Production process of polyurethane table tennis ball and table tennis ball

A production process and table tennis technology, applied to rackets, balls, and other household appliances, can solve the problems of hardness requirements and bounce requirements not meeting T3 standards, difficulty in reducing production costs, uneven wall thickness, etc., and achieve wall thickness. The thickness is controllable and uniform, the wall thickness is uniform and controllable, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A kind of production technology of polyurethane table tennis, comprises the steps:

[0075] 1) Mix polytetrahydrofuran ether diol with a number average molecular weight lower than 1000g / mol with triethylamine and liquid foaming agent water to form a combined polyether, wherein the weight ratio of triethylamine to polytetrahydrofuran ether diol is 0.001: 1. Measure and mix the combined polyether and diphenylmethane diisocyanate at a weight ratio of 1:1.05 and pour it into the table tennis cavity. The amount of foaming agent water is the total of polytetrahydrofuran ether glycol and diphenylmethane diisocyanate 1% by weight;

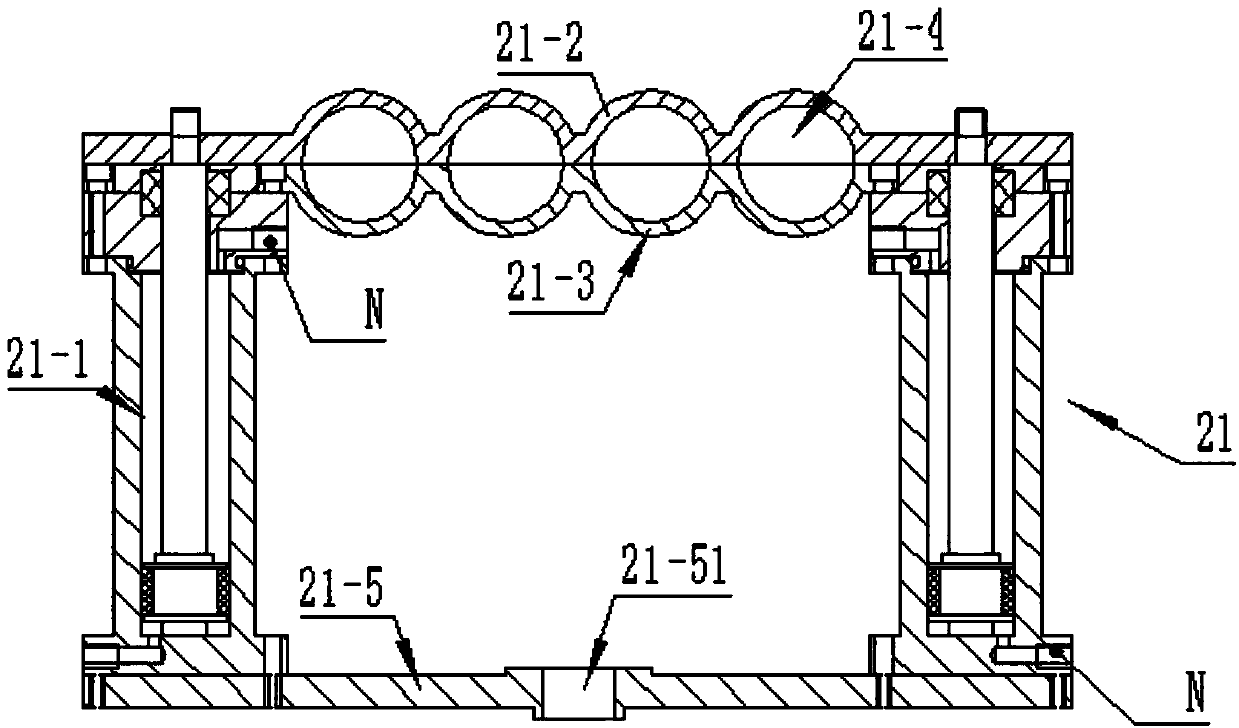

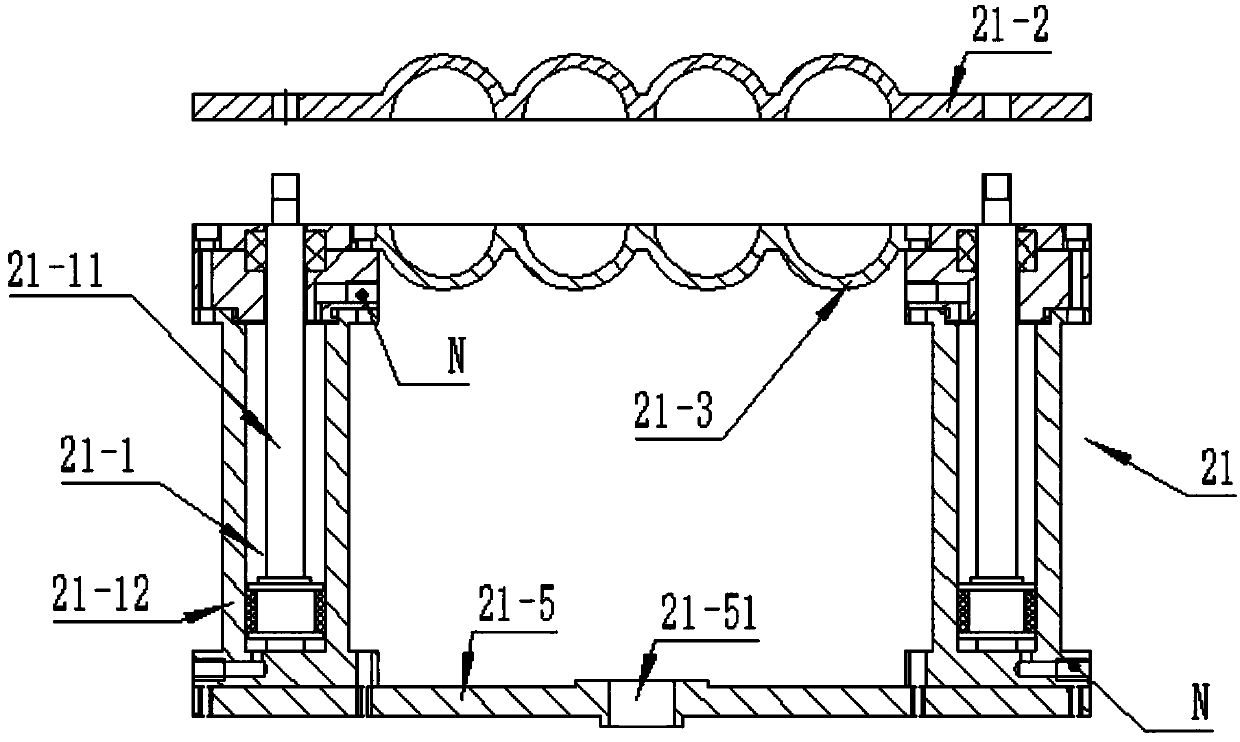

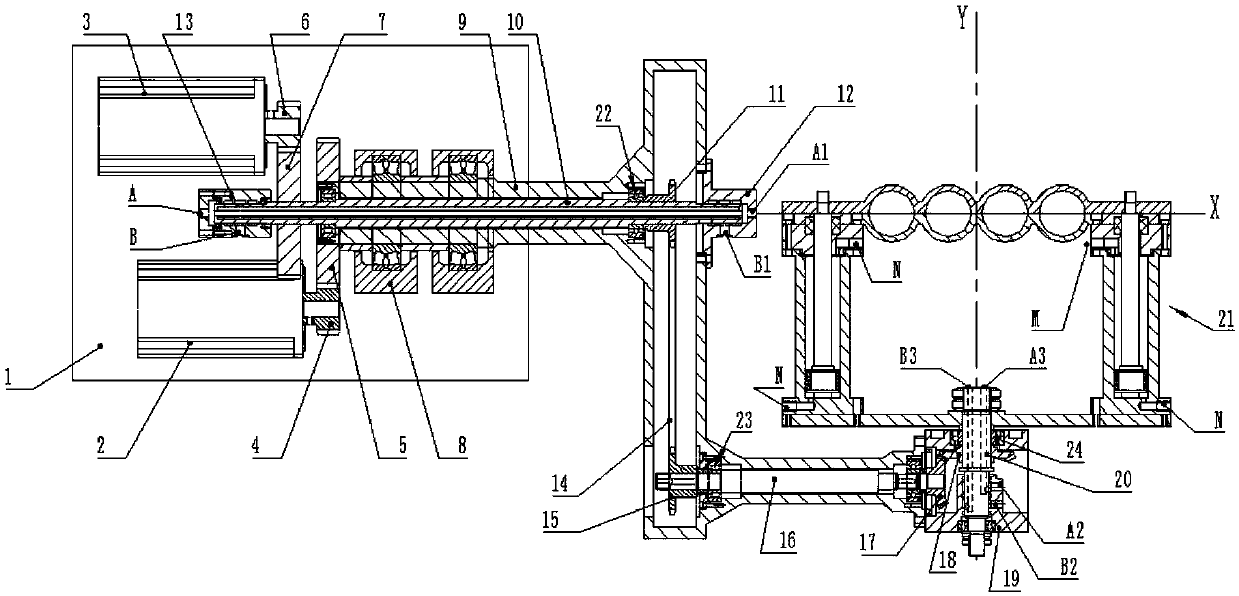

[0076]2) Control the table tennis mold cavity to rotate simultaneously along the X-axis and Y-axis perpendicular to each other, wherein the X-axis is parallel to the horizontal plane, and the Y-axis is perpendicular to the horizontal plane, and the rotating speed in the X direction is adjusted to 13r / min, Y The rotation speed in the direction is 10...

Embodiment 2

[0079] A kind of production technology of polyurethane table tennis, comprises the steps:

[0080] 1) Mix polyoxypropylene glycol with number average molecular weight lower than 1000g / mol with N-methylmorpholine and liquid foaming agent methyl isobutyl ether to form a combined polyether, wherein N-methylmorpholine and poly The weight ratio of oxypropylene diol is 0.003:1, the combined polyether and isophorone diisocyanate are measured and mixed according to the weight ratio of 1:1.1, and then poured into the table tennis mold cavity, and the blowing agent methyl isobutyl ether The amount is 2% of the total weight of polyoxypropylene diol and isophorone diisocyanate;

[0081] 2) Control the table tennis mold cavity to rotate simultaneously along the X-axis and Y-axis perpendicular to each other, wherein the X-axis is parallel to the horizontal plane, and the Y-axis is perpendicular to the horizontal plane, and the rotating speed in the X direction is adjusted to 10r / min, Y The...

Embodiment 3

[0084] A kind of production technology of polyurethane table tennis, comprises the steps:

[0085] 1) Mix polytetrahydrofuran-ethylene oxide copolymer glycol with a number average molecular weight lower than 1000g / mol, 1,4-diazabicyclo[2.2.2]octane, and liquid blowing agent fluorotrichloromethane to form a combined poly(tetrahydrofuran) Ether, wherein the weight ratio of 1,4-diazabicyclo[2.2.2]octane to polytetrahydrofuran-oxyethylene copolymerized glycol is 0.005:1, and the combination of polyether and 1,6-hexamethylene diisocyanate by weight The ratio of 1:1.05 is measured and mixed and poured into the cavity of the table tennis ball. The amount of the blowing agent fluorotrichloromethane is 3% of the total weight of polytetrahydrofuran ether glycol and diphenylmethane diisocyanate;

[0086] 2) Control the table tennis mold cavity to rotate simultaneously along the X-axis and Y-axis which are perpendicular to each other, wherein the X-axis is parallel to the horizontal plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com