Method for producing an upper part of a shoe, in particular of a sports shoe

A technology for shoe uppers and sports shoes, applied in the field of manufacturing shoes, can solve the problems of cost, impact on wearing comfort, non-uniformity, etc., and achieve the effects of economical manufacturing and high wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

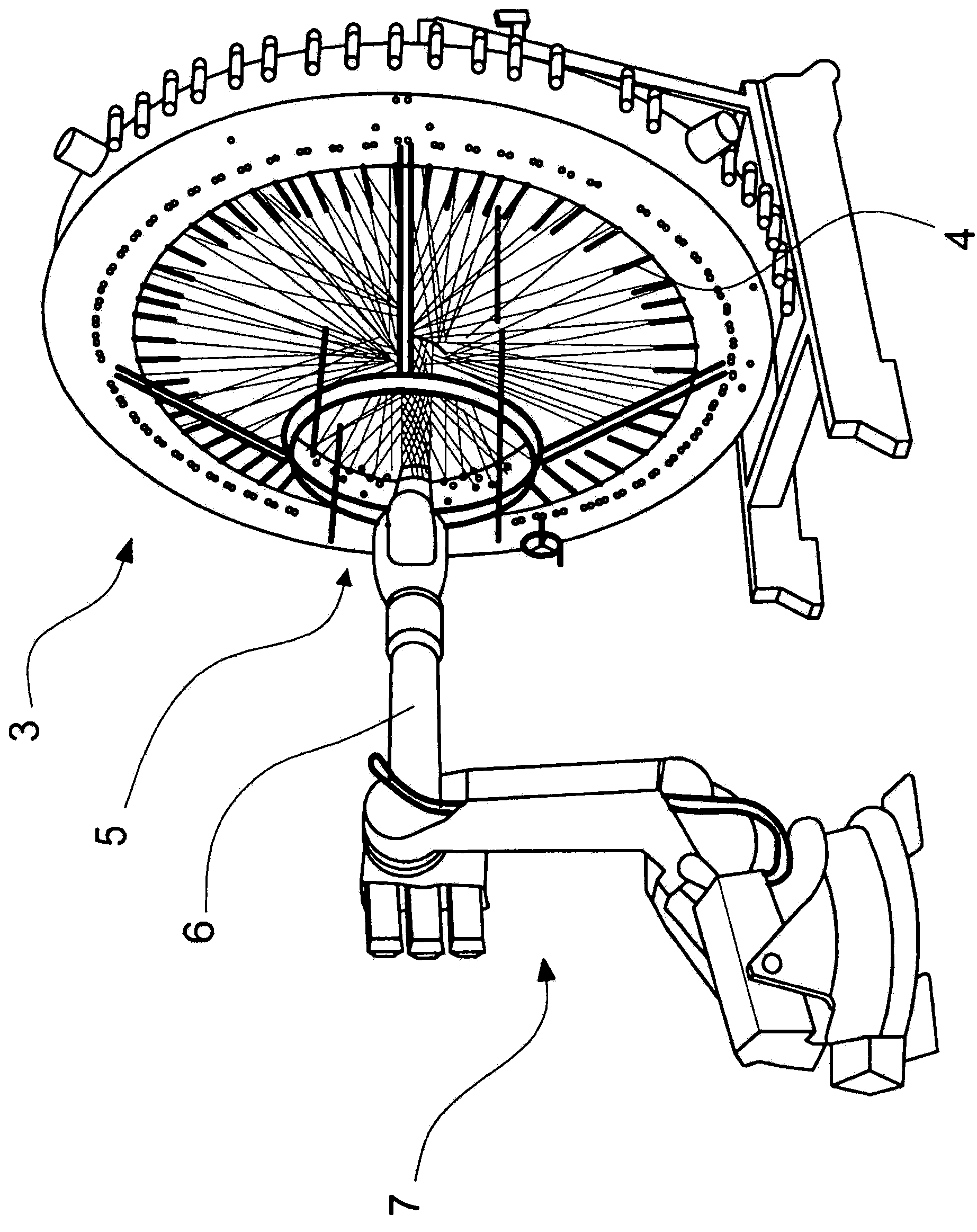

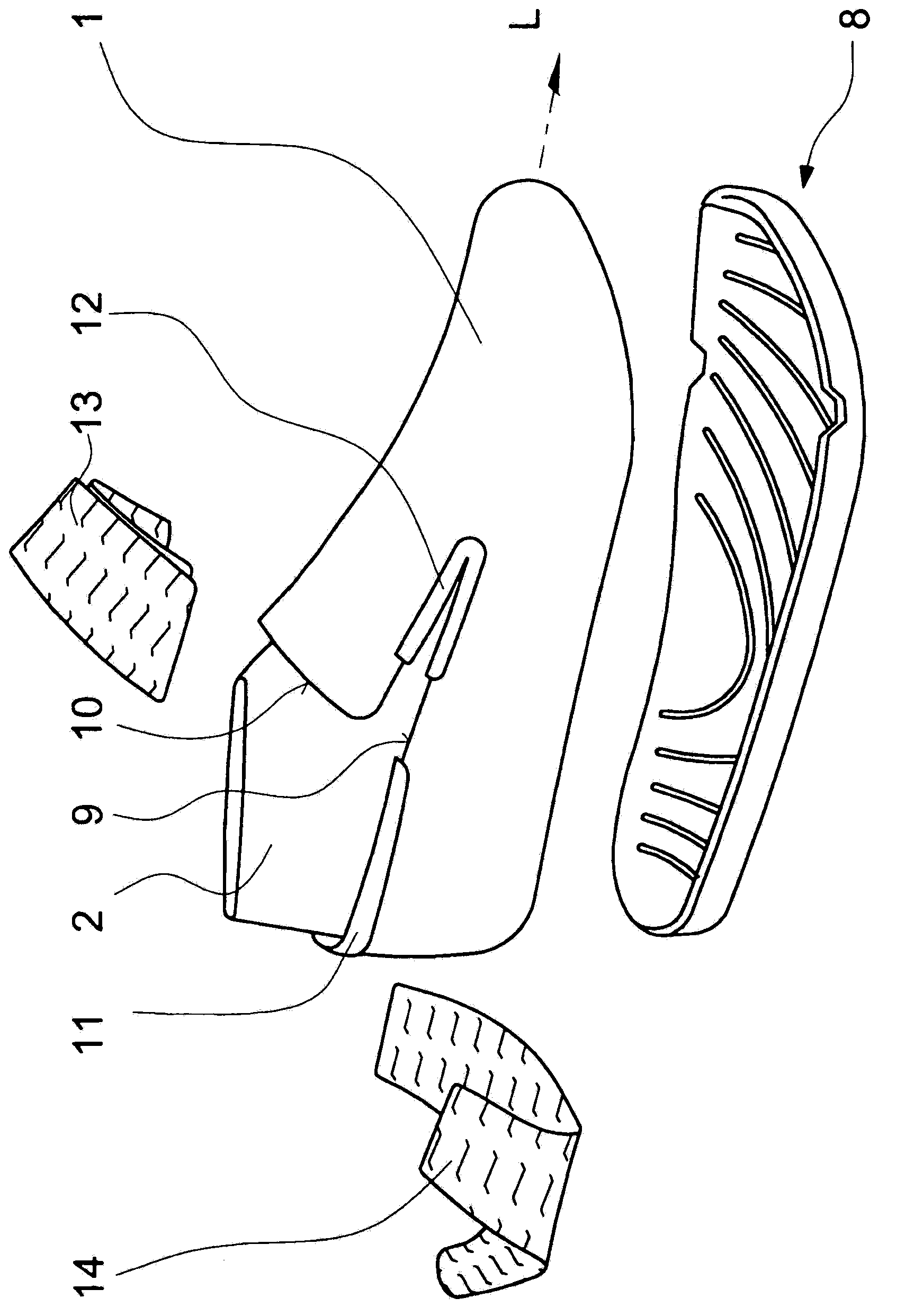

[0033] exist figure 1 and figure 2 can be seen in the manufacture as image 3 1 device visible in the upper part of the shoe. This equipment comprises a radial knitting machine 3 known as the radial knitting machine with reference to the above-mentioned reference explaining the mechanism and mode of operation of such a machine.

[0034] The radial knitting machine 3 has a circular creel 4 around the circumference of which a plurality of bobbins are arranged, on which bobbins are respectively wound with thread. The threads of the different bobbins are led to the center 5 where the triaxial weaving process takes place.

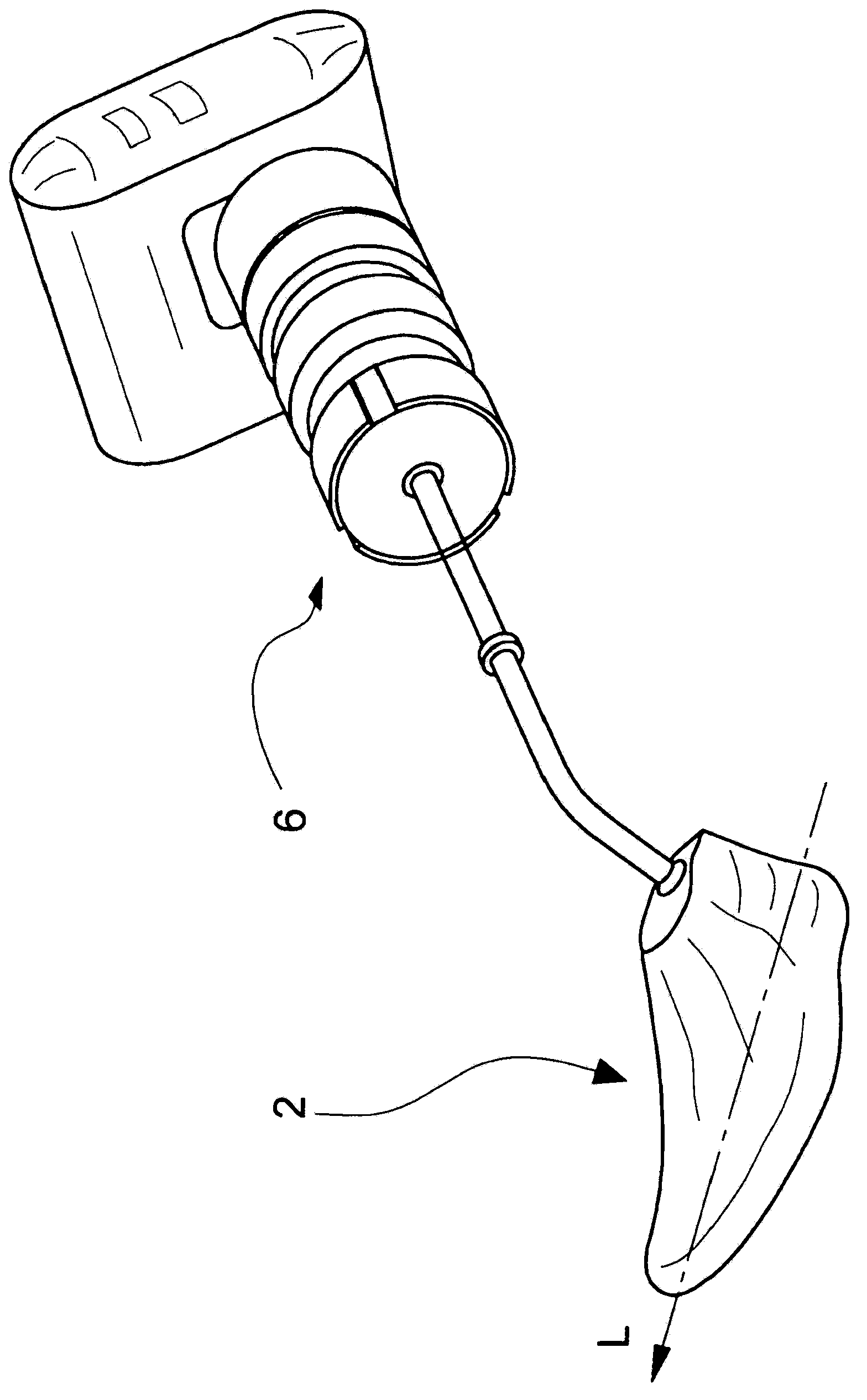

[0035] The other components of the device are the handling device 7 with the mechanical arm 6 at the end of said mechanical arm (as it is at figure 1 Visible in ) Arrange last 2. The last 2 defines the longitudinal direction L of the shoe.

[0036] During the production of the shoe upper 1 by means of three-axis knitting, it is carried out that the shoe l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com