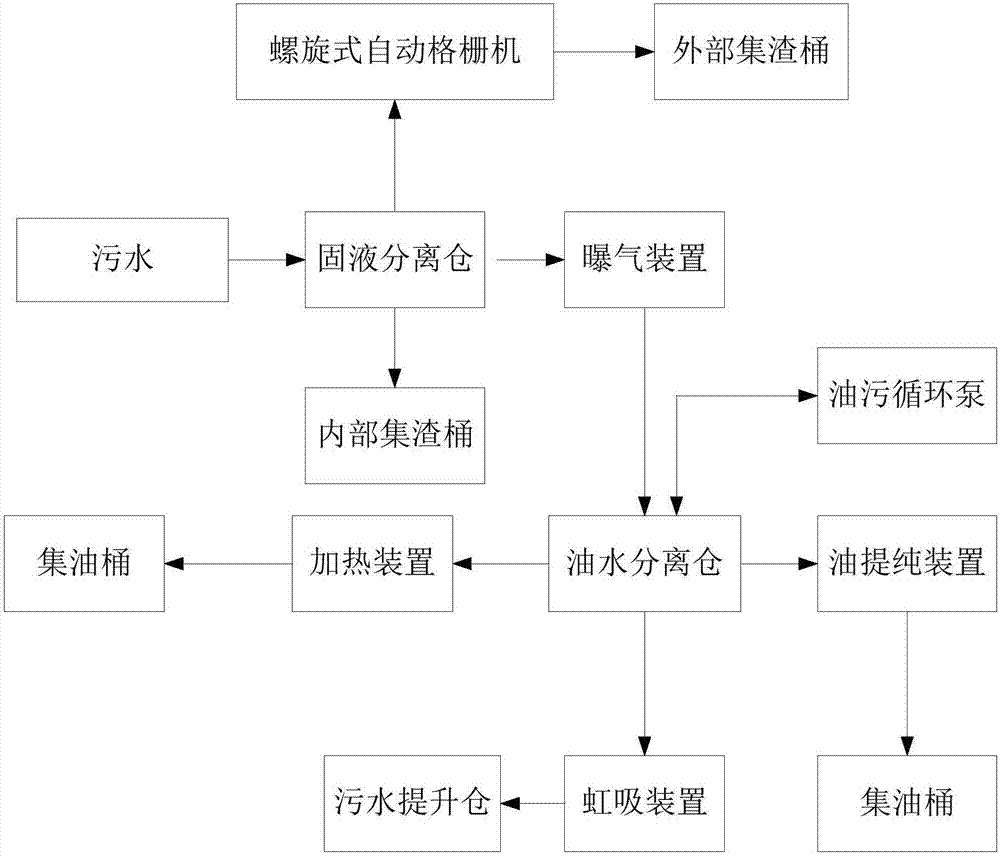

Combined automatic oil-water separation equipment

InactiveCN106902549AClear functionHigh replaceabilityLiquid separation by thermal diffusionNon-miscible liquid separationOil waterSewage

The invention relates to the technical field of environmental protection equipment, in particular to a combined automatic oil-water separation equipment. The combined automatic oil-water separation equipment provided by the present invention includes a solid-liquid separation device, an oil-water separation bin, and a sewage lifting bin. The solid-liquid separation device includes a solid-liquid separation bin, an internal slag collection bucket and a spiral automatic grid inside the solid-liquid separation bin. The grid machine, the whole equipment is composed of three parts: solid-liquid separation device, oil-water separation bin, and sewage lifting bin. When the separation device is working, the slag can be automatically discharged into the external slag collecting bucket through the spiral automatic grille machine in the solid-liquid separation bin, and the slag discharge butterfly valve can also be manually controlled to discharge the residue in the oil-water separation bin to the internal slag collecting bucket. It has both automatic slag discharge function and manual slag discharge function. The discharge of slag discharge is more thorough and the slag discharge effect is better.

Owner:天津铭铨志远科技有限公司

High-temperature resistant lubricating grease for bearings and a preparing method thereof

InactiveCN108034479AImprove the lubrication effectIncrease loading capacityLubricant compositionCalcium silicateHigh resistance

High-temperature resistant lubricating grease for bearings and a preparing method thereof are disclosed. A dielectric layer is prepared from polytetrafluoroethylene, agar, pentaerythritol, sulfosuccinate, polyphenyl ether, polyacrylamide, silicon oxide, calcium silicate and molybdenum disulfide. The method includes crushing, homogenizing, heating, mixing, stirring, cooling, grinding, filtration and filling steps. The lubricating grease has high resistance to high temperatures, can have high consistence and adhesive force in a high-temperature environment, and has good lubricating effects in ahigh-temperature environment. The preparing method is simple and the production cost is low.

Owner:贵州元诚实业有限公司

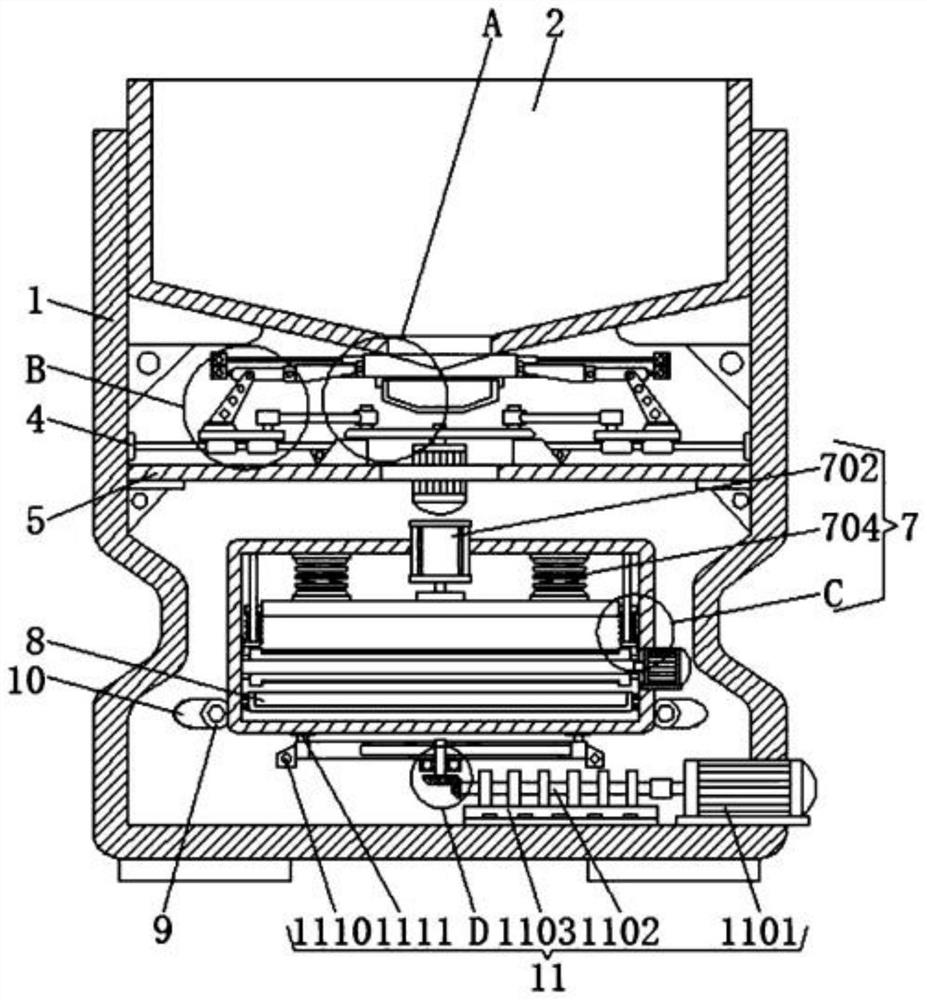

Motor stator cooling system and motor

ActiveCN113394890AAchieve coolingImprove cooling effectElectric machinesMagnetic circuit stationary partsThermodynamicsElectric machine

The invention relates to the technical field of motor cooling, and provides a motor stator cooling system and a motor, the motor stator cooling system comprises a stator sleeve, a stator core and a stator winding, the stator sleeve comprises a first sealing cavity, the first sealing cavity is connected with the stator core and wraps the stator winding, the interior of the first sealing cavity is suitable for being provided with a cooling medium, and the first sealing cavity is provided with a liquid inlet structure, a first cooling channel and a liquid outlet structure which are used for flowing of the cooling medium and are sequentially communicated; and according to the invention, the cooling medium in the first sealing cavity is used for cooling the stator winding, and compared with a heat dissipation and cooling mode that an external fan is used for blowing air for the existing stator winding, the stator winding is wholly immersed in the cooling medium, so that the stator winding can be fully cooled, the cooling effect on the stator winding is improved, and the normal operation and service life of the stator winding and the motor are ensured.

Owner:威海西立电子股份有限公司

Anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device and method

ActiveCN113142602AImprove processing efficiencyConvenient for picking meatHuskingHullingHydraulic cylinderProcess engineering

The invention discloses an anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device and method, and relates to the technical field of Yang-tonifying fruits. The anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device comprises a machine body; the top of the machine body is sleeved with a material collecting cylinder; a discharging port is formed in the middle of the bottom in the material collecting cylinder and penetrates through the bottom of the material collecting cylinder; an intermittent discharging mechanism is arranged below the discharging port; the left side and the right side of the inner wall of the machine body are fixedly connected with the left side and the right side of a fixing plate correspondingly; and a material guide plate is arranged below the discharging port. According to the anti-blocking intermittent discharging and power hull breaking combined Yang-tonifying fruit processing device, by arranging a hydraulic cylinder and the pressing plate, the hydraulic cylinder operates to drive the pressing plate to be attached to Yang-tonifying fruits on a conveying belt and extrude hulls to break the hulls, and a traditional hulling method consuming a large amount of time and manpower is replaced; and the problem that in the prior art, a hull breaking treatment device for the Yang-tonifying fruits is lacked is solved.

Owner:人民非物质文化传播有限公司

Oily self-lubricating bearing retainer material and preparation method thereof

InactiveCN110453503AAvoid wear and tearRepair friction and wearShaftsBearing componentsEngineeringUltimate tensile strength

The invention provides an oily self-lubricating bearing retainer material and a preparation method thereof, and belongs to the technical field of preparation of retainer materials. According to the preparation method, by adopting a lubricating oil microcapsule-phenolic resin solution as a raw material, in the use process of the retainer material, as the material surface is worn, lubricating oil microcapsules dispersed in the material are worn out, and lubricating oil oozes out, thereby lubricating a friction interface, achieving the effect of the frictional wear performance of the retainer material, avoiding the further wear of the retainer material, and ensuring the running precision and service life of a bearing. The lubricating oil microcapsules store the lubricating oil in the retainermaterial, and the oil content can reach up to 20% and is much higher than that of a porous oily phenolic retainer (less than 10%). The use of the lubricating oil microcapsules does not significantlyreduce the mechanical strength of the retainer material as pores, and when the content of the lubricating oil microcapsules is 35%, the ring tension of the retainer material is still higher than 80 MPa.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com