Installing construction method for semiconductor manufacture procedure gas conveying pipelines

A technology for conveying pipelines and construction methods, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as leakage of exhaust gas, safety accidents, etc., prevent deformation and leakage, ensure welding quality, and improve sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

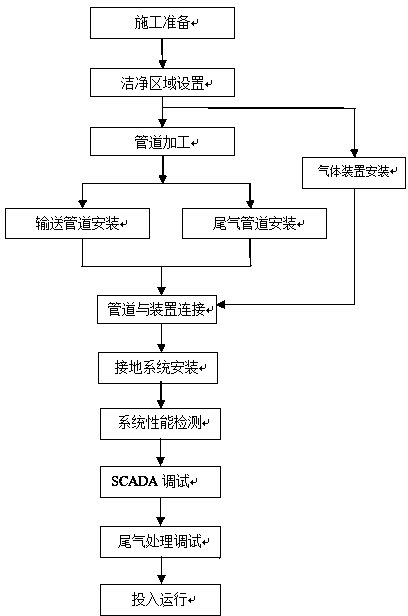

[0038] like figure 1 As shown, the present invention mainly includes the following steps: construction preparation, clean area setting, pipeline processing, pipeline installation, gas device installation, pipeline and gas device connection, grounding system installation, system performance testing and computer control system debugging. The above steps will be described in detail below.

[0039] (1) Construction preparation

[0040] According to the different characteristics of semiconductor process gases, the corresponding gas cabinets, valve boxes, pipe fittings, and valves must be purchased from designated manufacturers and sealed in packaging. Portable metal spectrometer is used to re-inspect the pipes, pipe fittings, and valves to detect relevant parameters such as strength, airtightness, impurities, and chemical intergranular corrosion. The materials can only be put into construction after passing the inspection. All materials should be packed with double-layer film to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com