Method for realizing zero emission of dyeing wastewater with high salinity in printing and dyeing enterprises

A dyeing wastewater with high salt content technology, which is applied in the field of reuse and desalination of dyeing wastewater, can solve the problems of large steam consumption, high power consumption, high operating costs, and difficult costs, so as to reduce the amount of evaporated water, reduce treatment costs, Effect of High Current Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

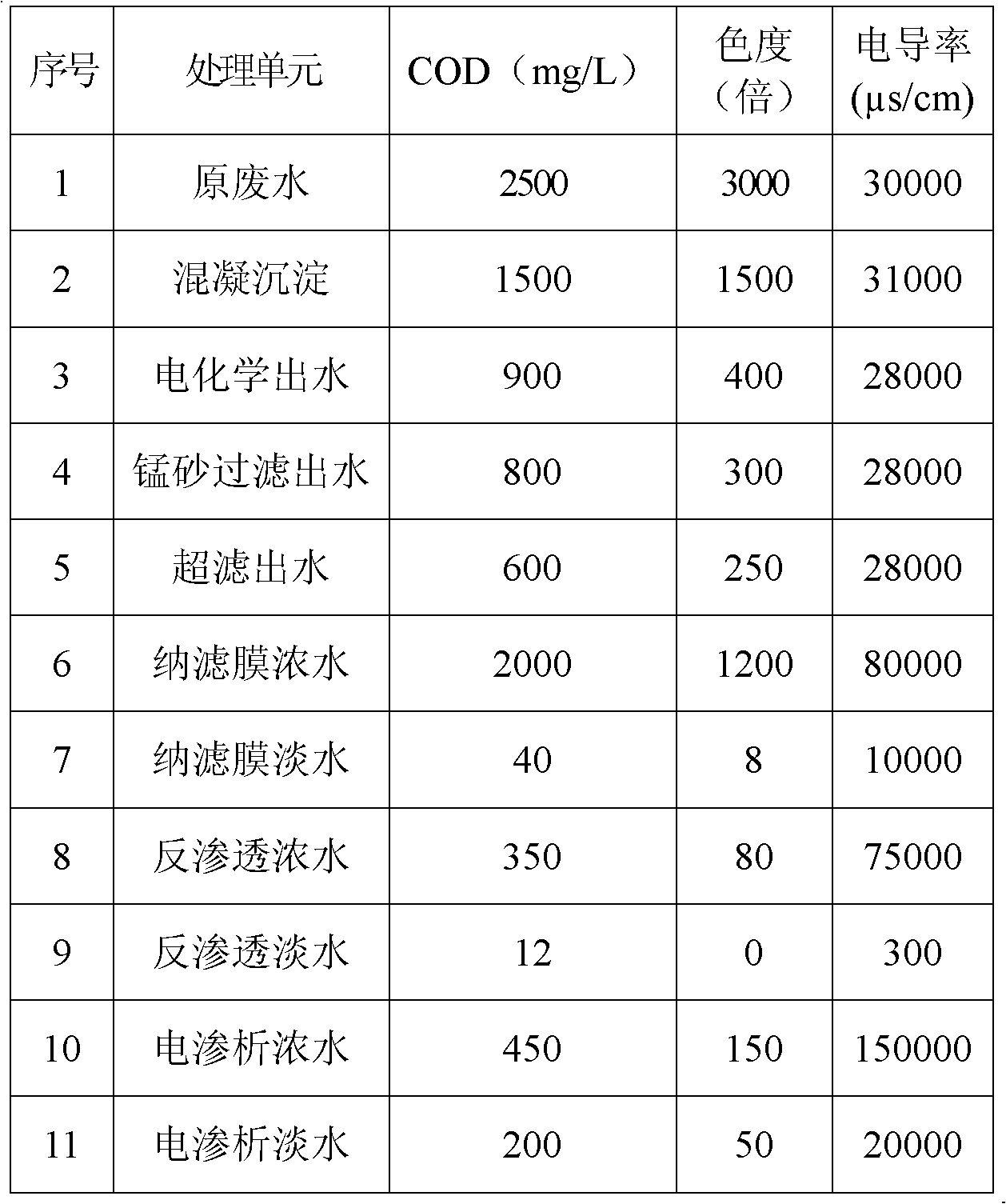

[0024] In a printing and dyeing enterprise, wastewater is generated in the desizing, smelting, dyeing, and rinsing sections. The main dyes in the dyeing section are reactive dyes, and the main additives used are sodium chloride and sodium hydroxide. In order to reduce the salt concentration of the discharged wastewater and reach the agricultural irrigation water quality standard (TDS<1000mg / L), the high-salt dyeing section wastewater is treated separately. Among them, the influent COD is 2000mg / L, the color is 1200 times, and the conductivity is 20000μs / cm.

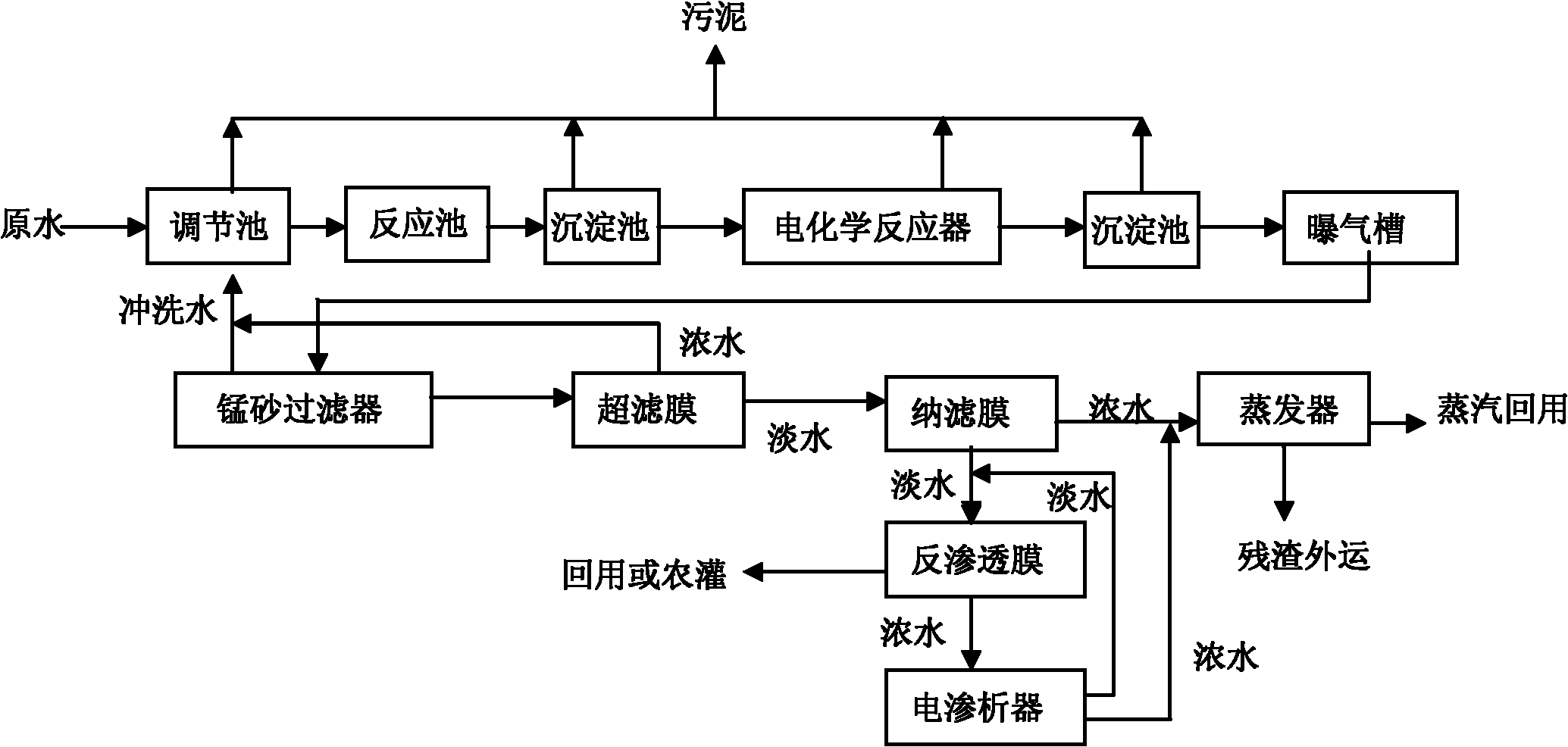

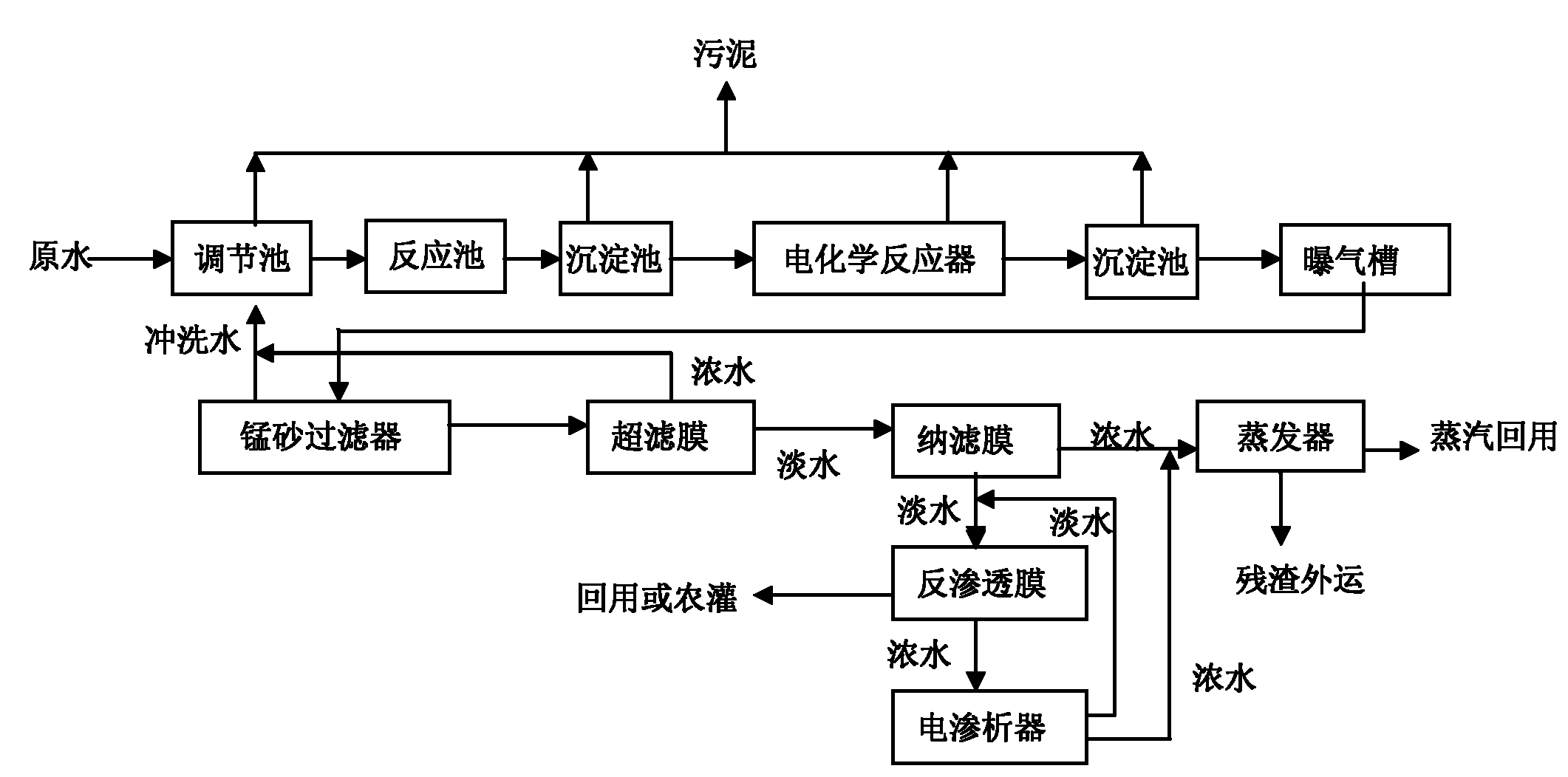

[0025] See the specific operation process figure 1 . First, the high-concentration dyeing wastewater is sent to the conditioning tank for homogenization; then into the reaction tank, adding 30~5000mg / L of ferrous sulfate to adjust the pH value of the printing and dyeing wastewater to 7, and coagulation reaction occurs; the effluent from the reaction tank enters the sedimentation tank for precipitation, and the wastewater is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com