Marine condenser with carbon steel and polyethylene hot-melted combined pipe box

A polyethylene and condenser technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of complex equipment structure, troublesome operation, corrosion of zinc blocks, etc., and achieve good penetration resistance and simple structure. , The effect of smooth and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

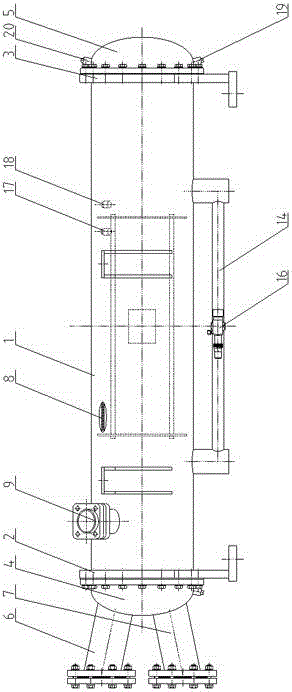

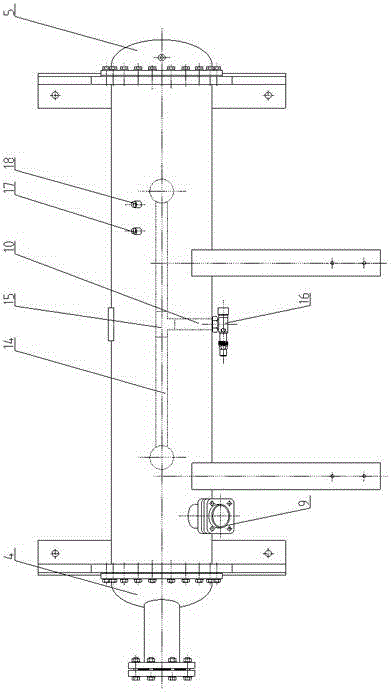

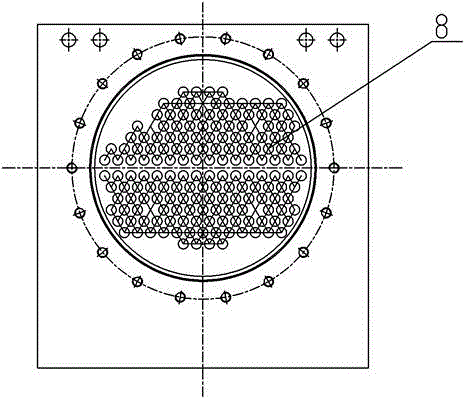

[0019] Embodiment: the marine condenser of the belt carbon steel of this example and polyethylene hot-melt joint pipe box, as figure 1 , figure 2 , including a cylinder body 1, a front tube sheet 2 and a rear tube sheet 3 are respectively provided at the front and rear ends of the cylinder body, the front tube sheet and the rear tube sheet include a steel base layer 12, and an aluminum bronze alloy layer 13 is provided on one side of the steel base layer. Such as Figure 4 , the front and rear tube plates are respectively connected with the front tube box 4 and the rear tube box 5, and the front tube box is provided with a water inlet 6 and a water outlet 7, such as image 3 , a number of heat exchange tubes 8 are arranged in the cylinder, and the material of the heat exchange tubes is BFe10-1-1 alloy. The inner sides of the front tube box and the rear tube box are provided with a plastic-lined layer 11, which is a heat-melt bonding layer of plastics and steel substrates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com