Dipping insulating paint and preparation method therefor

An impregnated insulation and unsaturated technology, which is applied in the direction of coating, epoxy resin coating, polyester coating, etc., can solve the problems of loss of insulating paint, less paint hanging on motors, and waste of insulating paint, so as to achieve energy-saving production efficiency and saving Material, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

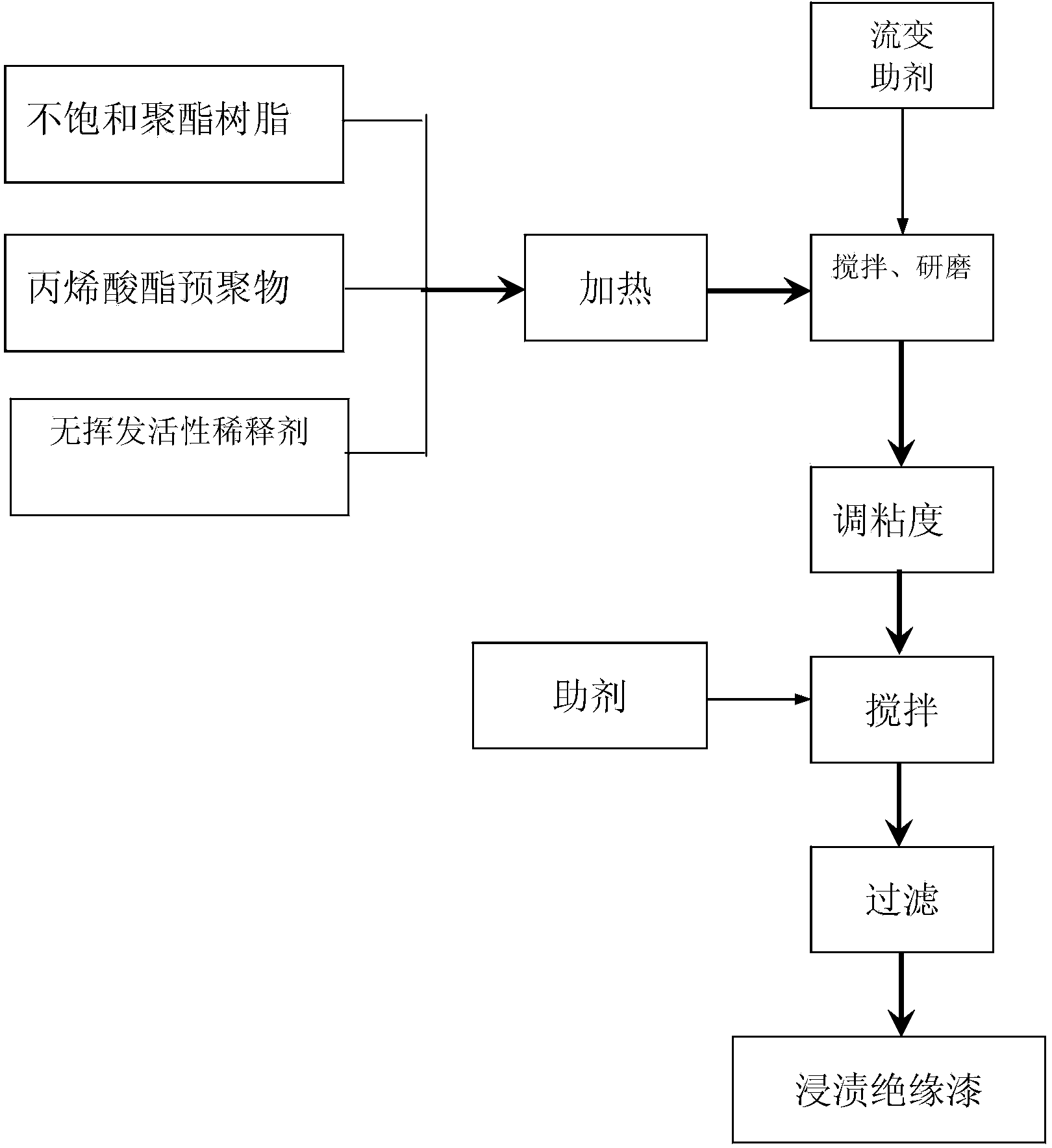

[0032] Such as figure 1 , the preparation method of impregnated insulating varnish of the present invention mainly comprises the following steps:

[0033] Step 1: Add all unsaturated polyester resin, acrylate prepolymer and 15-20 parts of non-volatile reactive diluent into the stirring tank, heat to 60-80°C, stir until the resin is completely dissolved and then cool down;

[0034] Step 2: Add a rheological additive to the resin solution in step 1, stir and grind;

[0035] Step 3: Adjust the paint to the specified viscosity range with active diluent;

[0036] Step 4: Add 1% to 2% of curing agent and 0.2% to 1% of additives such as polymerization inhibitor, leveling agent and defoamer;

[0037] Step 5: Filter to obtain impregnated insulating varnish.

[0038] The present invention has the following beneficial effects:

[0039] 1. Use non-volatile active diluent with high flash point and high boiling point to prepare solvent-free insulating paint. The product is environmental...

Embodiment 1

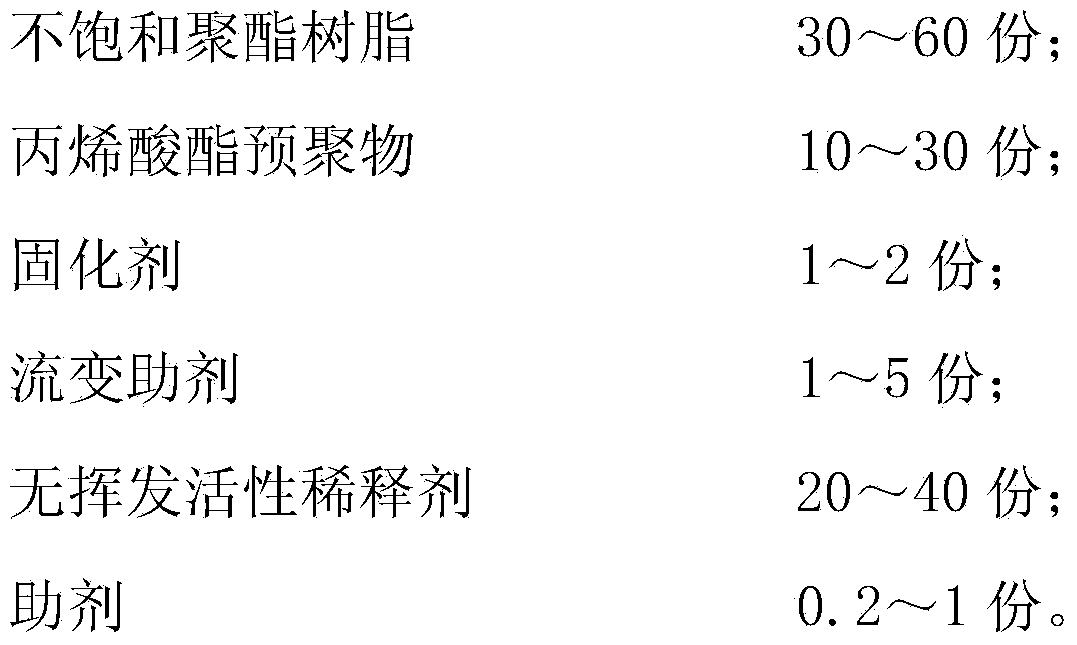

[0045] In parts by weight, the impregnated insulating varnish in this embodiment is made from the following raw materials:

[0046]

[0047]

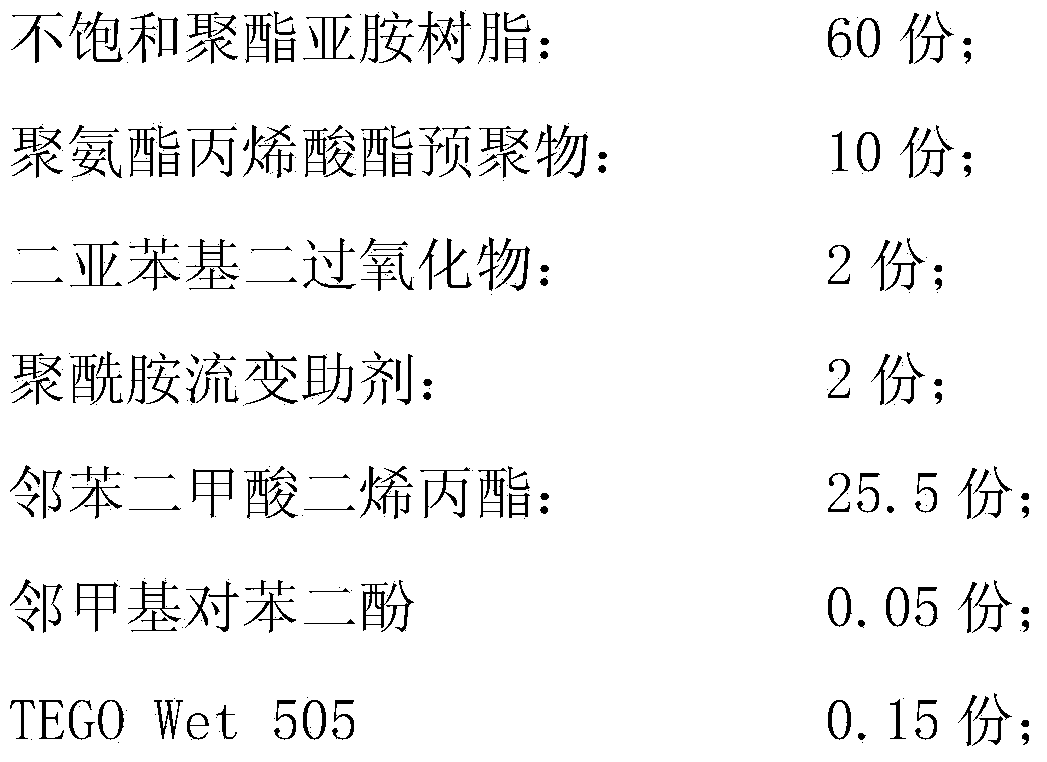

[0048]The preparation method of the above impregnated insulating varnish is as follows: add 60 parts of unsaturated polyesterimide resin, 10 parts of polyurethane acrylate prepolymer and 25.5 parts of diallyl phthalate into the stirring tank, and heat it to 60-80 ℃, stir until the resin is completely dissolved and then cool down, then add 2 parts of polyamide rheology additive, stir and grind, adjust the paint to the specified viscosity range with diallyl phthalate, then add 2 parts of diphenylene Diperoxide, 0.05 part of o-methylhydroquinone, 0.15 part of TEGO Wet505, 0.1 part of BYK307 and 0.2 part of TEGO Rad2500 were finally filtered to obtain impregnated insulating varnish.

Embodiment 2

[0050] In parts by weight, the impregnated insulating varnish in this embodiment is made from the following raw materials:

[0051]

[0052] The preparation method of the above impregnated insulating varnish is: add 46 parts of unsaturated polyester resin, 14 parts of epoxy acrylate prepolymer and 22 parts of neopentyl glycol dimethacrylate into the stirring tank, and heat to 60-80 ℃, stir until the resin is completely dissolved, then cool down, then add 1.5 parts of fumed silica, stir and grind, adjust the paint to the specified viscosity range with neopentyl glycol dimethacrylate, and then add 1 part of tert-butyl perbenzoate Esters, 0.05 parts of o-methylhydroquinone, 0.25 parts of TEGO Wet505, 0.1 parts of Levaslip435 and 0.1 parts of TEGO Rad2500, and finally filtered to obtain impregnated insulating varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com