Patents

Literature

83results about How to "No seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

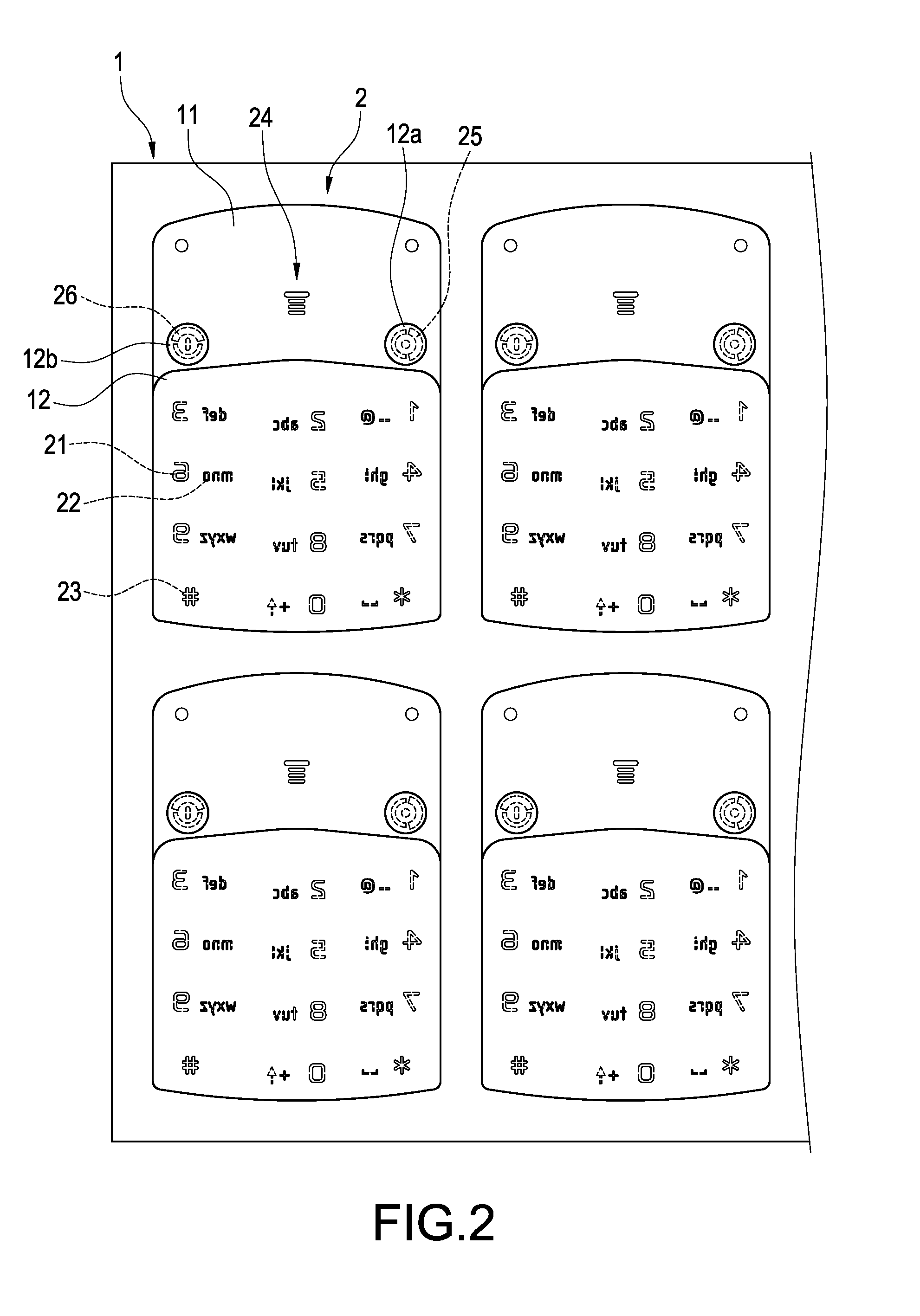

Wide angle scanner for panoramic display

InactiveUS20080002161A1Good colorNo seamsProjectorsColor television detailsRotational axisOptical axis

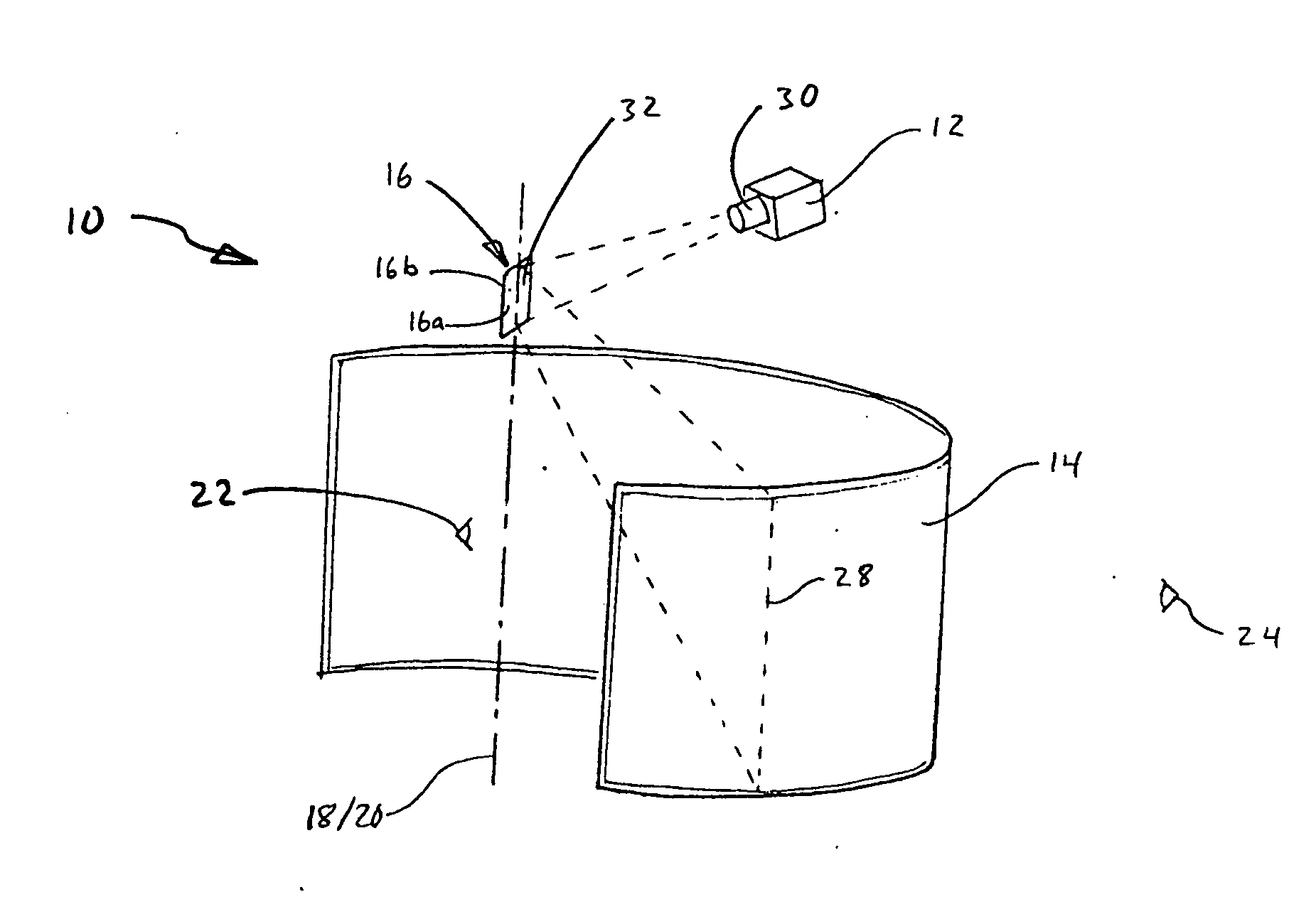

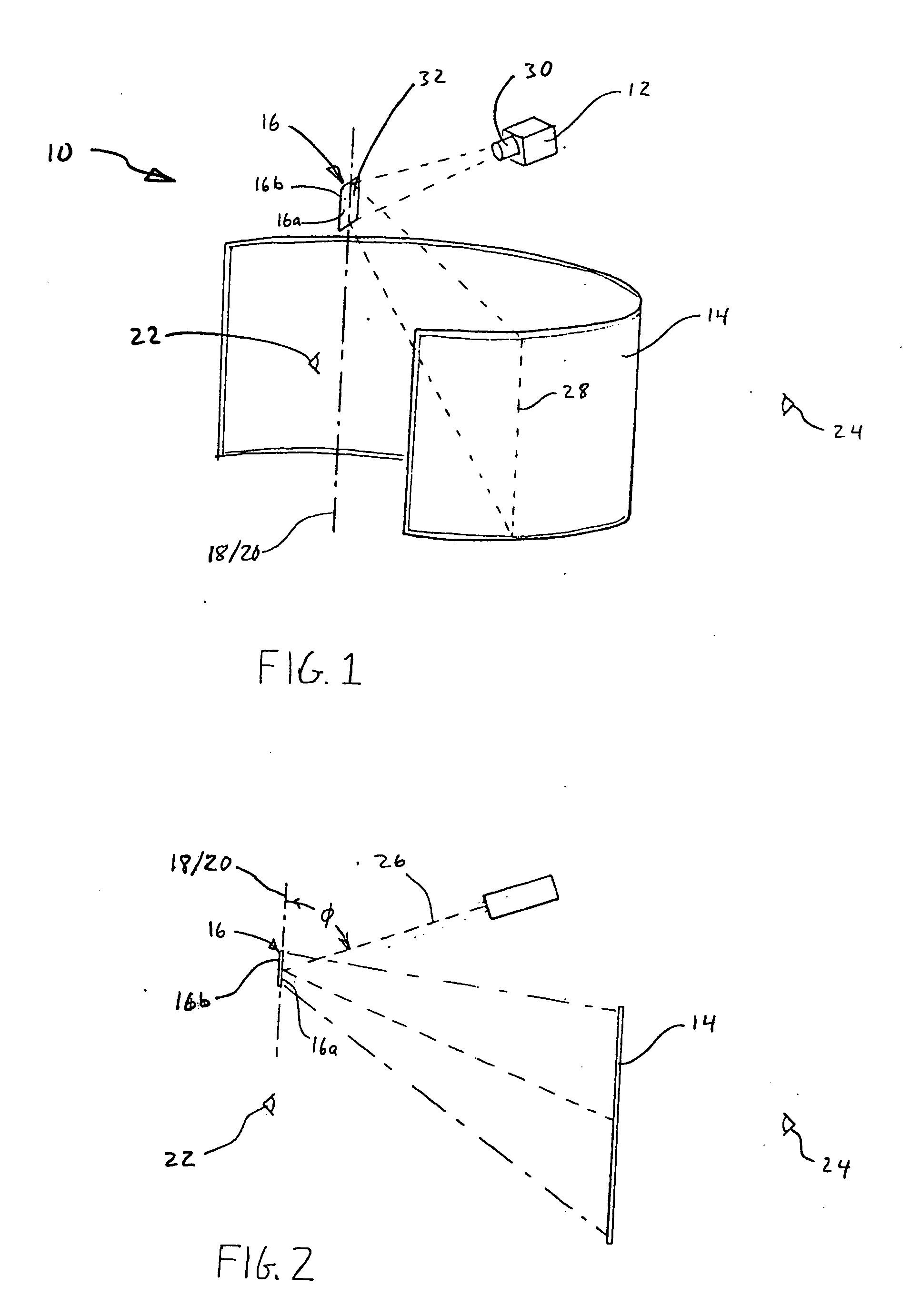

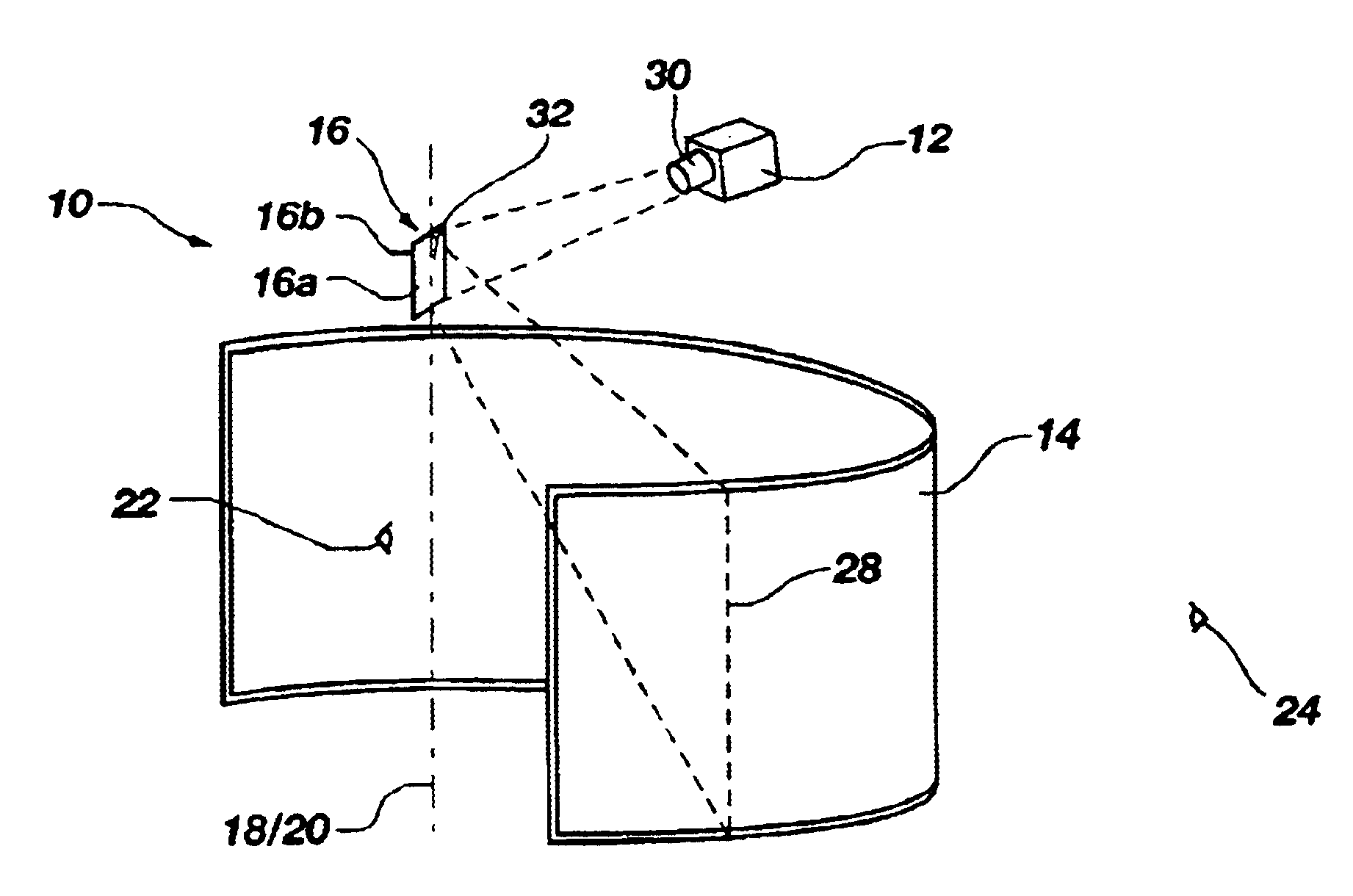

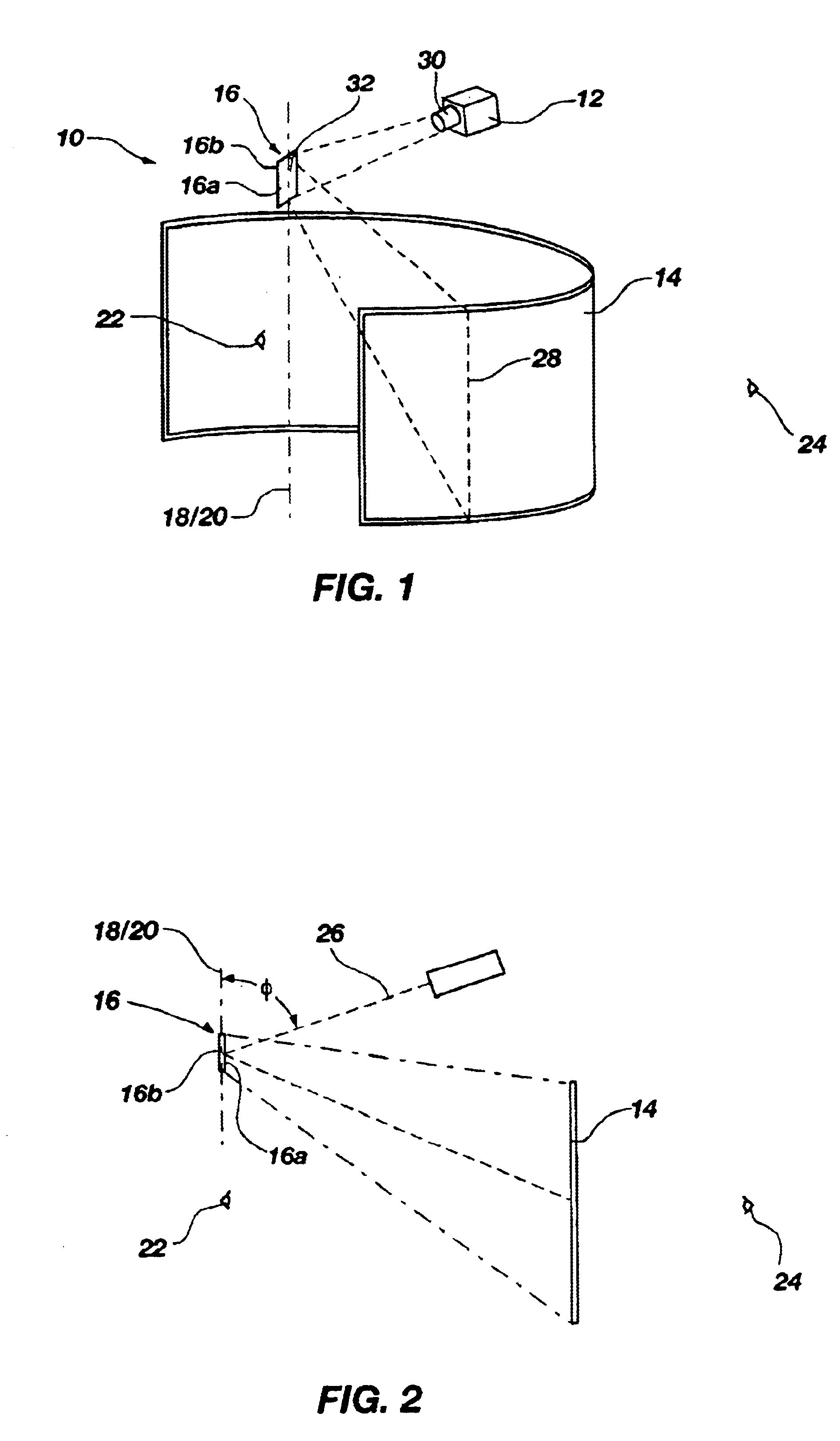

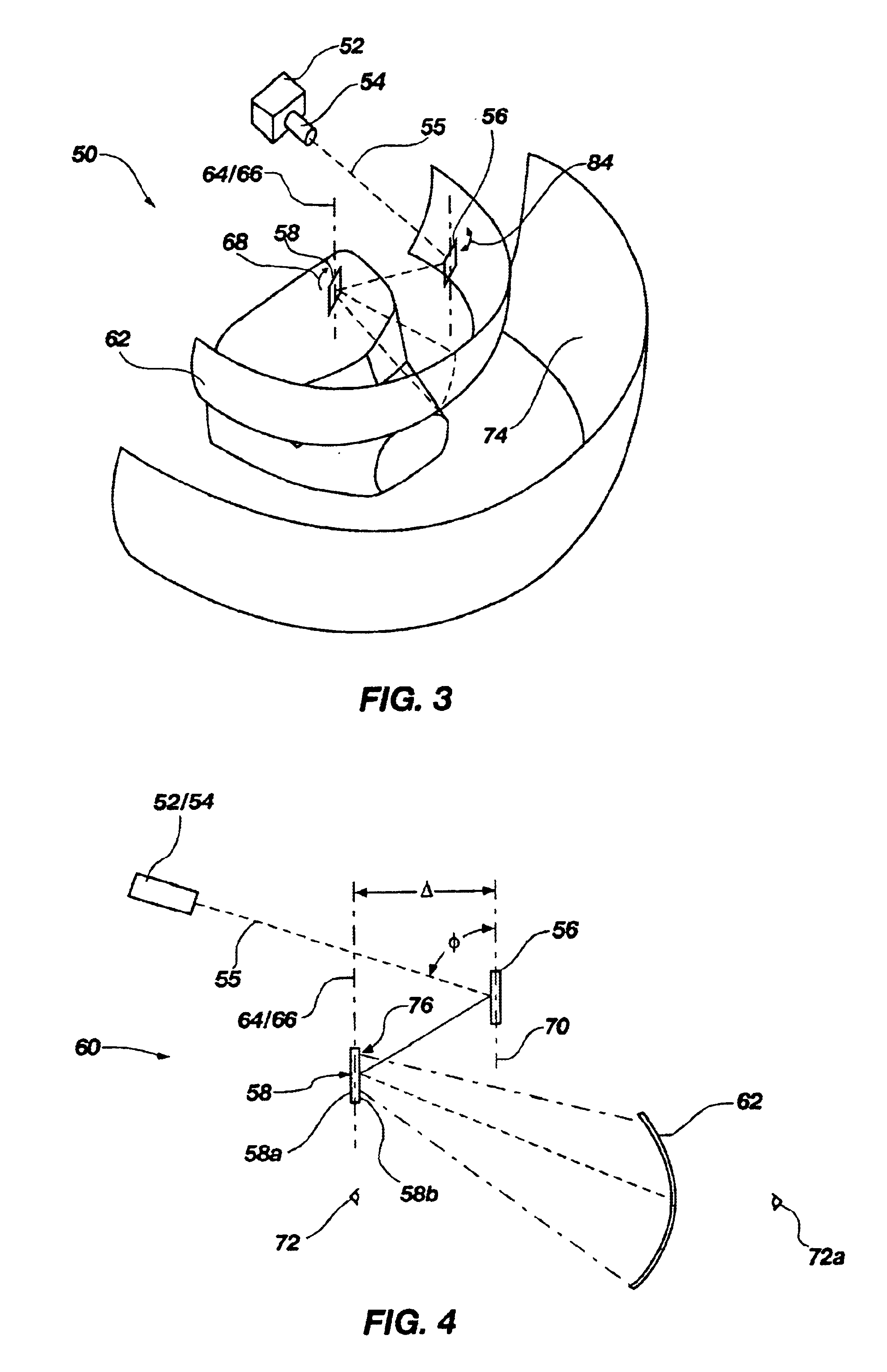

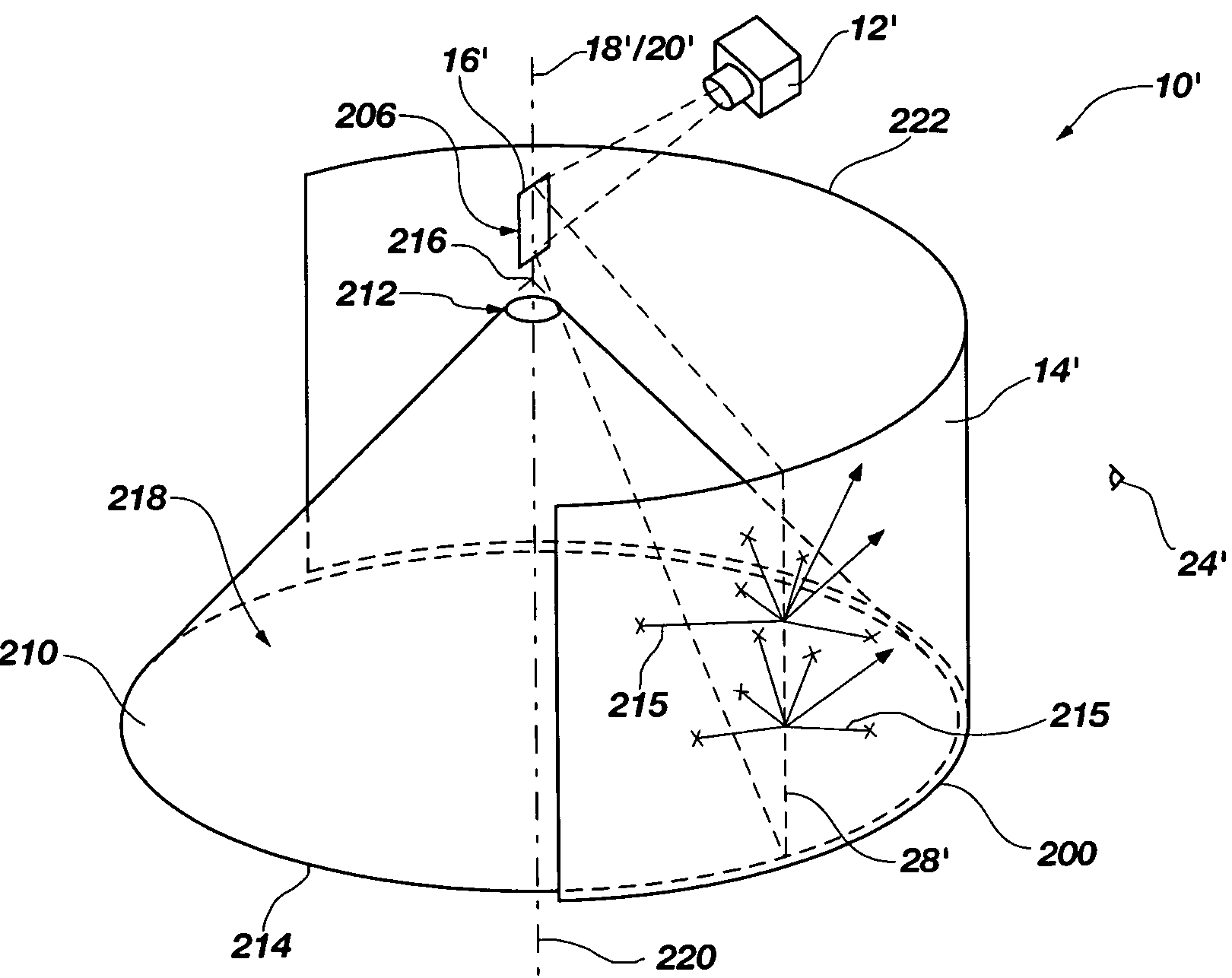

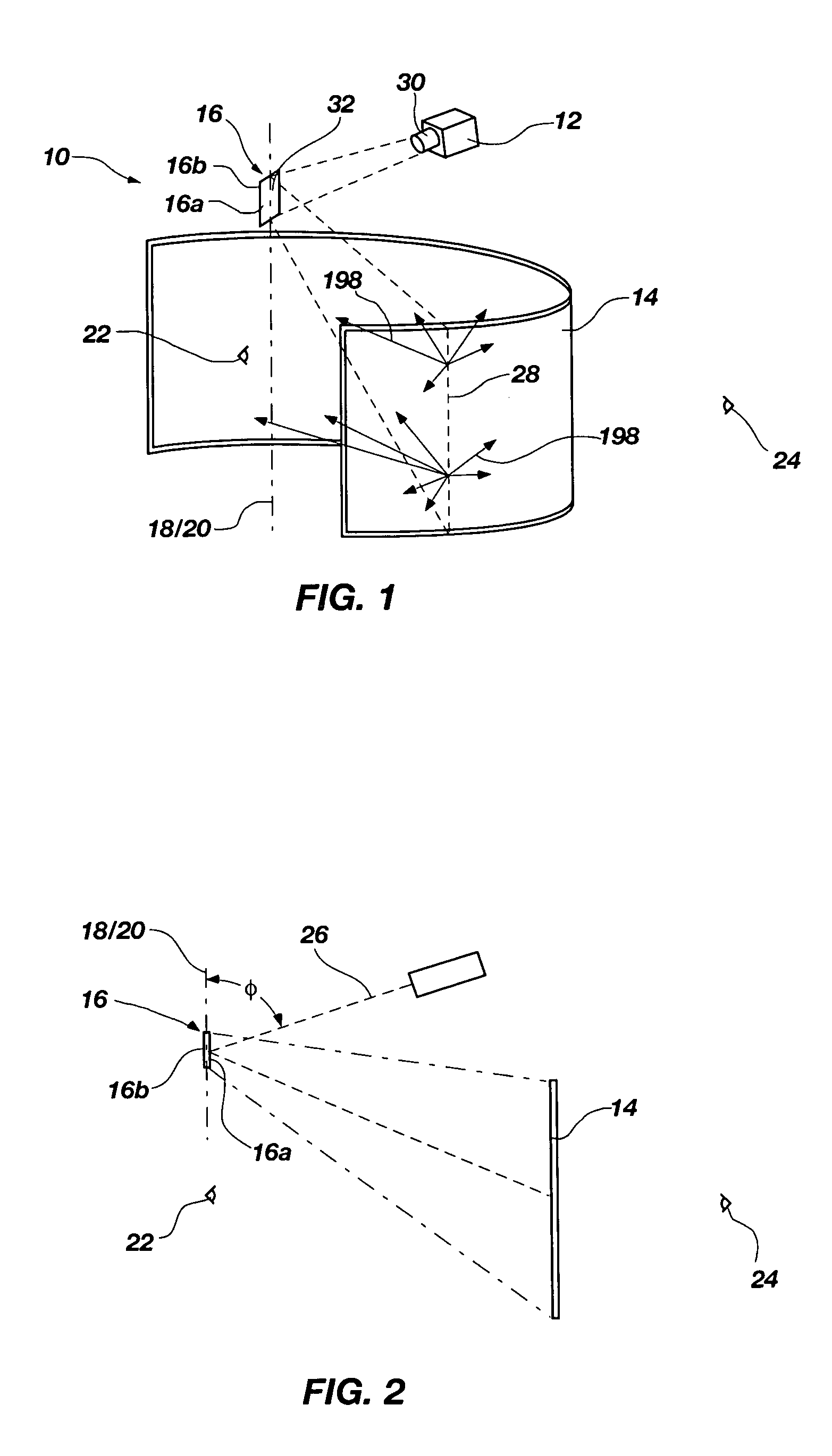

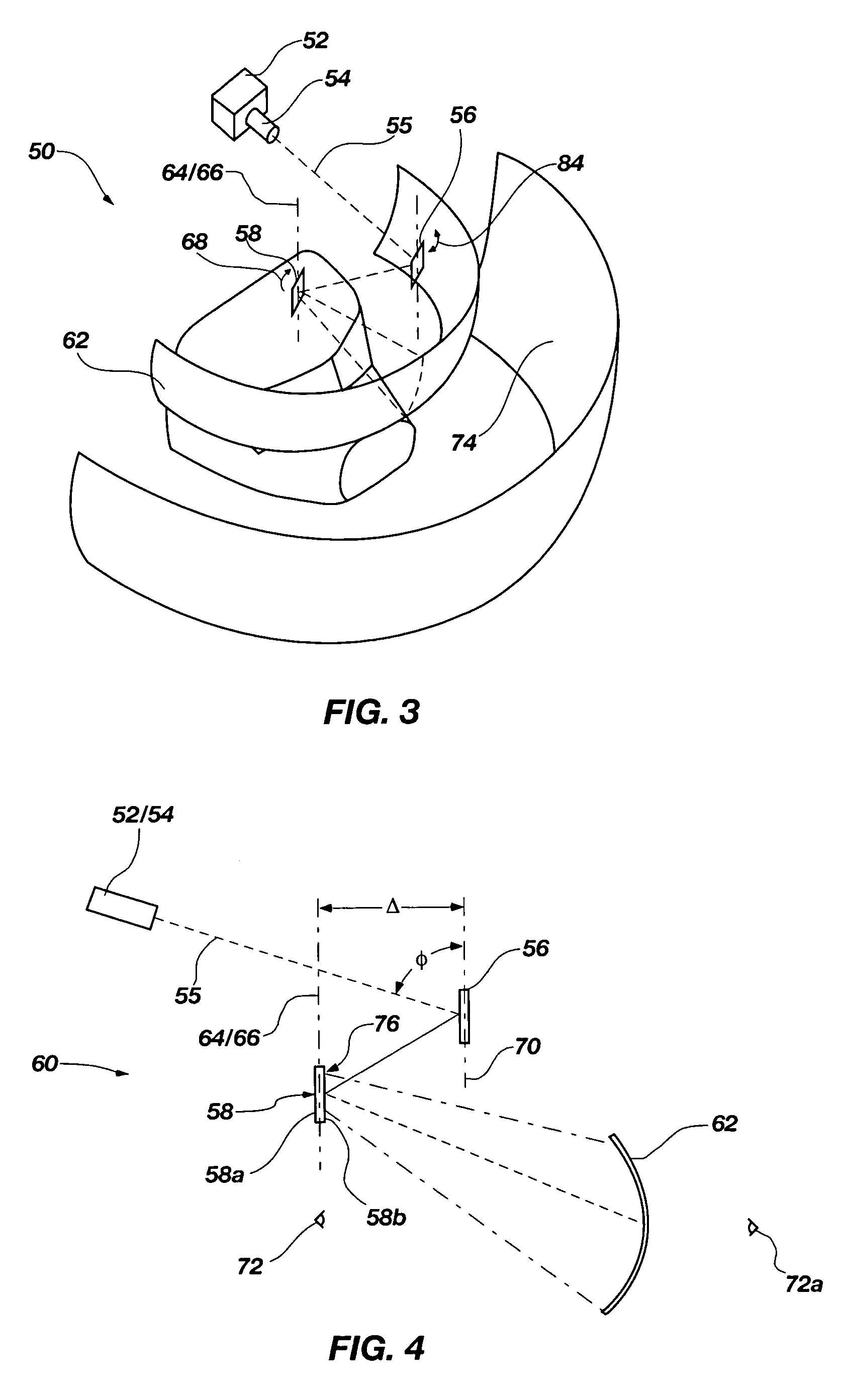

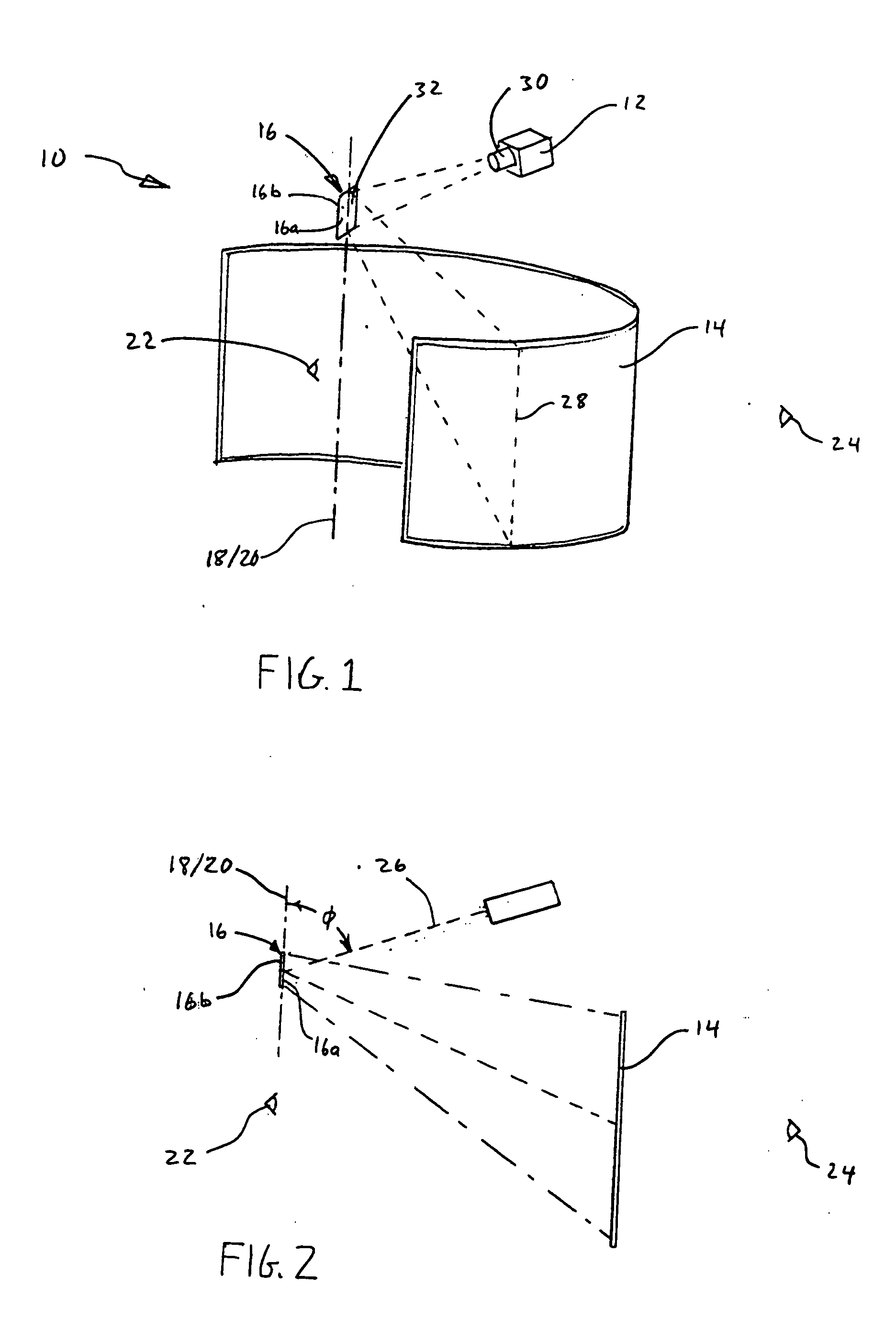

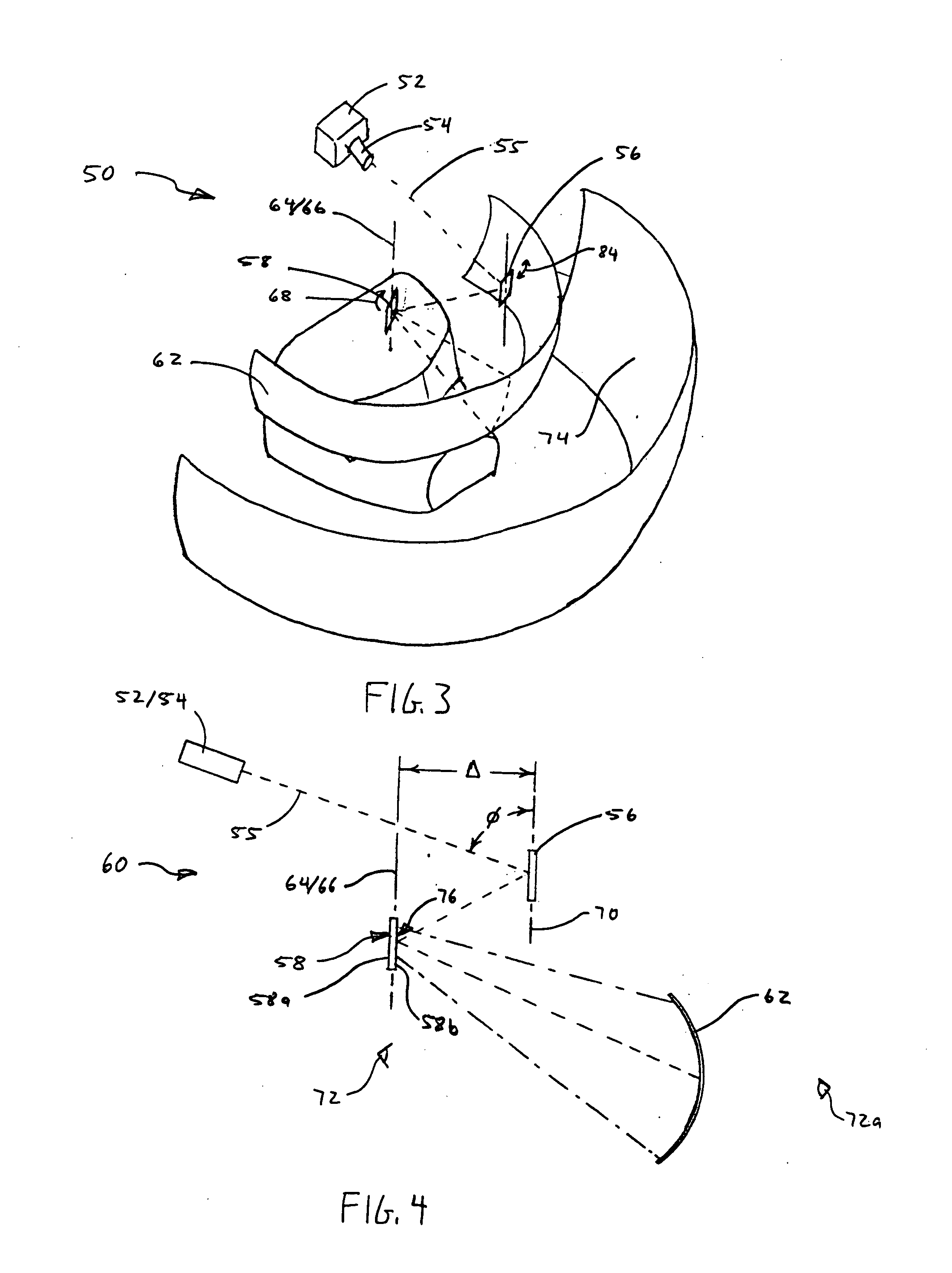

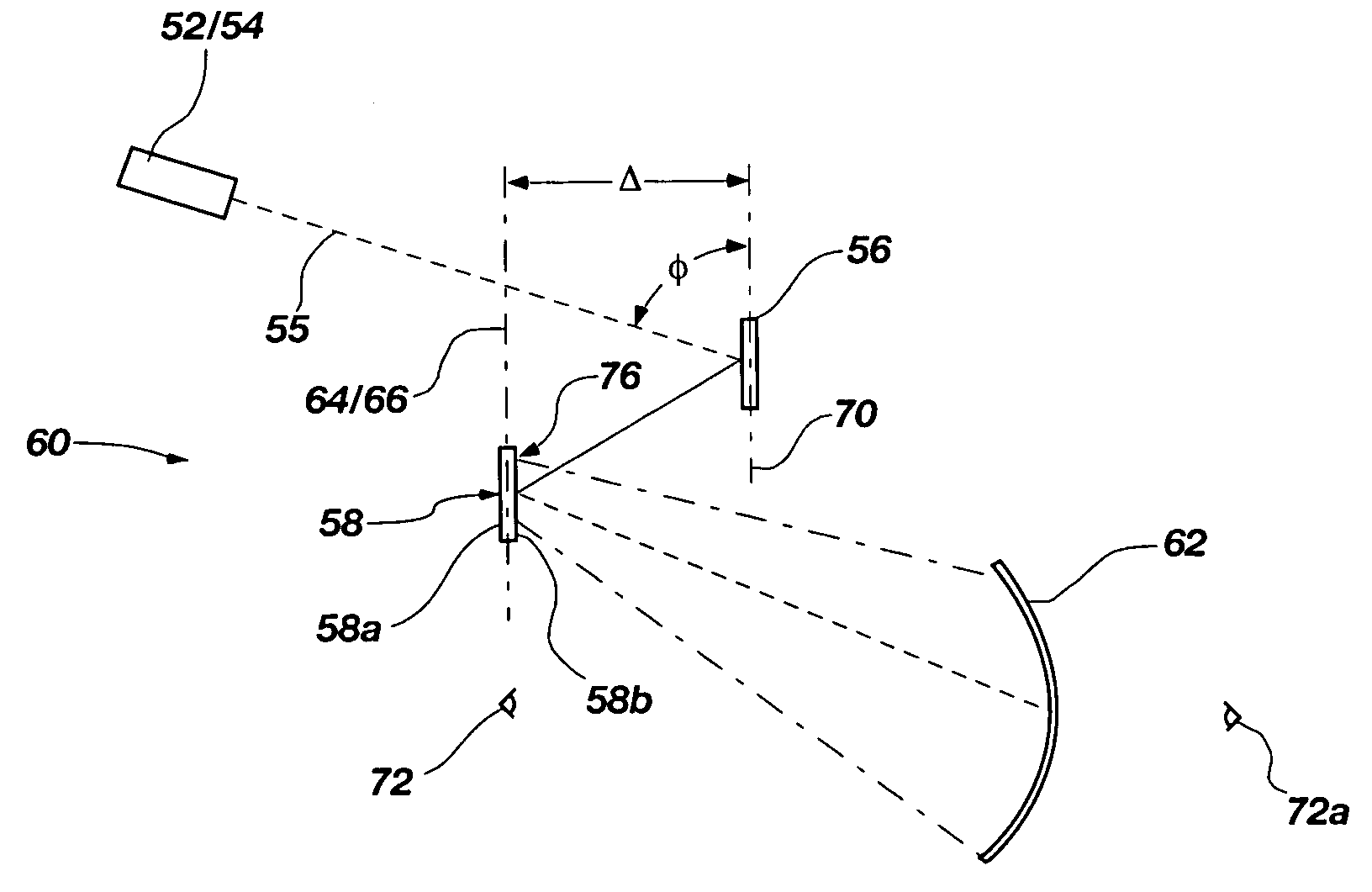

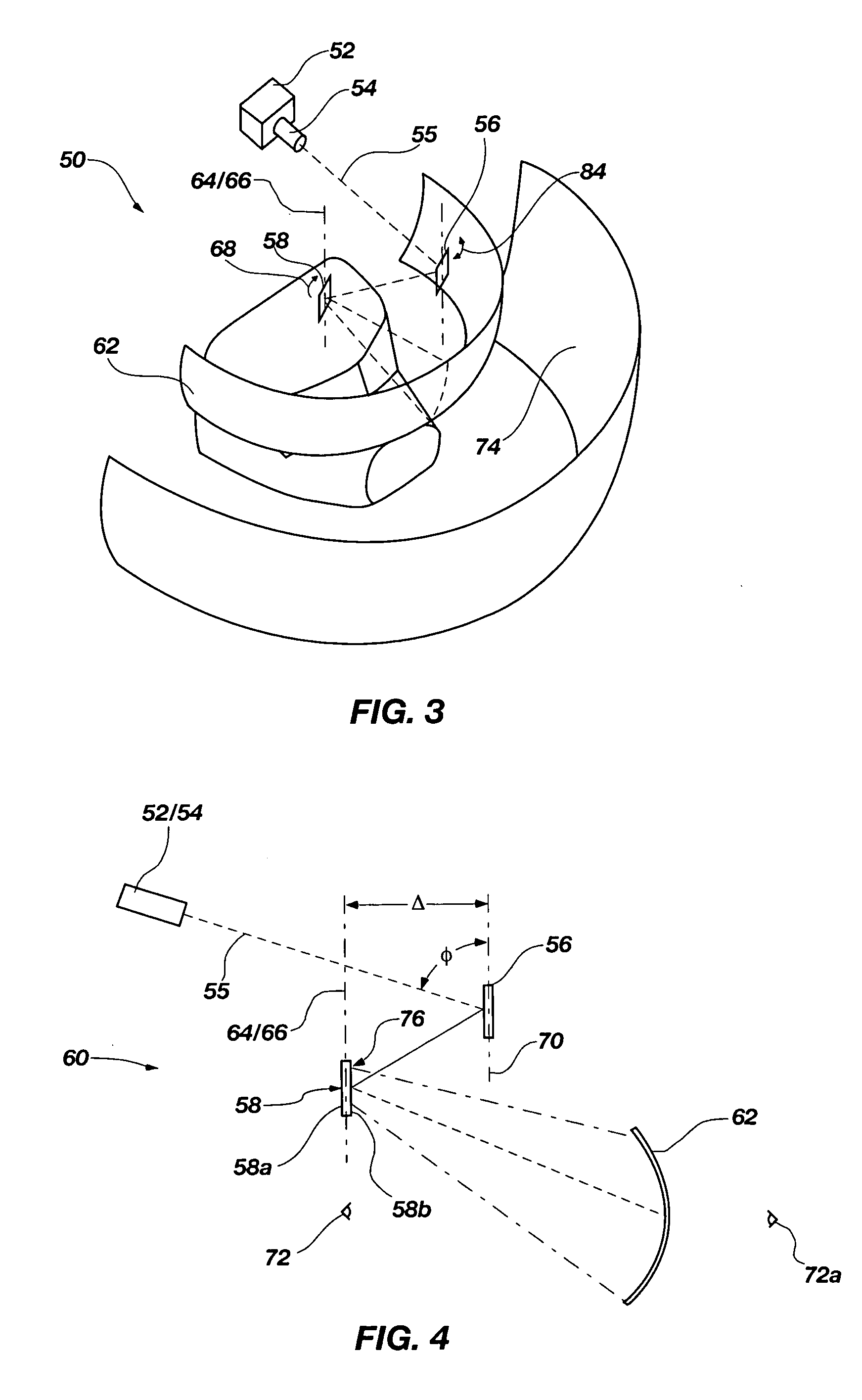

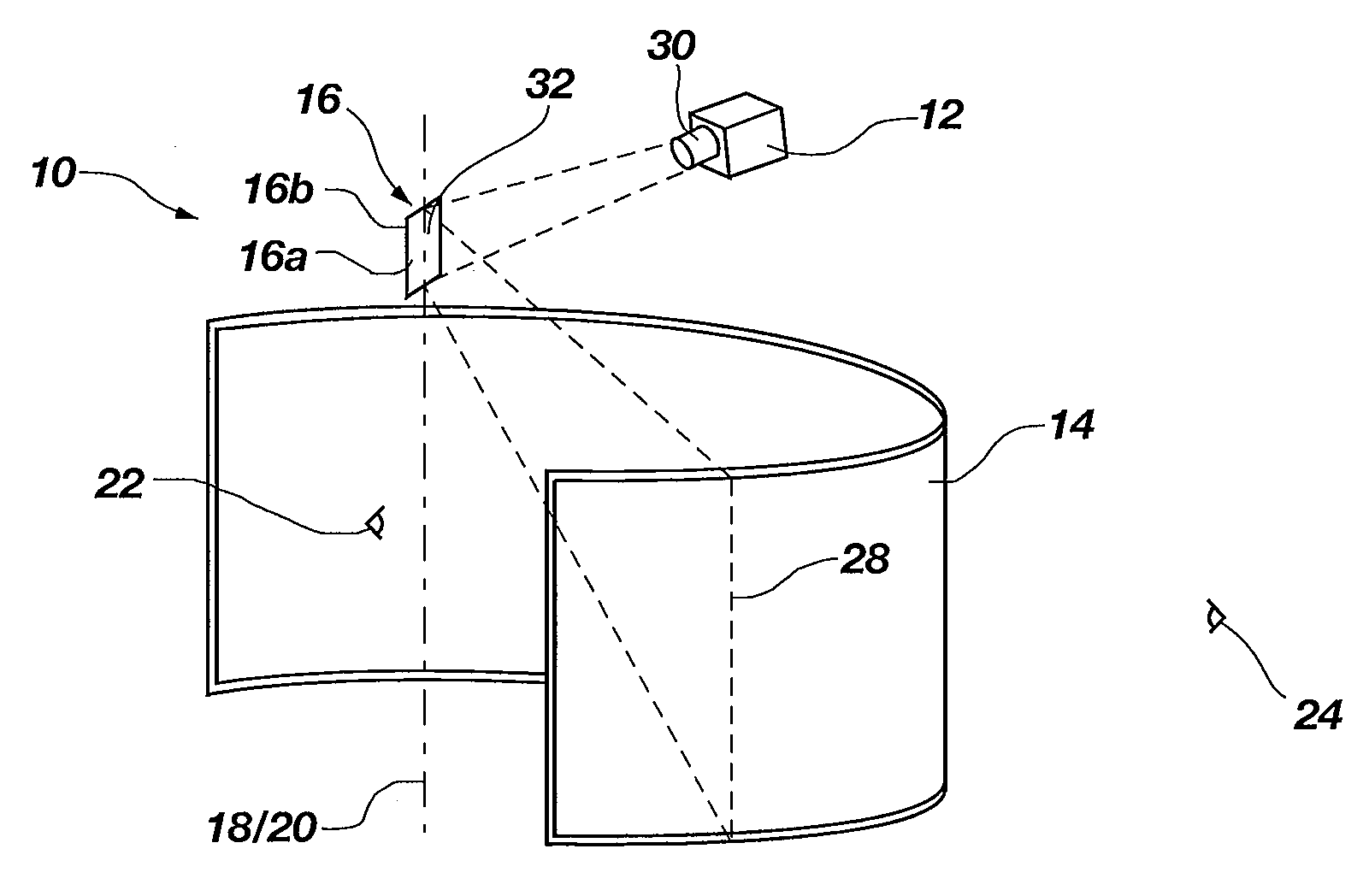

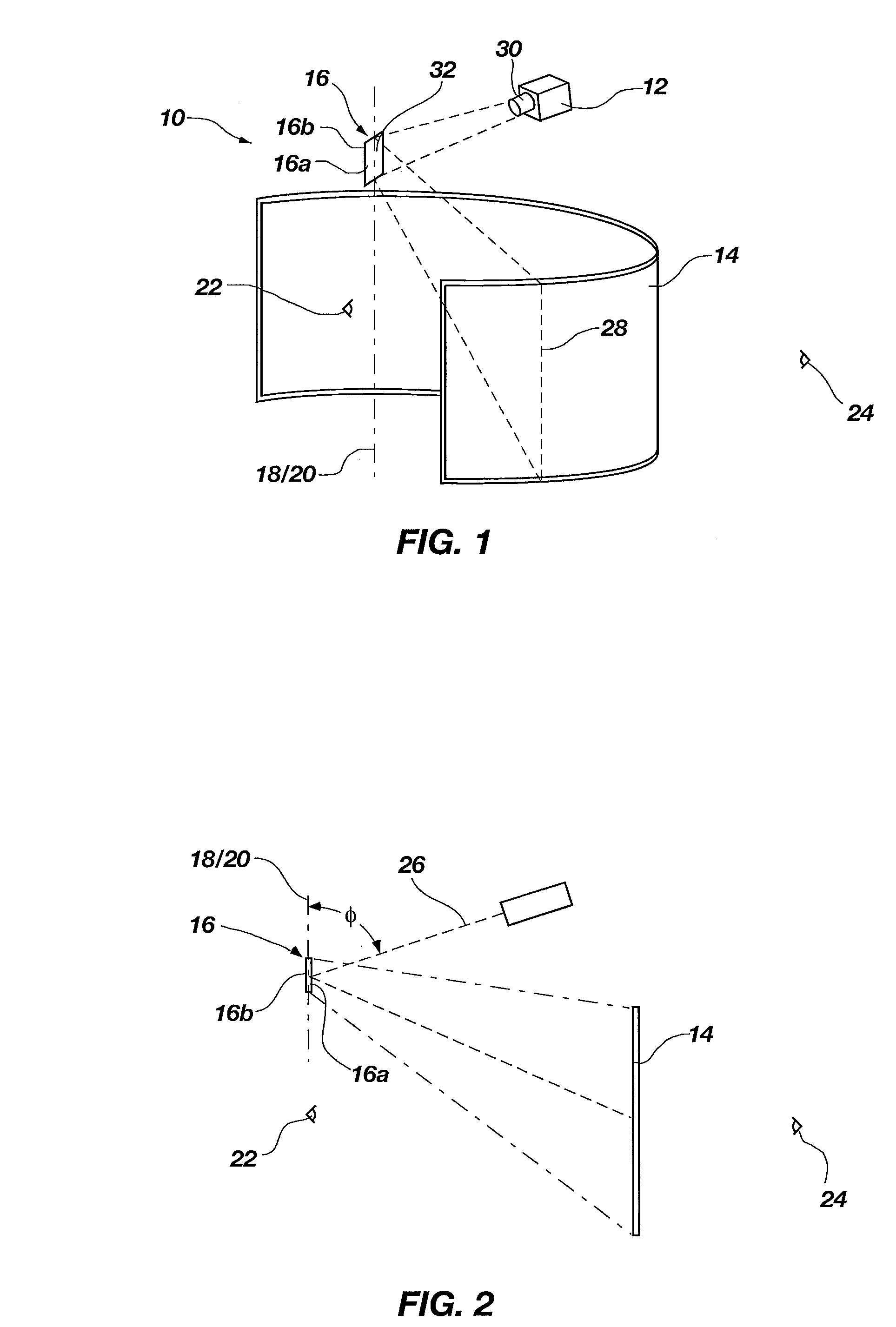

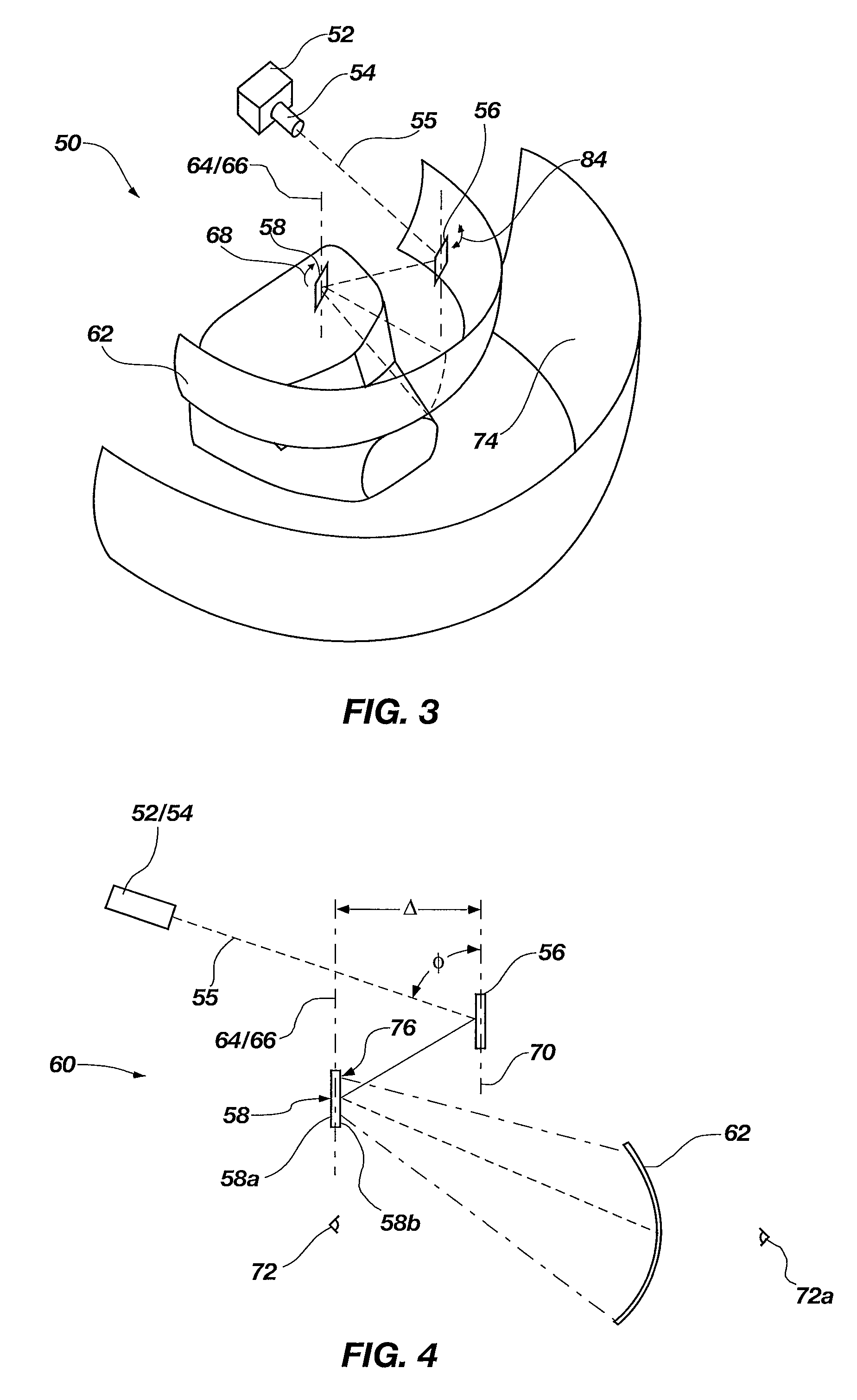

A wide angle display system includes a linear array projector, a curved display surface, and an n-sides scanning mirror. The projector is configured to project an image along an optical axis to the scanning mirror. The scanning mirror continuously rotates about a rotational axis at a speed 1 / n the refresh rate, so as to reflect and scan the image onto the display surface.

Wide angle scanner for panoramic display

A wide angle display system includes a linear array projector, a curved display surface, and a two-sided, substantially planar scanning mirror. The projector is configured to project an image along an optical axis to the scanning mirror. The scanning mirror continuously rotates about an axis substantially in the plane of the mirror, so as to reflect and scan the image onto the display surface.

Owner:EVANS & SUTHERLAND COMP

Reflection barrier for panoramic display

ActiveUS7012669B2Good colorNo seamsTelevision system detailsDigital data processing detailsProjection screenPartial reflection

Owner:EVANS & SUTHERLAND COMP

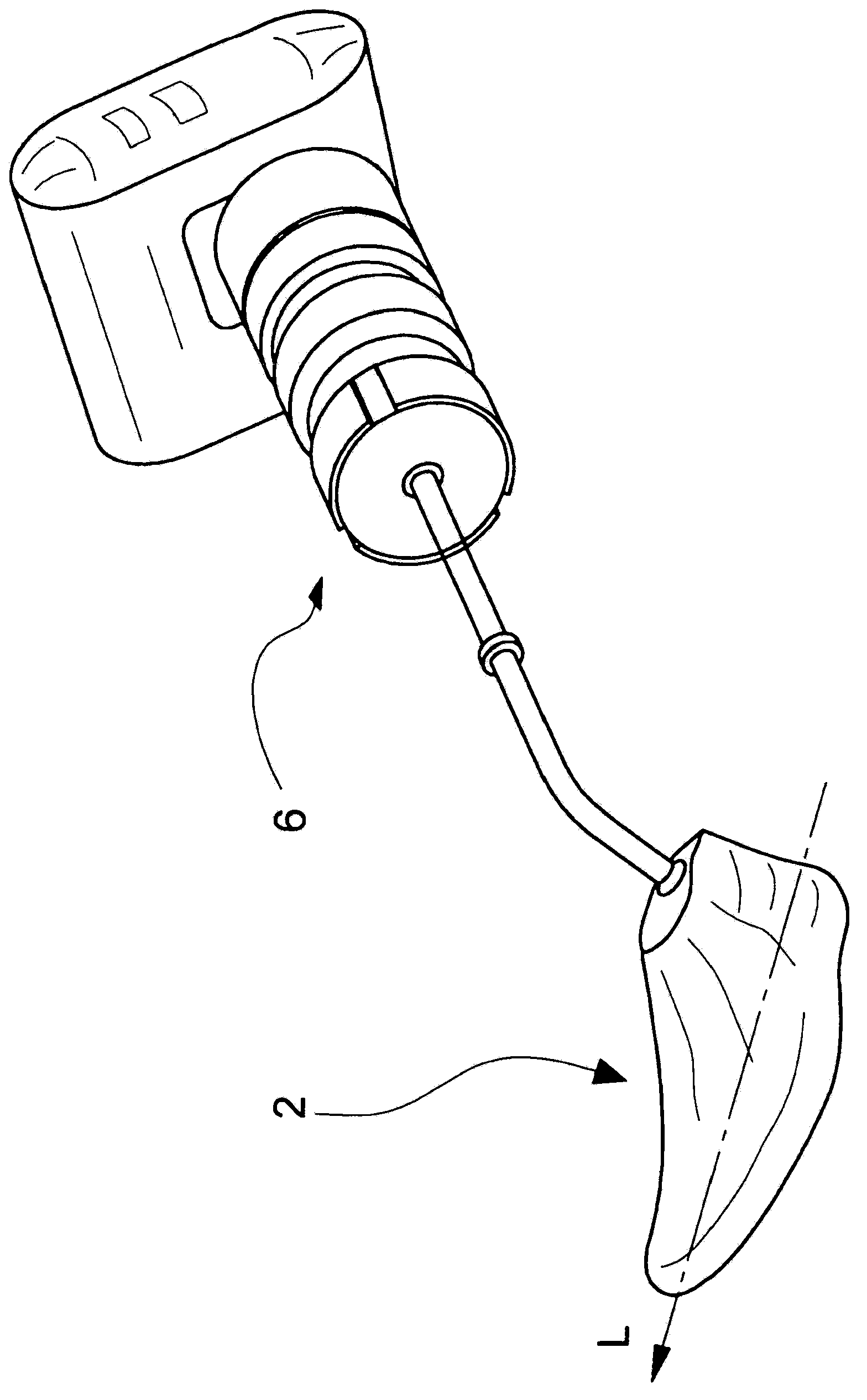

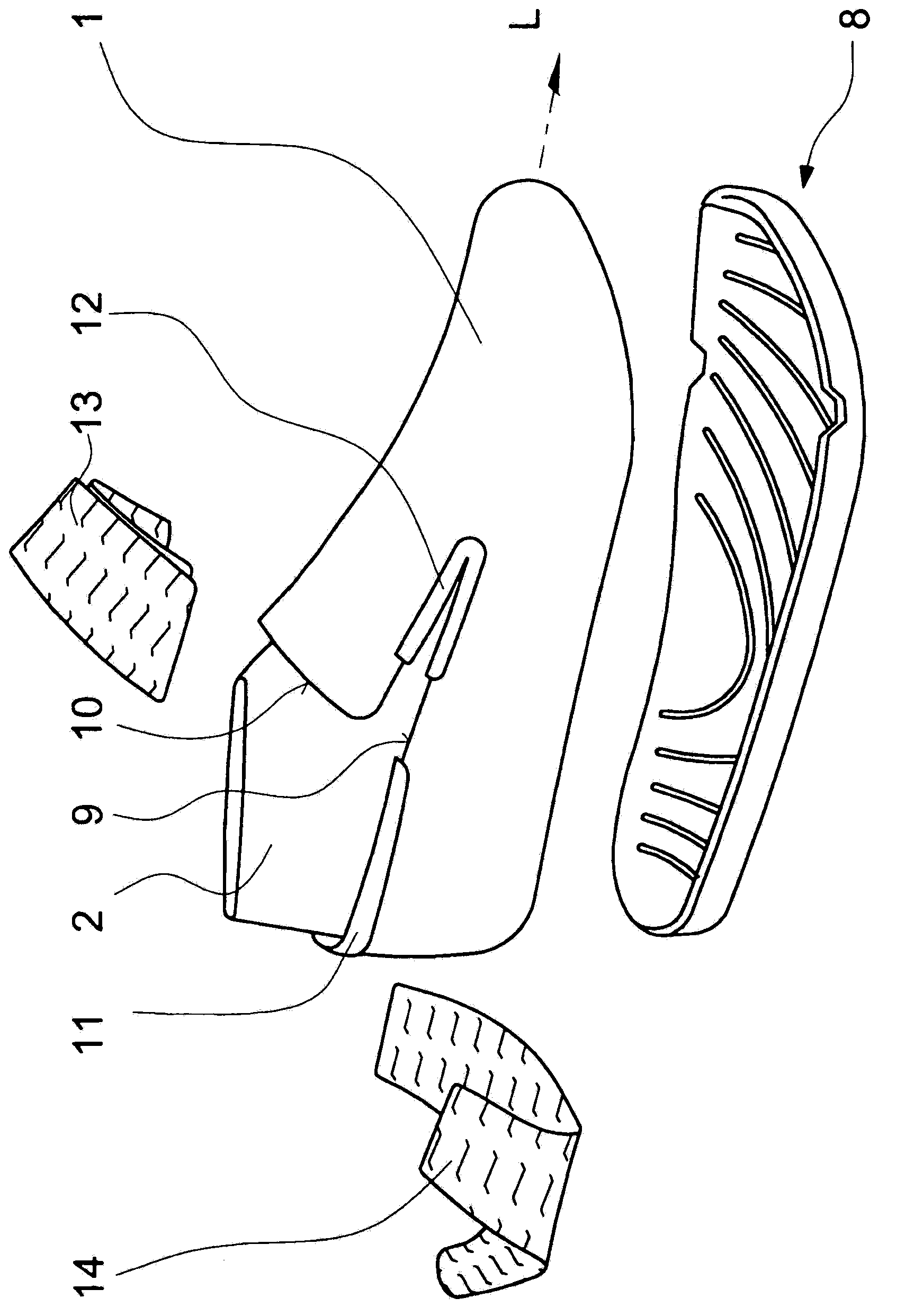

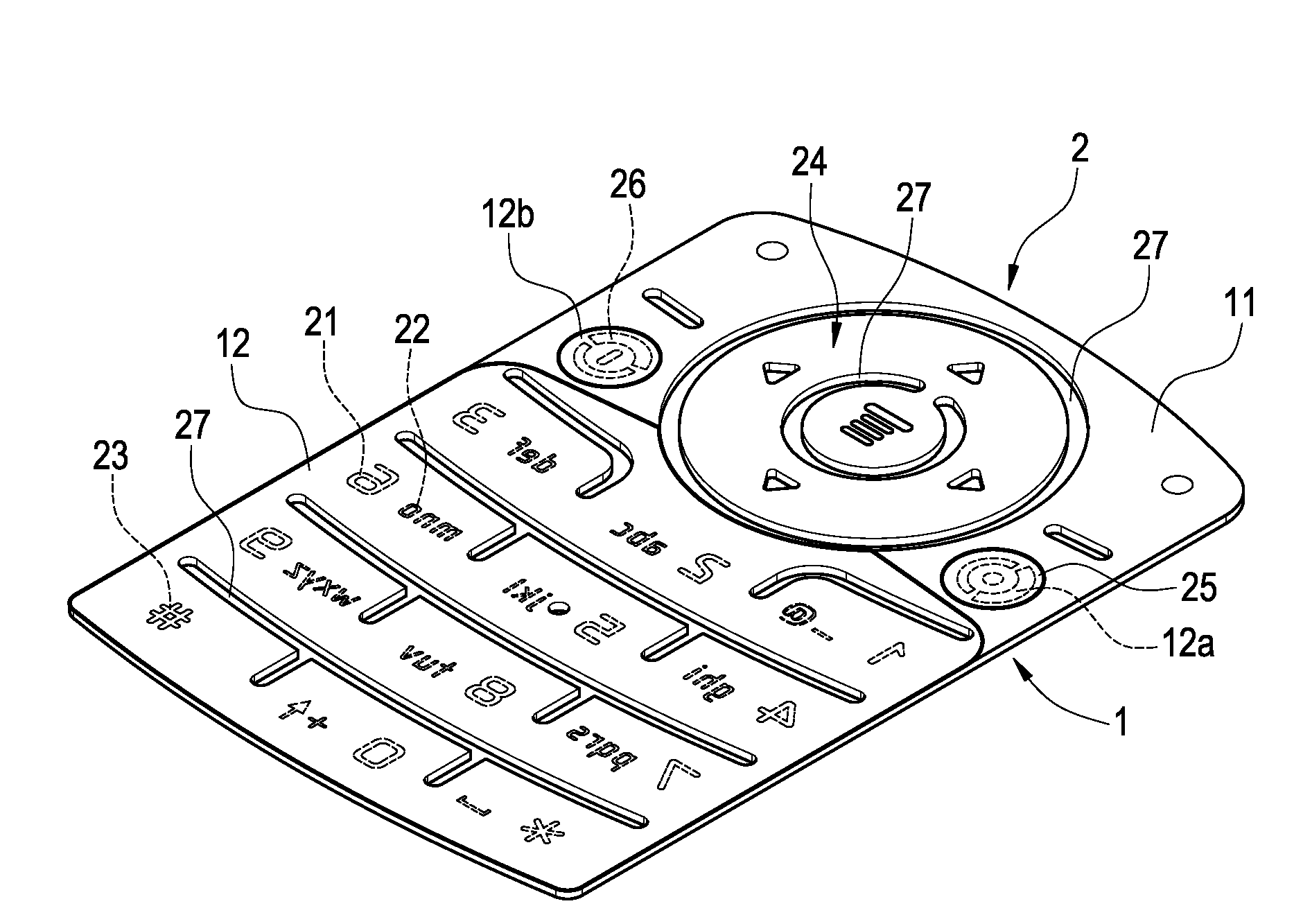

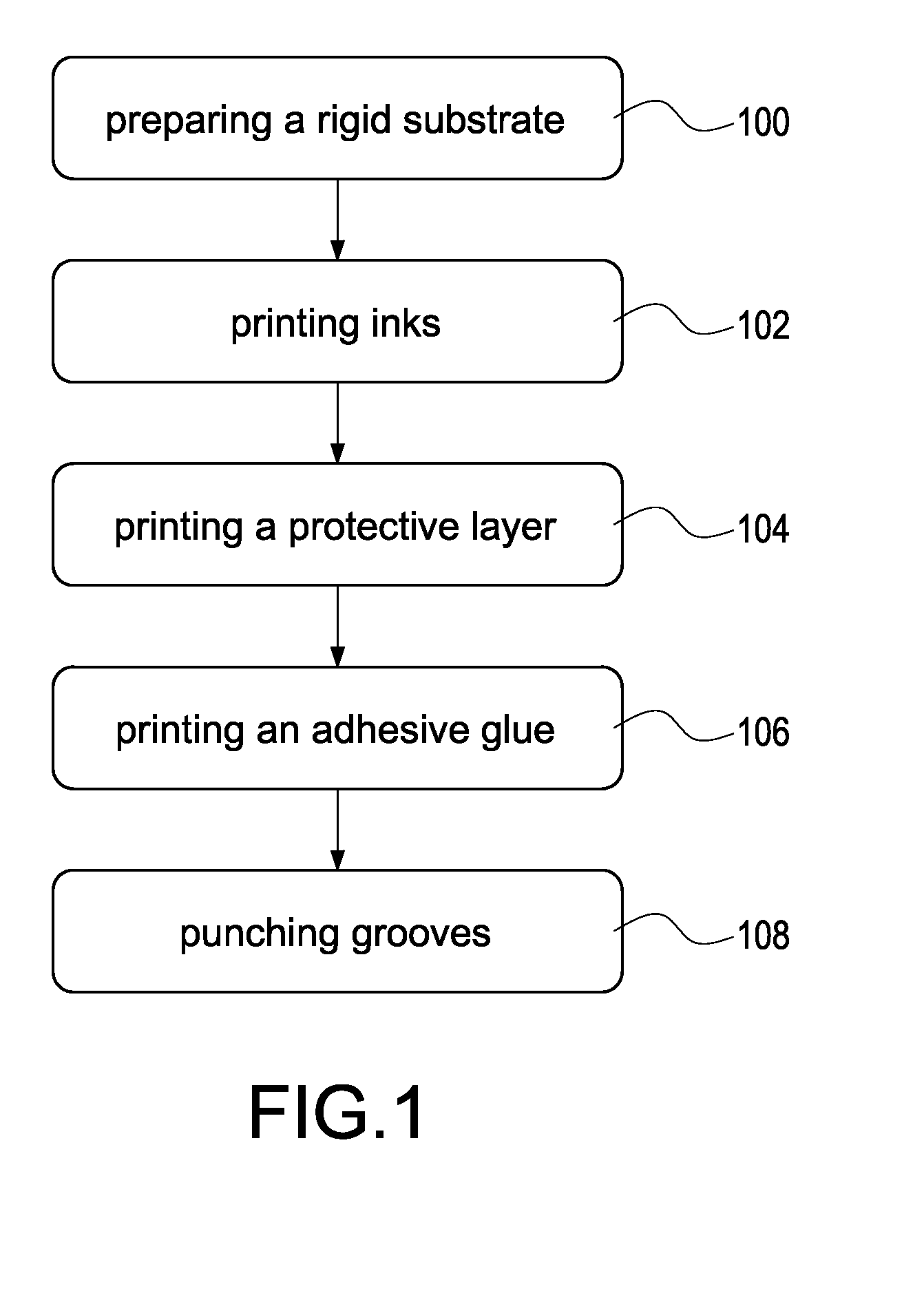

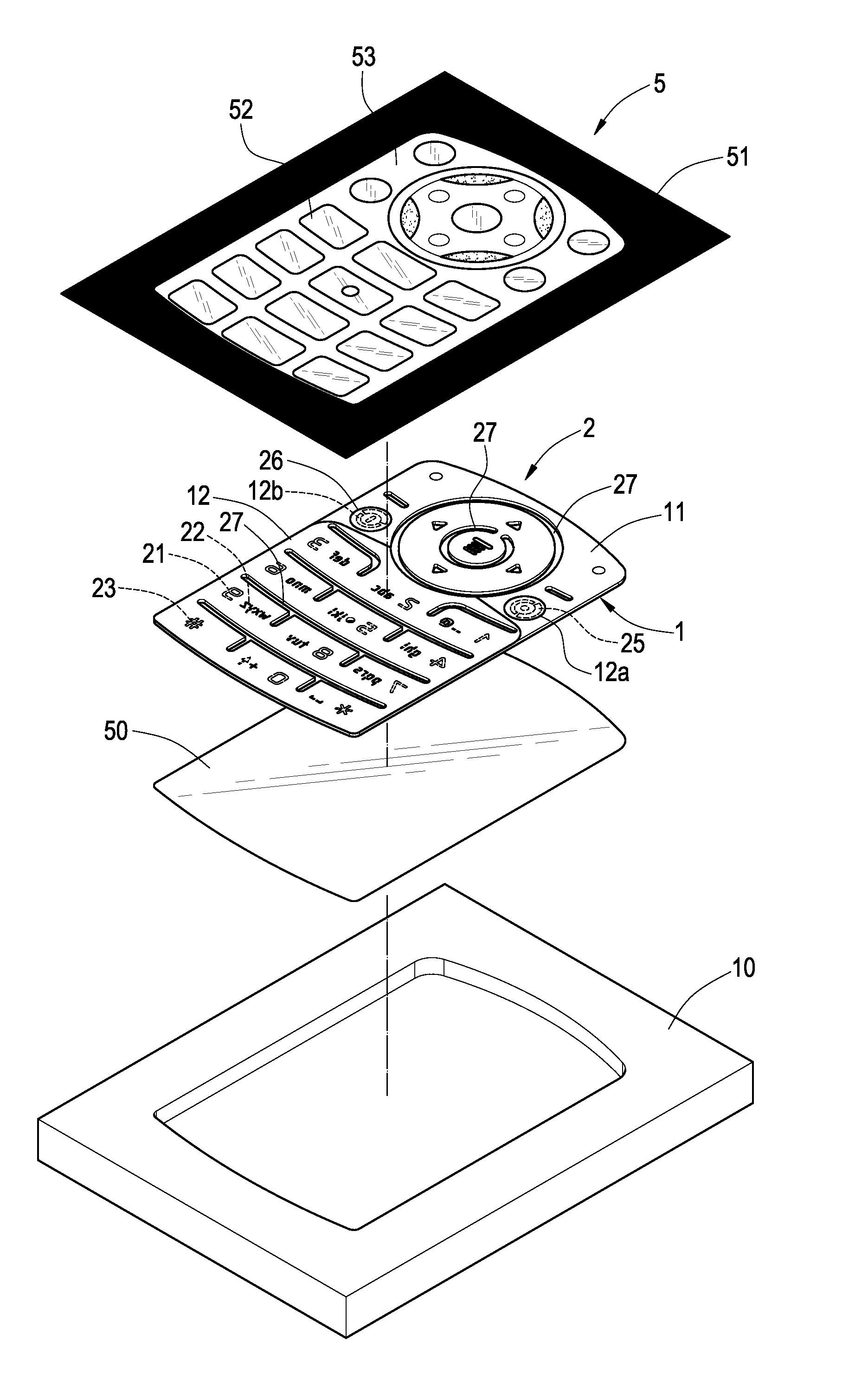

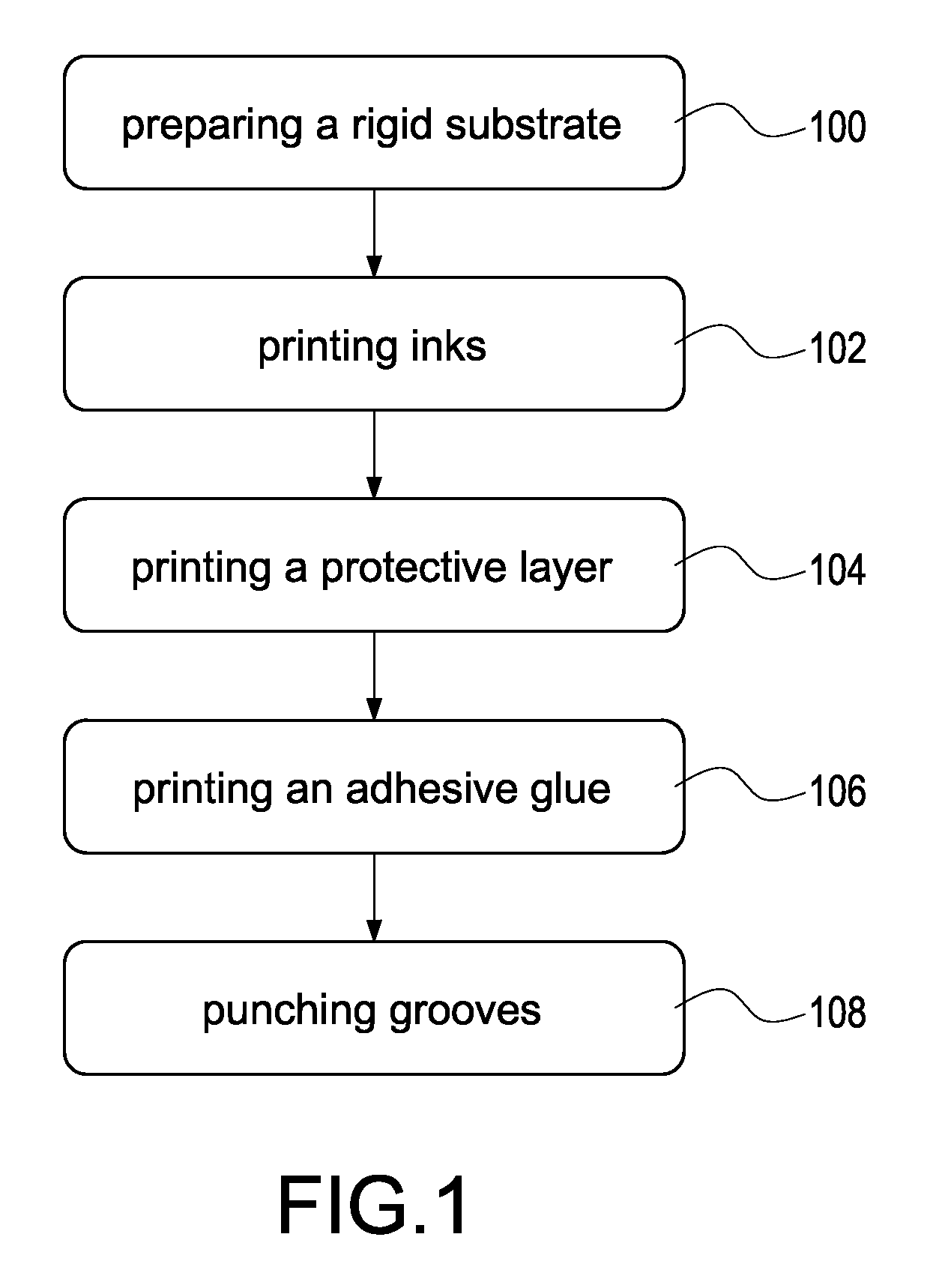

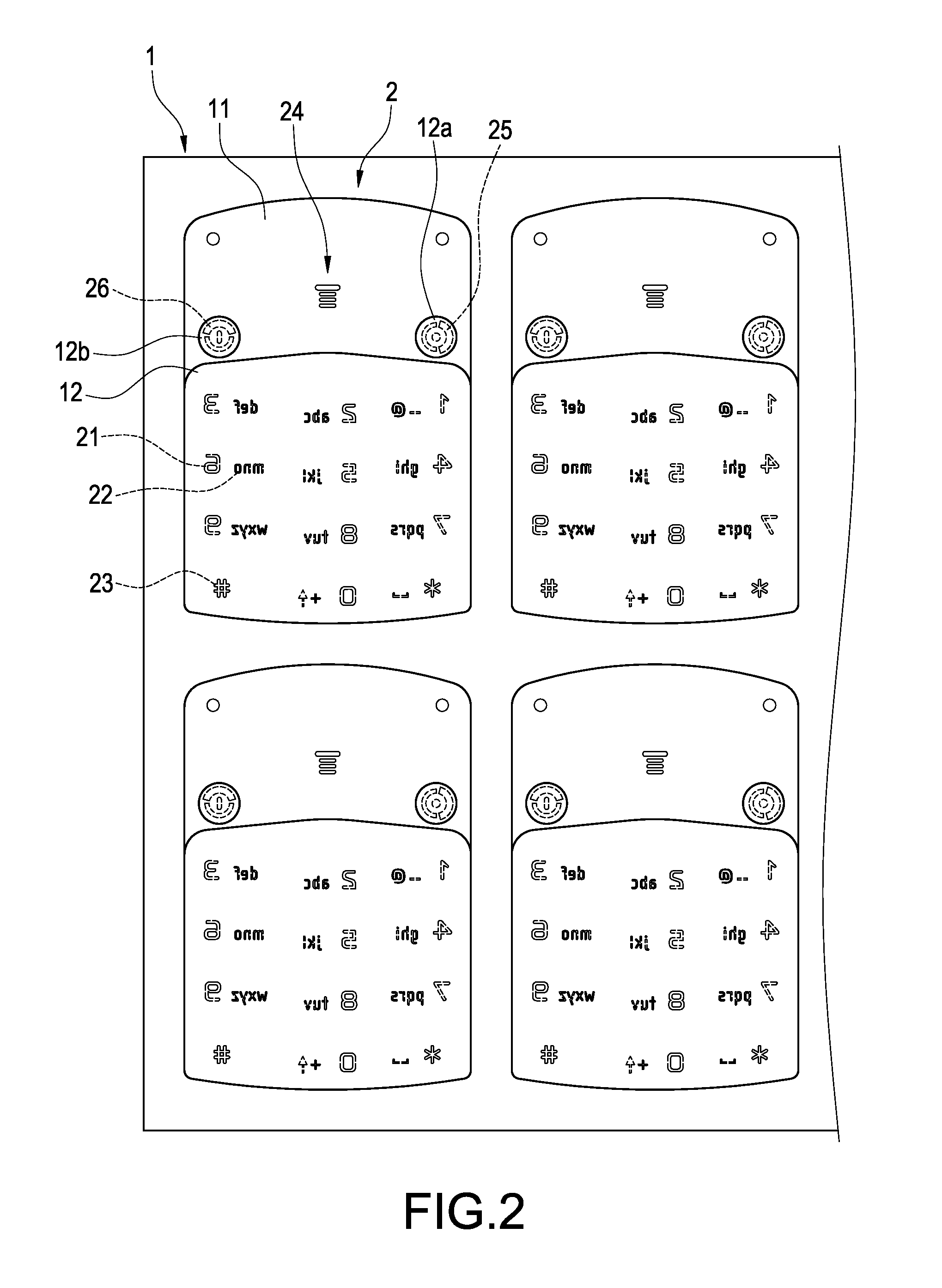

Method For Manufacturing Thin Keypad Assembly And Such Assembly

InactiveUS20080191904A1Surface cleaningNo seamsEmergency actuatorsEmergency casingsMicro structureLight guide

A method for manufacturing a thin keypad with no seams on a panel surface and such assembly includes the following steps. Inks of different colors are printed onto the surface of a rigid substrate so as to shape panel forms and light-transmitting numerals, letters, symbols, a navigation-key pattern, a dialing pattern and an ending pattern. The panel surface is formed with a plurality of grooves after machining and cutting. Then, inks of different colors are printed onto the surface of a soft substrate so as to form a lining sheet of a light-shielding layer and a reflective layer corresponding to patterns of the panel. The thus-formed panel and lining sheet are disposed into a mold. Rubber is filled in the mold and, after pressing, bound with the bottom of the lining sheet to form a light-guiding layer. At the same time, the light-shielding layer, the reflective layer and the rubber are extruded on the panel surface, so that no seams exist between the keys of the panel surface. Finally, laser is radiated to dot on the light-guiding layer to form thereon light-guiding micro structures having a light-condensing effect.

Owner:ICHIA TECH

Wide angle scanner for panoramic display

A wide angle display system includes a linear array projector, a curved display surface, and a two-sided, substantially planar scanning mirror. The projector is configured to project an image along an optical axis to the scanning mirror. The scanning mirror continuously rotates about an axis substantially in the plane of the mirror, so as to reflect and scan the image onto the display surface.

Owner:EVANS & SUTHERLAND COMP

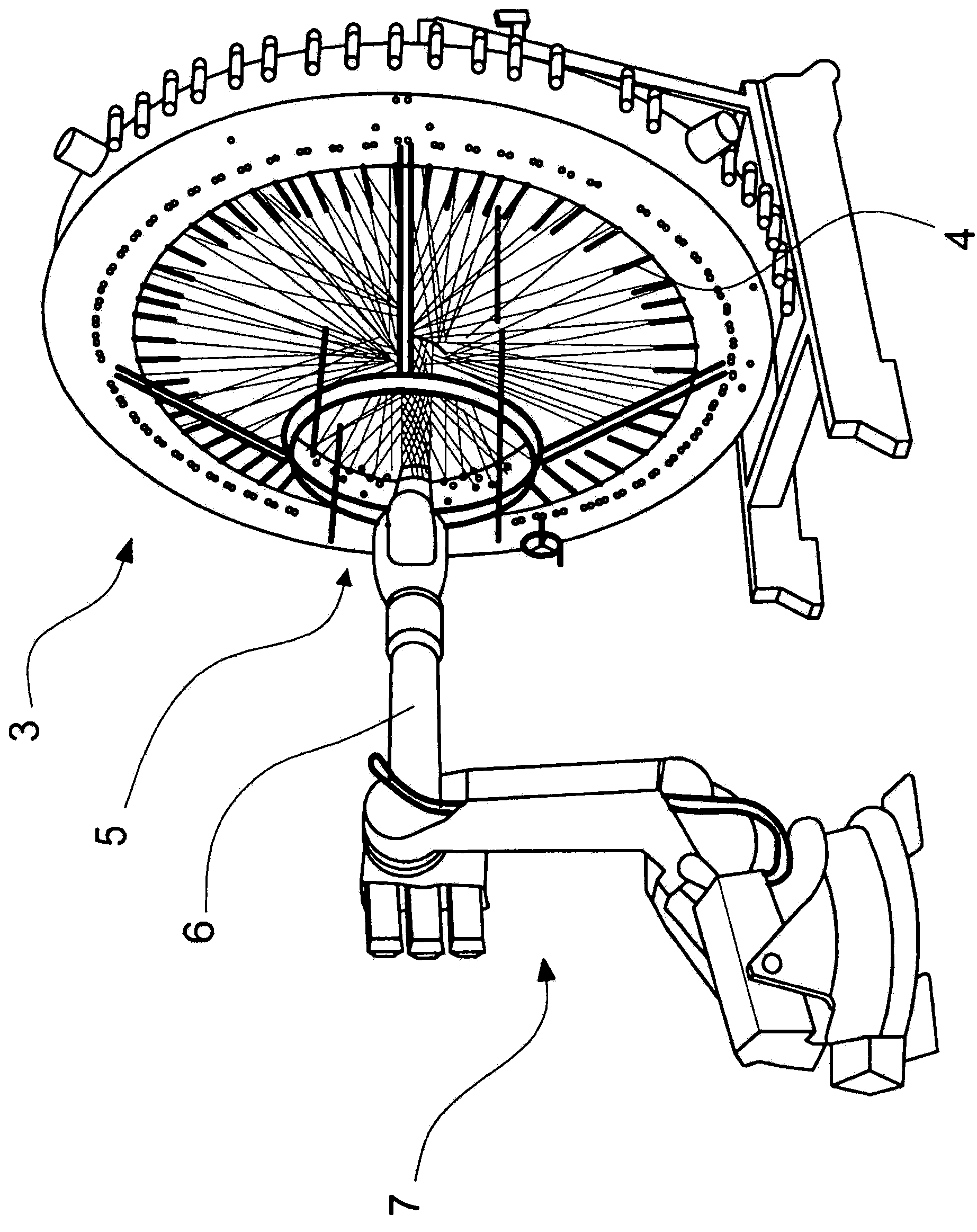

Reflection barrier for panoramic display

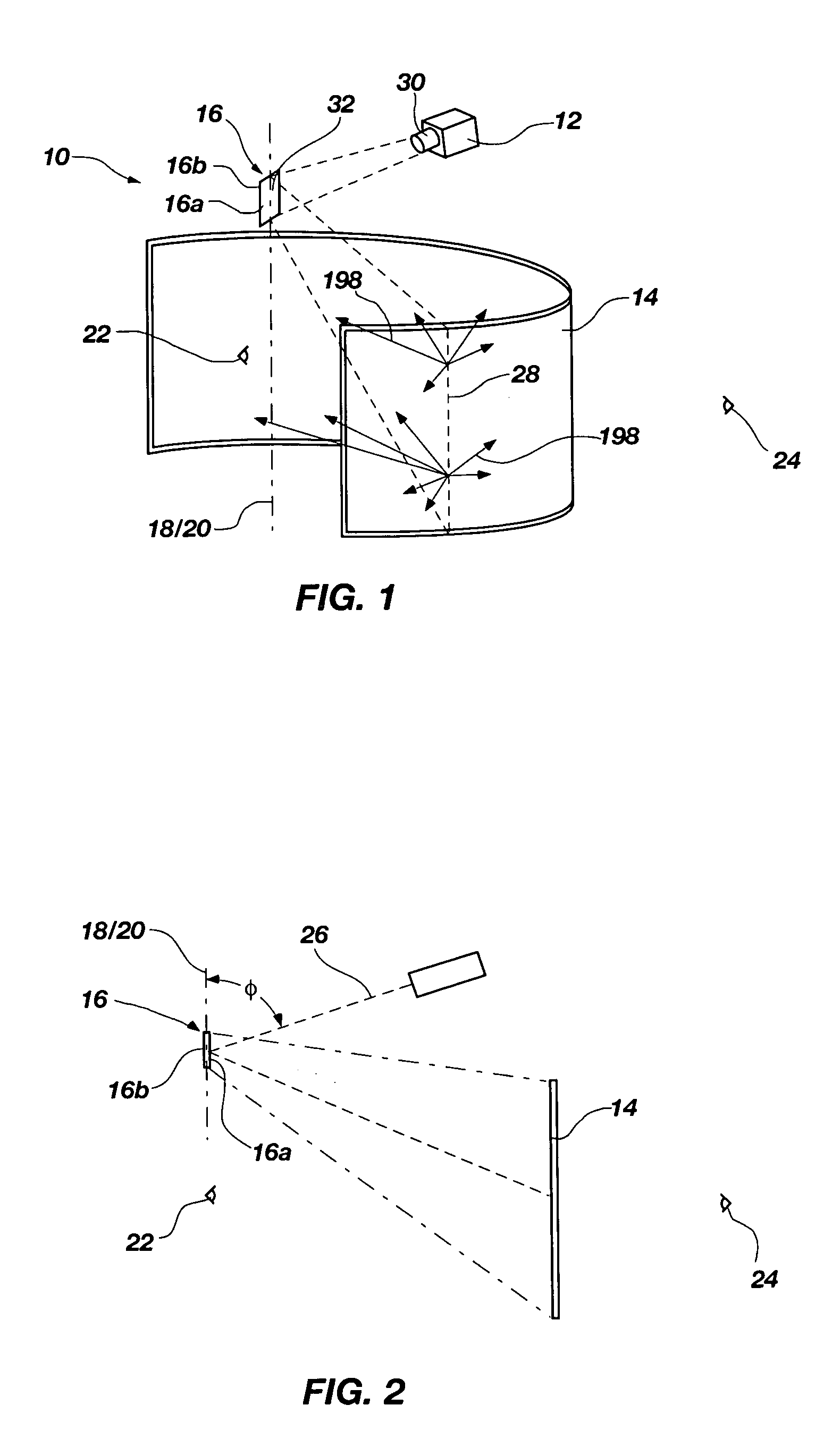

ActiveUS20050041211A1Good colorNo seamsTelevision system detailsDigital data processing detailsProjection screenPanorama

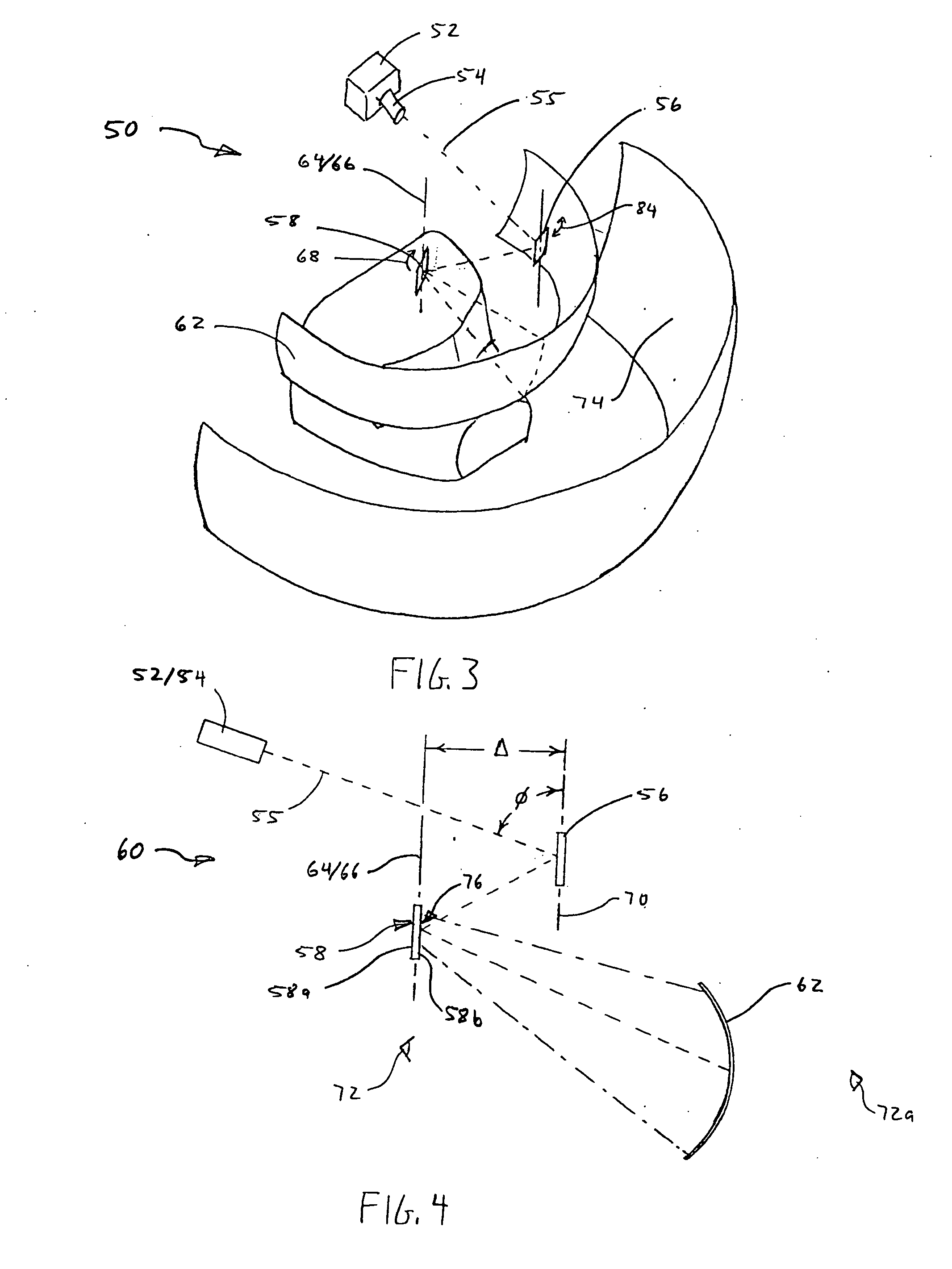

A panoramic display system includes a curved projection screen, a panoramic projector, and a substantially conically shaped barrier. The projector is configured to project an image onto the projection screen from a projection point located substantially above the projection screen. The conical barrier has a base disposed toward the bottom of the projection screen, and an apex region disposed toward the projection point. The barrier blocks scattered light from reflecting from portions of the curved screen to other portions thereof.

Owner:EVANS & SUTHERLAND COMP

Wide angle scanner for panoramic display

A wide angle display system includes a linear array projector, a curved display surface, and an n-sides scanning mirror. The projector is configured to project an image along an optical axis to the scanning mirror. The scanning mirror continuously rotates about a rotational axis at a speed 1 / n the refresh rate, so as to reflect and scan the image onto the display surface.

Owner:EVANS & SUTHERLAND COMP

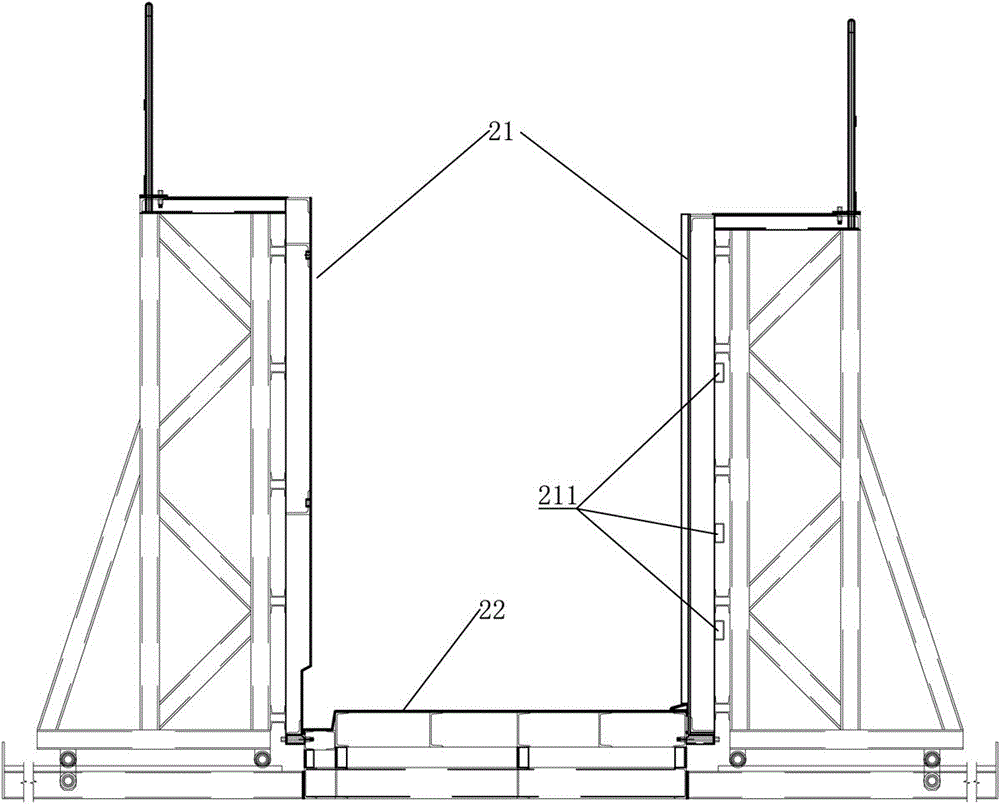

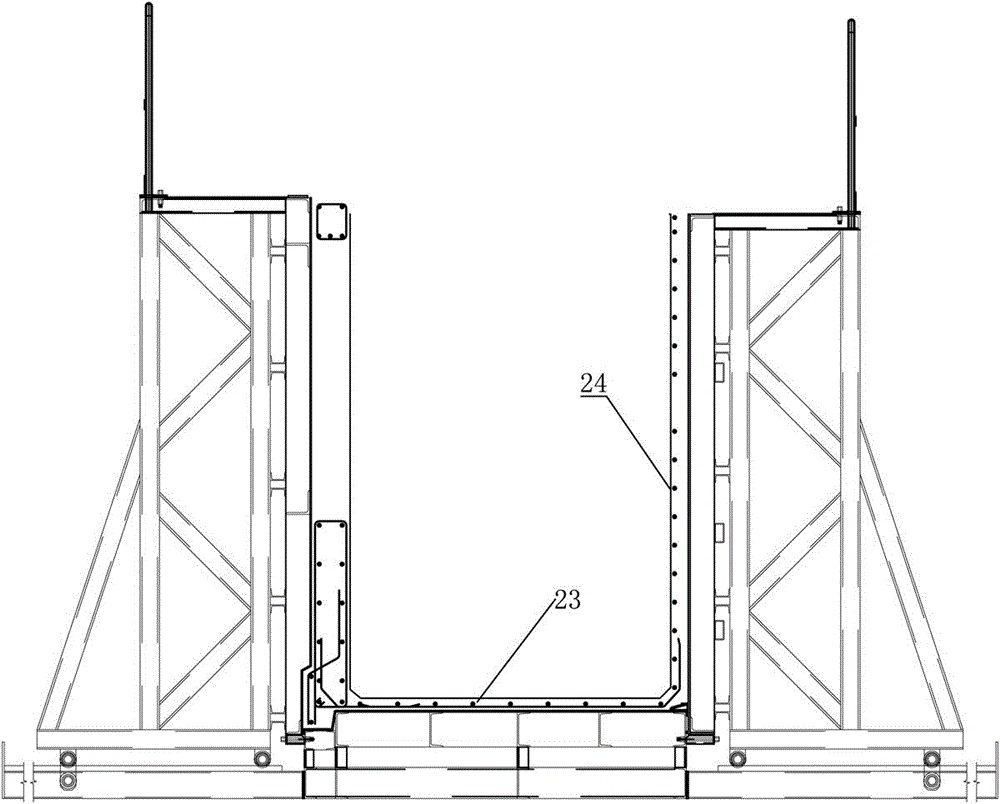

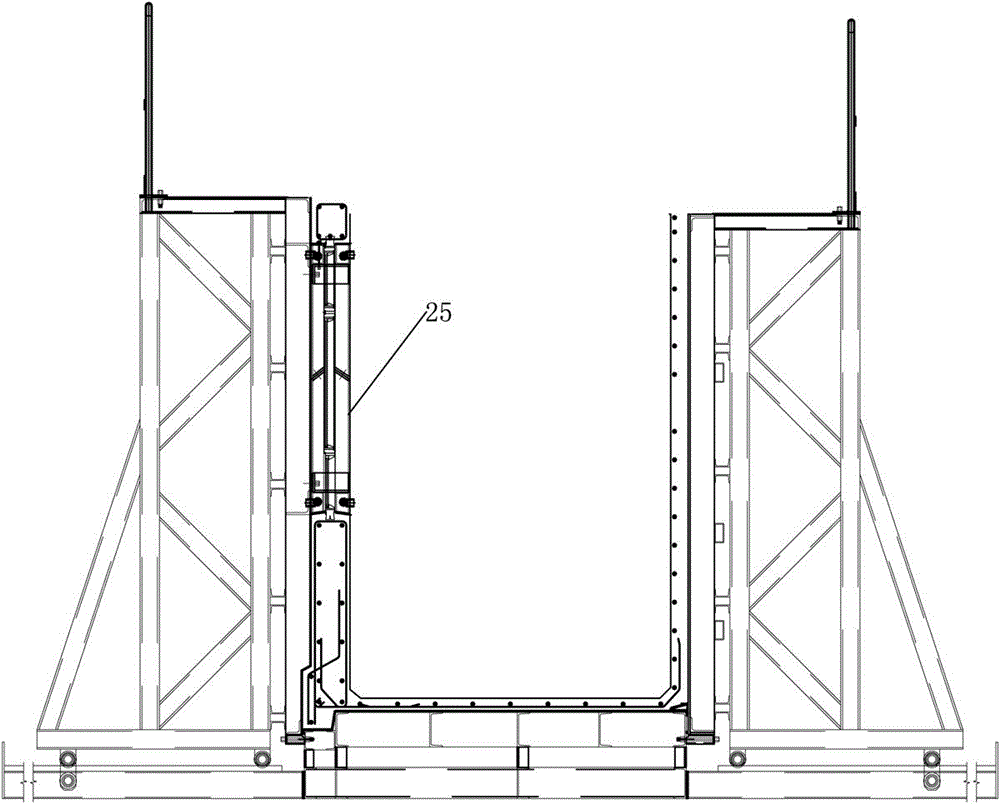

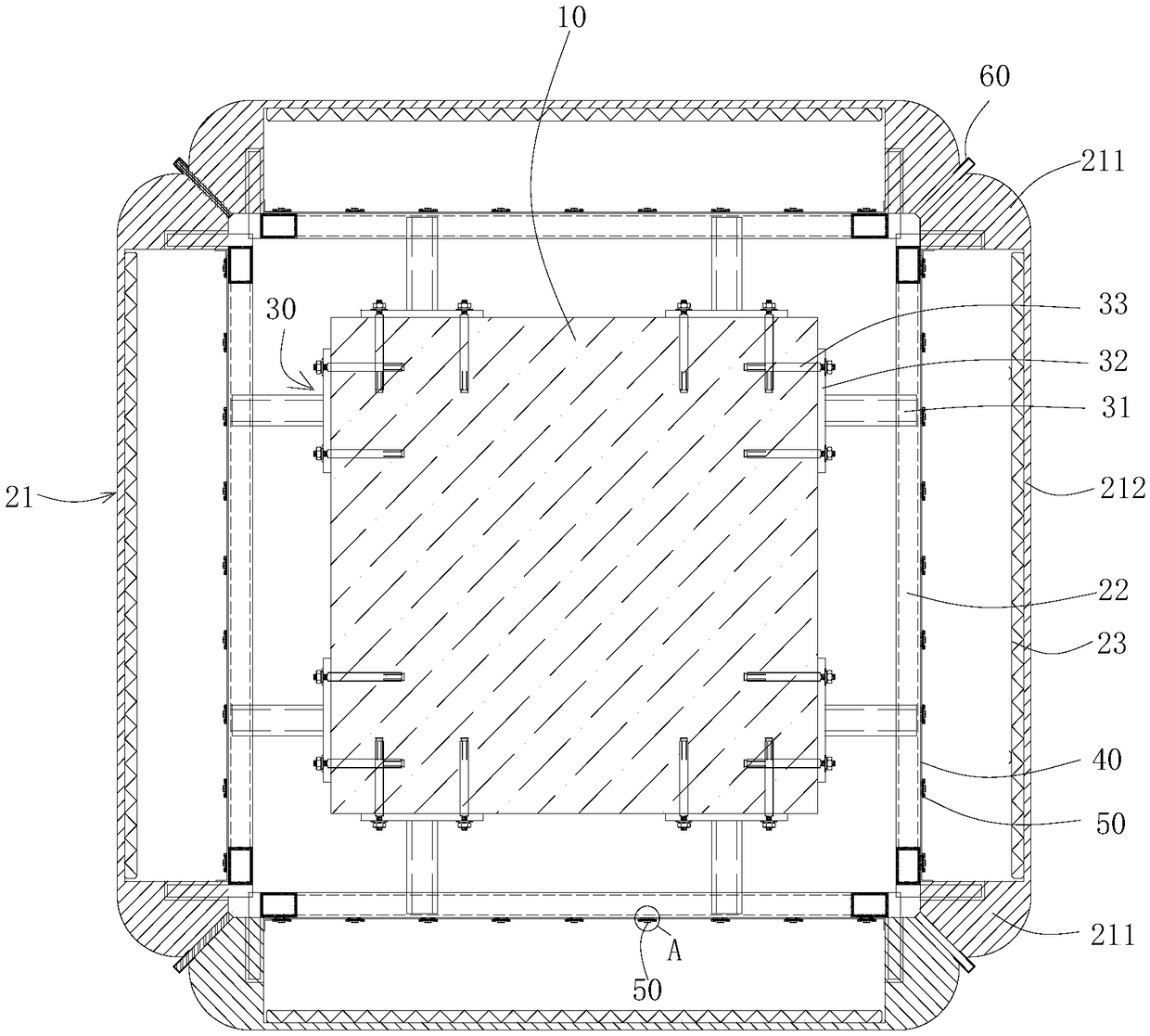

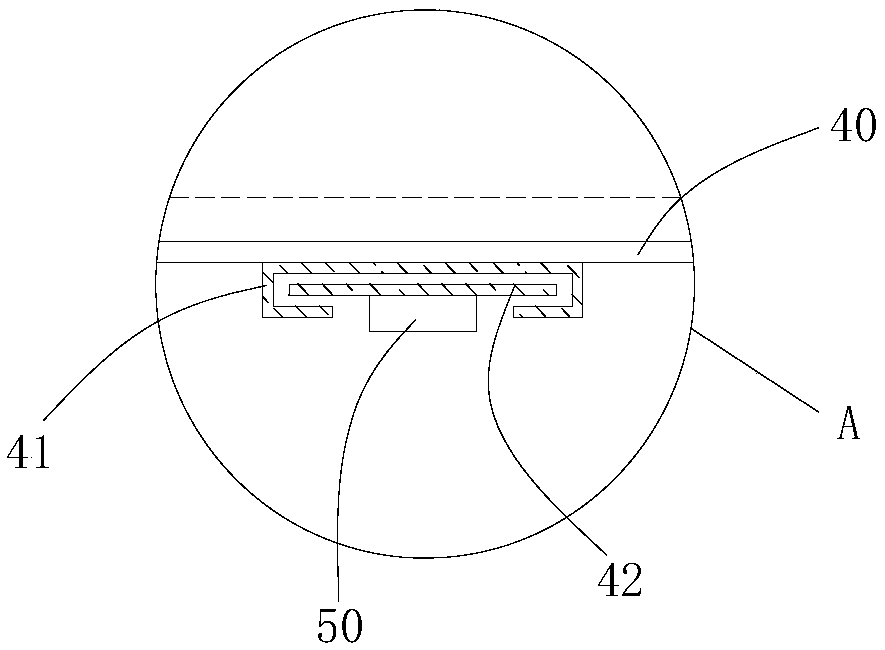

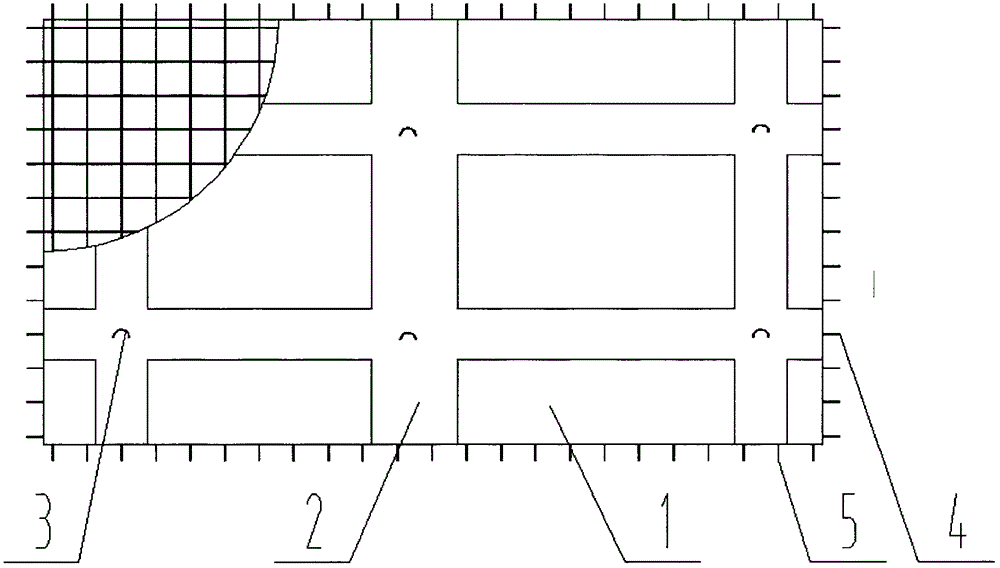

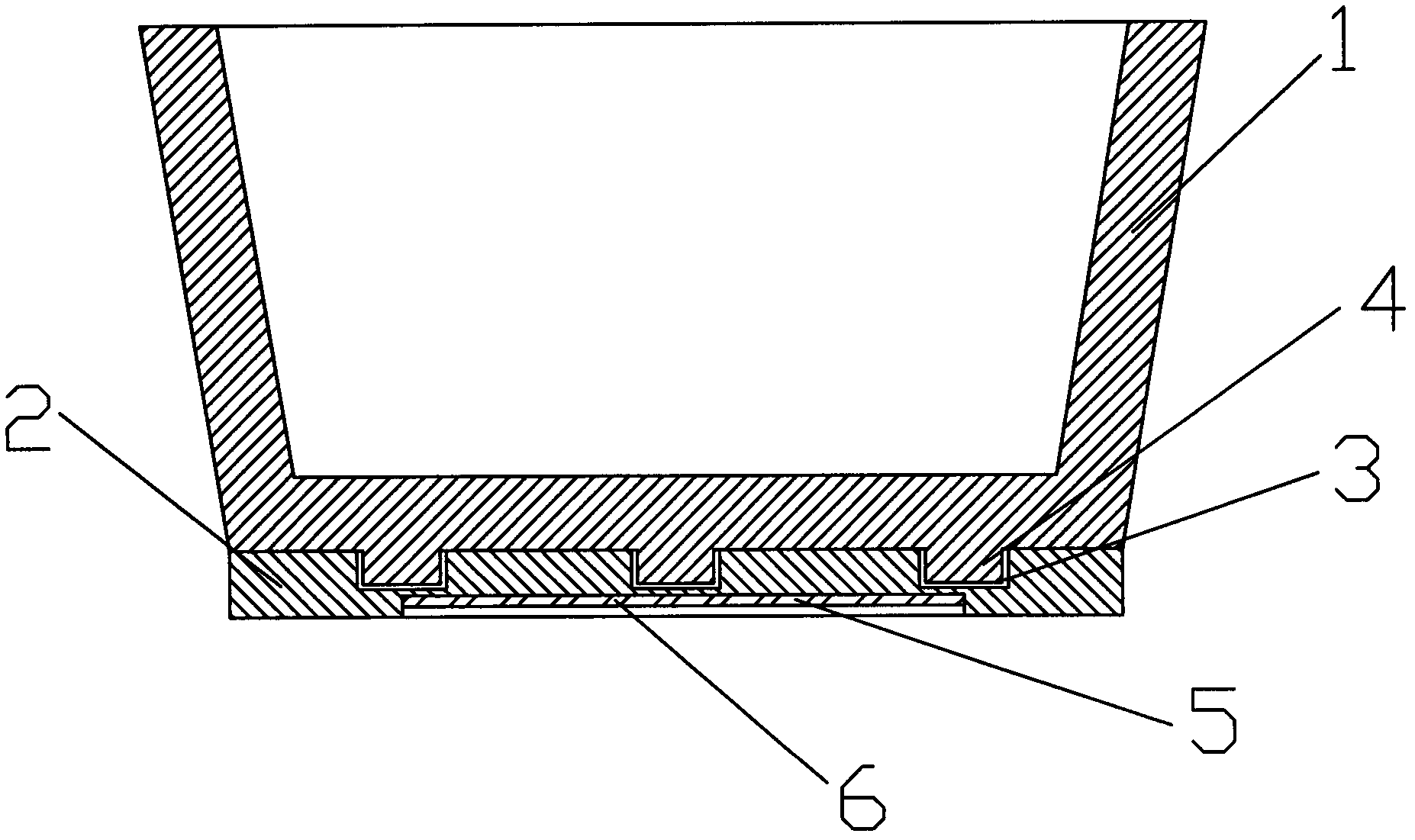

Prefabricated toilet and construction and installation method thereof

The invention discloses a prefabricated toilet and a construction and installation method thereof. The prefabricated toilet includes a bottom plate unit, four wall surface units and a ceiling plate unit which are mutually and fixedly connected; the bottom plate unit, the wall surface units and the ceiling plate unit are constructed by reinforced concrete; doors and windows are arranged on the wall surface units; at least one wall surface unit or a part of one wall surface unit of the four wall surface units is of a semi-prefabricated structural wall, the thickness of the semi-prefabricated structural wall is less than the whole thickness of a building structural wall, a plurality of raised columns are arranged on an outer side surface of the semi-prefabricated structural wall in the normal direction thereof, the height of the raised columns plus the thickness of the semi-prefabricated structural wall equals the whole thickness of the building structural wall, top surfaces of the plurality of raised columns are parallel to the outer side surface of the semi-prefabricated structural wall, and bolts for accurately positioning and installing cast-in-situ wall templates are arranged on the top surface of each raised columns. The prefabricated toilet is easy to construct and install, is firm and stable in structure, and can greatly improve the efficiency of on-site construction.

Owner:YAU LEE WAH CONSTRUCTION MATERIALS (HUIZHOU) COMPANY LIMITED

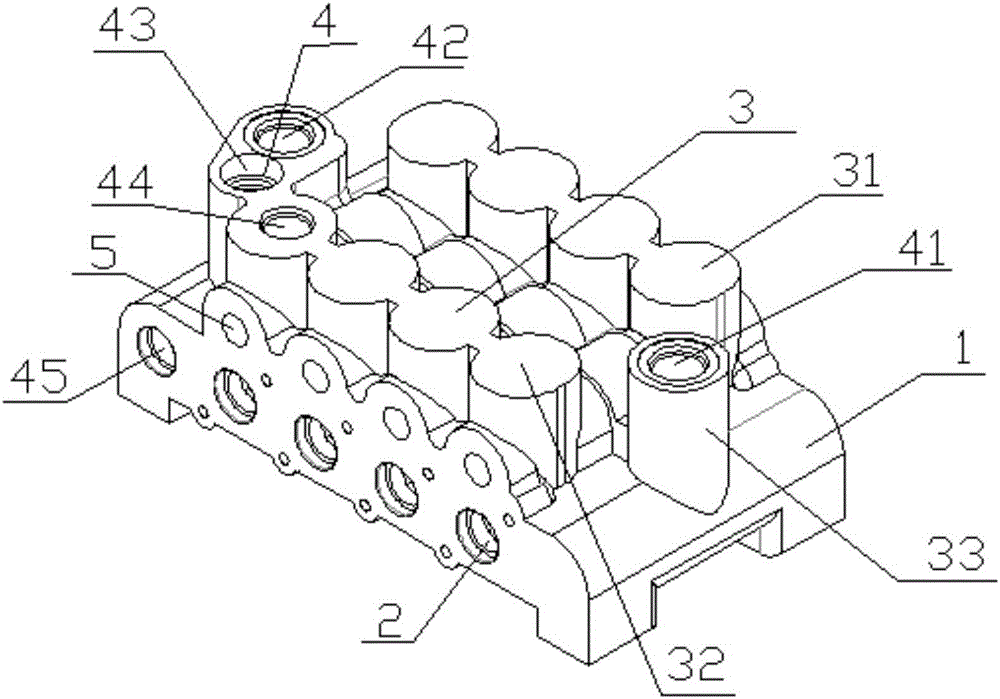

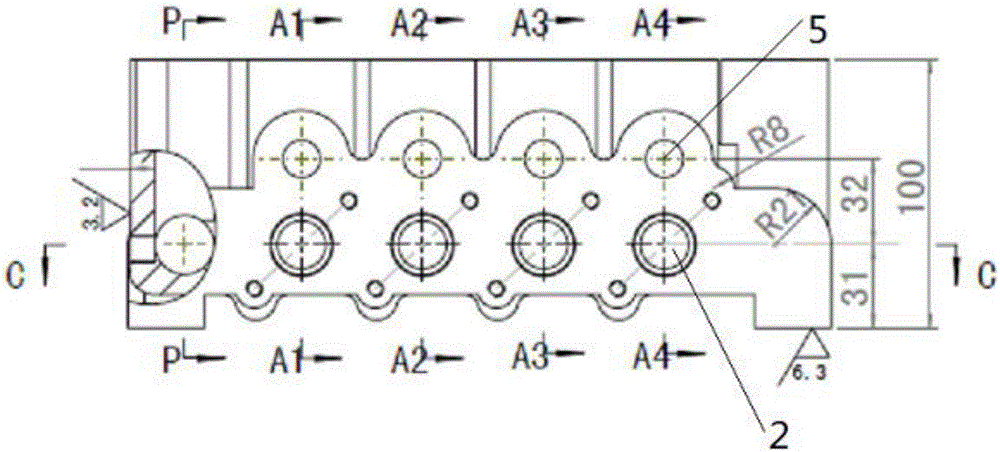

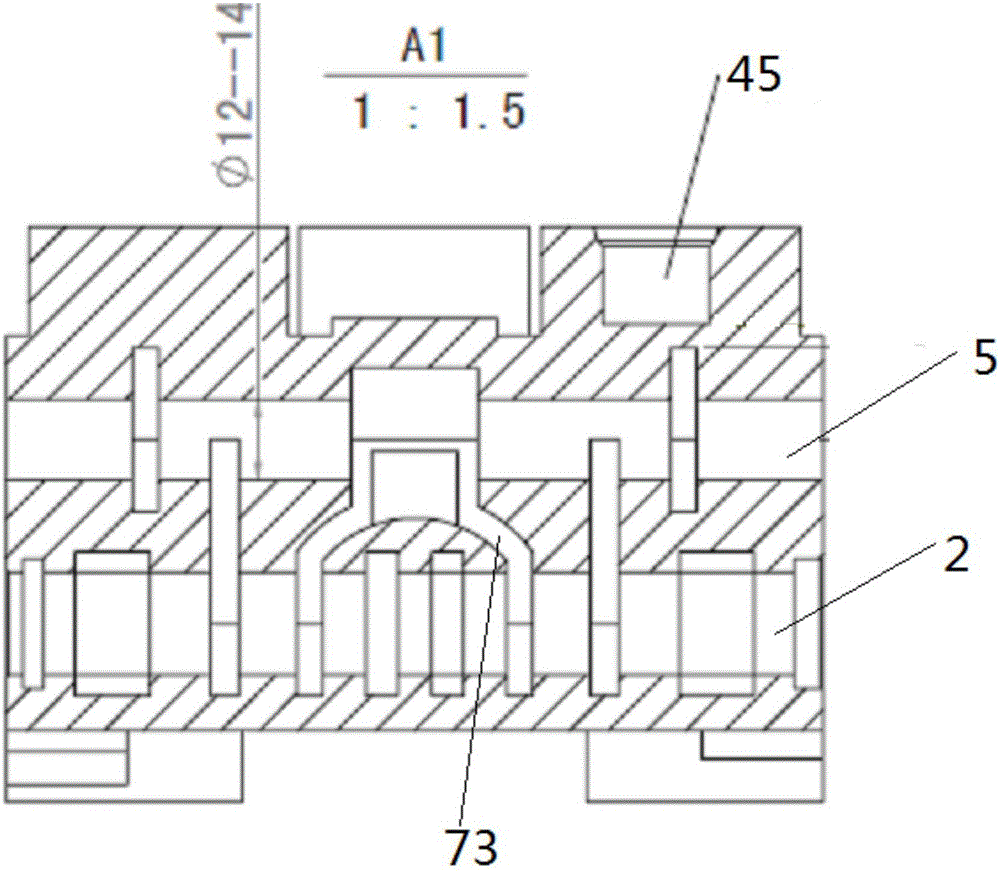

Quadruple valve body casting and mold thereof

The invention discloses a quadruple valve body casting. The quadruple valve body casting comprises a valve body, a transverse runner, longitudinal runners and a runner port. The valve body is in a cuboid shape. The longitudinal runners comprise the first longitudinal runners and the second longitudinal runners which are all of pipe-shaped structures. Cavity bodies are perpendicularly arranged on the second longitudinal runners, and the lower end of each cavity body is an opening. The invention further discloses a mold of the quadruple valve body casting. The mold comprises a shell mold body and a sand core. The sand core is assembled and formed by a main sand core body and a plurality of small sand core bodies. The main sand core body is formed by assembling a plurality of sand core bodies. Graphite arbors are placed in the main sand core body. Exhaust holes are formed in the two ends of the main sand core body and communicate with small sand core holes and main sand core holes. According to the quadruple valve body casting, the interiors of the runners are smooth, the runners in the casting are free of fash, and the sand core bodies are free of cracks; and the poured casting is smooth in appearance and free of pore defects, and the qualified rate of the casting reaches 95% or above.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

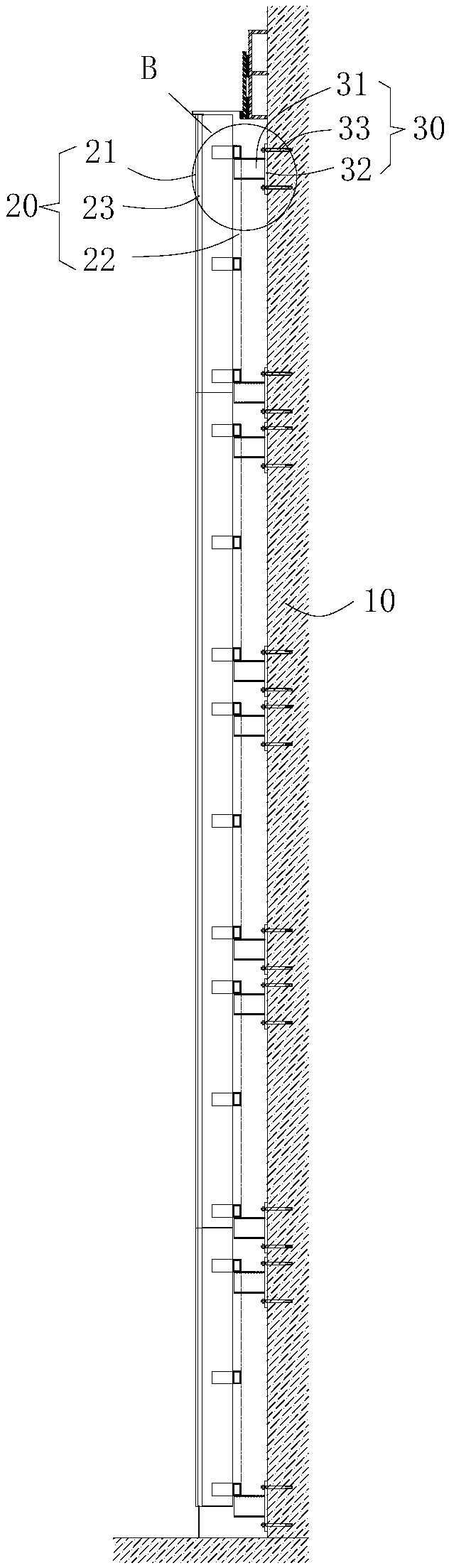

Hollow light-transmitting integral stone decoration vertical column and construction method thereof

PendingCN108915190ASolve the deformationFix damageCovering/liningsElongate light sourcesKeelSteel frame

The invention provides a hollow light-transmitting integral stone decoration vertical column. The hollow light-transmitting integral stone decoration vertical column comprises a vertical column and aplurality of stone unit plates which are hung on the side face of the vertical column, wherein a plurality of groups of keels which are distributed at intervals in the longitudinal direction are fixedto the side face of the vertical column; the keels extend out of a hanging plate along the side face vertical to the vertical column; the stone unit plates comprise stone plates, steel frames and light-transmitting plates; the stone plates comprise arc-shaped chamfered parts with the thicknesses of the two ends being larger, and planar light-transmitting parts which are positioned between two arc-shaped chamfered parts and are thinner; splicing faces positioned on the side faces of the arc-shaped chamfered parts are slopes; the light-transmitting plates are stuck to the inner side faces of the planar light-transmitting parts; the steel frames are fixedly stuck to the inner side faces of the arc-shaped chamfered parts; the steel frames are fixed to the hanging plate of the vertical column;the splicing faces of the stone unit plates on each side face of the vertical column are spliced to form a complete vertical column decoration face; the steel frames are stuck to a bottom plate; thebottom plate is provided with an LED (Light Emitting Diode) lamp strip. The hollow light-transmitting integral stone decoration vertical column has the characteristics of good decorative face integrity and high attractiveness.

Owner:SDCIC CONSTR GRP CO LTD

Manufacturing method of carbon fiber composite material part mold

ActiveCN105751409AImprove processing efficiencyNo seamsNon-macromolecular adhesive additivesMaterials scienceCarbon fiber composite

The invention relates to a manufacturing method of a carbon fiber composite material part mold, belongs to the field of mold manufacture and mainly aims at the problems of complicated manufacturing process, high cost and short service life of an existing carbon fiber composite material structure part. The manufacturing method comprises the following steps: manufacturing a foam model according to a part digifax, then manufacturing a surface part and a supporting part of the mold and finally bonding the surface part and the supporting part of the manufactured mold together through a resin material to obtain the mold. According to the manufacturing method provided by the invention, due to the adoption of a three-dimensional integrated coating technology, a mold forming surface material is free from lapping defects, and the part quality is improved; the mold takes the resin material as a main body, and steel is replaced, so that the light weight is realized, the mold surface processing efficiency is improved by more than 3 times, the manufacturing period is shortened, and the overall manufacturing cost is reduced by more than 20 percent.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

Thin Keypad Assembly

InactiveUS20100013776A1No seamsSurface of the keypad is often kept cleanInput/output for user-computer interactionEmergency actuatorsMicro structureLight guide

A thin keypad assembly includes a panel, a lining sheet and a light-guiding layer. The panel has hollowed numerals, letters, various symbols, a navigation-key pattern, a dialing pattern and an ending pattern, and grooves formed between keys. The lining sheet is disposed on the panel and has a navigation-key pattern thereon. The navigation-key pattern has a light-shielding layer and light-transmitting positions thereon, and the light-shielding layer has a light-reflecting layer thereon. The light-guiding layer is disposed on the lining sheet, and the position thereof corresponds to the key having a plurality of light-guiding micro structures and projecting bodies. The light-guiding layer, light-shielding layer and the light-reflecting layer extend onto the surface of the panel through the grooves.

Owner:ICHIA TECH

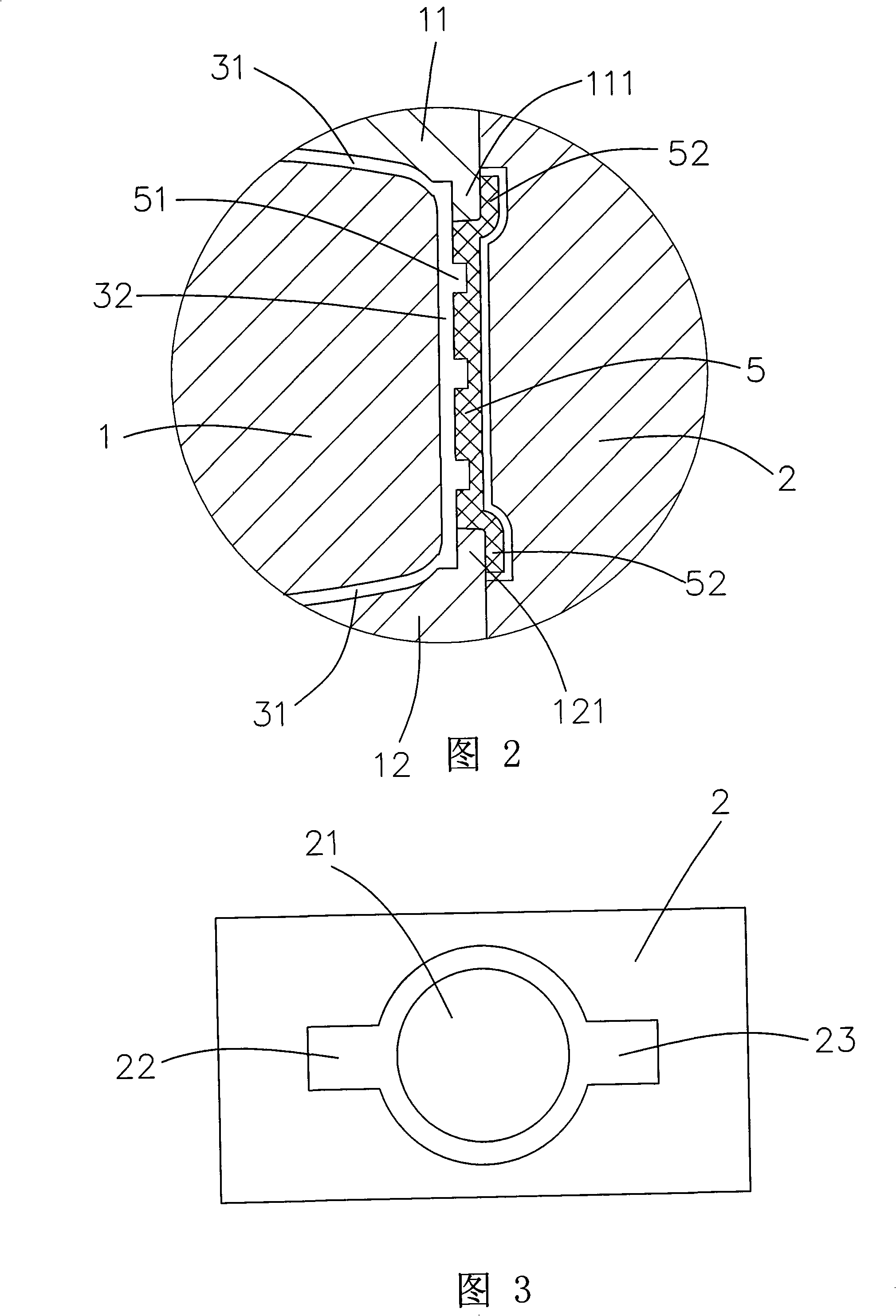

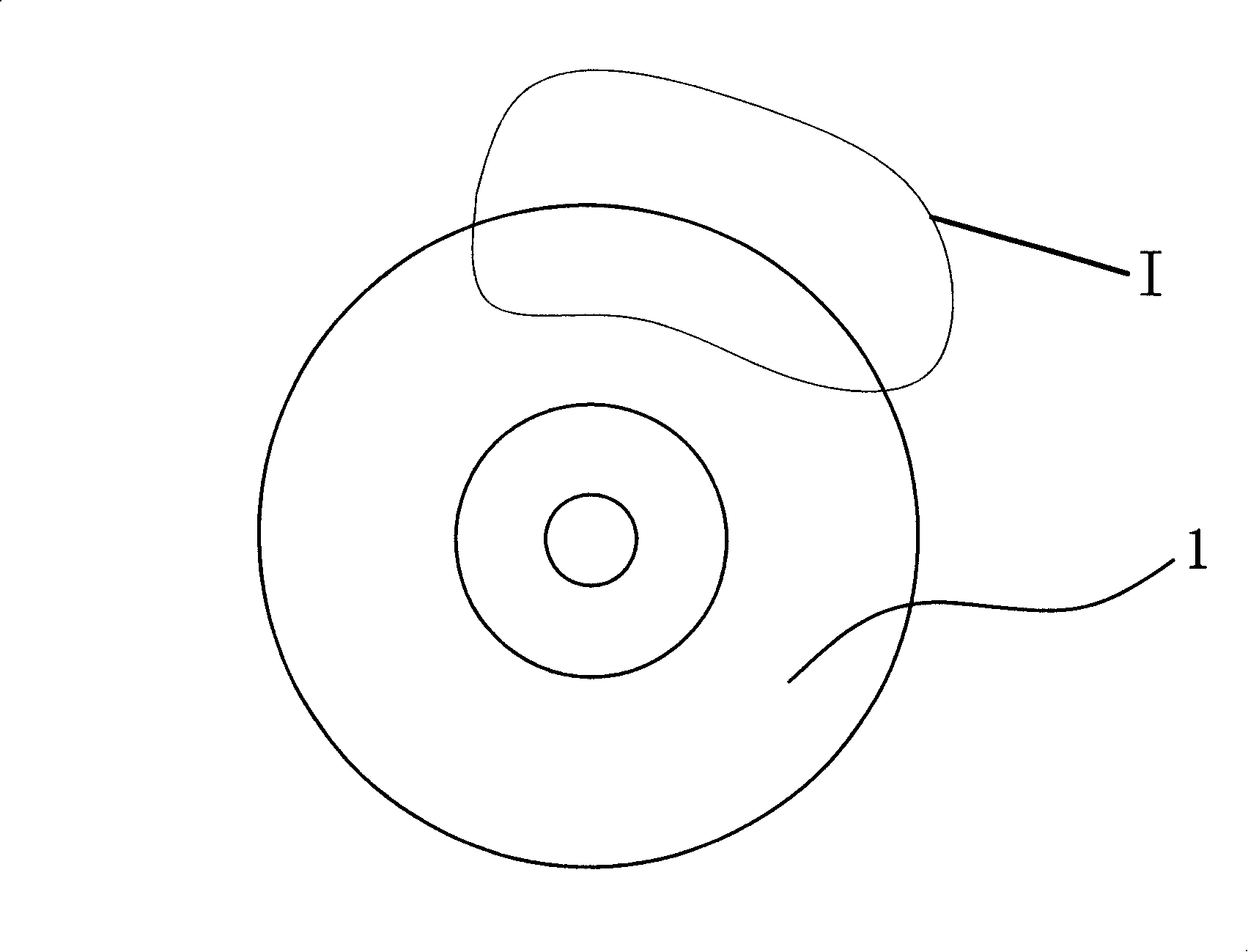

Production process of polyurethane table tennis ball and table tennis ball

InactiveCN107868215AUniform and controllable wall thicknessNo seamsHollow non-inflatable ballsDomestic articlesEngineeringTennis ball

The invention relates to a production process of a polyurethane table tennis ball. The production process comprises the following steps: weighing and mixing combined polyether and diisocyanate, injecting the mixture into a table tennis ball mold cavity, controlling the table tennis ball mold cavity to simultaneously rotate along an X axis and a Y axis which are perpendicular to each other, whereinthe X axis is parallel to a horizontal plane, and the Y axis is perpendicular to the horizontal plane; adjusting the rotating speeds in the two directions to 10 to 100 r / min, and controlling the rotating speeds in the X axis and the Y axis to be unequal, and placing the table tennis ball mold cavity in a constant-temperature environment at 45 to 70 DEG C for reaction for 3 to 10 min; and finallyopening the table tennis ball mold cavity for discharging, thus obtaining the table tennis ball. The table tennis ball obtained by the process disclosed by the invention is integrally molded at one time, so that no post-molding bonding or welding is needed; the wall thickness is uniform and controllable, and no connecting lines are formed; the table tennis ball produced by the process contains gaswith certain pressure; and furthermore, the pressure can meet a use requirement of the table tennis ball, and no extra inflation is needed.

Owner:肖玲丽

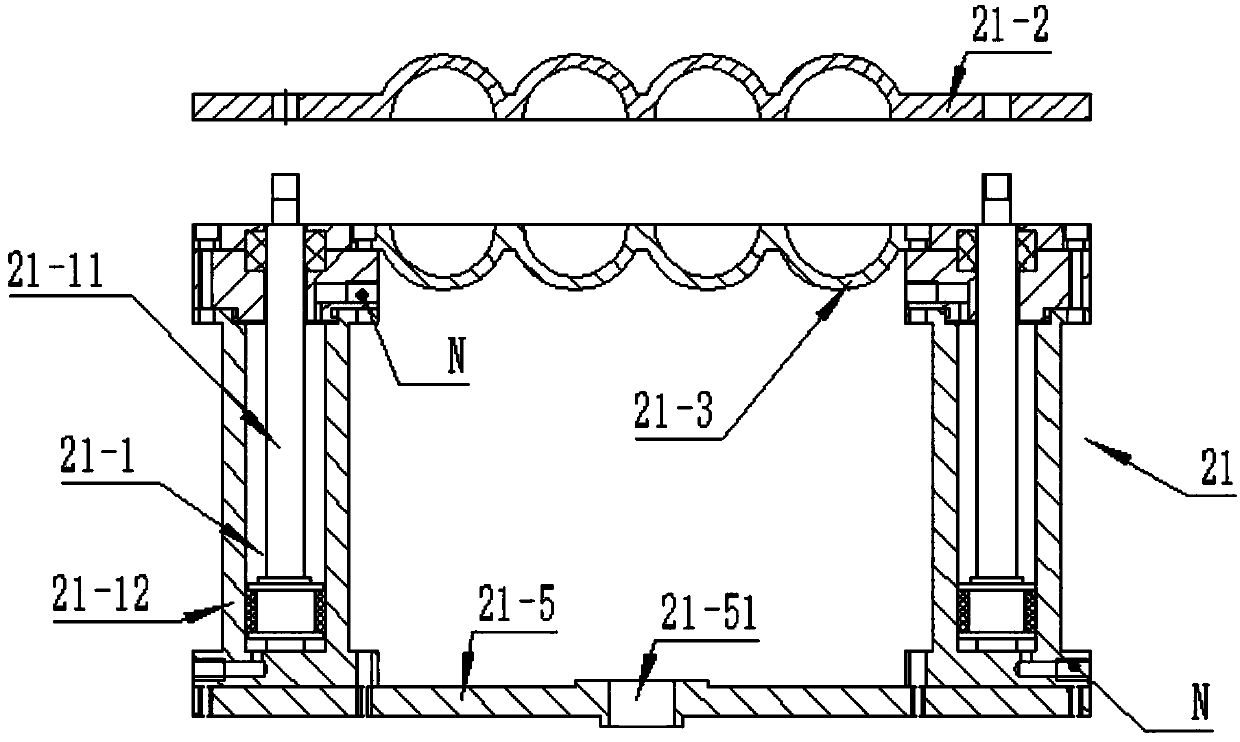

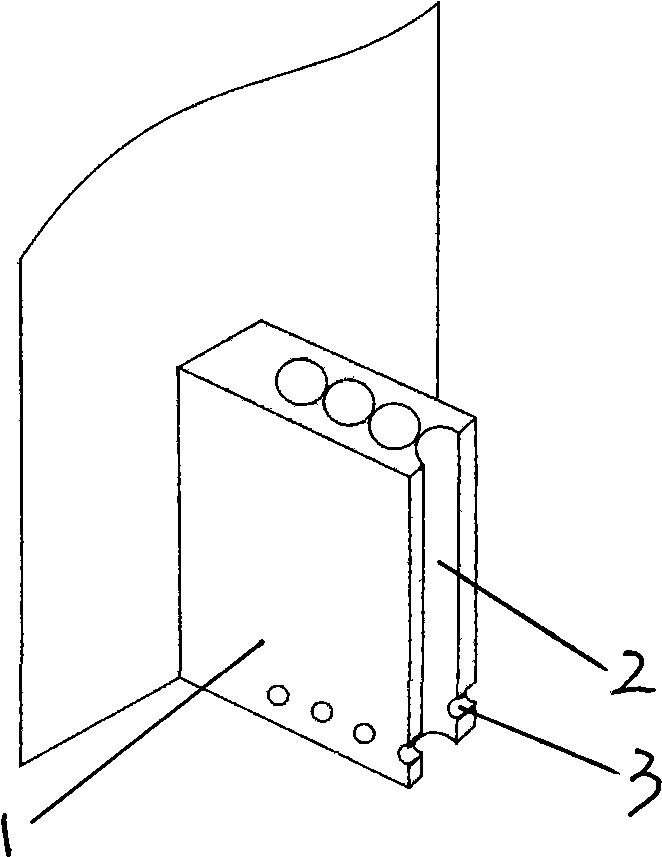

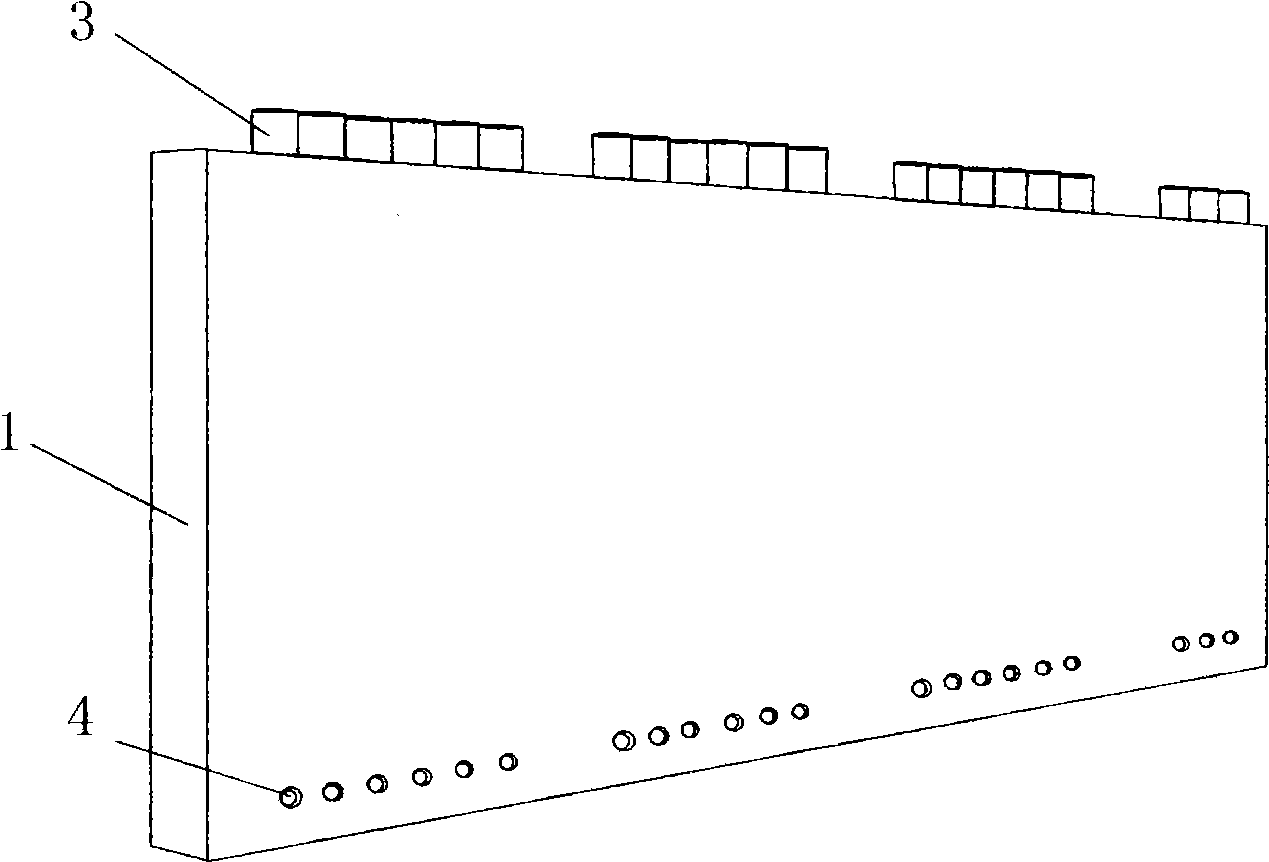

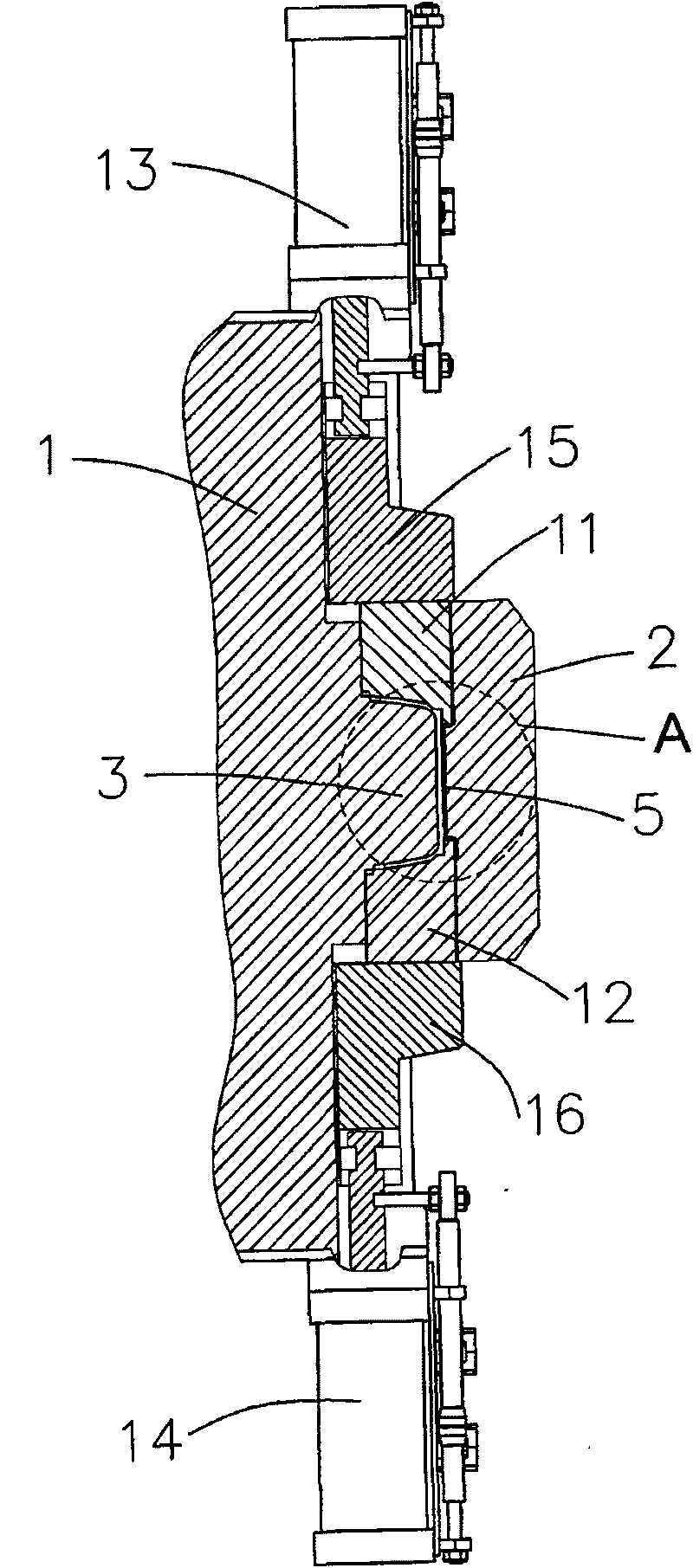

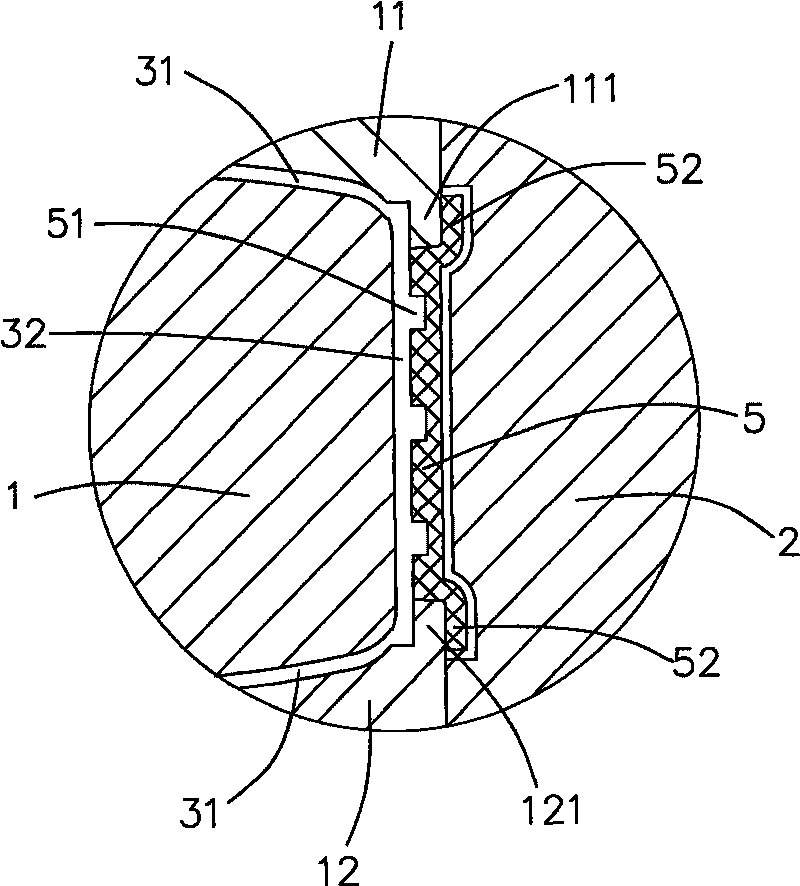

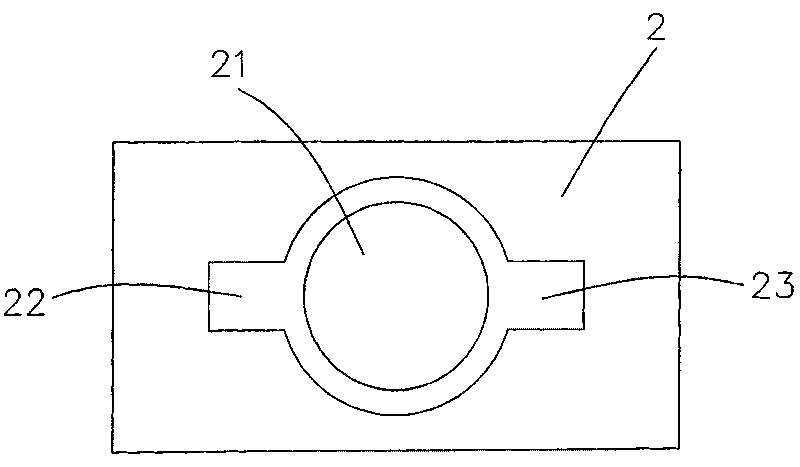

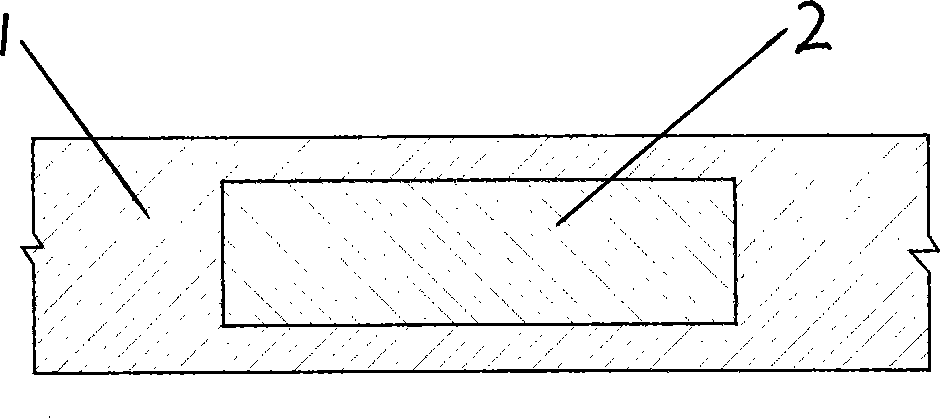

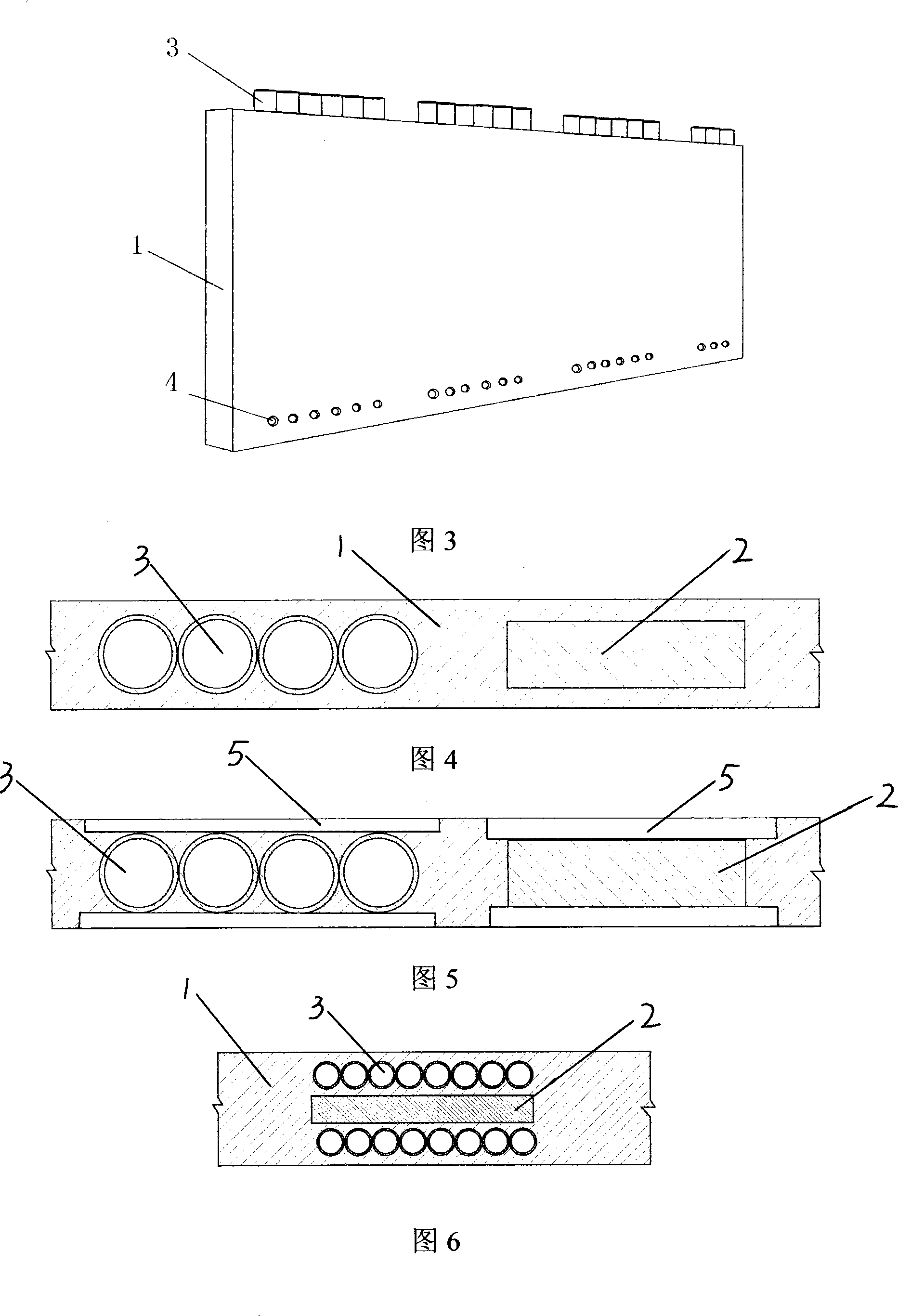

Cast-in-place hollow lightweight inner partition wall

The invention relates to a cast-in-place hollow lightweight inner partition wall in the building construction field and is characterized in that a hollow cylinder (2) is embedded in a wall body (1) which is manufactured by adopting a cast-in-place method. The cast-in-place method comprises the steps of: fixing a row of mold boards at one side of the partition wall needing to be casted, later fixing the hollow cylinder in the middle of the partition wall needing to be casted, and then fixing another row of mold boards at the other side of the partition wall needing to be casted, wherein the terminals of the two rows of mold boards are connected with the existing wall body or an L-type component or a T-type component; casting inorganic cementitious slurry with self-leveling property between the two rows of mold boards, forming the cast-in-place hollow lightweight inner partition wall by curing at normal temperature, and then dismantling the mold boards at the two sides of the partition wall. The cast-in-place hollow lightweight inner partition wall is embedded with a hollow cylinder in the wall body, has the advantages of compact structure, no paving seams, better strength and sound insulation effect, light wall body, simple construction and lower cost, does not need prefabricated wall panel and also does not need the extraction of the hollow cylinder.

Owner:杨小平

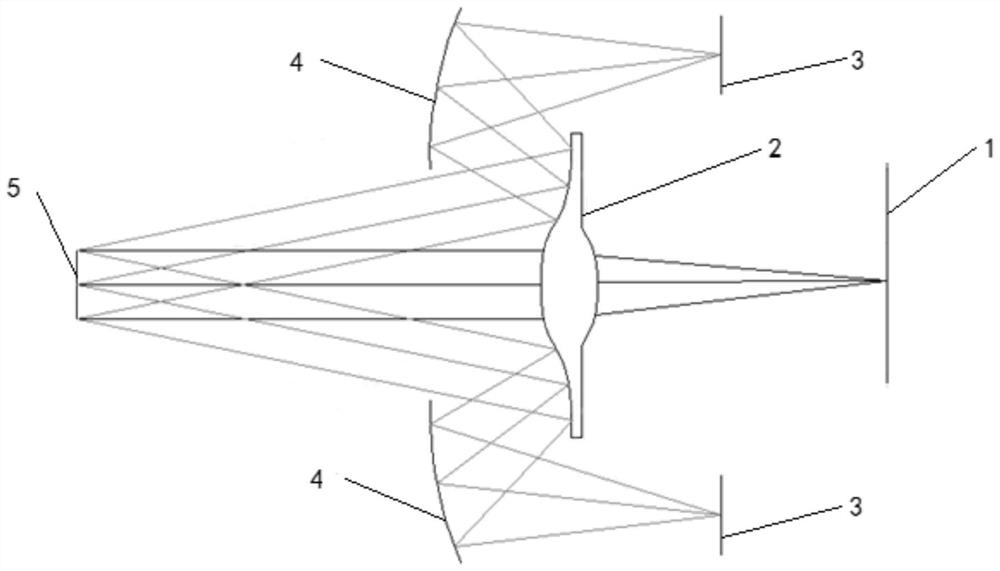

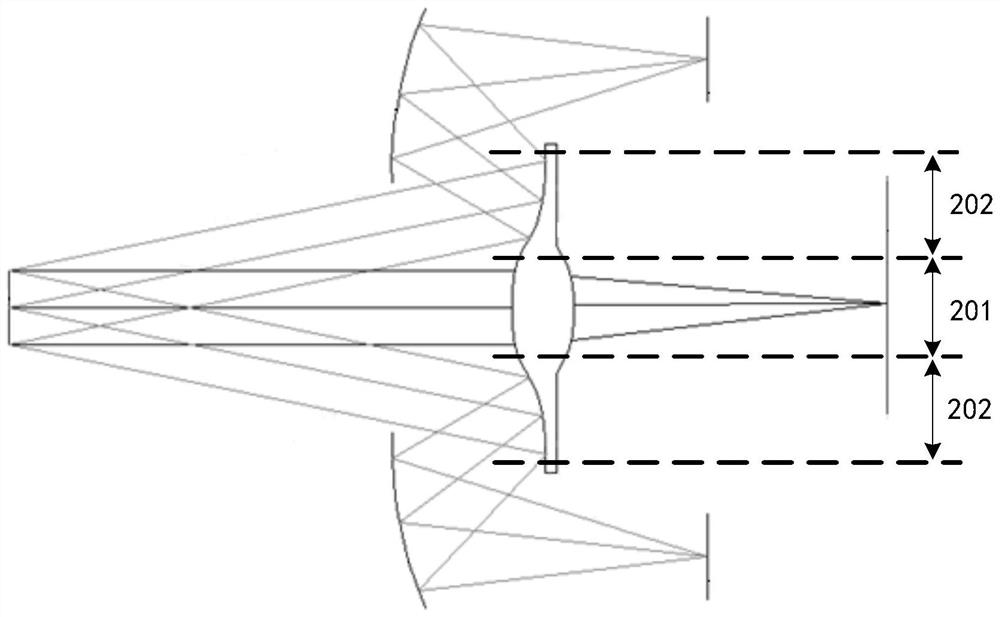

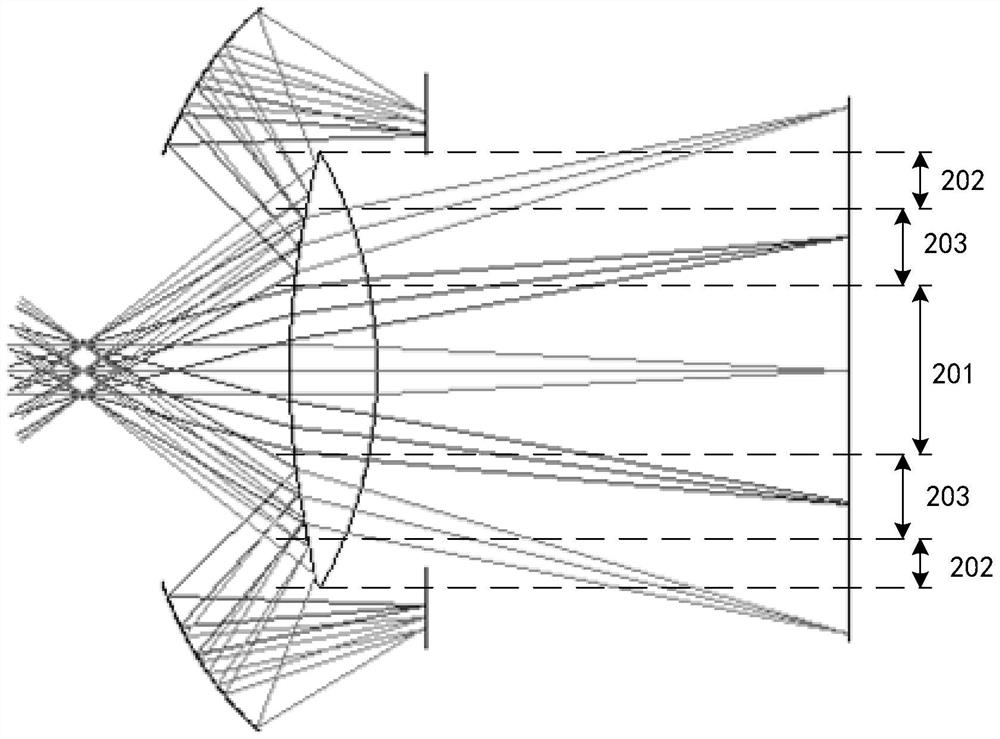

Display device and wearable display equipment

PendingCN114779475ASolve the patchwork problemCan't patchworkOptical elementsDisplay deviceLenticular lens

The invention provides a display device and wearable display equipment. The display device comprises a first display screen; the biconvex lens is arranged on the light emitting side of the first display screen and is used for transmitting the first emergent light of the first display screen so as to image a first display image of the first display screen; the second display screen is arranged at one end of the biconvex lens, so that second emergent light of the second display screen is not shielded by the biconvex lens; the reflecting mirror is arranged on the light emitting side of the second display screen, located on the side, away from the first display screen, of the biconvex lens and used for reflecting second emergent light of the second display screen to the biconvex lens; and the biconvex lens is used for reflecting the second emergent light reflected by the reflecting mirror, so that the second display image of the second display screen and the first display image form a continuous image, the display image imaged at the human eyes is ensured not to have a splicing seam, and the splicing seam problem of the display device is solved.

Owner:BOE TECH GRP CO LTD +1

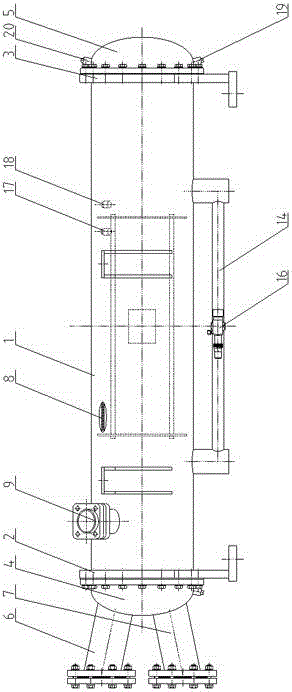

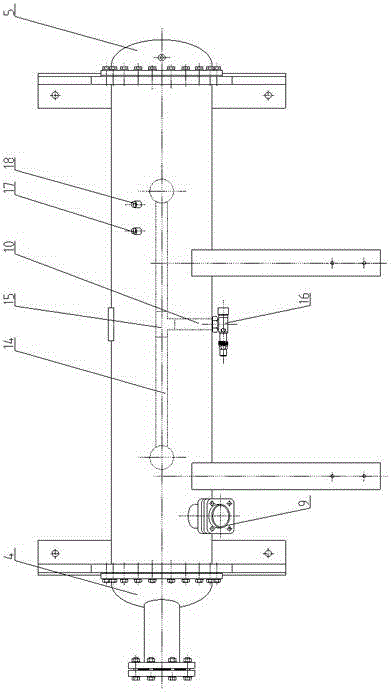

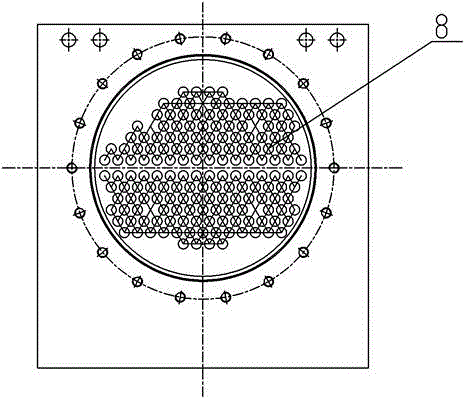

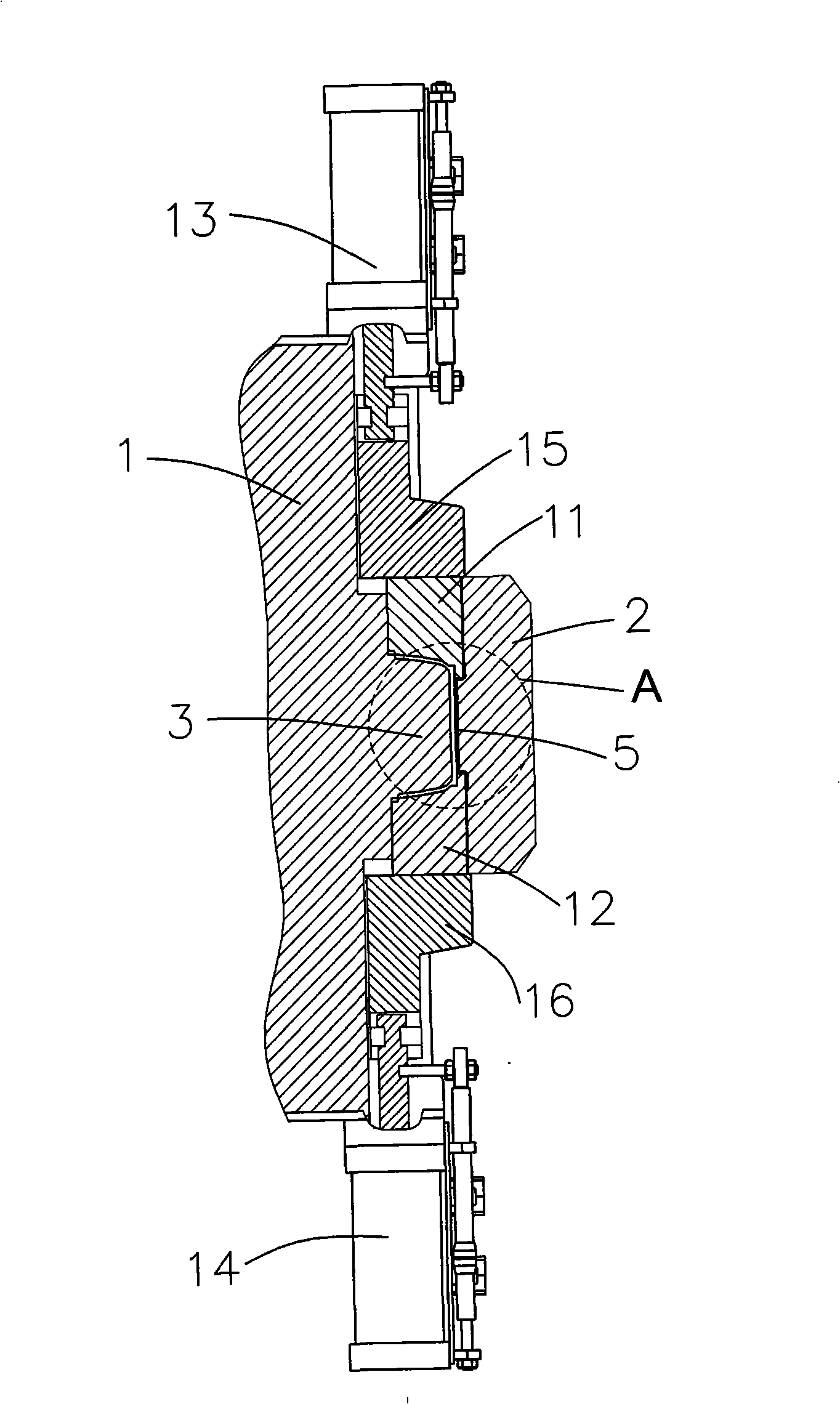

Marine condenser with carbon steel and polyethylene hot-melted combined pipe box

InactiveCN102914207AImprove bindingNot easy to delaminateEvaporators/condensersCorrosion preventionEngineeringHot melt

The invention relates to the field of refrigeration and especially relates to a marine condenser with a carbon steel and polyethylene hot-melted combined pipe box. The marine condenser is mainly used for solving the technical problems of the prior art that a zinc block is corroded when the zinc block is adopted by the condenser for protecting a pipe box, the pipe box is detached and overhauled, a gasket is manufactured again, the operation is troublesome, the position and the construction of the zinc block are specially designed, the parts of the pipe box are increased, the structure of the equipment is more complex, and the like. The marine condenser comprises a cylinder, wherein a front pipe plate and a rear pipe plate are respectively arranged at front and rear two ends of the cylinder; a front pipe box and a rear pipe box are respectively connected with the front and rear pipe plates; a water inlet and a water outlet are arranged on the front pipe box; a plurality of heat exchange pipes are arranged in the cylinder; a refrigerant inlet and a refrigerant outlet are connected with the exterior of the cylinder; plastic lining layers are arranged inside the front pipe box and the rear pipe box; and the plastic lining layers are plastic and steel substrate hot-melted combined layers.

Owner:HANGZHOU SAFETY EQUIP

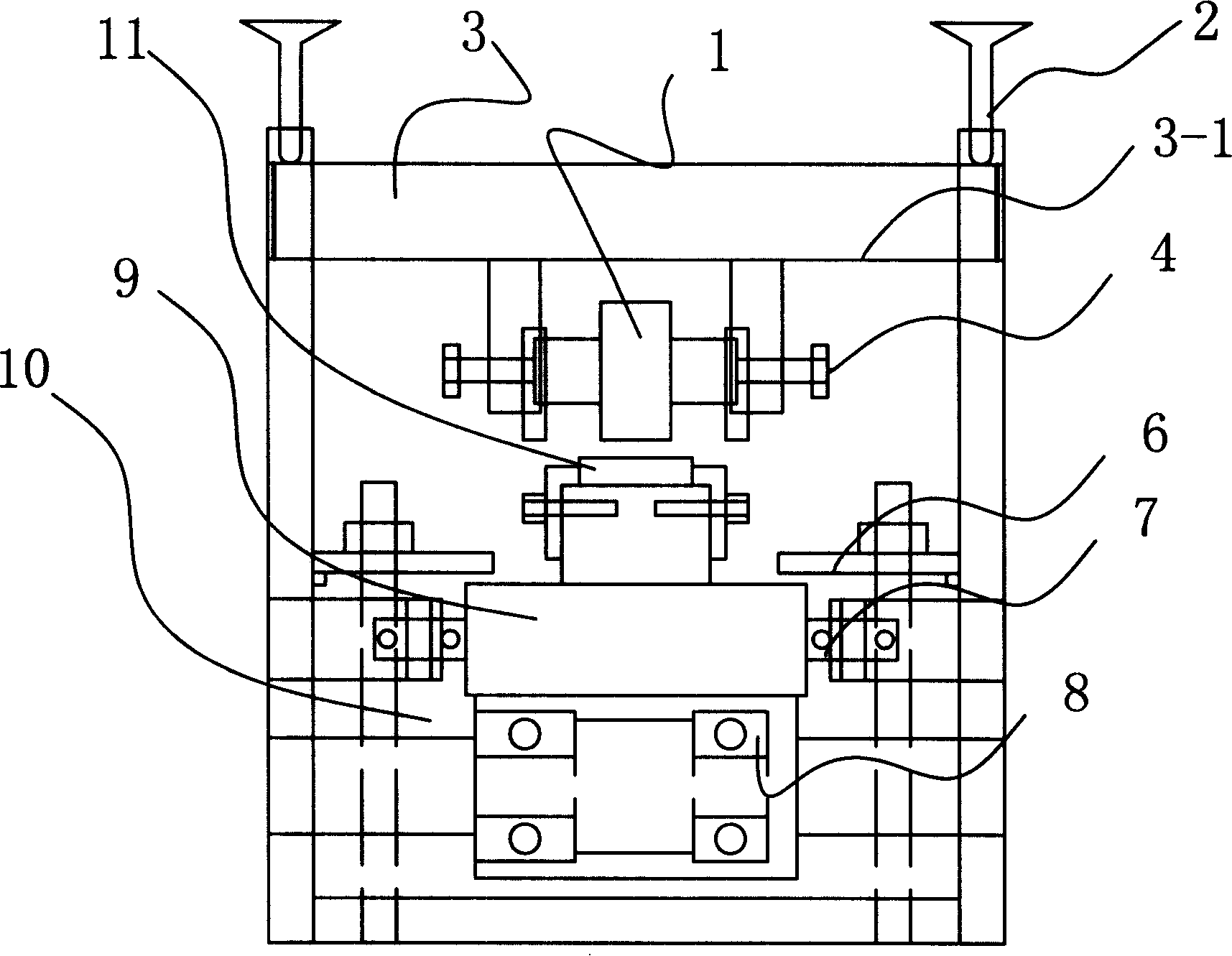

Cast die tool of multi-bottom pan and technique for producing multi-bottom pan using the die

A die-casting die of a double-bottom pan and a process for making the double-bottom pan by the die-casting die belong to the technical field of casting. The die-casting die comprises a fixed die and a moving die, wherein, the inner surface of the fixed die is provided with a pan body model and an aluminum liquid jet orifice, the inner surface of the fixed die is also provided with positioning seats symmetrically arranged at the two sides of the pan body model, the two positioning seats are respectively connected with a cylinder at the outside thereof and slide inwards and outwards with the reciprocating motion of the cylinder, the inner surfaces of the two positioning seats are corresponding to the outer peripheral wall shape of the pan body model; the inside part of the moving die is provided with a first concave cavity matched with the pan body model and a second concave cavity matched with the two positioning seats, and a 1-6mm gap is kept between the peripheral wall of the first concave cavity and the pan body model. The double-bottom pan made by the die-casting die has the advantages of firm connection, mark-free bottom surface and very nice appearance.

Owner:浙江乐家厨具有限公司

Cast-in-place lightweight inner partition wall

The invention relates to a cast-in-place light inner partition wall in the building material field and is characterized in that a lightweight insulation board (2) or a lightweight insulation board (2) and a hollow cylinder (3) are embedded in a wall body (1) which is manufactured by adopting a cast-in-place method. The cast-in-place method comprises the steps of: fixing a row of mold board at one side of the partition wall needing to be casted, later fixing the lightweight insulation board or the lightweight insulation board and the hollow cylinder in the middle of the partition wall needing to be casted, and then fixing another row of mold boards at the other side of the partition wall needing to be casted, wherein the terminals of the two rows of mold boards are connected with the existing wall body or an L-type component or a T-type component; casting inorganic cementitious slurry with self-leveling property between the two rows of mold boards, forming the cast-in-place lightweight inner partition wall by curing at normal temperature, and then dismantling the mold boards at the two sides of the partition wall. The cast-in-place lightweight inner partition wall is embedded with a lightweight insulation board, has more compact structure, no paving seams, better sound insulation effect and heat insulation effect, light wall body, simple construction and lower cost, and no need of prefabricated wall panel.

Owner:杨小平

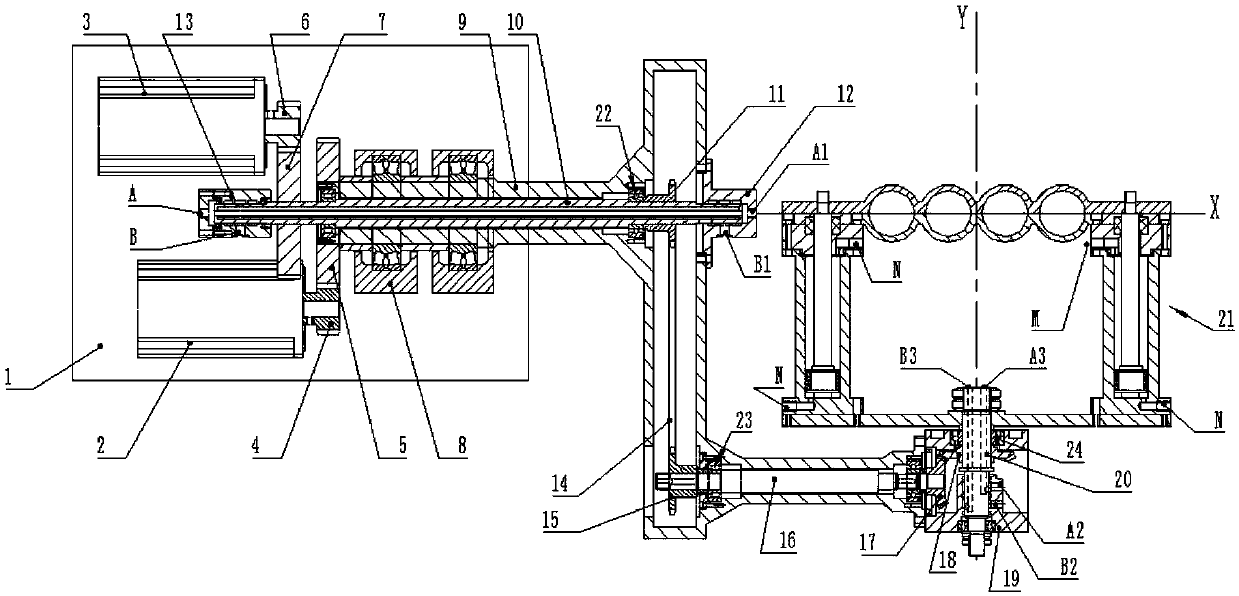

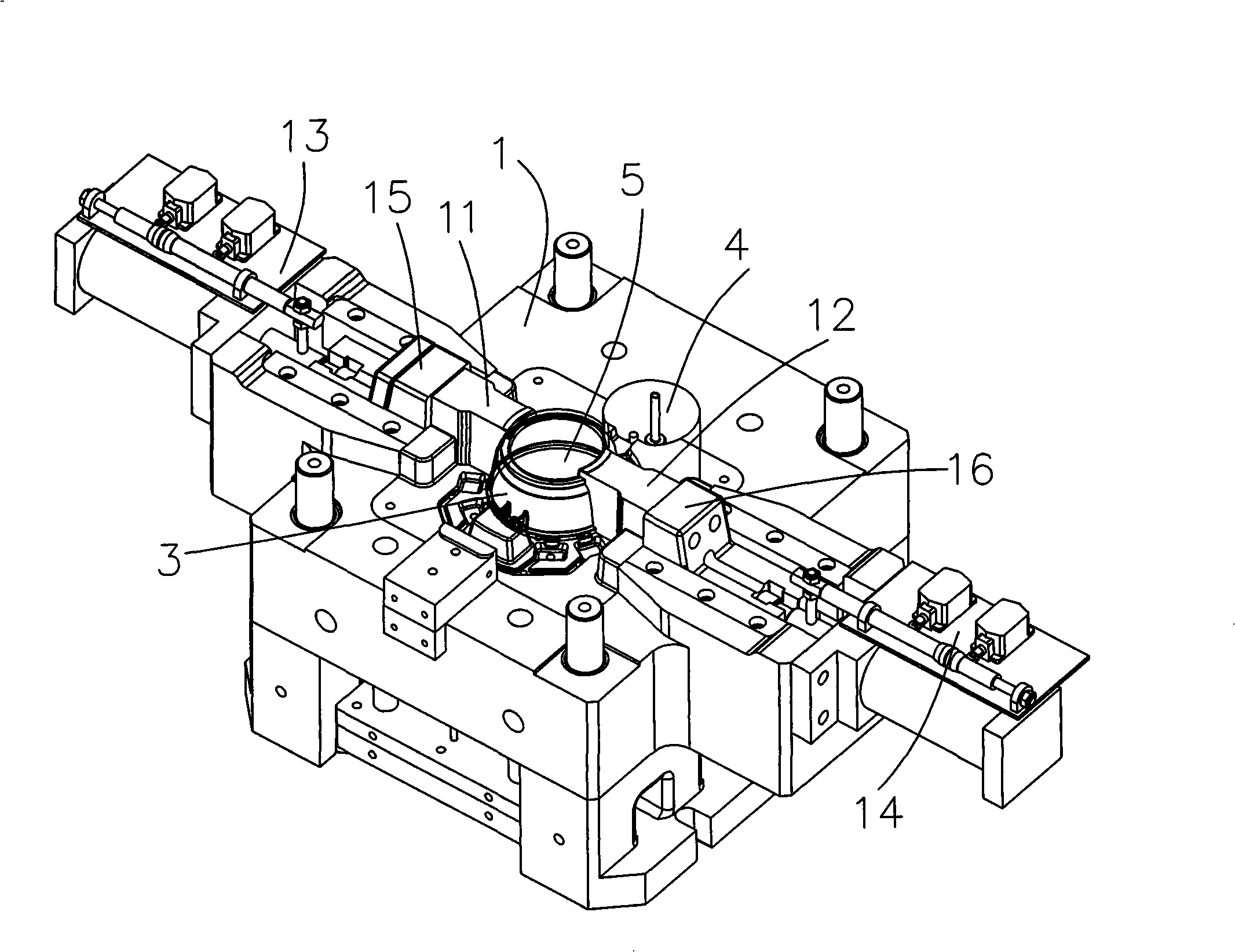

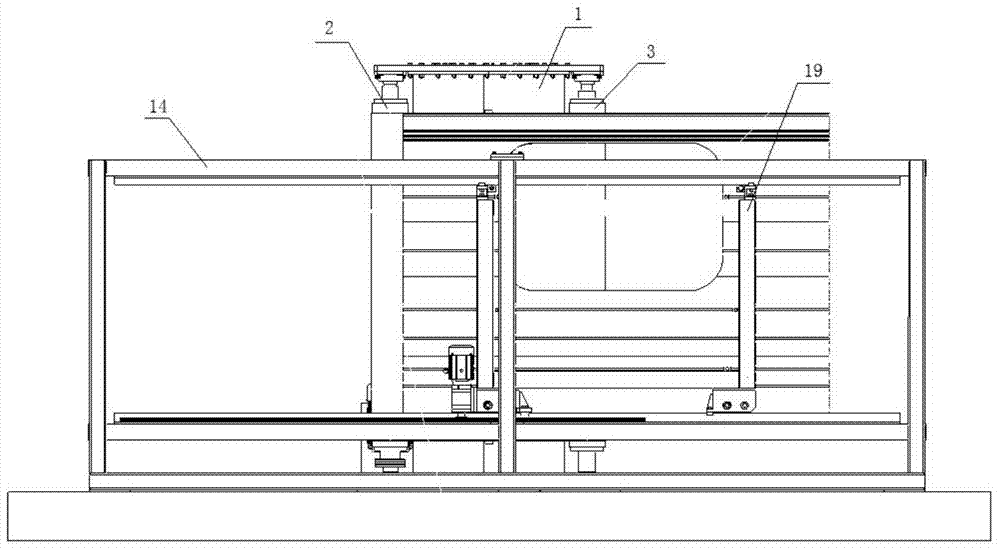

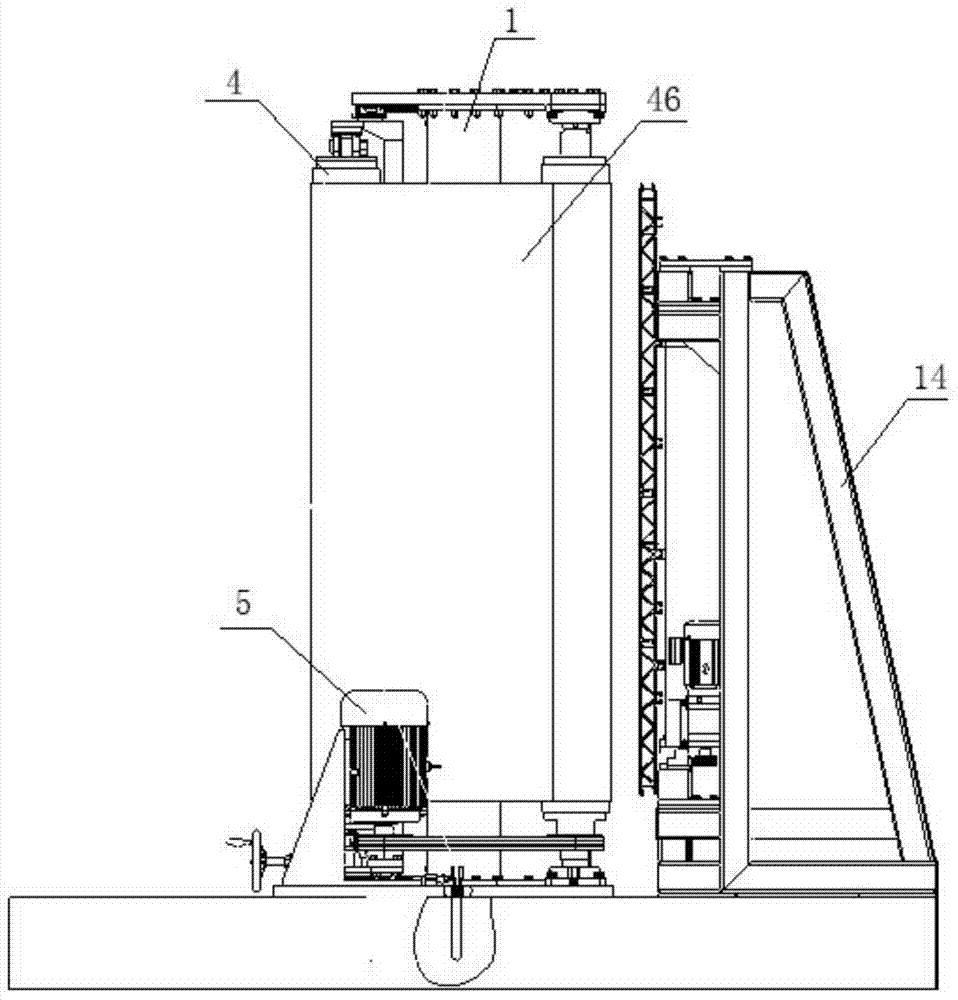

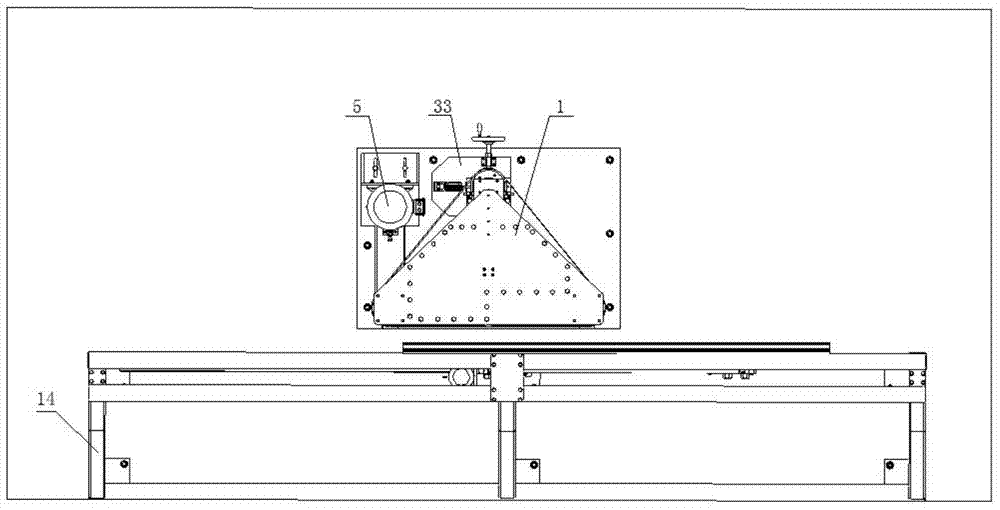

Vehicle wire drawing device and coating-free railway vehicle

ActiveCN104842242AEasy to achieve one-time wire drawingNo seamsBelt grinding machinesCarriagesEngineeringConstant pressure

The invention relates to a vehicle wire drawing device and a coating-free railway vehicle. The vehicle wire drawing device comprises a wire drawing machine used for drawing wires of vehicle parts to be machined; the wire drawing machine comprises a sanding belt, a driving roller and a support roller, wherein the sanding belt is in transmission connection with the driving roller and the support roller. A flexible follow-up device is arranged between the driving roller and the support roller and comprises a plurality of grinder rolls, a mandrel and a grinder roll cylinder, wherein the mandrel penetrates the centers of the grinder rolls and the grinder roll cylinder gives constant pressure of the grinder rolls. The grinder roll cylinder is hinged to the mandrel. The vehicle wire drawing device has an open layout and wide breadth, and is easy to draw wires of the vehicle parts in one step without joints. By the flexible follow-up device, influence on quality of wire drawing due to uneven surface of the vehicle parts is overcome. The tensioning mechanism realizes tensioning of the sanding belt and deviation of the sanding belt can be corrected.

Owner:CRRC QINGDAO SIFANG CO LTD

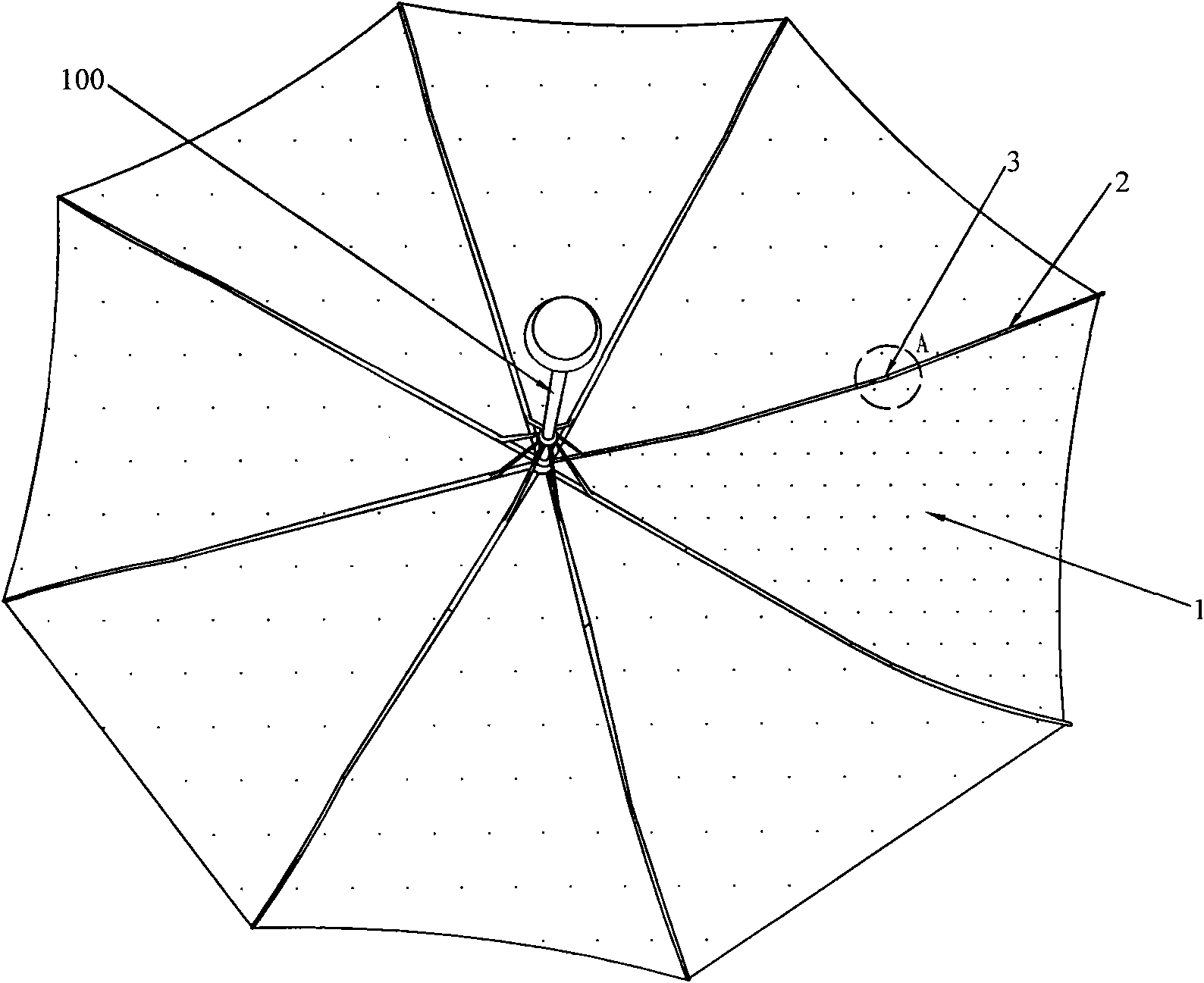

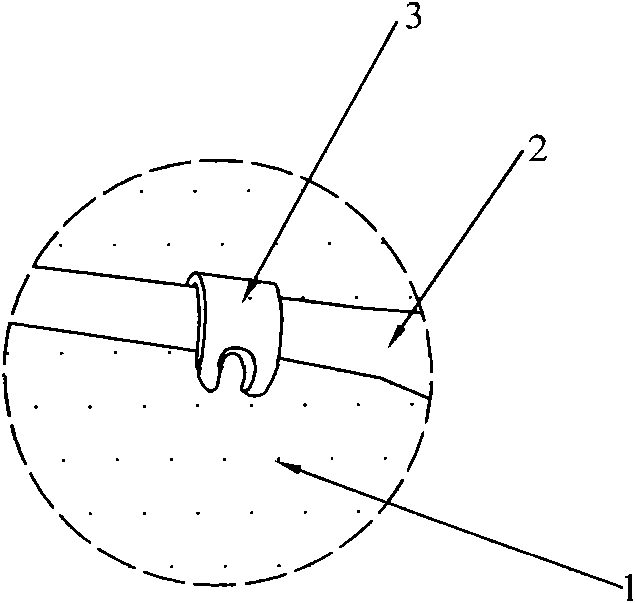

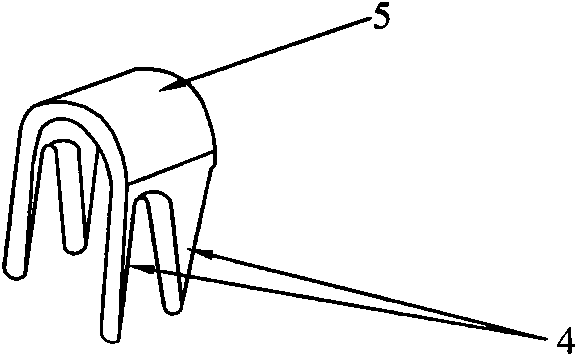

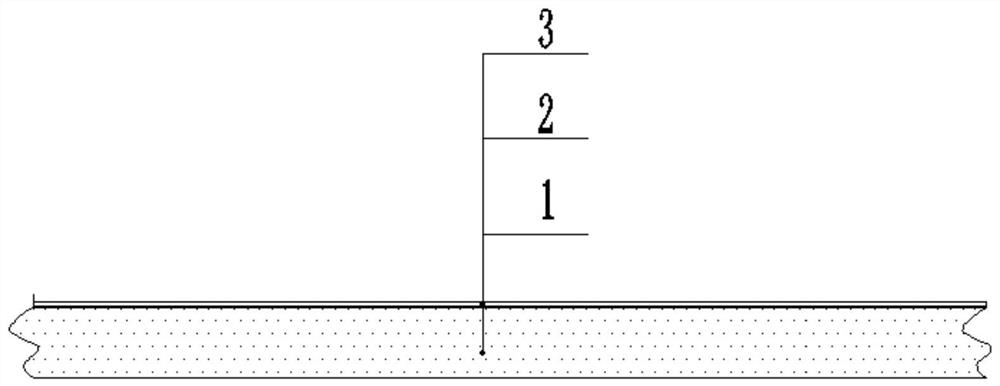

Manufacturing method of sewing-free umbrella

InactiveCN102048322AIncrease productivityUmbrella structure is simpleWalking sticksUmbrellasEngineering

Owner:虞成荣

Fireproof inorganic facing plate and manufacturing method thereof

PendingCN112248592ARoom for errorImprove applicabilityLamination ancillary operationsCovering/liningsAdhesive glueStructural engineering

The invention discloses a fireproof inorganic facing plate and a manufacturing method thereof. The facing plate comprises a base layer plate, an aluminum sheet layer and a facing layer, which are sequentially stacked; a trapezoidal groove is formed in the base layer plate in the thickness direction of the base layer plate, an opening of the trapezoidal groove faces the direction away from the aluminum sheet layer, and the central axis of the trapezoidal groove is perpendicular to the aluminum sheet layer; the height of the trapezoidal groove is the same as the thickness of the base layer plate, the extending direction of the trapezoidal groove is the straight line direction perpendicular to the section of the plate, the plate is bent around the center of the upper bottom of the trapezoidalgroove to be attached to an assembled wall corner, and the bent trapezoidal groove is filled with bonding glue. The trapezoidal groove is formed to ensure that the bent trapezoidal groove still has acertain opening angle, so that the bent trapezoidal groove is filled with adhesive glue conveniently, and the plate is high in applicability, has a fault-tolerant space, and can accommodate the wallcorner angle deviation phenomenon in the actual use process, the plates on the two sides of the groove are connected into a whole through glue, and transportation is convenient.

Owner:重庆集凯科技服务有限公司

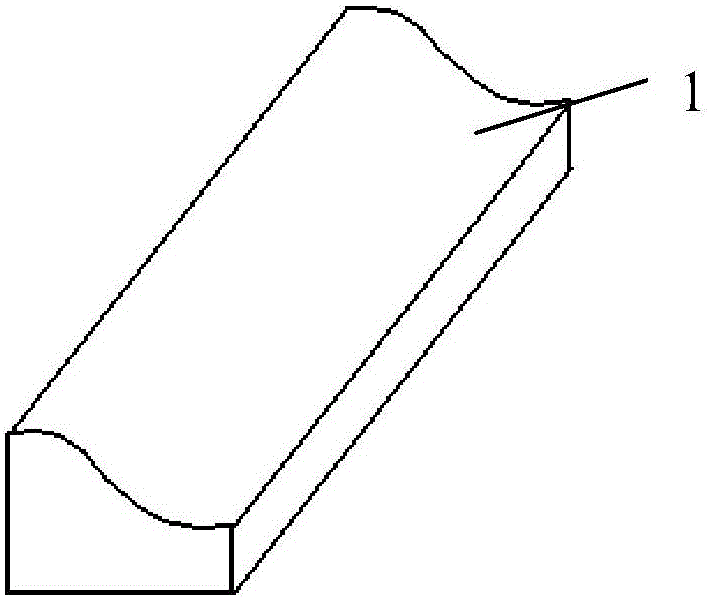

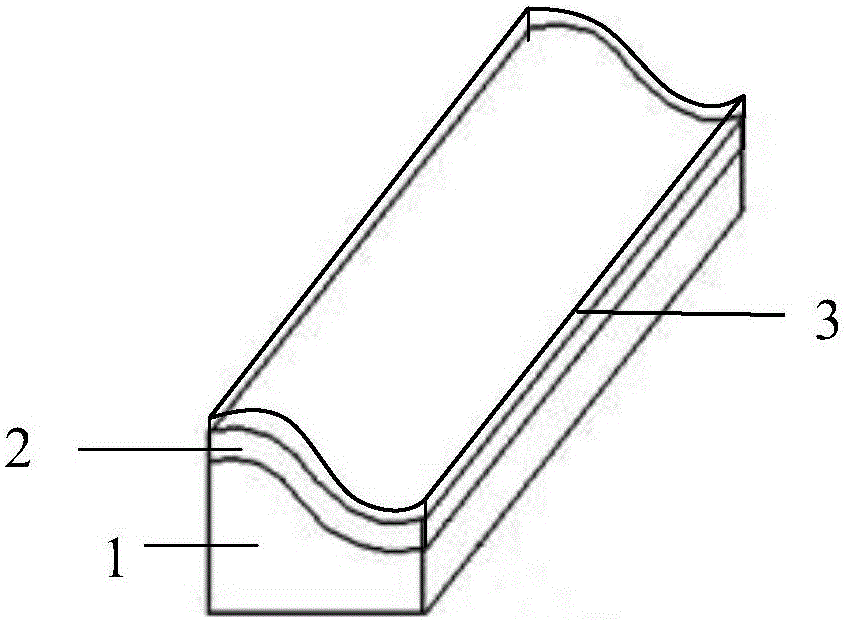

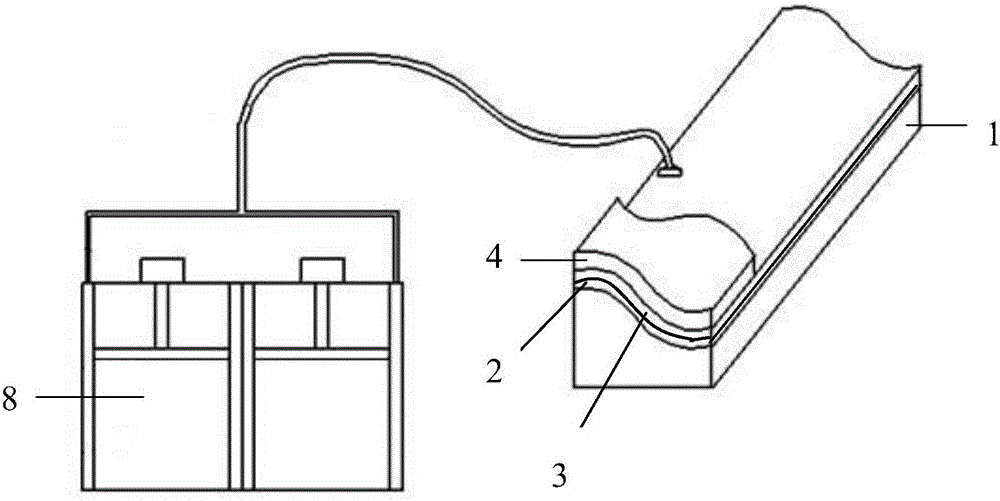

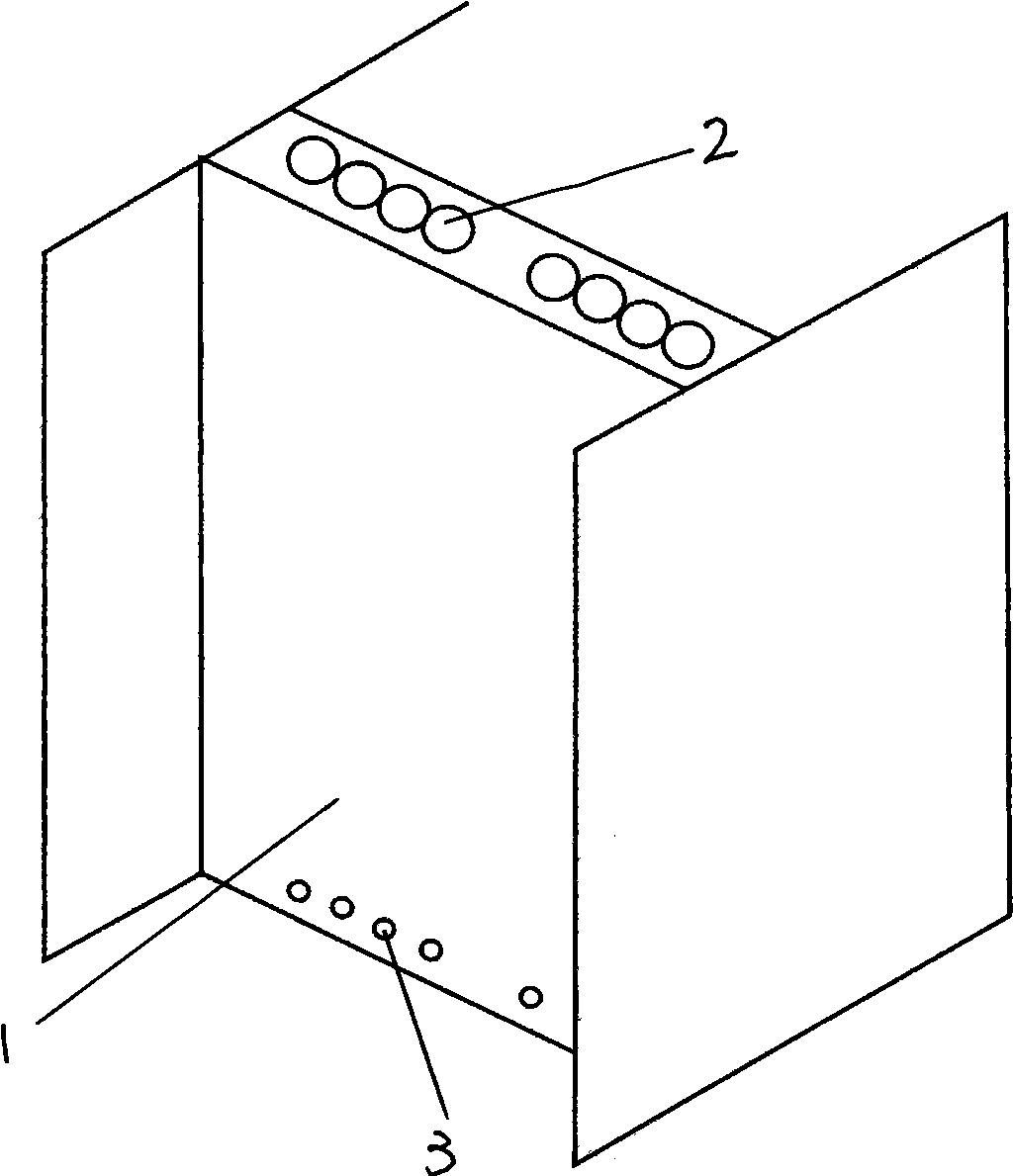

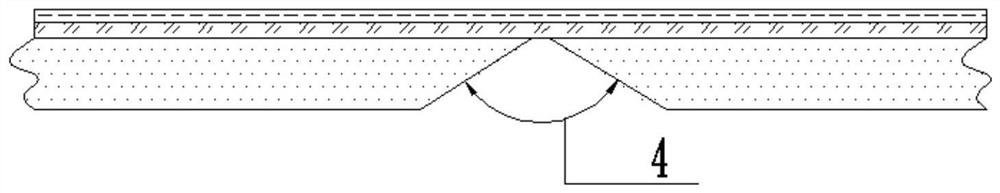

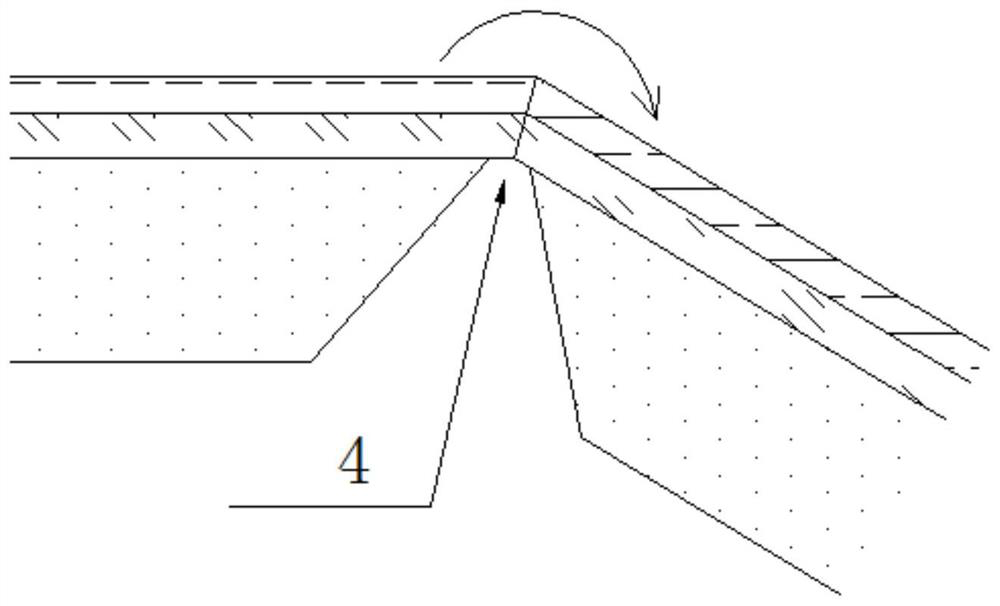

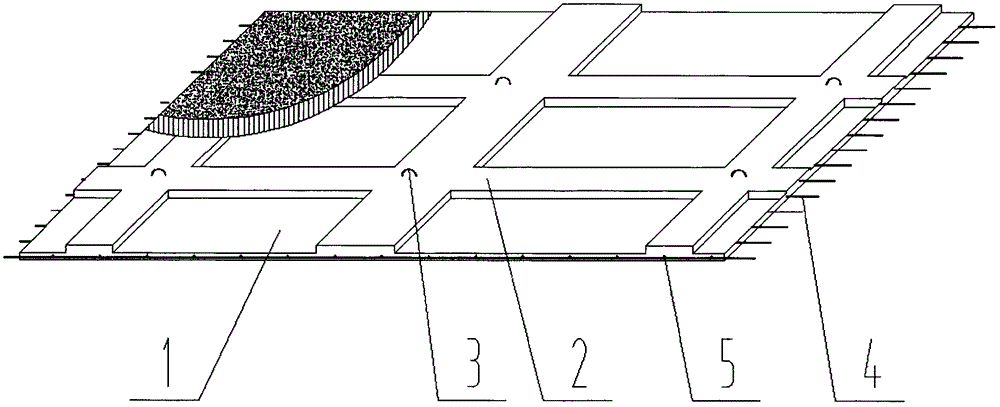

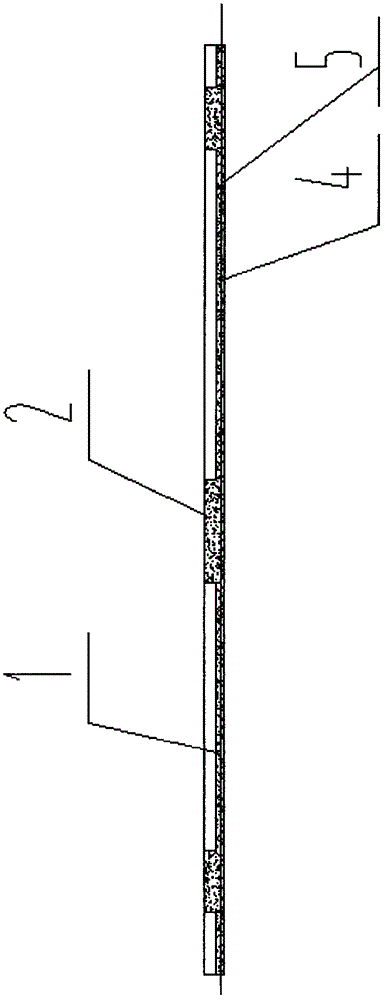

Concrete laminated slab prefabricated part with two-way ribs

A concrete laminated slab prefabricated component with two-way ribs relates to the field of concrete prefabricated parts technology and prefabricated structures in the construction industry. The thin plate (1) is made of a group of horizontally stressed steel bars (4) and a group of vertically stressed steel bars (5) bound together and then poured concrete, and the two sets of reinforcing ribs (2) are respectively arranged on the thin plate (1) in two directions perpendicular to each other, and the set of suspension rings (3) are respectively fixedly installed on the two sets of reinforcing ribs (2). Two-way ribs increase the stiffness of the component, reduce the deformation of the prefabricated component and the stress of the steel bar during construction; it is convenient to ensure the thickness of the protective layer for laying the steel bar on the slab; the thin concrete slab reduces the weight of the prefabricated component, which is conducive to the transportation and hoisting of the component; Tensile steel bars can be prestressed steel bars, which can save a lot of steel.

Owner:赵洪波

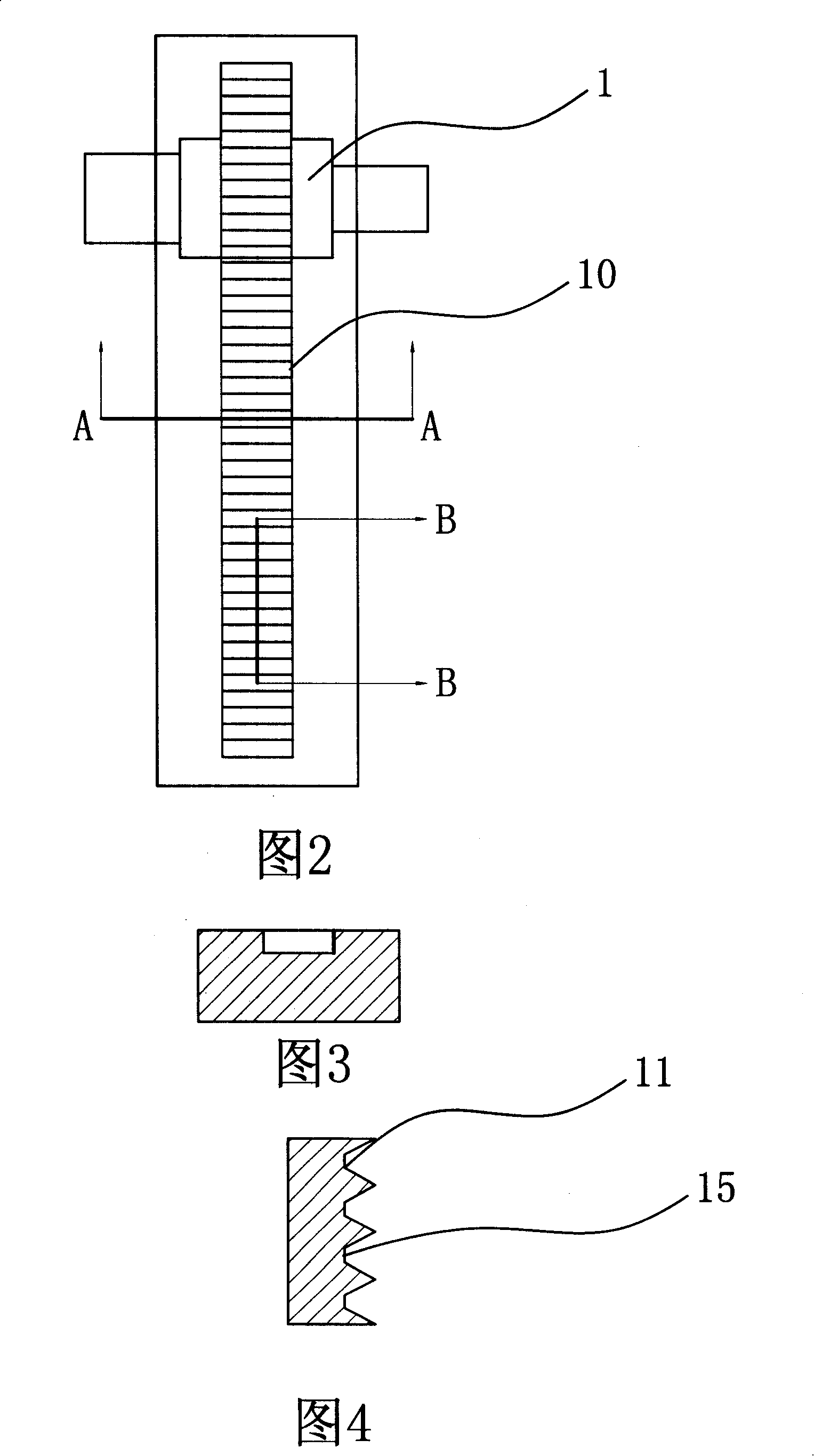

Method of manufacturing bit tool used for cutting plastic film particle

The invention relates to a method for processing a cutter, in particular to a method for manufacturing a cutter used for cutting plastic film particles. The method comprises the following steps: a rolling cylinder is made; a required tooth form is manufactured on the outer surface of the rolling cylinder and the hardness of the tooth form on the rolling cylinder is more than HRC60; a metal block with the HRC less than 25 is placed on a mould rack and the obtained rolling cylinder is used for rolling cutter teeth on the surface of the metal block; the obtained cutter is then treated thermally to ensure that the HRC of the cutter is more than 60. The invention is characterized in that: the obtained cutter has high hardness, precise arrangement of the cutter teeth, compact and sharp metal structure on the cutter tooth face, smooth cutter tooth face, no joint traces on the cutter, short production cycle of the cutter, wide material sources, low production cost and the invention is also characterized in that tools used in cutter production has long service life and the cutter is unlikely to catch the film particles during cutting; the particles manufactured by the obtained cutter are not inclined to be deformed, etc.

Owner:杜宁

Cast die tool of multi-bottom pan and technique for producing multi-bottom pan using the die

Owner:浙江乐家厨具有限公司

Preparation method of casting box sealing paste

ActiveCN112028596AImprove plasticityImprove sealingFoundry mouldsFoundry coresCasting moldIndustrial engineering

The invention discloses a preparation method of casting box sealing paste, and belongs to the technical field of casting materials; the method is simple in preparation method and wide in raw materialsource, and the prepared casting box sealing paste has good plasticity, is easy to form, good in sealing performance, high in refractoriness and strong in adhesive force, and can prevent box seam flash and fire escape during casting of a casting mold. The casting piece dimensional accuracy is improved; the paste is convenient to use, uniform and smooth in coating, capable of obviously saving working hours, good in box sealing effect and free of box cushioning. Castings do not produce blank seams; the finished product rate is greatly improved, the shelf life is long, the shelf life at normal temperature is long, hardening is avoided in winter, and an extrusion opening is not sealed and frozen.

Owner:和县华顺铸造有限公司

Novel glass super-hydrophobic transparent high-efficiency heat-insulating coating

PendingCN112322116AImprove insulation performanceImprove energy savingAntifouling/underwater paintsPaints with biocidesPROPYLENE GLYCOL BUTYL ETHERSlurry

The invention provides a novel glass super-hydrophobic transparent efficient heat-insulating coating and a preparation method thereof, and relates to the field of building materials, in particular tothe novel glass super-hydrophobic transparent efficient heat-insulating coating. The novel glass super-hydrophobic transparent high-efficiency heat-insulating coating comprises the following raw materials by weight: 2400 to 2600 kg of aqueous fluorocarbon resin (with solid content of 45 to 50%), 1200 to 1300 kg of slurry, 1100 to 1300 kg of deionized water, 130 to 160 kg of a 1053 dispersant, 50 to 70 kg of a DP082 antifoaming agent, 30 to 50 kg of a WT102 thickener, 80 to 100 kg of texanol, 90 to 110 kg of leveling agent and 4 to 6 kg of dipropylene glycol. The method comprises: uniformly mixing the water-based fluorocarbon resin with the slurry in proportion, then adding deionized water, a dispersing agent, an antifoaming agent, a thickener, texanol, leveling agent, dipropylene glycol monomethyl ether and dipropylene glycol butyl ether, adjusting the pH value to 7, and dispersing in a dispersion machine at a high speed of 1500 rpm for 30 min to obtain the glass super-hydrophobic transparent efficient heat-insulating coating.

Owner:成都享誉新材料科技有限公司

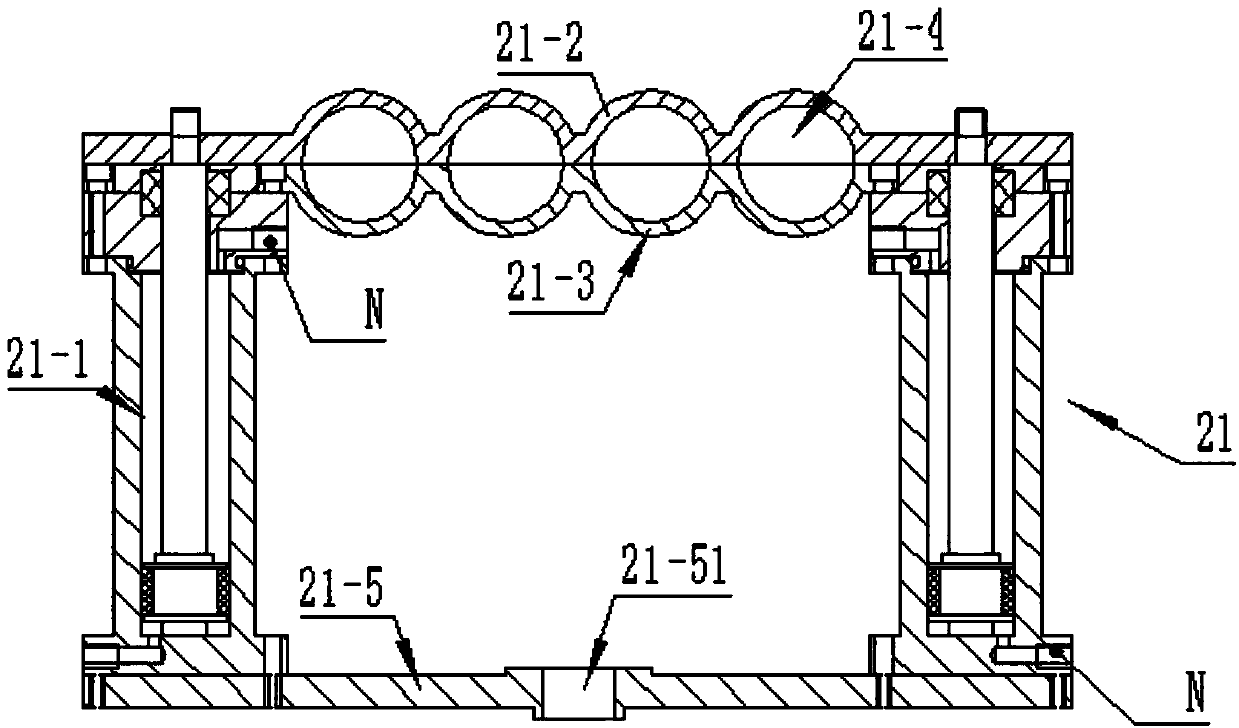

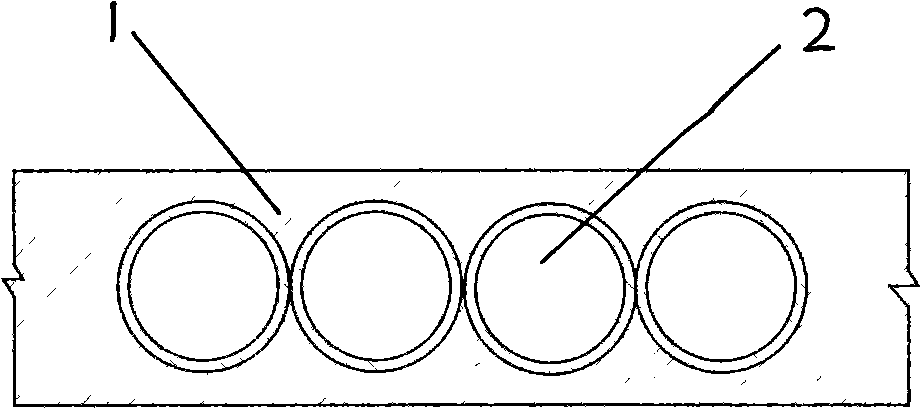

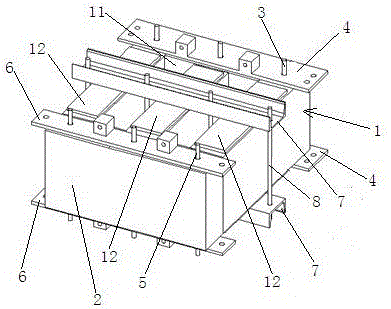

Laminated combination tooling for transformer

ActiveCN106024369AUniform tightening forceEasy to operateTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses a laminated combination tooling for a transformer. The laminated combination tooling comprises a group of mountain-shaped stacks and a group of upper iron yoke stacks; the mountain-shaped stacks are provided with a lower iron yoke part and three stem parts; the upper iron yoke stacks are arranged on the three stem parts of the mountain-shaped stacks; the upper iron yoke stacks and the mountain-shaped stacks form closed structures; first positioning steel poles are arranged in the lower iron yoke parts of the mountain-shaped stacks in a penetrating manner; first positioning sheets are respectively arranged at the front side and the rear side of the lower iron yoke part; the end parts of the first positioning steel poles penetrate through the first positioning sheets; second positioning steel poles are arranged in the upper iron yoke stacks in a penetrating manner; second positioning sheets are respectively arranged at the front and rear sides of the upper iron yoke stacks; the end parts of the second positioning steel poles penetrate through the second positioning sheets; one clamping channel steel crossing over the three stem parts is arranged on each of the front and rear sides of the mountain-shaped stacks; the two clamping channel steels are connected by screws. The laminated combination tooling disclosed by the invention has the advantages of higher convenience in operation, time saving, labor saving, cost saving and high production efficiency; in addition, the formed laminated structure meets the requirements and no joints are generated.

Owner:SUZHOU WUBIAN ELECTRICAL TECH CO LTD

Die-cast aluminum pot

InactiveCN103006033AFirmly connectedPrevent bottoming phenomenonCooking vesselsAluminium alloyThermal expansion

The invention discloses a die-cast aluminum pot, comprising an aluminum alloy pot body, wherein the bottom of the aluminum alloy pot body is provided with a stainless steel substrate, the upper surface of the stainless steel substrate is provided with a plurality of blind holes, the bottom wall of the aluminum alloy pot body is provided with convex columns which are in matched connection with the blind holes, the bottom of the stainless steel substrate is provided with an aluminum alloy sheet which is provided with a commodity marker, and an exhaust passage is formed between the aluminum alloy sheet and the stainless steel substrate. The die-cast aluminum pot disclosed by the invention can be prevented from a bottom falling phenomenon and a bulging phenomenon caused by heat expansion and cold contraction, no lapping defect appears on the bottom face of the pot body, the commodity marker cannot be damaged, and the die-cast aluminum pot is attractive in appearance and wide in application range.

Owner:陈新华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com