Activated charcoal gas cleaning method and device thereof

A gas purification device and activated coke technology, which is applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of low desulfurization efficiency, no adsorption, and high convective adsorption efficiency, and achieve high space utilization and adsorption efficiency. The effect of improving and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

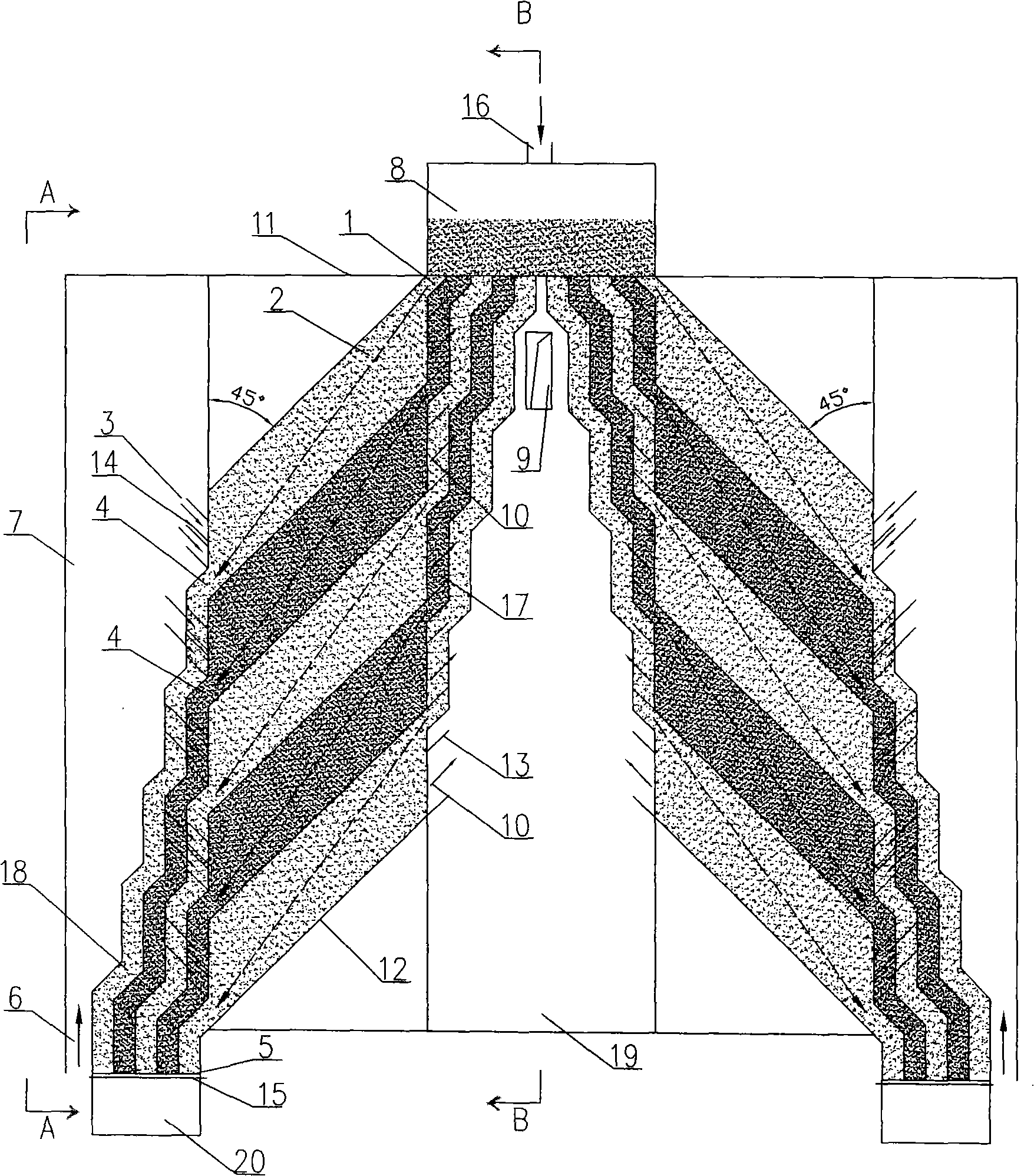

[0071] As shown in Figure 9, the difference between this embodiment and the first embodiment is that the feed structure is set as follows: a unit feed port 1 is provided above the unit activated coke bed 2, and the unit feed port 1 passes through the unit The feed port channel 17 is connected with a main feed channel 21, and the main feed channel 21 is connected with the storage bin 8 located below the main feed port 16.

Embodiment 3

[0073] As shown in Figure 10, the difference between this embodiment and the first embodiment is that the discharging structure is set as follows: a unit discharging port 1 is provided below the unit activated coke bed 2, and multiple unit discharging ports 1 It can be divided into several groups. Each group of unit outlet 1 is connected to the primary outlet channel 22 through the unit outlet channel 18, and the above-mentioned multiple primary outlet channels 22 are connected to the main outlet through the secondary outlet channel 23. The material port 20 is connected. According to the number of unit activated coke beds, a three-stage discharge channel or a discharge channel with more than three stages can also be arranged between the secondary discharge channel 23 and the total discharge port 20.

[0074]In each embodiment of the present invention, each unit activated coke bed is provided with an independent feed port and a discharge port to ensure the absorption efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com