Wind power speed increasing box spline connection lubricating and cooling system

A lubricating cooling and speed-increasing box technology, applied in the direction of gear lubrication/cooling, can solve problems such as spline failure, inability to ensure effective lubrication and cooling of key teeth, and achieve the effect of reducing heat wear and ensuring operating life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

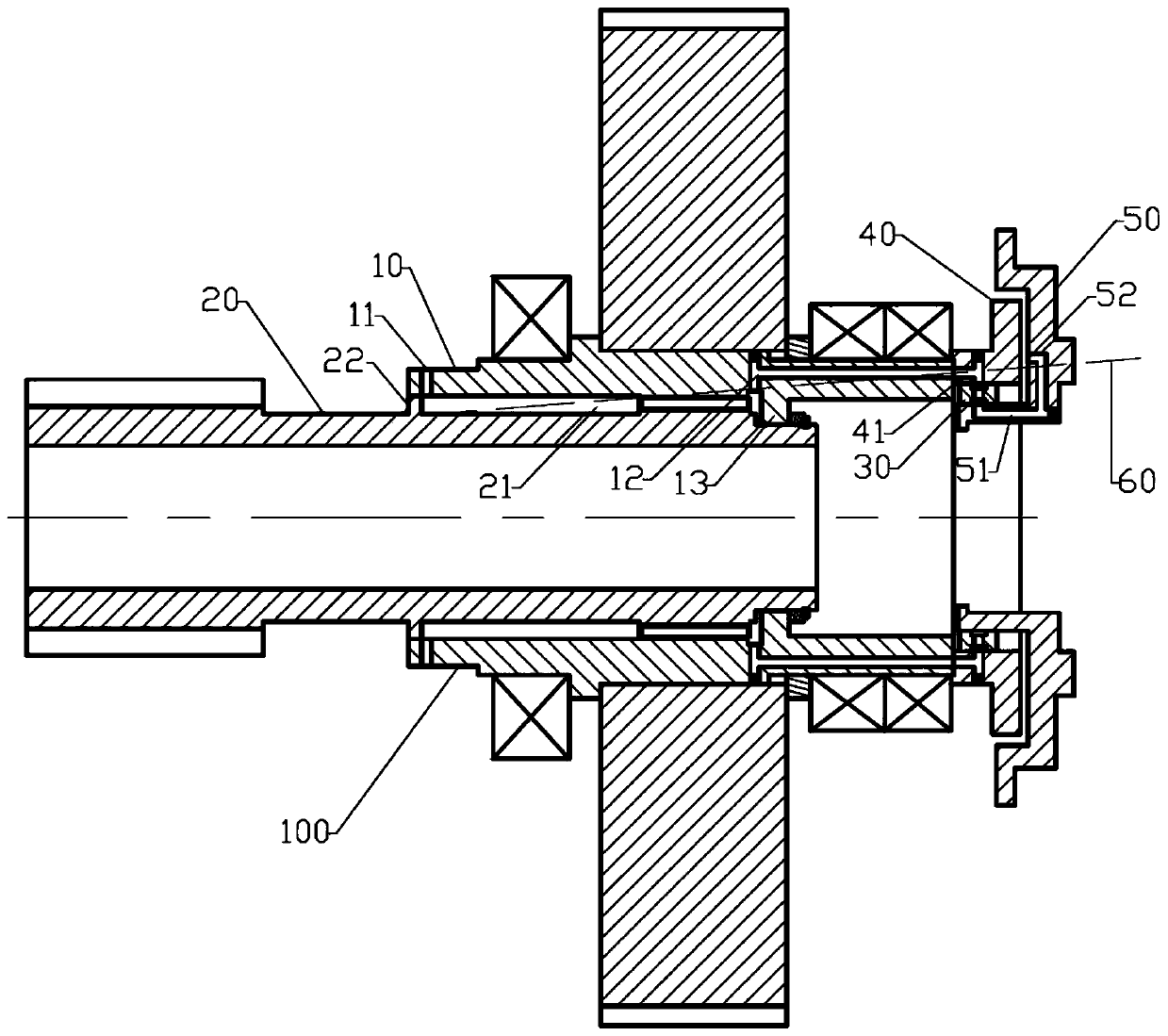

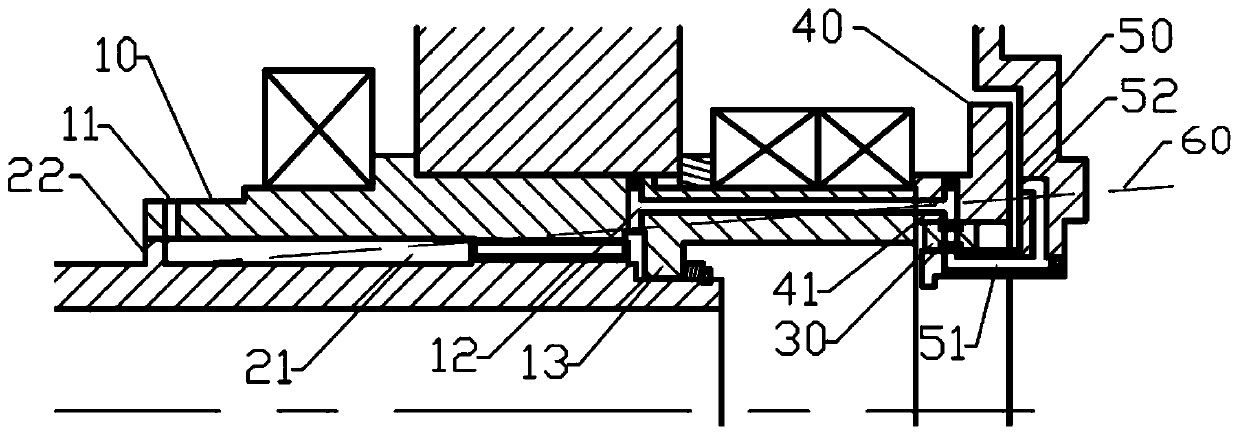

[0024] Such as figure 1 and figure 2 As shown, a spline connection lubrication and cooling system 100 for a wind power gearbox includes: a spline shaft 10 , a sun gear 20 , an oil pump gear 40 and a transparent cover 50 .

[0025] The spline shaft 10 and the sun gear 20 are connected by splines. The oil pump gear 40 is connected to the spline shaft 10 . The spline shaft 10 , the sun gear 20 and the oil pump gear 40 all rotate relative to the transparent cover 50 . Specifically, the transparent cover 50 is fixed to the box body of the speed-up box and is in a static state. The transparent cover 50 is a fixed part. The spline shaft 10, the sun gear 20 and the oil pump gear 40 are moving parts and are in a state of rotary motion.

[0026] An oil storage cavity 21 is provided between the spline shaft 10 and the sun gear 20 . In other word...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com