Multi-stage delayed steam injection string

A steam injection pipe string and steam injection technology, which is applied in the direction of wellbore/well components, production fluid, sealing/isolation, etc., can solve the problem of difficult control of the steam injection volume of the oil layer unit, and achieve improved steam injection efficiency and simple operation Convenience, effect of increasing oil well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical solutions, purposes and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

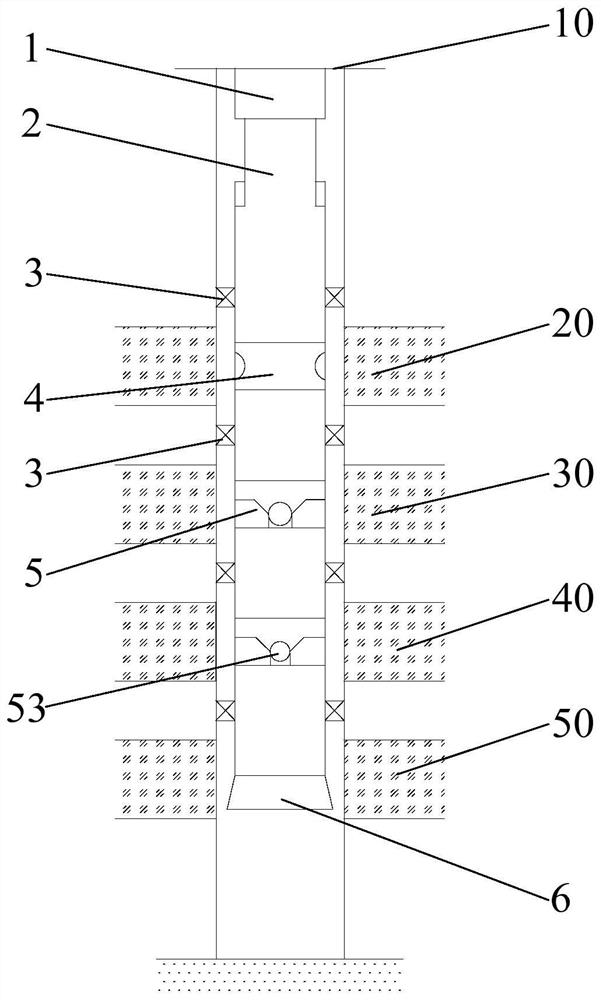

[0046] like figure 1 As shown, the present invention provides a multi-stage delayed steam injection string for injecting steam into an oil well having three or more oil layer units, the multi-stage delayed steam injection string includes a Delayed steam injection assembly and at least one layered steam injection assembly, specifically, when the oil well has three oil layer units, the multi-stage delayed steam injection string has one layered steam injection assembly, when the oil well has four oil layer units , the multi-stage delayed steam injection string has two layered steam injection components, when the oil well has five oil layer units, the multi-stage delayed steam injection string has three layered steam injection components, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com