Composite high-temperature profile control method for heavy oil well

A high-temperature, oil well technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as difficult to achieve high-temperature profile control and channel sealing, and low steam foam plugging strength, so as to increase production and production Yield, effect of increasing swept volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

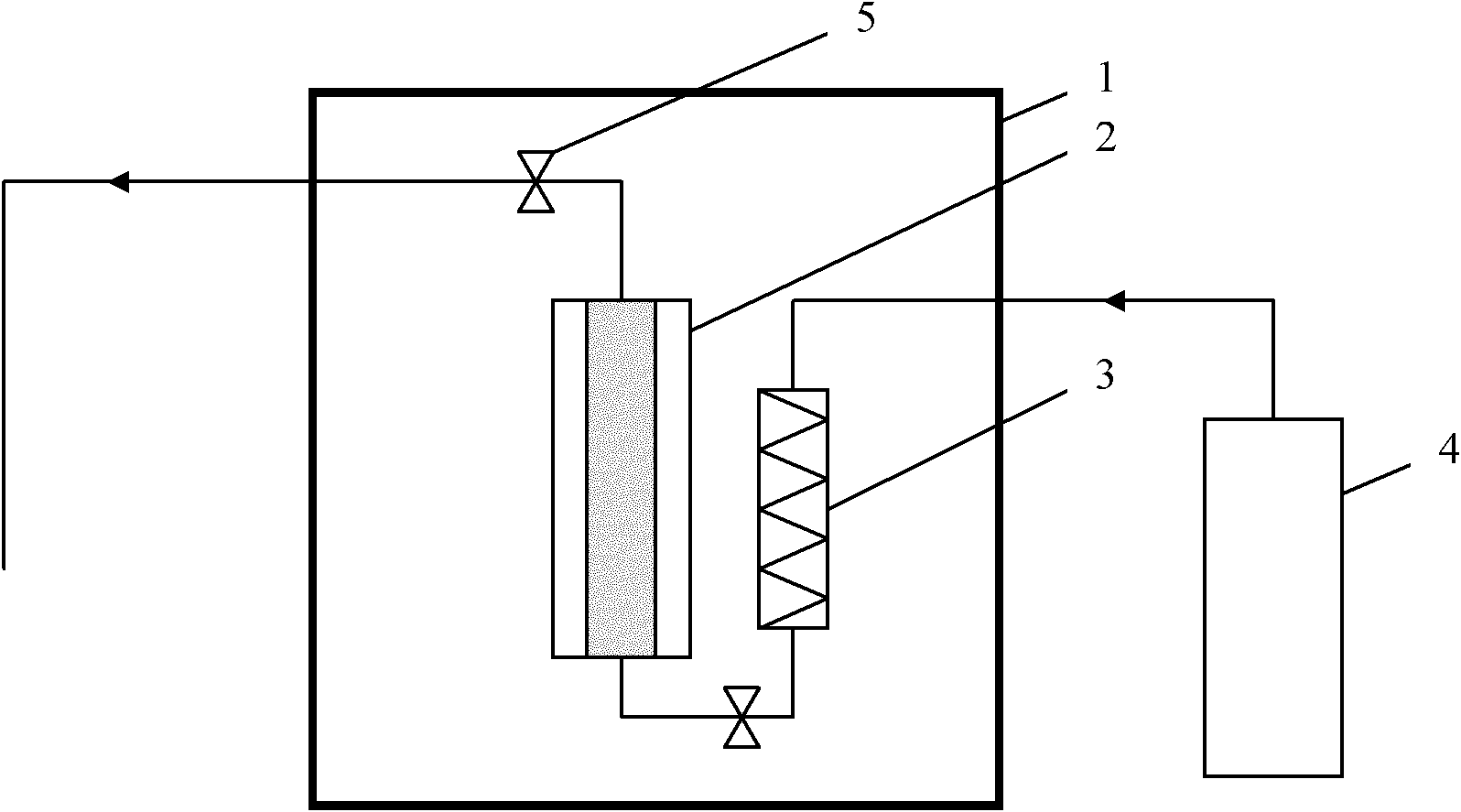

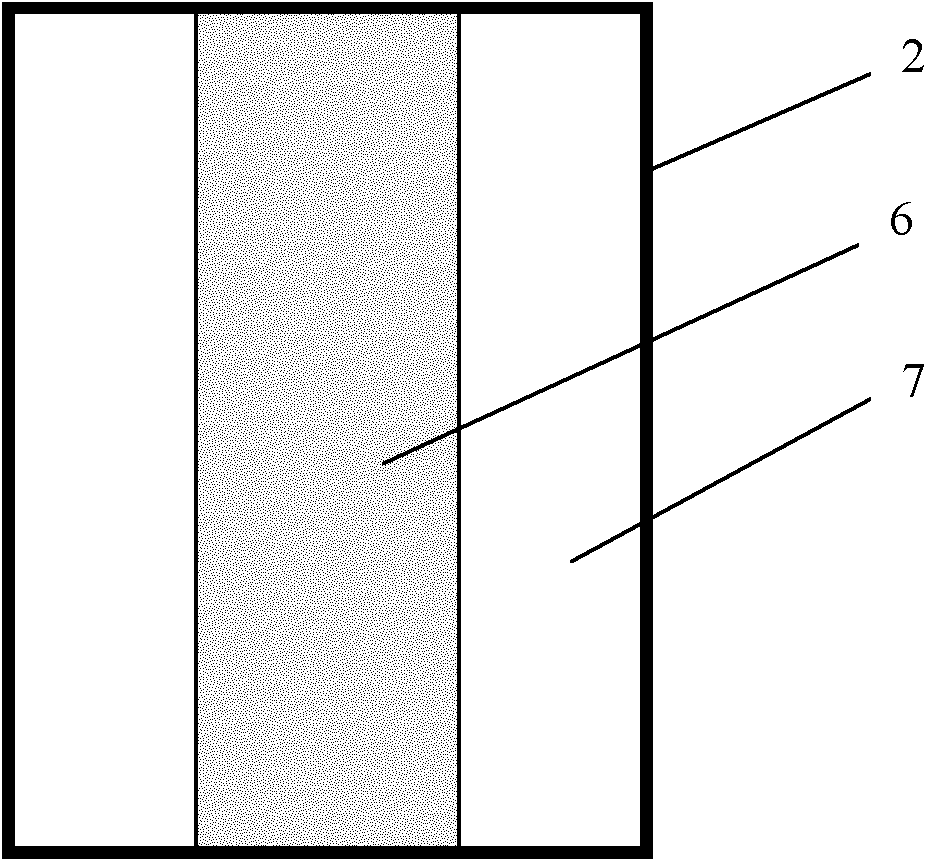

[0030] Experiments were carried out using the temperature-resistant and pressure-resistant experimental model. The model has a pressure resistance of 10MPa, a model diameter of 3.06cm, and a length of 21cm. In order to effectively test the profile control effect of plugging agents in heterogeneous formations, the experimental model is designed as a concentric heterogeneous model, the central high-permeability layer is filled with 20-40 mesh quartz sand, the diameter of the inner core cylinder is 1.70 cm, and the surrounding is filled with 120-140 mesh Mesh quartz sand. Experimental model see figure 1 , figure 2 . In the figure, 1 is a heating oven, 2 is an experimental core model, 3 is a steam generator, 4 is an injection pump, and 5 is a valve; in the experimental core model 2, 6 is a high-permeability core zone, and 7 is a low-permeability core zone. First, the solid-phase high-temperature profile control agent inorganic phenolic resin injected into the core model 2 (see...

Embodiment 2

[0032] The experiment was carried out according to the method in Example 1, wherein the solid-phase high-temperature plugging agent was changed to a double-liquid method high-temperature plugging agent, and water glass, isolation Liquid, calcium chloride 0.5PV (pore volume), then inject high-temperature steam, and at the same time inject temperature-resistant 1% sulfonate surfactant into the core to produce (1PV) the same effect is remarkable, and the recovery rate is increased by more than 10%.

Embodiment 3

[0034] It was constructed in Well Qi 40-2-24 in Liaohe Oilfield. This well is a steam huff and puff well that has been in production for more than 5 years. The steam huff and puff has eight cycles, and the steam absorption in the oil layer is seriously uneven in the vertical direction. Inject 200 cubic meters of high-temperature steam into the well, then inject 80 cubic meters of lignin gel plugging agent, and shut the well for 48 hours. Then start to inject steam, and inject 15 tons of sodium hexadecylbenzenesulfonate, a high-temperature blowing agent. After the composite high-temperature profile control measures before and after comparison, the steam injection pressure increased by 2MPa, and the steam absorption profile was significantly changed by the TPS-9000 test. Before the high-temperature profile control, layers 15, 20, and 21 were the main steam-absorbing layers, followed by No. 18 After the profile control, the steam absorption of the upper layer No. 15 was significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com