Preparation method of bendable fully degradable zinc alloy nerve guide

A nerve catheter and zinc alloy technology, applied in medical science, prosthesis, etc., can solve the problems of uncomfortable nerve repair, inability to bend zinc alloy nerve catheter, late research and development, etc., achieve inhibition of bacterial growth, good lumen support effect, prevention The effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

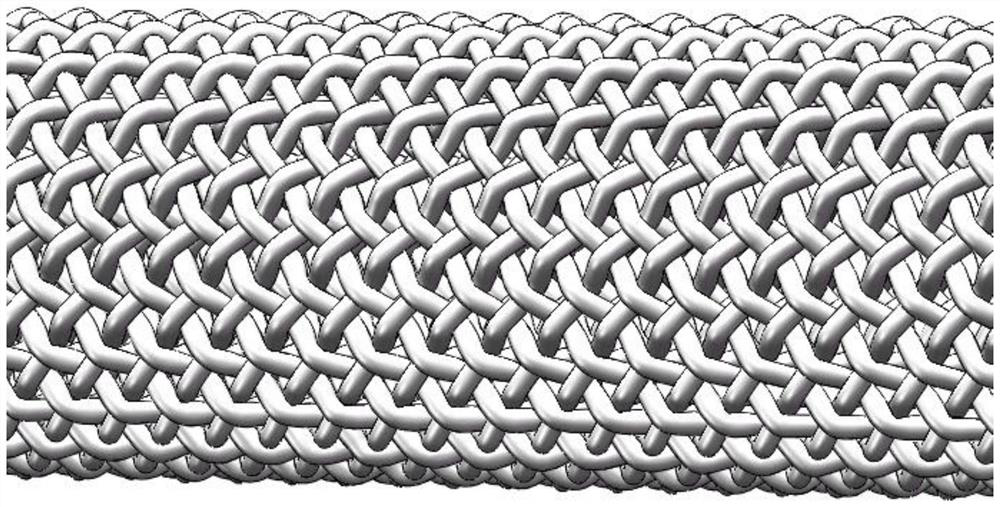

[0035] Such as figure 1 with figure 2 As shown, the specific embodiment provides a method for preparing zinc alloy wire and a bendable fully degradable zinc alloy nerve guide braided with zinc alloy wire for nerve defect repair. The nerve guide is a round tube structure formed by braiding multiple zinc alloy wires, in which each row of zinc alloy wires forms a certain angle with the tube axis of the round tube, and there is a slight distance between two adjacent zinc alloy wires .

[0036] Further, the diameter of each zinc alloy wire is 0.05-0.2 mm.

[0037] Further, the flexible fully degradable zinc alloy nerve guide has a length of 5-200 mm, an outer diameter of 1.0-10.0 mm, and a tube wall thickness of 0.1-0.4 mm.

[0038] Further, the gap is 0.005-0.20mm.

[0039] Further, each row of zinc alloy wires forms an angle of 30-60 degrees with the tube axis of the round tube.

[0040] The preparation method of the bendable fully degradable zinc alloy nerve guide includes...

Embodiment 2

[0061] This embodiment relates to a bendable fully degradable zinc alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 200mm, the wall thickness is 0.40mm, and the outer diameter is 10mm. The nerve guide is braided by filaments with a diameter of 0.2 mm, the distance between two adjacent rows of filaments in the same direction is 0.20 mm, and the braiding angle between each row of filaments and the tube axis is 45 degrees.

[0062] This embodiment relates to the aforementioned method for preparing a degradable zinc alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0063] Step 1, extruding the initial Zn-Li-Fe ternary zinc alloy blank with an outer diameter of 30 mm and a length of 20 mm at a temperature of 230° C. to obtain a zinc alloy thick wire of Φ3 mm;

[0064] Step 2, after drawing the Φ3mm zinc alloy thick wire through multiple passes, a zinc alloy wire with a diameter...

Embodiment 3

[0069] This embodiment relates to a bendable fully degradable zinc alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 10mm, the wall thickness is 0.16mm, and the outer diameter is 2mm. The nerve guide is braided by filaments with a diameter of 0.10 mm, the distance between two adjacent rows of filaments in the same direction is 0.10 mm, and the braiding angle between each row of filaments and the tube axis is 60 degrees.

[0070] This embodiment relates to the aforementioned method for preparing a degradable zinc alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0071] Step 1, extruding a Zn-Li binary zinc alloy initial billet with an outer diameter of 25mm and a length of 25mm at a temperature of 240°C to obtain a zinc alloy thick wire of Φ2mm;

[0072] Step 2, drawing the Φ2mm zinc alloy thick wire through multiple passes to obtain a thin wire with a diameter of 0.10mm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com