Self-flow-disturbing injection mold pouring system

A technology of injection mold and gating system, which is applied in the field of self-disturbing injection mold gating system, can solve the problems affecting the normal operation and service life of the mold, unfavorable mold space layout, and occupying mold space, so as to ensure normal operation and service life, The effect of reducing the cross-sectional area of the gate and increasing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

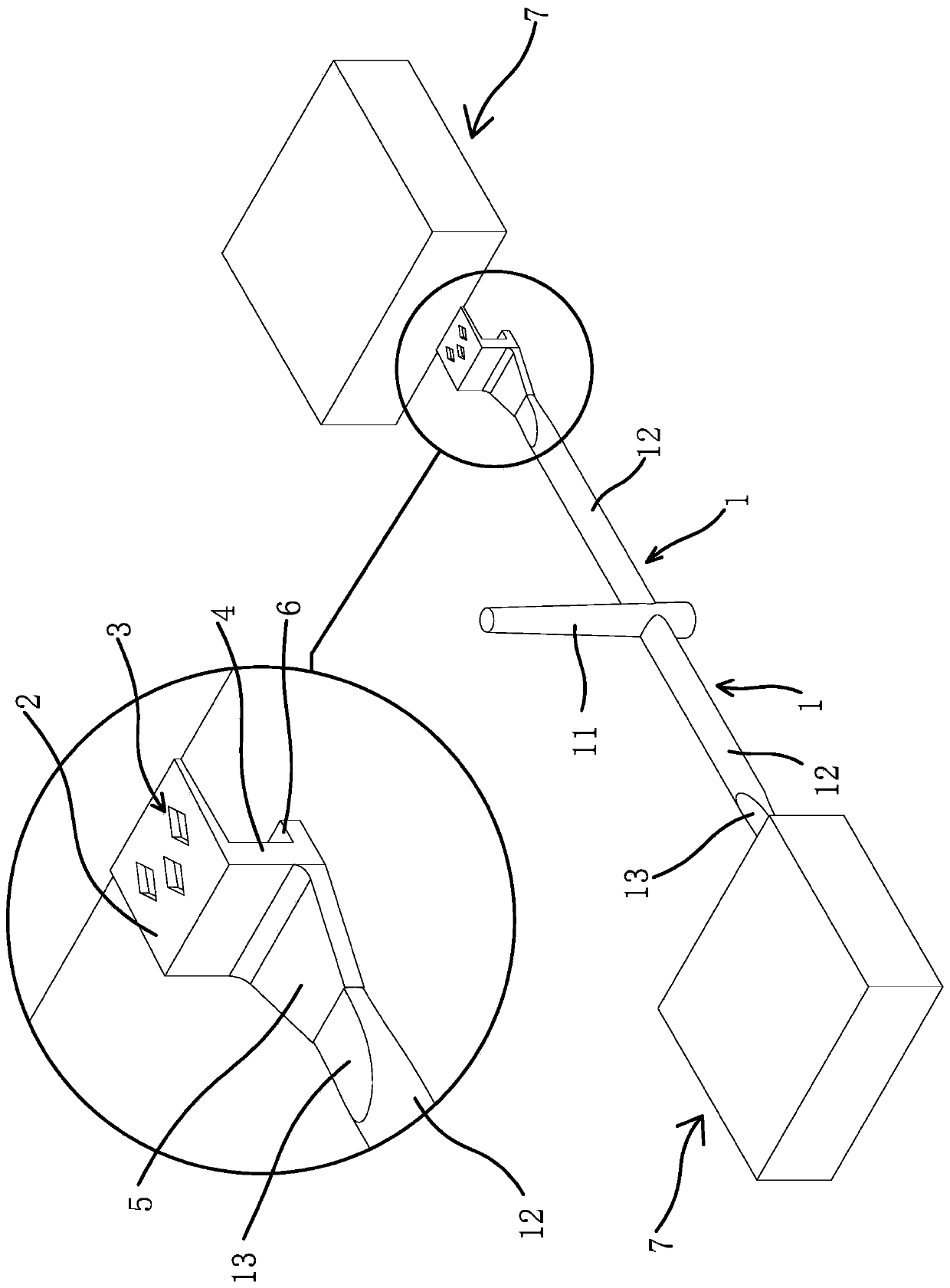

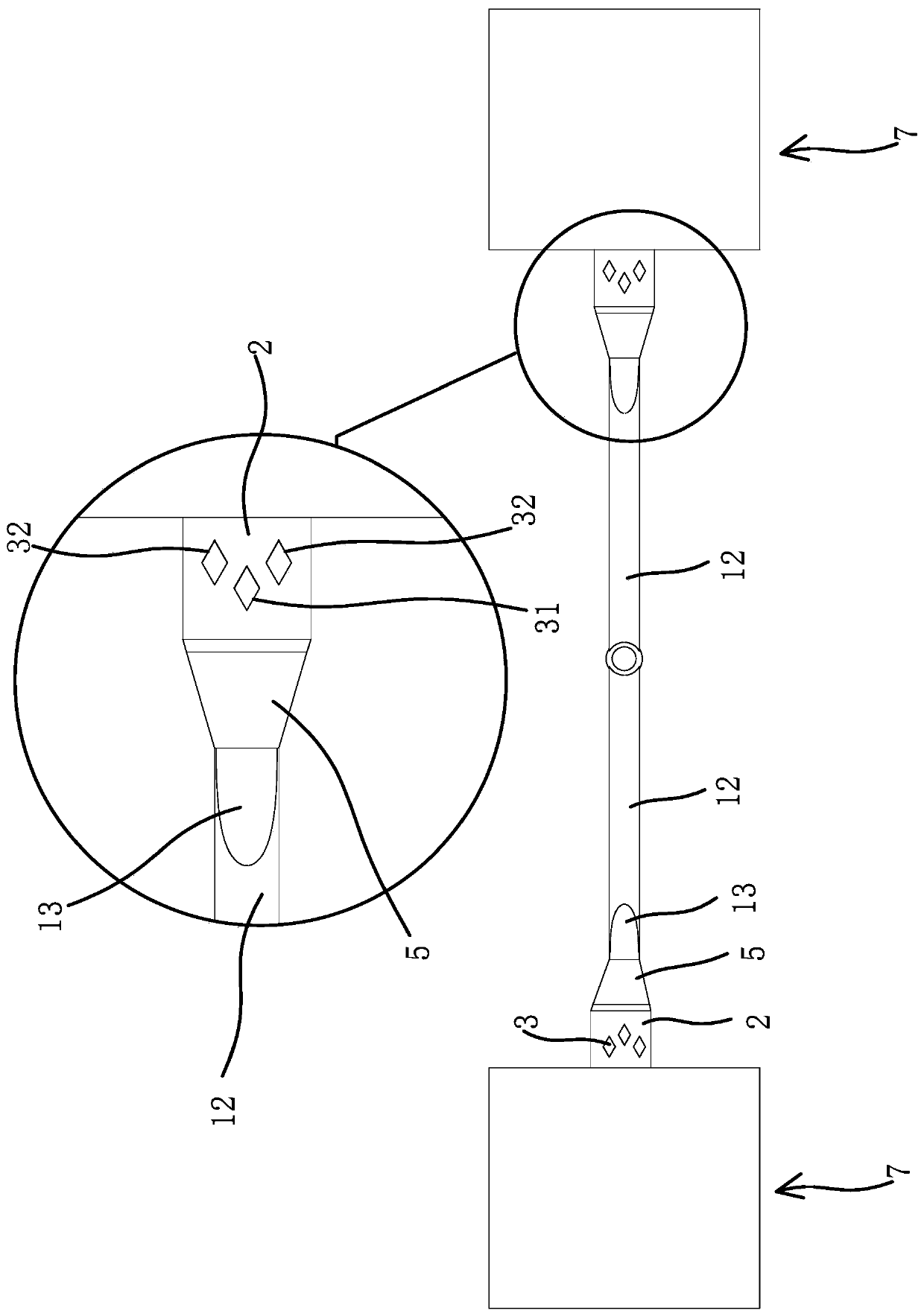

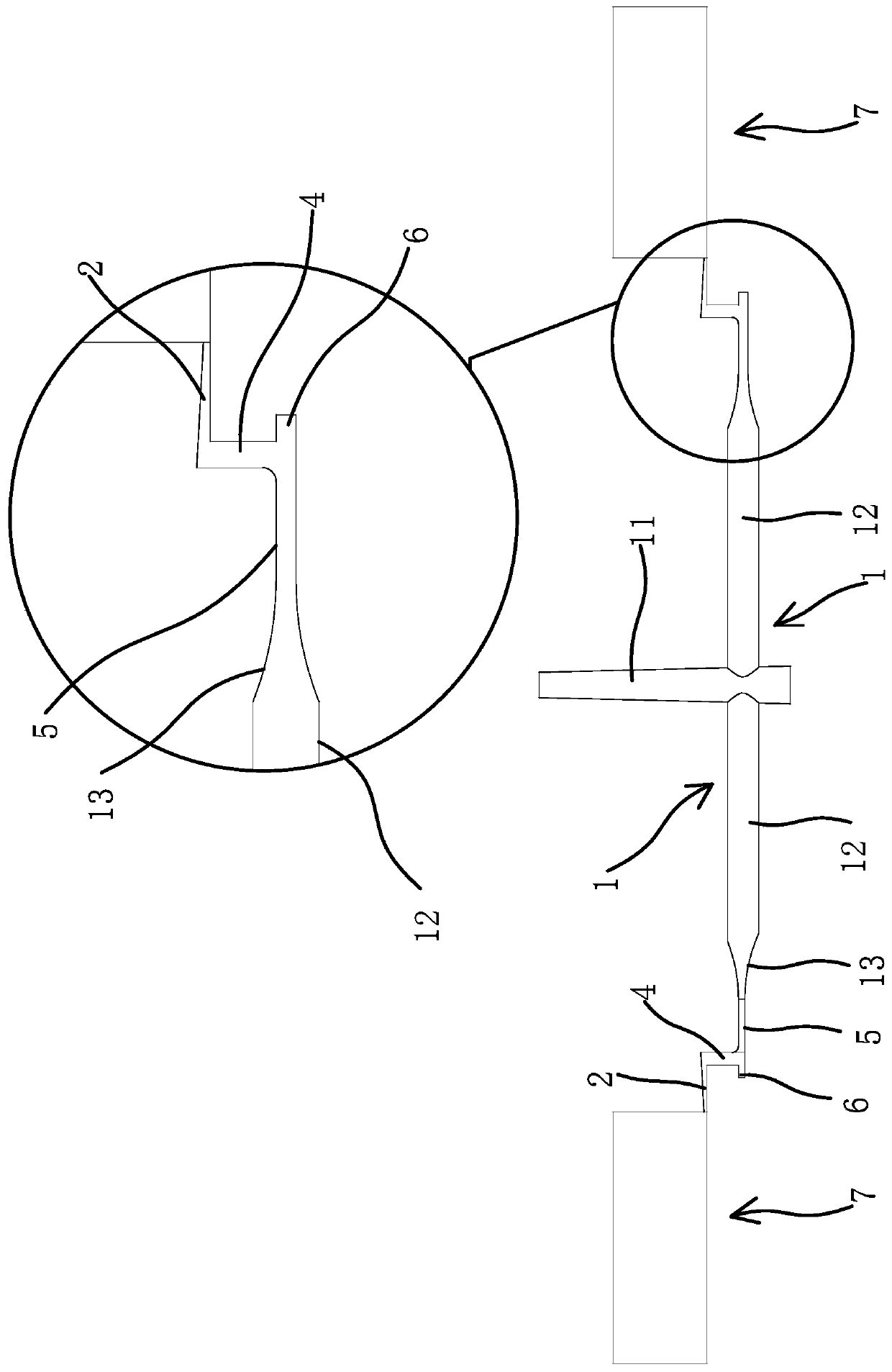

[0026] Such as Figure 1 to Figure 4As shown, this embodiment includes a circular tubular flow channel 1 for connecting external plastic melts. The flow channel 1 generally includes a vertically arranged main channel 11 and a branch channel 12 connected to the lower end of the main channel 11. The main channel 11 The opening at the upper end is the pouring inlet of the injection molding molten material. The existing injection mold is generally provided with two mold cavities 7 symmetrically in the center, so the number of runners 12 is generally two and symmetrically arranged on both sides of the main flow channel 11, so that the injection mold is formed in the injection mold for feeding the two mold cavities respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com