Wind power generator cooled by solar injection

A wind generator, jet-type technology, applied in the direction of wind generator components, wind engines, wind motor combination, etc., can solve the problem that it is difficult to meet the high-efficiency and reliable work requirements of high-power wind generators, and cannot meet the requirements of high-power wind power generation High efficiency, reliable operation, great influence of cooling temperature and other problems, to achieve remarkable environmental protection effect, good environmental protection benefit and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

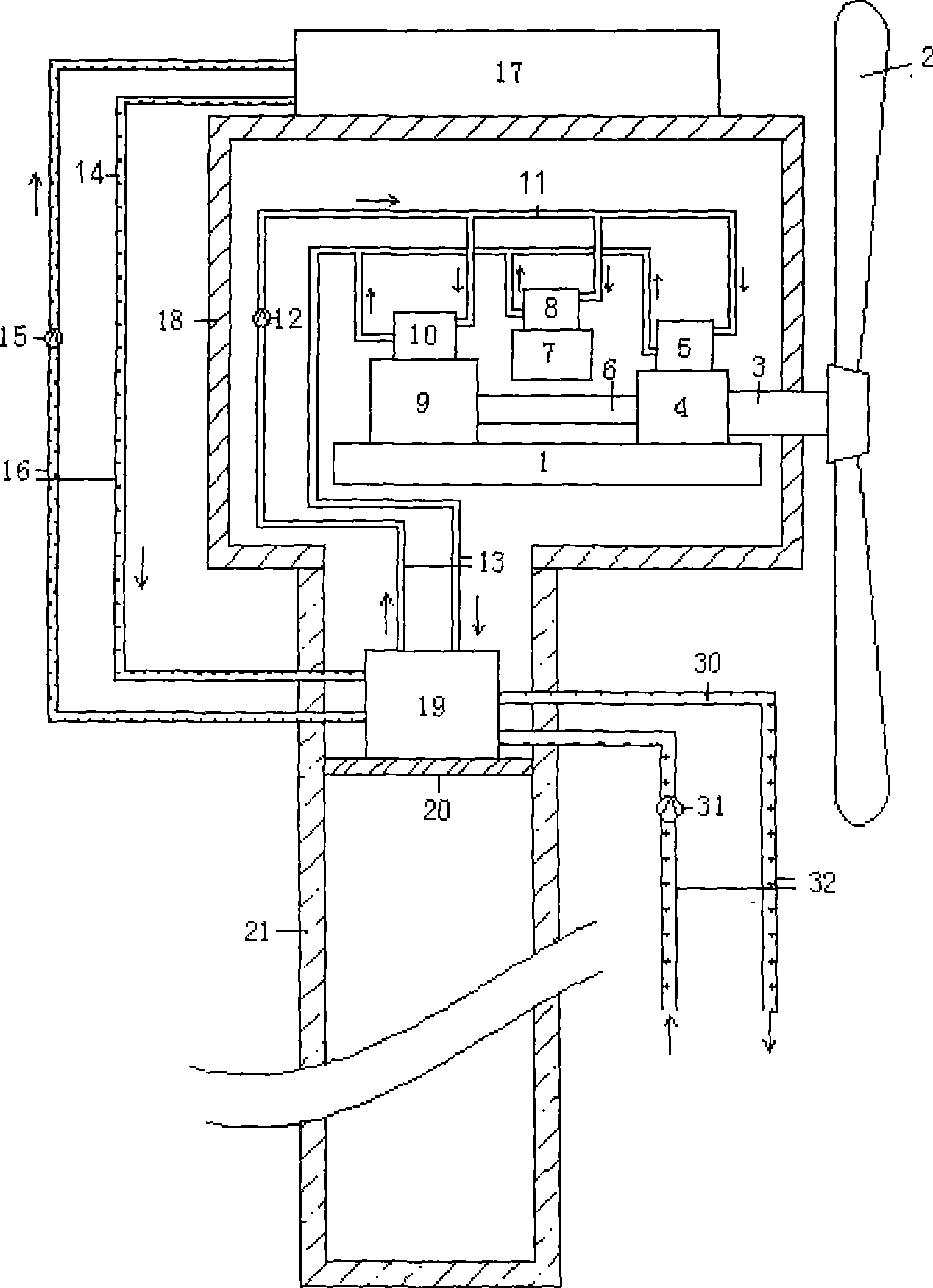

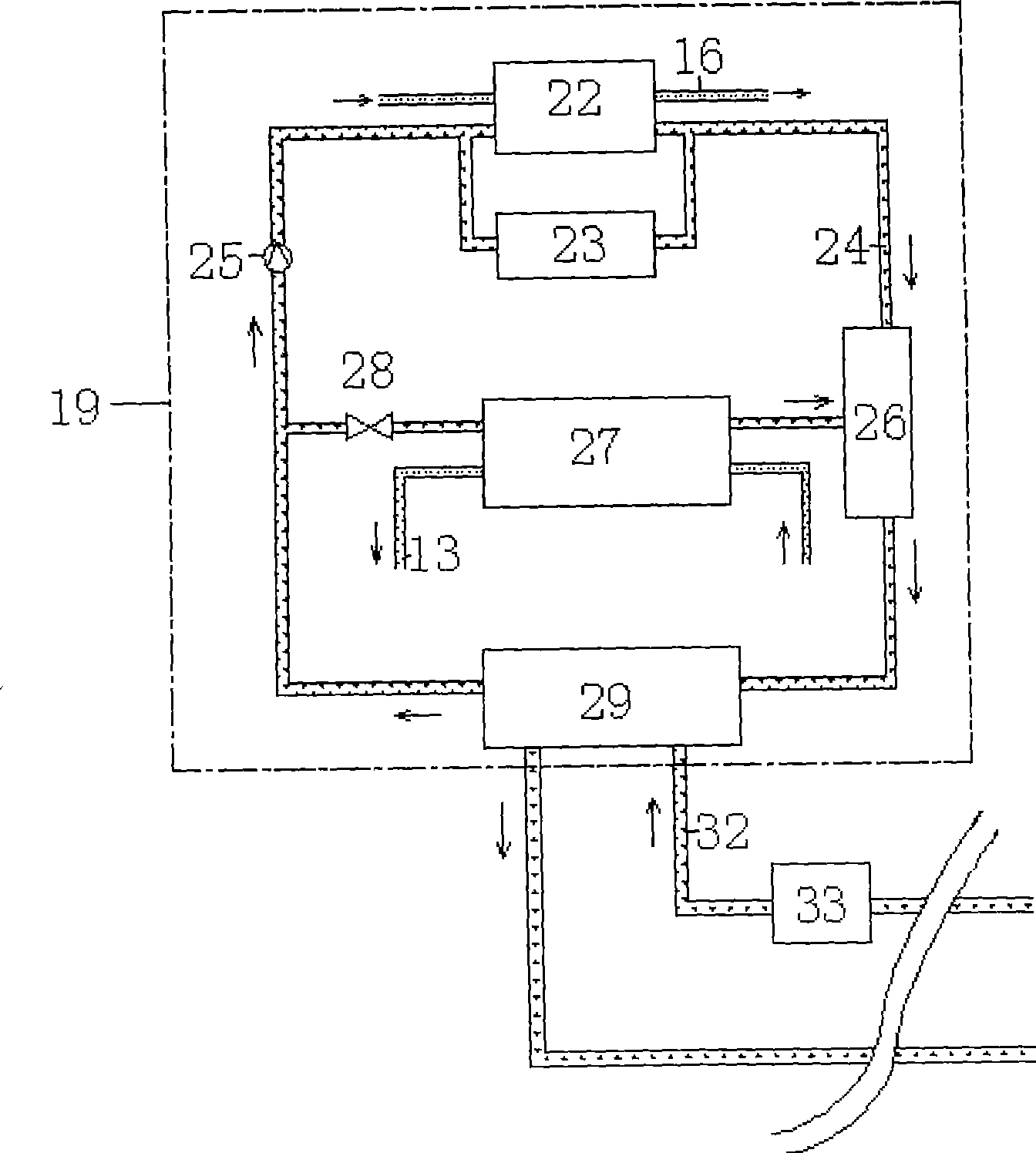

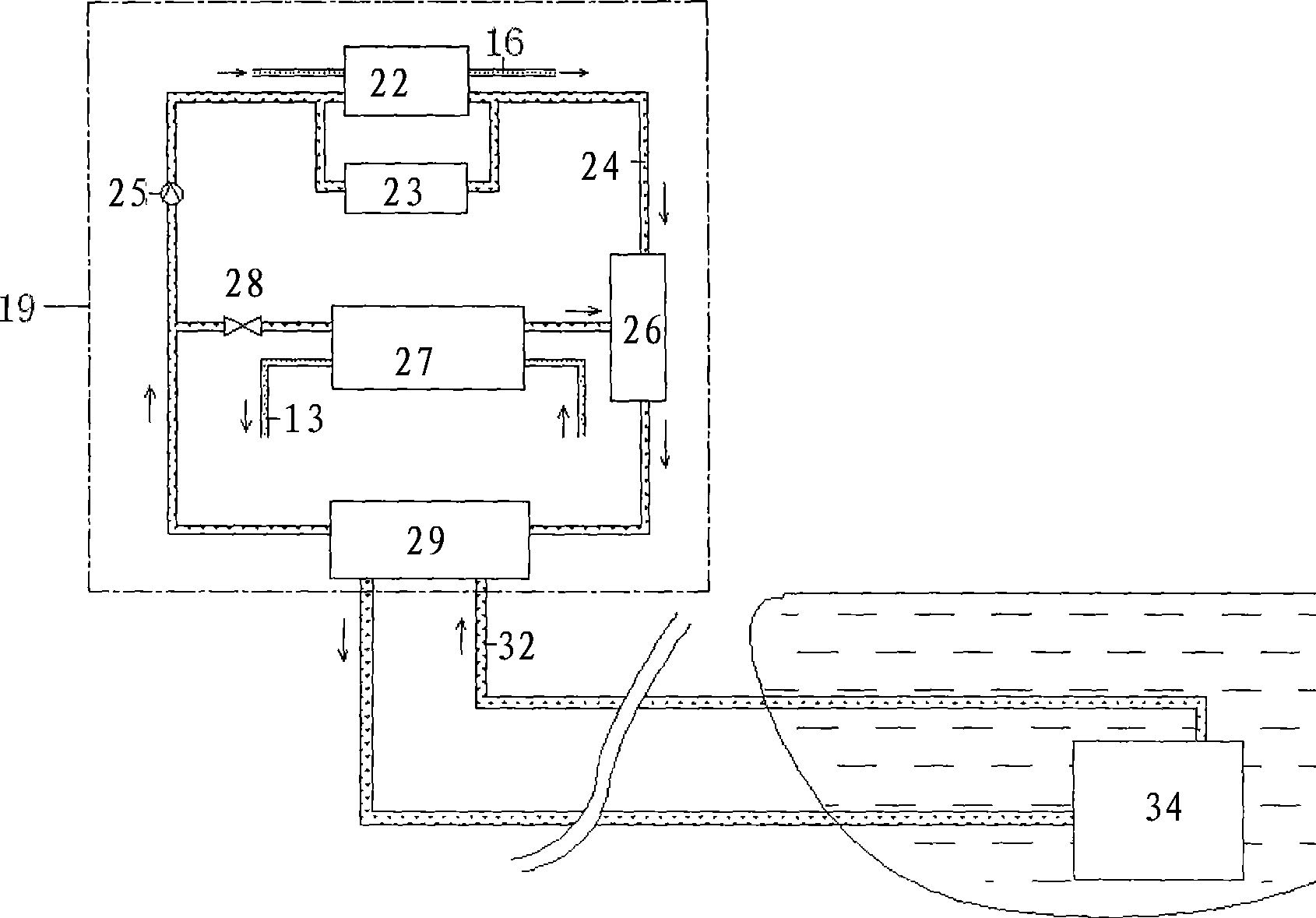

[0011] according to figure 1 As shown, the wind power generator adopting solar jet cooling of the present invention mainly includes a stand 1, a wind wheel 2, a low-speed shaft 3, a gear box 4, a gear box heat exchanger 5, a high-speed shaft 6, a control frequency converter 7, Control frequency converter heat exchanger 8, generator 9, generator heat exchanger 10, brine 11, circulation pump I 12, brine delivery pipe 13, heat storage agent 14, circulation pump II 15, heat storage agent delivery Pipe 16, nacelle cover 18, tower platform 20, tower frame 21, cooling medium 30, circulation pump III 31, cooling medium delivery pipe 32; It is characterized in that it also includes the solar heat collector 17 placed on the outer surface of the nacelle cover, and An ejector refrigerator 19 for cooling the brine 11 circulating through the gearbox heat exchanger, the control frequency converter heat exchanger and the generator heat exchanger.

[0012] When wind power generation works, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com