Concrete laminated slab prefabricated part with two-way ribs

A prefabricated component and concrete technology, applied in building components, floor slabs, building structures, etc., can solve the problems of complex construction process, large rigidity difference, waste of labor, etc., and achieve the effect of saving supports and formwork, easy control, and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

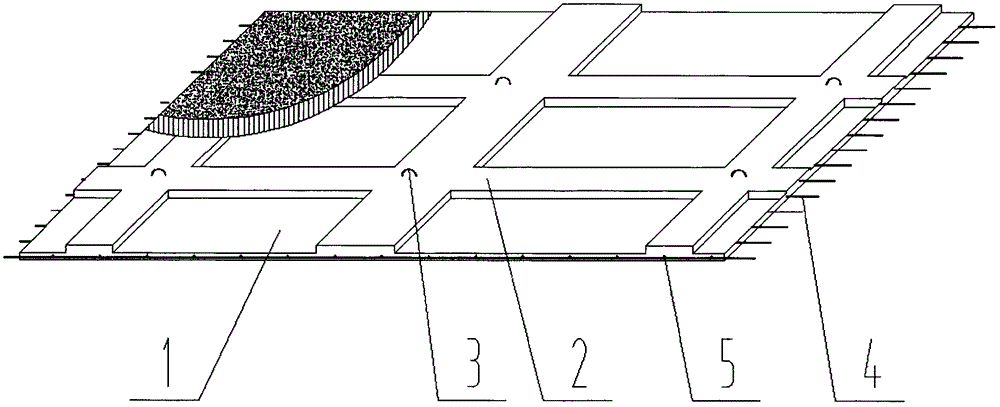

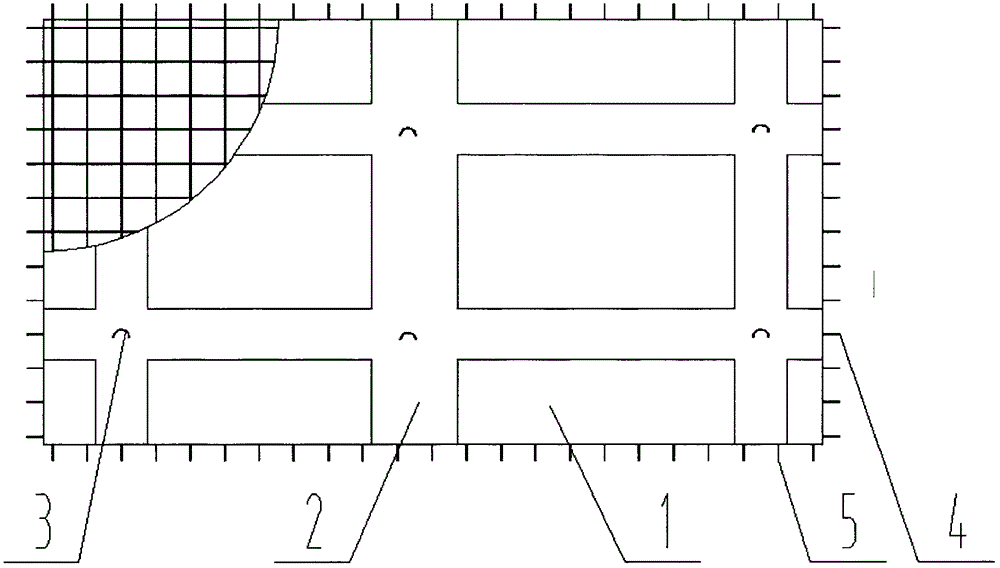

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

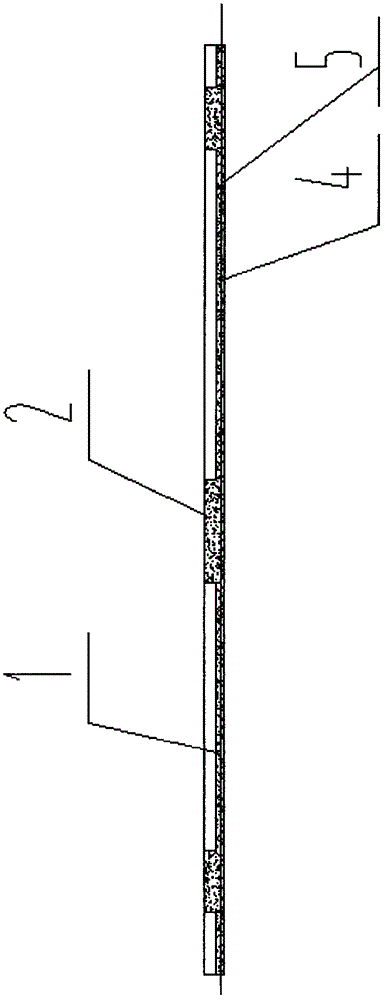

[0021] Such as figure 1 , 2 , 3, the present invention includes a thin plate 1, two sets of reinforcing ribs 2 and a set of suspension rings 3, and the thin plate 1 is poured after binding each other with a set of horizontally stressed reinforcing bars 4 and a set of vertically stressed reinforcing bars 5 The two sets of reinforcing ribs 2 are respectively arranged in two directions perpendicular to each other of the thin plate 1, and the set of lifting rings 3 are fixedly installed on the two sets of reinforcing ribs 2 respectively.

[0022] The thin plate 1 has a thickness of 30mm-50mm.

[0023] The said one set of horizontally stressed steel bars 4 and one set of vertically stressed steel bars 5 are ordinary hot-rolled steel bars or prestressed steel bars, respectively.

[0024] The two sets of reinforcing ribs 2 are arranged crosswise, and the set of suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com