Multistage delay steam injection string

A steam injection pipe string and steam injection technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the steam injection volume of the oil layer unit is not easy to control, so as to improve the efficiency of steam injection and reduce the loss of heat energy , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

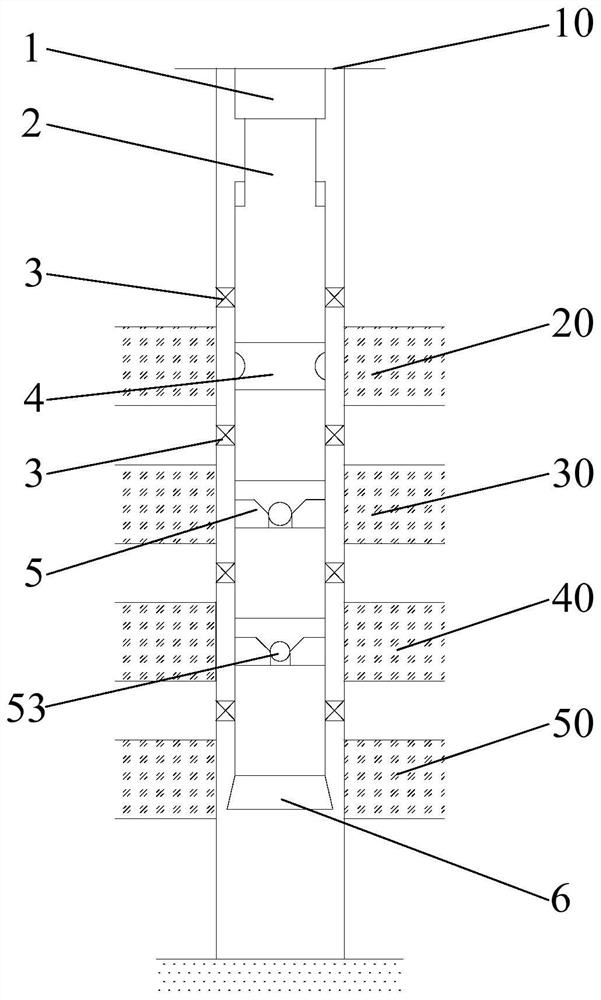

[0046] like figure 1 As shown, the present invention provides a multi-stage delayed steam injection string, which is used for steam injection to oil wells with more than three layers of oil layer units. The multi-stage delayed steam injection string includes sequentially arranged from top to bottom Delayed steam injection assembly and at least one layered steam injection assembly, specifically, when the oil well has three oil layer units, the multi-stage delayed steam injection string has a layered steam injection assembly, and when the oil well has four oil layer units , the multi-stage delayed steam injection string has two layered steam injection components, when the oil well has five reservoir units, the multi-stage delaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com