A kcmf type pressure expansion insert seal

An insertion sealing and expansion technology, applied in the direction of sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of small interference, wear of downhole sealing cylinder, delamination failure, etc., to avoid friction The effect of resistance and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

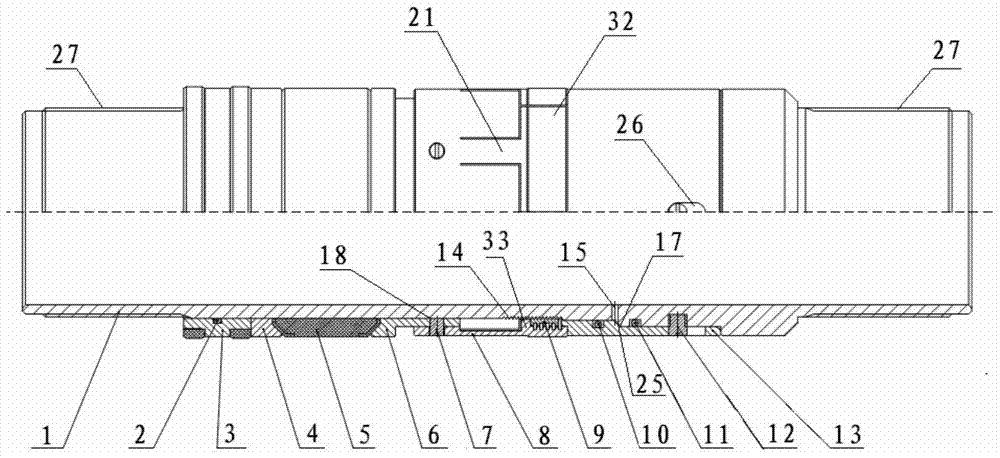

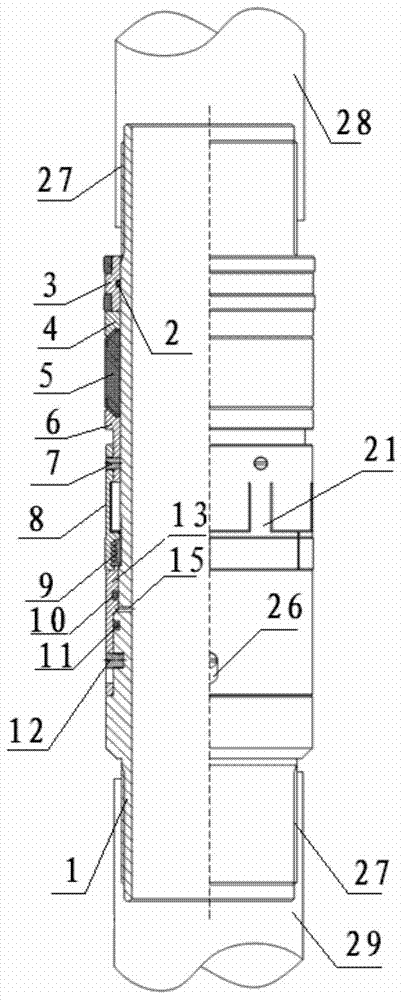

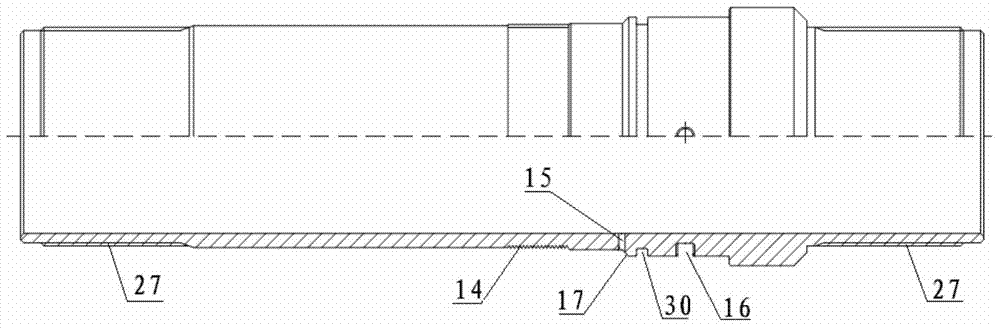

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] The KCMF type pressure expansion insert seal of the present invention includes a sealing module 3, the inner surface of the sealing module 3 is provided with an O-ring 2, and the sealing module 3 is sleeved on the hollow cylinder 1, and the hollow The two ends of the cylindrical body 1 are respectively provided with screw threads 27, which can be connected with the upper production string 28 and the lower production string 29 when entering the well. A spine structure 14 integrated with the hollow cylindrical body 1, a small radial through hole 15 that can be used as a hydraulic transmission passage, and a radial threaded blind hole 16 are sequentially provided downwards. The spine structure 14 can be is 1mm, and the thread angle can be 60°; the radial threaded blind holes 16 are evenly distributed along the circumference, and the number can be set to four; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com