On-line production technology and device of plastic elbow pipe

A technology of production process and production equipment, applied in the field of online production process and equipment of plastic elbows, can solve the problems of difficulty in guaranteeing roundness, low comprehensive efficiency, poor appearance quality, etc., and achieve uniform curvature radius, fast production speed and high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

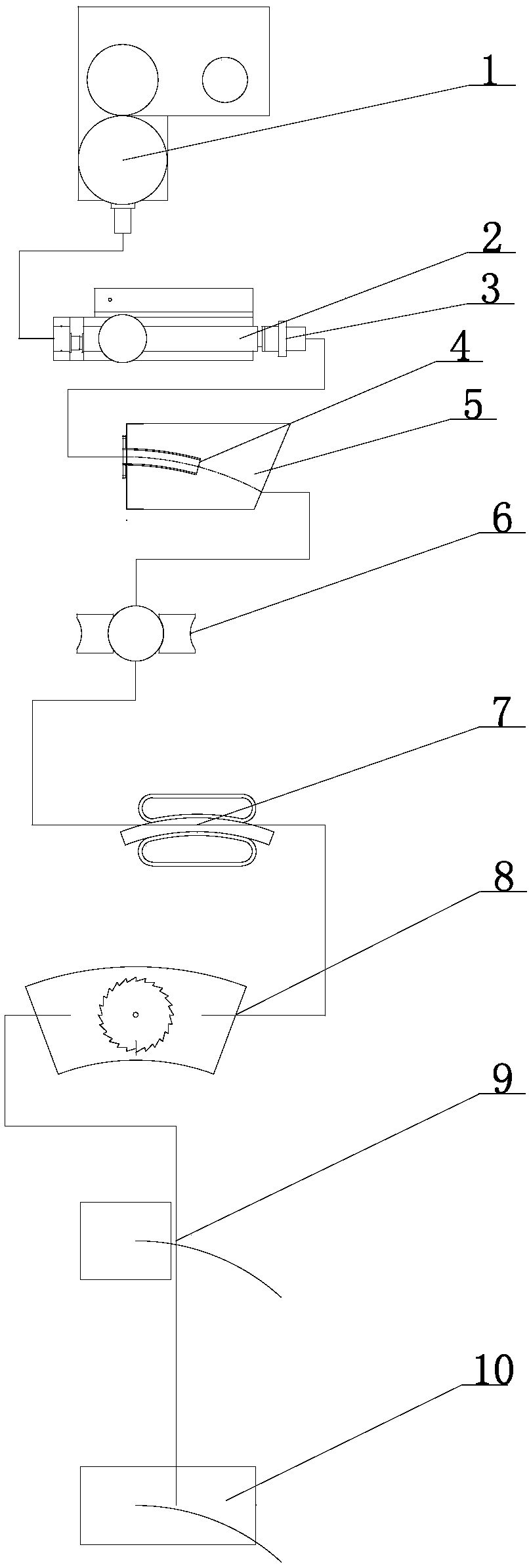

[0034] Such as Figure 1-5 As shown, the online production device of the plastic elbow includes a high-speed mixer 1 and an extruder 2, and is characterized in that: the high-speed mixer 1 and the extruder 2, the extrusion die 3 and the arc-shaped sizing sleeve 4 Connected in sequence, the arc-shaped sizing sleeve 4 is set in the arc-shaped vacuum sizing box 5, the arc-shaped vacuum sizing box 5 is connected with the roundness correction device 6, the arc-shaped pulling machine 7, the automatic arc-shaped cutting machine 8, and the arc-shaped heating The oven 9 and the arc flaring device 10 are connected in sequence.

[0035] The extruder 2 is a twin-screw extruder 2 .

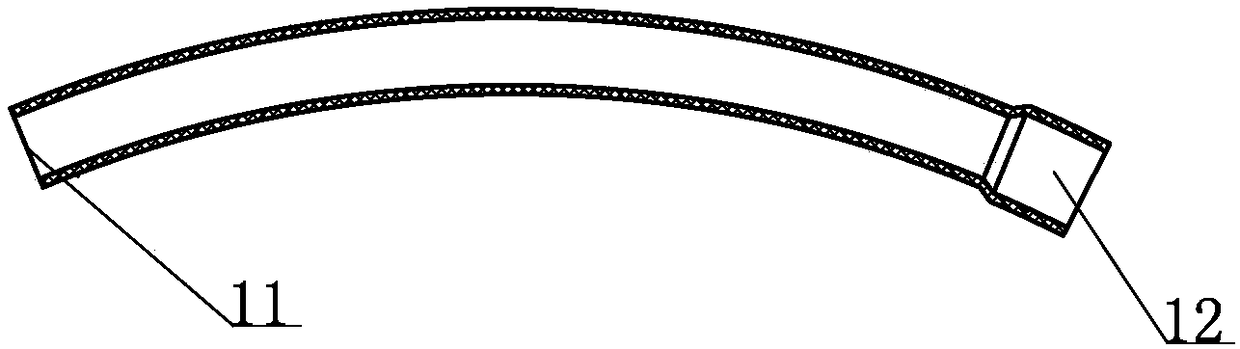

[0036] The radius of curvature of the arc-shaped sizing sleeve 4 is 9 times the diameter of the pipe.

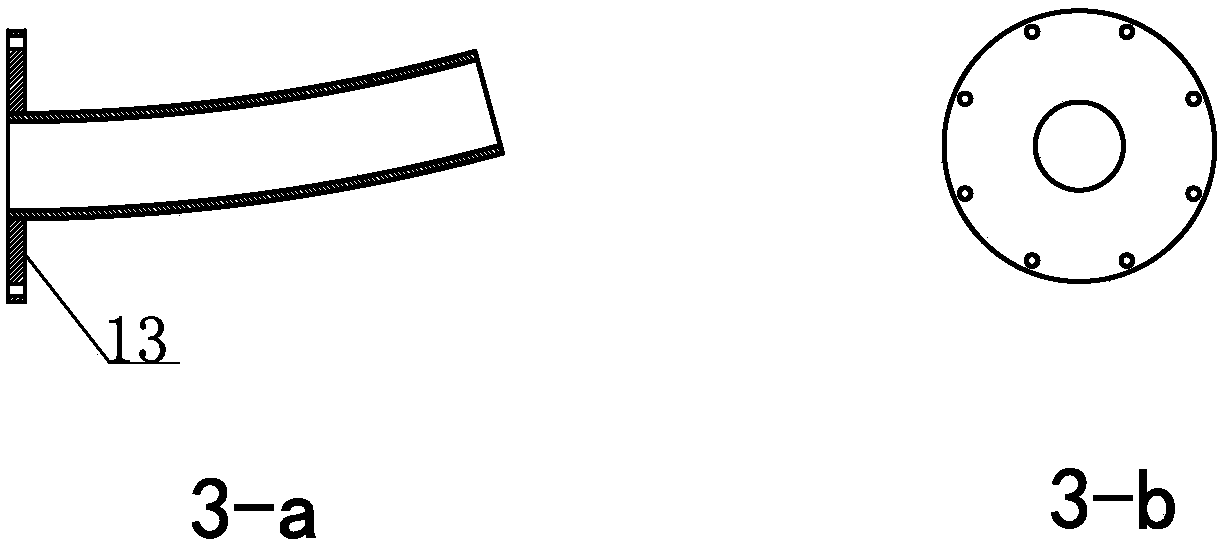

[0037] One end of the arc-shaped sizing sleeve 4 is provided with a flange 13 , and the flange 13 is arranged outside the arc-shaped vacuum sizing box 5 .

[0038] The arc-shaped tractor 7 includes two ch...

Embodiment 2

[0049] Other places are the same as in Example 1, the difference is:

[0050] The extruder 2 is a single-screw extruder 2 .

[0051] The radius of curvature of the arc-shaped sizing sleeve 4 is 11 times the diameter of the pipe.

[0052] During vacuum sizing, the pressure is controlled at -0.045~-0.070MPa, and the temperature of the spray water is controlled at 25±5°C.

[0053] Enter the automatic arc cutting machine 8 for cutting, and cut into pipes of required length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com