Fireproof inorganic facing plate and manufacturing method thereof

A board and inorganic technology, applied in the field of fireproof inorganic decorative panels and their production, can solve problems such as affecting design effects, reducing product quality, increasing construction costs and acquisition efficiency, and achieving high aesthetics, high quality, strong applicability, and easy transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

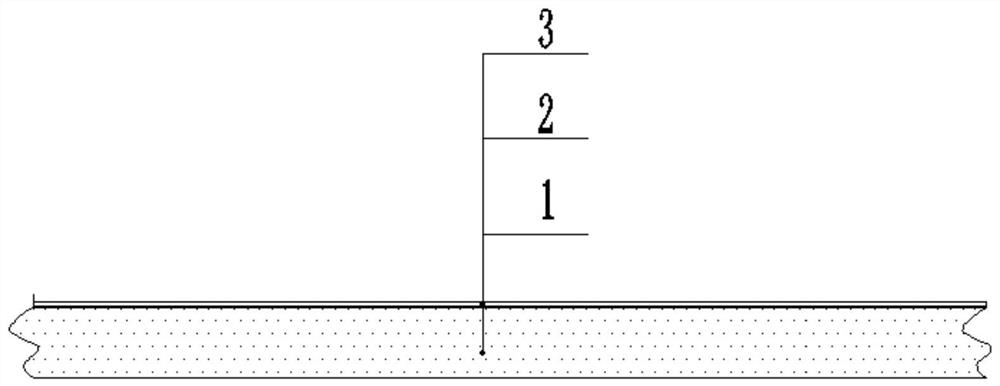

[0039] Such as figure 1 As shown, a fireproof inorganic decorative panel of the present invention includes a base plate 1, an aluminum skin layer 2 and a finish layer 3, the base plate 1, the aluminum skin layer 2 and the finish layer 3 are stacked in sequence, and the base plate 1 is a class A fireproof Inorganic base board or Class B fireproof inorganic base board, the aluminum skin layer 2 can be thin aluminum skin, the thickness of the aluminum skin layer 2 is 0.2mm~0.5mm, and the finishing layer 3 can be PVC film skin layer, melamine paper layer, roll-coated finishing layer , Spraying fluorocarbon layer or UV transfer printing finish layer, etc.

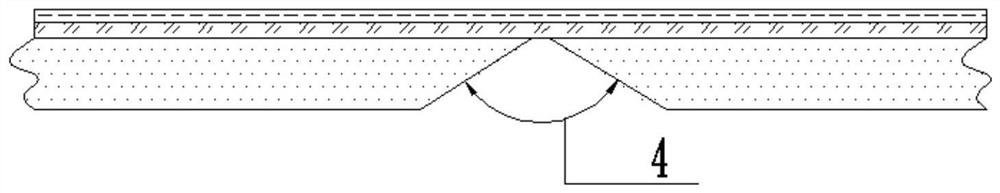

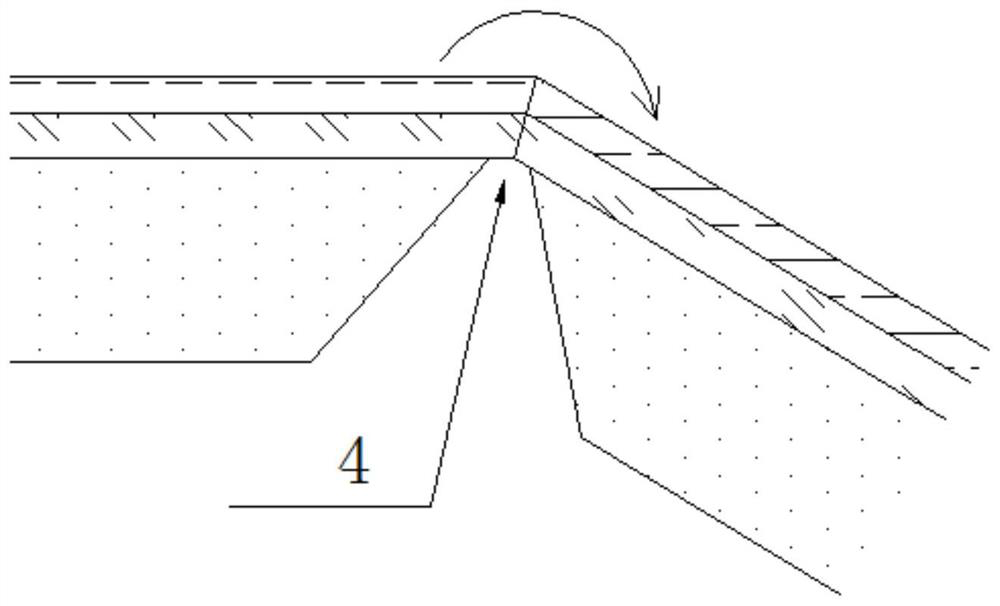

[0040] Such as figure 2 , image 3 with Figure 4 As shown, a trapezoidal groove 4 is provided on the base plate along the thickness direction of the base plate. The opening of the trapezoidal groove 4 faces away from the direction of the aluminum skin layer. The plates 1 have the same thickness, and the extending direction...

Embodiment 2

[0049] Such as Image 6 and Figure 7 As shown, a fireproof inorganic decorative panel of the present invention includes a base plate 1, an aluminum skin layer 2 and a finish layer 3, the base plate 1, the aluminum skin layer 2 and the finish layer 3 are stacked in sequence, and the base plate 1 is a class A fireproof Inorganic base board, the aluminum skin layer 2 is a thin aluminum skin, the thickness of the aluminum skin layer 2 is 0.2mm ~ 0.5mm, the finishing layer 3 is PVC film skin layer, melamine paper layer, roll coating finish layer, spray fluorocarbon layer or UV transfer printing finish layer.

[0050] A trapezoidal groove 4 is opened on the base plate along the thickness direction of the base plate. The opening of the trapezoidal groove 4 faces away from the direction of the aluminum skin layer. Similarly, the extending direction of the trapezoidal groove 4 is a straight line perpendicular to the section of the plate, and the plate is bent around the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com