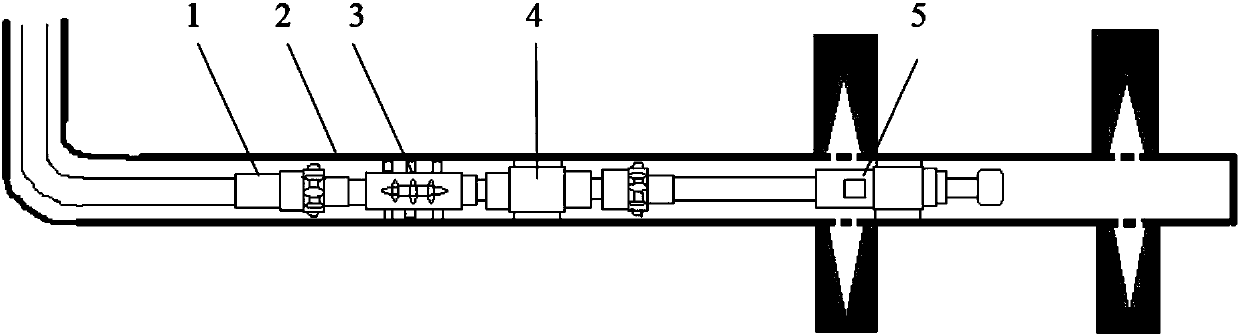

Packer for realizing infinite fracturing and working method thereof

A packer, infinite-level technology, applied in the field of oilfield development tools, can solve the problem that the packer cannot be reused, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

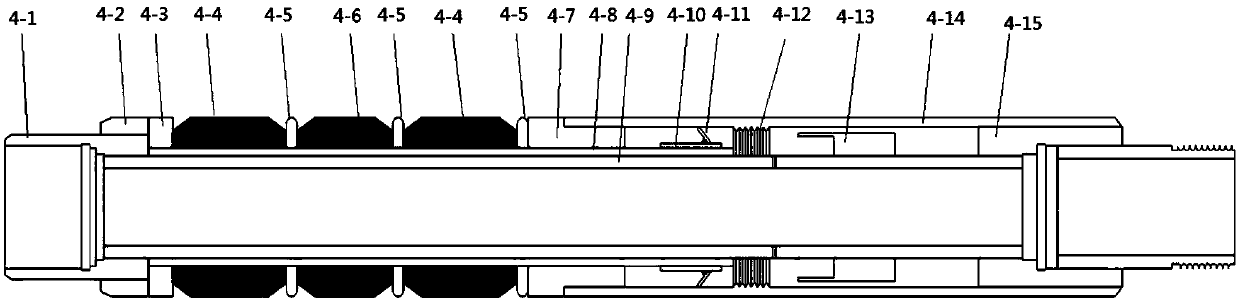

[0041] Such as figure 2 , Figure 7-Figure 9 shown.

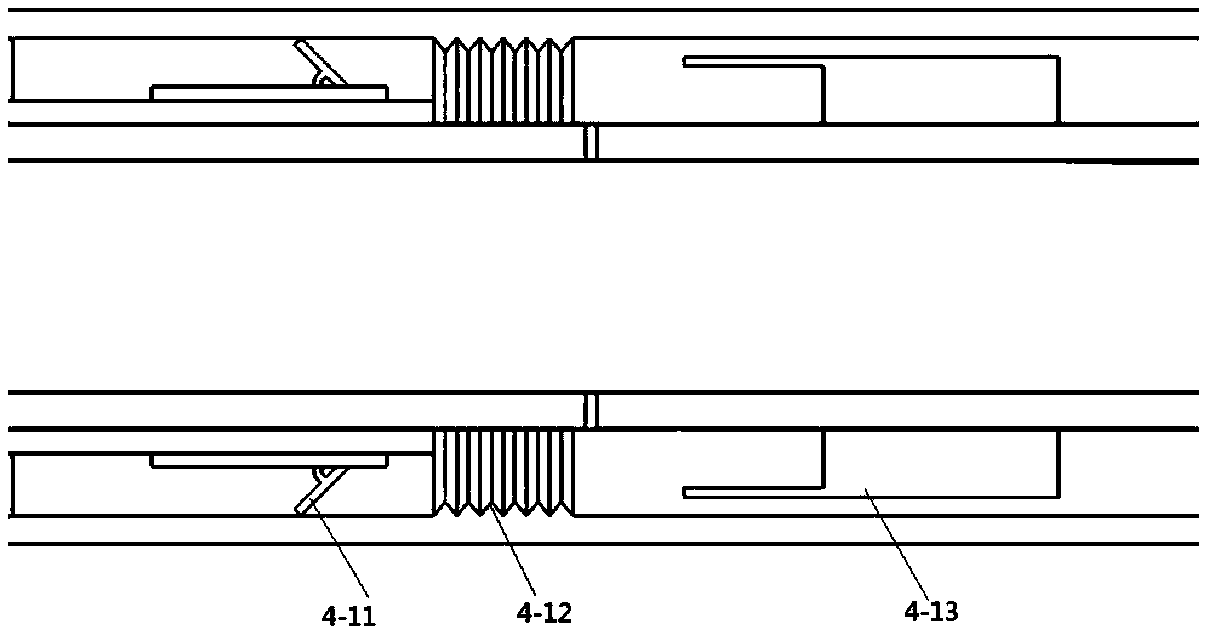

[0042] A packer for realizing infinite-stage fracturing, which is used for multi-stage fracturing or infinite-stage fracturing, including a center pipe 4-9, a liner 4-8 and a sealing mechanism that are sequentially socketed from inside to outside; The sealing mechanism includes a piston 4-7, a sealing sleeve 4-14 and a lower joint 4-15 connected in sequence; the sealing mechanism forms a sealing cavity on the outer wall of the central tube 4-9 and the liner 4-8; A locking ring sleeve 4-10 and an unsealing ring sleeve 4-13 are arranged in the sealing chamber, the locking ring sleeve 4-10 is fixedly socketed with the liner 4-8, and the unsealing ring sleeve 4-13 13 is fixedly socketed with the central tube 4-9; one side of the piston 4-7 is provided with an elastic mechanism to reset the piston 4-7; the outer wall of the locking ring 4-10 is provided with a lock Tighten the clamping plate 4-11; the inner wall of the seali...

Embodiment 2

[0046] As described in Example 1, the packer for realizing infinite fracturing, further, the elastic mechanism includes two long rubber cylinders 4-4 and one short rubber cylinder 4-6, and the adjacent rubber cylinders are arranged between There is a spacer ring 4-5; the spacer ring 4-5 is socket-connected with the liner 4-8; the rubber tube and the spacer 4-5 are slidably arranged on the outer wall of the liner 4-8.

Embodiment 3

[0048]As described in Example 1 to realize the packer for infinite stage fracturing, further, the end of the central pipe is provided with an upper joint 4-1 corresponding to the lower joint 4-15; the retaining ring 4- One side of 3 is provided with an adjustment ring 4-2; the adjustment ring 4-2 is connected with the upper joint thread 4-1. The adjusting ring 4-2 is used to adjust the squeezed degree of the rubber cartridge, thereby changing the outer diameter of the rubber cartridge, so as to meet the sealing requirements of pipes with different diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com