High-speed mixer

A high-speed mixer and machine body technology, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of material waste, dust pollution, accelerated physical changes, etc., to achieve fast and comprehensive opening, reduce labor, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

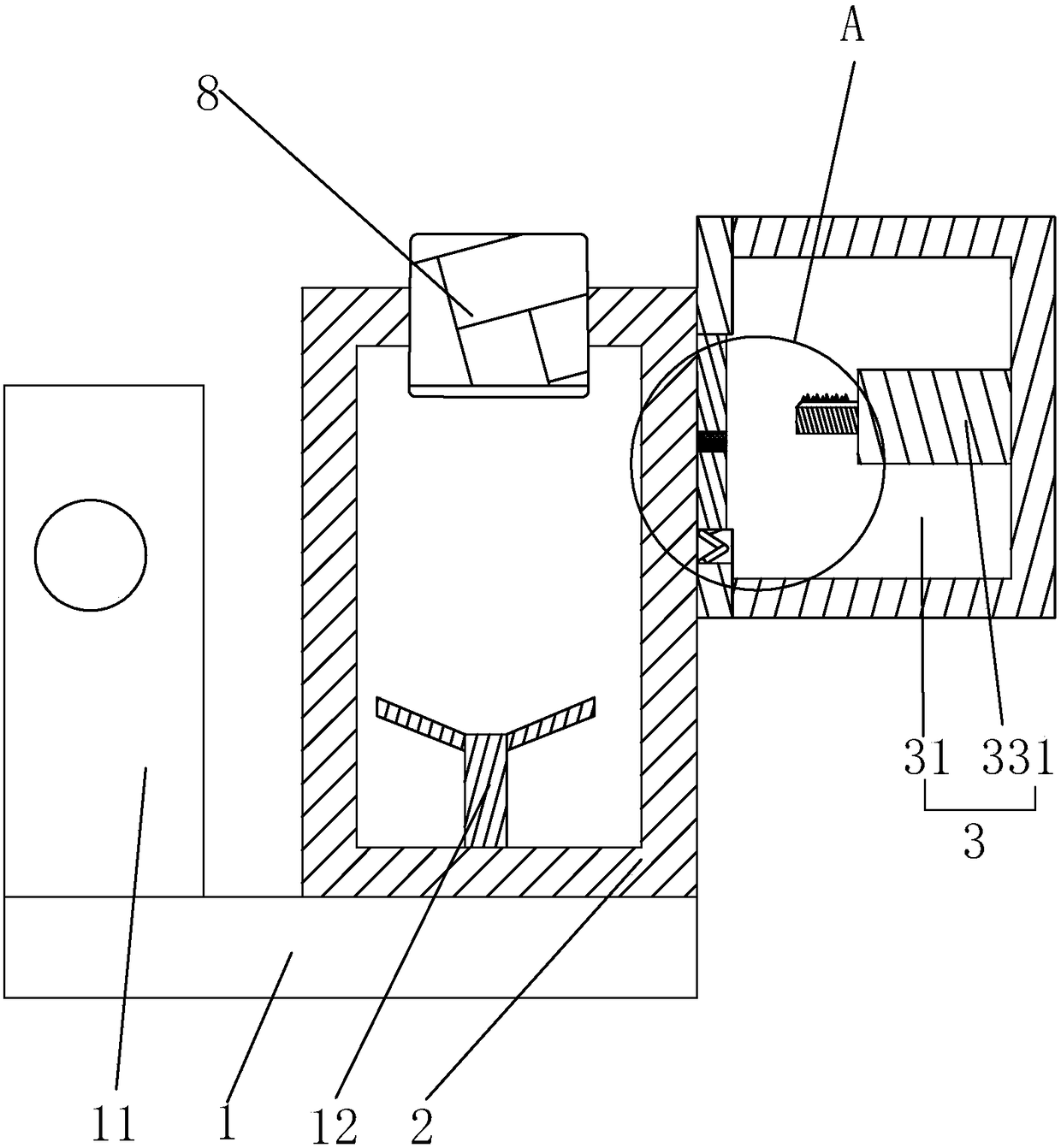

[0035] Embodiment 1: a kind of high-speed mixer, such as figure 1 As shown, it includes a body 1 and a power control unit 11. The body 1 is provided with a cylinder 2 for storing materials and performing mixing work. The upper end of the cylinder 2 is provided with a feeding port 21 communicating with the inside of the cylinder 2. The interior of the cylinder 2 is provided with a stirring blade 12 driven by a power control unit 11; the material enters the cylinder 2 through the feeding port 21, and the stirring blade 12 rotates in the cylinder 2 under the control of the power control unit 11 to realize the mixing of the material. The stirring mix works.

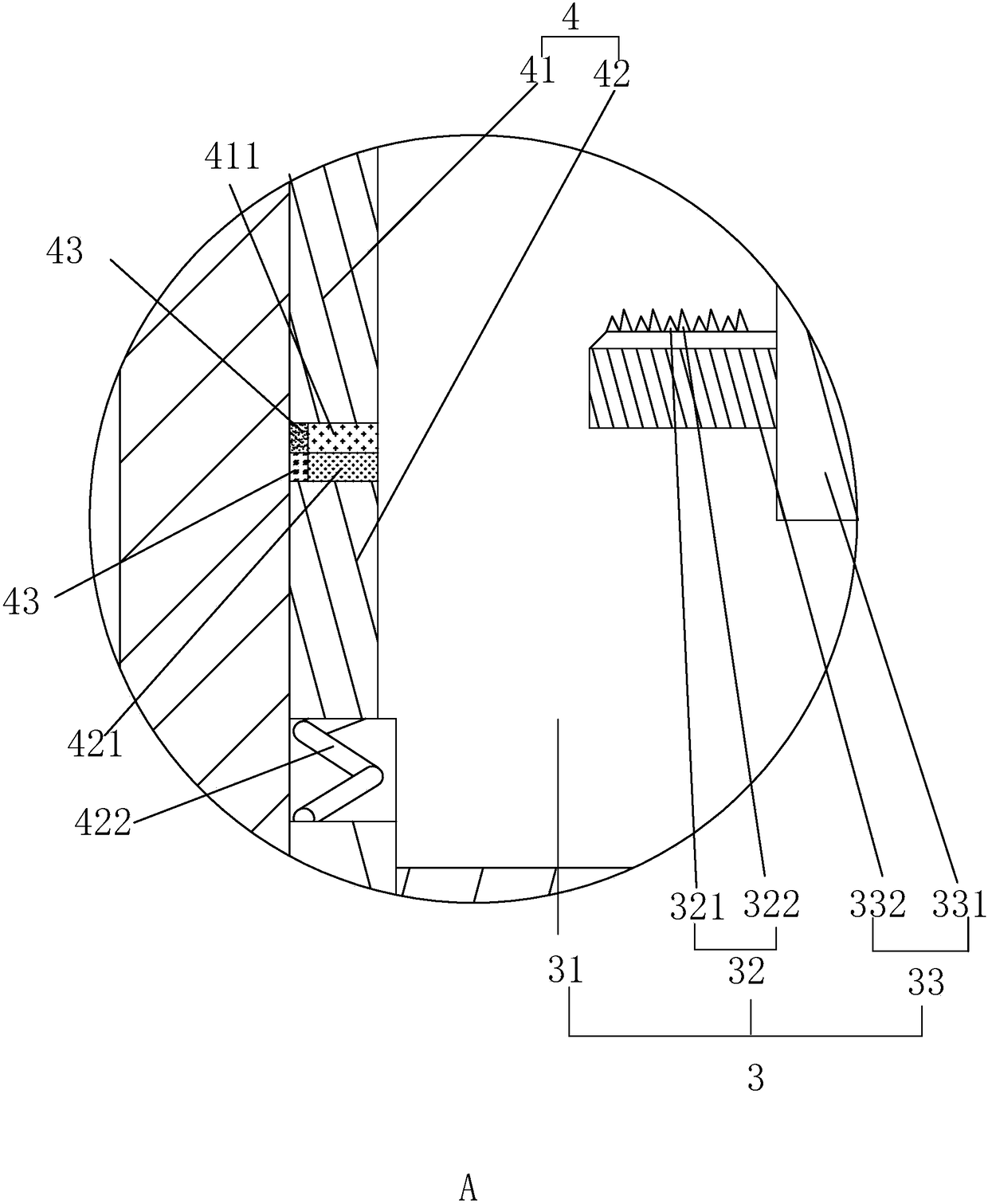

[0036] Such as figure 1 and 2As shown, at this time, an unsealing device 3 connected to the cylinder 2 is provided on the body 1 near the cylinder 2. The unsealing device 3 includes a working chamber 31 connected to the side wall of the cylinder 2. There is a power mechanism 33, that is, a drive cylinder 331 is fixedly con...

specific Embodiment approach

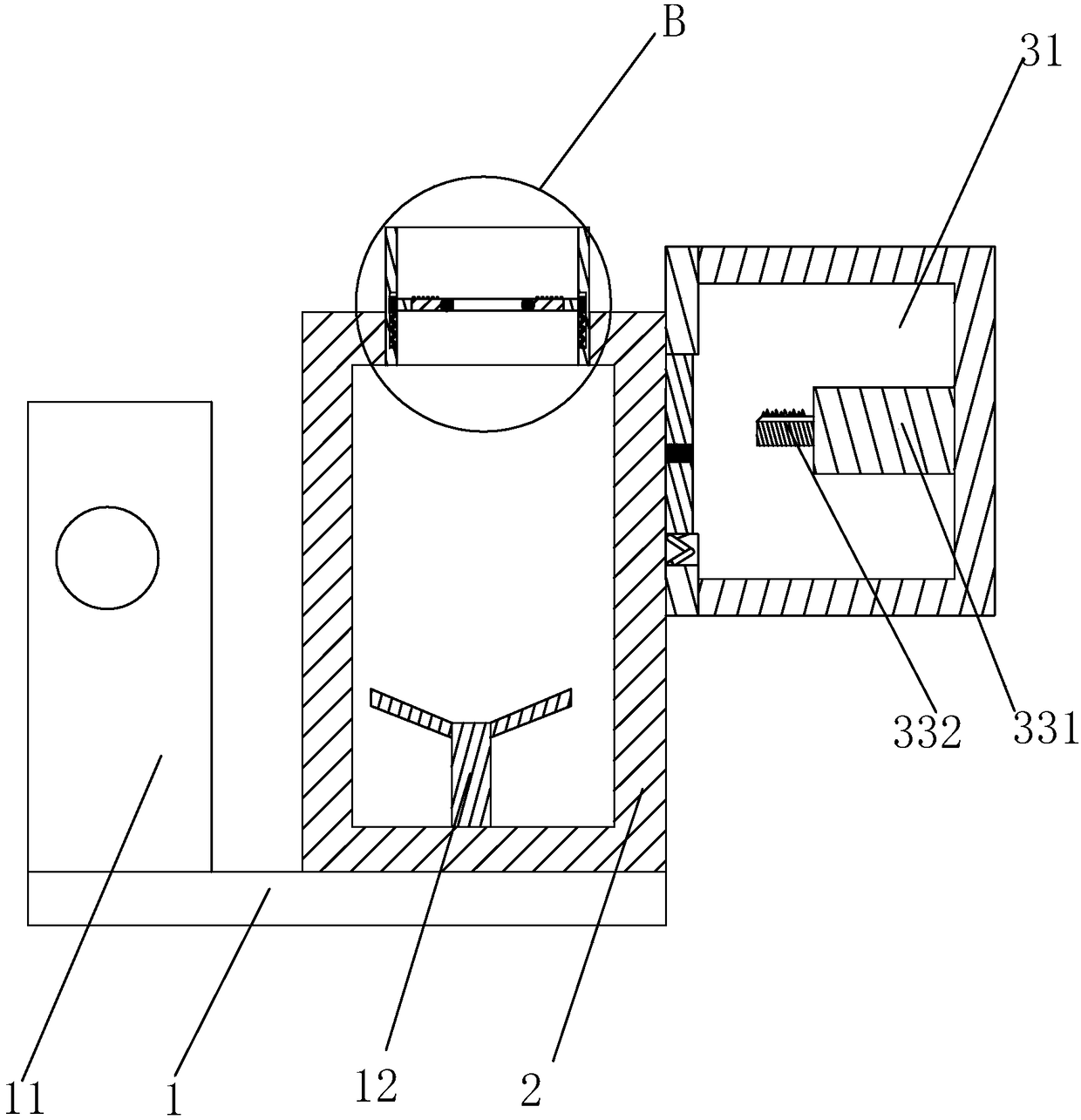

[0037] Specific implementation method: the woven bag 8 with the material is directly placed at the feeding port 21, and the woven bag 8 is embedded in the feeding port 21 under the gravity of the internal material, and the bottom of the woven bag 8 has a penetrating feeding port 21 to enter The part inside the cylinder body 2, at this time, the woven bag 8 has realized the sealing of the feeding port 21; the control electromagnet 1 411 and the electromagnet 2 421 are energized, and under the mutual repulsion of the two electromagnets, the upper door panel 41 is upward. Sliding, the lower door panel 42 slides downwards, and the compression spring 422 is completely compressed, at this time, the door body 4 is in an open state, that is, the communication between the working chamber 31 and the inside of the cylinder body 2 is realized; the driving cylinder 331 is controlled to work, and the piston rod 332 protrudes from the driving cylinder 331, and the process of the piston rod 33...

Embodiment 2

[0042] Embodiment 2: a kind of high-speed mixer, the difference with embodiment 1 is, as image 3 and 4 As shown, an outwardly extending protective rib 5 is provided at the feeding port 21; The outer peripheral wall of the support plate 61 is fixedly connected with a connection block 62, and the inner wall of the protective rib 5 is provided with a plurality of track grooves 63. There is a buffer spring 64, and the end of the buffer spring 64 away from the connecting block 62 is connected and fixed to the inner wall of the protective rib 5; a through hole 611 communicated with the feeding port 21 is provided at the support plate 61 near the middle position; and it rotates on the support plate 61 A blanking plate 7 is connected, and a plurality of protrusions 71 are arranged on the upper surface of the blanking plate 7 .

[0043] Specific implementation method: under the effect of protective rib 5, can make the woven bag 8 that material is housed in protective rib 5, at this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com