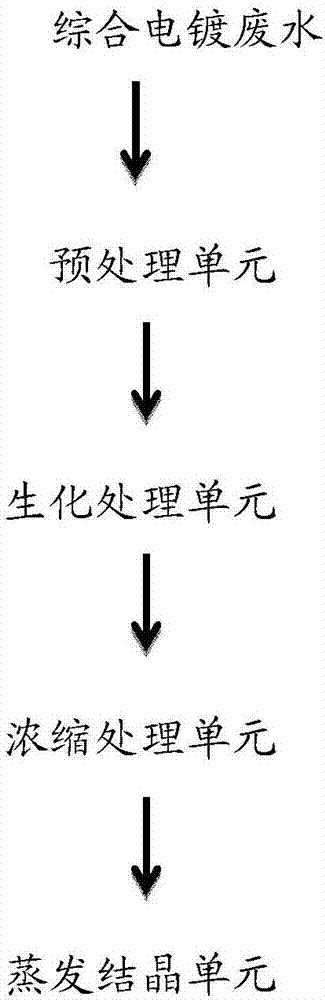

Comprehensive electroplating wastewater treatment method and system and application thereof

A treatment method and technology for electroplating wastewater, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as large acid and alkali consumption, low economic efficiency, and resin cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] (1) Comprehensive electroplating wastewater is pretreated to obtain pretreated water

[0157] First, take the comprehensive electroplating wastewater. The comprehensive wastewater mainly comes from the cleaning water produced by the cleaning of the plated parts, the cleaning of the filter, and the cleaning of the electrode plate after the galvanizing process. It mainly contains zinc ions, SS, COD and other pollutants.

[0158] The comprehensive electroplating wastewater was introduced into the pH adjustment tank, and sodium hydroxide solution with a concentration of 10% was added until the pH was 9-12; the treated wastewater was introduced into the chemical reaction tank, and the coagulant FeCl was added. 3 , then add flocculant PAM, and stir for 20-30min; introduce the treated wastewater into a precision-controlled high-efficiency sedimentation system; the precision-controlled high-efficiency sedimentation system is sequentially connected by a water distribution system,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com