Fuel cell system and low-temperature starting control method thereof

A fuel cell system, low-temperature technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of large gas consumption, reverse polarity, freezing, etc., to reduce the failure rate of low-temperature operation and increase temperature rise speed, guaranteed operating life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

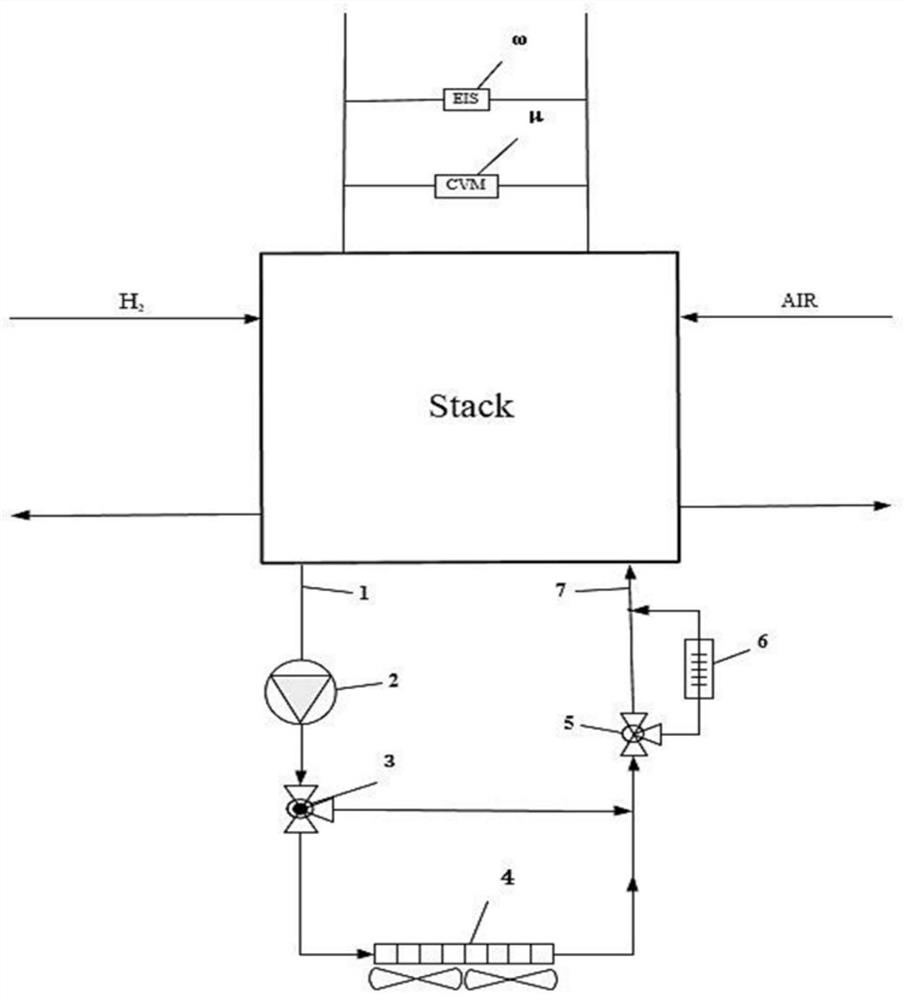

[0034] Such as figure 1 As shown, the present invention relates to a fuel cell system, including an air supply system, a hydrogen supply system, a cooling circulation system, an electric stack and a control system. The air supply system is connected to the cathode of the stack, the hydrogen supply system is connected to the anode of the stack, and the cooling circulation system is connected to the stack. The control system is used to control the air supply system, the hydrogen supply system and the cooling circulation system.

[0035] The air supply system and the hydrogen supply system are schematic diagrams of simple systems, which can provide basic reaction gas supply for fuel cell stacks.

[0036] The cooling circulation system includes a stack discharge temperature sensor 1, a circulating water pump 2, a thermostat 3, a radiator assembly (with fan) 4, a three-way valve 5, a PTC heater 6 and a temperature-pressure integrated sensor 7. All actuators or sensors are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com