Method for determining thickness of high speed railway bedding structure of ballast track

A technology of high-speed railway foundation and determination method, applied in the field of railway engineering, can solve problems such as inability to guarantee calculation accuracy, influence of calculation results, and only consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

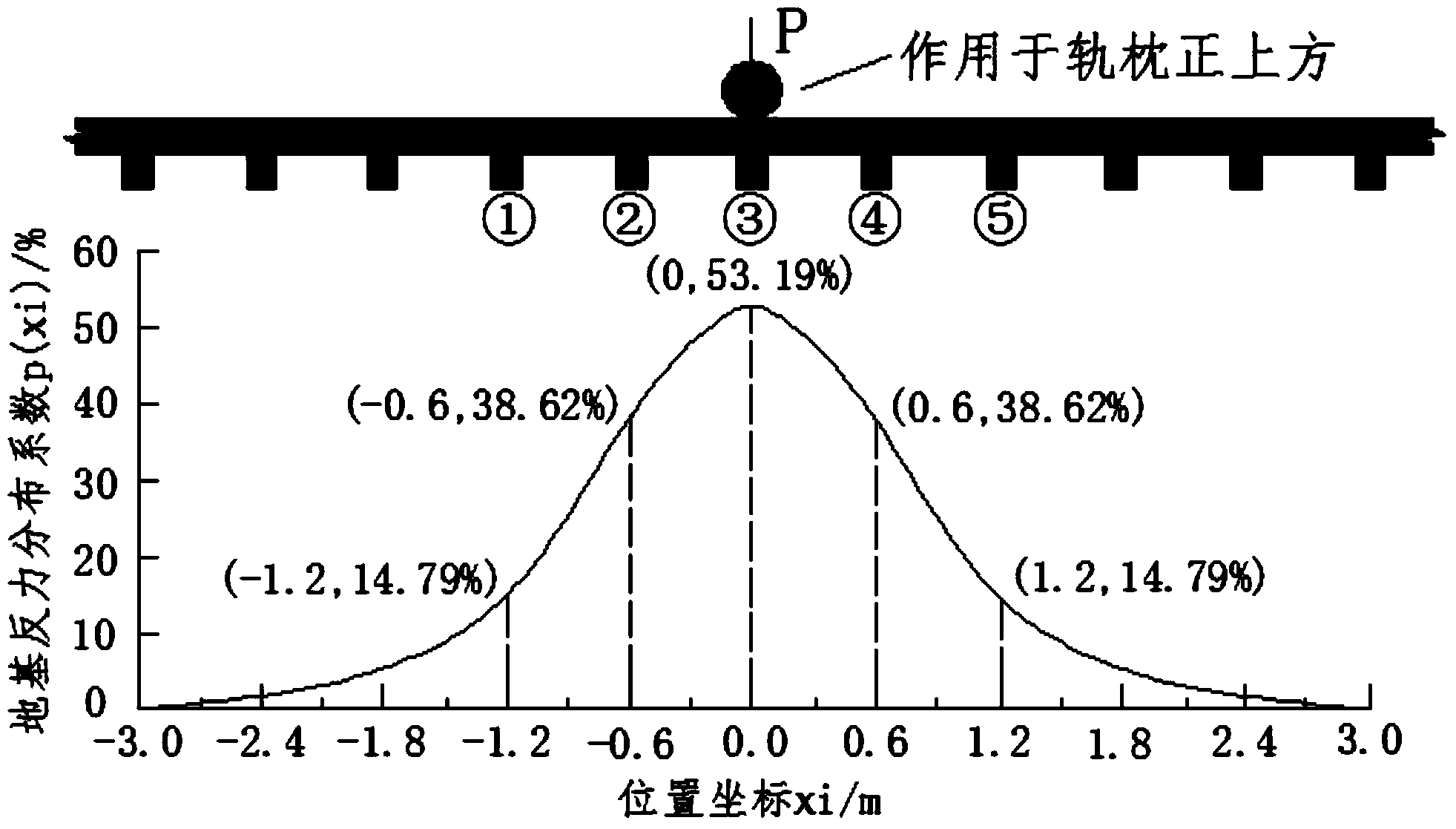

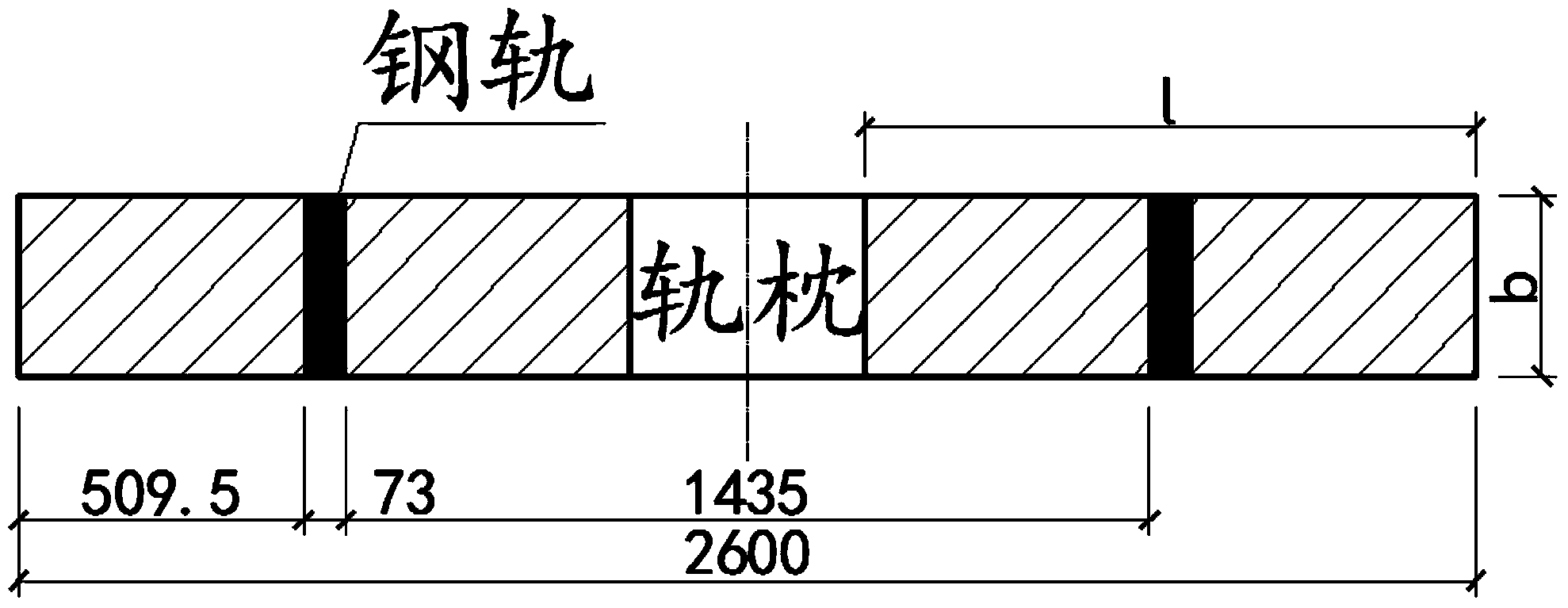

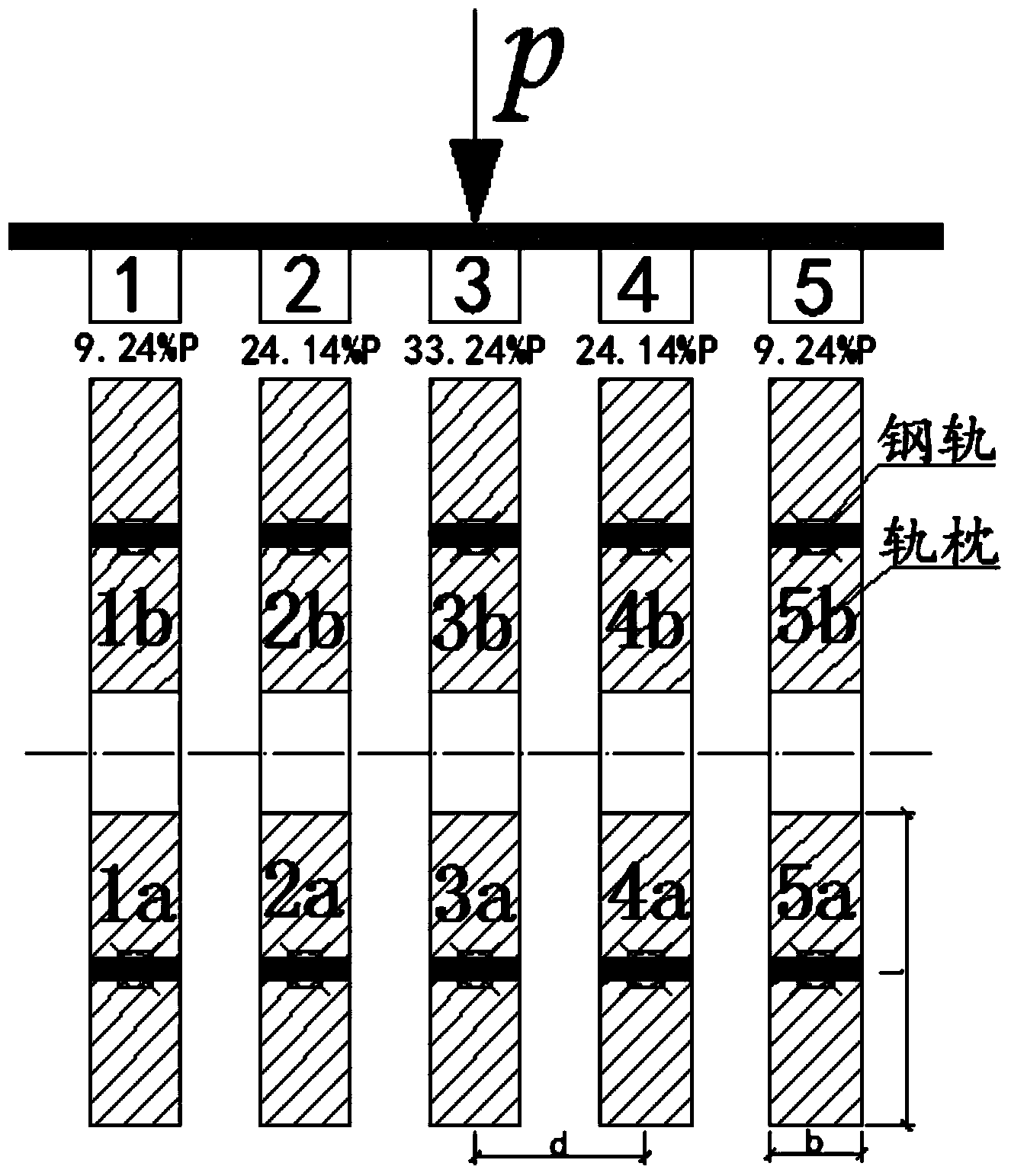

[0043] Figure 1-3 Shown, a kind of embodiment of the present invention is, a kind of method for determining the thickness of ballasted track high-speed railway bed structure, its steps are as follows:

[0044] A. Sharing of wheel load

[0045] Calculate the load P of the left wheel borne by the five sleepers i under the wheel ia , right wheel load P ib :

[0046] P ia = P ib = 1 2 P ( 1 + 0.003 v ) · e - ( i - 3 ) 2 3.125 / Σ i = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com