Quantitative product output mechanism of packaging equipment

A technology of packaging equipment and output mechanism, which is applied in the field of product quantitative output mechanism, can solve the problems of low operating efficiency and prolonging the service life of the equipment without using it, and achieve the effect of improving operating efficiency and ensuring operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

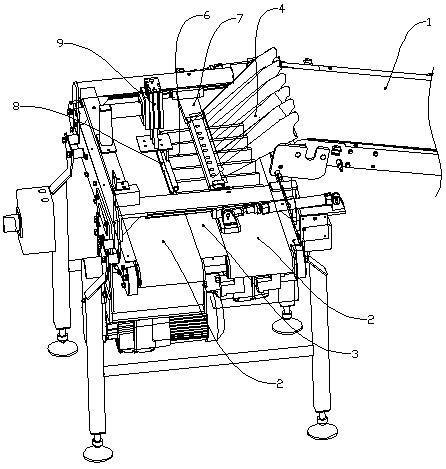

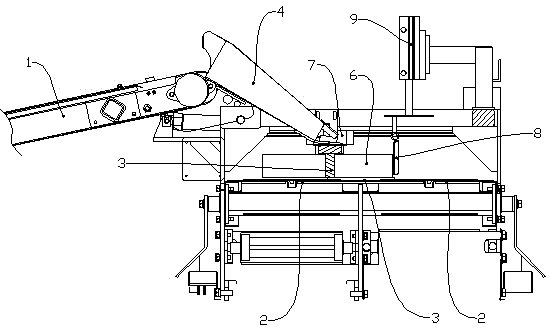

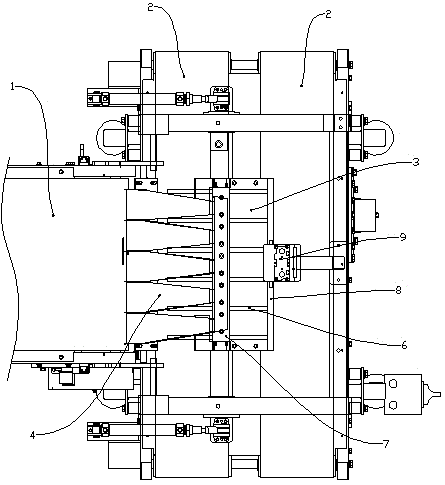

[0013] As shown in the figure, the product quantitative output mechanism of the packaging equipment includes a conveyor belt 1 capable of conveying products piece by piece, and two horizontal discharge conveyor belts 2 perpendicular to the conveying direction of the conveyor belt are arranged below the end of the conveyor belt. The running directions of the two discharge conveyor belts are opposite, and a fixed material receiving platform 3 is arranged between the two discharge conveyor belts; above the material receiving platform, there is a material guide groove 4 connected with the end of the conveyor belt 1, so that the end of the conveyor belt 1 The output product can slide onto the material receiving platform 3 along the material guide groove 4; the top of the material receiving platform 3 is provided with a pushing plate 5 that can reciprocate between two discharge conveyor belts 2 (see figure 2 ), the reciprocating movement of the pusher plate 5 can push the products o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com