Tubular material as well as preparation method and application thereof

A tubular and tubular technology, applied in the field of tubular materials, can solve the problems of nozzle blockage, destruction of temperature-sensitive components of materials, and discontinuous spinning, etc., to avoid uneven stress, uniform and controllable wall thickness, and mechanical properties. Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The invention provides a method for preparing a pipe, comprising the following steps:

[0057]a) adding the polymer solution to the poor solvent, making the polymer diffuse on the surface of the poor solvent to form a film to obtain a polymer film, and the solvent in the polymer solution is dissolved in the poor solvent;

[0058] b) using a mold to crimp the polymer film on the surface of the poor solvent to obtain a rod;

[0059] c) removing the mold to obtain a pipe.

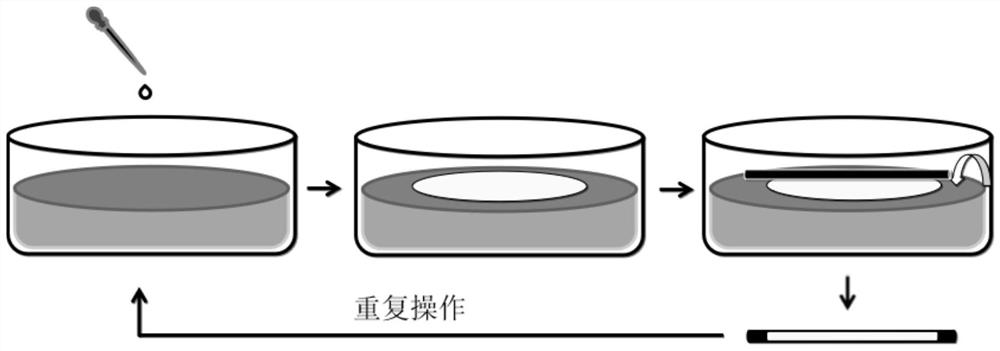

[0060] see figure 1 , figure 1 It is a schematic flow chart of the preparation method of the pipe provided by this application. The first step is to dissolve the polymer in a good solvent and then add it to a poor solvent. Crimp, remove the mold to obtain a pipe, or repeat the above steps to obtain a pipe comprising a multilayer polymer film.

[0061] In the present invention, firstly, the polymer is dissolved in its good solvent to obtain a polymer solution. In one embodiment, the polymer is a fil...

Embodiment 1

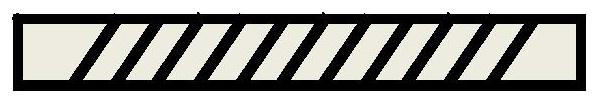

[0088] Polyurethane with a molecular weight of 80,000 was purchased from Shandong Youso Chemical Technology Co., Ltd., and N,N-dimethylformamide was used to prepare a solution at a concentration of 50 mg / ml. 5 drops at a rate of 10mL / min to the water surface at a distance of 5cm from the water surface, the solution will spread on the water surface to form a film, and then within 2min, use a polytetrafluoroethylene rod with a diameter of 5mm to directly wrap around the film from one side of the film. Shaft curling, the process is repeatable, see Figure 5 , Figure 5The schematic diagram of the crimping method of crimping and film formation provided by Example 1 of the present invention, the position of each crimp moves 3 cm to the right relative to the edge of the previous pipe, and the fourth crimp moves to the left 3 cm relative to the edge of the third crimp, that is, the same as the second crimp The position is the same, and according to this rule, the sixth, eighth, and ...

Embodiment 2

[0092] Polyurethane with a molecular weight of 30,000 is synthesized in the laboratory, using dimethyl sulfoxide to prepare a solution at a concentration of 150 mg / ml, and after it is completely dissolved, add 1 drop to the water surface at a distance of 3 cm from the water surface through an autosampler (same as the example) , the solution is spread on the water surface to form a film, and within 5 minutes, use a glass rod with a diameter of 5mm to curl from one side of the film, and each curl moves 5cm to the right relative to the edge of the previous pipe, as Figure 8 as shown, Figure 8 It is a schematic diagram of the curling method of curling and film formation provided by Example 2 of the present invention. Return to the first curling position when curling for the sixth time, and follow this rule, and measure until the wall thickness meets the requirements, then freeze it with liquid nitrogen and take it out. Pipes are obtained after trimming.

[0093] Carry out SEM c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com