Patents

Literature

46results about How to "Realize unblocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite blocking remover for oil well and application method thereof

ActiveCN102250601AAchieving Slow Controlled ReleaseReduce wasteCleaning apparatusDrilling compositionInorganic saltsChlorine dioxide

The invention relates to a composite blocking remover for oil well and an application method thereof. The composite blocking remover comprises two ingredients of A and B in a ratio of 1:5-8; the ingredient A comprises, by weight, 20-50 parts of chlorine dioxide maternal, 1-4 parts of heat-resistant agent, 10-20 parts of organic clay stabilizer, 5-10 parts of chlorine dioxide synergist and 5-10 parts of inorganic salt; and the ingredient B comprises, by weight, 30-60 parts of hydrophosphate, 2-6 parts of corrosion inhibitor, 1-5 parts of iron ion complexing agent, 5-12 parts of de-emulsifier, 4-12 parts of osmotic agent and 60-180 parts of water. The application method comprises steps that the ingredient A and the ingredient B are measured according to a formula and mixed with water; and the mixed liquor is injected into an oil well immediately. According to the invention, construction inconvenience and potential safety hazard caused by surface activation can be avoided, and construction frequency is reduced, so as to raise blocking removal effects by times.

Owner:石家庄卫科生物科技有限公司

Short-injection water injection well acidation injectivity process

The invention discloses a short-injection water injection well acidation injectivity process for petroleum industry, which is applied to a short-injection water injection well, improves the acidation effect and improves the water injection success rate. The process comprises the following steps: a prepose acid liquor soaking oil layer is inputted; the well is backwashed at high flow rate so as to discharge the prepose acid liquor; main acid is squeezed in; the well is backwashed by water mixed with gas, the back pressure on the bottom of the well is reduced, the ground layer is induced to flow, and the deep stoppage reactant can be discharged under the effect of the strata pressure. The prepose acid liquor is discharged through the repeated washing of the well, so the effect of the main acid is adequately played, the secondary pollution of the oil layer can be prevented, the deep acidation can be realized, the injectivity valid period is prolonged, the measure success rate is improved, and the recovery rate of the low-permeability reservoir can be improved. The effect of the used acid can be effectively played, the underground tube pile can be free from damaged, the consumption of the main acid can be reduced on the premise of ensuring the construction effect, and the production cost can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

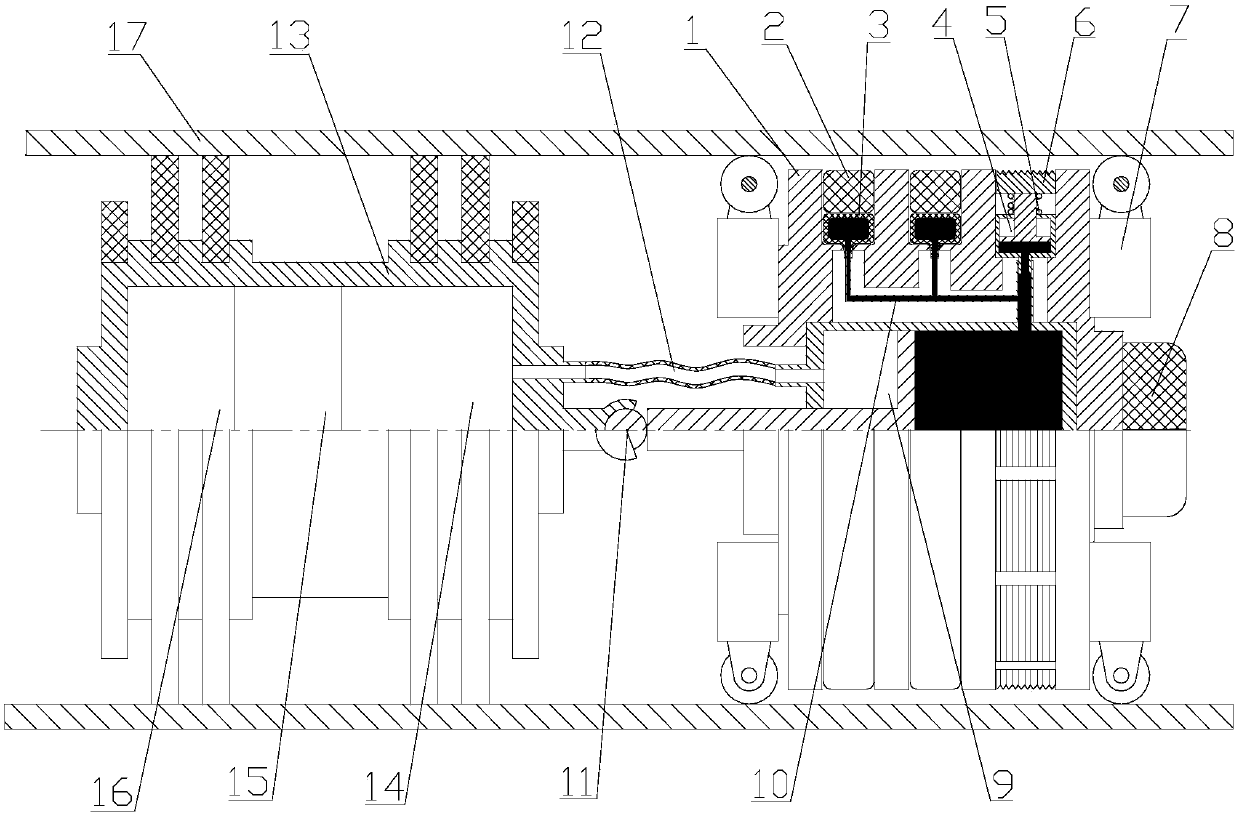

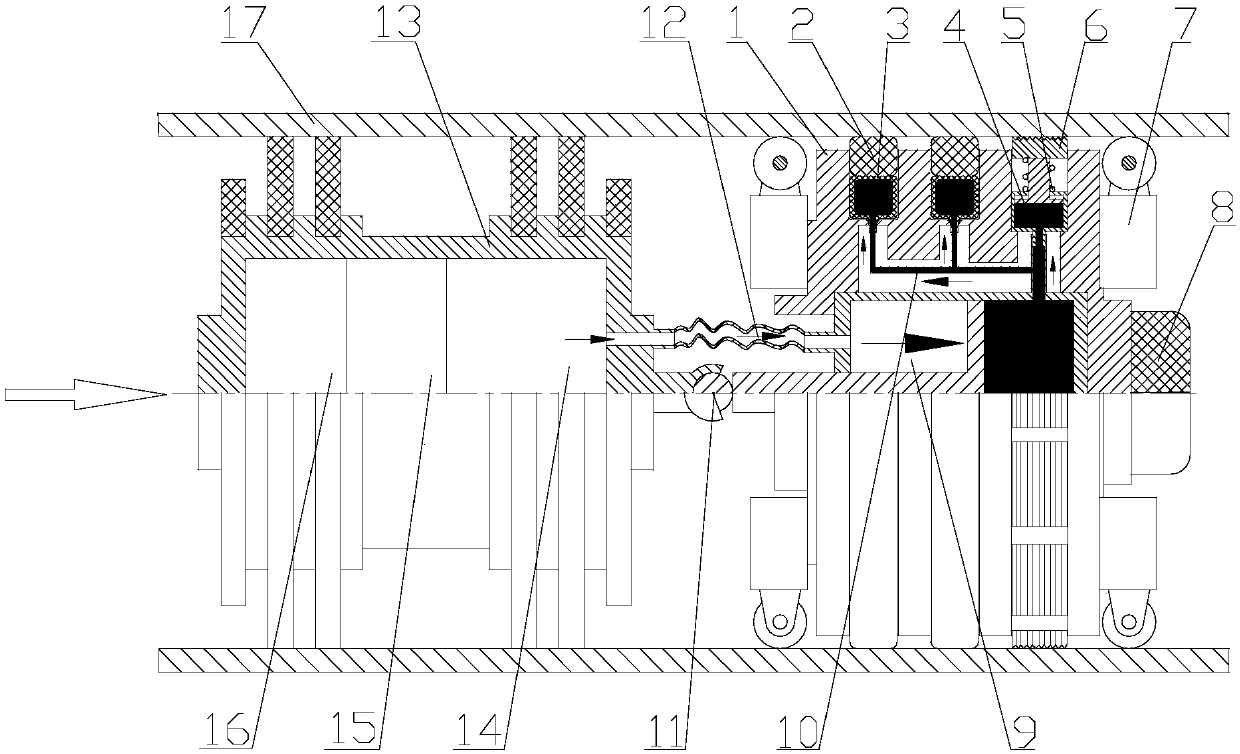

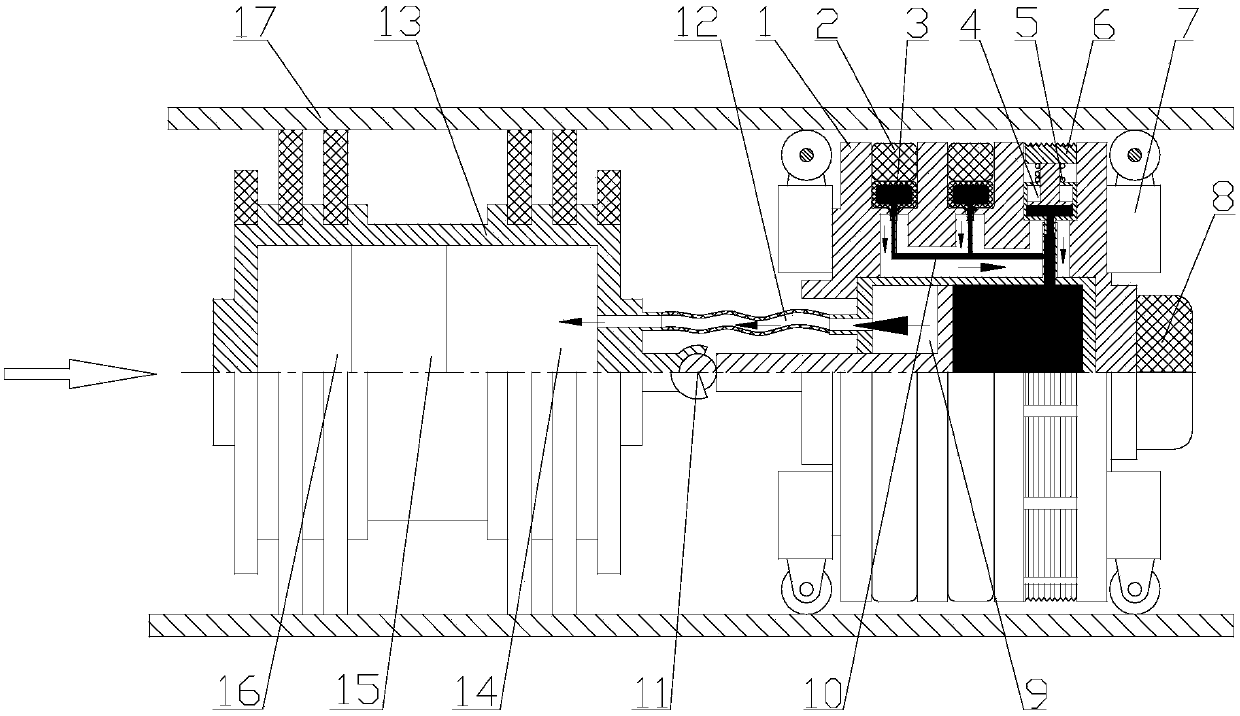

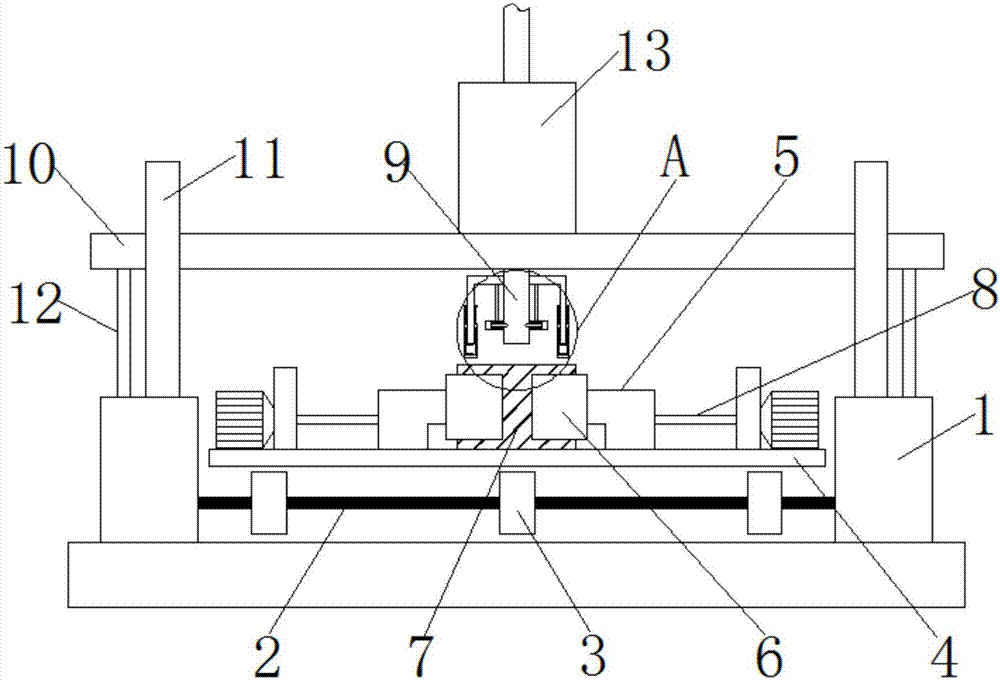

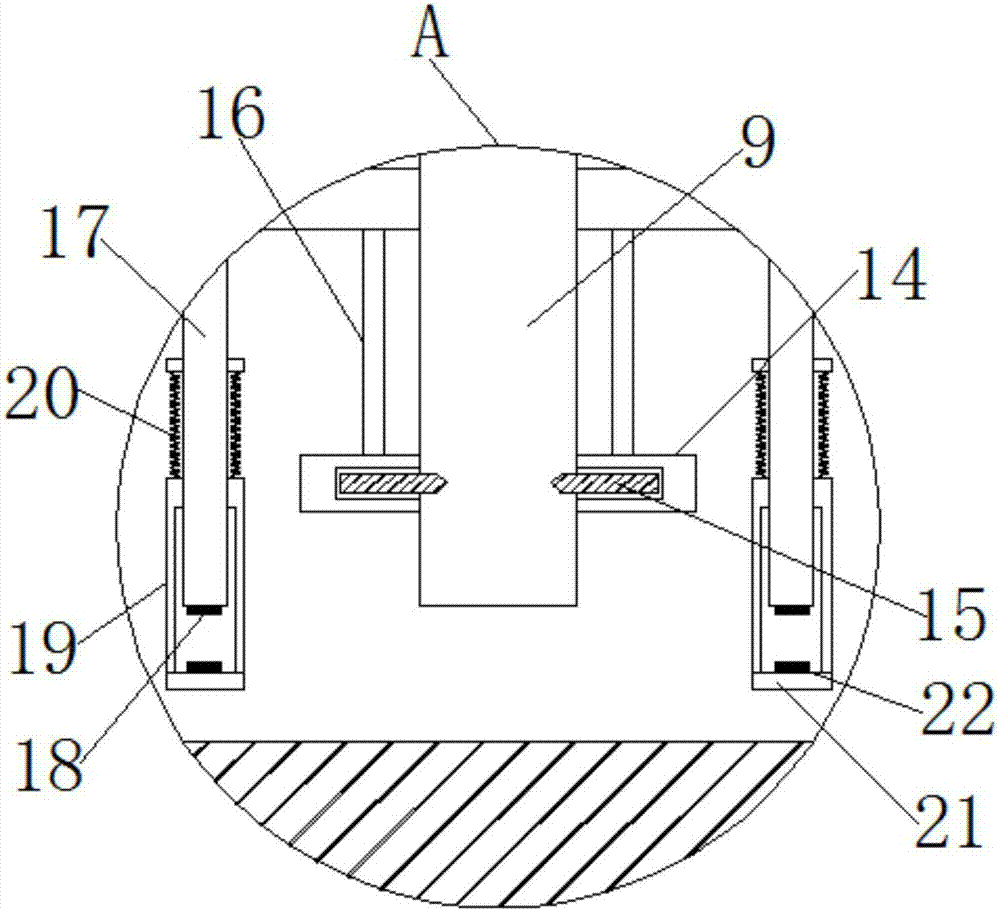

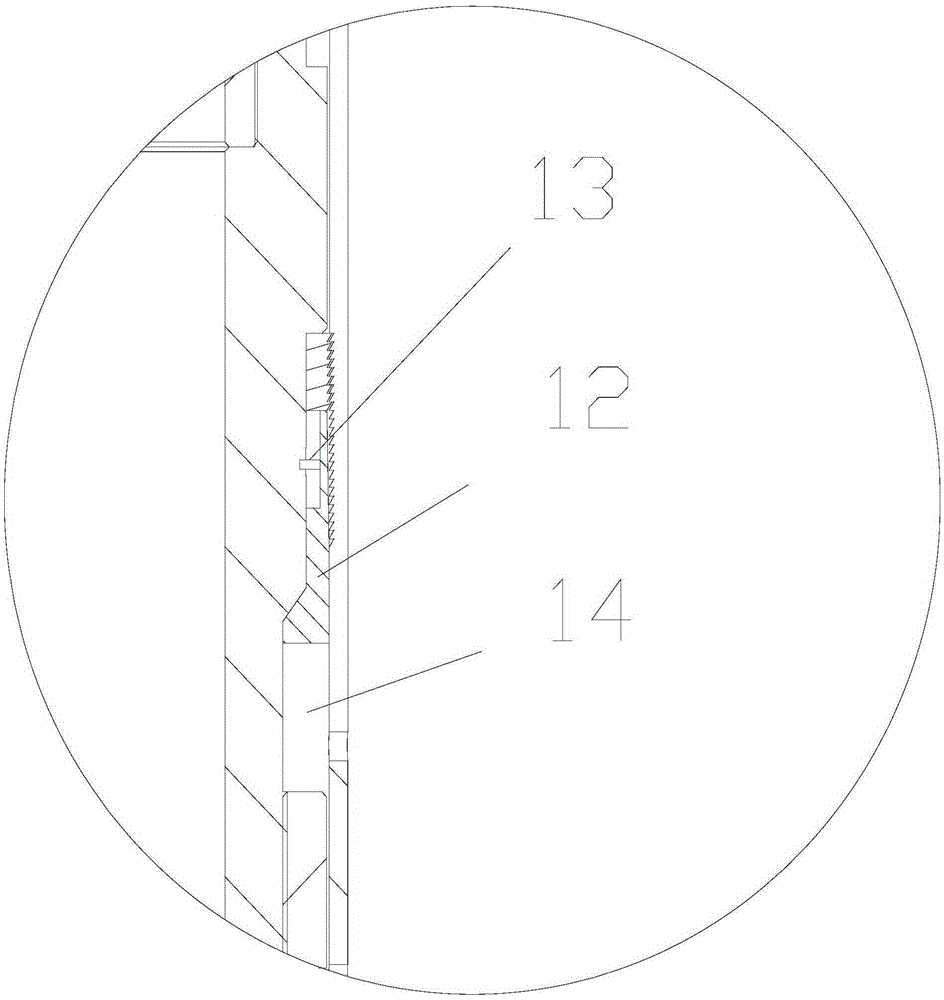

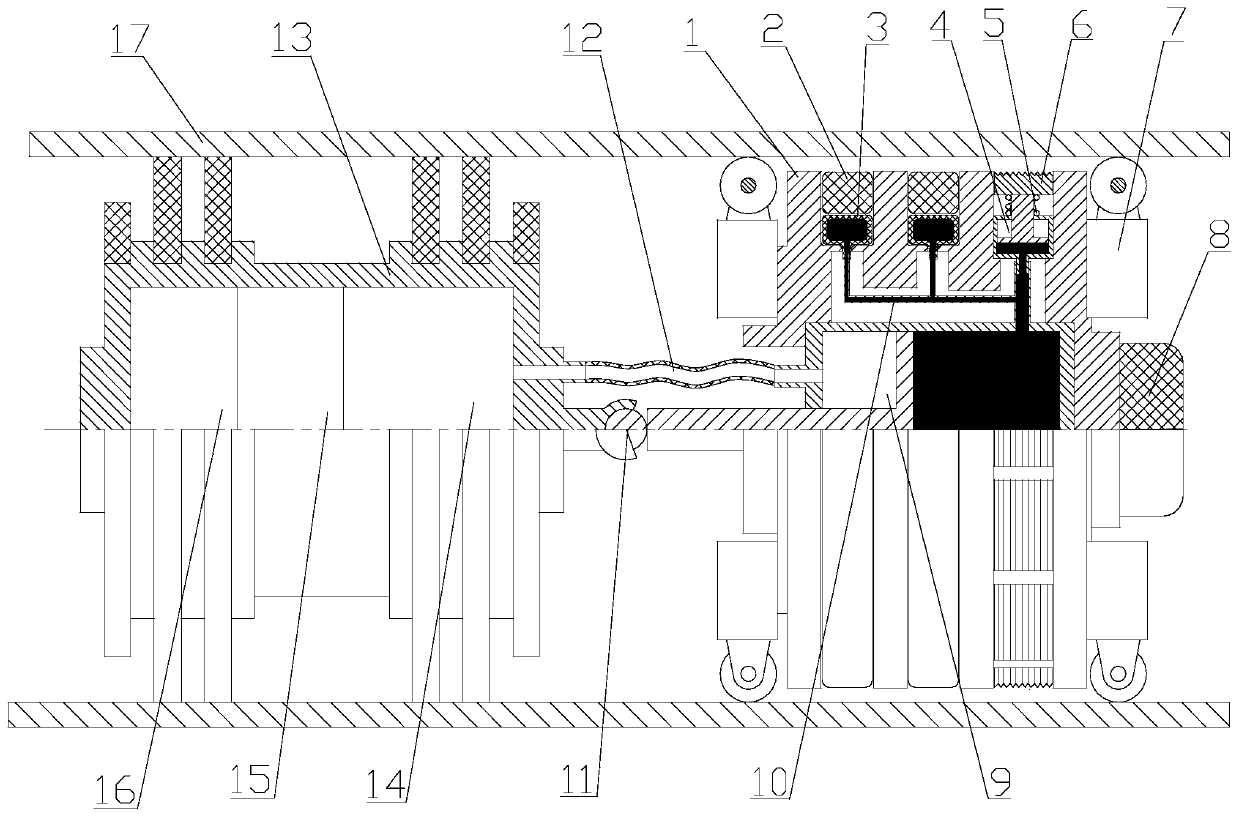

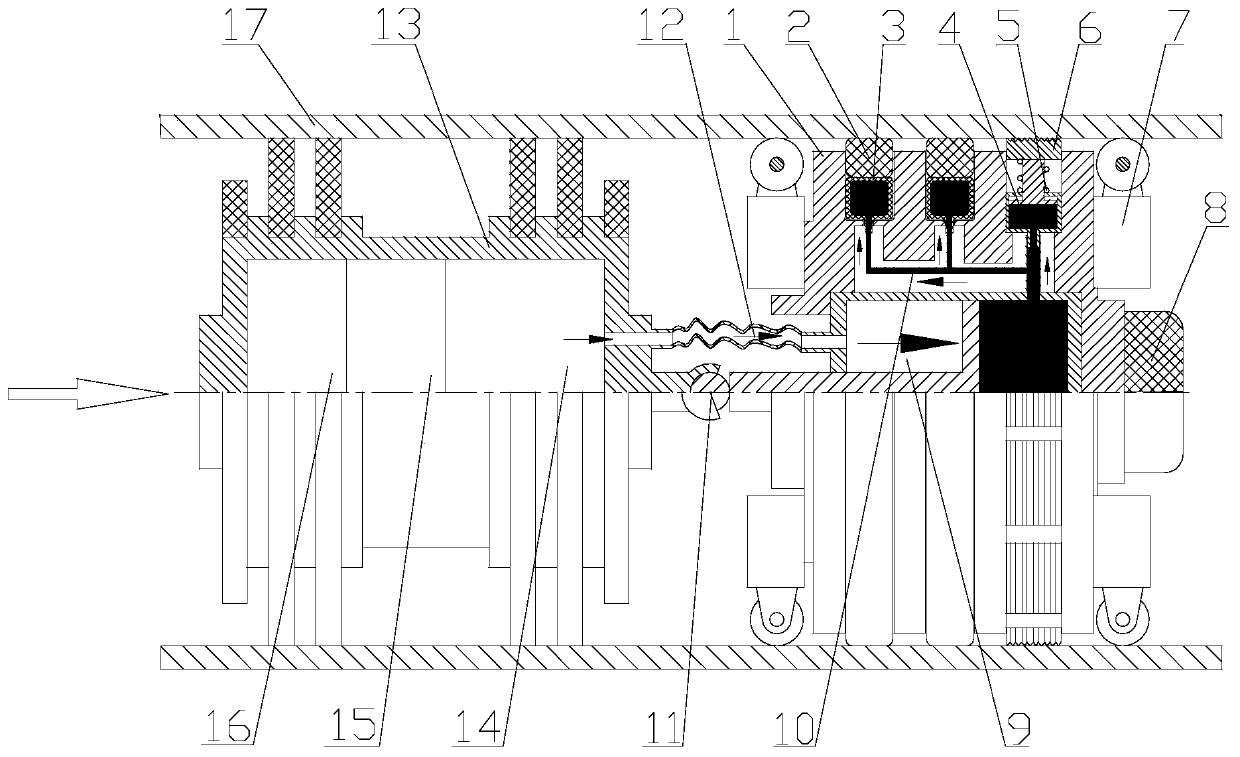

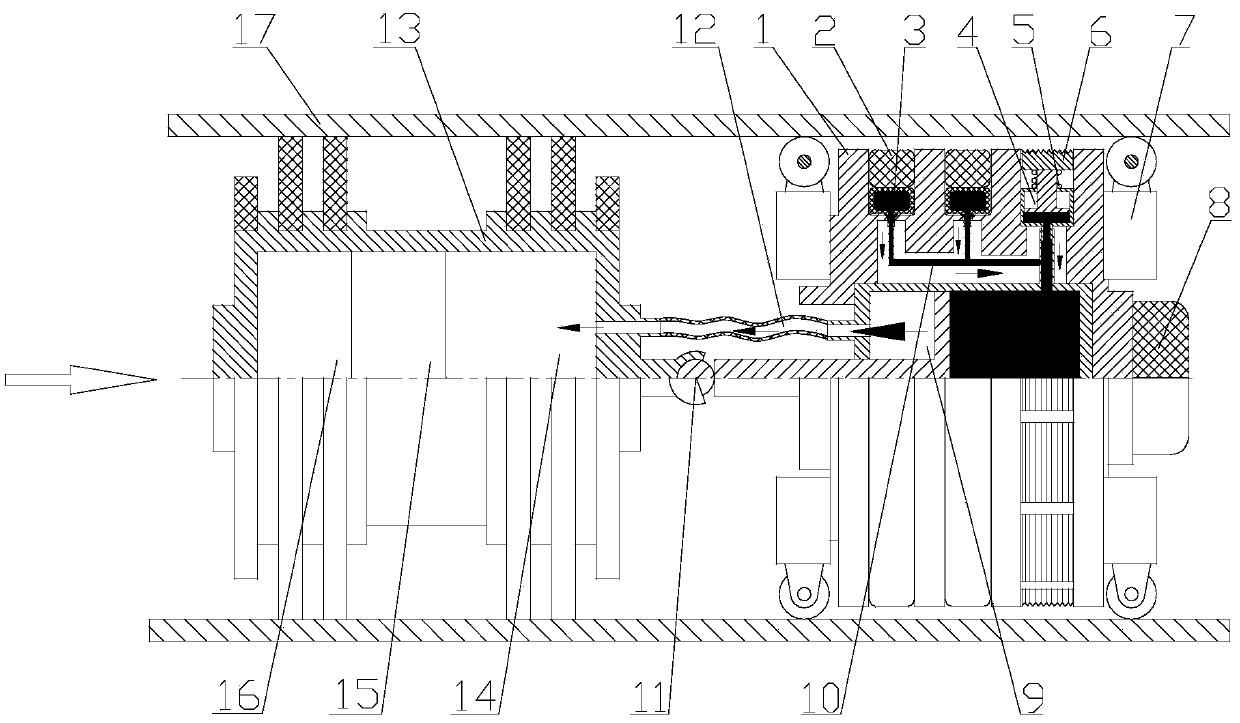

Novel intelligent plugging device

A novel intelligent plugging device mainly comprises a plugging assembly and a power assembly. During pipeline maintenance operation, the novel intelligent plugging device is pushed by an upstream medium in a pipe to move forwards, a communication module in the power assembly receives a plugging command, a control module drives a micro hydraulic module, high-pressure fluid is injected into a mainhydraulic cylinder of the plugging assembly through a high-pressure hose, and thus a packing ring and a locking slip expand in the radial direction so that plugging can be achieved; and after the operation is finished, the communication module receives a de-plugging command, the control module drives the micro hydraulic module to pump the high-pressure fluid back, the packing ring and the lockingslip recover to the original position so that de-plugging can be achieved, and the novel intelligent plugging device is pushed by the medium to return to the ball receiving end of the pipe. The novelintelligent plugging device has the advantages that the original pipe is not destroyed, plugging is more reliable, the maintenance time is shortened and the labor cost is reduced, and has the broad application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

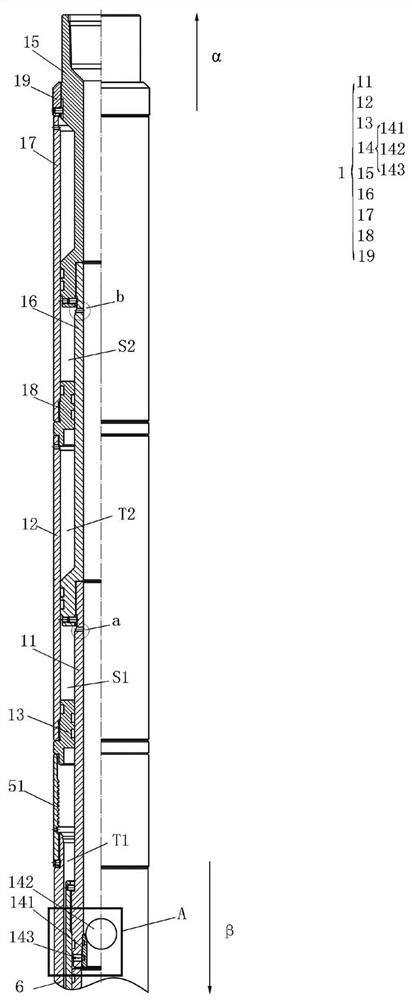

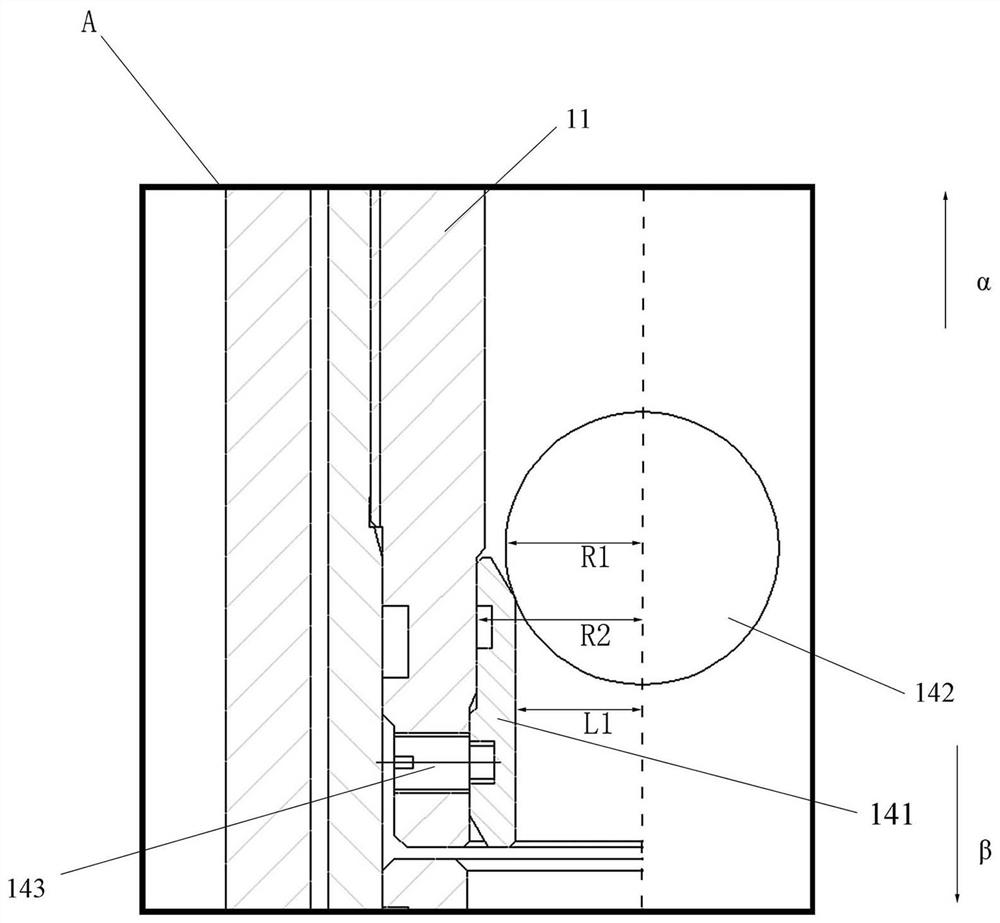

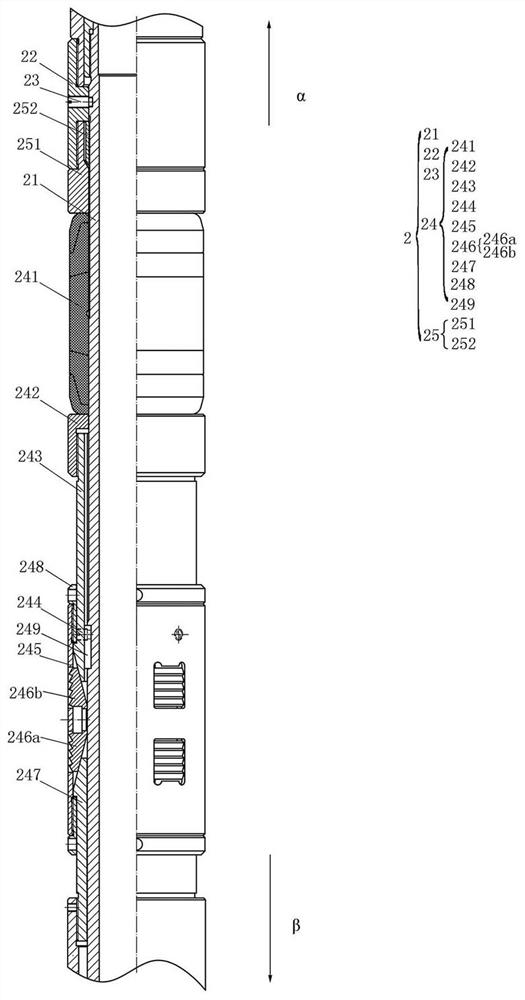

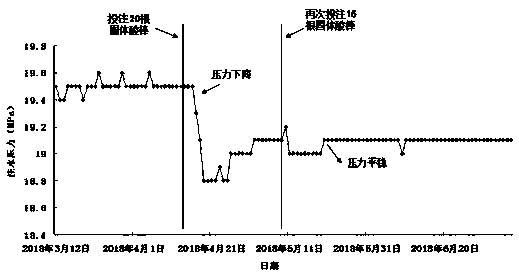

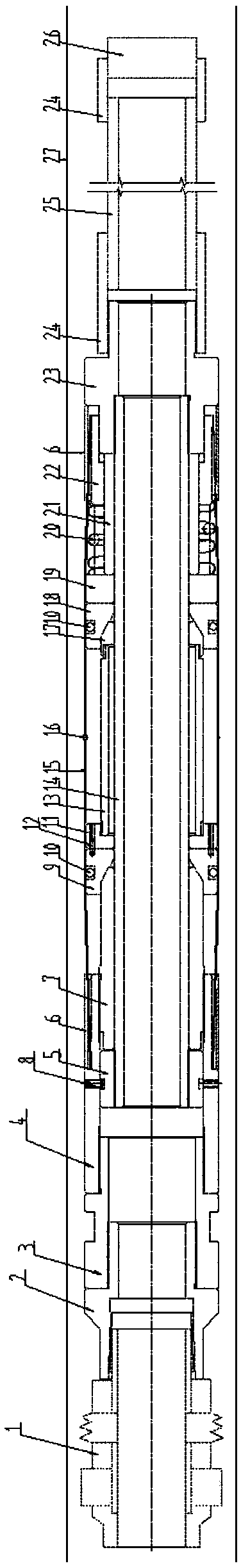

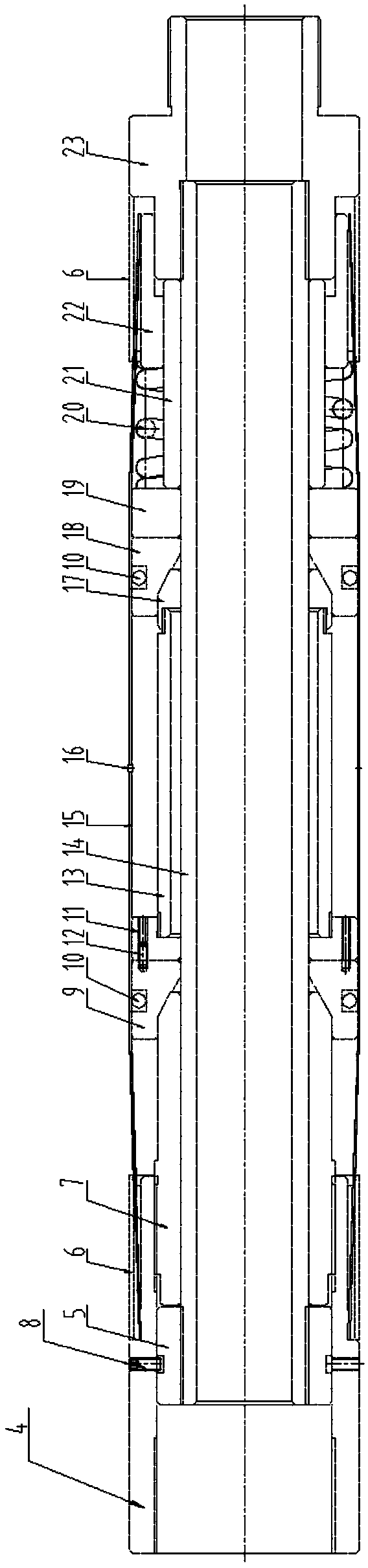

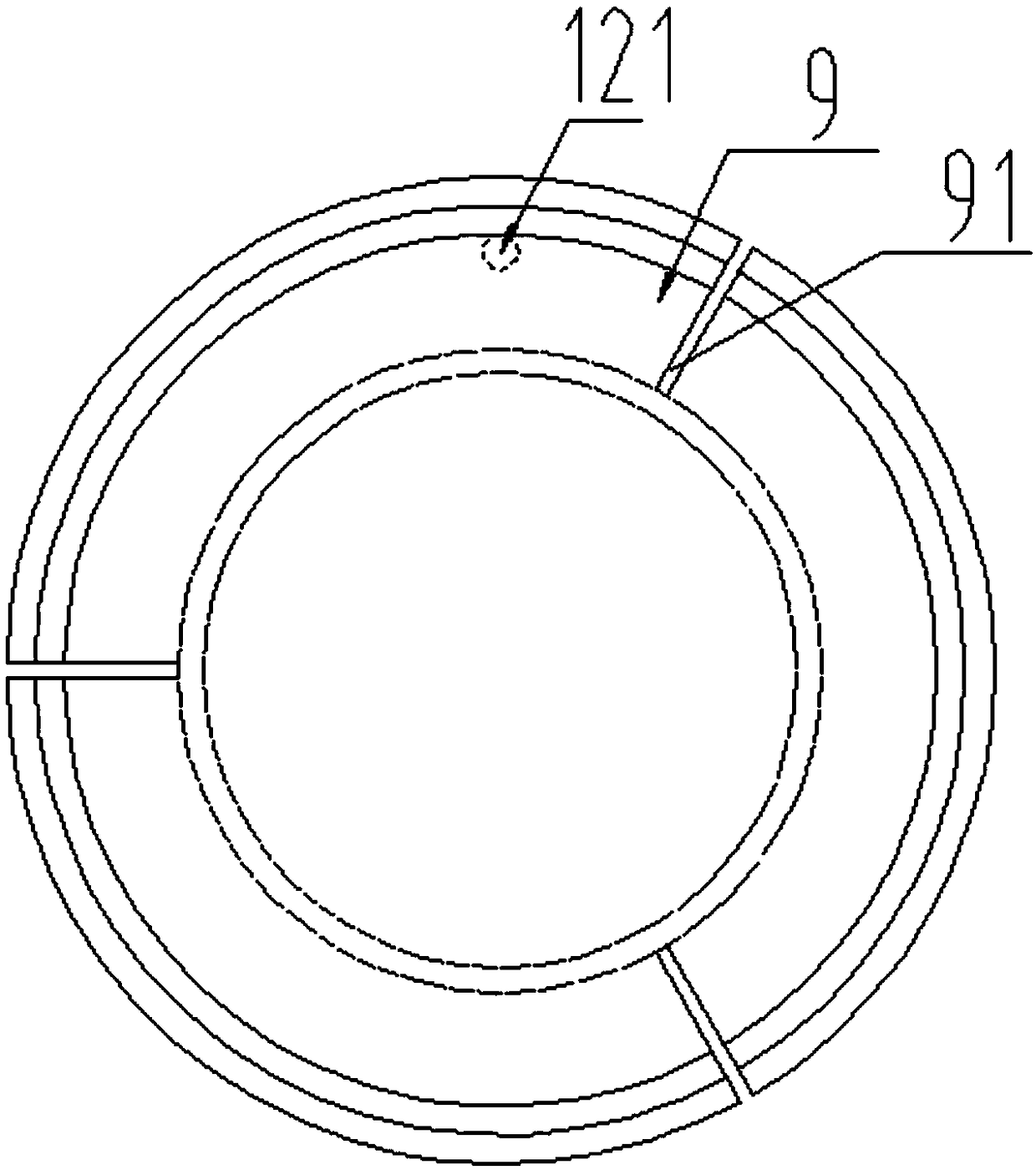

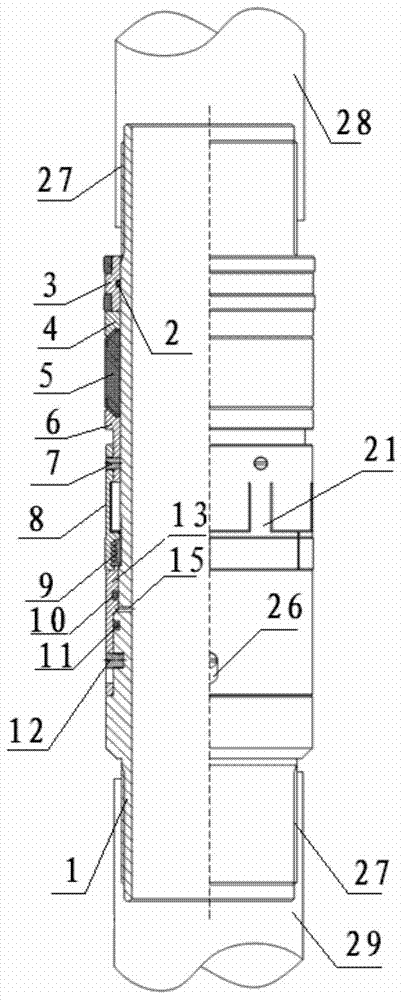

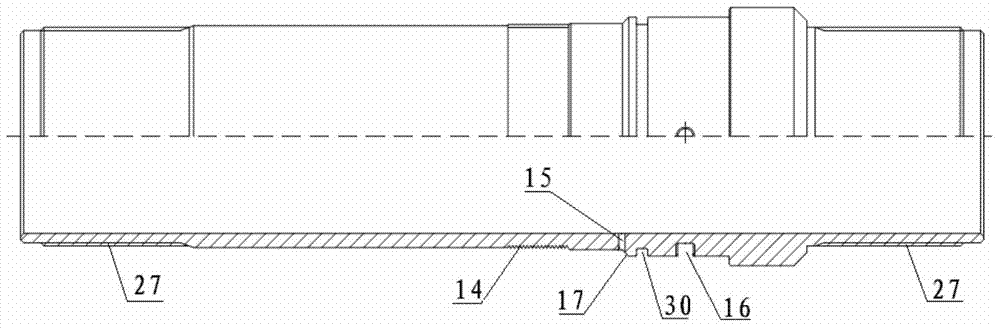

Suspension well completion integrated packer and well completion pipe string

ActiveCN113250647AIndependentFunctionality is not affectedSealing/packingCompressive resistanceMechanics

The invention provides a suspension well completion integrated packer and a well completion pipe string. The suspension well completion integrated packer comprises a setting mechanism, a tie-back cylinder, a releasing mechanism and a setting mechanism which are coaxially connected; the setting mechanism comprises a setting center pipe, a setting assembly, a first setting cylinder sleeve and a first annular setting piston; the setting mechanism comprises a setting center pipe, a thrust sleeve, a starting shearing fixing piece and a setting sealing assembly; and the releasing mechanism comprises a releasing elastic lock pipe, a releasing lock head, a releasing shearing fixing piece and a releasing assembly. The suspension well completion integrated packer can further comprise a tie-back mechanism; and the tie-back mechanism comprises a tie-back lock sleeve and a tie-back insertion pipe assembly. The setting mechanism of the suspension packer can achieve independent setting, the functions of other tools in the open hole segmented well completion pipe string are not affected, the releasing mechanism is high in compressive strength, and unsetting can be achieved after setting.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

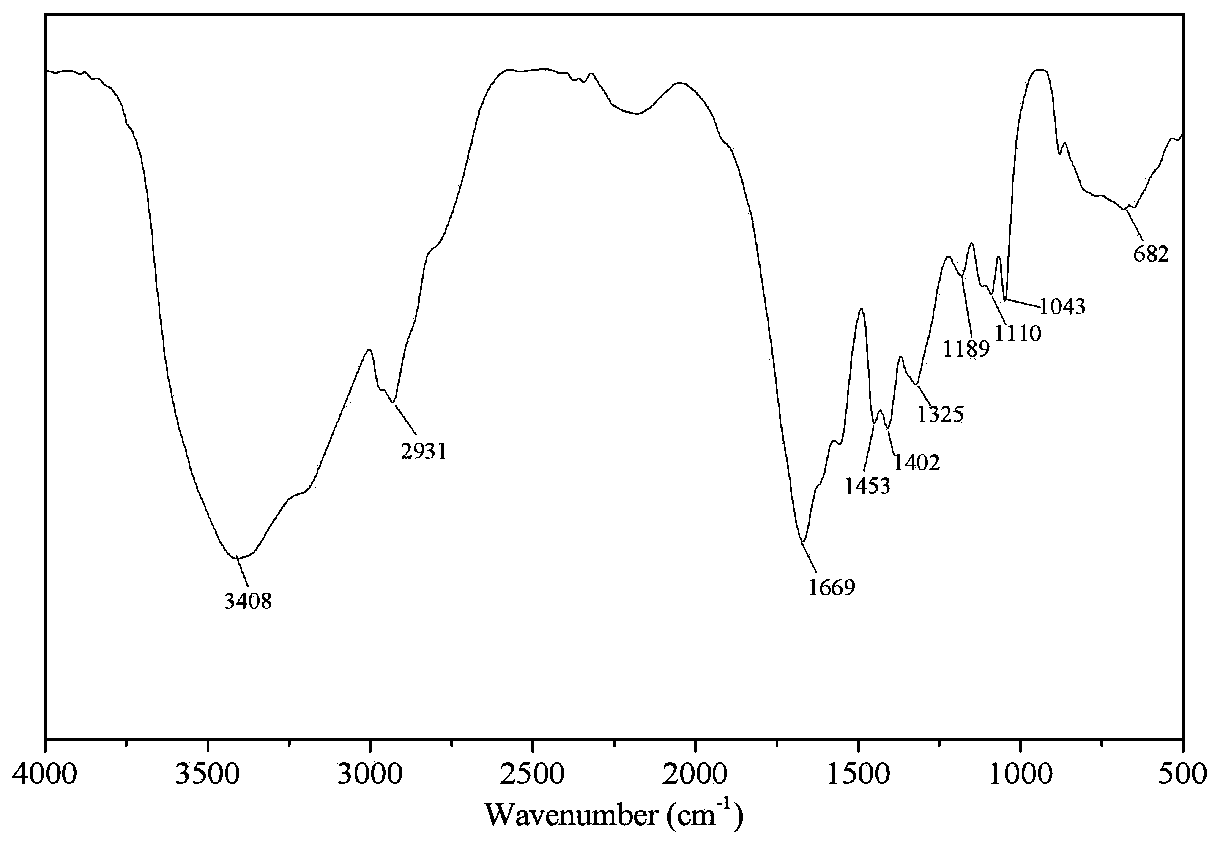

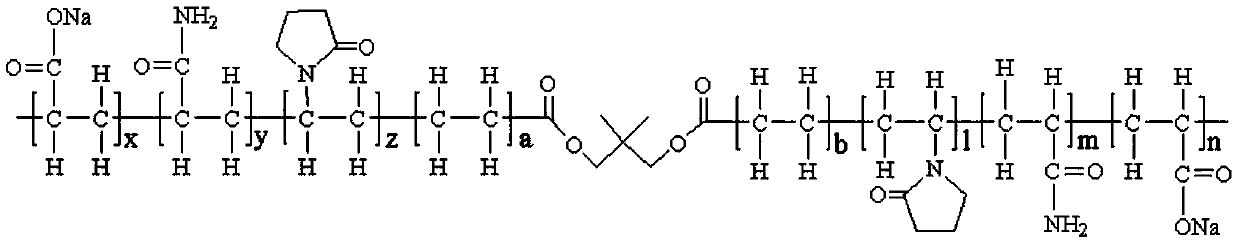

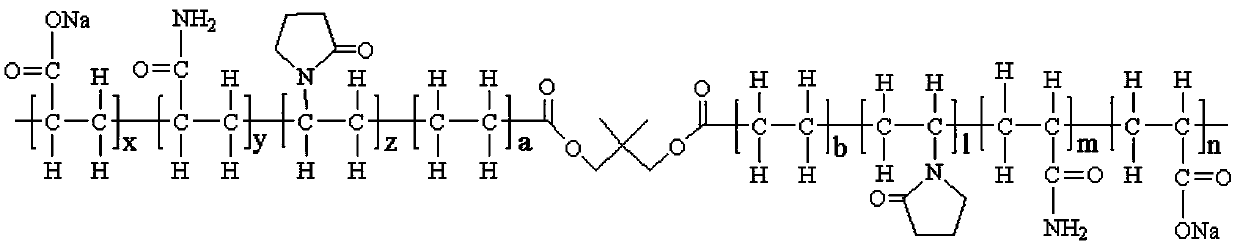

Water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and synthesis method of water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent

ActiveCN111484578AImprove temporary blocking strengthImprove rigidityDrilling compositionNeopentylglycol diacrylatePyrrolidinones

The invention relates to the technical field of oilfield chemistry. The invention discloses a water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and a synthesis method of the water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent. The temporary plugging agent is a quadripolymer mainly prepared from the following raw material monomers in percentage by mass: 30% to 40% of acrylic acid, 59.4% to 68.0% of acrylamide, 0.5% to 1.5% of N-vinyl pyrrolidone and 0.1% to 0.5% of neopentyl glycol diacrylate. According to the temporary plugging agent, the N-vinylpyrrolidone with a five-membered ring structure is introduced into a temporary plugging agent molecular chain, so that the rigidity and the stability of the temporary plugging agent molecular chain can be improved, and the temporary plugging strength of the temporary plugging agent is improved; the neopentyl glycol diacrylate with two carbon-carbon double bonds is used for synthesizing the temporary plugging agent, and plays a role of a cross-linking agent, so that the temporary plugging agent becomes a water-swelling body after absorbing water, and cracks can be plugged; the blocking removalmechanism of the temporary plugging agent is different from that of an existing water-soluble temporary plugging agent, no blocking removal agent needs to be additionally added in the blocking removalprocess, complete blocking removal only needs to be achieved under the action of temperature and water, and the blocking removal performance is good.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

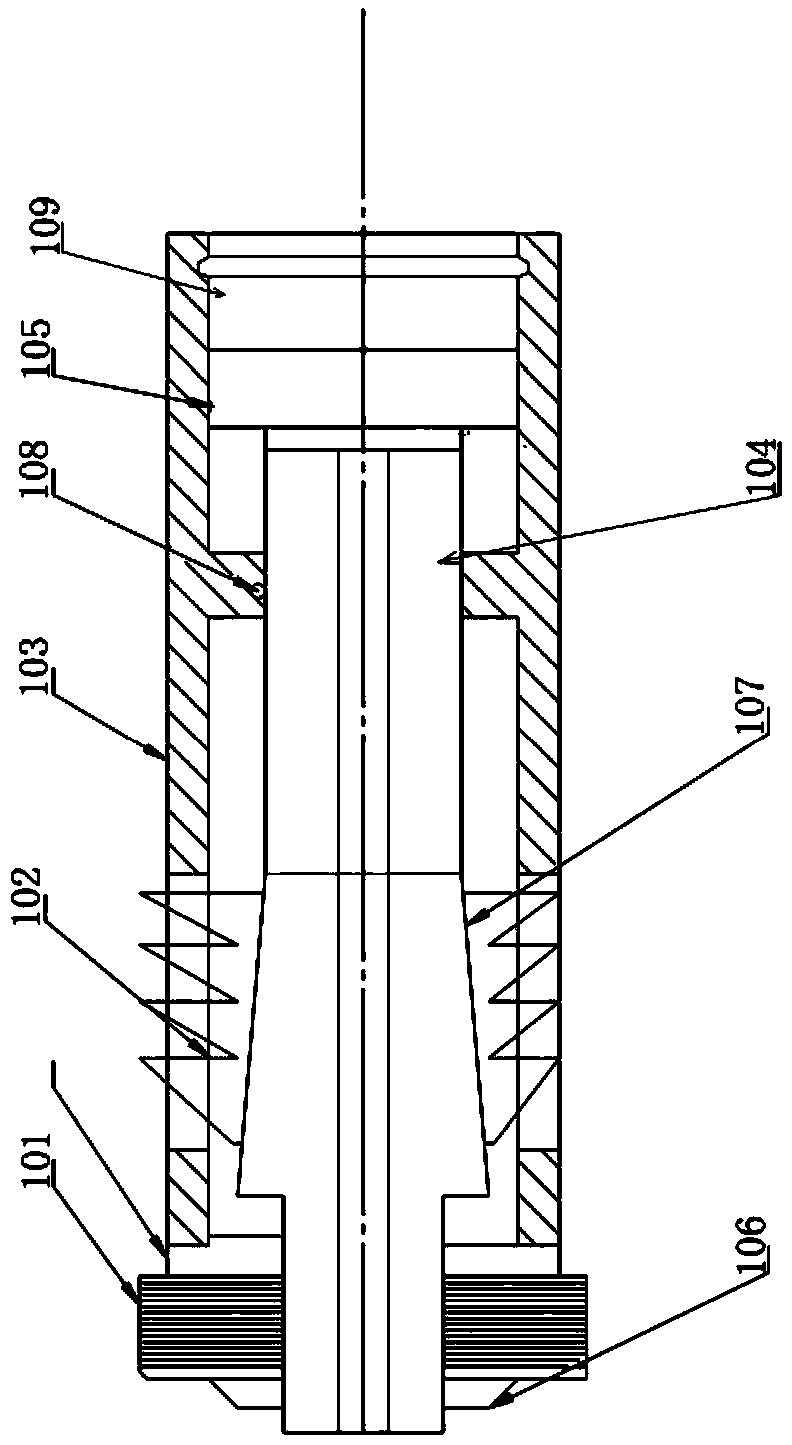

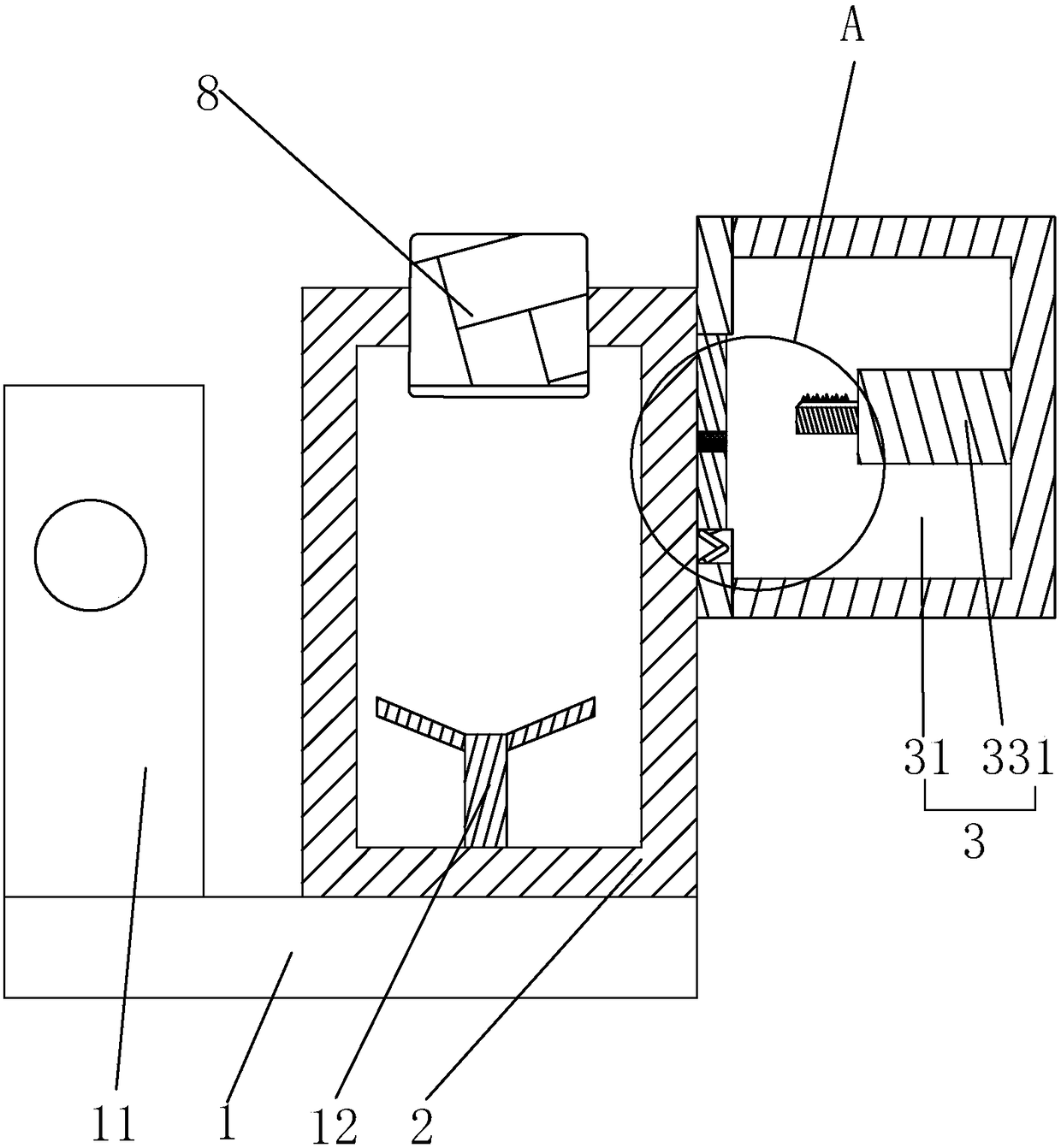

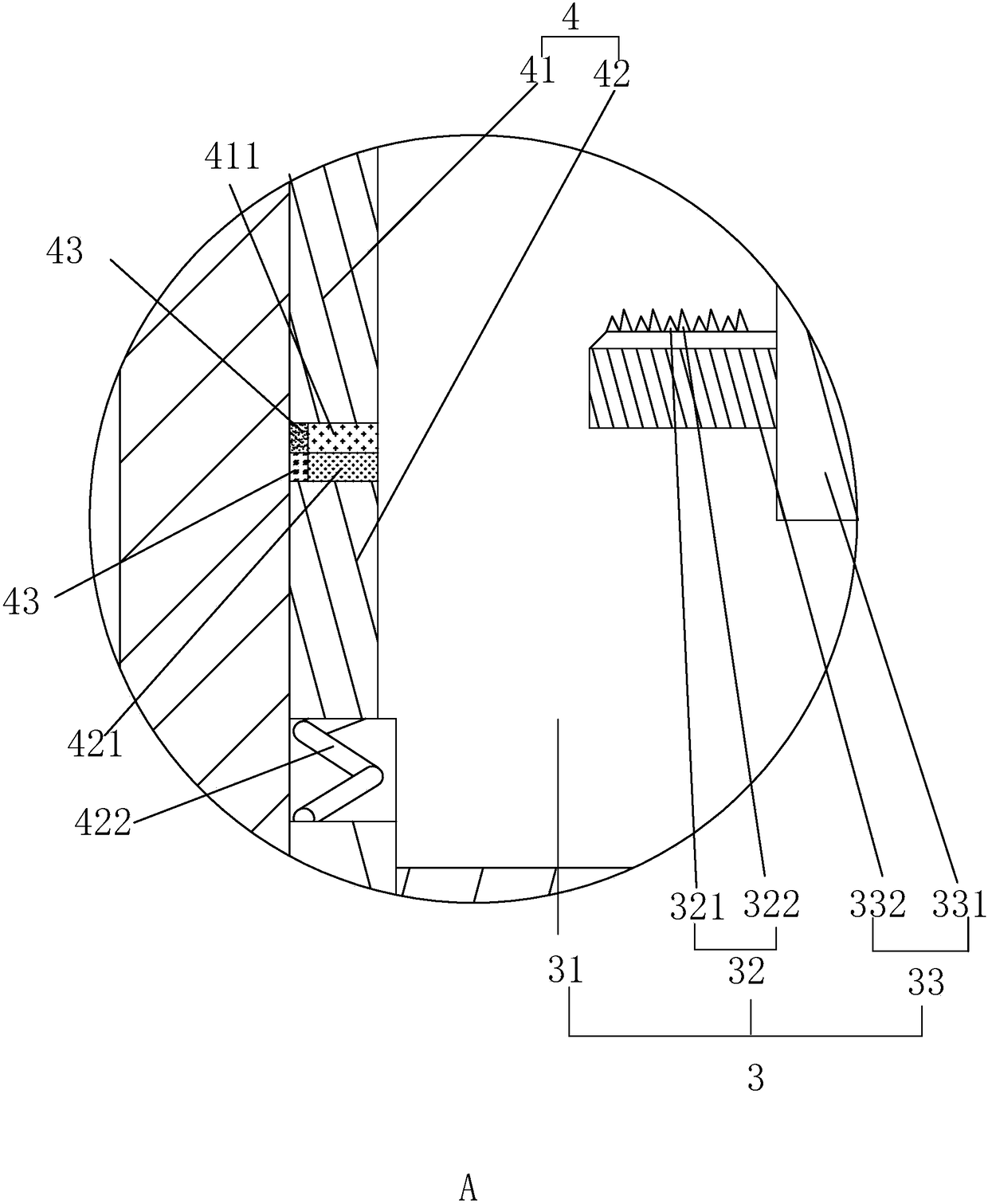

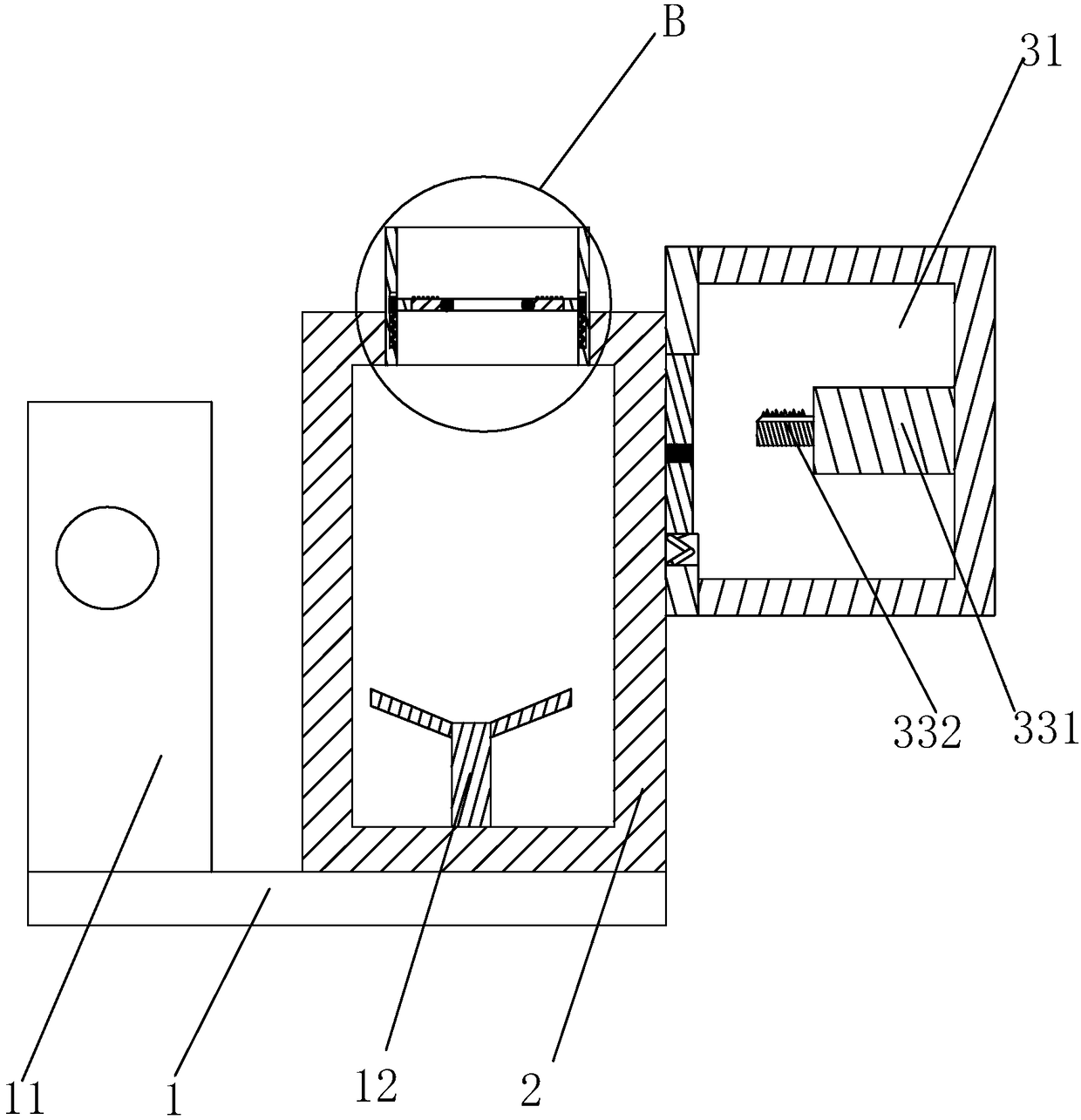

Device capable of replacing valve under pressure

ActiveCN103742710AReliable stuckEnsure construction safetyValve arrangementsPipe elementsHydraulic cylinderInternal pressure

The invention provides a device capable of replacing a valve under pressure. The device comprises a plugging device, a combining part, a blowout prevention pipe, a hydraulic cylinder, a piston rod and an operating rod. One end of the combining part is detachably connected to the plugging device, and the blowout prevention pipe contains the plugging device and the combining part and is connected with the hydraulic cylinder. The plugging device is mainly composed of a sealing rubber sleeve, a slip bowl seal assembly, a differential pressure type piston and slips, the slips can be automatically unfolded through fluid pressure, and thus safe bowl seal is achieved. One end of the combining part is connected with the hydraulic cylinder through the piston rod and the operating rod which penetrate through the blowout prevention pipe. The invention further provides a method for replacing a valve under pressure with the device capable of replacing a valve under pressure. The device achieves seal, bowl seal, seal removal and internal pressure balance of a tool, the complex functions can be continuously and automatically completed in one travel, and thus the device is easier and more reliable to operate. Uncertainty caused by manual operation is reduced, safety in the construction process is guaranteed, no pollution will be caused to the environment, and construction cost is greatly reduced.

Owner:袁占良

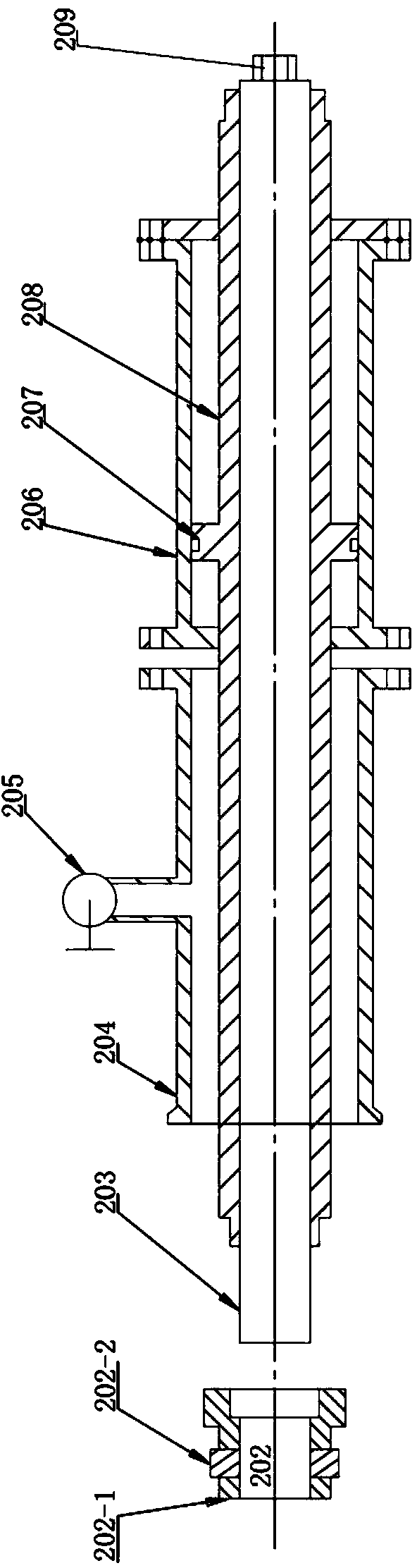

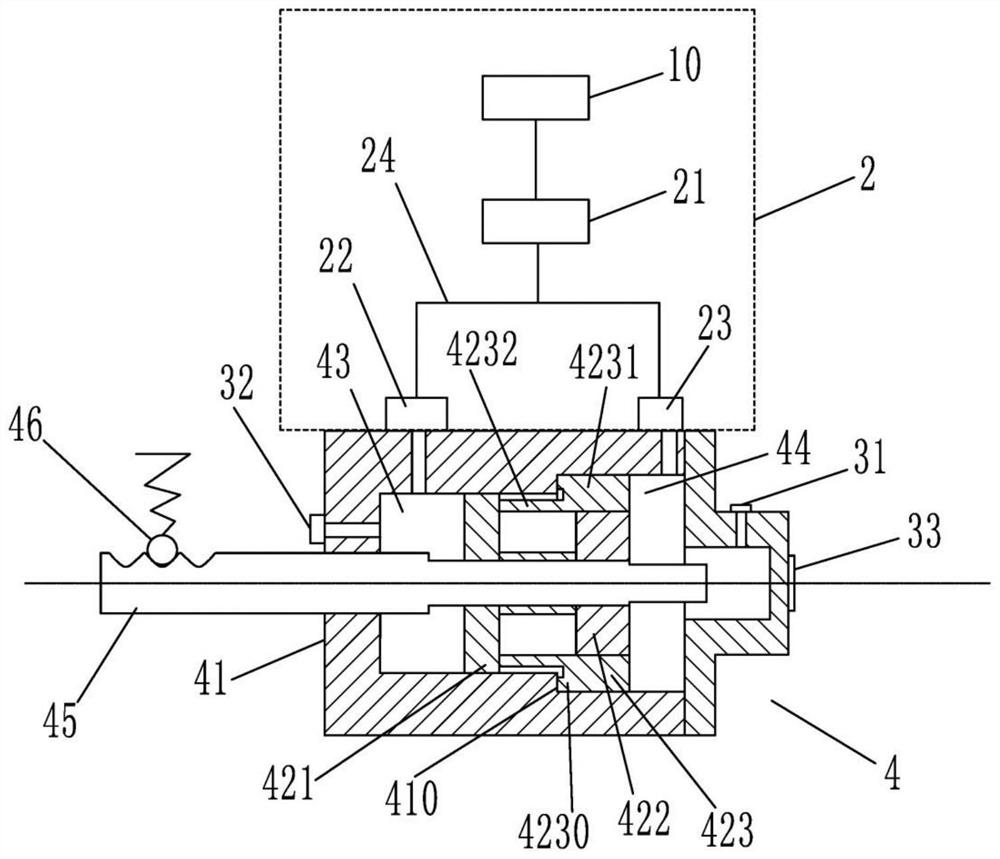

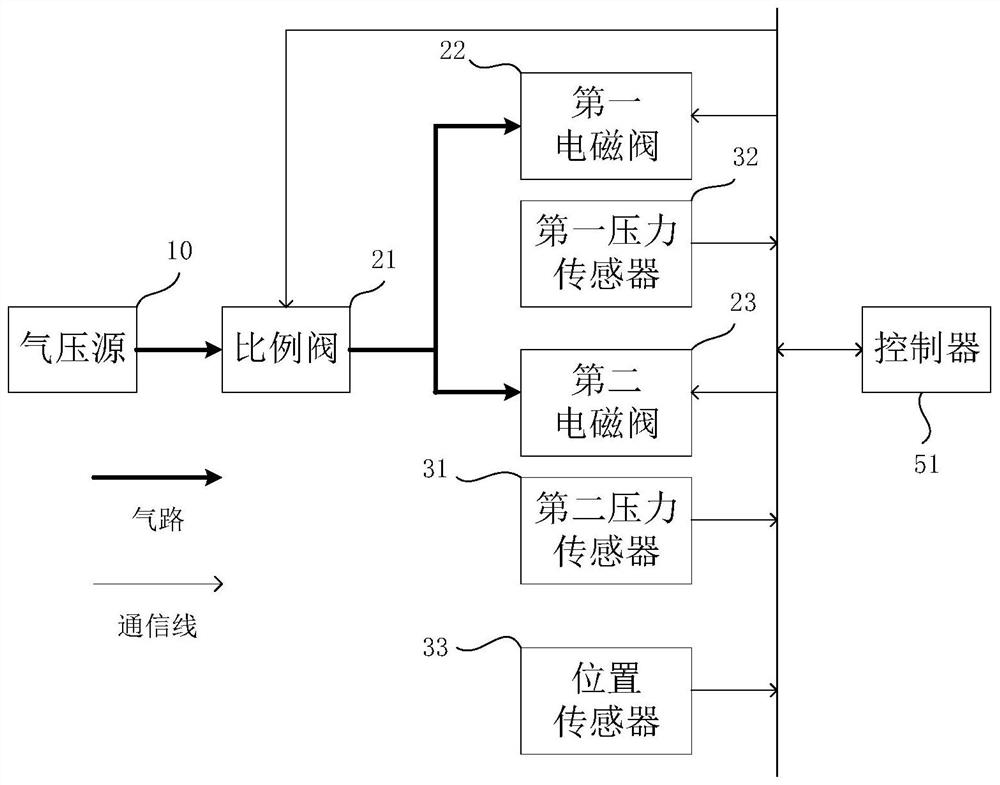

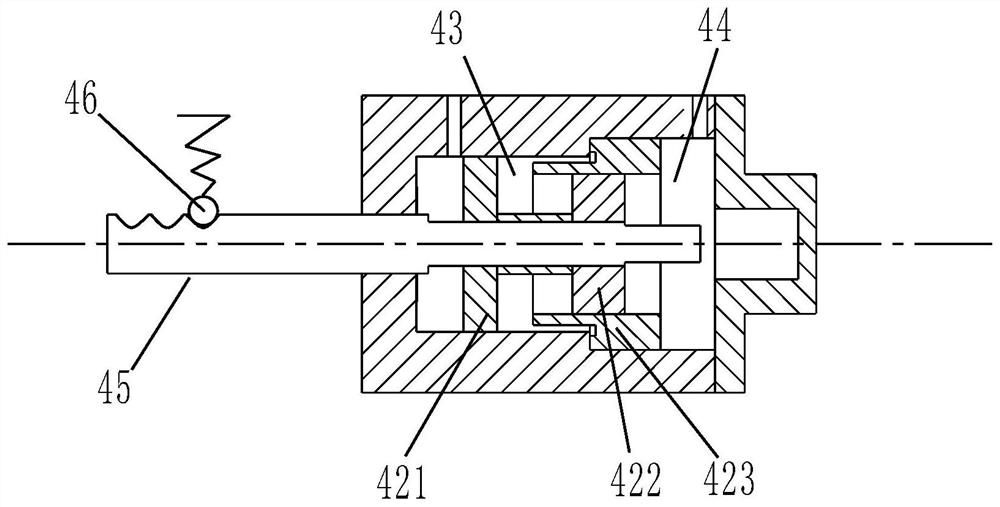

Piston cylinder system, control method, AMT gear shifting system and control method

ActiveCN113653686AGood pressure badReduce stickingServomotor componentsServomotorsClutchPiston cylinder

The invention relates to a piston cylinder system, a control method, an AMT gear shifting system and a control method, and relates to the technical field of AMT gearbox control. According to the piston cylinder system and the AMT gear shifting system, a piston structure with asymmetrical stress surfaces on the two sides is adopted, through flexible movement of a third piston and clutch matching of a second piston, when a piston rod moving from the left position to the middle position or from the right position to the middle position, the total stress area of the piston in a cavity on the upstream side of the piston rod is always larger than the stress area of the piston in a cavity on the downstream side of the piston rod, and therefore pressure difference can be better formed, and clamping stagnation is reduced. According to the method, the working condition that gear picking is difficult due to the fact that the pistons are clamped can be recognized according to the displacement amount of the piston rod in the gear picking (the piston rod moves towards the middle position) process, the gear picking force is controlled by controlling the flow of fluid entering the cavities, the gear picking force can be increased in time when the gear picking force is insufficient, and the problem of gear picking failure is solved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

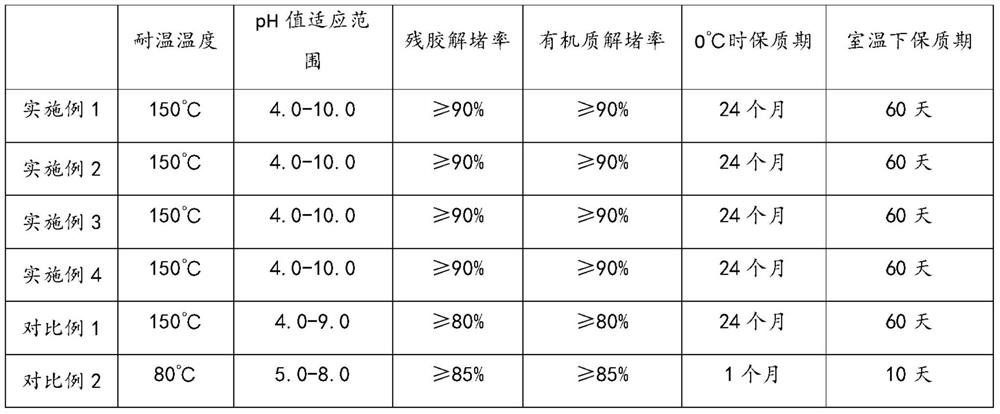

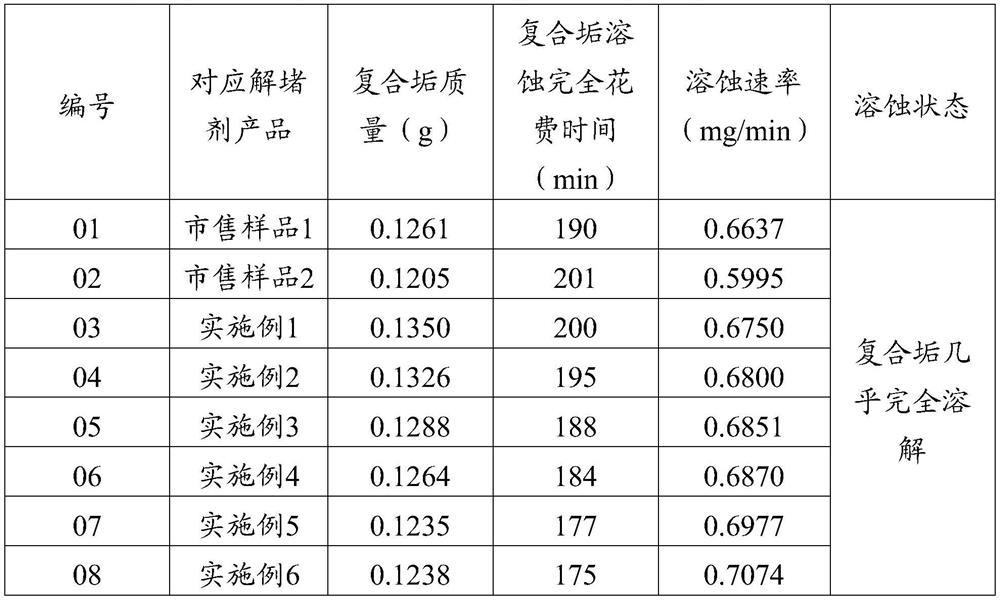

Biological enzyme composite blocking remover and preparation method thereof

ActiveCN112778991AReduce surface and interfacial tensionAvoid adsorptionDrilling compositionAmylaseActive agent

The invention relates to a biological enzyme composite blocking remover and a preparation method thereof, which belong to the technical field of oil field yield increase renovation. The blocking remover comprises the following components by mass: 0.1-0.5% of biological enzyme, 3-5% of a biological surfactant, 5-10% of a biological enzyme stabilizer, and the balance of water; the biological enzyme comprises at least one of xylanase, lipase, cellulase, mannase, protein complex enzyme, amylase and xanthan gum lyase; the biological surfactant is prepared from at least one of the following components: the biological surfactant is mainly prepared from rhamnolipid, sophorolipid and N-acetylgalactosamine; and the biological enzyme stabilizer comprises at least one of the following components: disodium ethylene diamine tetraacetate, citric acid and triethanolamine. The biological enzyme composite blocking remover provided by the invention can solve the problems of permeability reduction and the like caused by low-permeability and medium-low-permeability reservoir reconstruction residual gum and organic matter (wax, asphaltene and the like) blocking in the later development period.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

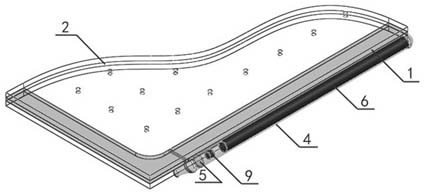

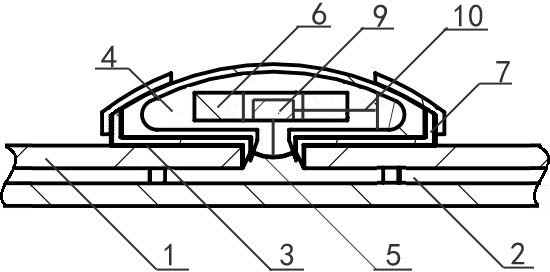

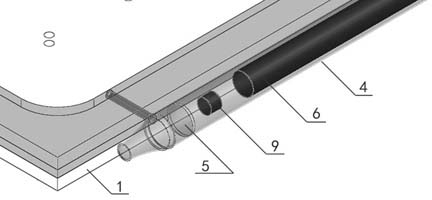

Vacuum glass panel with external cavity

InactiveCN102503098ARealize unblockingAchieve activityGlass reforming apparatusGetterMaterials science

The invention provides a vacuum glass panel with an external cavity, which is used for well solving the problem of the accommodation of a getter or other devices. The external cavity is only connected with a vacuum layer through a small pore canal or an airtight pipeline prearranged in an edge sealing layer of the vacuum glass panel, so that the influence on the stress of the vacuum glass panel is very small. The size of the internal space of the cavity and accommodating quantity can be determined as required; and meanwhile, material selection of the cavity is wide, so that the requirement of accommodation of various large-sized getters can be met. In the vacuum glass panel provided with a plurality of external cavities, the getters can be activated or deblocked segmentally as required, so that long-term preservation of a vacuum degree is facilitated.

Owner:胡效国

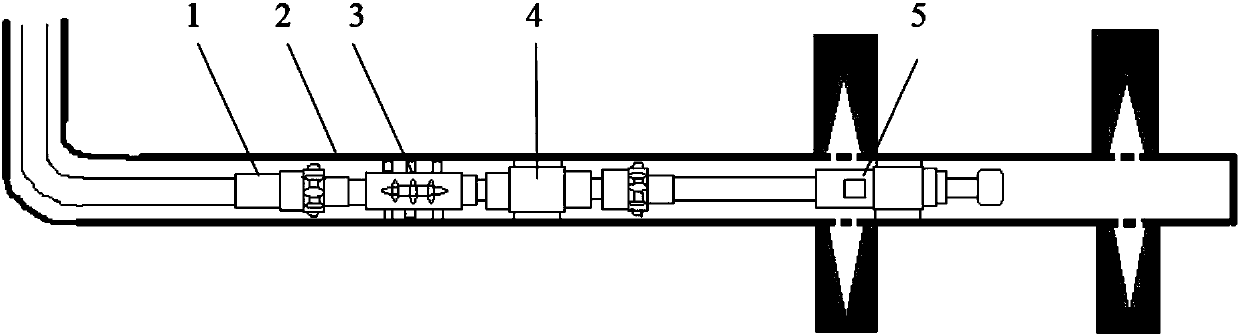

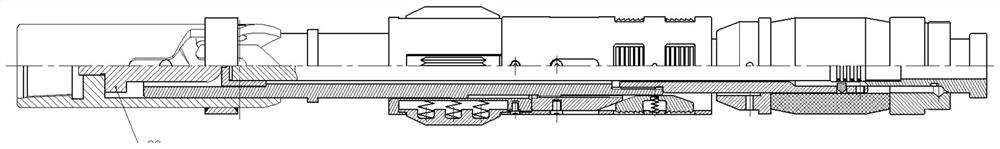

Electric fishing tool of preset downhole throttler and fishing method thereof

PendingCN111550212AReduce fishing friction resistanceImprove the success rate of salvageFluid removalMarine engineeringReciprocating motion

The invention provides an electric fishing tool of a downhole throttler and a fishing method thereof. The electric fishing tool comprises an upper joint, an external cylinder, a lower joint, a pressing cap and a working external cylinder which are sequentially connected from top to bottom, the lower end surface of the pressing cap abuts against a pressing sleeve, a claw seat is arranged on the outer wall of the pressing sleeve in a sleeving mode, a claw is embedded into the claw seat, a motor is installed in the external cylinder, a screw rod is rotatably connected into a hollow rotor shaft ofthe motor in a penetrating mode, the screw rod is connected with a central ejecting rod, and the central ejecting rod can be inserted into a throttler to unseal the throttler. According to the electric fishing tool, power is provided relying on the forward and reverse rotation of the motor, the up-down reciprocating movement of the central ejecting rod of the throttler is driven until the centralejecting rod enters into the preset downhole throttler, and the unsealing of the preset downhole throttler in service is achieved; and an inner cavity of the external cylinder can be used as a storage space for lubricating grease, during fishing, the lubricating grease stored in the inner cavity can be squeezed between an oil pipe and the throttler, the fishing friction resistance is reduced, andthe fishing success rate is increased.

Owner:PETROCHINA CO LTD

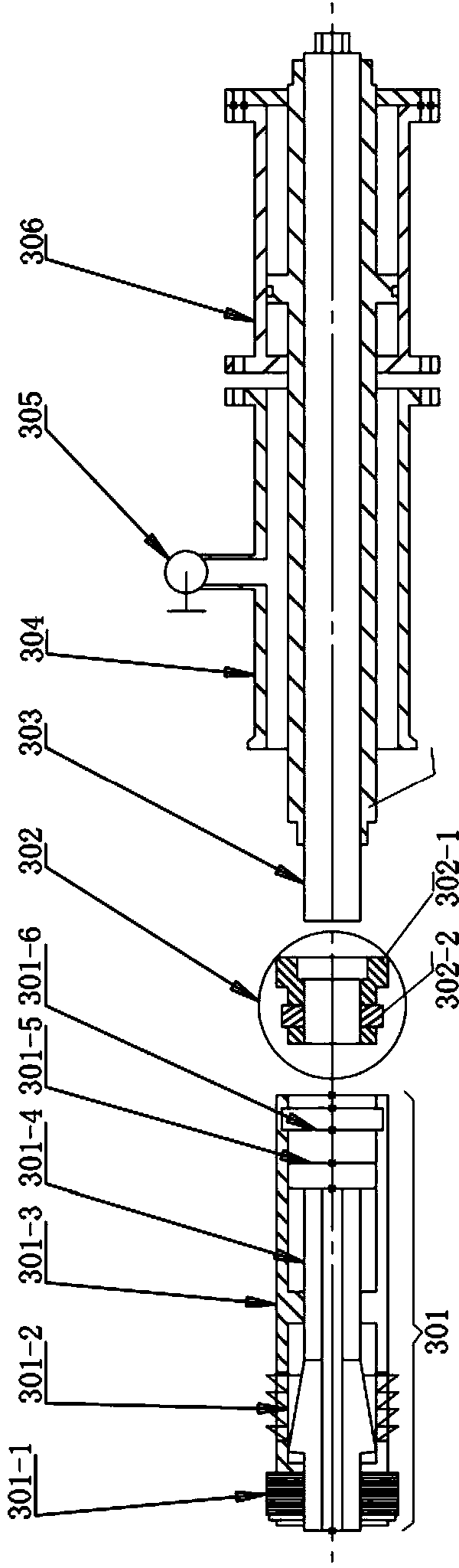

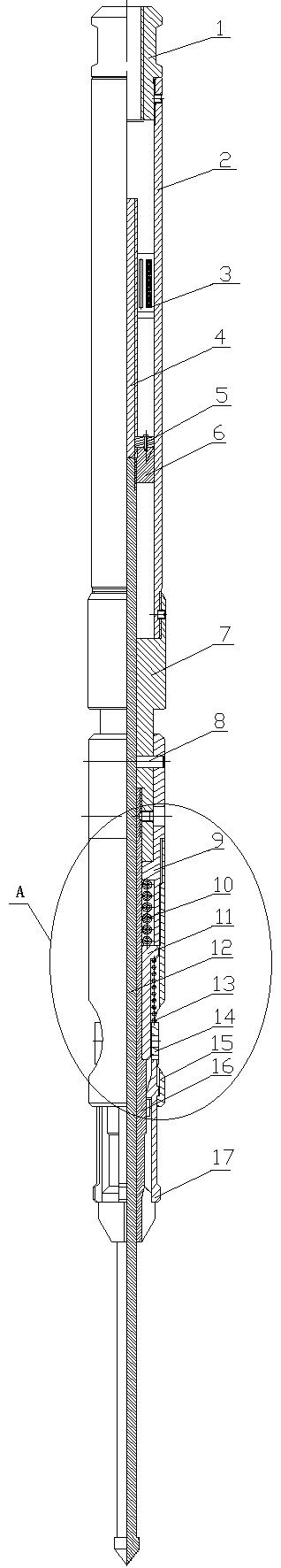

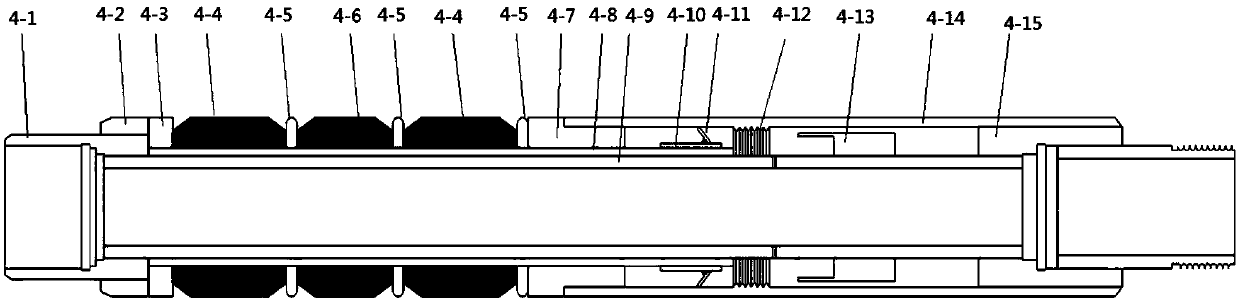

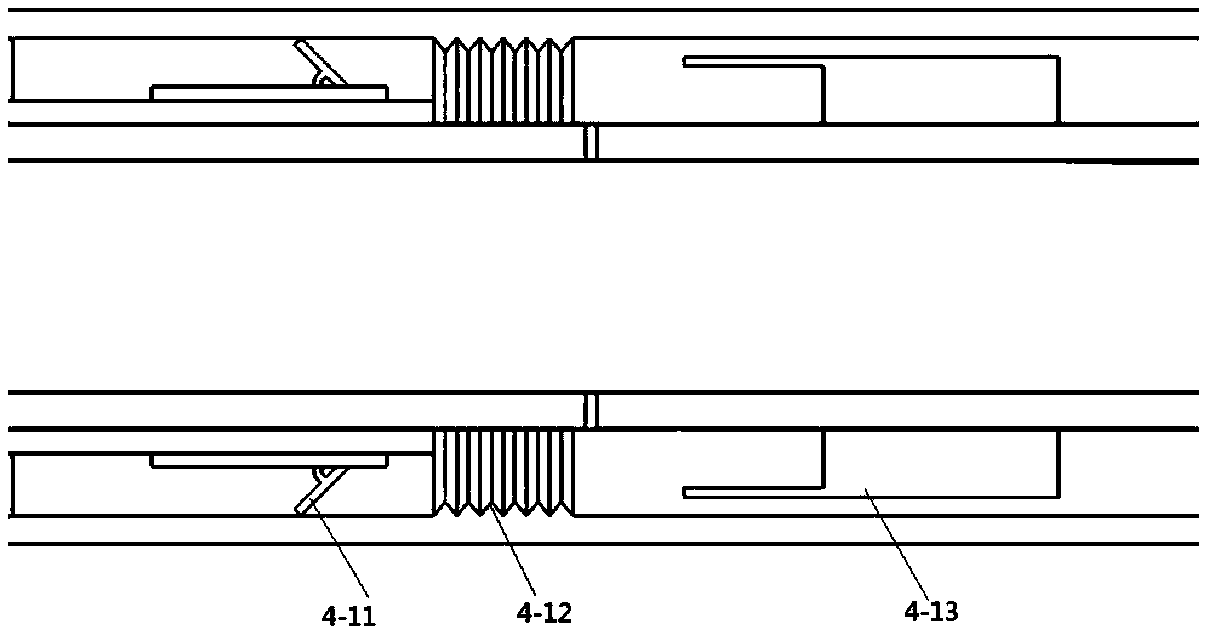

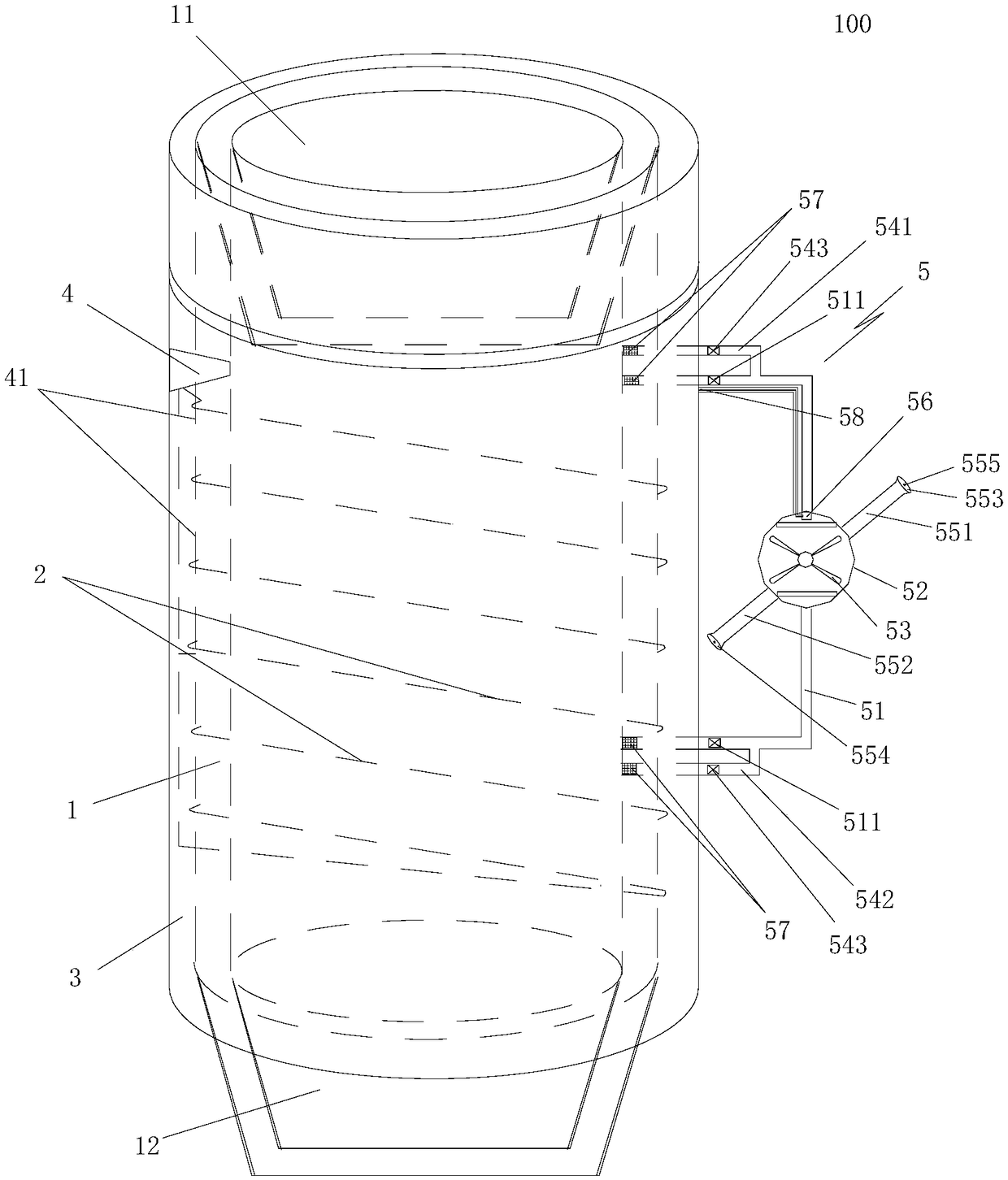

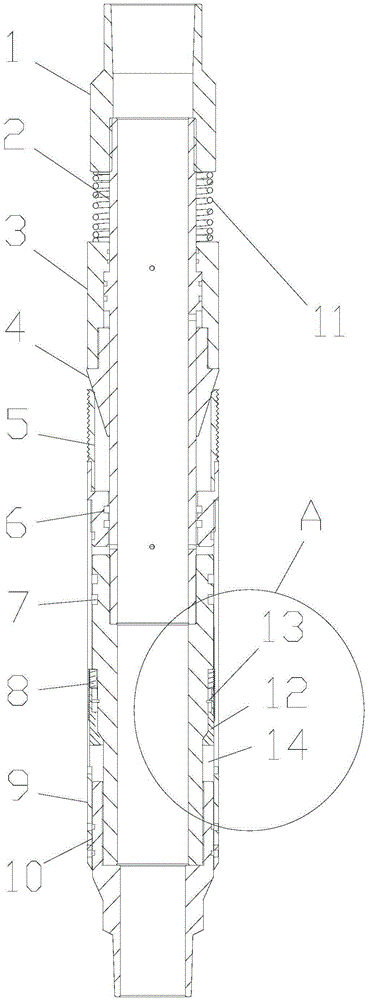

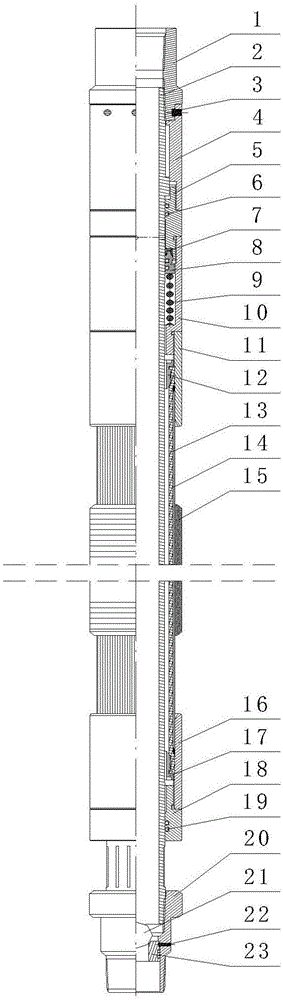

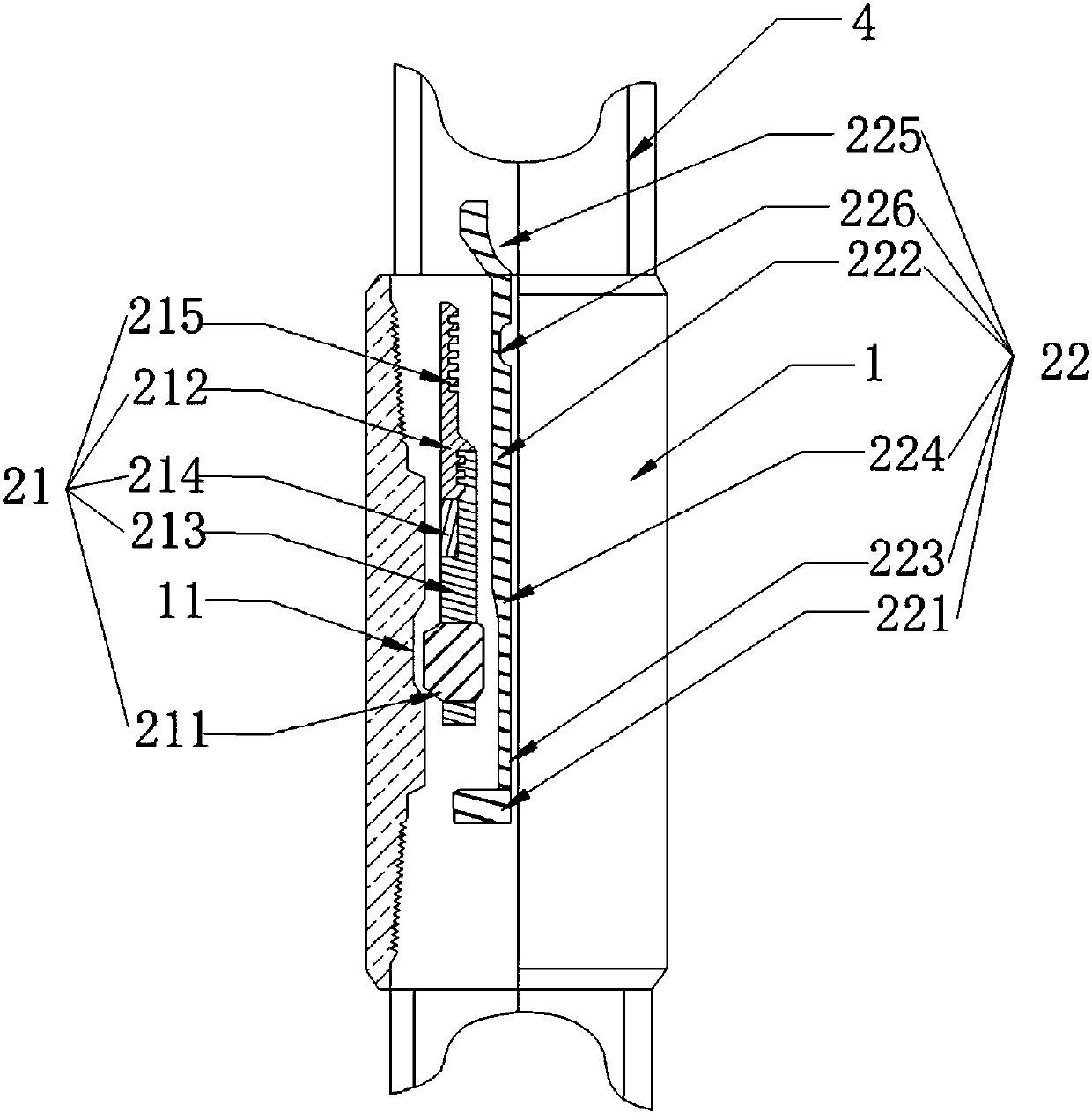

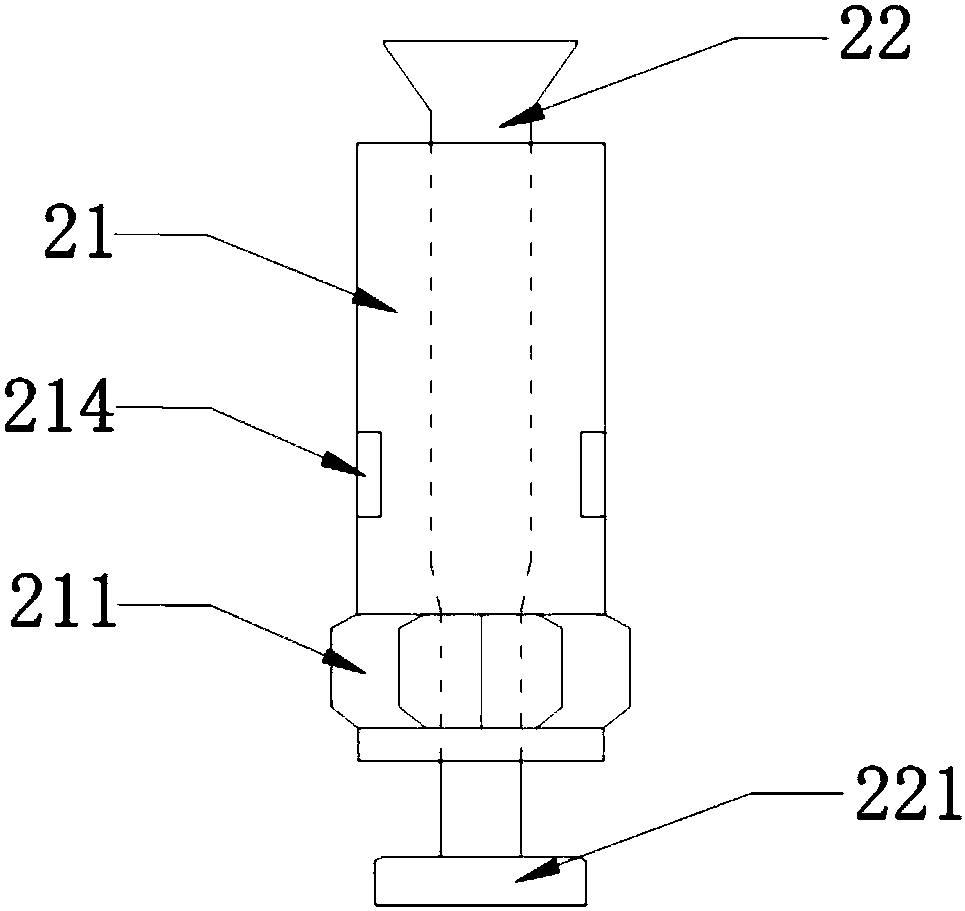

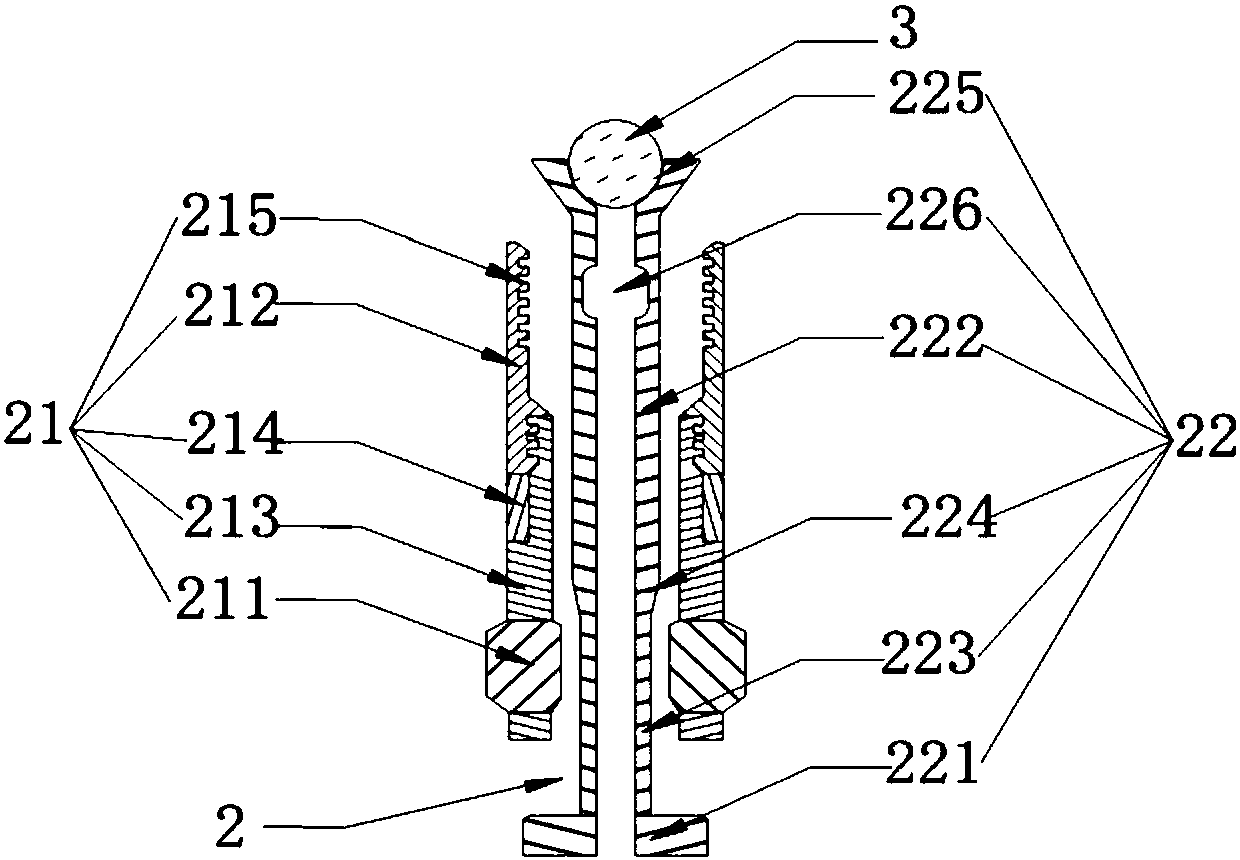

Packer for realizing infinite fracturing and working method thereof

PendingCN107605423AGood repeatabilityEasy to unpackFluid removalSealing/packingEngineeringMechanical engineering

The invention relates to a packer for realizing infinite fracturing and a working method thereof. The packer comprises a central pipe, a lining pipe and a sealing mechanism which are sequentially connected in a sleeving way from inside to outside, wherein the sealing mechanism comprises a piston, a sealing sleeve and a lower joint which are sequentially connected; sealing cavities are defined by the sealing mechanism on the outer side walls of the central pipe and the lining pipe; the sealing cavities are internally provided with locking ring sleeves and unsealing ring sleeves. According to the packer for realizing the infinite fracturing, disclosed by the invention, hydraulically controlled sealing and unsealing are realized by adopting a novel mechanism; a traditional sealing pin and a traditional unsealing pin are prevented from being used, repeated sealing and unsealing of the packer are facilitated, and the infinite fracturing is further realized; the stability of the packer is increased to a large extent, and the production efficiency of a whole fracturing process is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

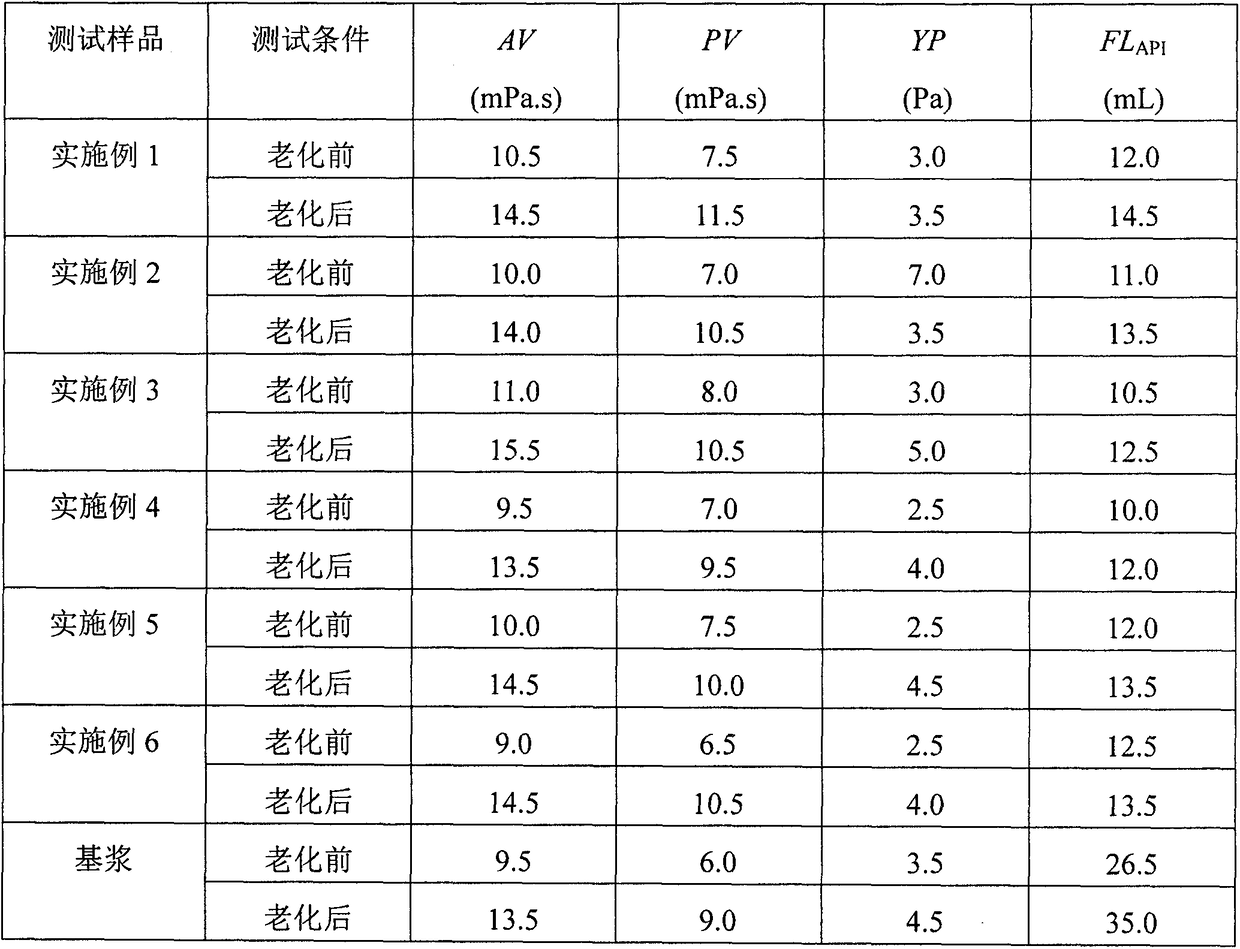

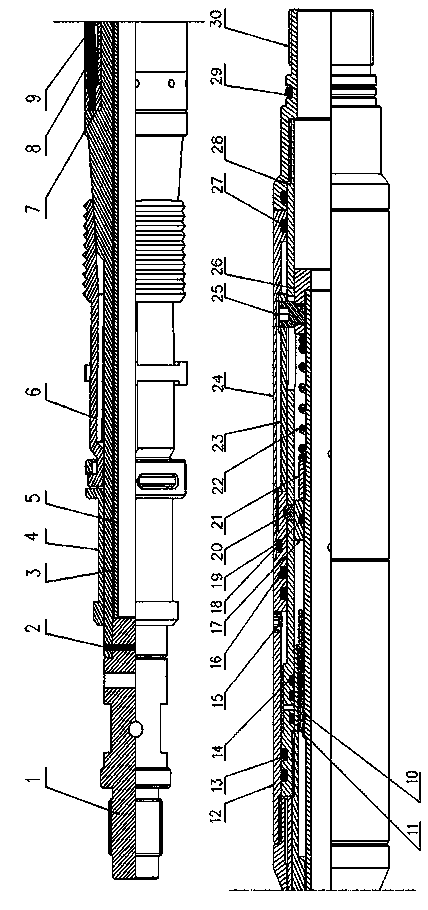

Cellulose nanocrystal used as water-based drilling fluid anti-collapse agent and preparation method of cellulose nanocrystal

InactiveCN108559463ANo fluorescenceGood anti-collapse effectDrilling compositionWater basedFluorescence

The invention relates to a cellulose nanocrystal used as a water-based drilling fluid anti-collapse agent and a preparation method of the cellulose nanocrystal and belongs to the field of petroleum and natural gas resource exploration and development and natural polymer material preparation. The cellulose nanocrystal used as the water-based drilling fluid anti-collapse agent is prepared from, by weight, 3-12% of cellulose pulp, 54-75% of oxalate dihydrate, 0.25-3.5% of high-priced metal salt and balance water, and made by a reaction at 95-100 DEG C for 7-16 hours under mechanical stirring conditions. The product size is 100-700nm, the cellulose nanocrystal has the advantages of being excellent in anti-collapse capability, free of toxicity and fluorescence, environmentally friendly and thelike and also has good filtrate loss performance, and the temperature resistance is up to 180 DEG C. Since the cellulose nanocrystal is prepared by using natural biomaterials, the cellulose nanocrystal automatically degrades after a period of time to achieve automatic deblocking, and damage to a reservoir is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

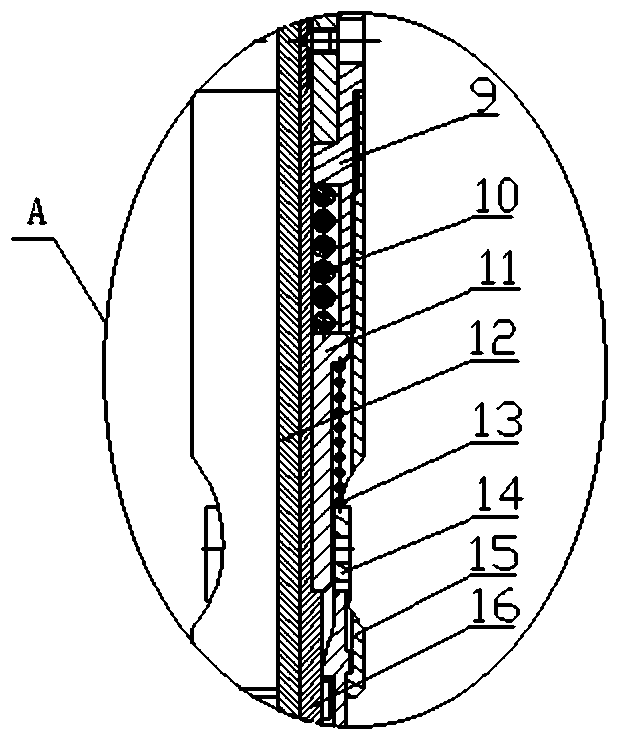

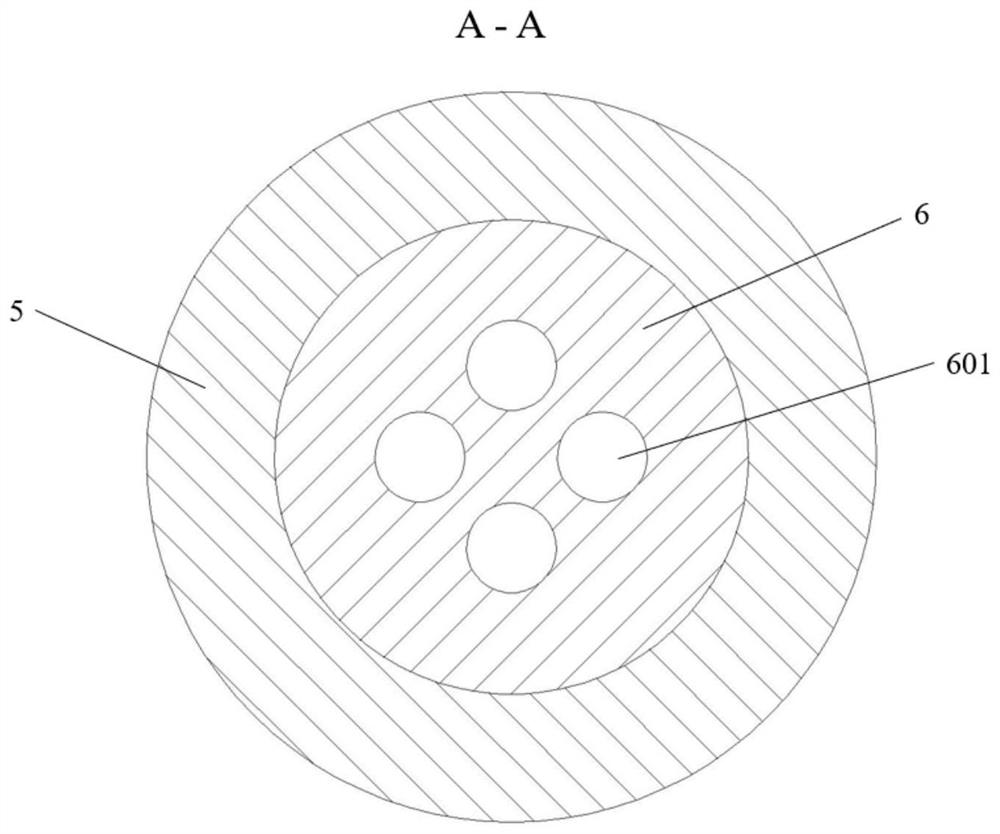

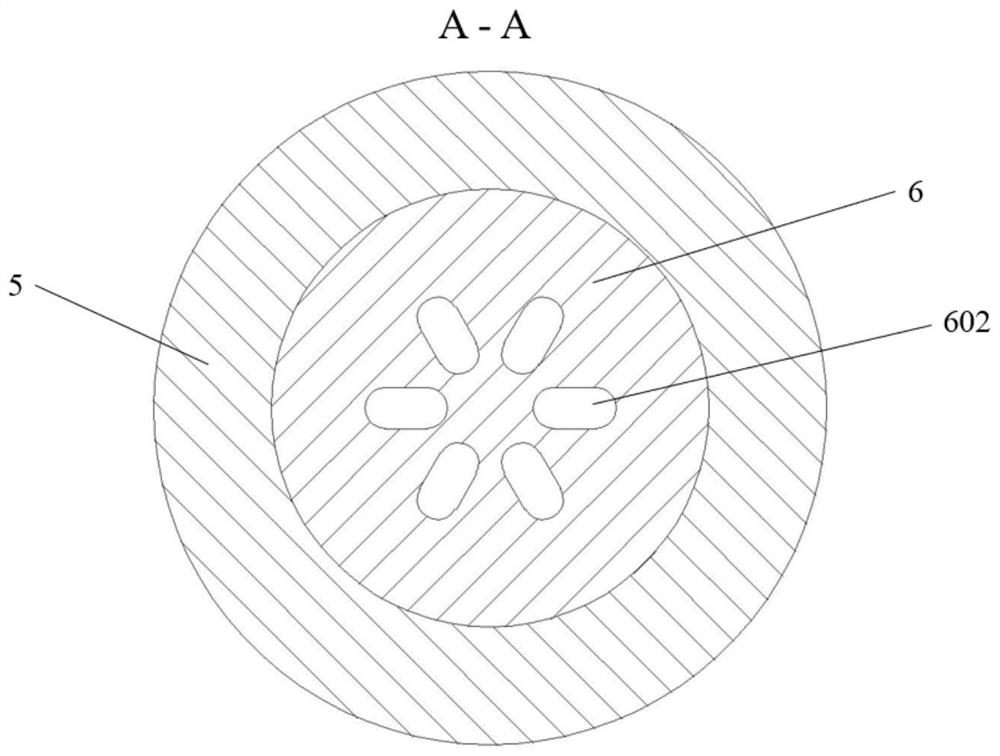

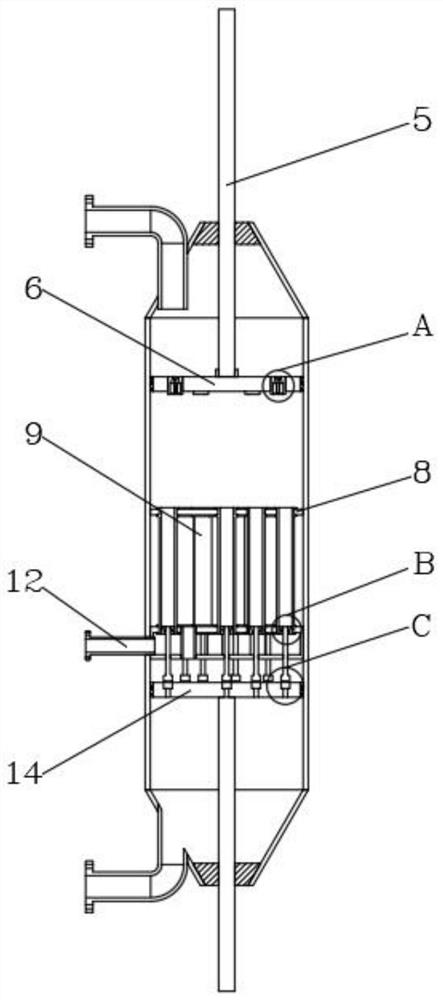

Induction heating-type short joint of marine riser used for prevention and control of hydrates during deepwater drilling

ActiveCN108979561AAvoid formingRealize unblockingDrilling rodsCleaning apparatusElectricityInsulation layer

The invention relates to an induction heating-type short joint of a marine riser used for prevention and control of hydrates during deepwater drilling. The joint comprises a communicating tubular short joint body. Induction heating coils are fixedly arranged on the outer wall surface of the tubular short joint body in a winding manner. The outside of the tubular short joint body is wrapped by a water-proof insulation layer. The induction heating coils are arranged between the tubular short joint body and the water-proof insulation layer in a sealing manner. The water-proof insulation layer isequipped with an electrifying interface connected with a power supply. The induction heating coils are electrically connected with the electrifying interface. The induction heating-type short joint ofthe marine riser used for prevention and control of hydrates during deepwater drilling is continuously powered on such that eddies are generated in the interior of the marine riser, heating the riserand the internal space thereof. Natural gas hydrates are effectively prevented from being formed in the riser. After the natural gas hydrates are formed in the interior of the riser, the induction heating coils of the short joint of the marine riser are used for power supply. By means of eddies generated in the riser, the hydrates obstructing the riser are heated in order to break the balance state. Therefore, the hydrates are decomposed in order to remove obstructions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

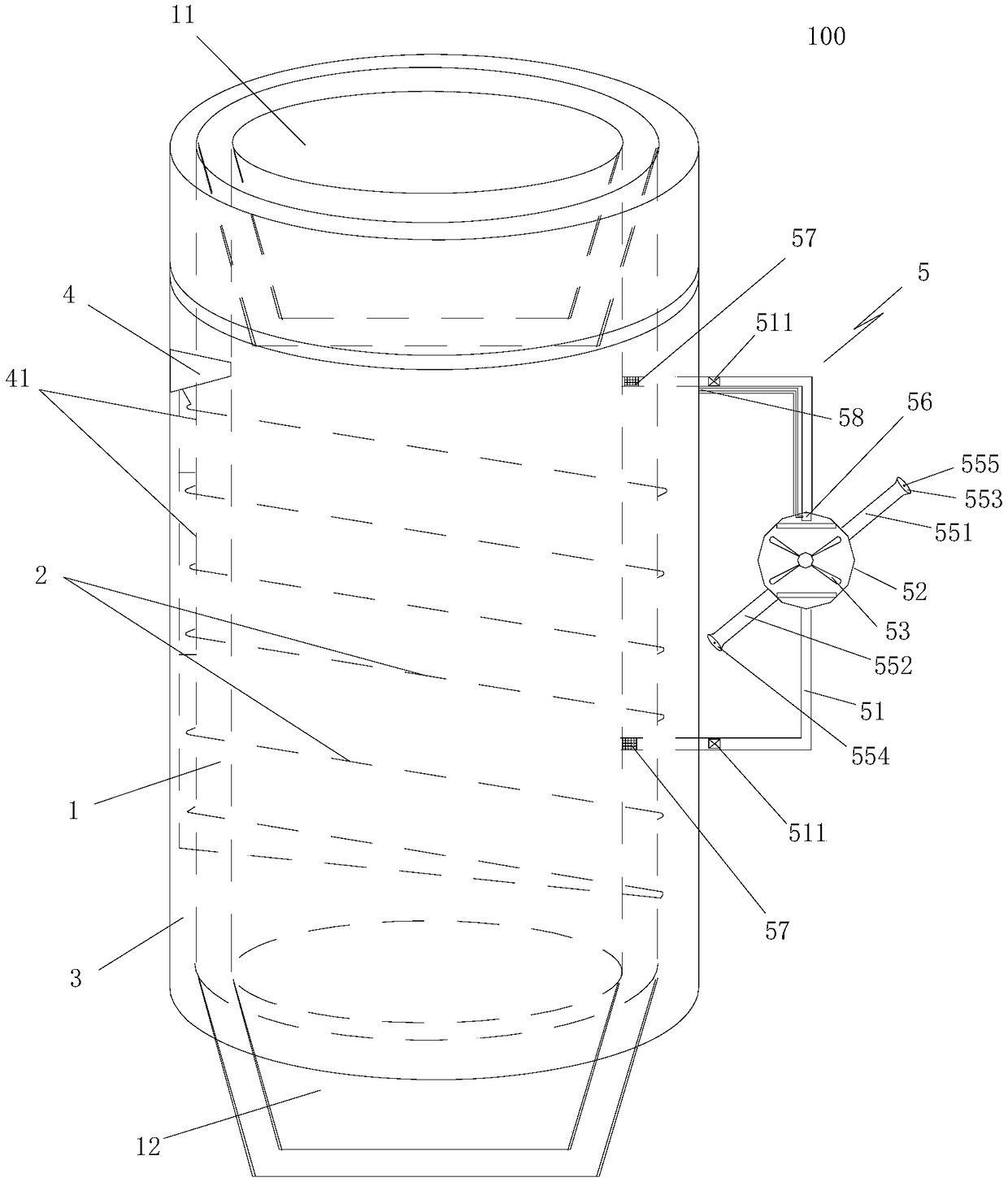

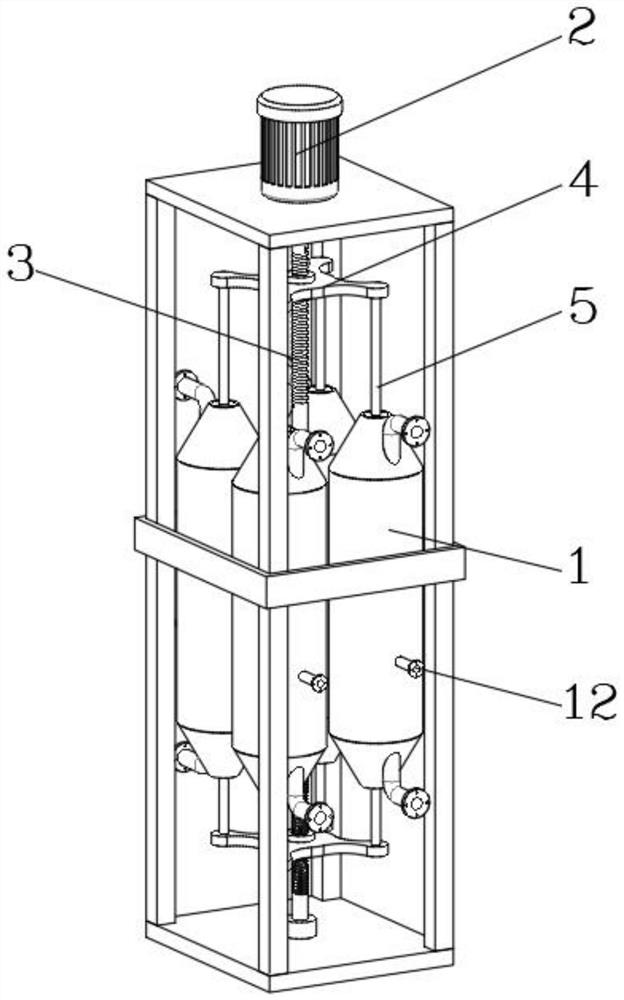

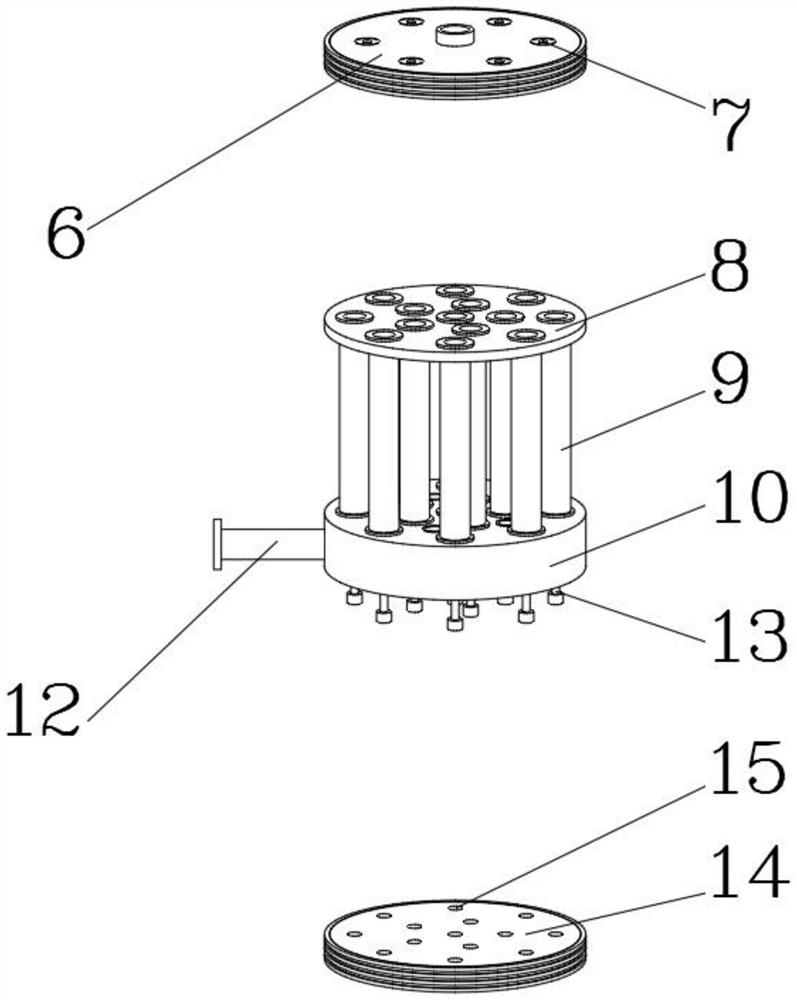

Multi-stage accelerated rotational flow cavitation device

InactiveCN114733424APromote generationSpeed up the flowTransportation and packagingMixersMixed flowCavitation bubble

The invention relates to a multi-stage acceleration rotational flow cavitation device which comprises a first-stage shrinkage pipe, an acceleration pipe, a flow mixing plate, a rotational flow acceleration section, a second-stage shrinkage pipe, a nozzle pipe, a natural vibration cavitation cavity and a flow guide body, and the first-stage shrinkage pipe is located above the acceleration pipe and is in threaded connection with the acceleration pipe; the flow mixing plate is mounted at the uppermost end in the accelerating tube, and an inclined through hole is formed in the flow mixing plate; the rotational flow acceleration section is positioned below the flow mixing plate; the second-stage shrinkage pipe is located below the rotational flow acceleration section, and the diameter of each section of the second-stage shrinkage pipe is smaller than that of the first-stage shrinkage pipe; the nozzle pipe is located below the accelerating pipe, and a converging and flushing nozzle is arranged on the nozzle pipe; the flow guide body is installed at the bottom end of the nozzle pipe, and a through hole matched with the confluence flushing nozzle is formed in the flow guide body in the circumferential direction. The device is simple in structure and high in efficiency, the number of cavitation bubbles is increased through mutual impact of fluid, gas-liquid separation is generated through the rotational flow acceleration section, generation of cavitation bubbles is promoted again, different cavitation strengths are generated through the confluence nozzle, and oil and gas well blockage removal is better facilitated.

Owner:SOUTHWEST PETROLEUM UNIV

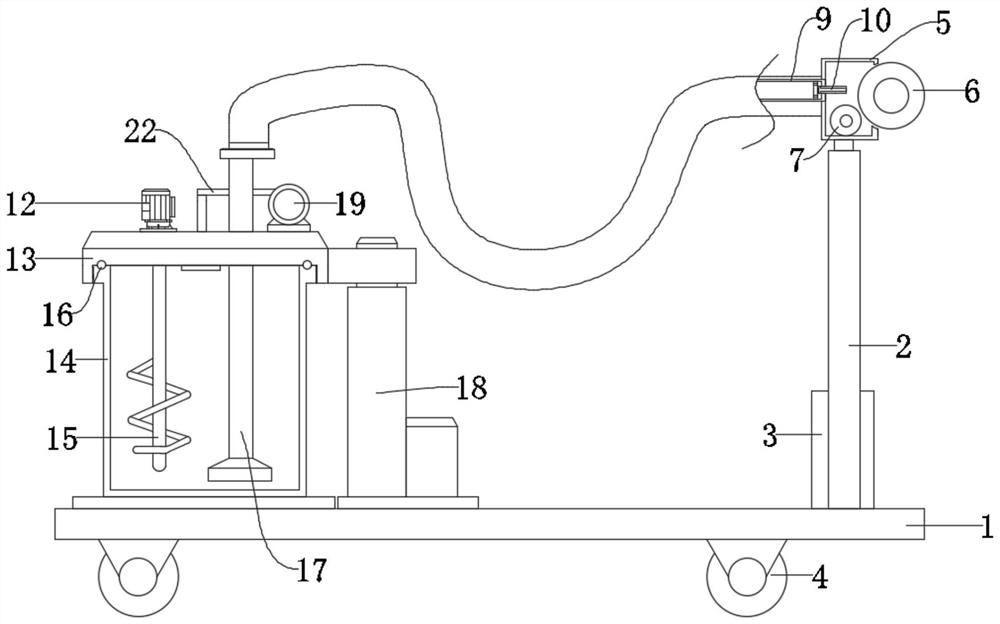

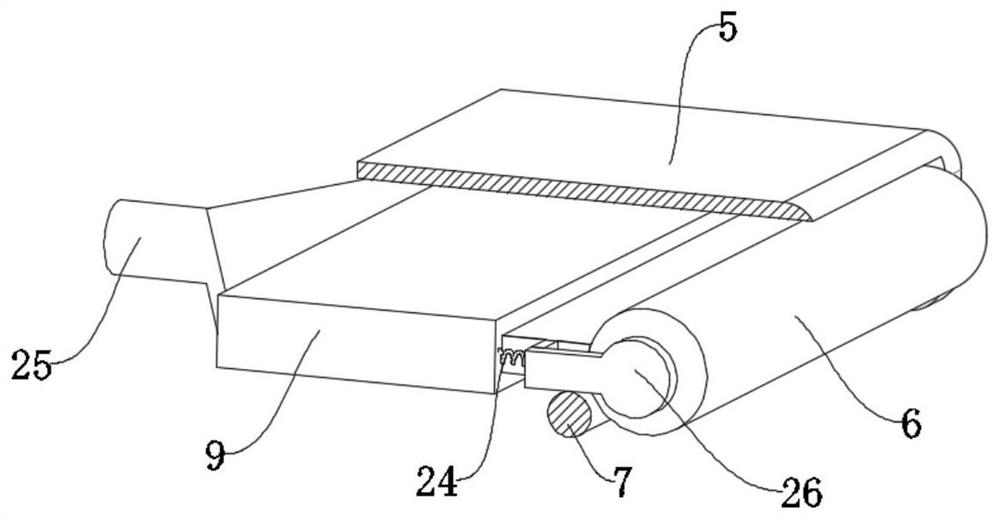

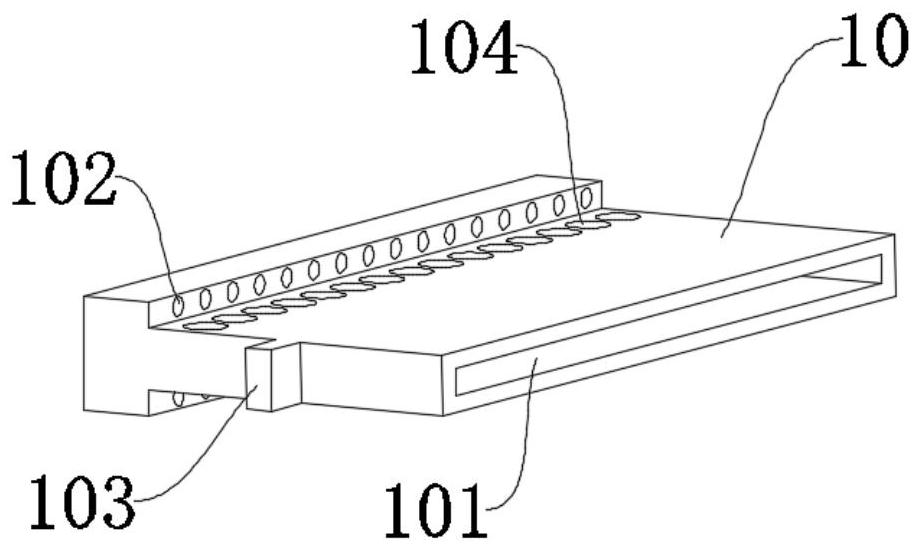

Grouting device in ceramic production process

The invention relates to the technical field of ceramic machinery, in particular to a grouting device in a ceramic production process. The grouting device comprises a workbench, wherein two support seats are installed on the workbench, and a rotating shaft is connected between the two support seats. According to the device, a grouting cylinder is installed on a support plate on the support seats, a mold is installed below a grout outlet tube on the grouting cylinder, and automatic grouting for the mold can be achieved. Seals and support frames are installed on two sides of the grout outlet tube, second contact piece support rods are movably installed on the corresponding support frames, floating blocks on the corresponding second contact piece support rods are pushed by grout in the mold to move vertically, and accordingly, contact and separation of the two contact pieces can be realized, the effect of connecting electrification coils in the seals is achieved, and sealing and unsealing of the grouting tube by sealing plates is achieved by acting force of an induction metal block on the sealing plates. In this way, the effect of automatic and accurate control of the injection amount of the grout is achieved, and waste or insufficient injection is avoided.

Owner:大埔县发源发展有限公司

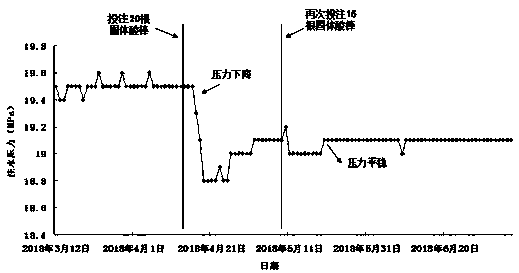

Solid acid rod for water injection well and preparation and injection methods of solid acid rod

ActiveCN110028946AGood corrosion inhibition effectImprove acidification effectFluid removalDrilling compositionSolid acidEthyl acetate

The invention discloses a solid acid rod for a water injection well as well as preparation and injection methods of the solid acid rod. The solid acid rod is prepared from 25%-35% of maleic acid-acrylic acid copolymer, 10%-20% of ethyl acetate, 10%-18% of water-soluble imidazoline oleate corrosion inhibitor, 5%-12% of sodium alpha-olefin sulfonate, 20%-30% of diethylenetriaminepentaacetic acid iron(III) diammonium and 5%-15% of polyvinyl acetate emulsion. The appearance of the solid acid rod is cylindrical.

Owner:PETROCHINA CO LTD

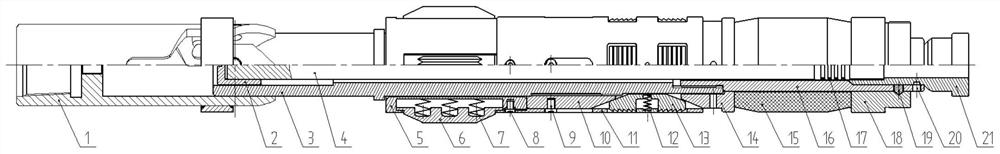

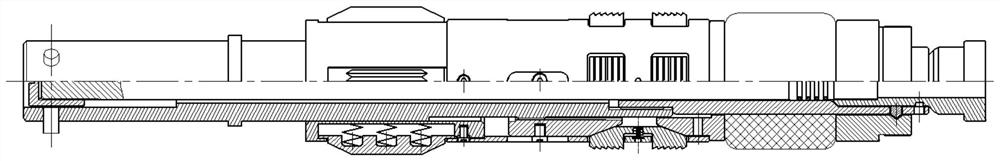

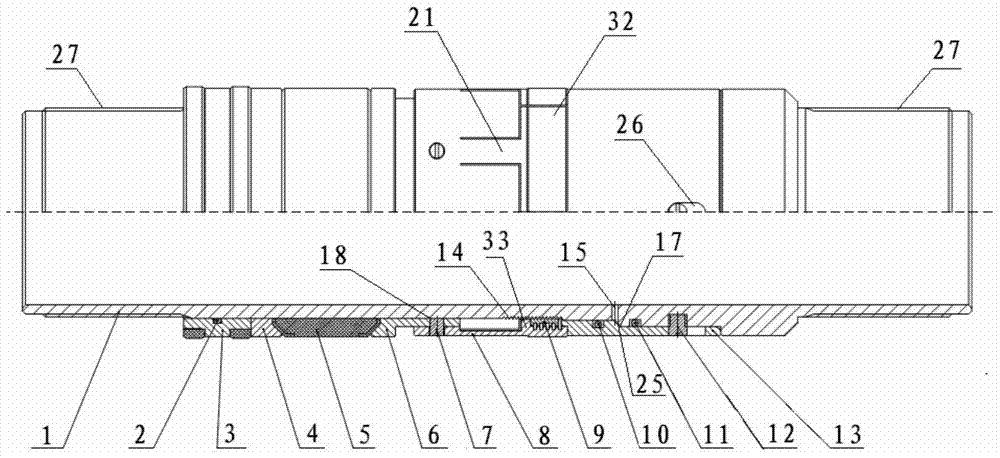

Retrievable differential pressure sealing suspension feeder

The invention relates to a retrievable differential pressure sealing suspension feeder. The retrievable differential pressure sealing suspension feeder is characterized in that an upper connector, a body and a central tube are fixed in the front of a setting packer through shear pins; a fishing neck is disposed on the body; the body is sleeved with a slip insert and rubber cylinder assembly; a piston is connected to the body in a threaded manner; the piston is sleeved with a cylinder sleeve and forms a closed air chamber through an O-shaped seal ring; a lock block is disposed on the piston; a compression spring is fixed on the central tube through a fixing ring and a pressure ring; a lower connector is connected with the piston in a threaded manner. The retrievable differential pressure sealing suspension feeder has the advantage that anchoring and packing unblocking are achieved through the compression spring and differential pressure release.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Microcrystalline cellulose used as temporary protective plugging agent for drilling fluid reservoir and preparation method thereof

The invention relates to microcrystalline cellulose used as a temporary protective plugging agent for a drilling fluid reservoir and a preparation method thereof, and belongs to the field of oil and natural gas resource exploration and development and natural polymer material preparation. The microcrystalline cellulose is prepared by mixing 2 wt%-12 wt% of cellulose slurry, 20 wt%-42 wt% of oxalicacid dihydrate, 0.25 wt%-3.5 wt% of high-valence metal salt and the balance water under the temperature of 95 DEG C-100 DEG C and the condition of conducting mechanical stirring for 3h-5h. The dimension of a product is 20 microns-80 microns, the product has the advantages of no toxin, no fluorescence, environmental friendliness, low cost and the like, effective plugging on micro pores and micro cracks of an oil and gas reservoir can be achieved, because the microcrystalline cellulose is prepared from natural biological materials, the product is self-degraded after a period of time, automaticunsealing can be achieved, and the purpose of protecting the reservoir is achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Mechanical temporary plugging bridge plug

ActiveCN112855074AImprove sealingReliable blocking throwSealing/packingShear pinEnvironmental geology

The invention discloses a mechanical temporary plugging bridge plug, and relates to the technical field of oil field downhole tools. The mechanical temporary plugging bridge plug comprises a central pipe assembly, a core rod assembly, a friction anchoring assembly, a rubber sleeve, a rubber sleeve lower baffle ring and a clamping block, wherein the core rod assembly is hermetically inserted in the central pipe assembly from bottom to top, the friction anchoring assembly, the rubber sleeve and the rubber sleeve lower baffle ring are all sleeved on the outer side of the central pipe assembly, the rubber sleeve lower baffle ring is connected with the central pipe assembly through the clamping block, the core rod assembly comprises a core rod and a core rod lower connector with the diameter larger than that of the core rod, the inner side of the clamping block penetrates through the center pipe assembly and then abuts against the core rod lower connector, the outer side of the clamping block is matched with the rubber sleeve lower baffle ring through an inclined face, the friction anchoring assembly comprises a friction assembly and an anchoring assembly, and the anchoring assembly is in threaded connection with the central pipe assembly. After setting, the elastic force of the rubber sleeve is locked through the clamping block and does not directly act on an unsetting shear pin; and meanwhile, the inner side is blocked by the core rod assembly with the thick lower part and the thin upper part, so that the mechanical temporary plugging bridge plug can bear high pressure at the shaft bottom and is more reliable in setting.

Owner:大庆市亚盛油田技术开发有限公司

Hydraulic tubing anchor

The invention relates to the technical field of oil field oil well drilling and production, in particular to a hydraulic tubing anchor. The hydraulic tubing anchor comprises an upper connector, a center pipe, an upper piston, a cone, a slip, a slip seat, lower pistons, a horse thread ring, a horse thread barrel, a lower connector and a spring. The upper connector is fixed to the upper portion of the center pipe, the spring is located between the upper piston and the upper connector and connected to the center pipe in a sleeving mode, the lower portion of the slip is matched with the slip seat, the periphery of the slip seat is connected with the upper portion of the horse thread barrel, and the horse thread ring is arranged between the lower piston and the horse thread barrel. A floating block is arranged between the lower pistons, inclined threads matched with the horse thread barrel are arranged on the horst thread ring and the floating block respectively, the floating block is connected with the lower pistons through shear pins, and the lower connector is connected with the lower portions of the lower pistons. The device has a one-way locking function, that is, in the upward moving process of the slip, the lower portion is fixed through the inclined threads, and the clamp is effectively prevented from loosening.

Owner:TIANJIN HUIZHU PETROLEUM EQUIP SCI & TECH CO LTD

A new type of intelligent occluder

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Long rubber barrel packer for oil field water exclusion production

PendingCN106761538ALong effective sealing surfaceImprove the success rate of isolationSealing/packingOil fieldOil production

The invention discloses a long rubber barrel packer for oil field water exclusion production. The long rubber barrel packer at least comprises a central pipe, wherein the upper end of the central pipe is connected with an upper connector and the lower end of the central pipe is connected with a lower connector; a connecting sleeve, a connector, a spring seat sleeve, a middle rubber barrel assembly and a sliding sleeve sleeves the central pipe in sequence from top to bottom; the upper end of the connecting sleeve is connected with the upper connector and the lower end of the connecting sleeve is connected with the upper end of the connector; the inner circular surface of the lower end of the connector is connected with a piston switch; the outer circular surface of the lower end of the connector is connected with the upper end of the spring seat sleeve; the lower end of the spring seat sleeve is connected with the upper end of the middle rubber barrel assembly; the lower end of the middle rubber barrel assembly is connected with a sliding sleeve; the lower connector is internally provided with a positioning step; the positioning step is fixedly provided with a ball seat through an unpacking shear pin; the packer is combined with an oil field rod type oil pump oil production technology, and seat packing and production can be realized through a one-trip string; meanwhile, unpacking fishing can be carried out by lifting a pipe column and an expansion type packer is applied to the water exclusion production for the first time; the long rubber barrel packer has a longer effective packing surface and the packing success rate is improved.

Owner:PETROCHINA CO LTD

Elastic sieve pipe and sand prevention pipe column

The invention discloses an elastic sieve pipe and a sand prevention pipe column. The elastic sieve pipe comprises a central slotted sieve pipe, a pressure transmitting piece, a supporting cylinder sleeve, a reset mechanism, and an outer-layer slotted sieve pipe; the outer side of the upper end of the central slotted sieve pipe is fixed to the lower end of an upper joint through a central sieve pipe coupling, a control pin and an upper cylinder body, and the lower end of the central slotted sieve pipe is fixedly connected with the upper end of a lower joint; the pressure transmitting piece is arranged outside the central slotted sieve pipe in a sleeving mode, and an upper expansion mechanism and a lower expansion mechanism are arranged at the two ends of the pressure transmitting piece correspondingly; the supporting cylinder sleeve and the reset mechanism are arranged between the lower expansion mechanism and the lower joint; the two ends of the outer-layer slotted sieve pipe are positioned through sieve pipe protecting sleeves, and the middle of the outer-layer slotted sieve pipe is matched with the upper expansion mechanism and the lower expansion mechanism; and when the pipe column is tripped, the control pin is sheared off, the gravity of the pipe column is transmitted to the upper expansion mechanism and the lower expansion mechanism, and thus the elastic sieve pipe is set. According to the elastic sieve pipe and the sand prevention pipe column, it can be ensured that set sand is basically avoided in a wellbore, the good sand prevention effect is achieved, the pump inspection cycle is effectively prolonged, meanwhile, during using, tripping and salvaging operation is easy and convenient, safety and reliability are achieved, and the cost is low.

Owner:PETROCHINA CO LTD

Wall surface spraying device for building

InactiveCN112177292ASimple structurePracticalBuilding constructionsEngineeringStructural engineering

The invention discloses a wall surface spraying device for a building. The wall surface spraying device comprises a bottom plate, wherein a coating barrel and a spraying device are arranged on the bottom plate; an upper cover is arranged above the coating barrel; the upper cover is in threaded connection with the coating barrel; the spraying device comprises a feeding assembly and a brushing assembly; a piston plate is arranged in a discharging plate in a sliding manner; steps are fixedly connected to two sides of the piston plate; springs are arranged between the steps and the discharging plate; a bracket is connected to the steps; a brushing wheel is rotationally arranged on the bracket; a protective cover is fixedly connected to the discharging plate; and an absorption wheel is rotationally arranged on the protective cover. According to the device, the coating is sprayed onto the brushing wheel through a through hole I, a through hole II and a discharging hole during brushing, the brushing wheel is just attached to the absorption wheel, and the redundant coating is further adsorbed by the absorption wheel, so that the actual using effect is improved. Therefore, dropping liquid of the coating can be effectively prevented, and the device has excellent application prospects.

Owner:李成信

Composite blocking remover for oil well and application method thereof

ActiveCN102250601BAchieving Slow Controlled ReleaseReduce wasteCleaning apparatusDrilling compositionInorganic saltsChlorine dioxide

The invention relates to a composite blocking remover for oil well and an application method thereof. The composite blocking remover comprises two ingredients of A and B in a ratio of 1:5-8; the ingredient A comprises, by weight, 20-50 parts of chlorine dioxide maternal, 1-4 parts of heat-resistant agent, 10-20 parts of organic clay stabilizer, 5-10 parts of chlorine dioxide synergist and 5-10 parts of inorganic salt; and the ingredient B comprises, by weight, 30-60 parts of hydrophosphate, 2-6 parts of corrosion inhibitor, 1-5 parts of iron ion complexing agent, 5-12 parts of de-emulsifier, 4-12 parts of osmotic agent and 60-180 parts of water. The application method comprises steps that the ingredient A and the ingredient B are measured according to a formula and mixed with water; and the mixed liquor is injected into an oil well immediately. According to the invention, construction inconvenience and potential safety hazard caused by surface activation can be avoided, and construction frequency is reduced, so as to raise blocking removal effects by times.

Owner:石家庄卫科生物科技有限公司

Non-oxidizing polymer cracking agent

PendingCN112175598AGood blocking effectStrong corrosion resistanceDrilling compositionQuinolineActive agent

The invention relates to the technical field of cracking agents, in particular to a non-oxidizing polymer cracking agent. The non-oxidative polymer cracking agent comprises the following components inpercentage by mass: 0.5-2% of a main cracking agent, 0.2-3% of an auxiliary cracking agent, 0.5-3% of a clay stabilizer, 0.5-3% of a corrosion inhibitor, 0.5-3% of a surfactant and the balance of water, wherein the main cracking agent is one or more of glutaraldehyde, acetone, formaldehyde, vinyl ether, adipic dihydrazide and quinoline; and the auxiliary cracking agent is one or more of sodium nitrite, potassium nitrite, nitrososulfuric acid and silver nitrite. The non-oxidizing polymer cracking agent disclosed by the invention does not contain an oxidizing agent, is safe to use and transport, and is excellent in blockage removal performance.

Owner:GUANGHAN HUAXING NEW TECH DEV INST GENERAL PARTNERSHIP +1

a packer

The invention provides a packer. The packer comprises a casing coupling or tubing coupling (hereinafter referred to as 'an oil casing coupling') of which the inner wall is provided with a locating groove, a locking structure and a soluble ball, wherein the locking structure comprises the oil casing coupling and a central pipe, and the central pipe penetrates through the oil casing coupling; a locking dog clamped with the locating groove in the oil casing coupling is arranged at the lower part of the oil casing coupling; a recovery coupling is arranged at the lower end of the central pipe; and an arc-shaped groove matched with the soluble ball is formed in the upper end of the central pipe at the upper part. The oil casing coupling is redesigned, the groove (namely the locating groove, wherein the locking structure in the locating groove of the oil casing coupling can realize locating, locking and fixing) is processed, and the locating structure can bear the pressure difference of the top side, the bottom side or the top side and the bottom side in the locating groove, so as to block top-bottom circulation of liquid or gas and ensure ground production and operation and personnel security. According to the packer, multiple packing and unpacking operations can be finished in the oil casing coupling, the operation is simple and the borehole operation efficiency is high.

Owner:陈晓新

A kcmf type pressure expansion insert seal

Owner:CNOOC ENERGY TECH & SERVICES

Assembly line type immersion work harmful water treatment device for chemical production

InactiveCN113461239ATo achieve the purpose of cleaning the ultrafiltration deviceEasy to handleSpecific water treatment objectivesWater contaminantsElectric machineryAssembly line

The invention belongs to the technical field of wastewater treatment, and discloses an assembly line type immersion work harmful water treatment device for chemical production. The assembly line type immersion work harmful water treatment device comprises a wastewater treatment tank, a motor, a ball screw, a slide block and a push rod. The motor is arranged above the wastewater treatment tank, and an output shaft of the motor is in transmission connection with the ball screw; the two sliding blocks are movably connected to the top and the bottom of the ball screw in a sleeving mode correspondingly. The water pressure in the cavity is increased, so that water in the cavity between the partition plate and the drainage tank can penetrate through the ultrafiltration device to re-enter the inner cavity of the ultrafiltration device, and accumulated particles between micropores of the ultrafiltration device and membrane filaments are backwashed out due to reverse flow in the micropores of the ultrafiltration device, so that the purpose of cleaning the ultrafiltration device is achieved. The ultrafiltration device does not need to be disassembled and the like, so that the treatment is convenient, and the influence of cleaning time on subsequent wastewater treatment is not reduced.

Owner:盐城星禾子科技有限公司

High-speed mixer

PendingCN108786554ALabor savingReduce wasteRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a high-speed mixer, comprising a body. The body is provided with a barrel for storing materials and mixing the materials; the upper end of the barrel is provided with a feed port communicated with the inside of the barrel; the part of the body close to the barrel is provided with an unblocking device connected with the barrel; the unblocking device includes a working chamber connected with the sidewall of the barrel; a blade is slidably connected inside the working chamber and can horizontally slide in the working chamber; a door that controls the working chamber and the barrel to internally open or close is arranged in the working chamber; electromagnet I controlled by a circuit signal is fixed to the bottom of the door; electromagnet II that repels the electromagnet I is fixed right under the door in the working chamber. The high-speed mixer has the advantages that material waste can be effectively reduced and pollution of surrounding air due to powdery materials can be effectively decreased.

Owner:YANCHENG SHENYUAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com