Silicon dioxide coating resisting to high temperature and corrosion and preparation method and application thereof

A silicon dioxide and corrosion-resistant technology, applied in coatings, metal material coating processes, liquid chemical plating, etc., can solve problems such as being easily affected by water vapor in the air, poor hydrophobic performance, and unfavorable industrial production , to achieve the effect of ensuring long-term safe and stable operation, ensuring service life and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

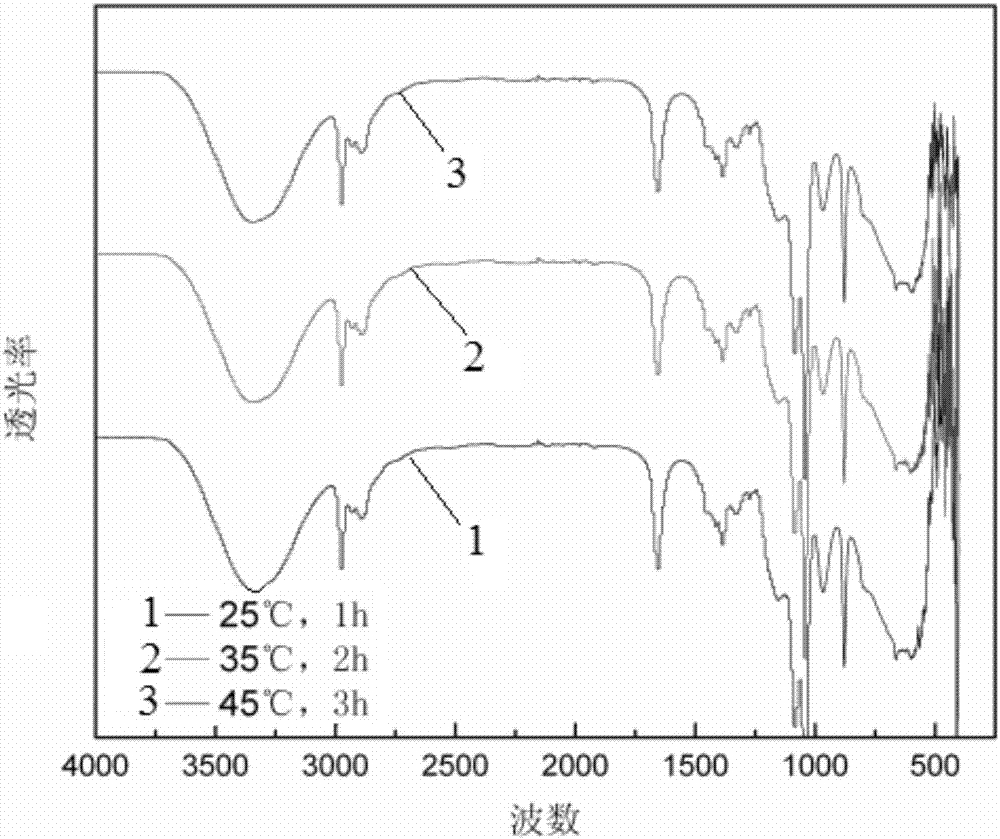

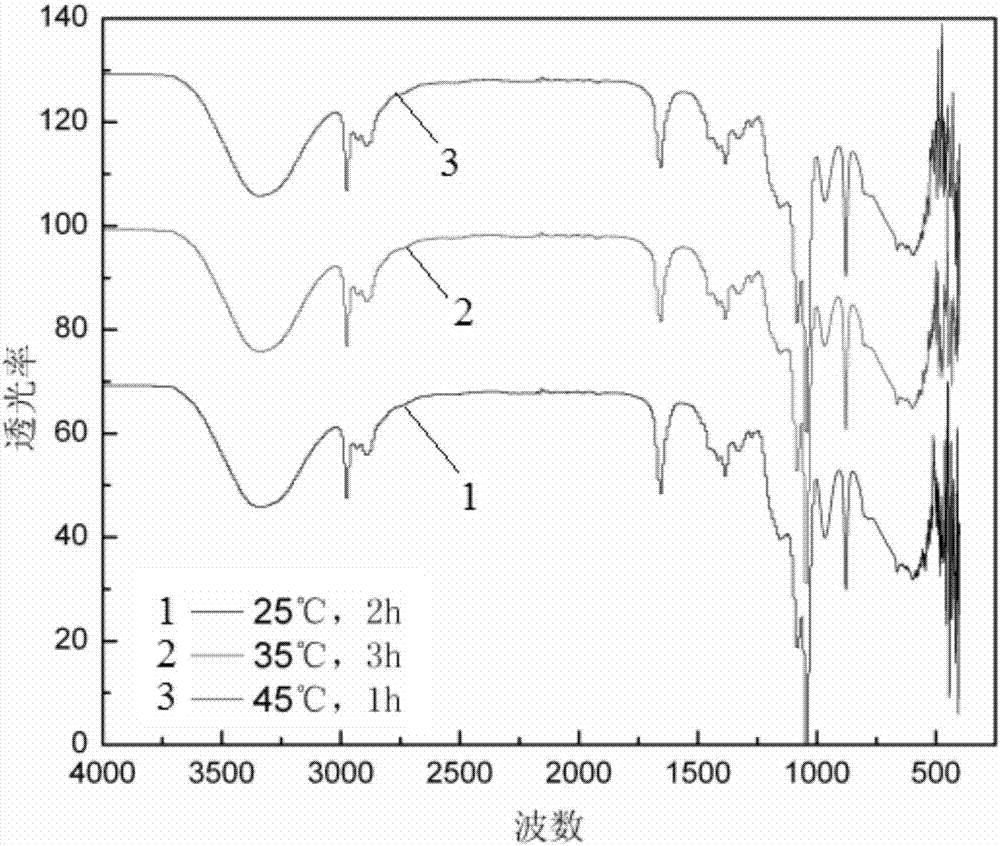

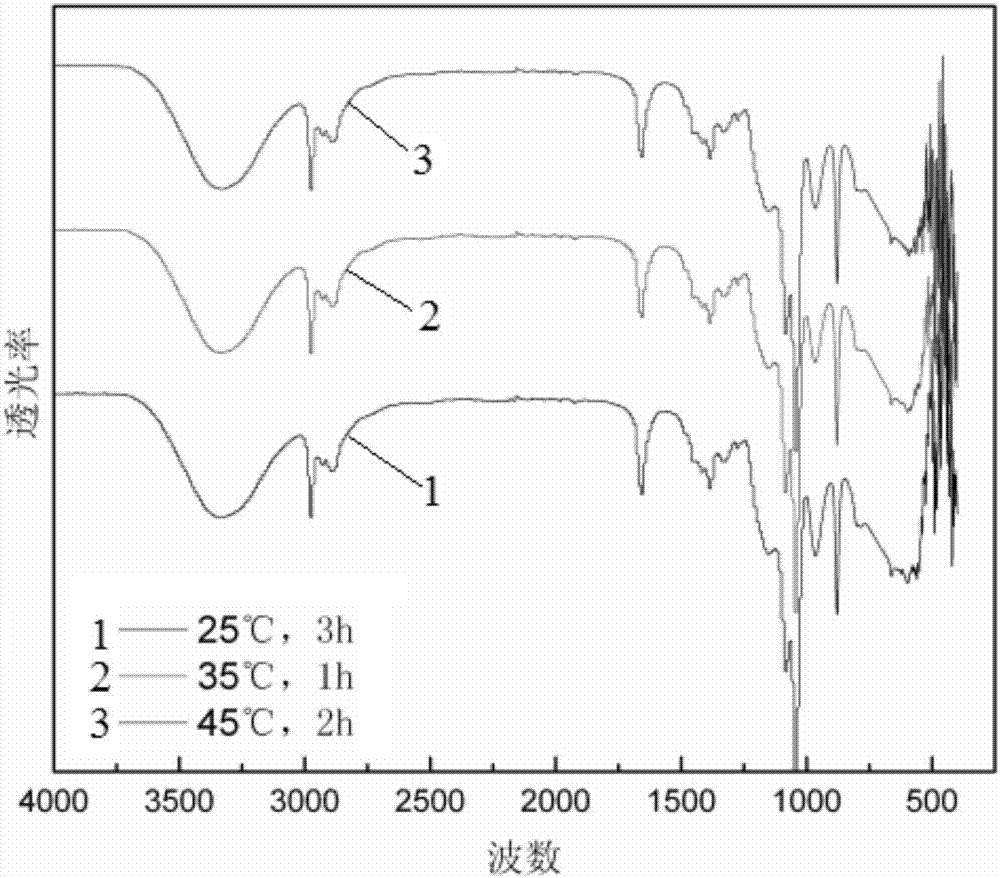

[0033] Specific embodiment one: the preparation method of the high-temperature and corrosion-resistant silicon dioxide coating of this embodiment is carried out according to the following steps:

[0034] Step 1. Weigh the raw materials according to the molar ratio of ethyl orthosilicate, absolute ethanol and deionized water as 15:21:81,

[0035] Then dehydrated ethanol was divided into two equal parts, wherein a part of dehydrated ethanol and ethyl orthosilicate were mixed and stirred for 20 minutes to obtain solution A,

[0036] Another part of absolute ethanol and deionized water was mixed and stirred for 20 minutes, then fluorosilane coupling agent was added dropwise to obtain solution B, and then solution A and solution B were mixed and stirred for 30 minutes in a water bath at 45°C under condensing and reflux conditions, and continued to stir At the same time, in step 1, add 3 drops of fluorosilane coupling agent per 2 g of 65% (mass) nitric acid, slowly drop N,N-dimethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com