Hybrid toughened and high-filled rigid polyvinyl chloride product

A technology of rigid polyvinyl chloride and polyvinyl chloride, which is applied in the production of UPVC building boards and UPVC pipes, can solve the problems of high cost and unfavorable industrial continuous production, and achieve the effect of cost reduction, uniform and controllable wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0025] Prepare 110 type drainage pipes by a twin-screw extruder, wherein the instrument used is a SJSZ-65 type twin-screw PVC extruder, and its preparation process comprises the following steps:

[0026] (1) Carry out high-speed mixing of PVC and various processing aids according to the implementation formula of the present invention, after hot mixing to 135°C, cold mixing to 45°C;

[0027] (2) Put the homogeneously mixed material in step (1) into the feeder, ready for production test;

[0028] (3) Setting of production process parameters:

[0029] The feeding speed is 602.0~610.5 r / min, the main engine speed is 904~960 r / min, the main engine torque is 40~42 A, the traction speed is 493.6 cm / min, and the temperatures in the four zones of the twin-screw extruder are: 1 Zone 185~187℃, Zone 2 190~194℃, Zone 3 165~168℃, Zone 4 158~160℃. The temperature of the six zones of the die head of the main machine are: zone 1 and zone 2 160~165°C, zone 3 and zone 4 165~170°C, zone 5 and z...

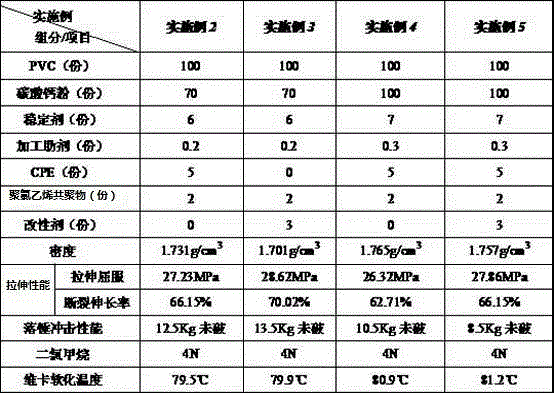

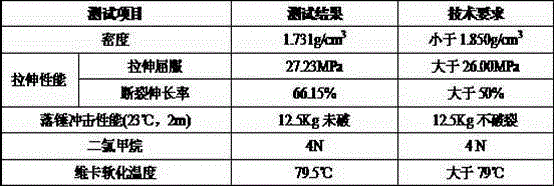

Embodiment 2

[0032] Weigh 6 parts by weight (weight, the same below) of 6318 type stabilizer, 0.2 parts by weight of HBX-800J type processing aid, 5 parts by weight of Jinhong 135A type chlorinated polyethylene, and 2 parts by weight of Wuhan Zhonglian polyvinyl chloride copolymer , equipped with a small material bag; then weigh 100 parts by weight of SG-5 type PVC and 70 parts by weight of Zhongyuan calcium powder. According to the above preparation process, the materials were mixed, and then the PVC-U 110 type drainage pipe was prepared through the SJSZ-65 type twin-screw PVC extruder. Then select samples for density, tensile, drop impact, dichloromethane, Vicat softening temperature and other tests.

[0033] Table 1 Example 2 test results

[0034]

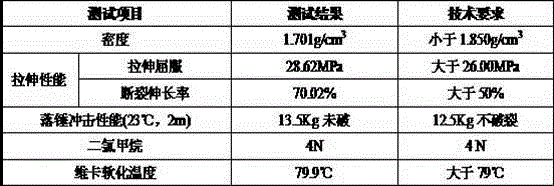

Embodiment 3

[0036] Weigh 6 parts by weight (weight, the same below) of 6318 type stabilizer, 0.2 parts by weight of HBX-800J type processing aid, 3 parts by weight of this modifier, 2 parts by weight of Wuhan Zhonglian polyvinyl chloride copolymer, equipped with small materials bag; then weigh 100 parts by weight of SG-5 type PVC, and 70 parts by weight of Zhongyuan calcium powder. According to the above preparation process, the materials were mixed, and then the PVC-U 110 type drainage pipe was prepared through the SJSZ-65 type twin-screw PVC extruder. Then select samples for density, tensile, drop impact, dichloromethane, Vicat softening temperature and other tests.

[0037] Table 2 Example 3 test results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com