Patents

Literature

51results about How to "Realize setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orthogonal light path-based equipment for online monitoring concentration of organic carbon/elemental carbon in PM (Particulate Matter) 2.5

ActiveCN104132893AReal-time acquisitionAutomate analysisColor/spectral properties measurementsMicrocontrollerOptoelectronics

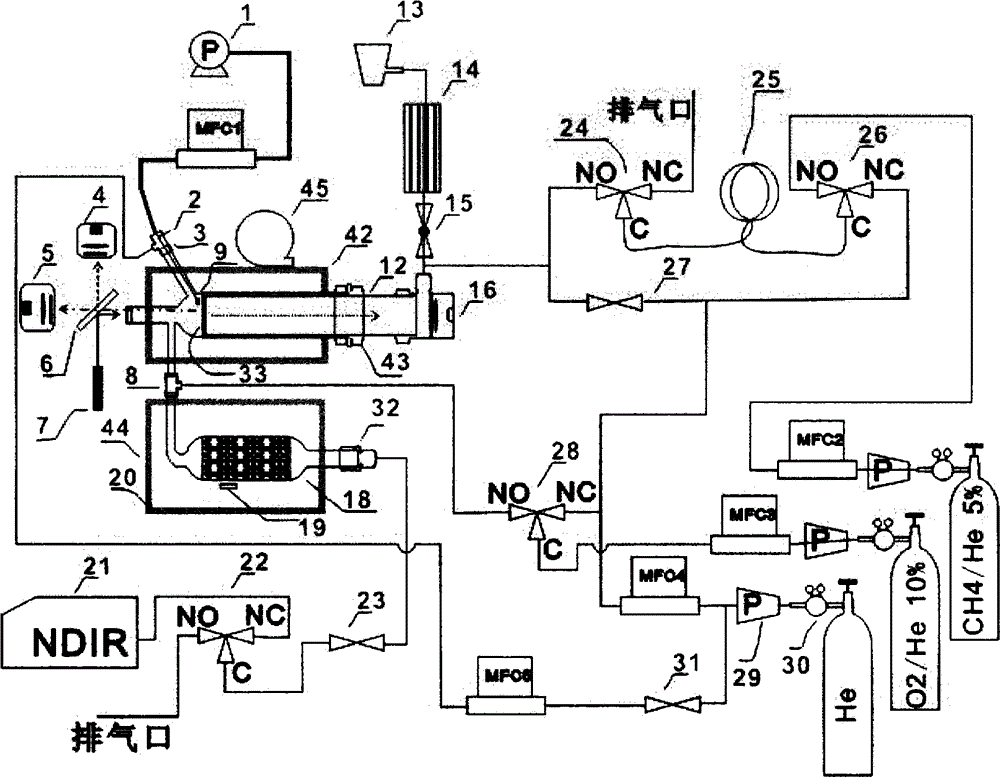

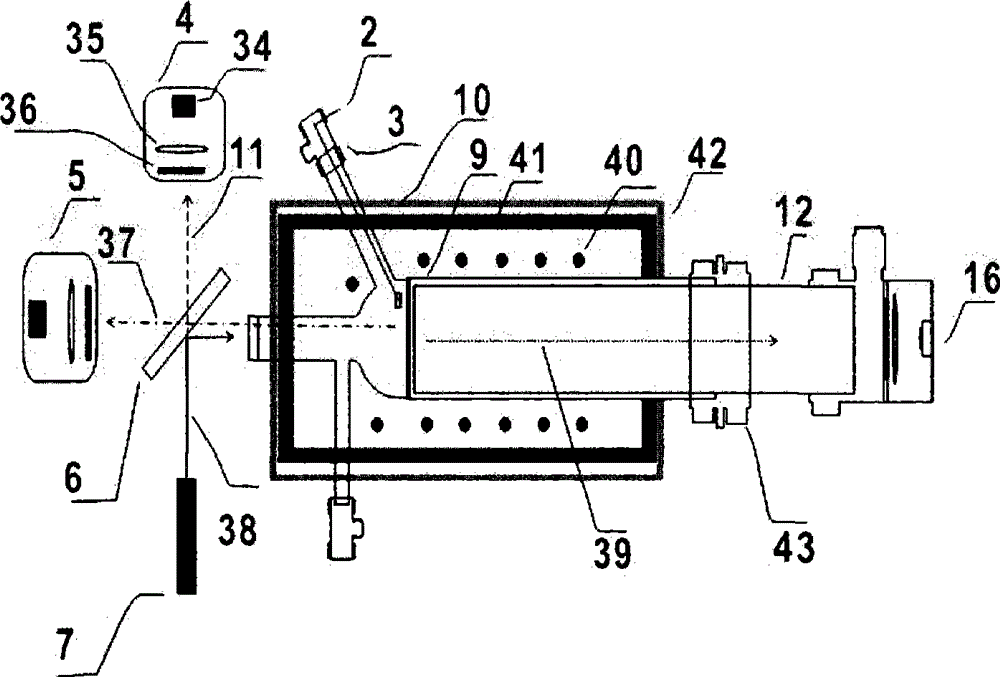

The invention discloses orthogonal light path-based equipment for online monitoring the concentration of organic carbon / elemental carbon in PM (Particulate Matter) 2.5. The orthogonal light path-based equipment comprises an on-line sampling unit, a sample processing and detecting unit and an orthogonal light path system, and is characterized in that the sampling unit comprises a vacuum pump, a mass flow controller, a quartz filtering membrane, a ball valve, a volatilizable organic matter denuder, and a PM2.5 cutting head; the sample processing and detecting unit comprises a digestion furnace, an oxidation furnace, a gas path control network, a carrier gas source and a non-deviation infrared detector; the orthogonal light path system comprises a laser, a light beam splitter, a reference light path photoelectric detection unit, a quartz filtering membrane transmission light path photoelectric detection unit and a reflection light path photoelectric detection unit; and three gases of high-purity He, 5 percent O2 / He and 5 percent CH4 / He are required to be controlled by a gas path valve network by a singlechip. The orthogonal light path-based equipment is capable of simultaneously detecting light intensity values of incident laser, sampled reflected light and transmitted light of the quartz filtering membrane, and relatively accurately achieving the segmentation of the organic carbon and the elemental carbon.

Owner:CECEP TIANRONG TECH CO LTD

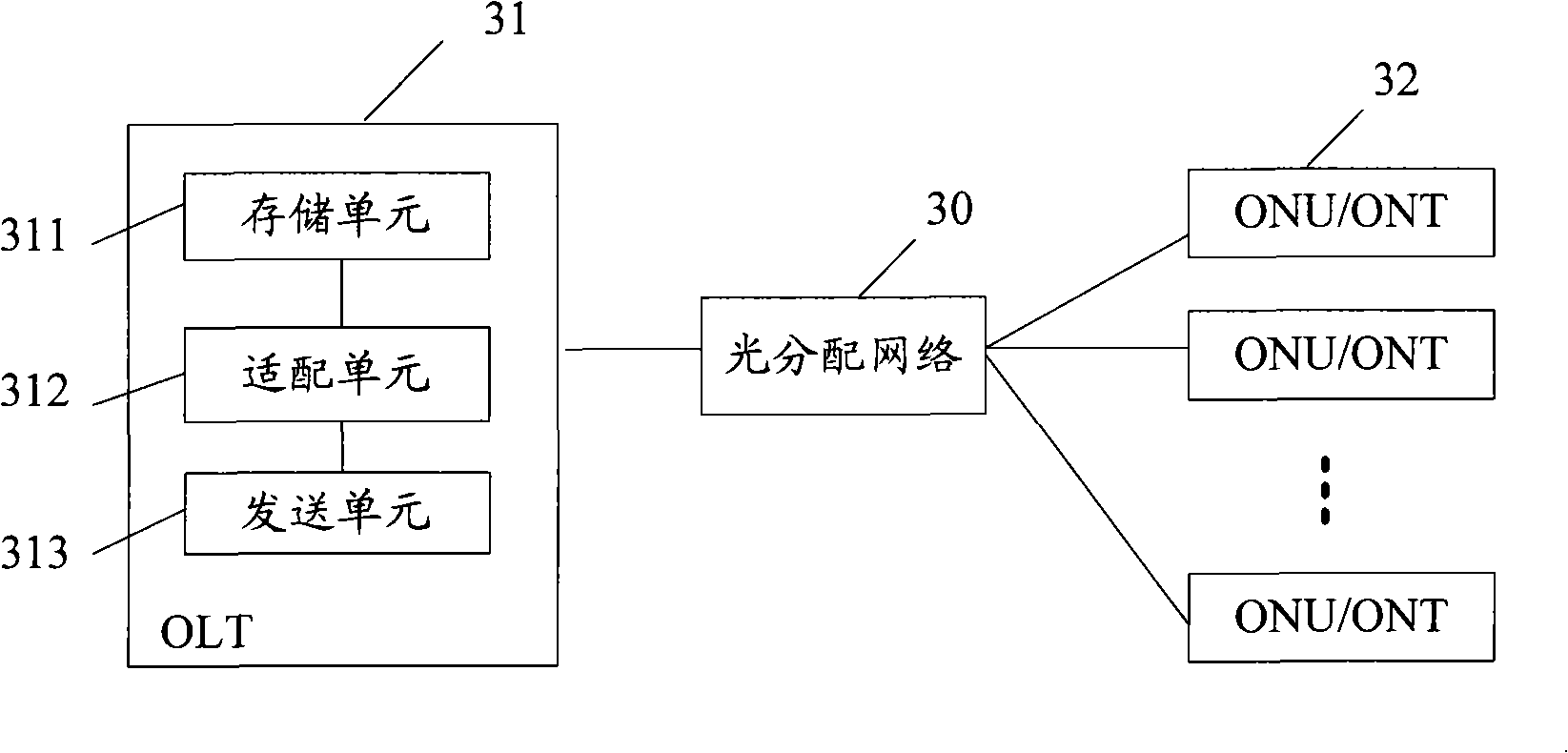

Method, system and equipment for distributing bandwidth of optical network

ActiveCN101330450AAvoid lossRealize distributionMultiplex system selection arrangementsTime-division multiplexComputer networkOptical network unit

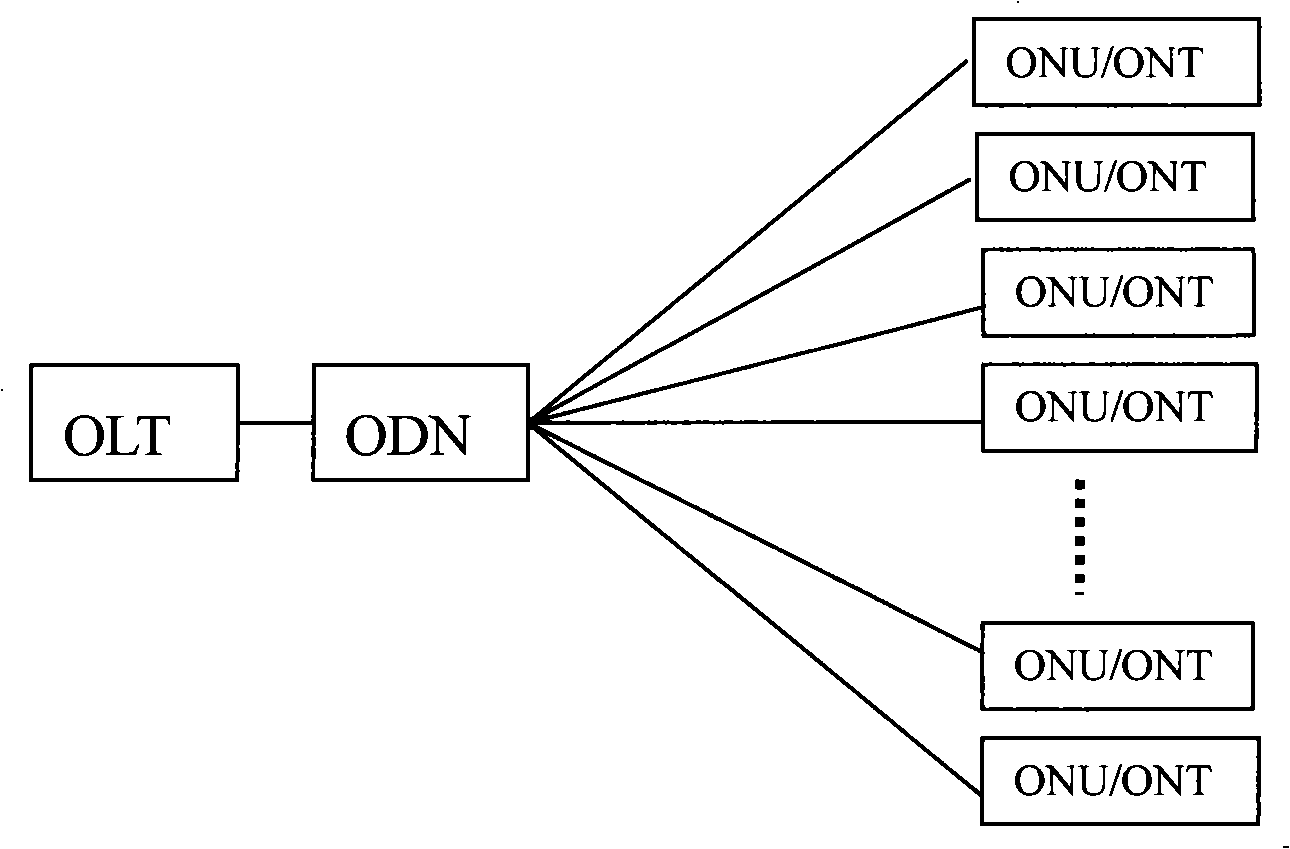

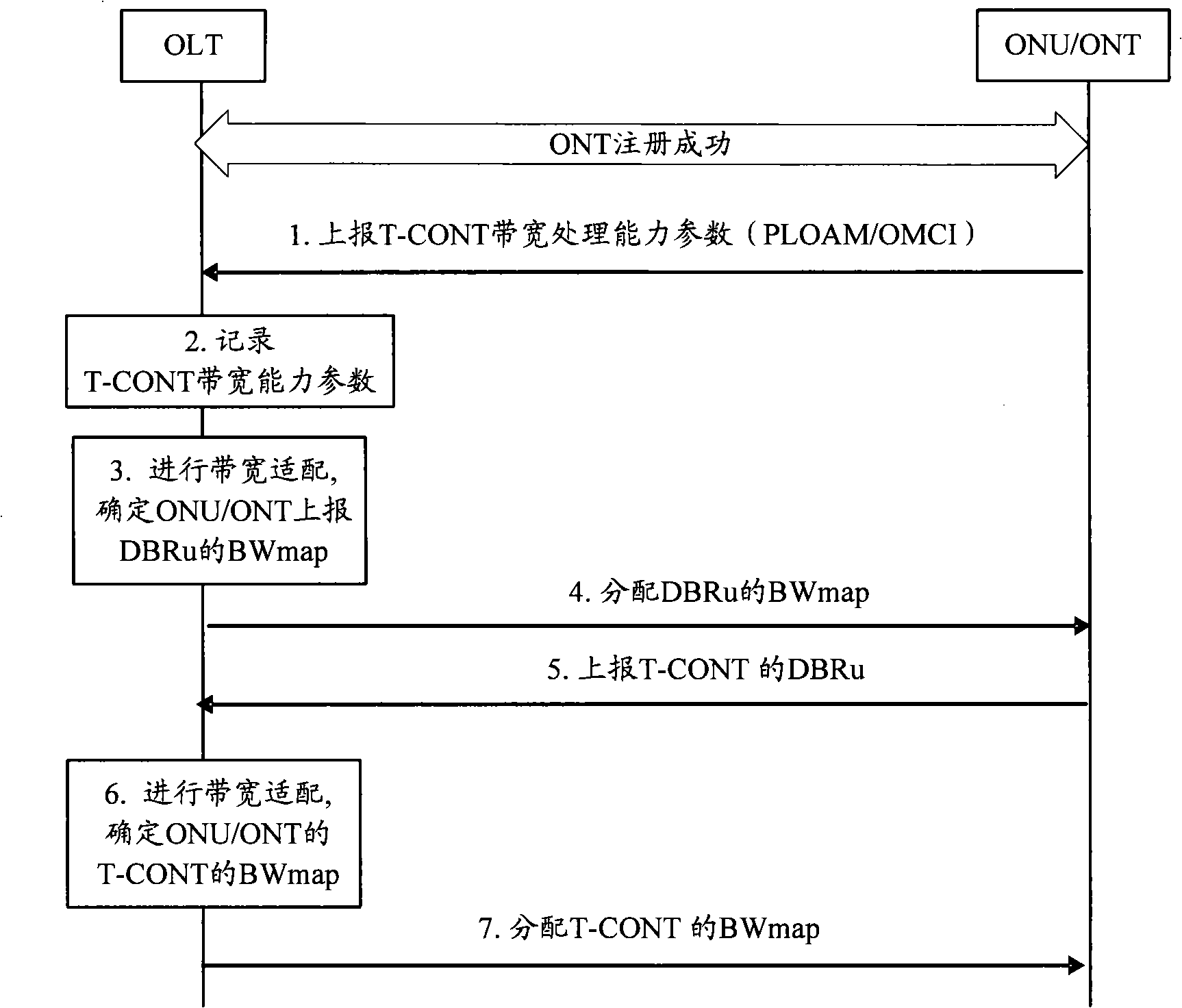

The invention discloses a bandwidth allocation method in an optical network and a system thereof. The method comprises the following steps: acquiring the bandwidth processing capacity parameters of a transmission container passage of an optical network unit (ONU) or an optical network terminal (ONT) by an optical line terminal (OLT); conducting bandwidth adaptation according to the bandwidth processing capacity parameters, and determining a bandwidth allocation diagram of the transmission container passage of the ONU or the ONT; sending the bandwidth allocation diagram to the ONU or the ONT. The invention further discloses an optical line terminal (OLT) and an optical network terminal (ONT). The method can compromise the ONTs with different capacities, and realize allocation and setting of any bandwidth values in the transmission container passage.

Owner:HUAWEI TECH CO LTD

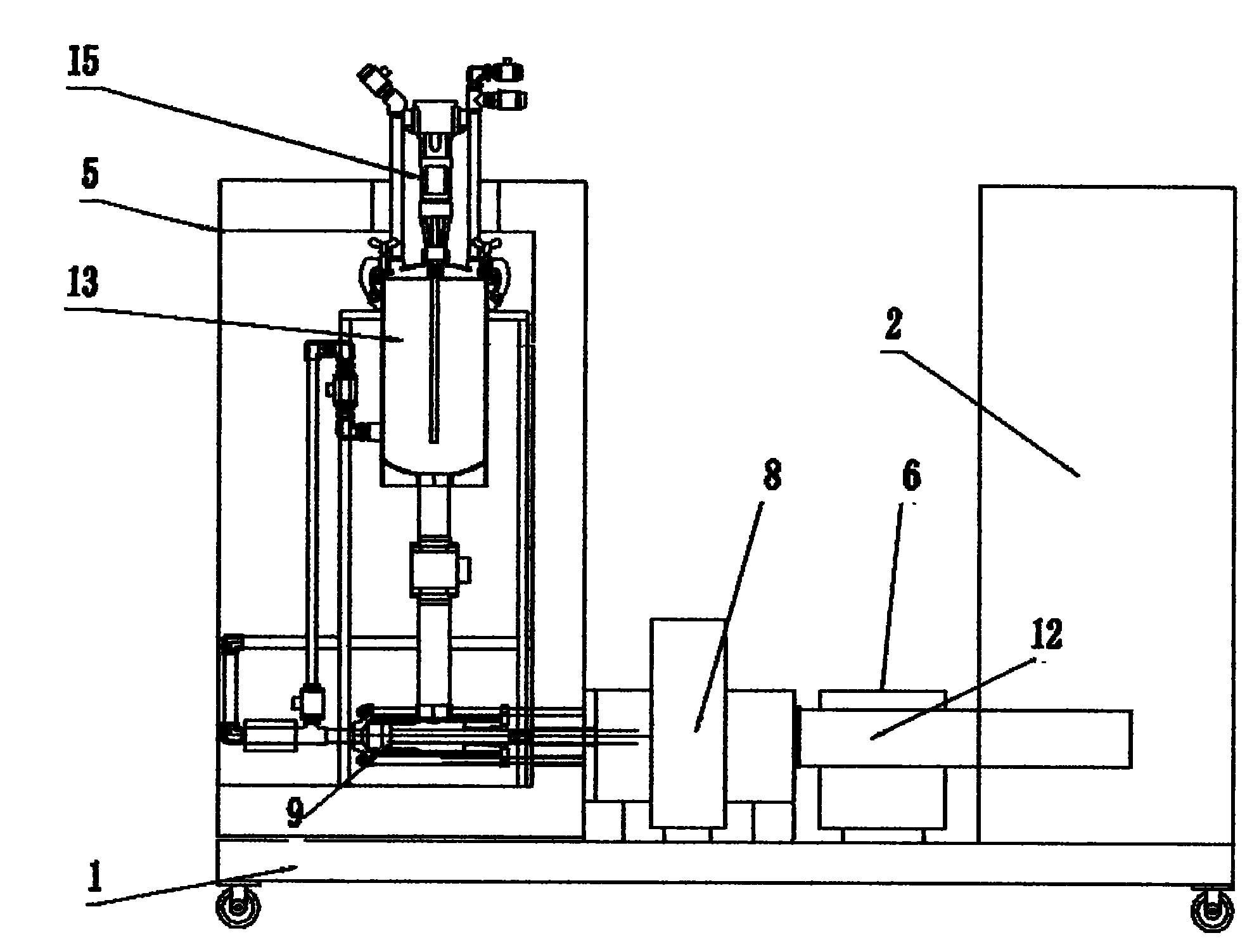

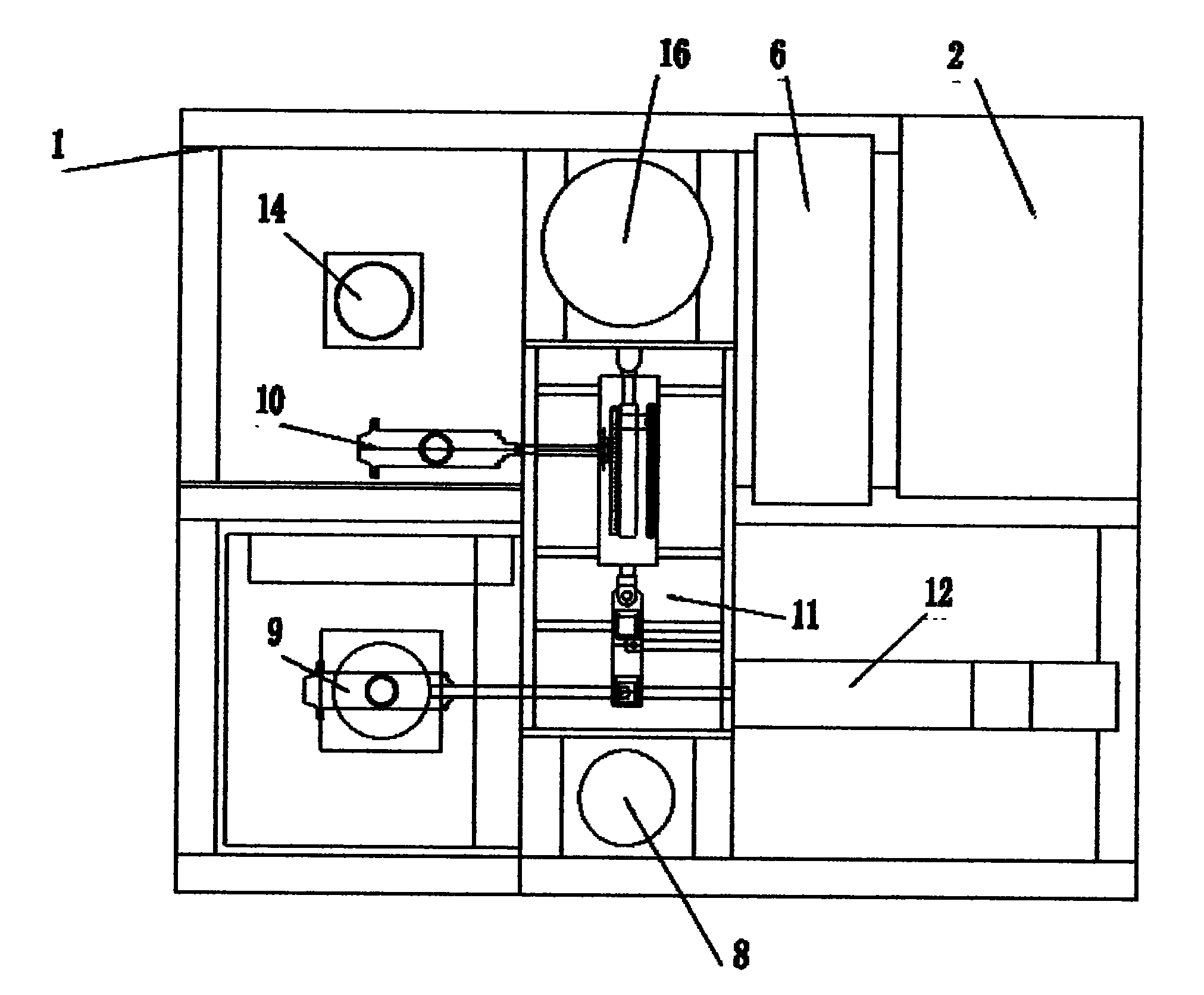

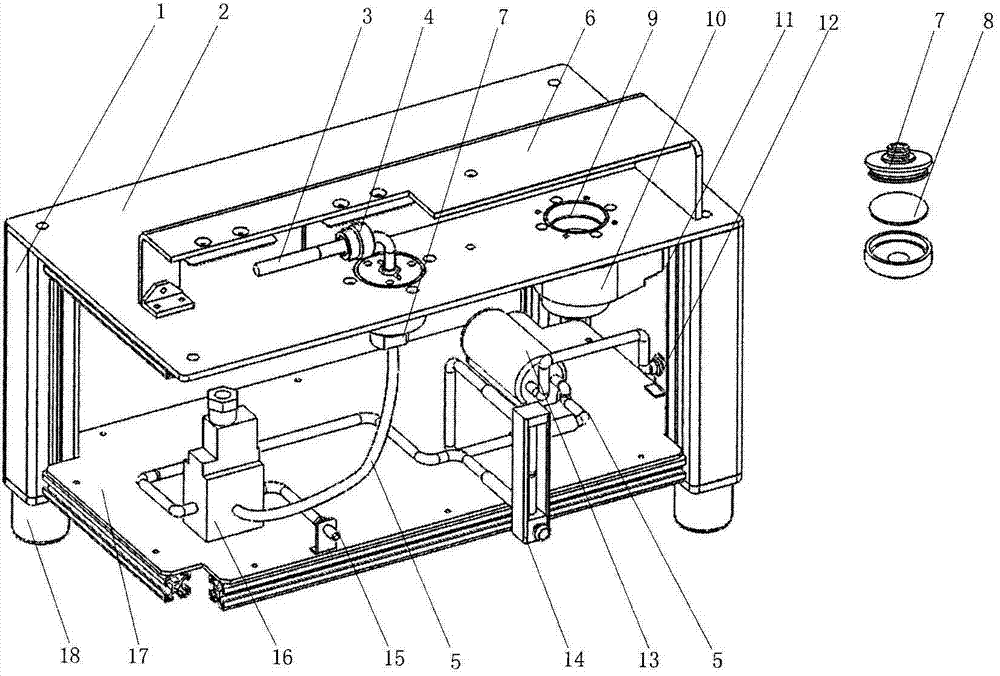

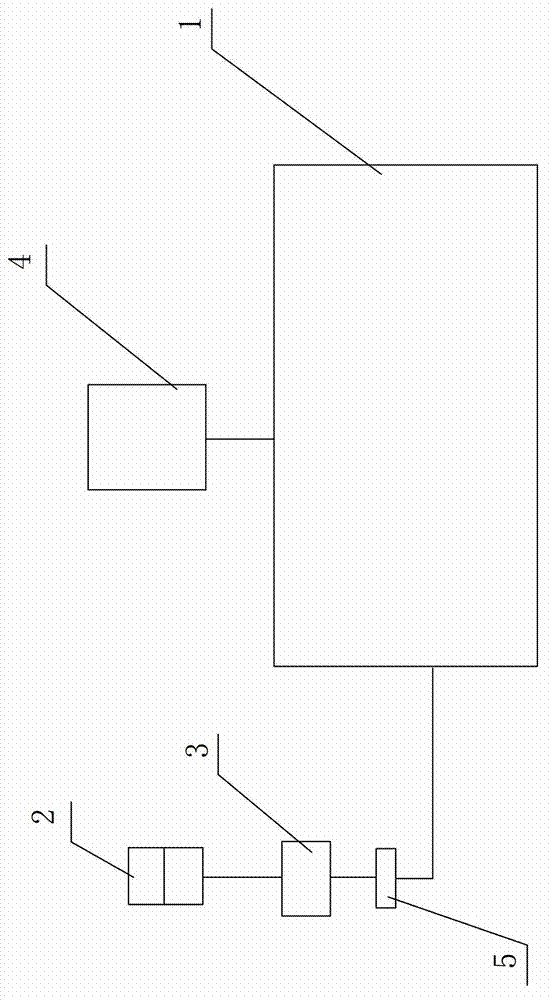

Precise epoxy injector

The invention provides a precise epoxy injector which is high in accuracy, high in degree of intelligence, good in stability and high in using temperature. The precise epoxy injector comprises a rack, and a control system, a raw material processing system, a heating system, a loading backflow system, a mixing system, a cleaning system and a vacuum pump which are positioned on the rack, wherein the control system is respectively connected with the raw material processing system, the heating system, the loading backflow system, the mixing system, the cleaning system and the vacuum pump; the raw material processing system is respectively connected with the heating system and the loading backflow system; the loading backflow system is connected with the mixing system; the mixing system is connected with the cleaning system; and the raw material processing system is connected with the vacuum pump. According to the precise epoxy injector, the degree of the operation intelligence and the control accuracy are greatly improved. The precise epoxy injector is high in stability and high in using temperature, and can be applied to most of epoxy resin systems. Various injection parameters in the injection process can be set and automatically controlled.

Owner:刘汝斌 +1

Smoking machine with constant flow velocity

ActiveCN103487296AStable suction flowClean in timeWithdrawing sample devicesGlass coverThermodynamics

The invention provides a smoking machine with a constant flow velocity. The smoking machine comprises a cigarette clamp holder, a total particulate matter catcher, a reversing valve, a gas flow detection control device, a vacuum pump and a mainstream smoke collecting opening, wherein the cigarette clamp holder is arranged on an upper panel; the total particulate matter catcher is connected onto a mainstream smoke pipeline at the back end of clamp holder; an organic glass cover used for collecting sidestream smoke is mounted on the upper panel; a sidestream smoke outlet is formed in the upper panel positioned in the glass cover; a sidestream smoke filter screen is additionally arranged at the sidestream smoke outlet, and the sidestream smoke outlet is communicated with a sidestream smoke blower and a sidestream smoke collecting opening; the total particulate matter catcher is mounted on the upper panel; the reversing valve, the gas flow detection control device and the vacuum pump are arranged on a bottom plate; a cleaning gas circuit interface is arranged on the reversing valve. The smoking machine with the constant flow velocity, provided by the invention, has the advantages that smoking flow quantity of a cigarette can be stabilized, the setting and control of the constant flow velocity can be achieved, a smoke passage can be cleaned timely, influences on experimental results are reduced greatly, the mainstream smoke and sidestream smoke can be collected in an expanded manner during cigarette burning, and analysis and detection to compositions of the mainstream smoke and the sidestream smoke can be achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

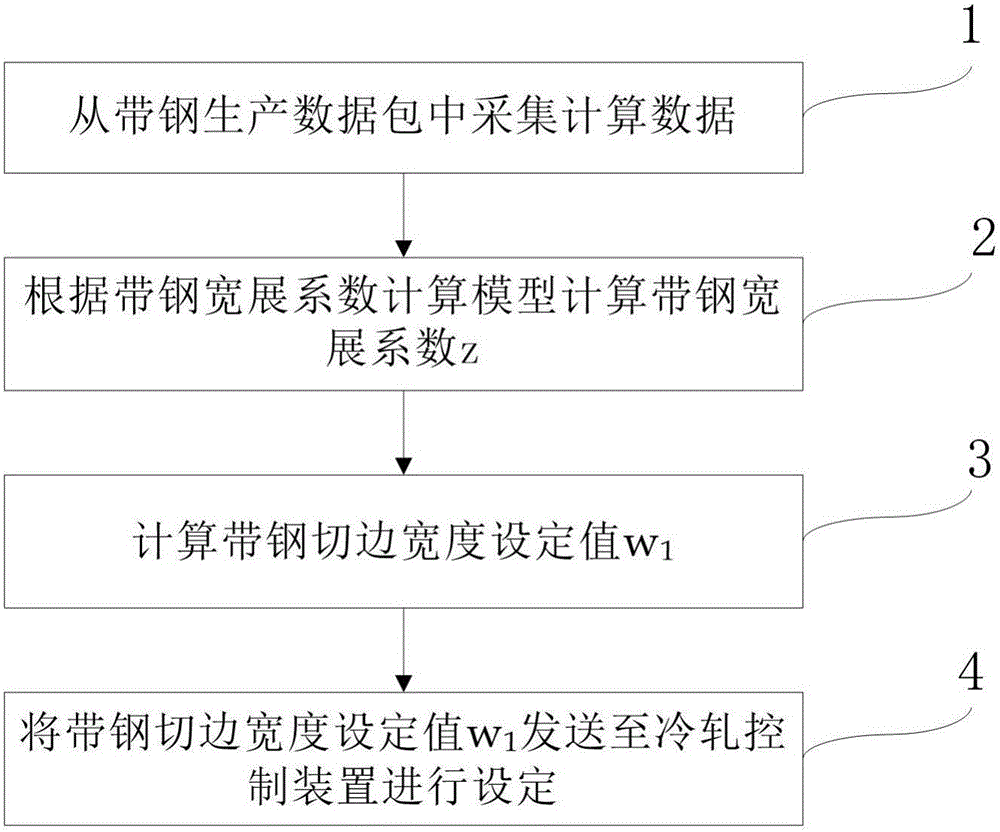

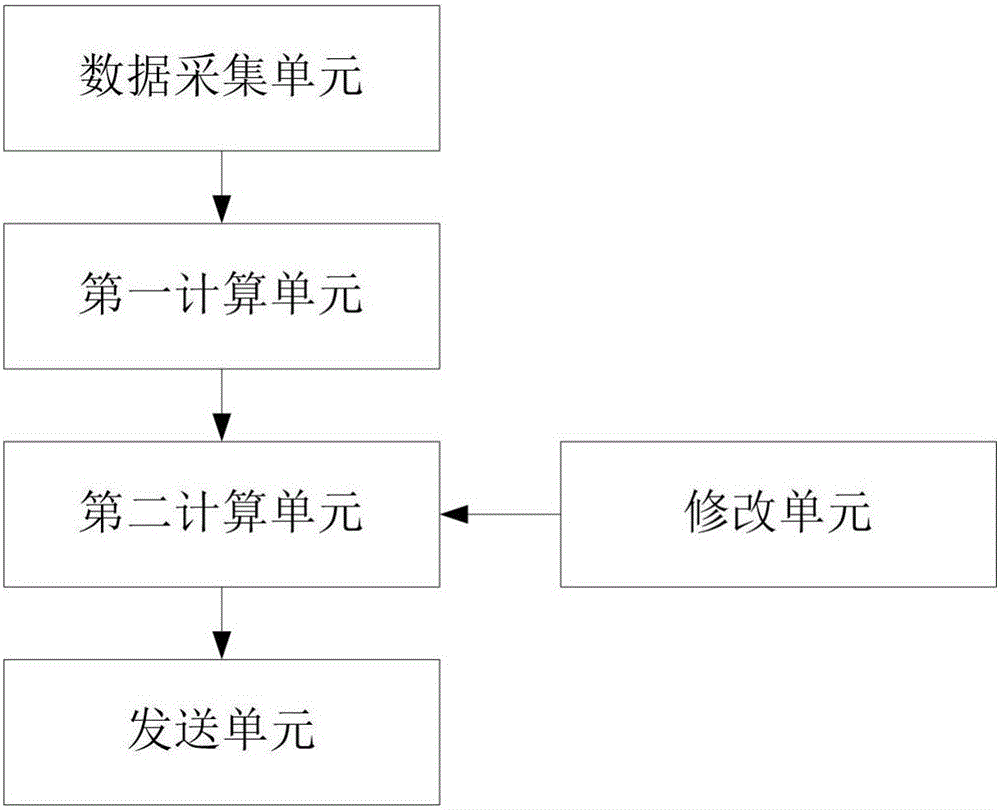

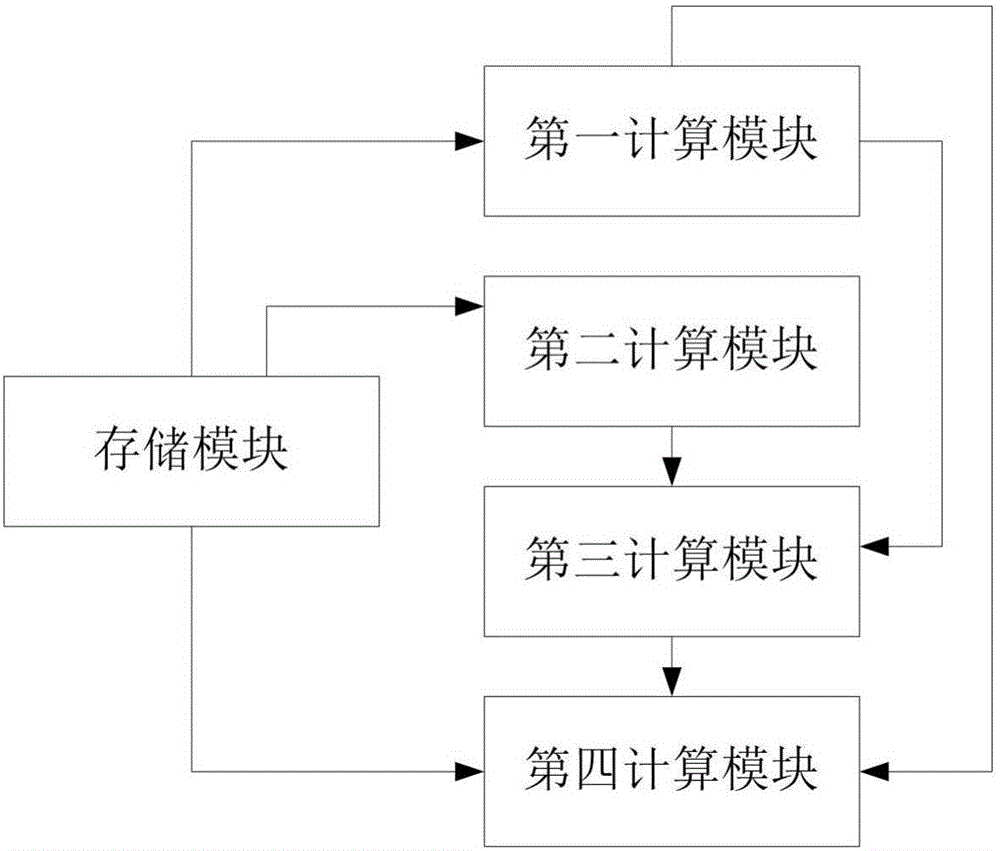

Setting method, device and system for trimming width of cold rolled strip steel

ActiveCN105880297AImprove accuracyRealize automatic calculationMetal rolling stand detailsRoll mill control devicesNetwork packetStrip steel

The invention relates to the technical field of cold rolling, in particular to a setting method, device and system for a trimming width of cold rolled strip steel. The method comprises the steps of acquiring calculation data in a strip steel production data packet; calculating a strip steel elongation coefficient according to a strip steel elongation coefficient calculation model; calculating a strip steel trimming width set value; and sending the strip steel trimming width set value to a cold rolling control device for setting. The device comprises a data acquisition unit, a first calculation unit, a second calculation unit, a sending unit and a modification unit. The system comprises a cold rolled strip steel trimming width setting device, an upper computer and the cold rolling control device. According to the setting method, the device and the system for the trimming width of cold rolled strip steel provided by the invention, the trimming width of cold rolled strip steel is automatically calculated and set, the accuracy of the cold rolled strip steel trimming width set value is improved, and a lot of manpower and material resources are saved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

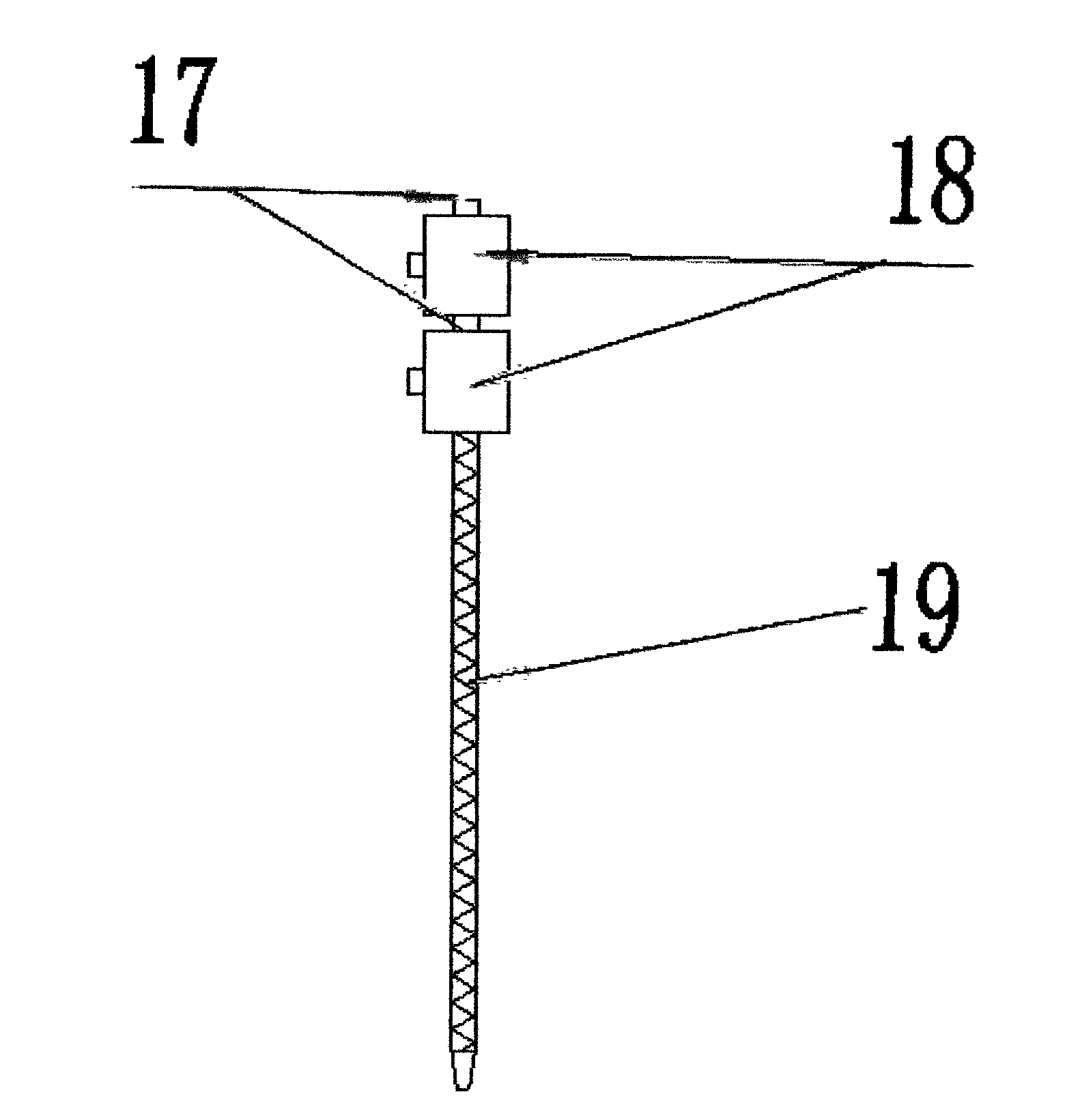

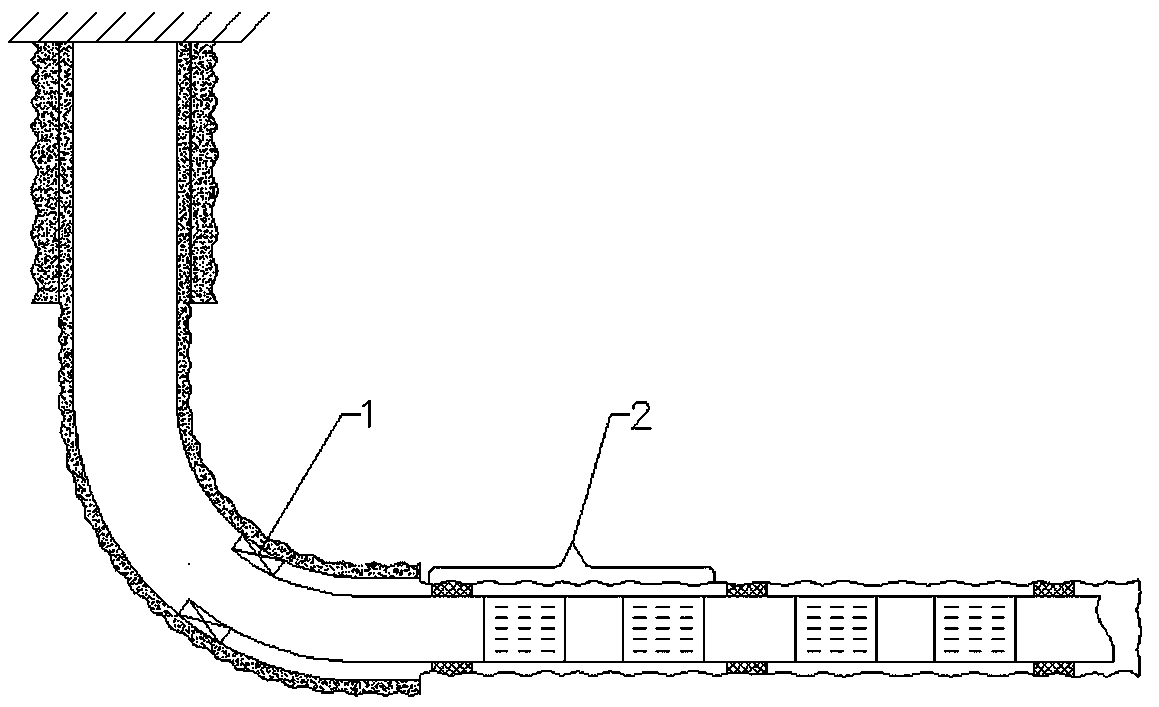

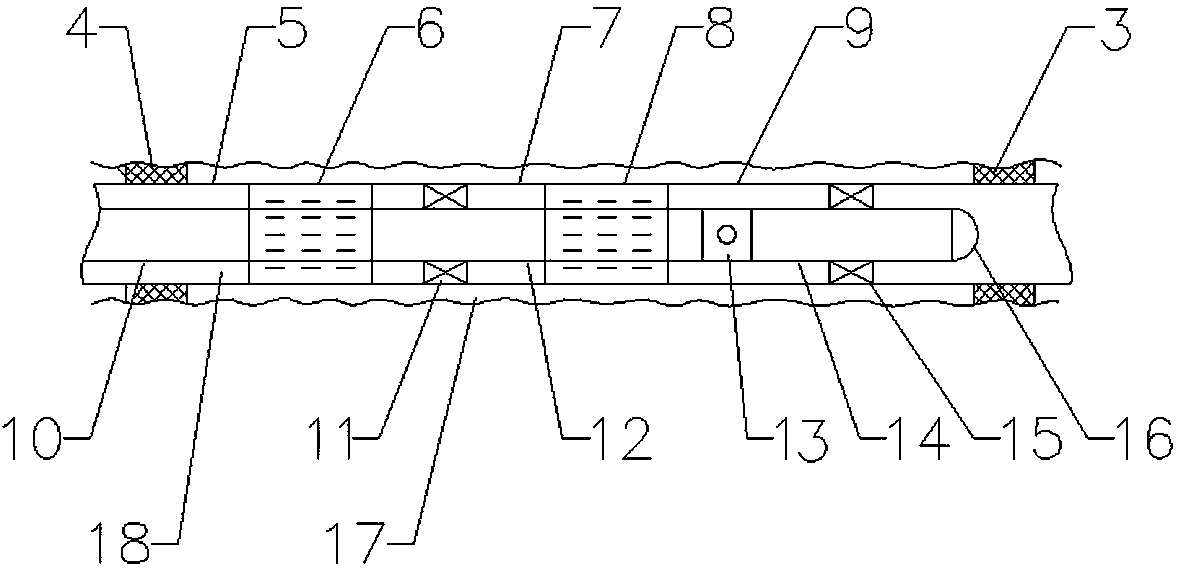

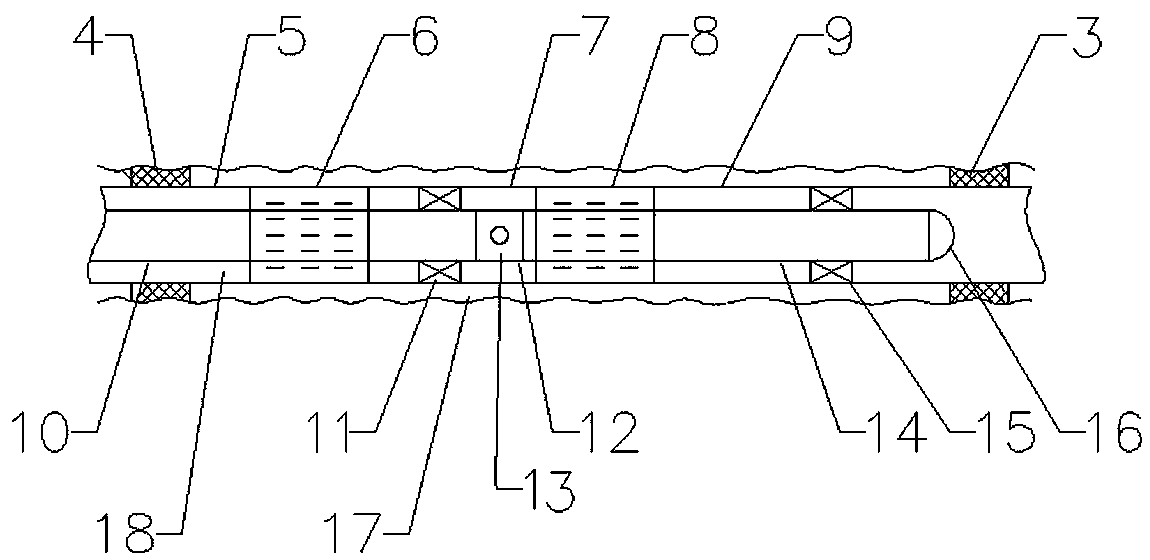

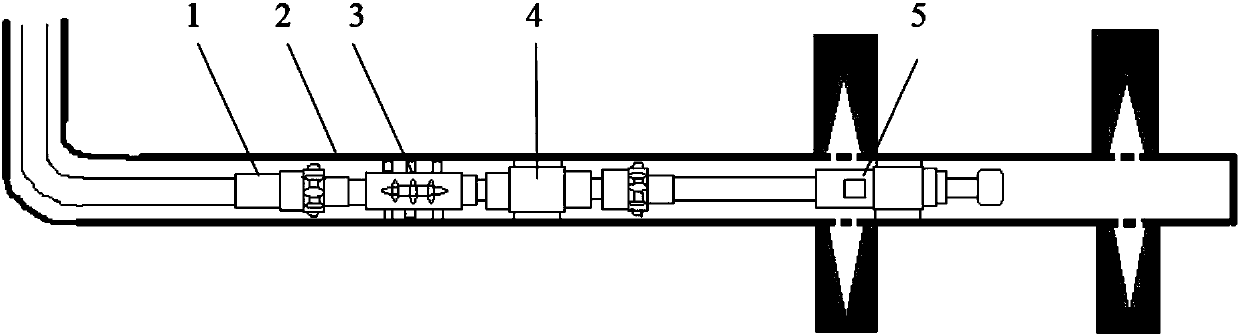

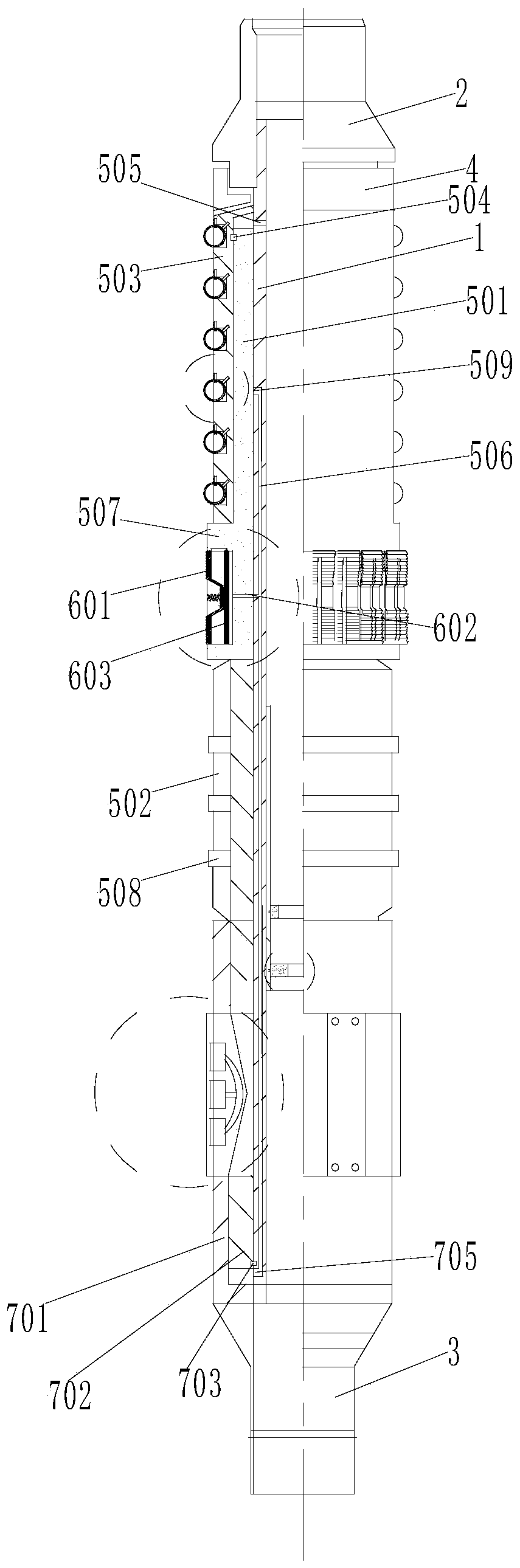

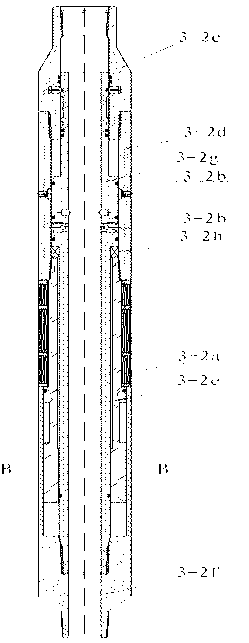

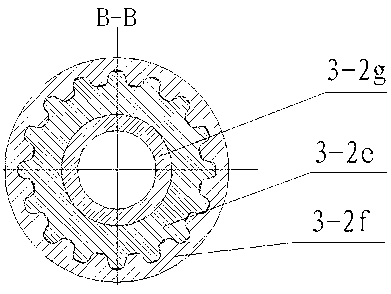

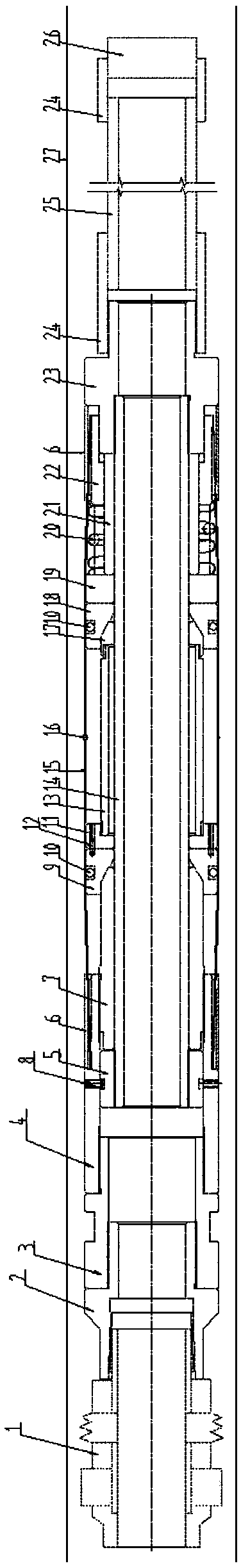

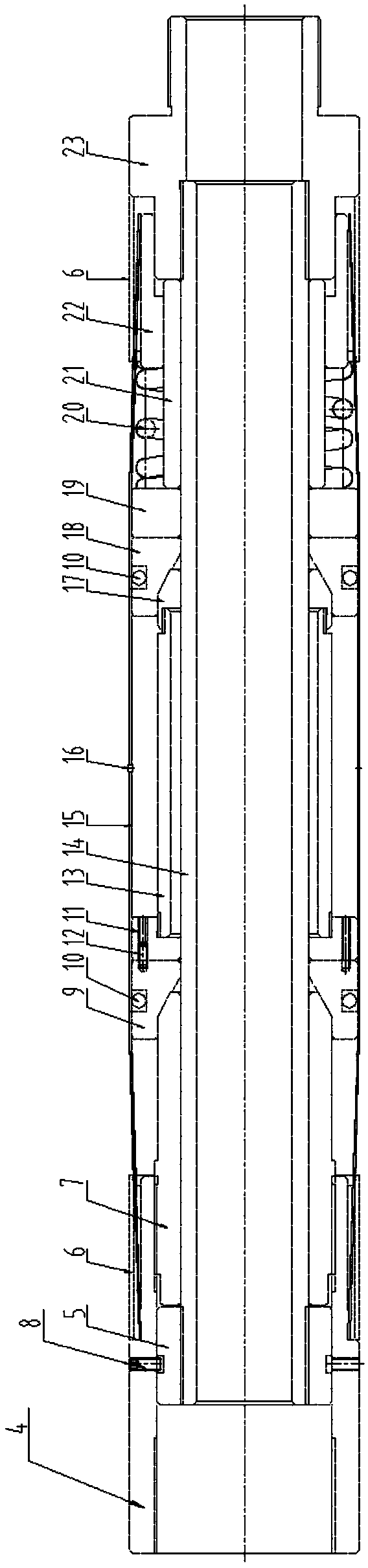

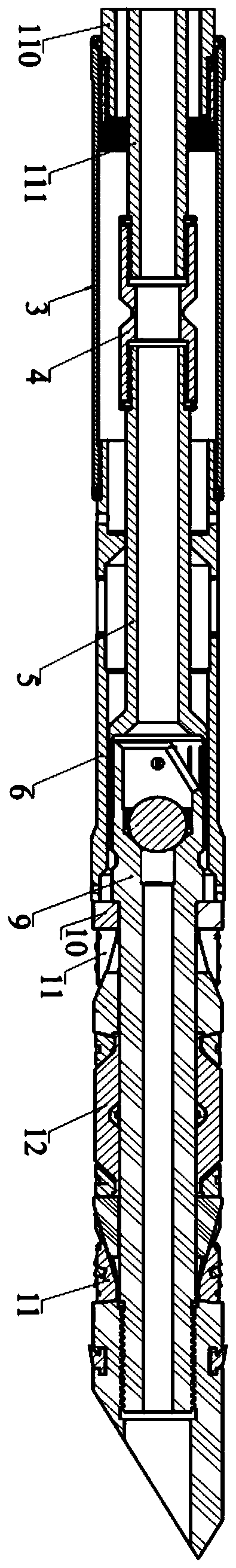

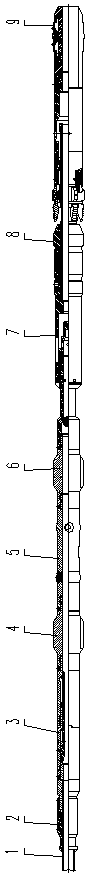

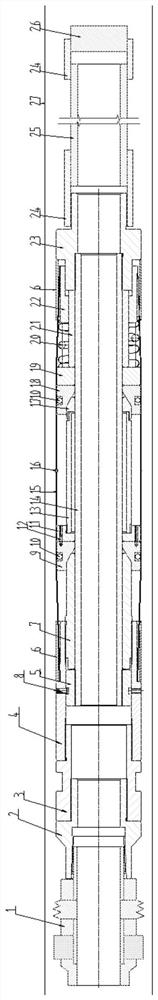

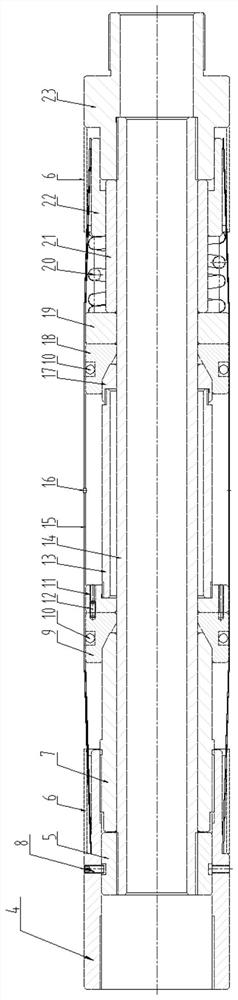

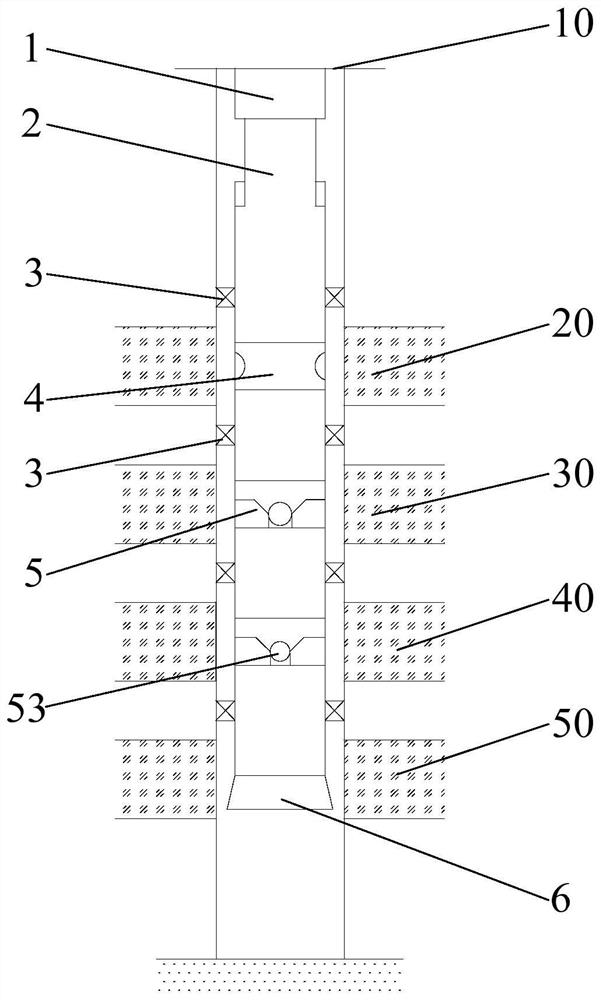

Classified acid pickling acidification method of horizontal well

ActiveCN108086954ASimple structureImplement segmented picklingCleaning apparatusFluid removalHorizontal wellsPetroleum engineering

The invention relates to a classified acid pickling acidification method of a horizontal well. The classified acid pickling acidification method of the horizontal well includes the following steps that 1, a completion pipe string comprising a drilling liner hanger and completion units is put in the well, and first casing pipe packers and second casing pipe packers on the completion units are set on the wall of the well; 2, acid pickling pipe strings are put in casing pipes, first oil pipe packers are set between a liquid inflow sieve pipe and a liquid outflow sieve pipe, and second oil pipe packers are set in the position away from the liquid inflow sieve pipe and close to the ends of oil pipes; 3, processing liquid is injected into the oil pipes, and the processing liquid enters the annulus of the wall of the well from a setting throttler and the liquid inflow sieve pipe to process the wall of the well. The completion units in the completion pipe string are matched with the acidification pipe string, segmented acid pickling acidification is achieved, the wall of the well can be specifically subjected to acid pickling acidification, the completion units and the acidification pipe string are simple in structure, spot operation is convenient, and the method is widely applied to construction of acid pickling acidification of sandstone and carbonatite oil and gas reservoir horizontal wells.

Owner:PETROLEUM ENG TECH RES INST CHINA PETROLEUM & CHEM CORP NORTH CHINA OIL & GAS CO +1

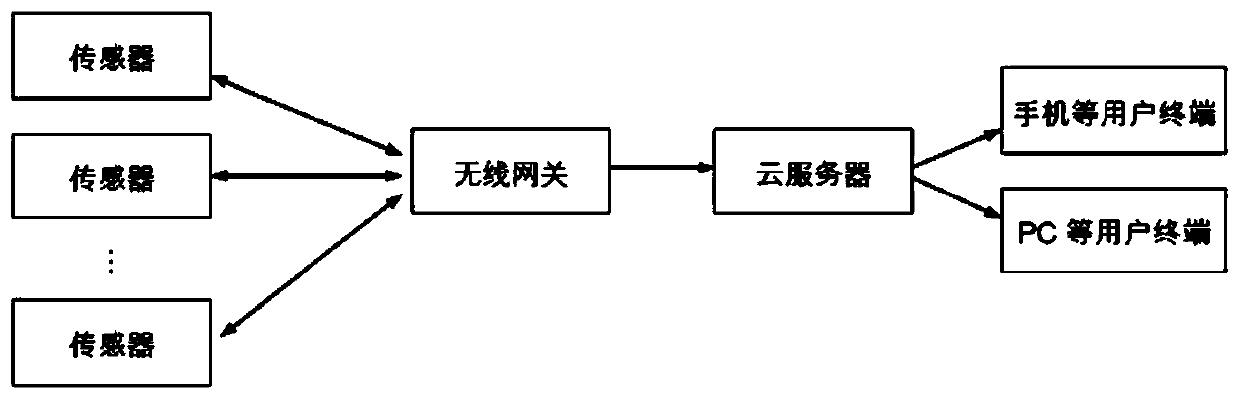

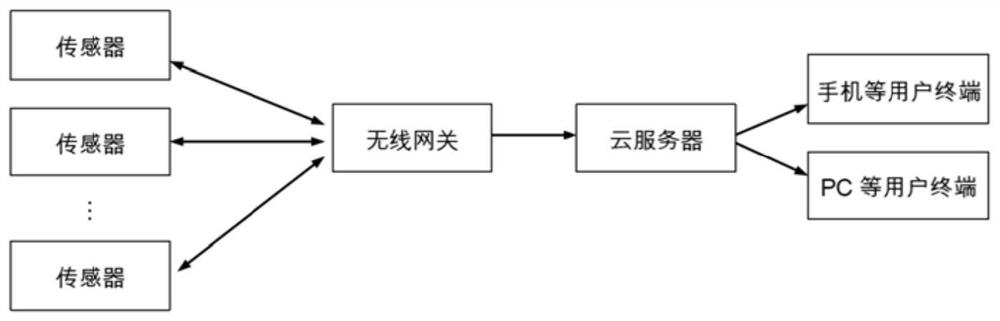

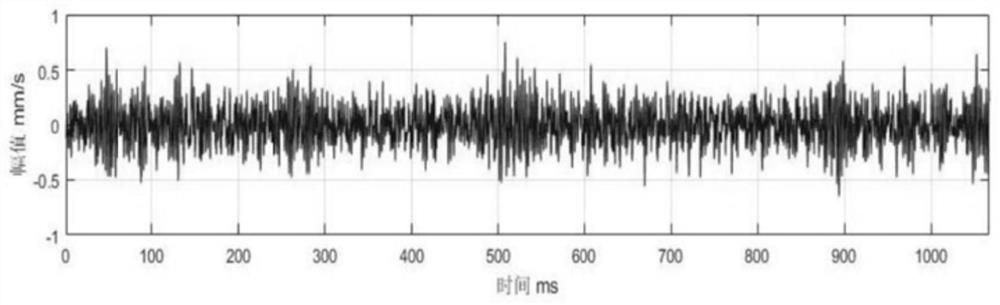

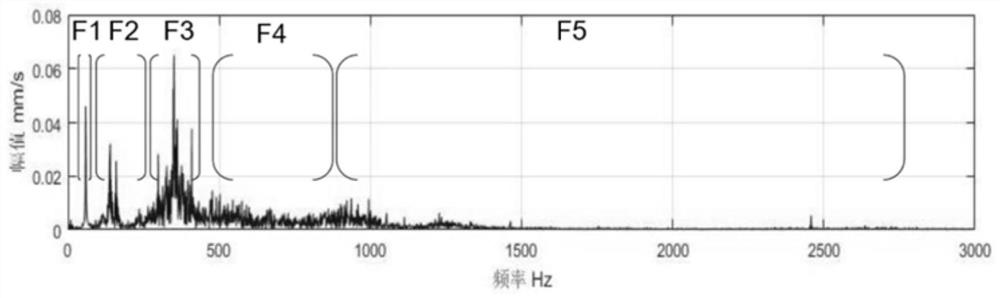

Edge calculation method for monitoring rotating equipment, medium and system

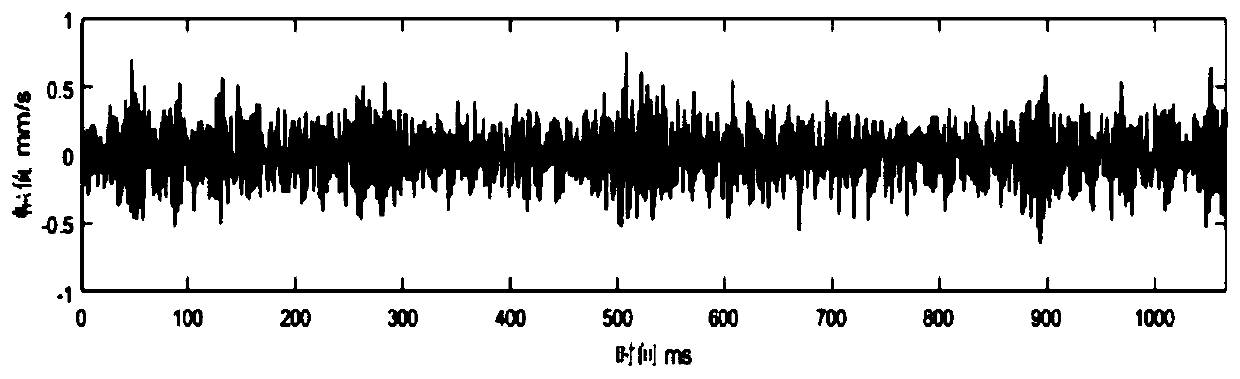

ActiveCN110530507AIntegrity guaranteedLow costSubsonic/sonic/ultrasonic wave measurementVibration amplitudeTime domain

The invention, which belongs to the field of equipment fault monitoring, relates to an edge calculation method for monitoring rotating equipment, a medium and a system. The method comprises the following steps: step one, preprocessing a collected vibration signal of rotating equipment by using an edge computing unit; to be specific, implementing the preprocessing by calculating a pass frequency value of the vibration signal according to the vibration signal, performing frequency domain conversion on the vibration signal, dividing the converted frequency domain vibration signal into a pluralityof narrowband signals, carrying out inverse Fourier transform on each narrowband signal to obtain a time domain signal of each narrowband, calculating a vibration amplitude corresponding to each narrowband signal, and determining whether the pass frequency value and the vibration amplitude of each narrow band exceed standards or not, and generating equipment state information according to determination results; and step two, transmitting characteristic data to a cloud server. According to the invention, the collected vibration waveform data of the rotating equipment are converted into the characteristic data transmitted to the cloud server, so that the cost of network transmission is reduced; and the integrity of transmission information is considered at the same time.

Owner:郑州恩普特科技股份有限公司 +1

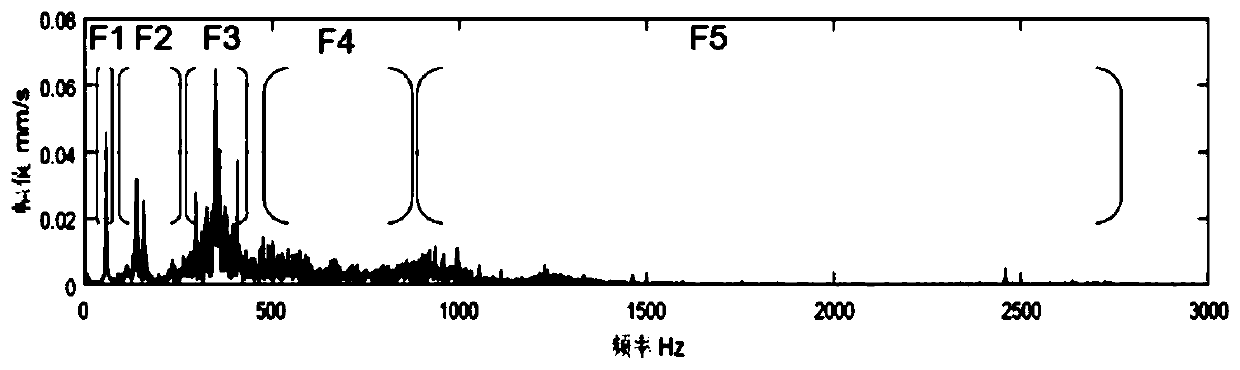

Intelligent controller convenient to use

InactiveCN106249612AEasy to controlRealize settingComputer controlProgramme total factory controlAutomatic controlControl mode

The invention discloses an easy-to-use intelligent controller, which includes a host and several actuators. The host includes a voice receiving device, a voice sending device, a wireless communication device 1 and a single-chip microcomputer connected to the three. The wireless communication device One communicates with the intelligent user equipment, the actuator includes a wireless communication device two and a single-chip microcomputer two connected to each other, the host and any actuator are connected through the wireless communication device one and the wireless communication device two, the The second single-chip microcomputer is connected with the control mainboard of the household appliance. Therefore, the easy-to-use intelligent controller provided by the present invention can realize the safe use and automatic control of various household appliances, has low modification cost, and has a simple and easy-to-learn control method, which is suitable for the elderly, children and disabled people.

Owner:SUZHOU JIANZHEN UNION TECH CO LTD

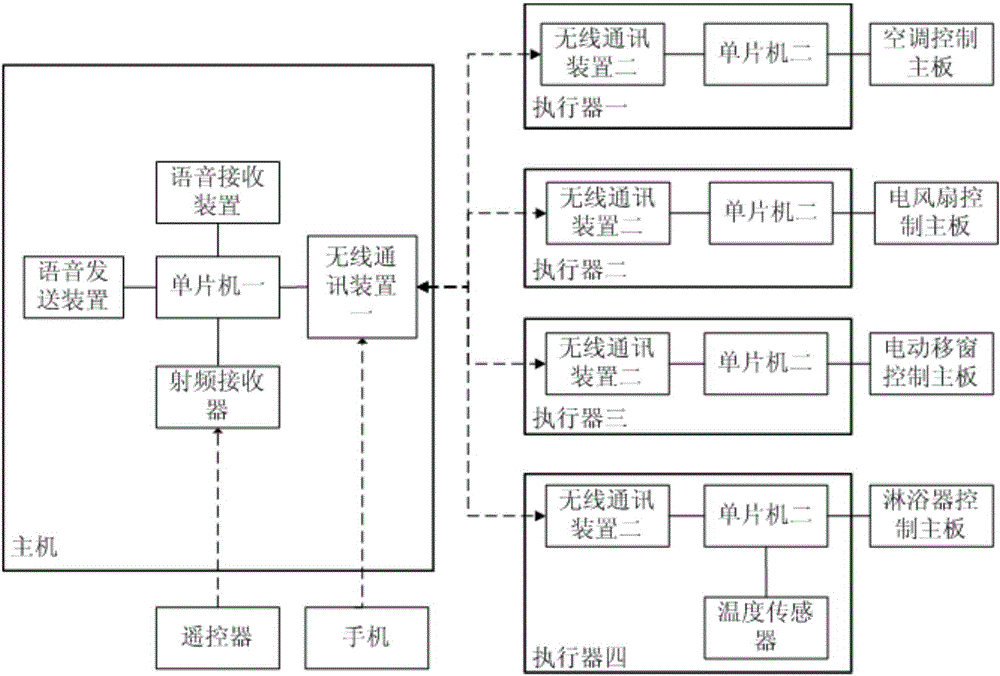

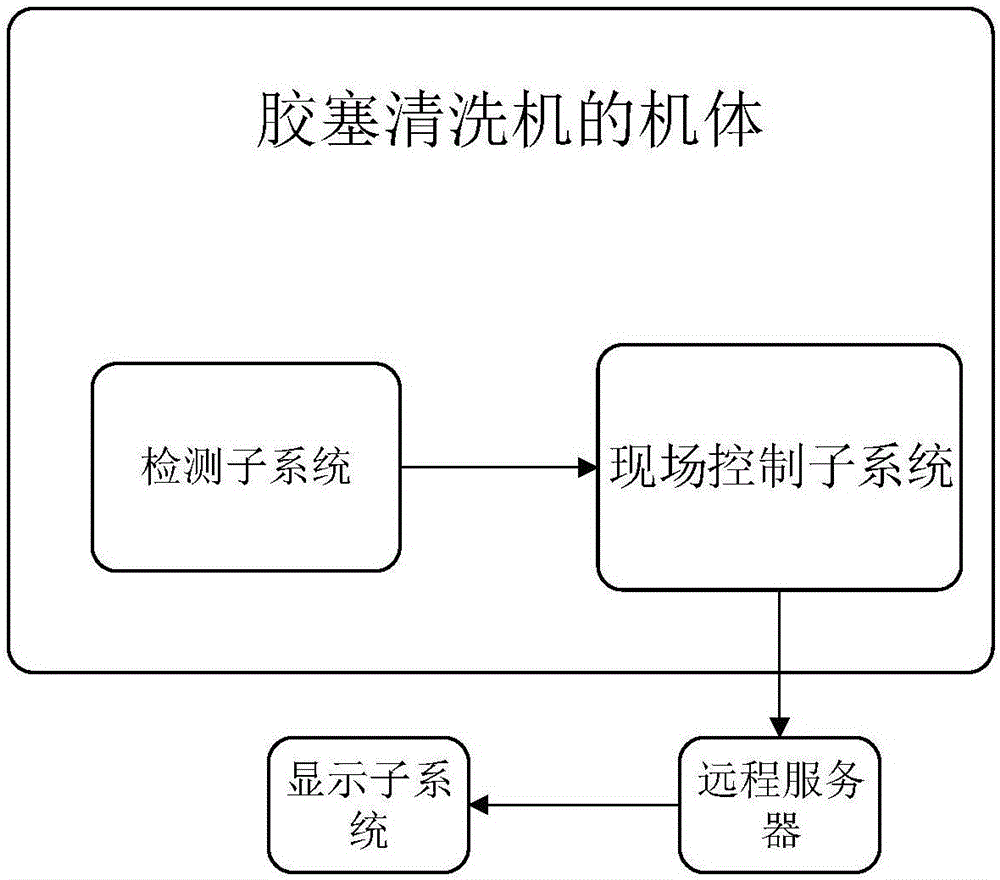

Rubber plug cleaning machine

ActiveCN105750257AEasy to manage centrallyEasy to controlCleaning using liquidsMonitoring systemEngineering

The invention provides a rubber plug cleaning machine.The rubber plug cleaning machine comprises a monitoring system.The monitoring system comprises a detection subsystem, a field control subsystem, a remote server and a display subsystem.The detection subsystem is used for detecting a machine body to acquire detection information, wherein the detection information comprises the temperature information, pressure information, water level information and humidity information of a cleaning tank, the rotating speed information of a transmission device and the valve bank information of a pipeline part.The field control subsystem is used for judging the current operating state of the machine body according to the detection information acquired by the detection subsystem and controlling the machine body according to the current operating state or by responding to a control instruction of the remote server.The remote server is wirelessly connected with the field control subsystem, acquires the detection information through the field control subsystem and sends the control instruction to the field control subsystem according to the detection information or external input information.The display subsystem displays the current operating state and / or the detection information of the detection subsystem.

Owner:SUZHOU INST OF INDAL TECH

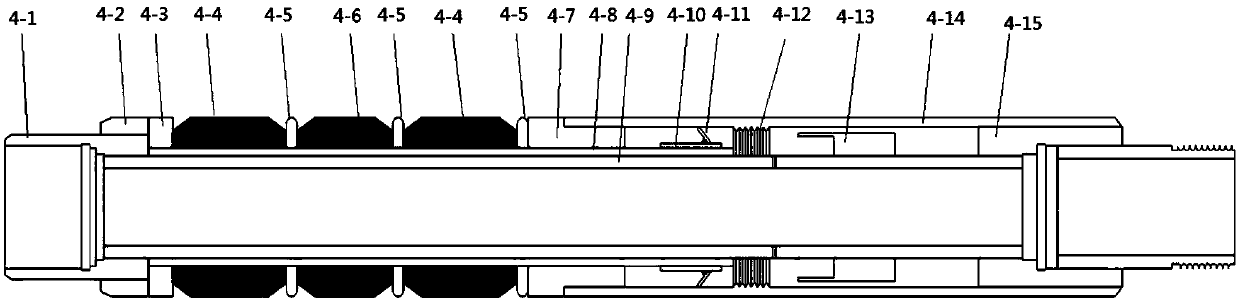

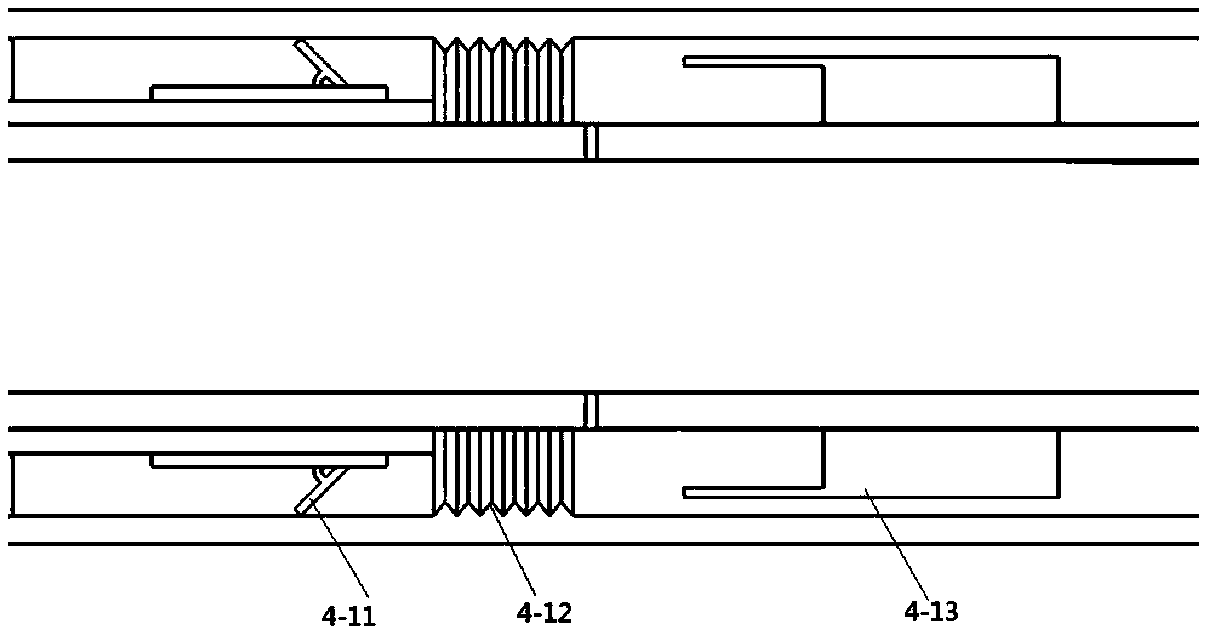

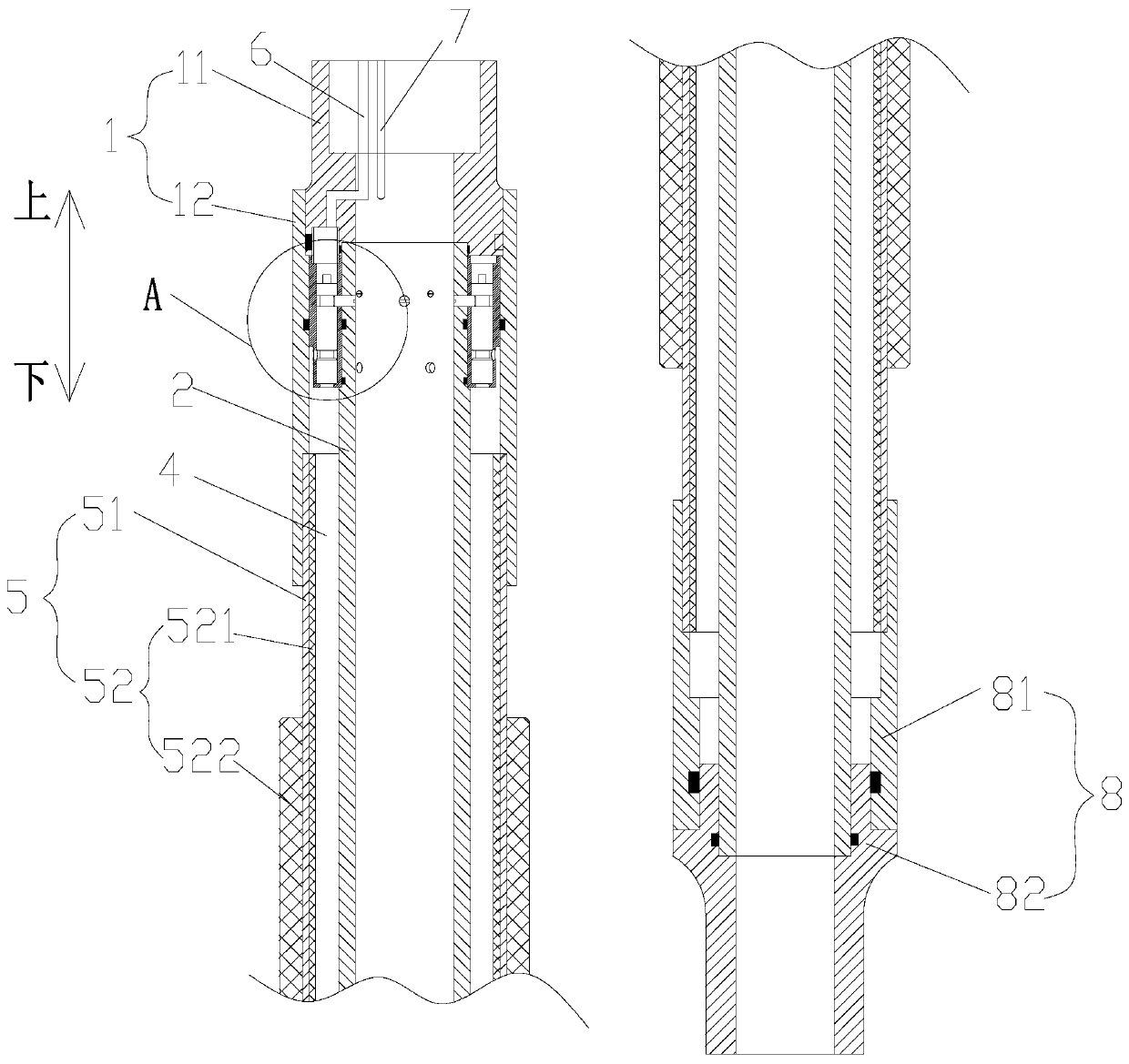

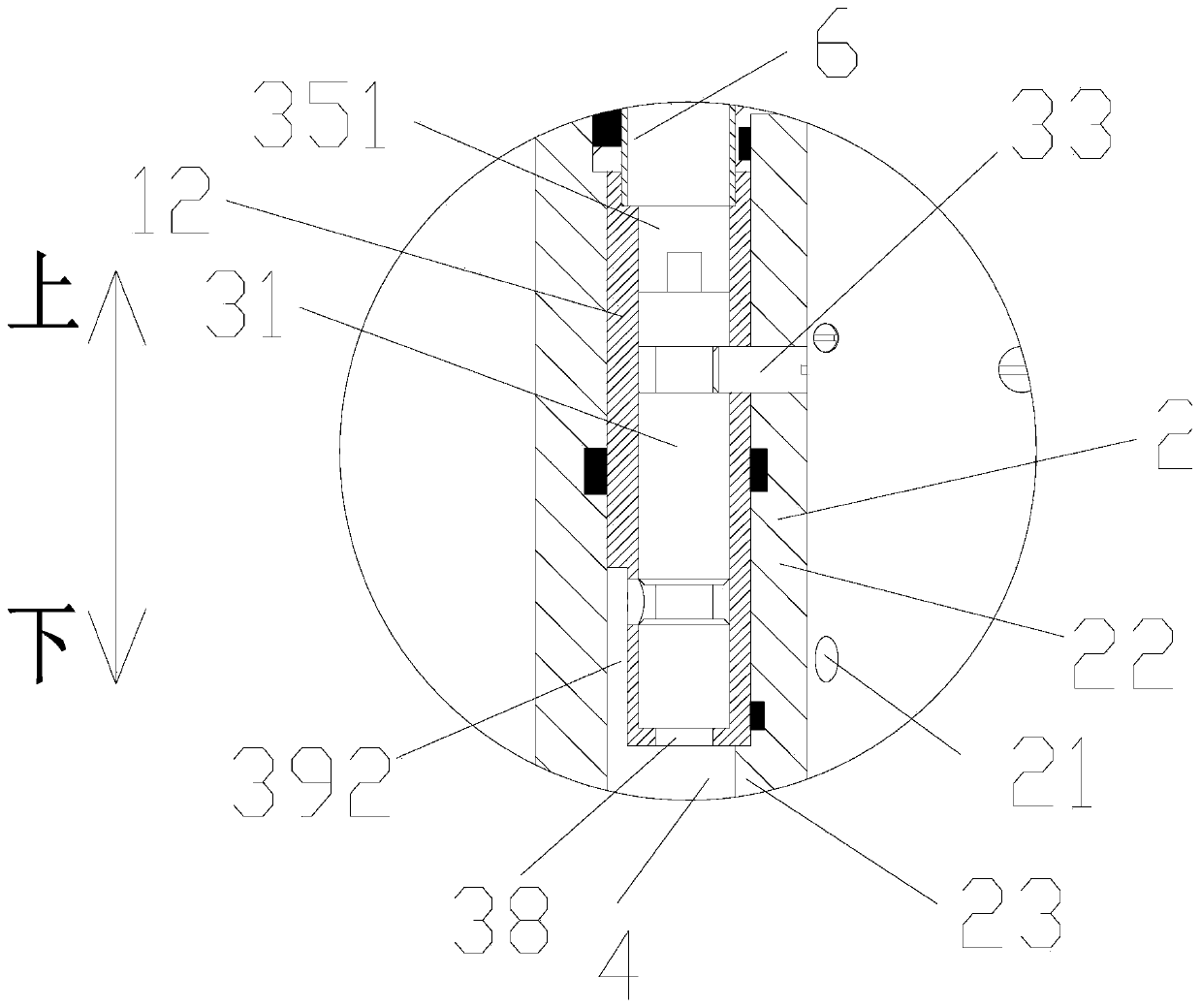

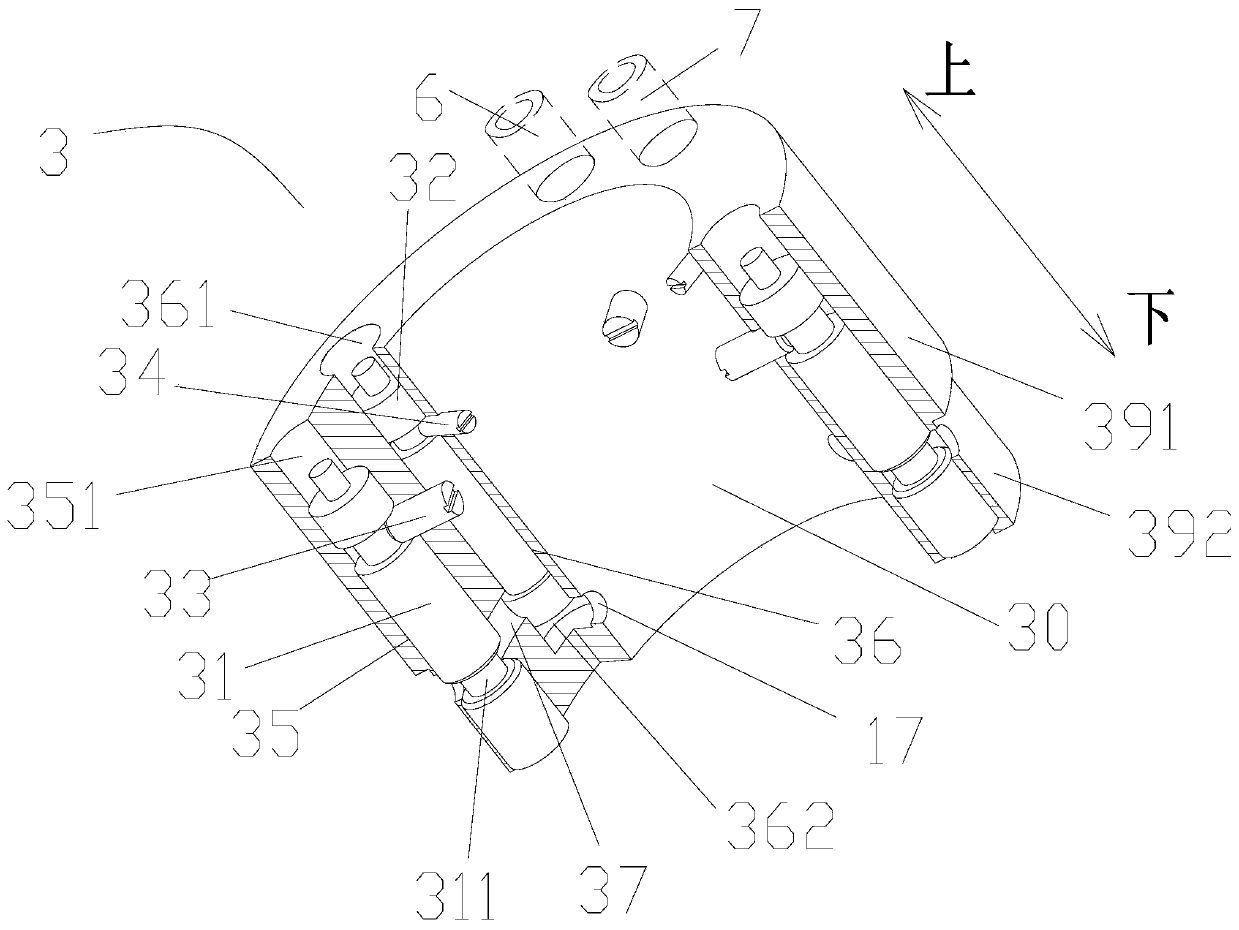

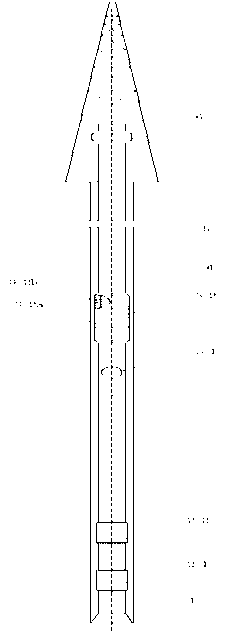

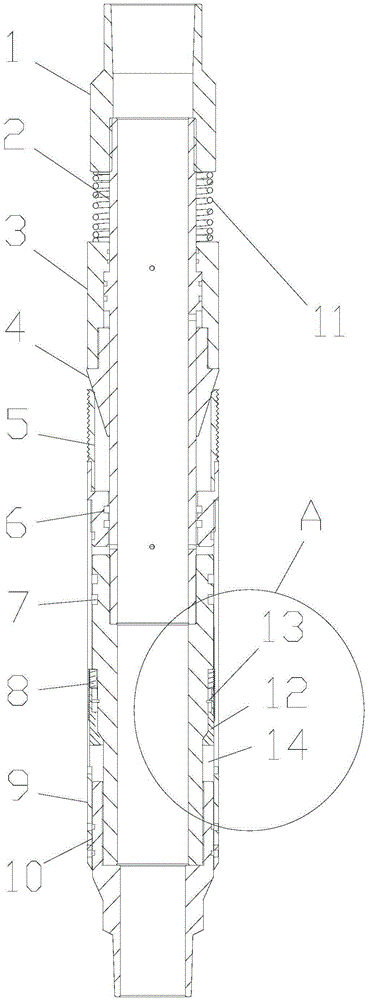

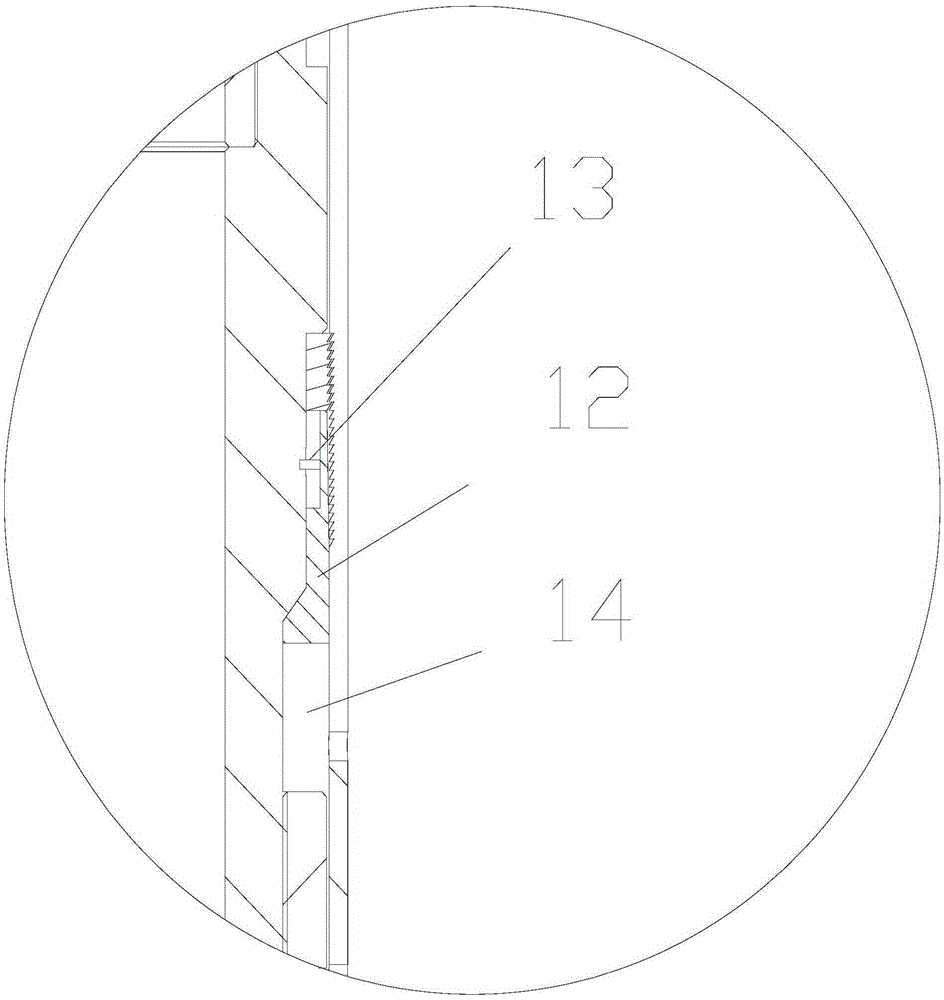

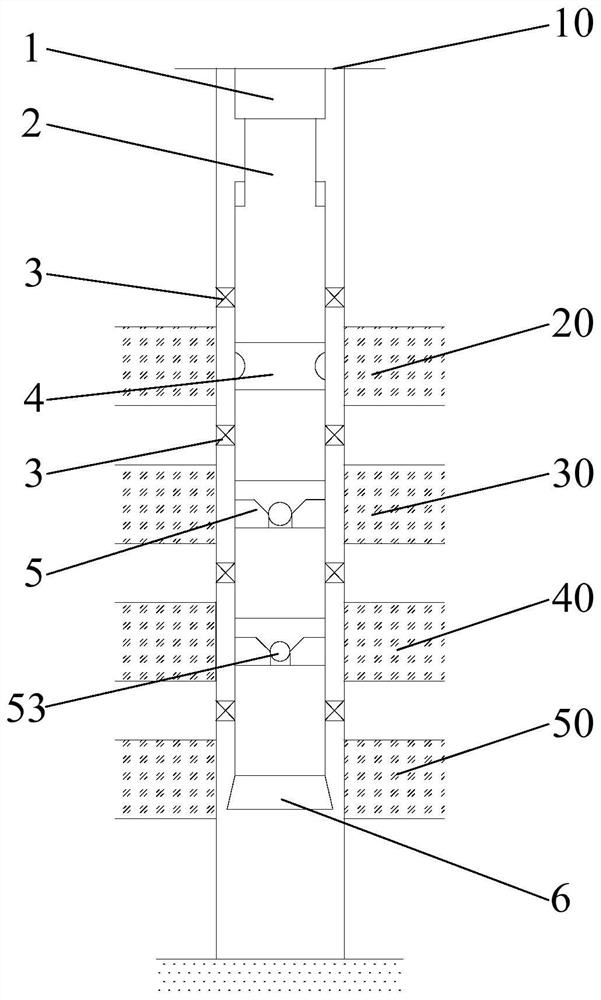

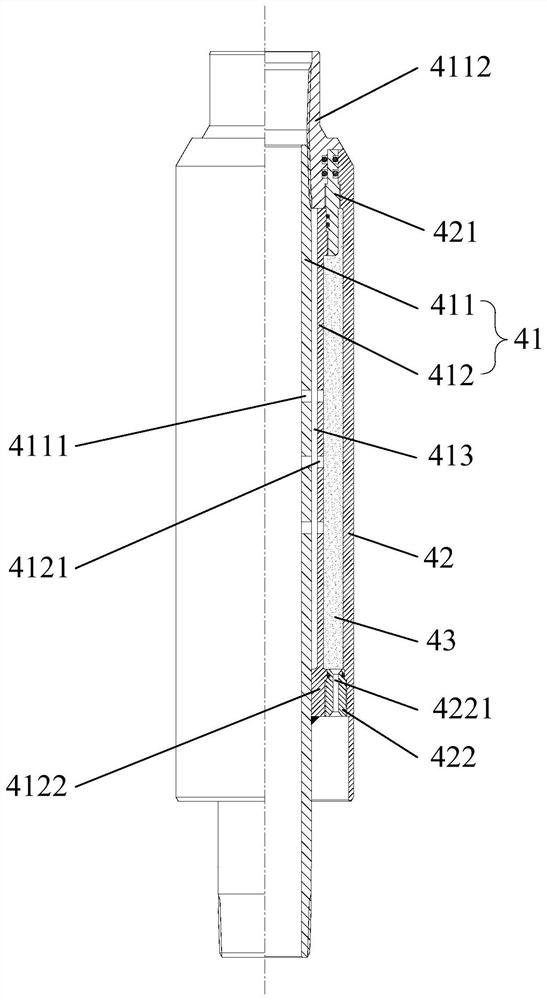

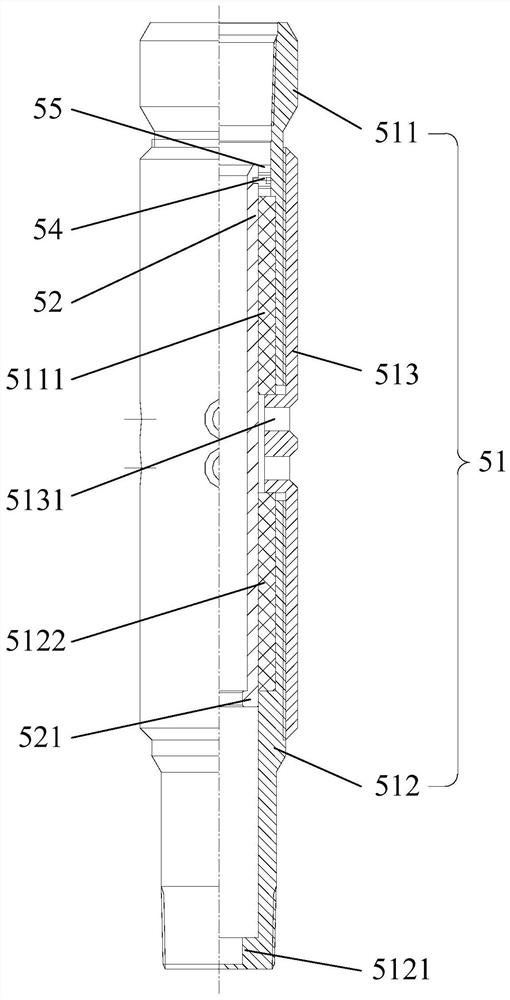

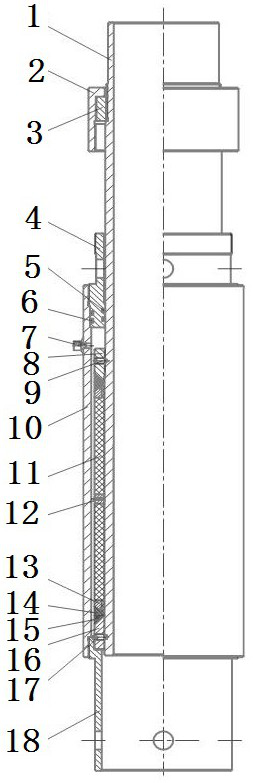

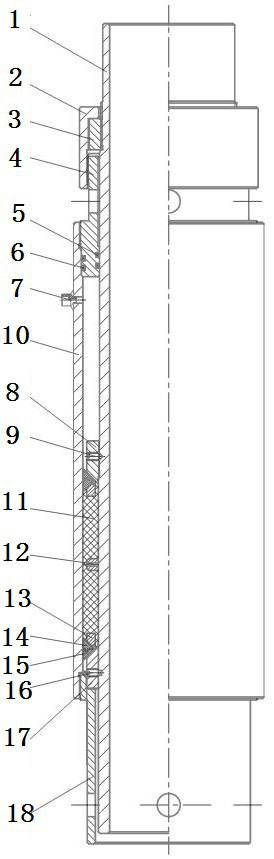

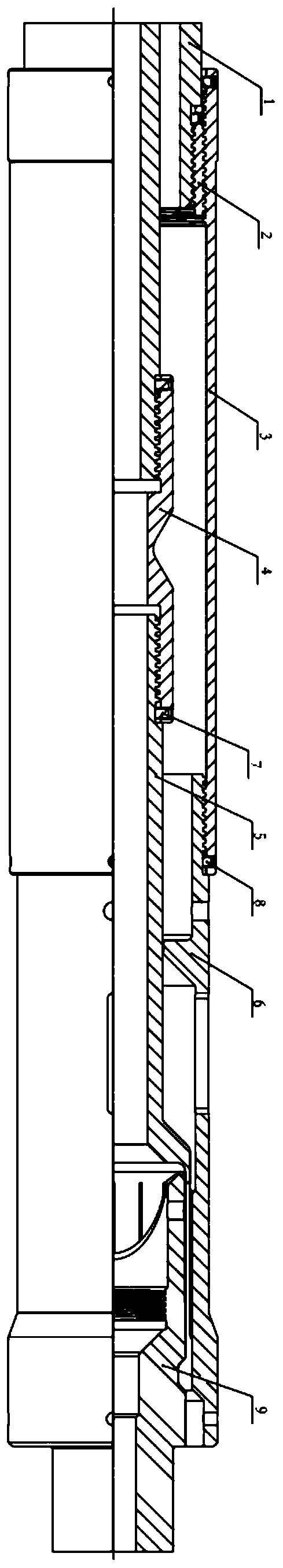

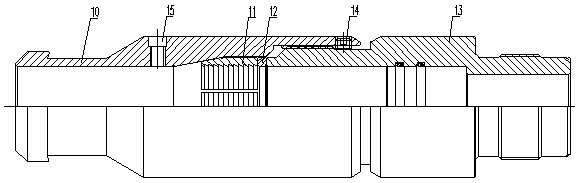

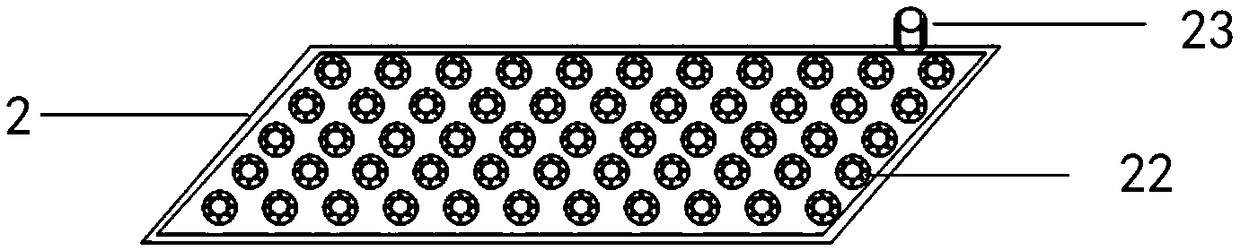

Packer for realizing infinite fracturing and working method thereof

PendingCN107605423AGood repeatabilityEasy to unpackFluid removalSealing/packingEngineeringMechanical engineering

The invention relates to a packer for realizing infinite fracturing and a working method thereof. The packer comprises a central pipe, a lining pipe and a sealing mechanism which are sequentially connected in a sleeving way from inside to outside, wherein the sealing mechanism comprises a piston, a sealing sleeve and a lower joint which are sequentially connected; sealing cavities are defined by the sealing mechanism on the outer side walls of the central pipe and the lining pipe; the sealing cavities are internally provided with locking ring sleeves and unsealing ring sleeves. According to the packer for realizing the infinite fracturing, disclosed by the invention, hydraulically controlled sealing and unsealing are realized by adopting a novel mechanism; a traditional sealing pin and a traditional unsealing pin are prevented from being used, repeated sealing and unsealing of the packer are facilitated, and the infinite fracturing is further realized; the stability of the packer is increased to a large extent, and the production efficiency of a whole fracturing process is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

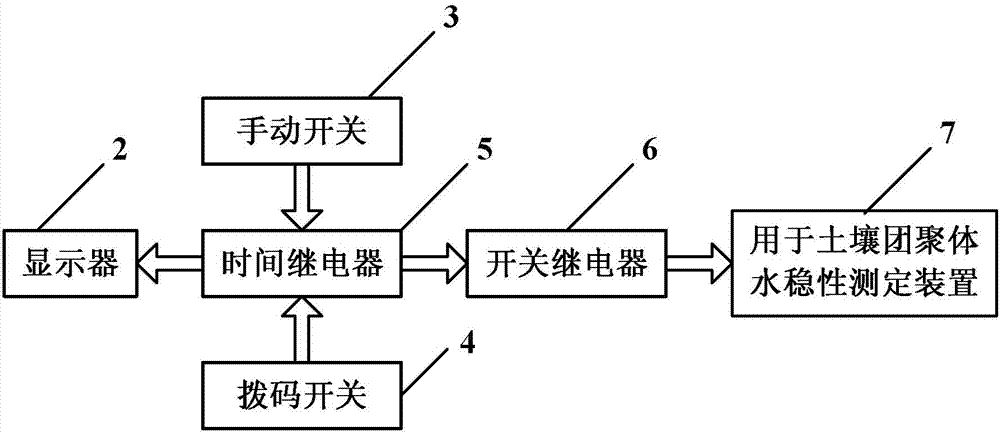

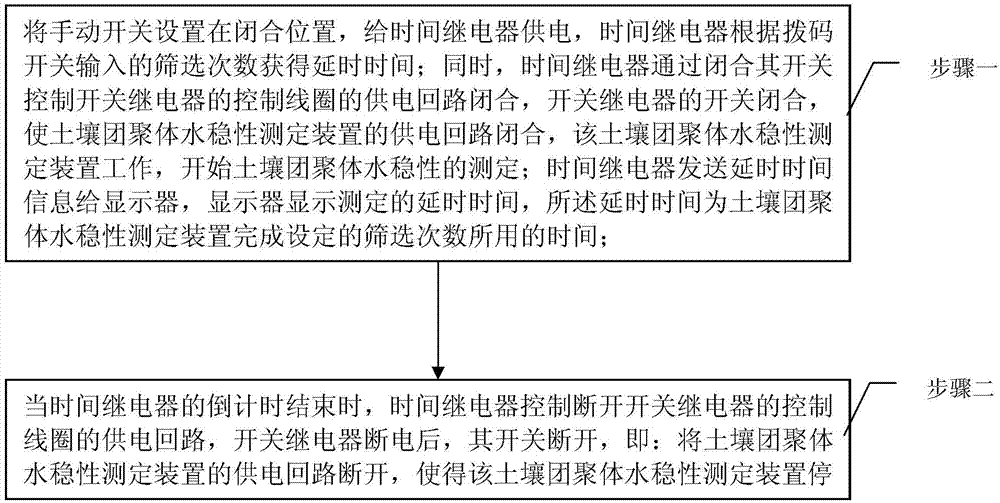

Device and method for controlling screening times for soil aggregate water-stability measuring device

The invention relates to a controller and a control method for a measuring device, in particular to a device and a method for controlling the screening times for a soil aggregate water-stability measuring device. The invention solves the problem in the conventional soil aggregate water-stability measuring device that the screening times cannot be controlled through an external device. A manual switch is connected in a powder supply circuit of a time relay in series for controlling the on / off of a power supply of the time relay; a toggle switch outputs a screening times signal to the time relay, the time relay sends a delay time signal to a display for displaying the remaining time, and a switch of the time relay is connected in a power supply circuit of a control coil of a switch relay in series for controlling the start or the stop of the switch relay; and a switch of the switch relay is connected in a power supply circuit of a soil aggregate water-stability measuring device in series for controlling the start or the stop of the soil aggregate water-stability measuring device. The device and the method can be widely used for controlling the screening times for the soil aggregate water-stability measuring device.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

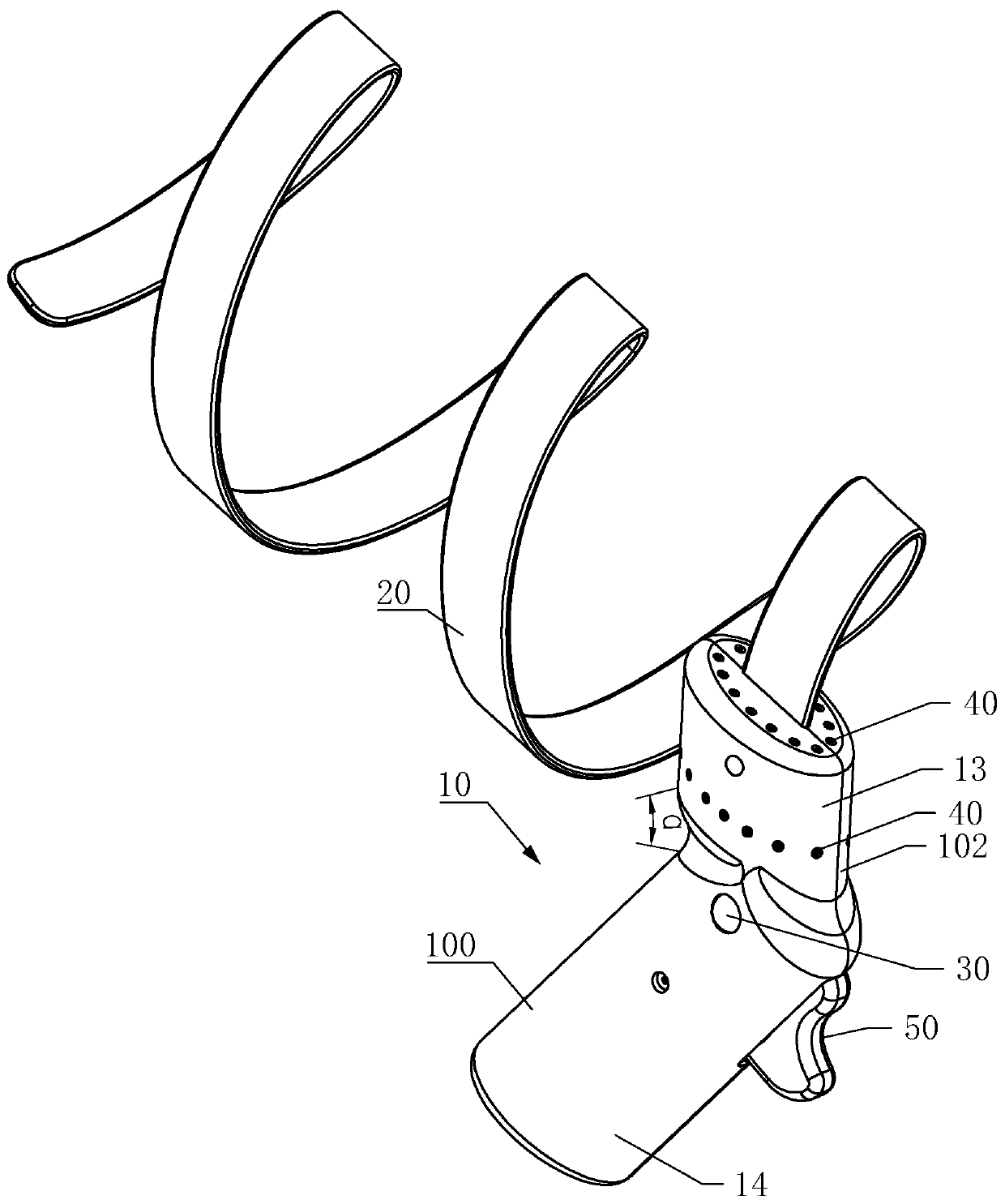

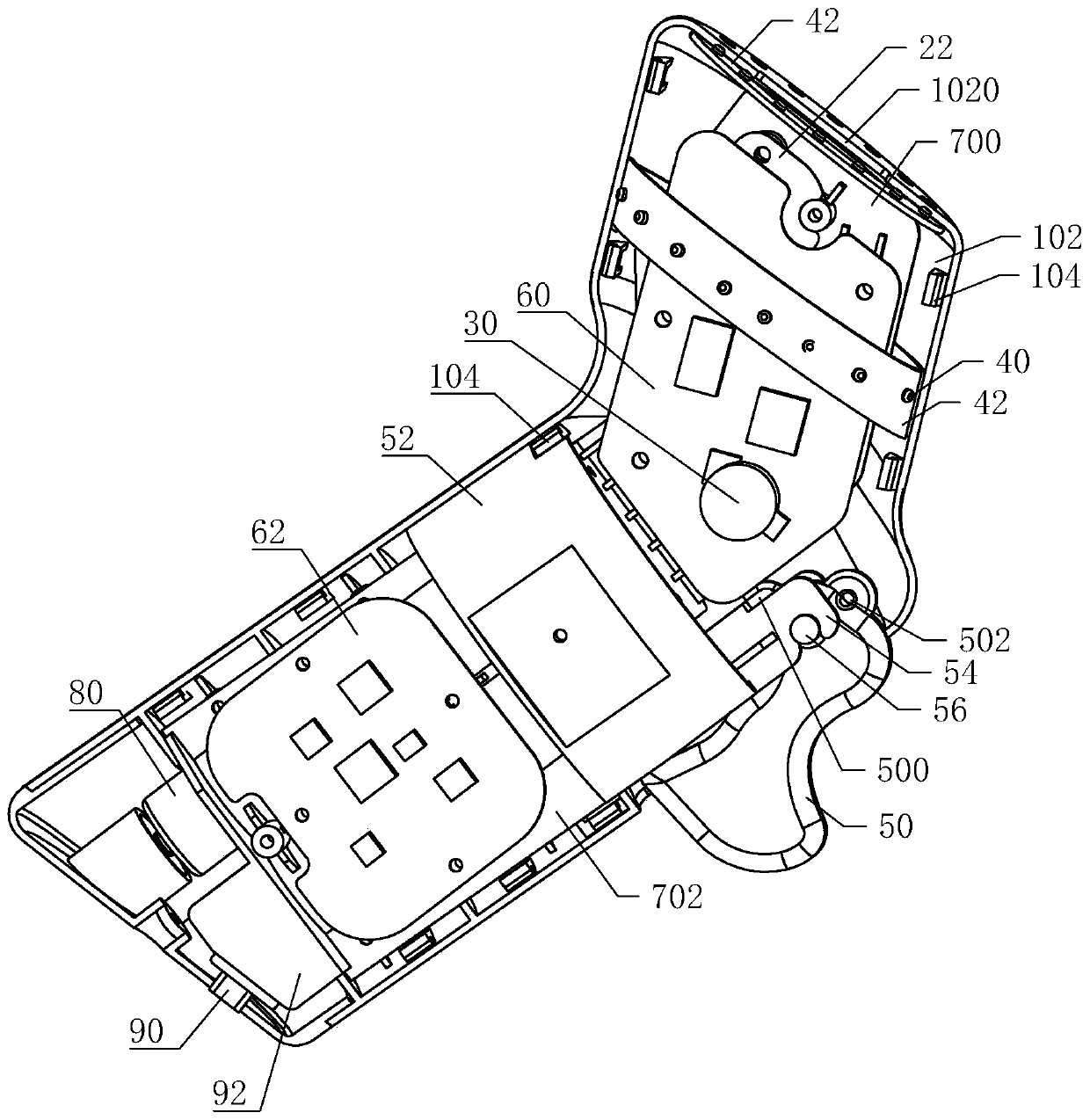

Game control device

The invention discloses a game control device. The device comprises a main body used for being held, a bandage, a key component, a vibration motor and a plurality of LED lamps; when in use, the main body is fixed through winding the bandage on an arm, so that the main body is prevented from dropping down after a user loosens grip during an experience process, and thus user experience is enhanced;meanwhile, the handle is matched with head-mounted equipment with the aid of the LED lamps and the key component, to set a game scene and select environment variables; the vibration motor also can form force feedback, and thus validity of the user experience of virtual environment can be further improved in combination with audio of the head-mounted equipment.

Owner:GEER TECH CO LTD

Intellectualized grain drier

InactiveCN103371222AReduce manufacturing costSolve the installationSeed preservation by dryingProgramme control in sequence/logic controllersControl systemProgrammable logic controller

The invention discloses an intellectualized grain drier. The intellectualized grain drier comprises a grain drier mechanical part, a drier control system and a moisture meter, wherein the drier control system comprises an integrated circuit board inside the drier control system, and the moisture meter comprises a sensor part and a host machine control part which are of an integrated structure. The intellectualized grain drier is further characterized in that the host machine control part of the moisture meter comprises a communication chip; a host machine control plate of the grain drier comprises a communication module sharing a free protocol with the communication chip inside the host machine control part of the moisture meter; the integrated circuit board of the grain drier is controlled by a PLC (Programmable logic Controller). The intellectualized grain drier solves the problems, caused by a split structure, such as installation and wiring troubles, large size and great failure judgment difficulty; the communication chip of the moisture meter and the host machine control plate of the grain drier use free protocol communication, and the integrated circuit board of the grain drier is controlled by the PLC, so that intellectualized control of the grain drier can be realized.

Owner:JIANGSU TIANYU AGRI MACHINERY

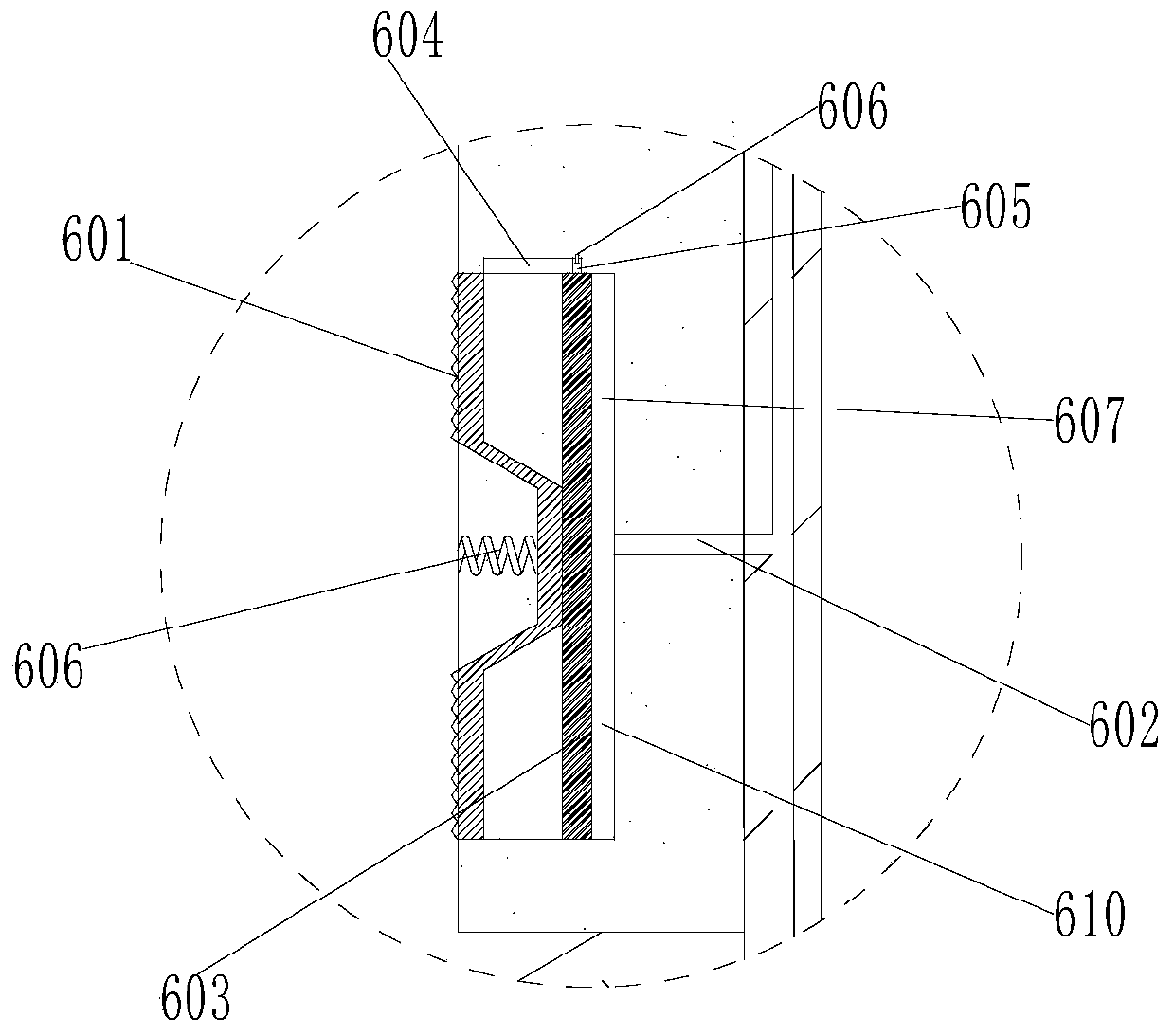

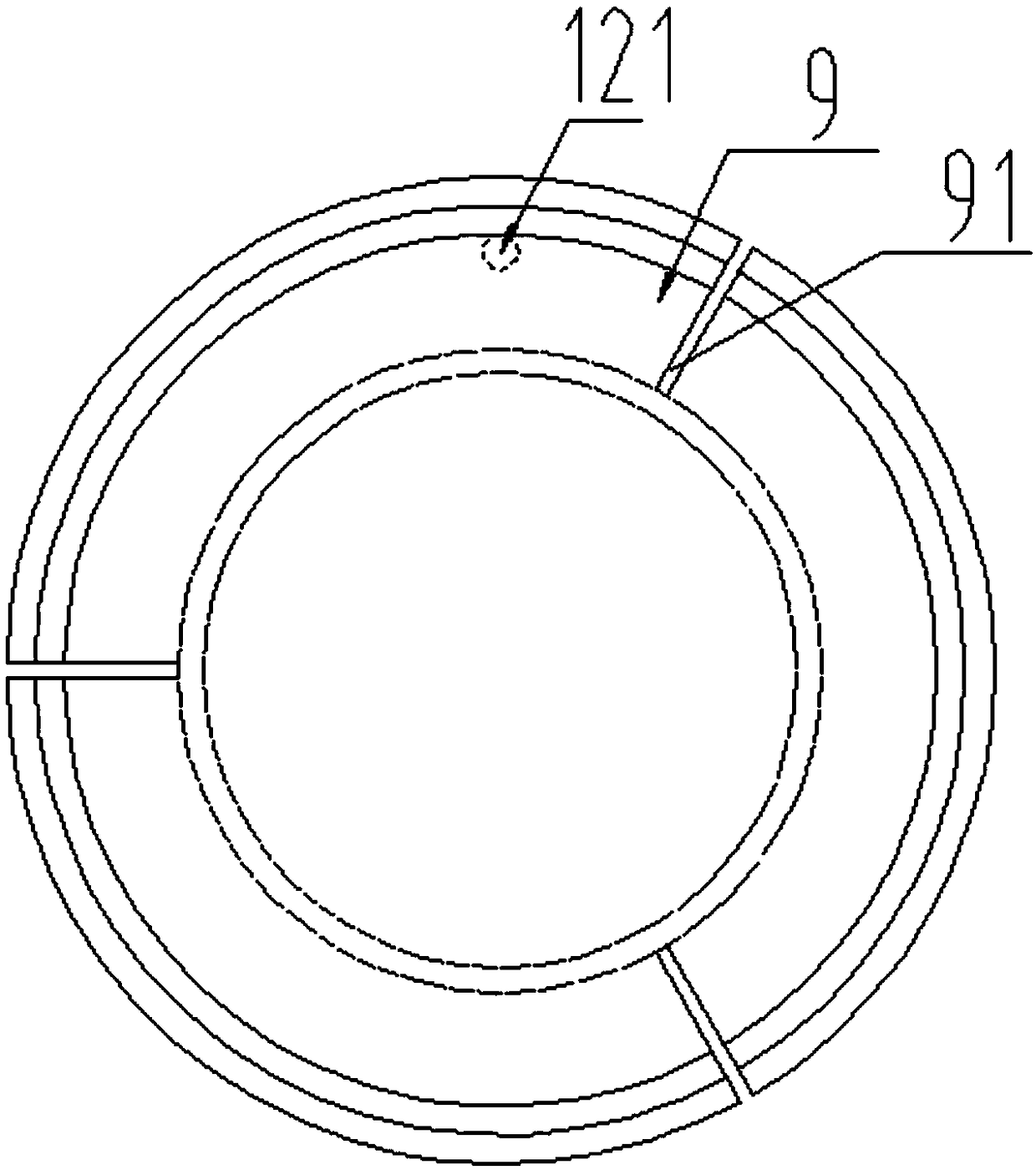

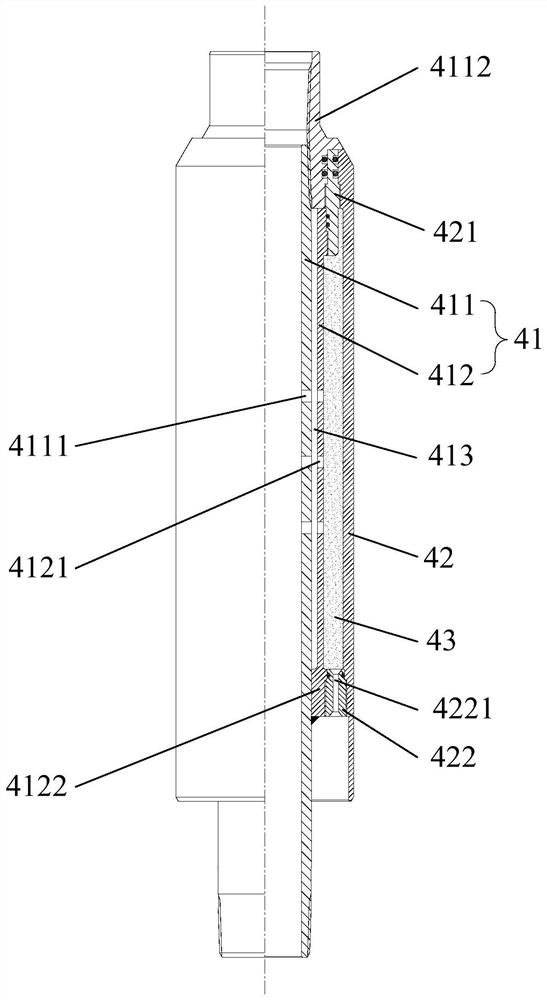

High-temperature and high-pressure resistant multi-stage fracturing acidizing packer

ActiveCN110043216AImprove high temperature resistanceEven by forceFluid removalSealing/packingHigh pressureOil pressure

The invention discloses a high-temperature and high-pressure resistant multi-stage fracturing acidizing packer which comprises a central pipe, a setting assembly, a clamping assembly and a heat dissipation assembly. The setting assembly completes setting under the action of oil pressure, the clamping assembly is positioned on the lower part of the central pipe and is used for preliminarily fixingthe relative positions of the central pipe and an oil pipeline, and the heat dissipation assembly is arranged on the outer wall of the setting assembly and absorbs heat for cooling in a high-temperature state. The anti-high-temperature and high-pressure multi-stage fracturing acidizing packer has the beneficial effects of bidirectional clamping, high-temperature heat dissipation and multi-radius floating ball oil resistance.

Owner:淮安市井神钻采机具有限公司

A plunger expansion packer

The invention relates to the technical field of oil and gas well drilling, well completing, well cementing or well logging, in particular to a plunger type expansion packer. The two ends of an expansion tube are fixedly connected with an upper casing and a lower casing correspondingly. The two ends of a central tube are fixedly connected with the upper casing and the lower casing correspondingly.A starting valve core is fixed in a starting cylindrical cavity through a starting nail. A plugging valve core is fixed in a plugging cylindrical cavity through a plugging nail. A flow inlet hole penetrating through the central tube communicates with an inner cavity of the central tube and the starting cavity. The lower end of the plugging cylindrical cavity is provided with a through hole communicating with an expansion cavity. A middle channel penetrates through the side wall of the plugging cylindrical cavity and communicates with the starting cavity and the expansion cavity. A plugging opening and a starting opening are formed in the side wall of the plugging cylindrical cavity and the side wall of the starting cylindrical cavity correspondingly. A starting valve covers the starting opening when the starting valve core is fixed by the starting nail. The middle channel is unblocked when the plugging valve core is fixed by the plugging nail. After the plugging nail is broken, the plugging valve core can move to cover the plugging opening, and plugging performance is good.

Owner:SOUTHWEST PETROLEUM UNIV

Hydraulic excavator intelligent ground levelling device and control method thereof

InactiveCN110230334AAchieve self-regulationRealize settingSoil-shifting machines/dredgersElectricityControl theory

The invention discloses a hydraulic excavator intelligent ground levelling device and a control method thereof. A controller of the intelligent ground levelling device is electrically connected with an instrument and a ground levelling module; and a moving arm cylinder position sensor, a bucket arm cylinder position sensor, a bucket cylinder position sensor, a moving arm ascending electromagneticvalve, a moving arm descending electromagnetic valve, a bucket rod external swinging electromagnetic valve, a bucket rod adduction electromagnetic valve, a bucket external swinging electromagnetic valve, a bucket adduction electromagnetic valve and a ground levelling operating switch are electrically connected with the ground levelling module separately. According to the hydraulic excavator intelligent ground levelling device, through modularized configuration of the intelligent ground levelling function, self adjustment of the bucket angle is realized, setting of the external swinging angle is realized and the self learning of the ground levelling function is realized; and through the ground levelling switch, automatic ground levelling is realized, and both automatic adduction ground levelling and automatic external swinging ground levelling are realized.

Owner:XCMG EXCAVATOR MACHINERY

Drill string equipped with downhole blowout preventer and working method thereof

Owner:SOUTHWEST PETROLEUM UNIV

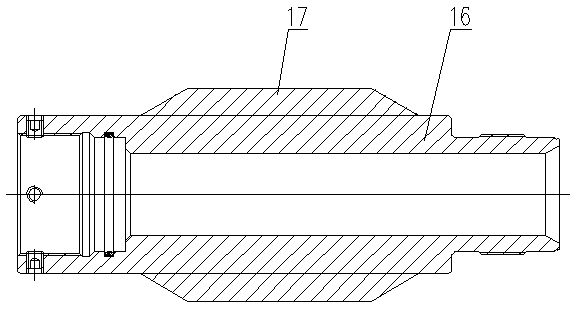

Hydraulic tubing anchor

The invention relates to the technical field of oil field oil well drilling and production, in particular to a hydraulic tubing anchor. The hydraulic tubing anchor comprises an upper connector, a center pipe, an upper piston, a cone, a slip, a slip seat, lower pistons, a horse thread ring, a horse thread barrel, a lower connector and a spring. The upper connector is fixed to the upper portion of the center pipe, the spring is located between the upper piston and the upper connector and connected to the center pipe in a sleeving mode, the lower portion of the slip is matched with the slip seat, the periphery of the slip seat is connected with the upper portion of the horse thread barrel, and the horse thread ring is arranged between the lower piston and the horse thread barrel. A floating block is arranged between the lower pistons, inclined threads matched with the horse thread barrel are arranged on the horst thread ring and the floating block respectively, the floating block is connected with the lower pistons through shear pins, and the lower connector is connected with the lower portions of the lower pistons. The device has a one-way locking function, that is, in the upward moving process of the slip, the lower portion is fixed through the inclined threads, and the clamp is effectively prevented from loosening.

Owner:TIANJIN HUIZHU PETROLEUM EQUIP SCI & TECH CO LTD

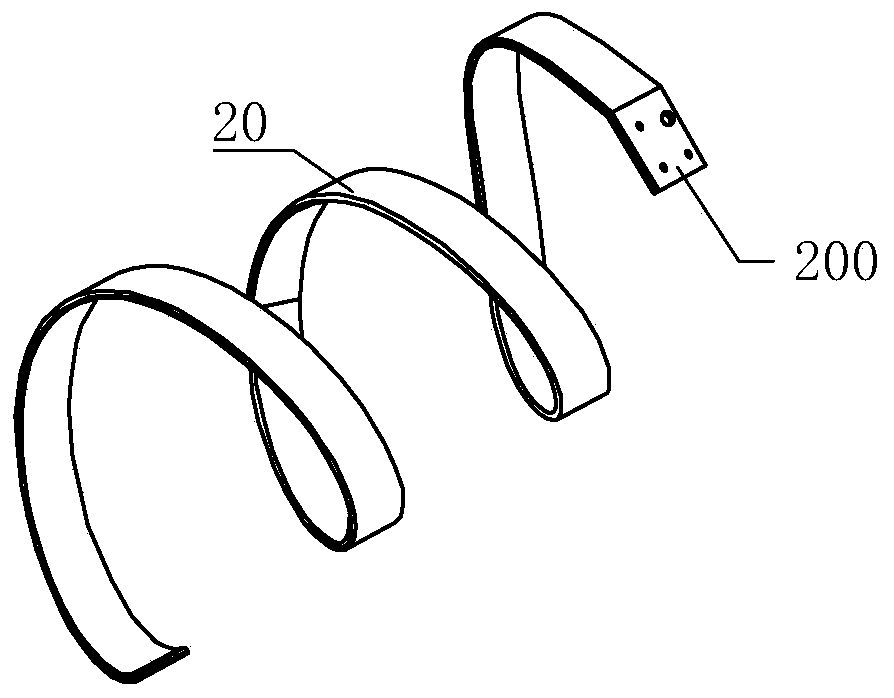

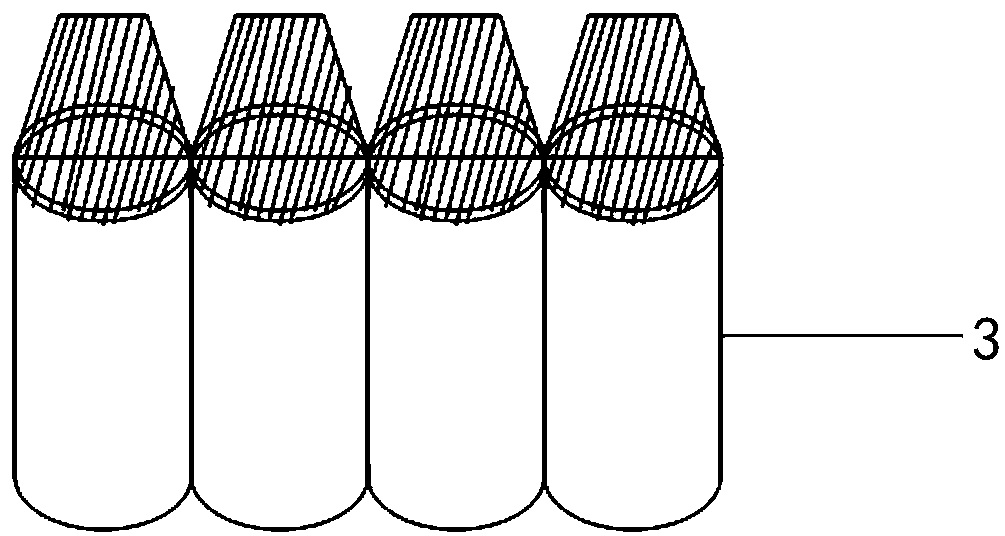

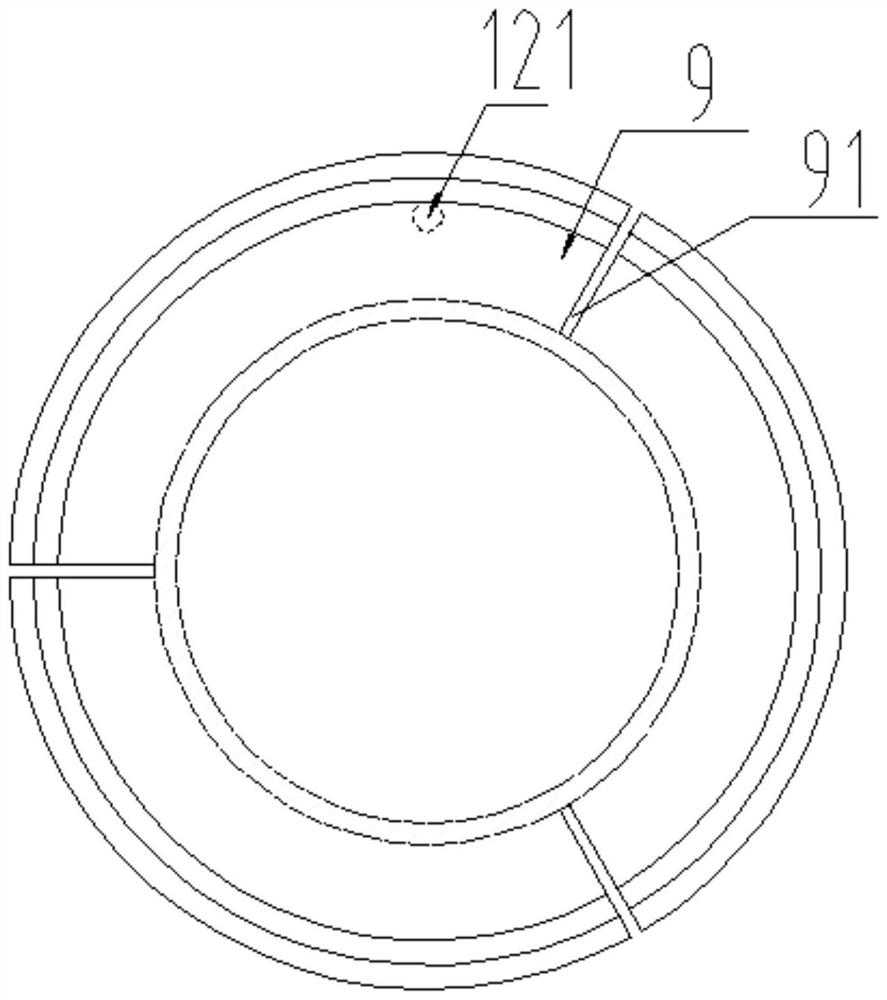

Elastic sieve pipe and sand prevention pipe column

The invention discloses an elastic sieve pipe and a sand prevention pipe column. The elastic sieve pipe comprises a central slotted sieve pipe, a pressure transmitting piece, a supporting cylinder sleeve, a reset mechanism, and an outer-layer slotted sieve pipe; the outer side of the upper end of the central slotted sieve pipe is fixed to the lower end of an upper joint through a central sieve pipe coupling, a control pin and an upper cylinder body, and the lower end of the central slotted sieve pipe is fixedly connected with the upper end of a lower joint; the pressure transmitting piece is arranged outside the central slotted sieve pipe in a sleeving mode, and an upper expansion mechanism and a lower expansion mechanism are arranged at the two ends of the pressure transmitting piece correspondingly; the supporting cylinder sleeve and the reset mechanism are arranged between the lower expansion mechanism and the lower joint; the two ends of the outer-layer slotted sieve pipe are positioned through sieve pipe protecting sleeves, and the middle of the outer-layer slotted sieve pipe is matched with the upper expansion mechanism and the lower expansion mechanism; and when the pipe column is tripped, the control pin is sheared off, the gravity of the pipe column is transmitted to the upper expansion mechanism and the lower expansion mechanism, and thus the elastic sieve pipe is set. According to the elastic sieve pipe and the sand prevention pipe column, it can be ensured that set sand is basically avoided in a wellbore, the good sand prevention effect is achieved, the pump inspection cycle is effectively prolonged, meanwhile, during using, tripping and salvaging operation is easy and convenient, safety and reliability are achieved, and the cost is low.

Owner:PETROCHINA CO LTD

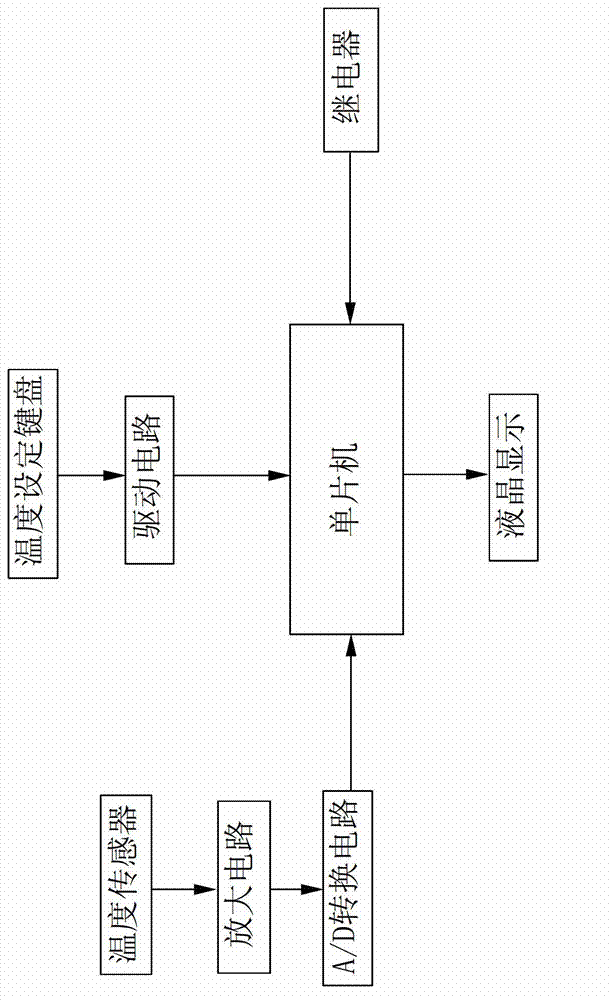

Novel electric blanket

InactiveCN103110309AEasy to useHigh degree of automationSleeping rugTravelling rugAuto regulationTemperature control

The invention discloses a novel electric blanket which comprises an electric blanket body, a power supply, a low-voltage transformer and an automatic temperature control device. An input end of the transformer is connected with the power supply, an output end of the transformer passes a rectifier to be connected with the electric blanket body, and the automatic temperature control device is arranged in the electric blanket body and used for automatically controlling and regulating temperature of the electric blanket so as to close the electric blanket automatically. By the low-voltage transformer, high-voltage power supply of a traditional electric blanket is converted into low-voltage supply, so that the electric blanket is safer and more reliable in use. The automatic temperature control device arranged on the electric blanket body is capable of setting and automatically regulating and controlling the temperature of the electric blanket, when dangerous situations occur, an alarm is given automatically, the power supply of the electric blanket is cut off, and accordingly automation degree of the electric blanket is effectively improved. Besides, the novel electric blanket has the advantages of simple structure, high automation degree, safety and reliability.

Owner:张美沛

Multistage delay steam injection string

ActiveCN111980648ARealize layered and quantitative steam injectionImprove steam injection efficiencyFluid removalWell/borehole valve arrangementsThermodynamicsEngineering

The invention provides a multistage delay steam injection string. The multistage delay steam injection string comprises a delay steam injection assembly and at least one layered steam injection assembly which are sequentially arranged from top to bottom, wherein the delay steam injection assembly comprises a delay steam injection valve and two upper packers, the delay steam injection valve comprises an inner barrel and an outer sleeve, a steam injection annulus is formed between the outer sleeve and the inner barrel, steam inlet holes communicating with the steam injection annulus is formed inthe side wall of the inner barrel, steam outlet holes communicating with the steam injection annulus is formed in the side wall of the outer sleeve, and the steam injection annulus is filled with gelcapable of blocking the steam inlet holes and the steam outlet holes; and the layered steam injection assembly comprises a layered steam injection valve and a lower packer, the layered steam injection valve comprises a valve body, a sliding sleeve and a throwing ball, a steam injection hole are formed in the side wall of the valve body, the sliding sleeve is provided with a first position for blocking the steam injection hole and a second position for communicating the steam injection hole with the interior of the valve body, and the throwing ball can be connected with the sliding sleeve in asealed mode and enables the sliding sleeve to move from the first position to the second position. According to the multistage delay steam injection string, layered quantitative steam injection of the multi-oil-layer unit is achieved, and the steam injection efficiency of a heavy oil well is improved.

Owner:PETROCHINA CO LTD

Edge computing method, medium and system for rotating equipment monitoring

ActiveCN110530507BIntegrity guaranteedLow costSubsonic/sonic/ultrasonic wave measurementVibration amplitudeServer

The invention relates to an edge computing method, medium and system for rotating equipment monitoring, belonging to the field of equipment fault monitoring. The method includes the following steps: 1) using an edge computing unit to preprocess the collected vibration signal of the rotating equipment; the preprocessing process includes: A. calculating the pass frequency value of the vibration signal according to the vibration signal; B. performing the vibration signal in the frequency domain Convert, divide the converted frequency-domain vibration signal into several narrow-band signals; C. Perform inverse Fourier transform on each narrow-band signal to obtain the time-domain signal of each narrow-band, and obtain the corresponding vibration amplitude of each narrow-band signal ; D. Determine whether the pass frequency value and the vibration amplitude value of each narrow band exceed the standard, and generate equipment status information according to the judgment result; 2) Transmit the characteristic data to the cloud server. The invention converts the collected vibration waveform data of the rotating equipment into characteristic data and transmits it to the cloud server, thereby reducing the cost of network transmission and taking into account the integrity of the transmission information.

Owner:郑州恩普特科技股份有限公司 +1

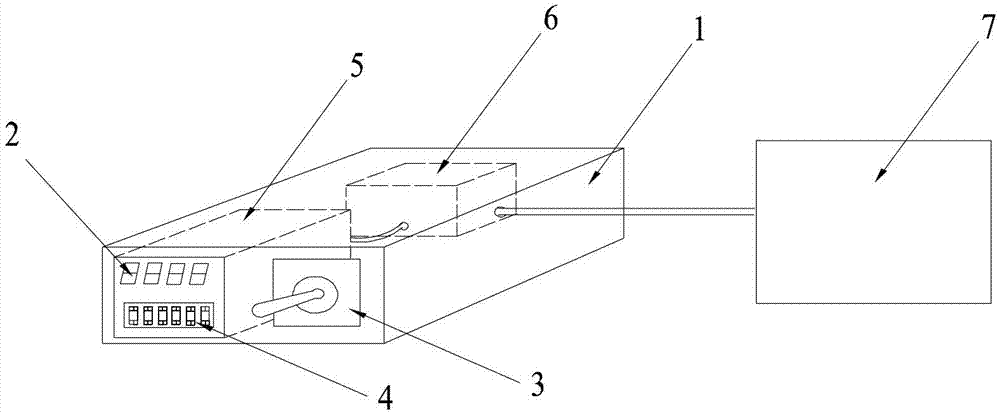

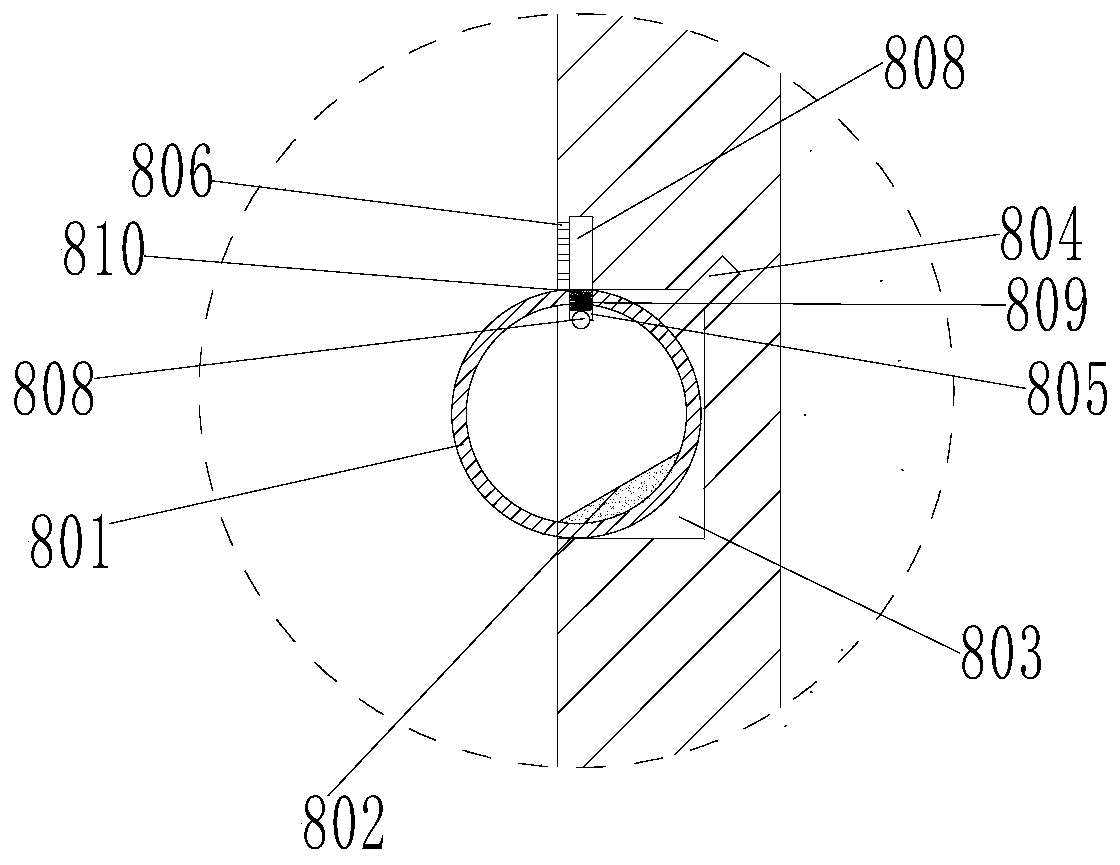

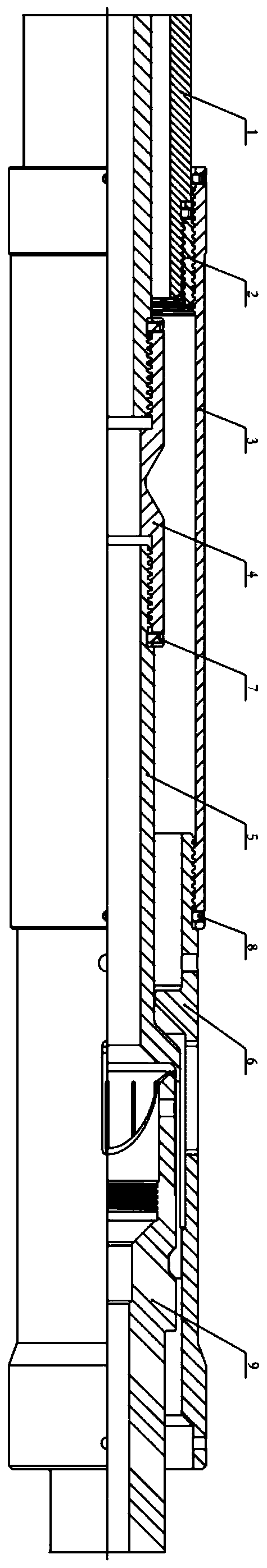

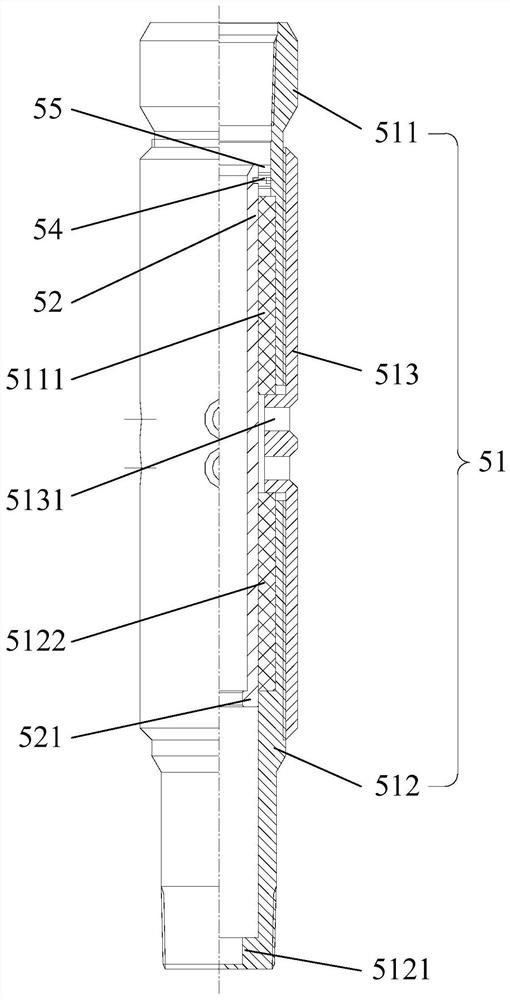

Packer test device and use method

ActiveCN109799081BRealize settingEasy to operateMachine part testingTest rigElectrical and Electronics engineering

The invention discloses a packer test device and an application method thereof. The packer test device comprises a center tube, a limiting threaded sleeve, a connection threaded sleeve, a sealing ring, a shell, an injection head, a push barrel and a packer; the packer comprises a fixing threaded sleeve, a rubber barrel, a spacer ring, a pressure ring, a male expander ring, a female expander ring and a sliding sleeve; the fixing threaded sleeve is fixed to the center of the center tube; the sliding sleeve is fixed to the lower end of the center tube through a shear pin; the limiting threaded sleeve is arranged at the upper portion of the center tube; the sealing ring is positioned between the limiting threaded sleeve and the fixing threaded sleeve; the upper end of the shell is fixedly connected with the sealing ring; the lower end of the shell is connected with the push barrel; the injection head is positioned on the shell; the injection head is in clearance communication with the sealing ring and the fixing threaded sleeve; the connection threaded sleeve is positioned in the limiting threaded sleeve. The packer test device allows pressure test to be quickly carried out for normaltemperature and high temperature packers; setting activation force, setting travel and setting force can be tested for a packer; the local structures, such as the packer structure and inner diameter of the shell, can be changed separately to carry out testing.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

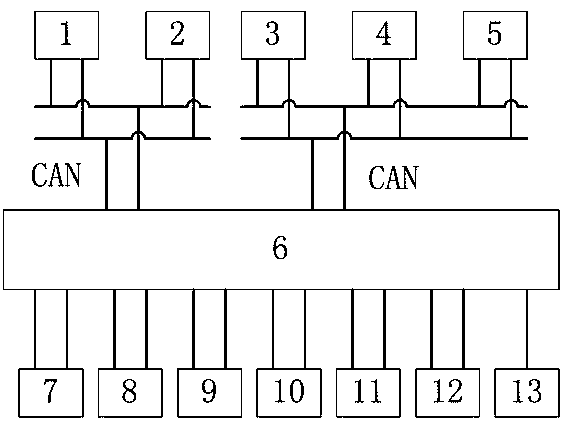

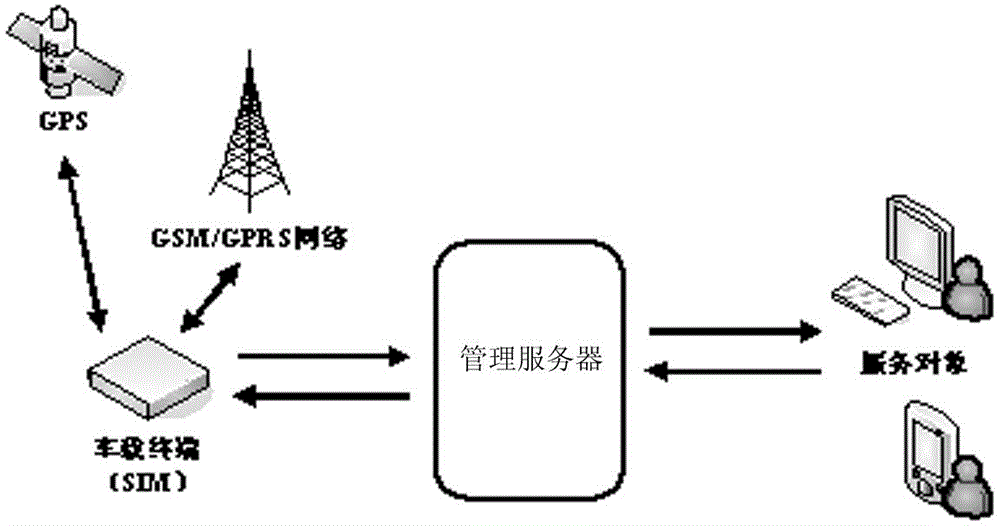

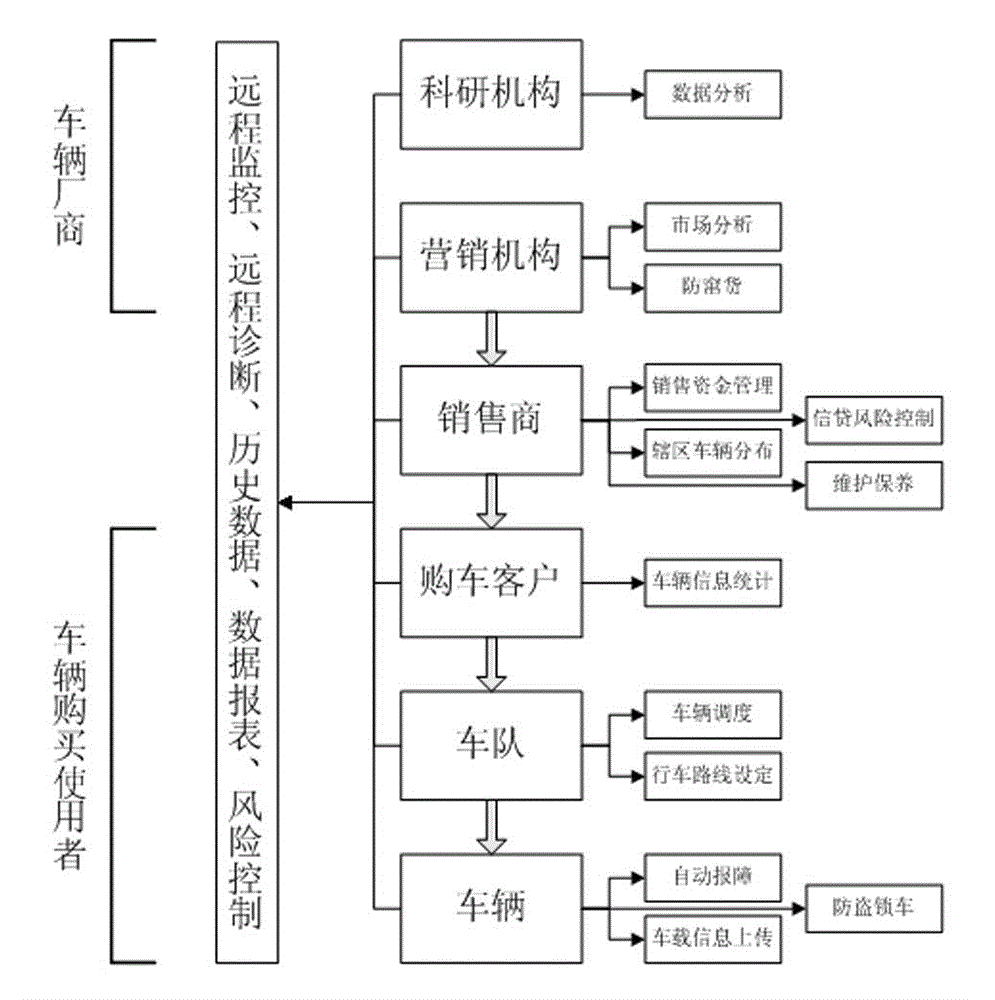

A vehicle information remote management and service system and its implementation method

ActiveCN102394918BImprove management qualityReduce riskElectric testing/monitoringTransmissionComputer moduleData acquisition

The invention provides a vehicle information remote management and service system and a realization method thereof, relating to a remote management service of vehicle information, especially relating to a system which provides a corresponding service for users of different levels in different links of a vehicle life period. The vehicle information remote management and service system comprises a global positioning system (GPS), a vehicle information terminal, a management server and a client terminal. The vehicle information terminal is installed in a vehicle and comprises a GPS module, a vehicle data reception module and a communication module. With the vehicle information terminal as a center, the following three networks are formed: a GPS data acquisition network which is formed by the GPS module in the vehicle terminal and a positioning satellite, a vehicle data acquisition network which is formed by the vehicle data reception module in the vehicle terminal and a bus or sensor in the vehicle, and a wireless communication network which is formed by the communication module in the vehicle terminal and the management server at a center. The management server is provided at a management center, and the client terminal is installed in a computer or a mobile phone.

Owner:TIANZE INFORMATION IND

A residue-free release mechanism

Owner:诺斯石油工具(天津)有限公司

A stepless drag fracturing process in casing and fracturing tool string

ActiveCN107178354BEnsure safetyLocate the underground locationDrilling rodsFluid removalShale gasEnergy consumption

The invention relates to a casing differential-free dragging fracturing technology and a fracturing tool string and belongs to the field of oil-well underground operation. According to the invention, the steps of positioning in well, sealing, jetting holes, fracturing, circularly backwashing and unsealing pipe columns are adopted for performing multistage staged fracturing on unconventional hydrocarbon reservoirs, such as tight gas reservoirs and shale gas reservoirs, so that the problems that the present multistage staged fracturing technology is complex in process, a compression packer is drilled after the fracturing operation is completed, the process consumes long time, the cost is high and the stratum is easily polluted can be solved. The casing differential-free dragging fracturing technology can effectively reduce the construction energy consumption, has the advantages of no differential limitation, no limitation to fracturing layer interval, no requirement for drilling and shorter construction time and has positive popularizing significance in performing multistage staged fracturing on the unconventional hydrocarbon reservoirs, such as tight gas reservoirs and shale gas reservoirs.

Owner:荆州市赛瑞能源技术有限公司

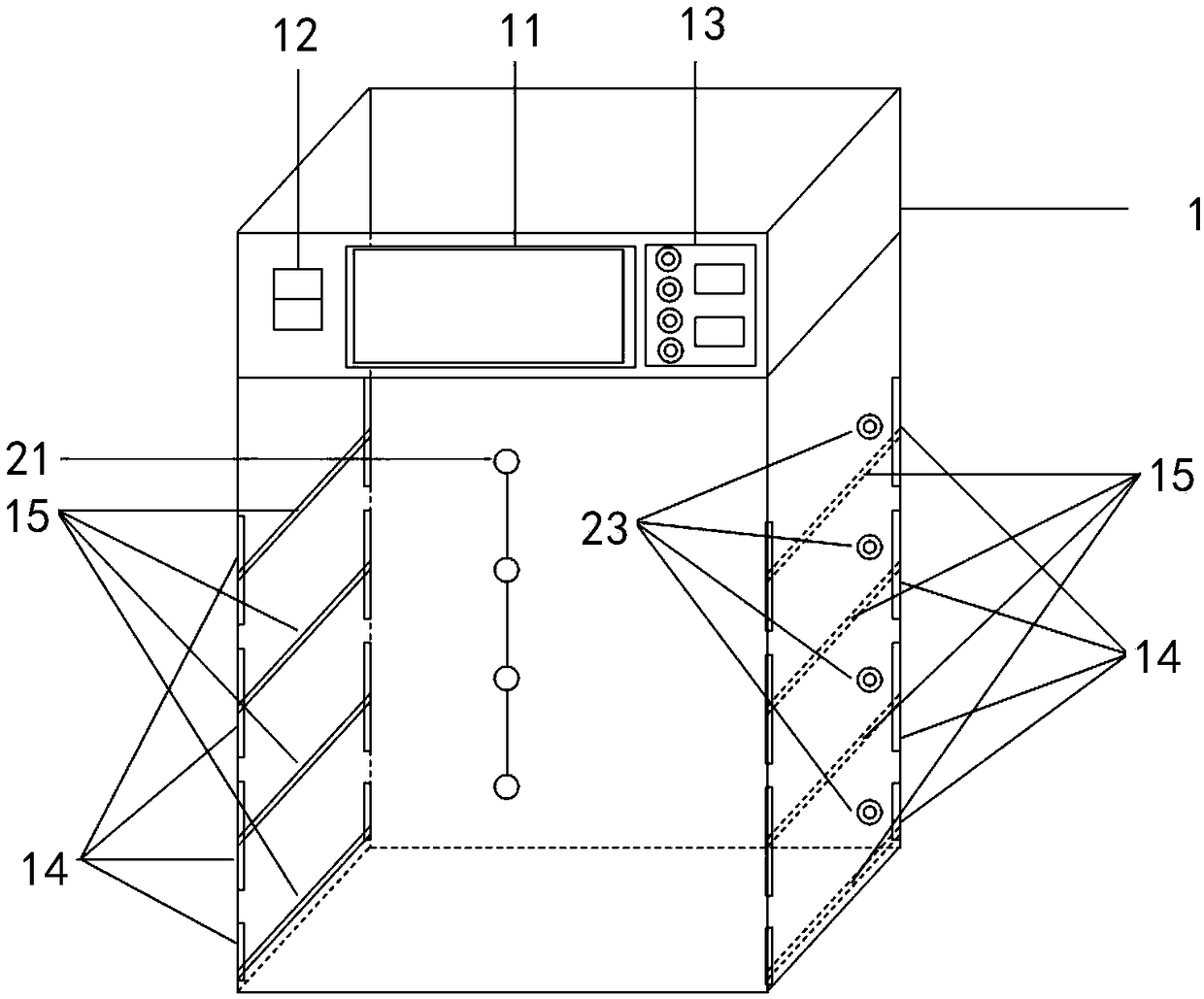

Adjustable type LED illumination experiment apparatus

PendingCN108353852ASimple structureReasonable designLight fasteningsSemiconductor devices for light sourcesControl systemOrganic matter

The invention provides an adjustable type LED illumination experiment apparatus which comprises a cabinet and a plurality of light source plates, wherein a control system is arranged in the cabinet and connected with a display screen, a switch key and a control key on the cabinet; the cabinet has an operation space, and a plurality of slots are formed in the operation space; the plurality of lightsource plates are detachably connected with the plurality of slots and divide the operation space into a plurality of separation spaces, a photoreceptor is arranged in each separation space, a plurality of LED beads are arranged on each light source plate and connected to an adaptor, and the adaptor is connected with the control system of the cabinet. According to the adjustable type LED illumination experiment apparatus, the apparatus can be used for LED illumination in the research processes of the influences to the tissue cells, microorganisms, organic matters, inorganic matters or the like to realize adjustment control and real-time observation of experiment parameters, and corresponding experiment spaces are provided.

Owner:HARBIN MEDICAL UNIVERSITY

Elastic screen and sand control string

Owner:PETROCHINA CO LTD

Multi-stage delayed steam injection string

ActiveCN111980648BRealize layered and quantitative steam injectionImprove steam injection efficiencyFluid removalWell/borehole valve arrangementsThermodynamicsEngineering

The present invention provides a multi-stage delayed steam injection pipe string, which includes a delayed steam injection assembly and at least one layered steam injection assembly arranged sequentially from top to bottom, and the delayed steam injection assembly includes a delayed steam injection valve and Two upper packers, the delay steam injection valve includes an inner cylinder and an outer casing, a steam injection annulus is formed between the outer casing and the inner cylinder, and a steam inlet hole connected with the steam injection annulus is provided on the side wall of the inner cylinder , the side wall of the casing is provided with a steam outlet hole connected with the steam injection annulus, and the steam injection annulus is filled with gel that can block the steam inlet and outlet holes; the layered steam injection component includes a layered injection The steam valve and the lower packer, the layered steam injection valve includes a valve body, a sliding sleeve and a throwing ball. The side wall of the valve body is provided with a steam injection hole, and the sliding sleeve has a first position for blocking the steam injection hole and makes the steam injection hole In the second position communicated with the inside of the valve body, the throwing ball can be sealingly connected with the sliding sleeve and move the sliding sleeve from the first position to the second position. The invention realizes layered and quantitative steam injection of multi-oil layer units, and improves the steam injection efficiency of heavy oil wells.

Owner:PETROCHINA CO LTD

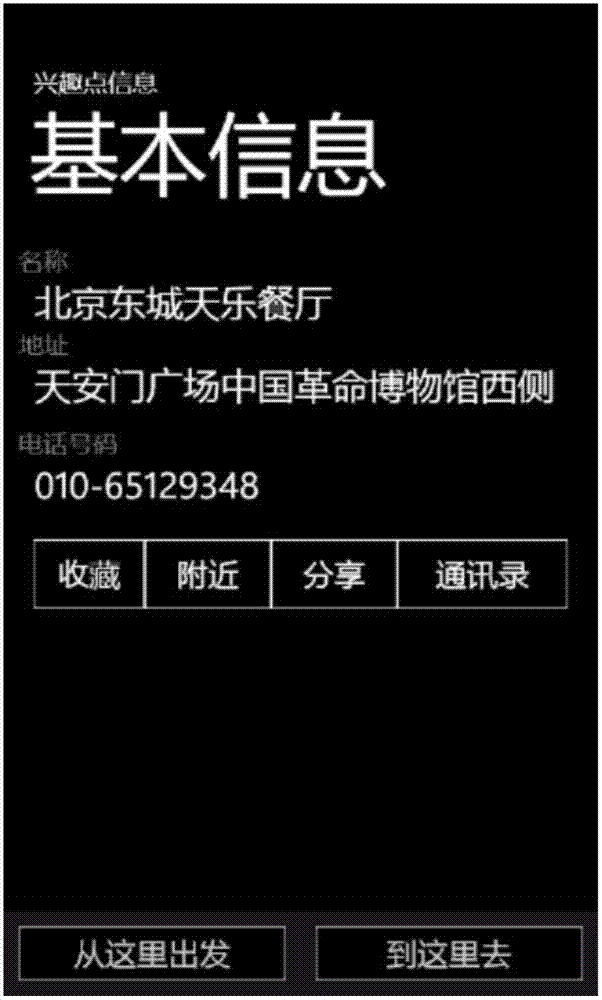

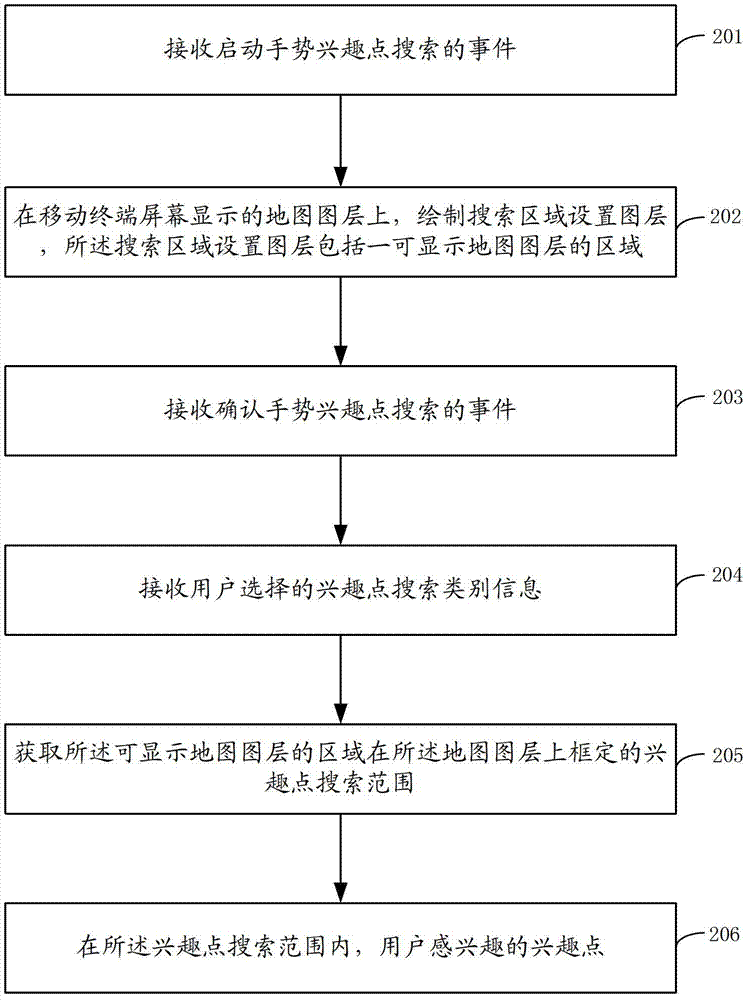

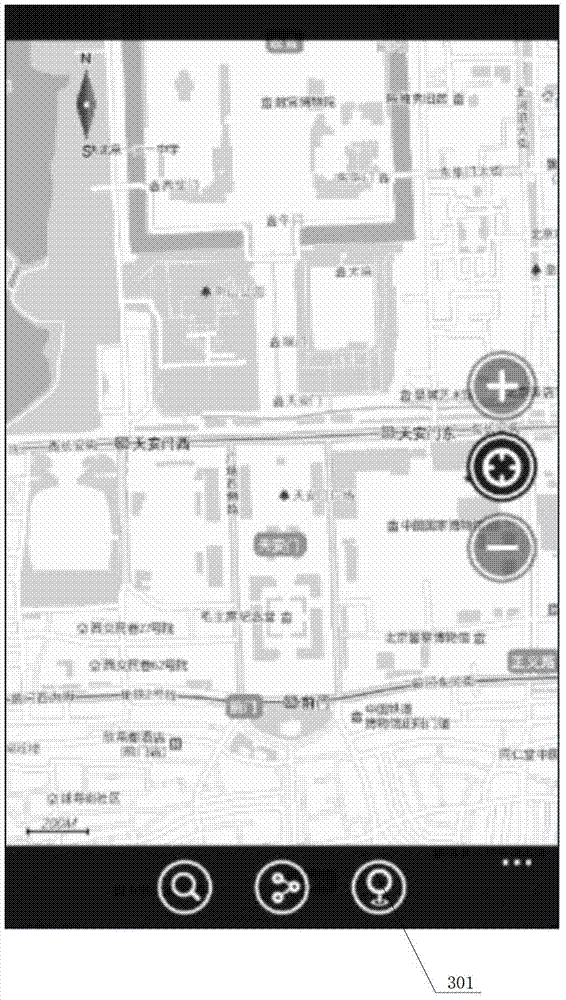

Interest point search method and device, mobile terminal

ActiveCN103514169BSimplify the search processIncrease flexibilityMaps/plans/chartsGeographical information databasesComputer science

Owner:ALIBABA (CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com