Combined automatic oil-water separation equipment

An oil-water separation and combined technology, used in liquid separation, separation methods, immiscible liquid separation, etc., can solve the problems of clogging the solid-liquid separation bin, the inability to remove sundries, affecting the normal operation of the machine, etc., to achieve installation and maintenance. Convenience, ensure normal operation and service life, good replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

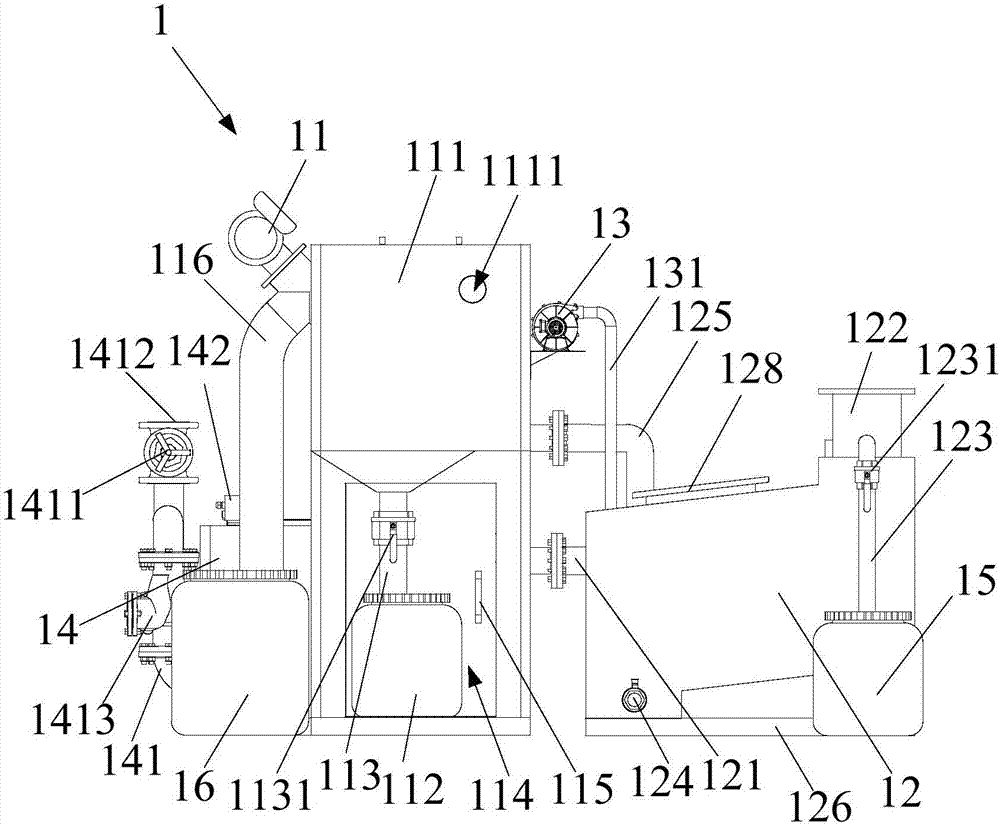

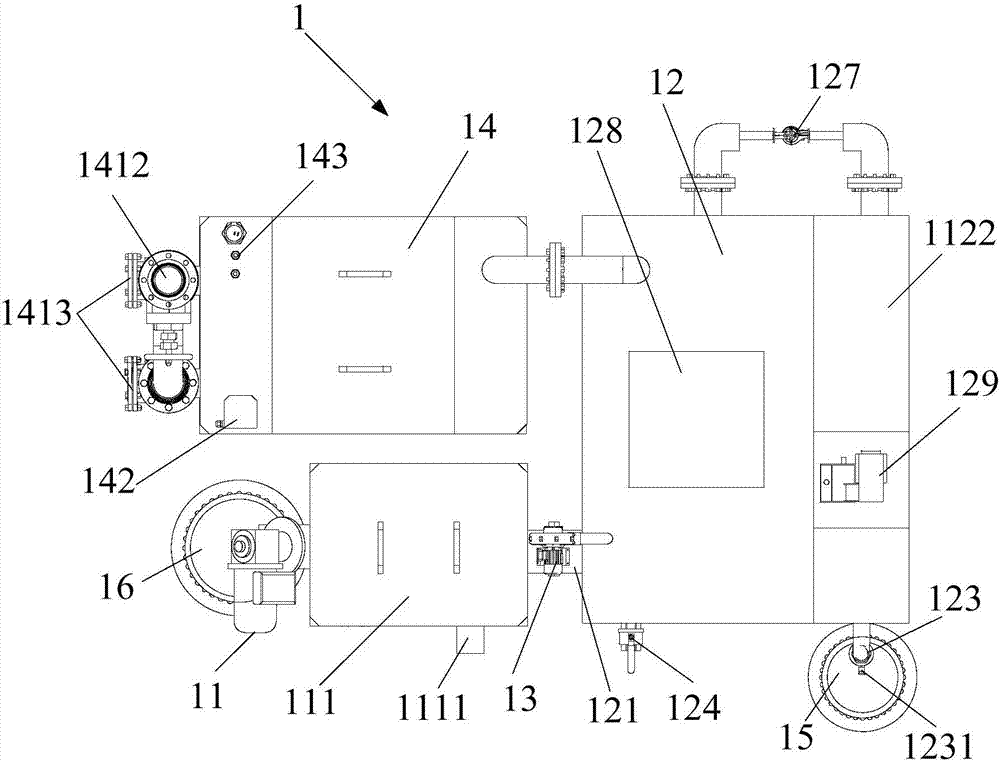

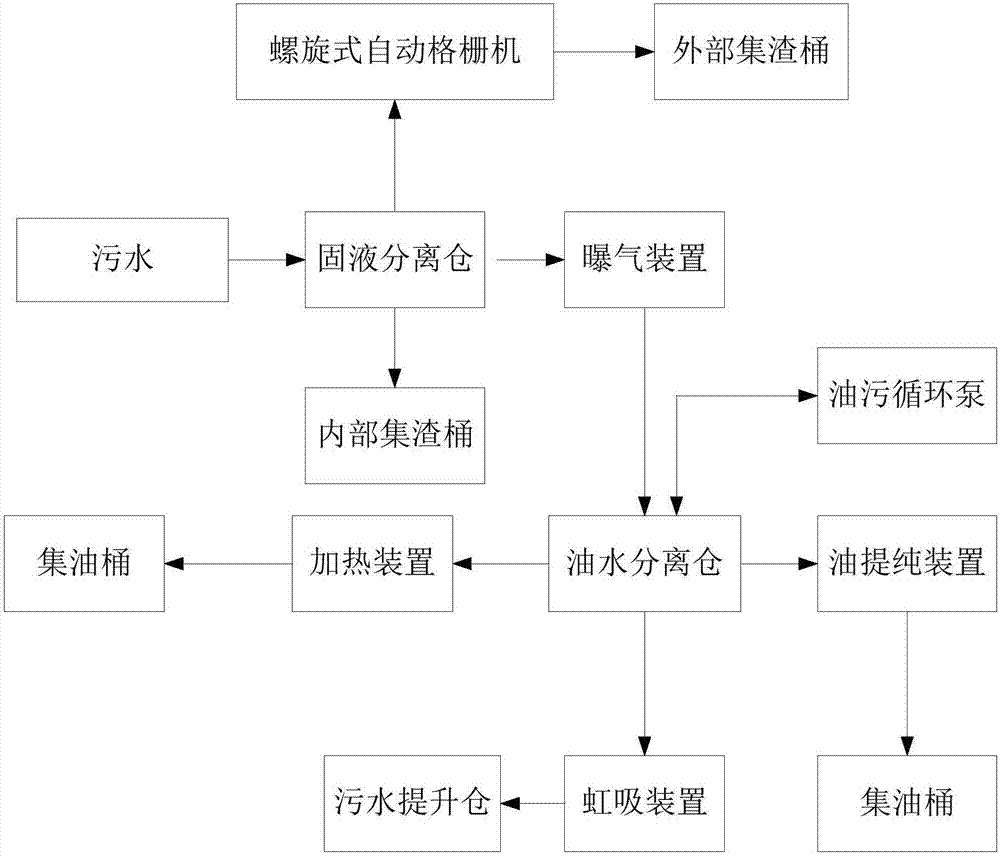

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a combined automatic oil-water separation device 1, comprising a solid-liquid separation device 11, an oil-water separation bin 12, a sewage lifting bin 14, an oil collection barrel 15 and an external slag collection barrel, the solid-liquid separation device 11 includes a solid-liquid separation bin 111, an internal slag collection barrel 112, and a spiral automatic grill machine located inside the solid-liquid separation bin 111. The slag bucket 112 is in communication, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com